Feature-Based Framework for Inspection Process Planning

Abstract

1. Introduction

2. Background and Methodology

2.1. Literature Review on Features Definitions and Modeling Frameworks

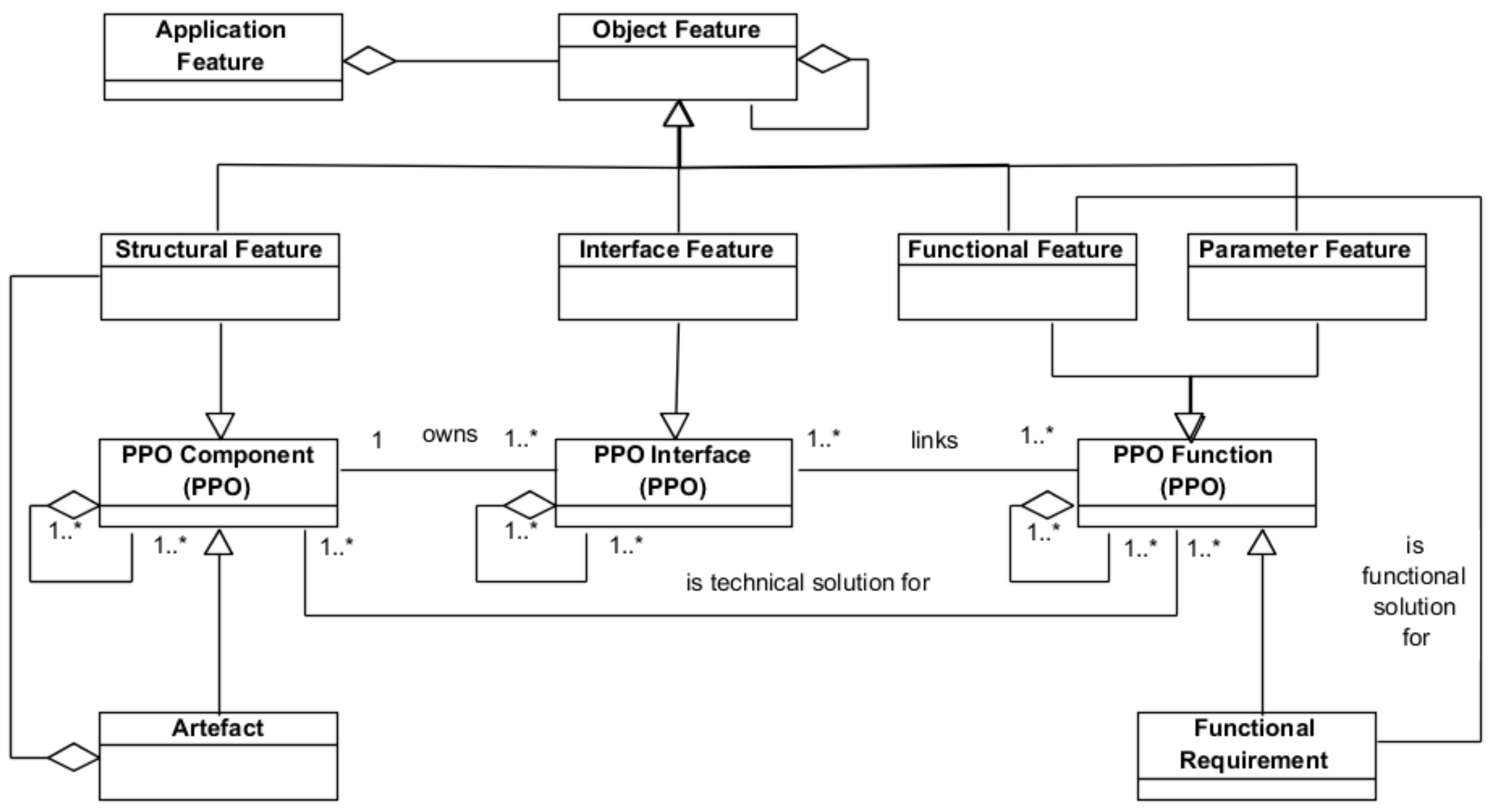

2.2. Unified Application Feature Framework

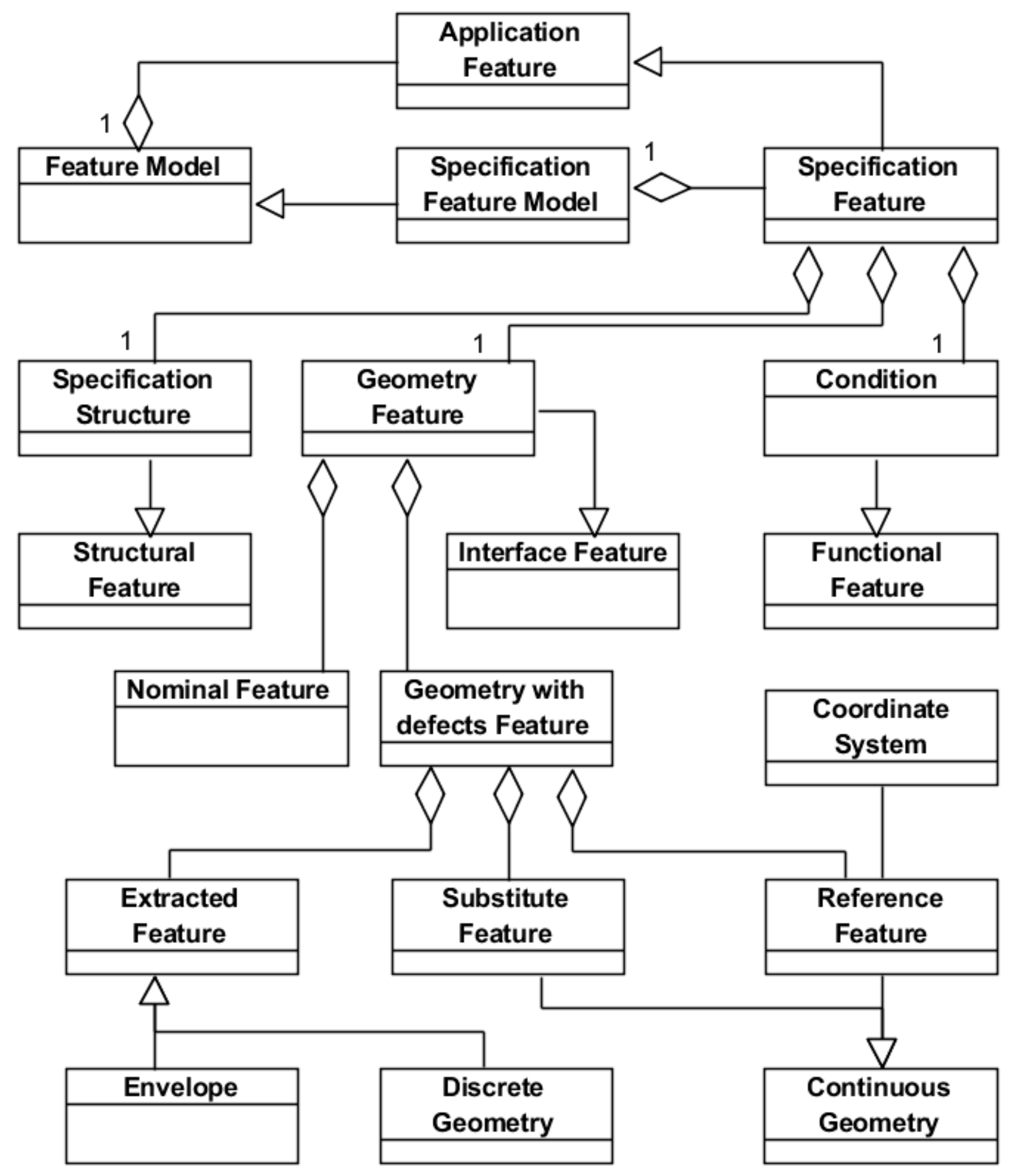

2.3. Feature-Based Framework for Geometric Specification

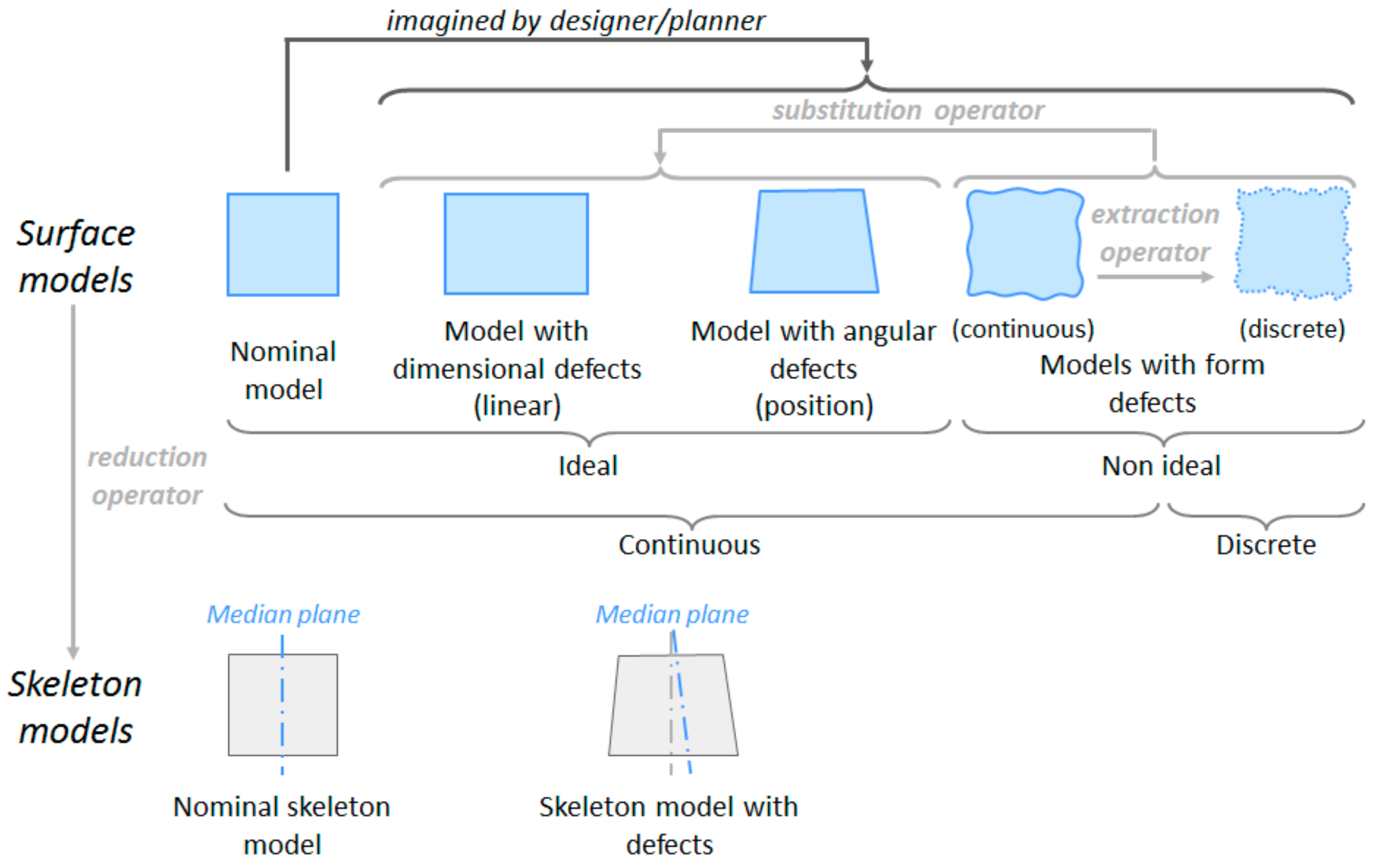

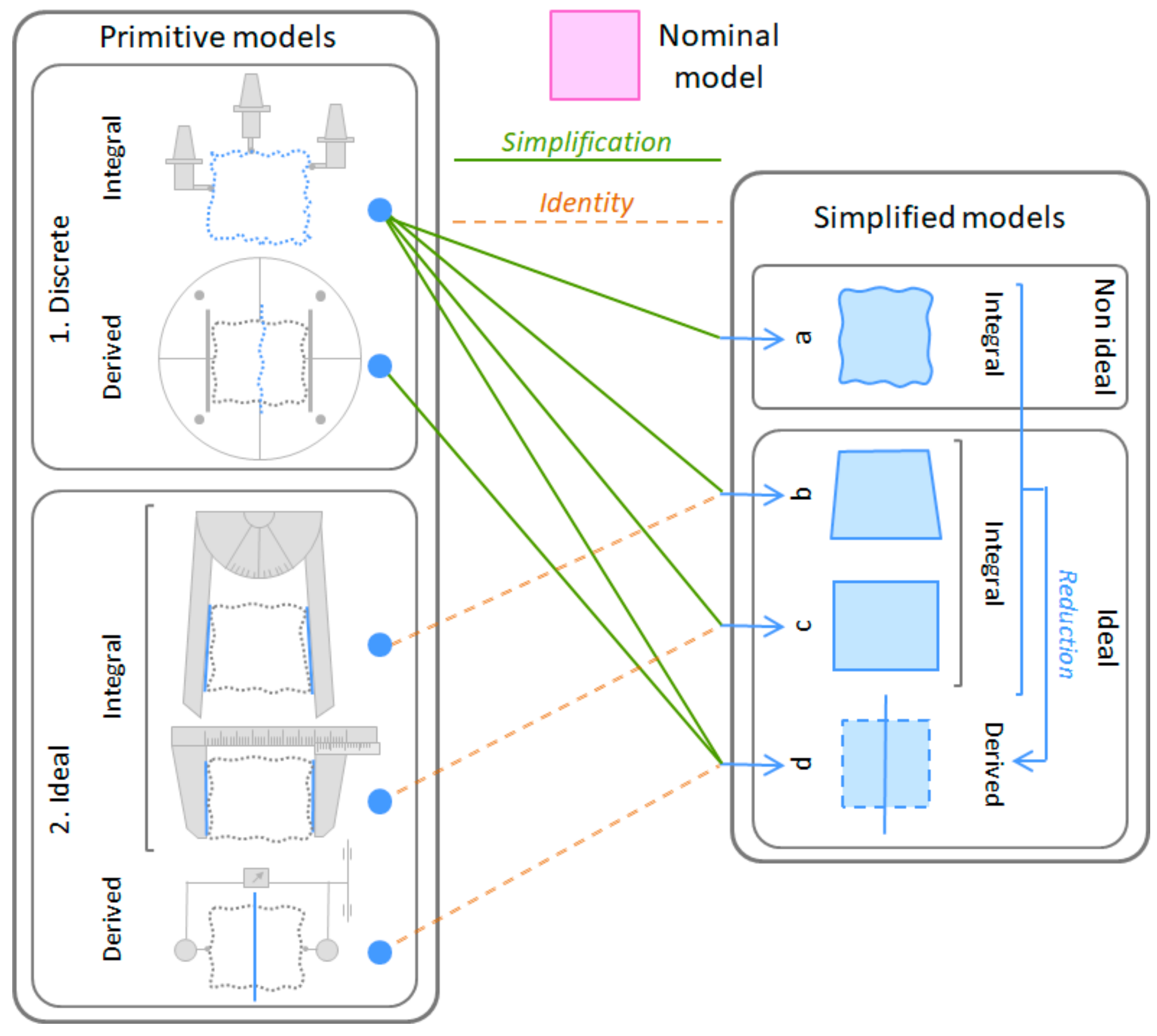

2.3.1. Geometry Model for Specification

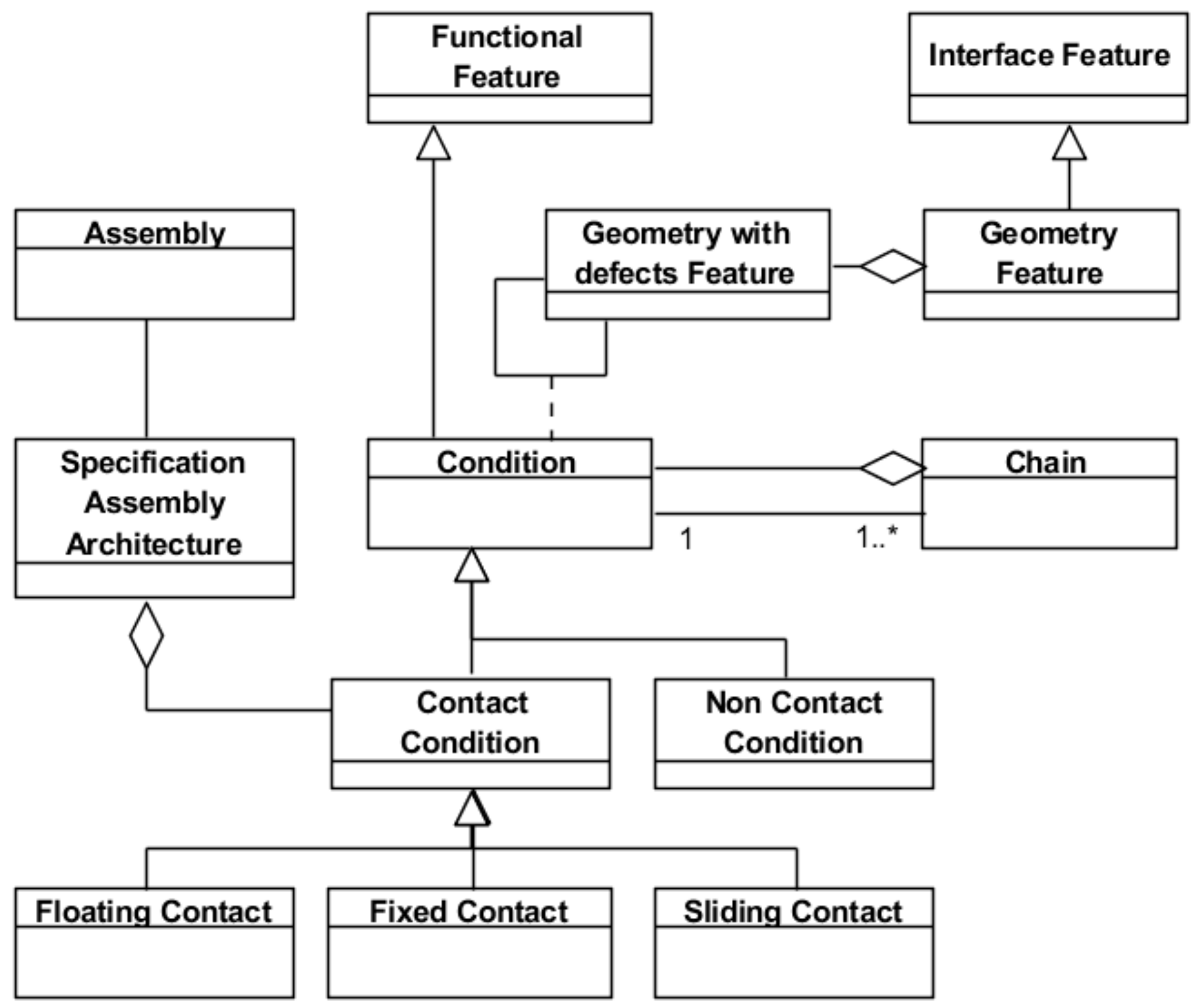

2.3.2. Specification Feature Model

2.3.3. Assembly Model for Specification

2.4. Methodolgy

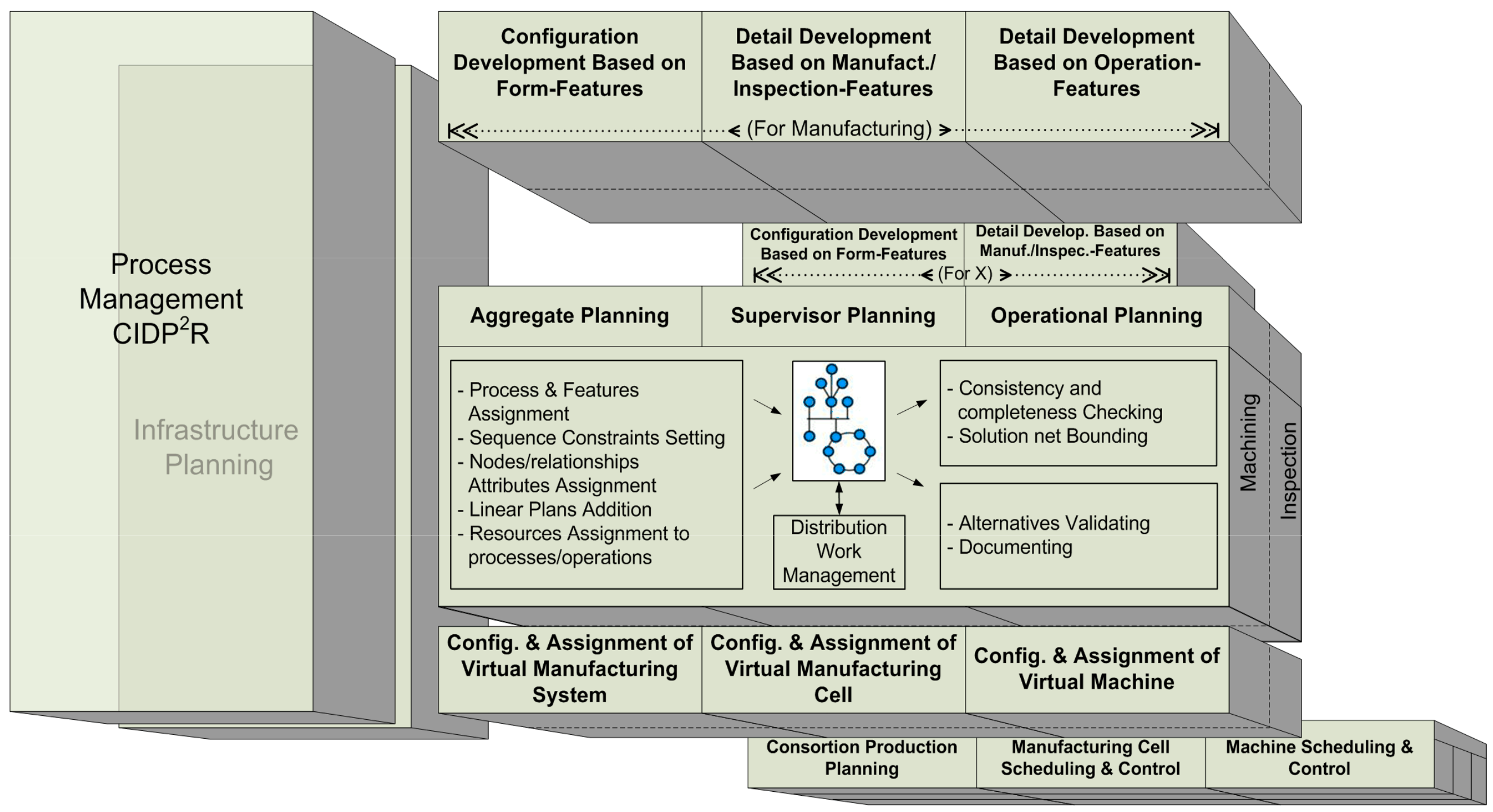

- Development of a functional model for inspection process planning in an integrated product and process (machining an inspection) development context, especially fostering in-line inspection. In this way, part quality inspection plans can feed product quality assurance and the resulting activation of management strategies. These strategies allow for smooth defect propagation throughout the process stages and to the final customer. The functional model, developed using IDEF0, enables to identify the main information requirements and shows at the aggregate level the relationships between the tasks involved in inspection process planning, machining process planning and product design. Furthermore, in order to ease the integration of all these planning tasks, a dual activity model for both process planning tasks is established. This activity model is supported by a common part representation based on a single feature concept, the Specification Feature.

- Study of the following topics:

- Tolerance information models used in CAT (Computer-Aided Tolerancing) applications, both for the interpretation models (such as vector equation model, variational surface model, kinematic model, degree of freedom (DOF) model, etc.) and for the representation models (such as surface graph model, technologically and topologically related surface (TTRS) models, category theory model, GeoSpelling model, ontology-based model, etc.). In particular, the concepts considered by the Geospelling language and the GPS standard are revisited.

- Measurement processes and systems. More particularly, the ways in which the part can be situated (oriented and/or located) in relation to the geometries of the measurement resource are studied. Additionally, the alignment operations, either physical or by means of calculations (verification operator), that are performed during the verification process, are also analyzed.

- The role of tolerancing in the context of the uncertainty management, in order to ensure that the product meets its functional requirements.

- Development of a proposal for the specification exercises carried out in inspection process planning, which is dual to the one established for the specification exercises in product design. Accordingly, inspection plan specification (including analysis and validation) is addressed using similar assembly models, geometry models, which incorporate the representation of defects, and tools and techniques for variability management.

- Analysis of the general UAF framework and Specification Feature Model to determine their suitability to provide a specific solution for inspection planning.

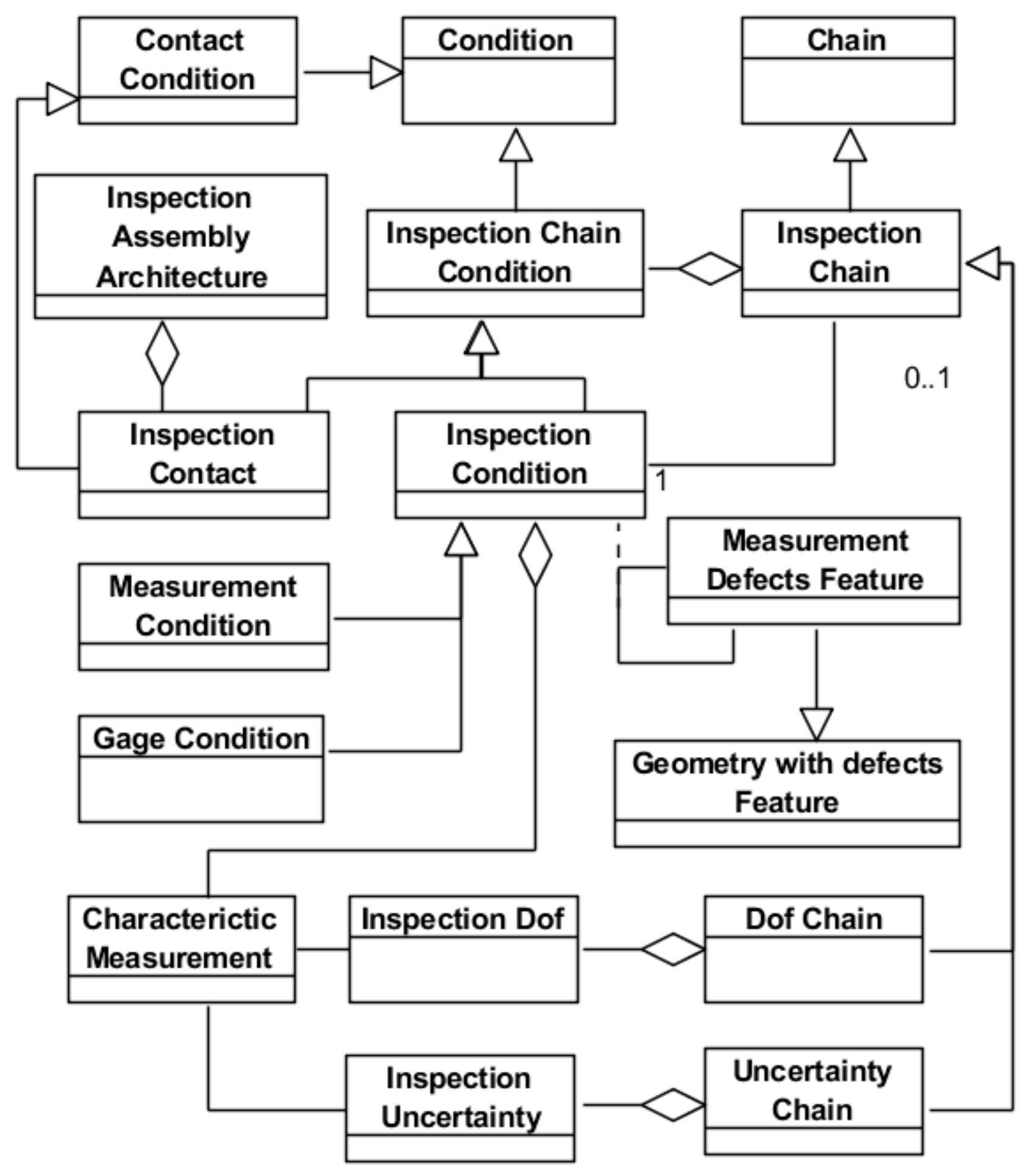

- Development of an Inspection Feature Model and an Inspection Assembly Model based on the general UAF framework and Specification Feature Model. In particular, the models for the inspection planning domain should be adequate to support the definition, analysis and validation of the set-ups included in the inspection plan and the allocation of the inspection resources.

- Categorization of Measurement Resources in generic types that include all type of measurement equipment, ranging from basic instruments to coordinate-based machines. The generic types of Measurement Resources have been established based on the degrees of freedom characterising the movement axes of the inspection equipment and the axes including sensors to register measurement data.

- Development of an Inspection Feature Library. The library classes are based on the study, from measurement viewpoint, of the different geometry types that can be present in mechanical parts. The definition of the different types of features considers the way each type of feature interacts with the resource interface features corresponding to the defined Categories of Measurement Resources. The knowledge about compatibility between the part and resource interfaces is essential for the inspection planner in order to allocate the most appropriate resource. This knowledge is embedded in the form of compatibility constraints and properties of interaction

- Validation of the proposed models by the application to several case studies. The aim is just to validate that the concepts supporting the Inspection Feature Model are adequate to select and analyze an inspection solution. A developed graph-based methodology that supports the inspection chains representation corresponding to each characteristic to be verified in one set-up is used in order to facilitate analysis and validation exercises of the inspection solution.

3. Results: Feature-Based Framework for Inspection

- The definition of an assembly (product artefact) that can be a technical solution for the required functionality expressed as functional conditions. The technical solution is a set of parts with their particular geometrical shapes that are kinematically related through their geometrical interfaces.

- Since the part geometrical interfaces will have defects (intrinsic or extrinsic), different characteristics limiting them have to be specified. A specified characteristic is a characteristic with the permissible (maximum and minimum) limits, where a characteristic is a linear or angular distance defined between geometric elements (ideal or non-ideal) [27]. Each specified characteristic requires the definition of a GPS operator that establishes the procedure to obtain it from the data of the involved geometrical elements.

- The validation whether the total assembly performance (tolerance) meets the functional condition. This is calculated through a chain that considers the characteristics of the assembly components (individual parts) and the contact conditions.

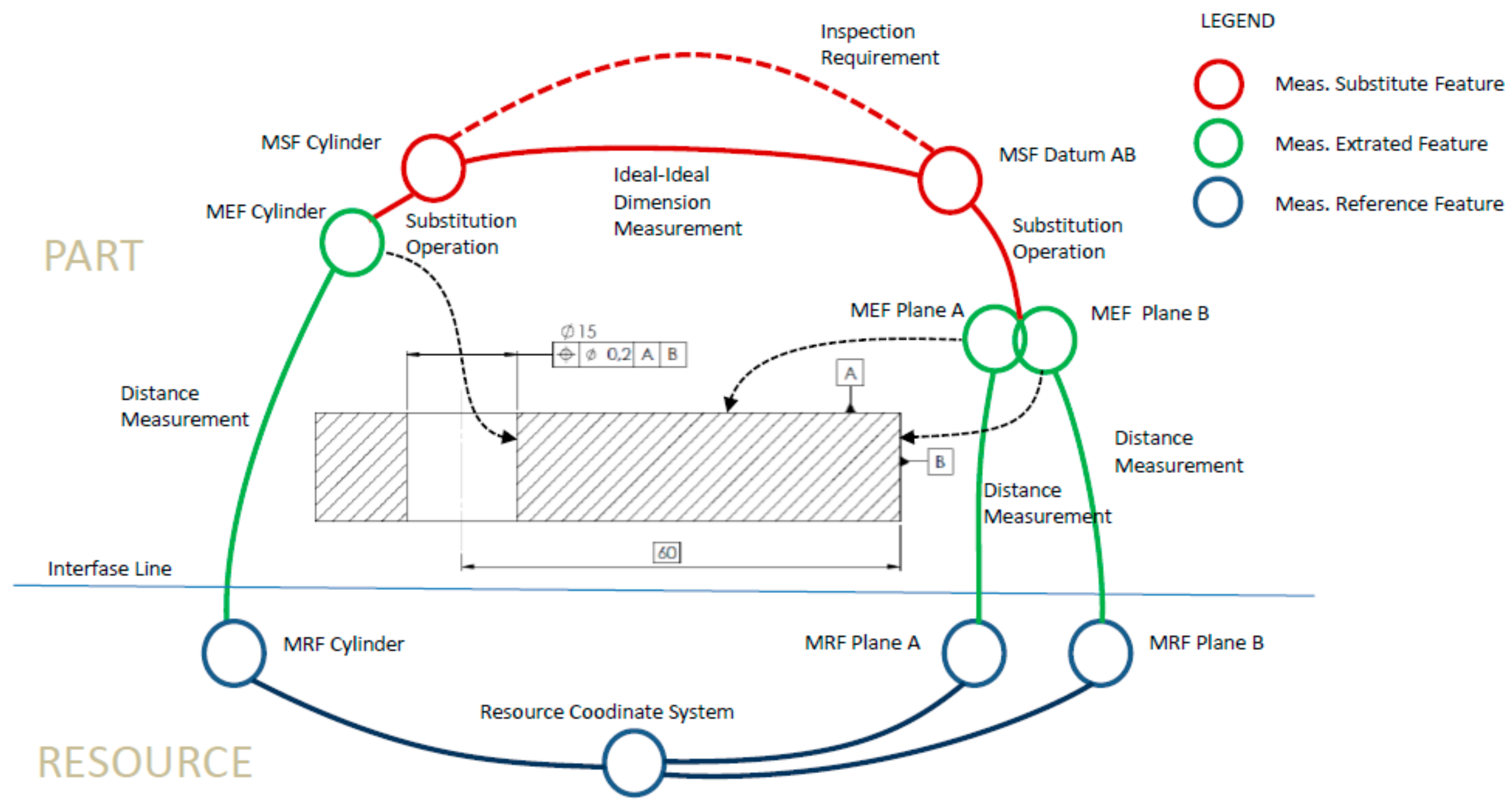

- The definition of an assembly (inspection artefact), formed by the subject part of the inspection and a set of components (measurement resource, fixture, probe, etc.). This assembly must be a technical solution capable of extracting part geometric information needed for the verification of the specified characteristic.

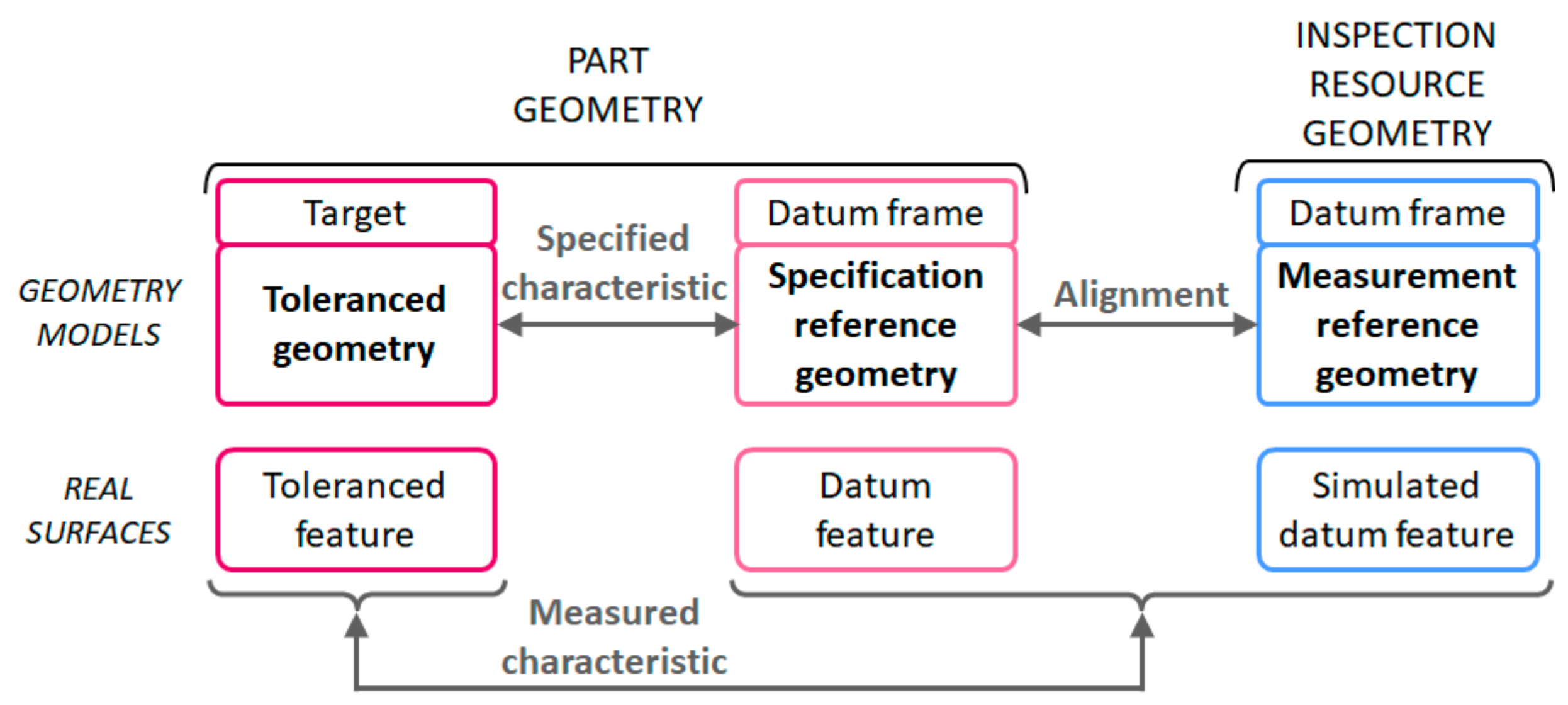

- Since the extracted part geometry will have defects, the planner, similarly to the designer, uses ideal geometry models that enable him/her to represent the measured geometry with defects. Working on these imaginary ideal geometries with defects, which belong to both the part and the rest of the assembly components (measurement resource, fixture, probe, etc.), the planner establishes the GPS operator to obtain characteristics to be measured corresponding to the specified characteristics.

- The validation whether the total uncertainty (method and implementation) of the inspection assembly meets the requirements of the verification of the specified characteristic. This uncertainty is calculated through a chain that considers the characteristics of the assembly components (part and inspection resource) and contact conditions.

3.1. Geometry Model for Verification

- Discrete models with defects (integral or derived profiles/surfaces) consisting of sets of points, segments or tessellation elements (with a particular pattern). These models are obtained when measurement is performed by equipment that provides coordinate information, such as CMM (Coordinate Measurement Machine), optical equipment, surface form/texture metrology, etc. The coordinate information is referred to the equipment coordinate system that is realised by the movements of its guideways. To make this equipment very flexible, its guideways can be linear, resulting in rectangular coordinate systems, or a combination of linear and angular movements, resulting in spherical, cylindrical, etc., coordinate systems. There is equipment with two guideways that can be used to obtain two dimensional discrete models and others with three or more guideways that can be used when three dimensional discrete models are required.

- Ideal models with dimensional defects that keep the nominal form. These models are obtained when measurement is performed either by conventional equipment (calliper, micrometer, goniometer, etc.) or by equipment and set-ups used in comparison measurements. The first ones provide a specific linear or angular distance between two ideal geometries that are embodied by the measurement equipment. The second ones provide two linear or angular distances (maximum and minimum deviations) that enable the construction of two ideal geometries (surfaces or profiles) that are internally or externally enveloping the real part geometry. The construction of these two ideal enveloping geometries is performed by the movement of the measurement equipment guideways (sweeping movement). When surface models (3D) are required, it will be necessary to use two axes for the sweeping movement (two isoparametric lines), resulting in an enveloping surface. However, if plane profile models (2D) are desired, just one axis for the sweeping movement will be required, resulting in an enveloping line. When surface models of a complete partitioned geometry using any of these two types of measurement processes (conventional equipment or set-ups for comparison measurements) are desired, measurements in several planes (parallel, coaxial, etc.) will be required in order to cover the whole partitioned surface. Obviously, the uncertainty of these surface models with dimensional defects will depend on the possibility of coincidence of the reference geometry with these profiles, as it will be explained in the next section.

- Positioning embodiment, when the reference is realised by physical contact with surfaces of the equipment or set-up (e.g., gusset plates, mandrel, precision jaws, precision fixture, etc.) or is realised as an offset of the previous ones by gauges used during the setting or calibration process of the equipment.

- Kinematic embodiment, when the reference is realised by the movement of the measurement equipment guideways. Obviously, this reference is located in the inspection resource, since the guideways used to generate it have a specific location in the equipment. The number of measurement equipment guideways has to provide the minimum number of independent axes required by the type of tolerance geometry.

- Calculated embodiment, when the reference is obtained by mathematical association operations using the part extracted points, segments or tessellation elements and appropriate criteria such as least square, minimum outer diameter, etc.

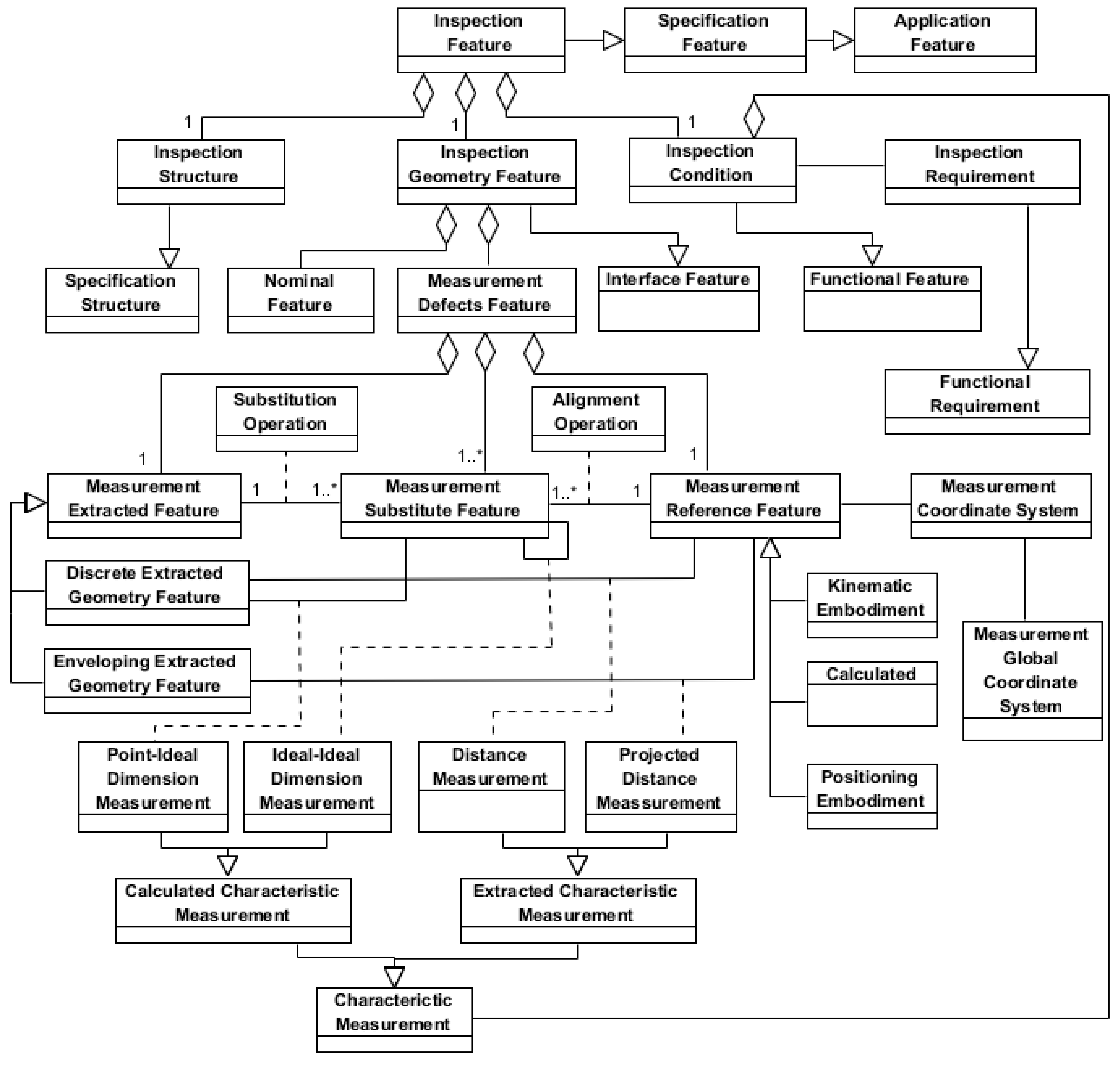

3.2. Inspection Feature Model

- The Distance Measurement is the relation between an extracted discrete geometry (Discrete Extracted Geometry Feature) and a reference geometry (Measurement Reference Feature). For example, the measurement of a distance between a point and a plane.

- The Projected Distance Measurement is the relation between an extracted enveloping geometry (Enveloping Extracted Geometry Feature) and a reference geometry (Measurement Reference Feature). For example, the measurement of an angular distance using a goniometer where both instrument probes contact part surfaces resulting in two ideal geometries (straight lines) whose included angle is the characteristic measurement. Both ideal geometries are enveloping extracted geometries (only one limit in this case) from the part and result in two substitute geometries (Measurement Substitute Feature) through an operator (Measurement Substitution Feature) that in this case is as simple as the identity. It must be noticed that one of them is used as the measurement reference (Measurement Reference Feature) being the alignment (Alignment) in this case the identity. Obviously, the type of reference in this case is established by the part-instrument contact (Positioning Embodiment). In the case of enveloping geometries with two limits, these will have the same form and location than the reference surface used for the measurement and are obtained by a sweeping process on that reference surface. This sweeping process is performed using the measurement equipment guideways.

- The Point-Ideal Dimension Measurement establishes the relation between an extracted discrete geometry (Discrete Extracted Geometry Feature) and a substitute geometry (Measurement Substitute Feature) as a sequence of GPS operations that results in the quantification of the characteristic to be verified. For example, when for the verification of a parallelism between two planes a surface plate and a height gauge are used. In this case, one of the planes contacts the surface plate (Positioning Embodiment) establishing the measurement reference (Measurement Reference Feature) and the ideal substitute geometry (Measurement Substitute Feature) by an alignment (Alignment) that is the identity. The other plane is sampled with the height gauge obtaining a discrete geometry (Discrete Extracted Geometry Feature) as a set of points. The GPS operator to verify the specified characteristic is the result of the difference between the maximum and minimum height (measured from the reference plane) of the set of sampled points.

- The Ideal-Ideal Dimension Measurement establishes the relation between two ideal substitute geometries (Measurement Substitute Feature) as a sequence of GPS operations between those ideal geometries resulting in the quantification of the characteristic to be verified. For example, using the previous example of a parallelism specification between two planes, but now using a CMM. In this case, both planes are sampled as a set of points in relation to the same reference measurement (Measurement Reference Feature). From the extracted geometry of both planes (Discrete Extracted Geometry Feature) the corresponding ideal substitute geometry (Measurement Substitute Feature) is obtained by an appropriate substitution operator (Measurement Substitution Feature). Between the two ideal substitute geometries, a GPS operator containing basically construction and evaluation operations is used to quantify the specified characteristic.

3.3. Inspection Assembly

3.4. Case-Study

- Measurement of the cylinder using a resource of type “measurement on axis” (e.g., center bench). Planes A and B would be used to locate the part on the resource by means of a location gage 3–2.

- Measurement of the cylinder and of plane B using a resource of type CMM. Plane A would be used to locate the part on the resource.

- Measurement of the cylinder and of planes A and B using a resource of type CMM. No specific location of the part is required in this case.

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Lu, Y.; Morris, K.C.; Frechette, S. Current Standards Landscape for Smart Manufacturing Systems; NISTIR 8107. 2016. Available online: http://nvlpubs.nist.gov/nistpubs/ir/2016/NIST.IR.8107.pdf (accessed on 1 October 2017).

- Zhang, Y.; Zhang, G.; Liu, Y.; Hu, D. Research on services encapsulation and virtualization access model of machine for cloud manufacturing. J. Intell. Manuf. 2015, 28, 1109–1123. [Google Scholar] [CrossRef]

- Wang, X.V.; Givehchi, M.; Wang, L. Manufacturing system on the cloud: A case study on cloud-based process planning. Procedia CIRP 2017, 63, 39–45. [Google Scholar] [CrossRef]

- Sang, Z.; Xu, X. The framework of a cloud-based CNC system. Procedia CIRP 2017, 63, 82–88. [Google Scholar] [CrossRef]

- Mourtzis, D.; Vlachou, E.; Xanthopoulos, N.; Givehchi, M.; Wang, L. Cloud-based adaptive process planning considering availability and capabilities of machine tools. J. Manuf. Syst. 2016, 39, 1–8. [Google Scholar] [CrossRef]

- Givehchi, M.; Haghighi, A.; Wang, L. Cloud-DPP for distributed process planning of mill-turn machining operations. Robot. Comput.–Integr. Manuf. 2017, 47, 76–84. [Google Scholar] [CrossRef]

- Sormaz, D.N.; Arumugam, J.; Rajaraman, S. Integrative process plan model and representation for intelligent distributed manufacturing planning. Int. J. Prod. Res. 2017, 42, 3397–3417. [Google Scholar] [CrossRef]

- Rosado Castellano, P.; Romero Subirón, F.; Vila Pastor, C. A model for collaborative process planning in a engineering and product network. In Proceedings of the 13th International Research/Expert Conference “Trends in the Development of Machinery and Associated Technology”, Hammamet, Tunisia, 16–21 October 2009. [Google Scholar]

- Romero Subirón, F.; Estruch Ivars, A.; Rosado Castellano, P. A framework for the development of an IT platform for collaborative and integrated development of product, process and resources. In Proceedings of the 13th International Research/Expert Conference “Trends in the Development of Machinery and Associated Technology”, Hammamet, Tunisia, 16–21 October 2009. [Google Scholar]

- Wu, Y.; He, F.; Zhang, D.; Li, X. Service-Oriented Feature-Based Data Exchange for Cloud-Based Design and Manufacturing. IEEE Trans. Serv. Comput. 2015, 11, 341–353. [Google Scholar] [CrossRef]

- González Contreras, F.; Romero Subirón, F.; Bruscas Bellido, G.M.; Gutiérrez Rubert, S.C. Modelado de actividades para el desarrollo integrado de planes de mecanizado e inspección en entornos distribuidos y colaborativos. In Proceedings of the 3rd Manufacturing Engineering Society International Conference, Alcoy, Spain, 17–19 June 2009. [Google Scholar]

- Romero, F.; Rosado, P.; Bruscas, G.M. Application Feature Model for Geometrical Specification of Assemblies. Procedia Eng. 2015, 132, 1128–1135. [Google Scholar] [CrossRef]

- Romero, F.; Rosado, P.; Bruscas, G.M. Application Feature Models for Product and Process Analysis Based on Assembly Models. J. Manuf. Technol. Res. 2016, 8, 135–151. [Google Scholar]

- Shah, J.J.; Mäntylä, M. Parametric and Feature-Based CAD/CAM; John Wiley & Sons: Toronto, ON, Canada, 1995; ISBN 0-471-00214-3. [Google Scholar]

- Riebisch, M. Towards a More Precise Definition of Feature Modelling Variability for Object-Oriented Product Lines; Riebisch, M., James, D.S., Coplien, O., Eds.; BookOnDemand Publ. Co.: Norderstadt, Germany, 2003; pp. 64–76. [Google Scholar]

- Zha, X.F.; Sriram, R.D. Feature-based component model for design of embedded systems. In Intelligent Systems in Design and Manufacturing V; International Society for Optics and Photonics: Philadelphia, PA, USA, 2004. [Google Scholar] [CrossRef]

- Thörn, C.; Sandkuhl, K. Feature Modeling: Managing Variability in Complex Systems. In Complex Systems in Knowledge-Based Environments: Theory, Models and Applications. Studies in Computational Intelligence; Tolk, A., Jain, L.C., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; Volume 168, pp. 129–162. ISBN 978-3-540-88074-5. [Google Scholar]

- Sanfilippo, E.M.; Borgo, S. What are features? An ontology-based review of the literature. Comput.-Aided Des. 2016, 80, 9–18. [Google Scholar] [CrossRef]

- Brown, D.C. Functional, Behavioral and Structural Features. In Proceedings of the ASME 2003 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, 15th International Conference on Design Theory and Methodology, Chicago, IL, USA, 2–6 September 2003. [Google Scholar] [CrossRef]

- Czarnecki, K.; Eisenecker, U.W. Generative Programming: Methods, Tools and Applications; Addison-Wesley: Reading, MA, USA, 2000. [Google Scholar]

- Kühn, A.; Bremer, C.; Dumitrescu, R.; Gausemeier, J. Feature models supporting trade-off decisions in early mechatronic systems design. In Proceedings of the NordDesign 2014 10th Biannual NordDesign Conference—Creating Together, Espoo, Finland, 27–29 August 2014. [Google Scholar]

- Sanfilippo, E.M. Ontological Foundations for Feature-Based Product Modelling. Ph.D. Thesis, Department of Information Engineering and Computer Science, Università Degli Studi Di Trento, Trento, Italy, 2016. [Google Scholar]

- Tang, S.H.; Chen, G.; Ma, Y.S. Fundamental Concepts of Generic Features. In Semantic Modelling and Interoperability in Product and Process Engineering; Ma, Y., Ed.; Springer Series in Advanced Manufacturing; Springer: London, UK, 2013; ISBN 978-1-4471-5072-5. [Google Scholar]

- Ballu, A.; Dufaure, J.; Teissandier, D. An adaptive tolerance model for collaborative design. In Digital Enterprise Technology. Perspectives and Future Challenges; Cunha, P.F., Maropoulos, P.G., Eds.; Springer: Boston, MA, USA, 2007; ISBN 978-0-387-49864-5. [Google Scholar]

- Noël, F.; Roucoules, L. The PPO design model with respect to digital enterprise technologies among product life cycle. Int. J. Comput. Integr. Manuf. 2008, 21, 139–145. [Google Scholar] [CrossRef]

- Edholm, P.; Johannesson, H.; Söderberg, R. Geometry interactions in configurable platform models. In Proceedings of the DESIGN 2010 the 11th International Design Conference, Dubrovnik, Croatia, 21–24 May 2010. [Google Scholar]

- ISO17450-1: Geometrical Product Specifications (GPS)—General Concepts—Part 1: Model for Geometrical Specification and Verification; International Organization for Standardization (ISO), Technical Committee: Geneva, Switzerland, 2011.

- Schleich, B.; Anwerb, N.; Mathieu, L.; Wartzack, S. Skin Model Shapes: A new paradigm shift for geometric variations modelling in mechanical engineering. Comput.-Aided Des. 2014, 50, 1–15. [Google Scholar] [CrossRef]

- Costadoat, R. Contribution à la Recherche de Spécifications Pour la Gestion des Variations au Plus tôt Dans le Cycle de Conception. Ph.D. Thesis, Université de Paris Sud 11, École Normale Supérieure de Cachan, Paris, France, 2010. [Google Scholar]

- Henzold, G. Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection, 2nd ed.; Elsevier: Oxford, UK, 2006; ISBN 978-0-7506-6738-8. [Google Scholar]

- Kandikjan, T.; Shah, J.J.; Davidson, J.K. A mechanism for validating dimensioning and tolerancing schemes in CAD systems. Comput.-Aided Des. 2001, 33, 721–737. [Google Scholar] [CrossRef]

- Shen, Z.; Shah, J.J.; Davidson, J.K. Analysis neutral data structure for GD&T. J. Intell. Manuf. 2008, 19, 455–472. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romero Subirón, F.; Rosado Castellano, P.; Bruscas Bellido, G.M.; Benavent Nácher, S. Feature-Based Framework for Inspection Process Planning. Materials 2018, 11, 1504. https://doi.org/10.3390/ma11091504

Romero Subirón F, Rosado Castellano P, Bruscas Bellido GM, Benavent Nácher S. Feature-Based Framework for Inspection Process Planning. Materials. 2018; 11(9):1504. https://doi.org/10.3390/ma11091504

Chicago/Turabian StyleRomero Subirón, Fernando, Pedro Rosado Castellano, Gracia M. Bruscas Bellido, and Sergio Benavent Nácher. 2018. "Feature-Based Framework for Inspection Process Planning" Materials 11, no. 9: 1504. https://doi.org/10.3390/ma11091504

APA StyleRomero Subirón, F., Rosado Castellano, P., Bruscas Bellido, G. M., & Benavent Nácher, S. (2018). Feature-Based Framework for Inspection Process Planning. Materials, 11(9), 1504. https://doi.org/10.3390/ma11091504