Characterization of a New Dry Drill-Milling Process of Carbon Fibre Reinforced Polymer Laminates

Abstract

1. Introduction

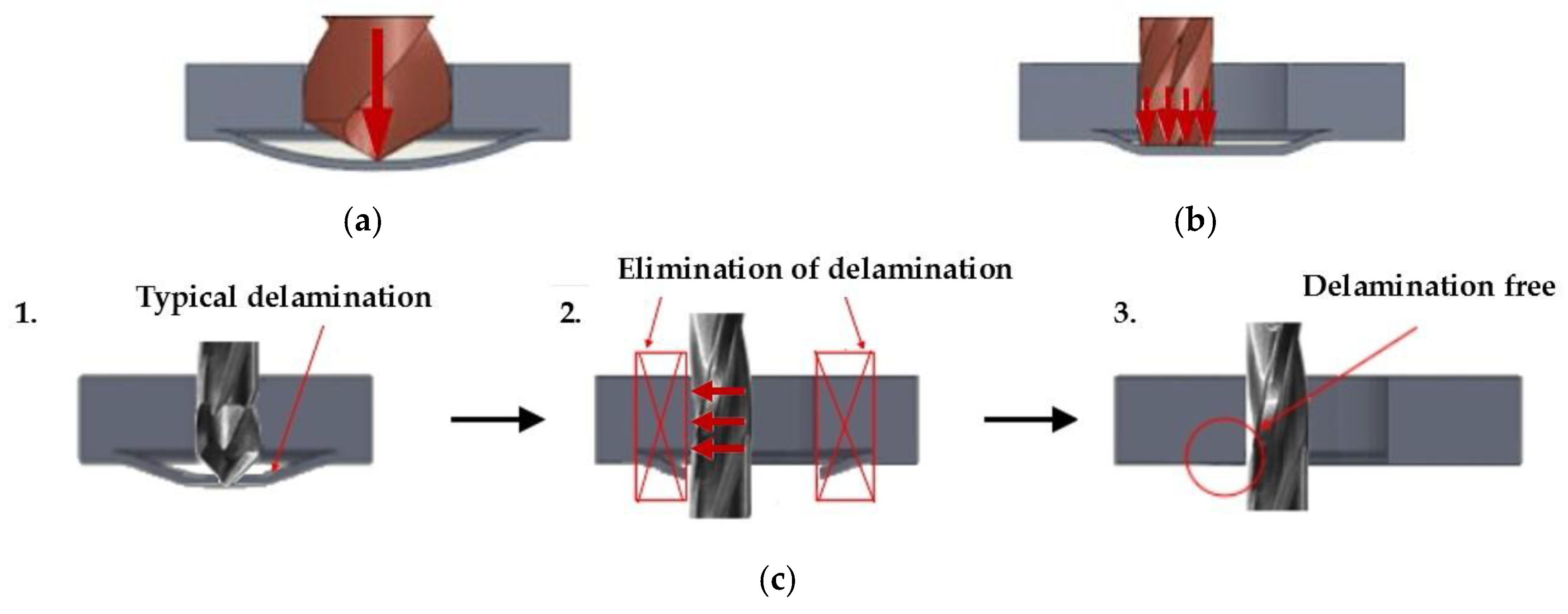

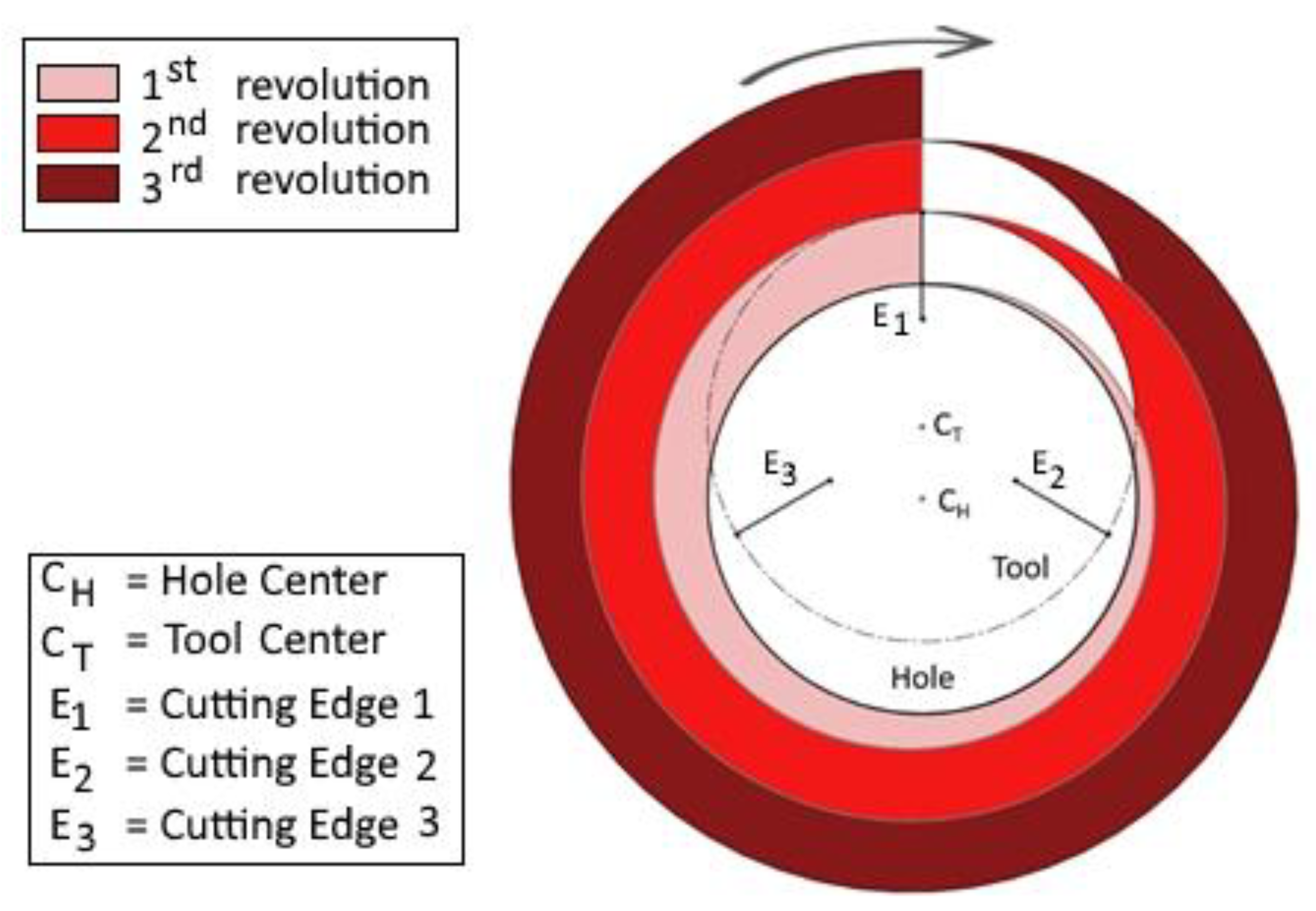

2. Proposed Drill-Milling Process

3. Materials and Methods

3.1. Preparation of the Specimen

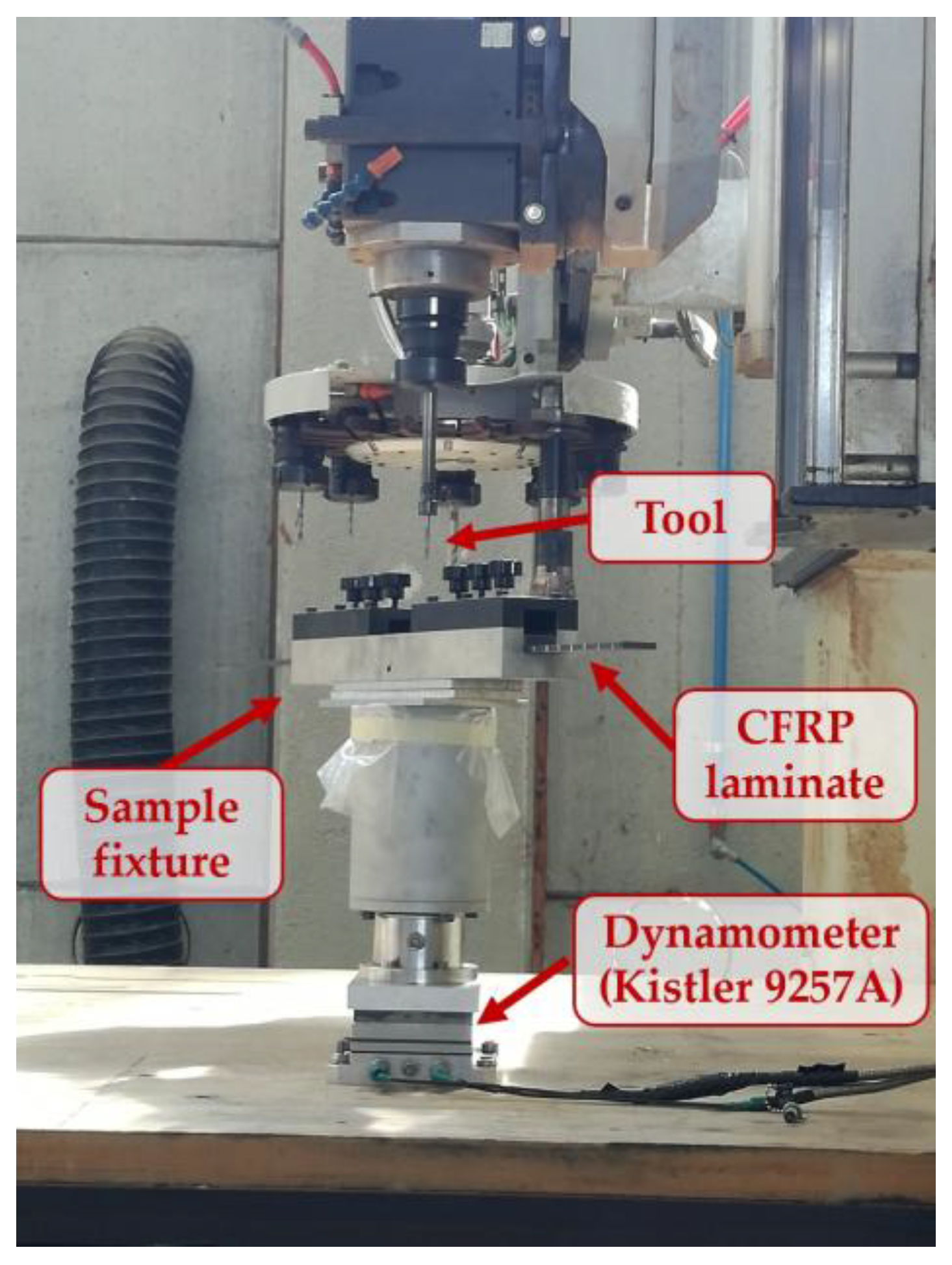

3.2. Equipment

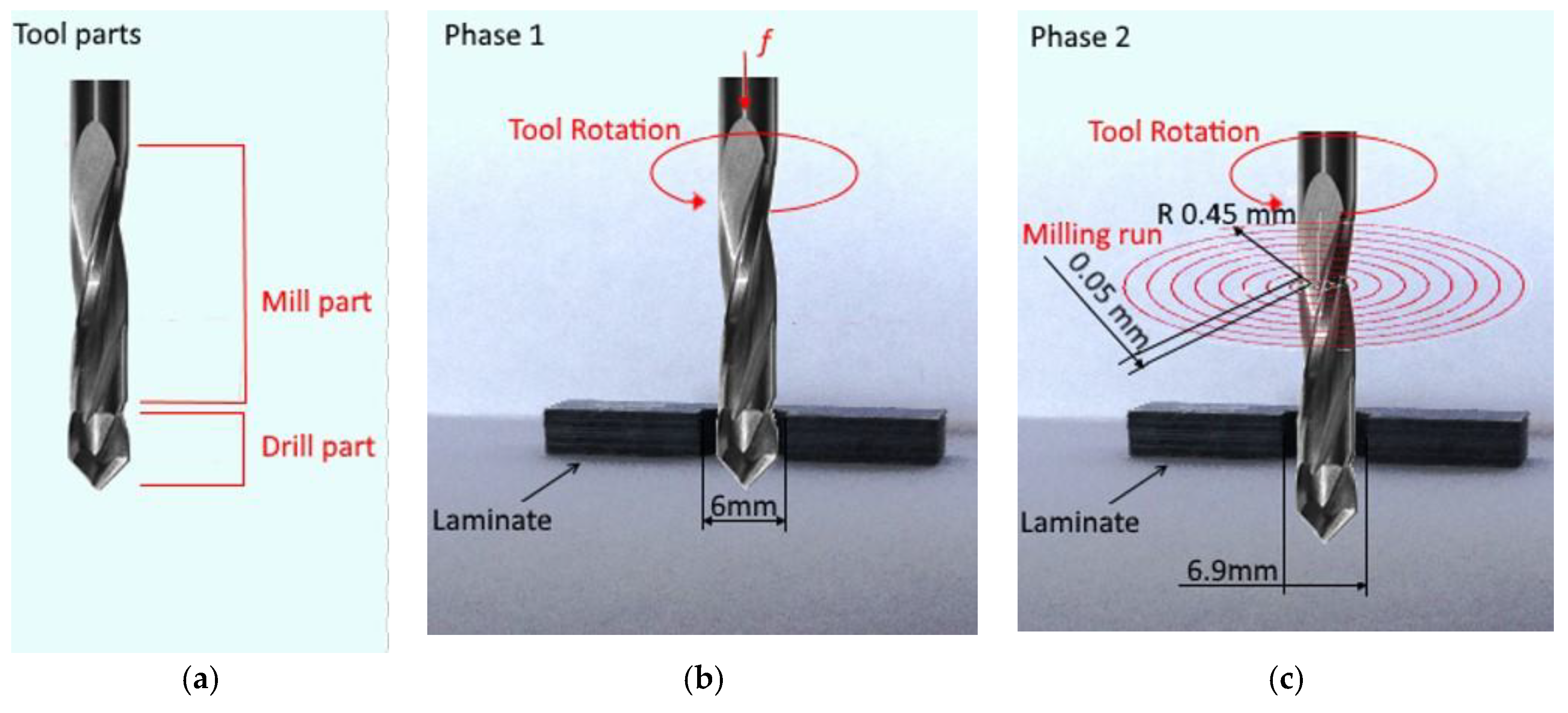

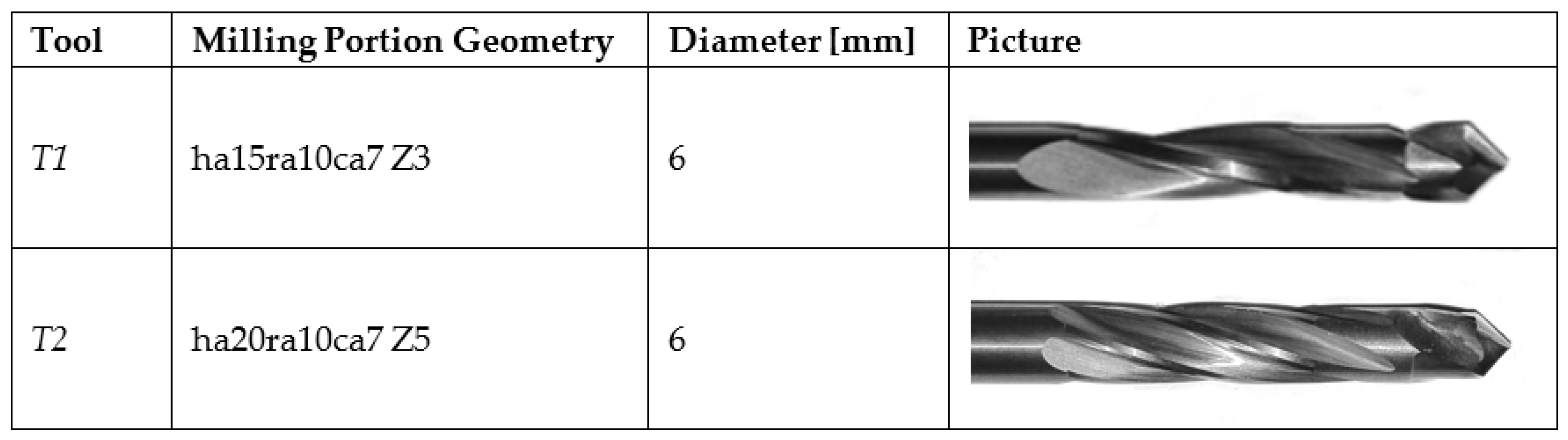

3.3. Tool

3.4. Dimensional Analysis

3.5. Surface Finish

4. Results and Discussion

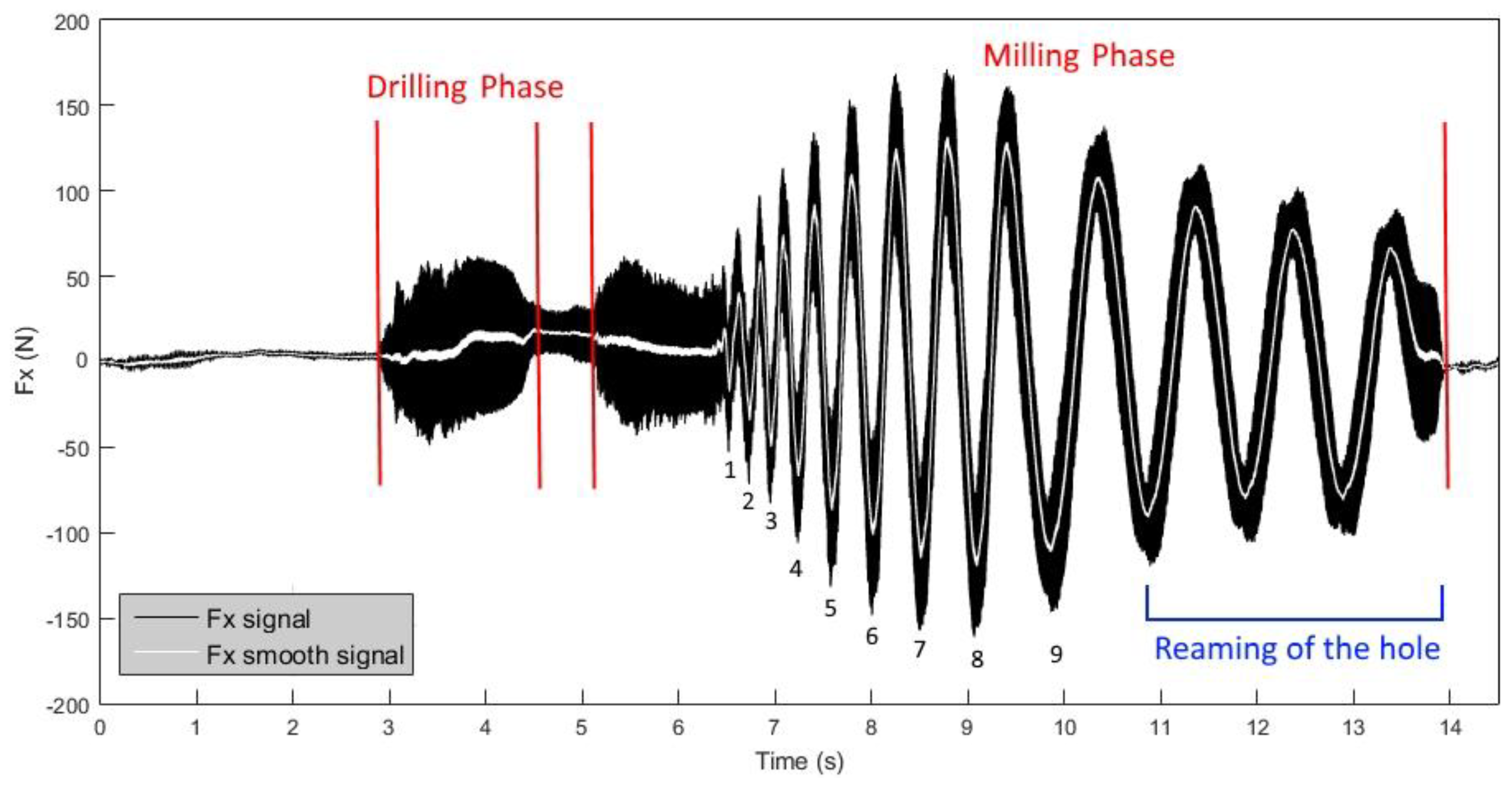

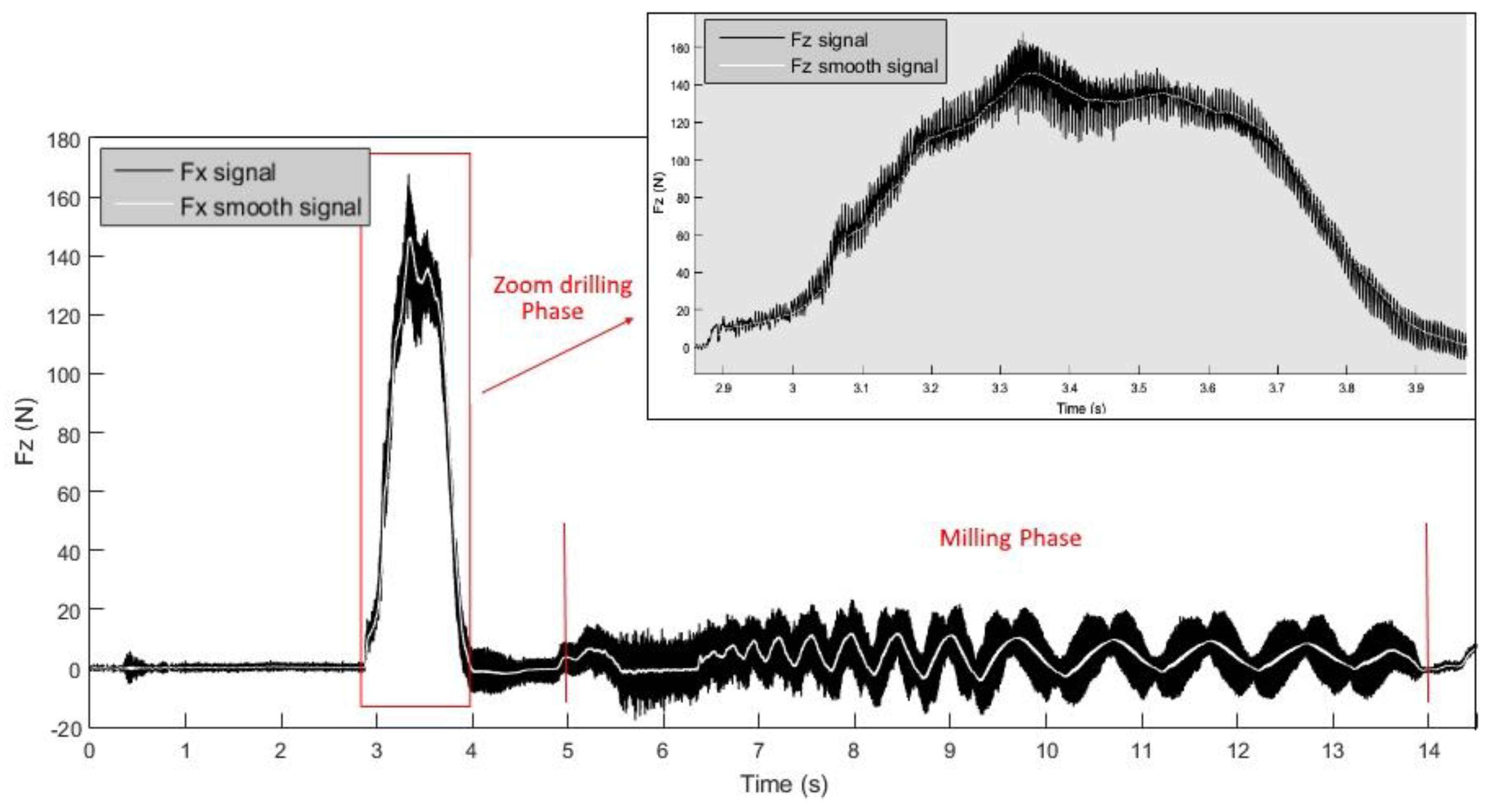

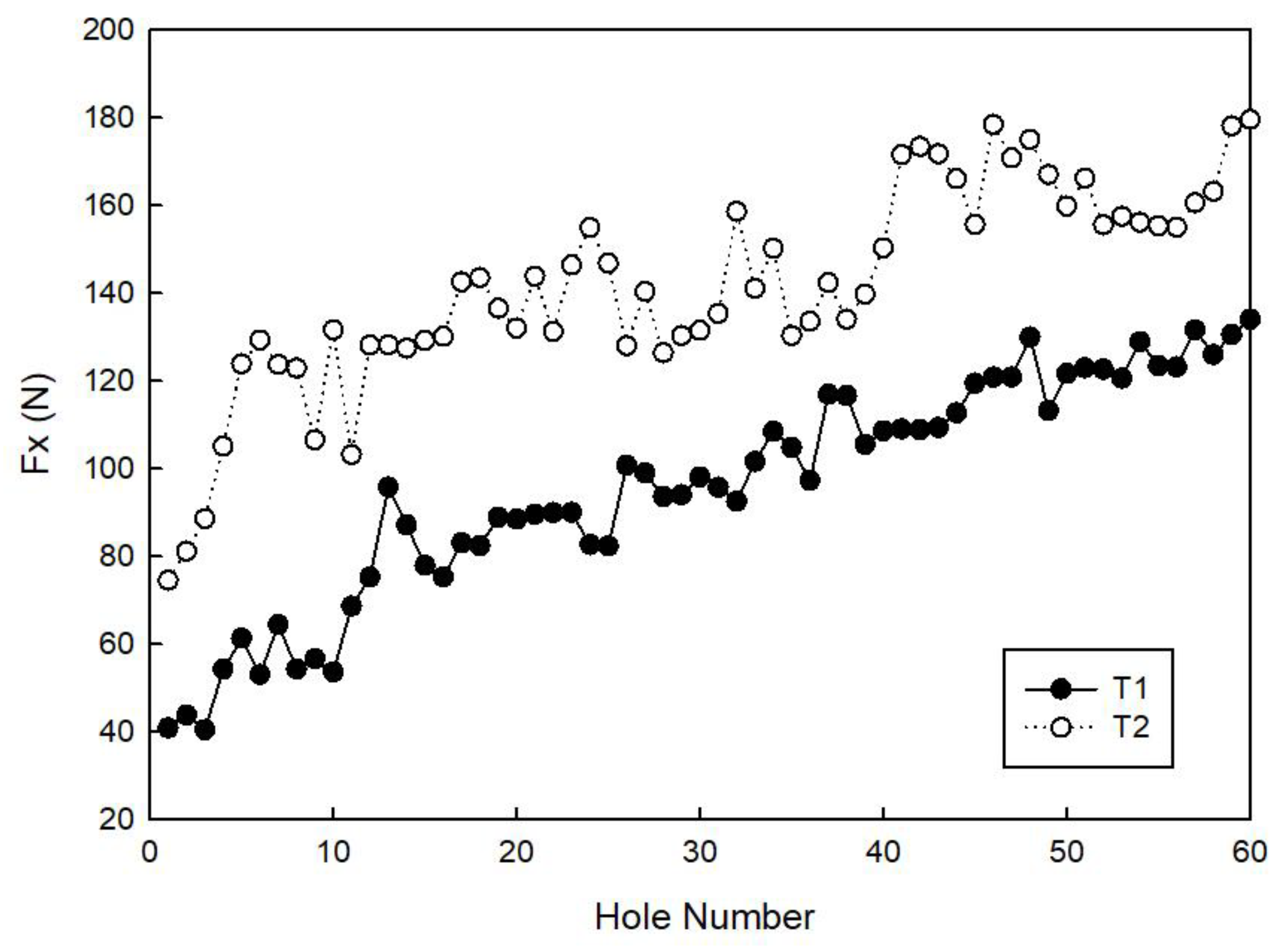

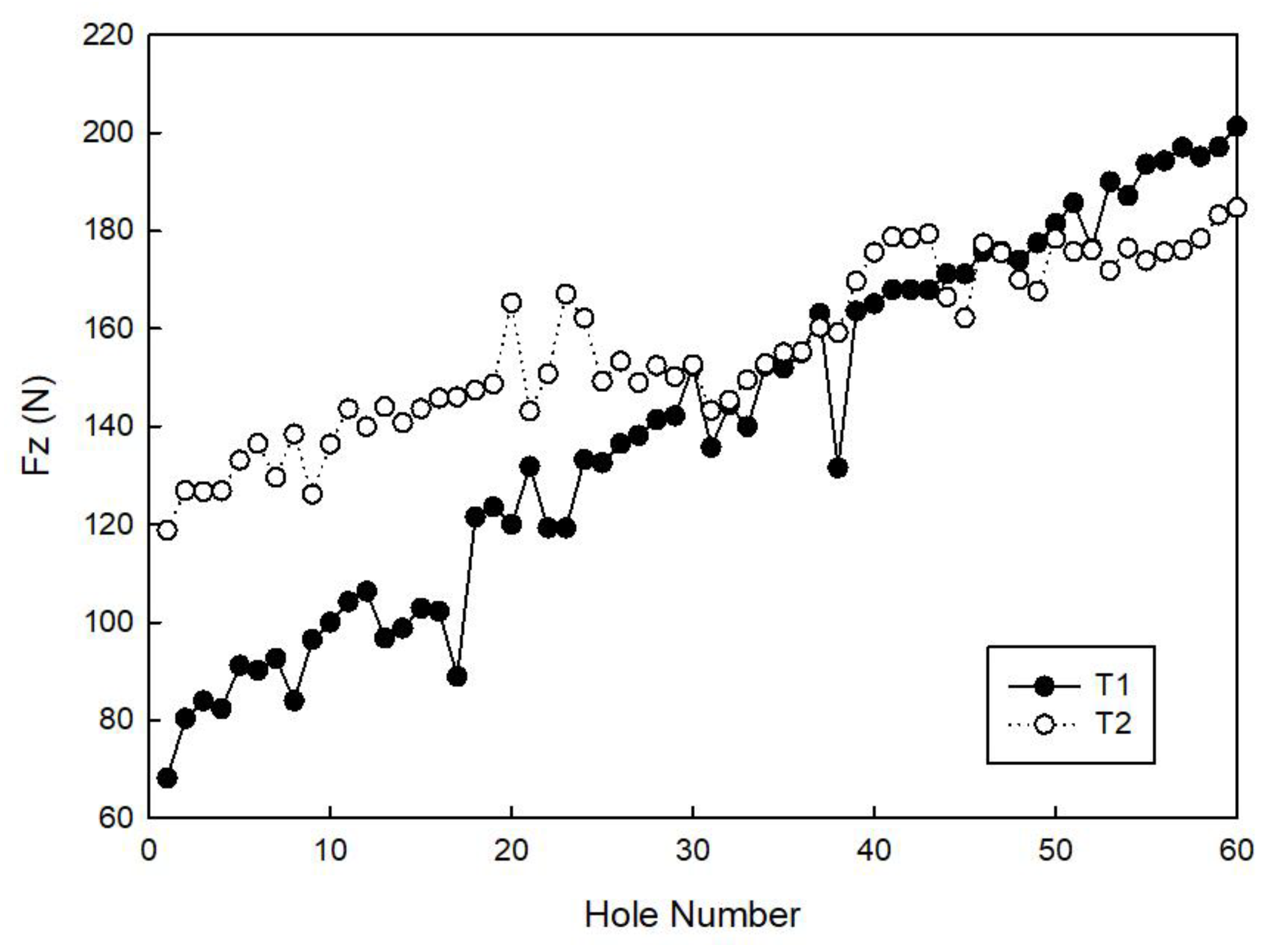

4.1. Cutting Forces

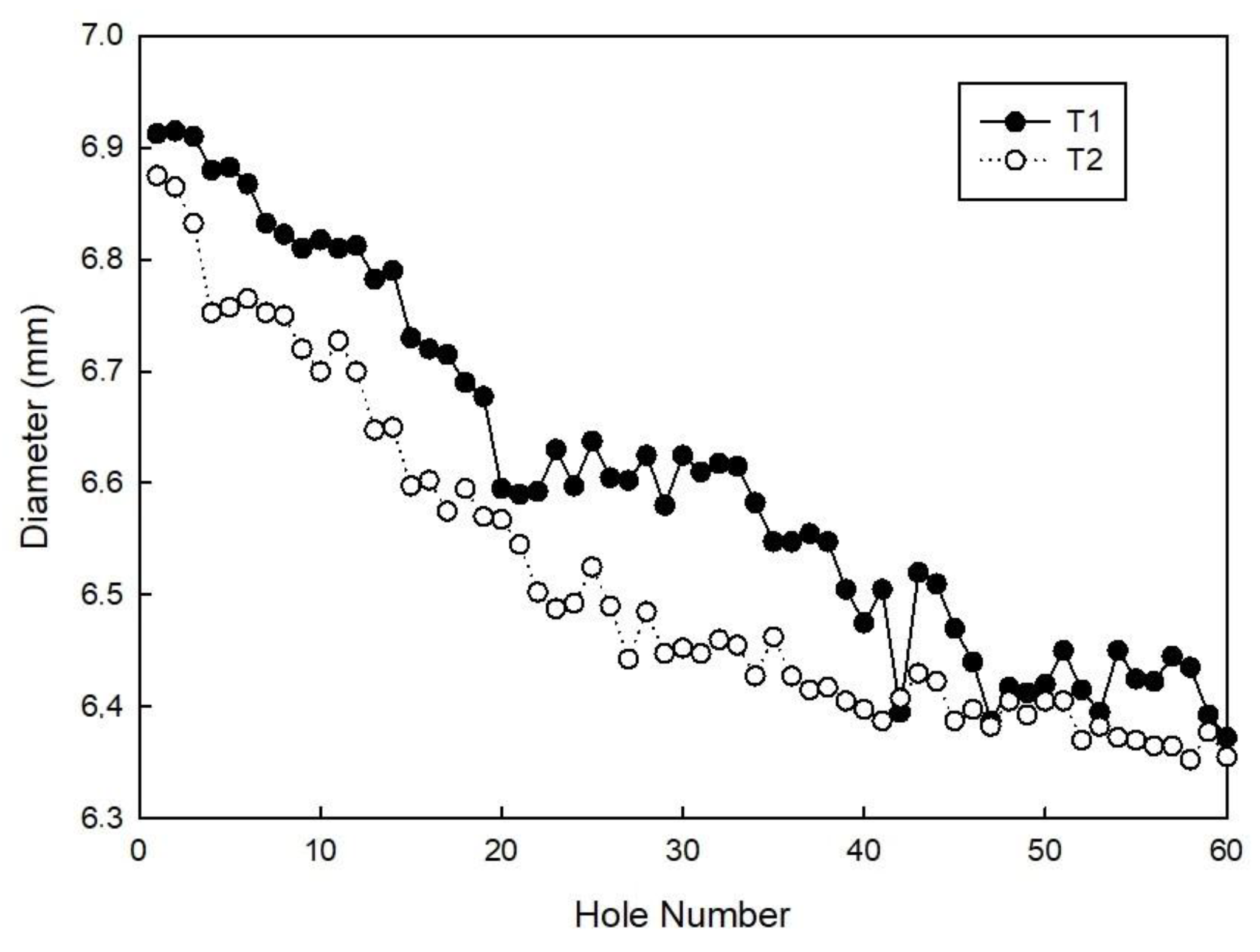

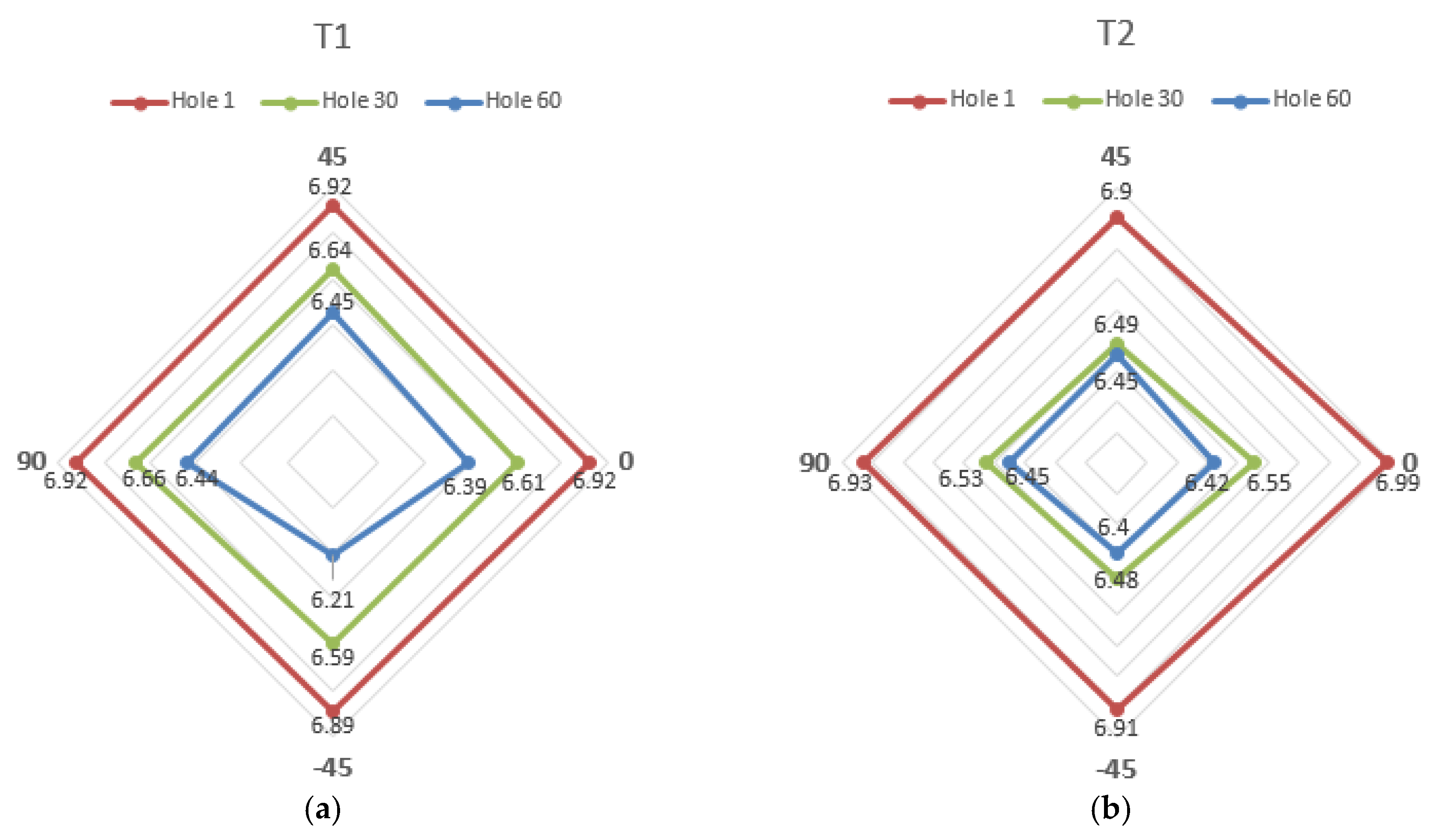

4.2. Metrological Analysis

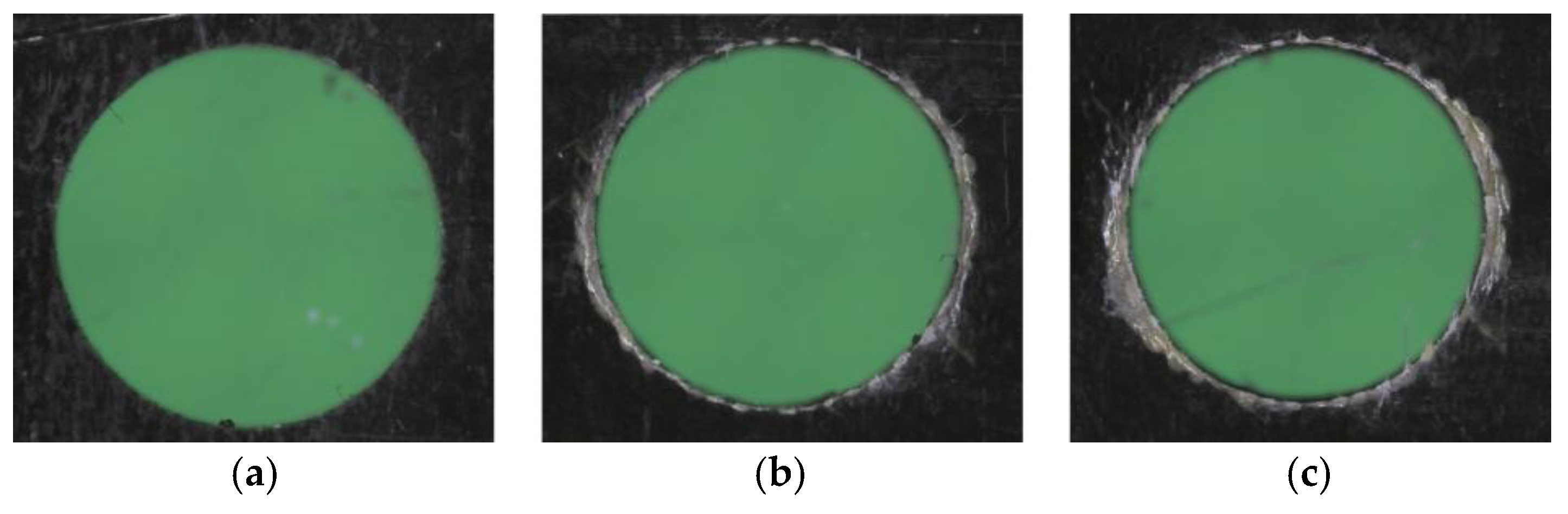

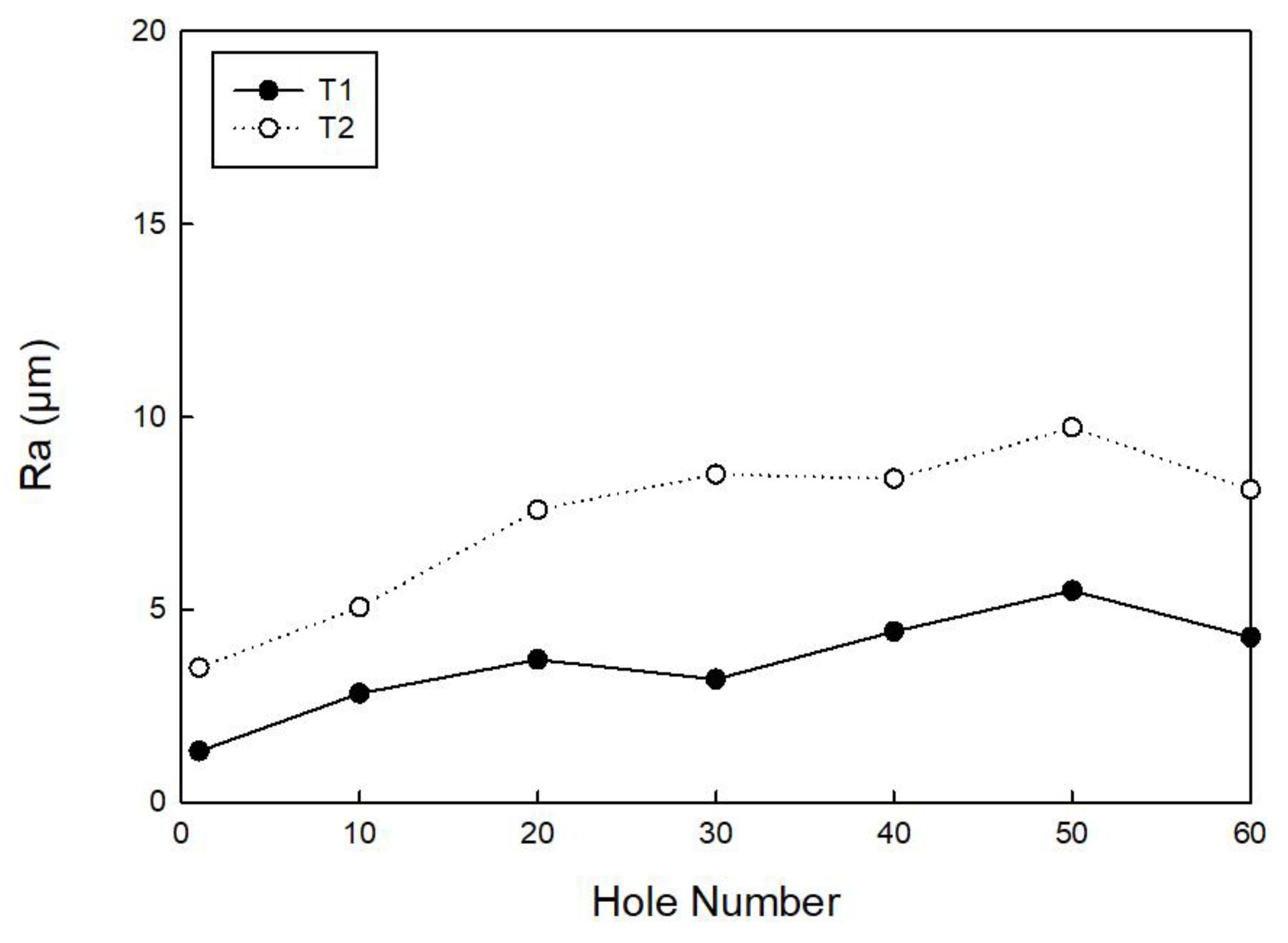

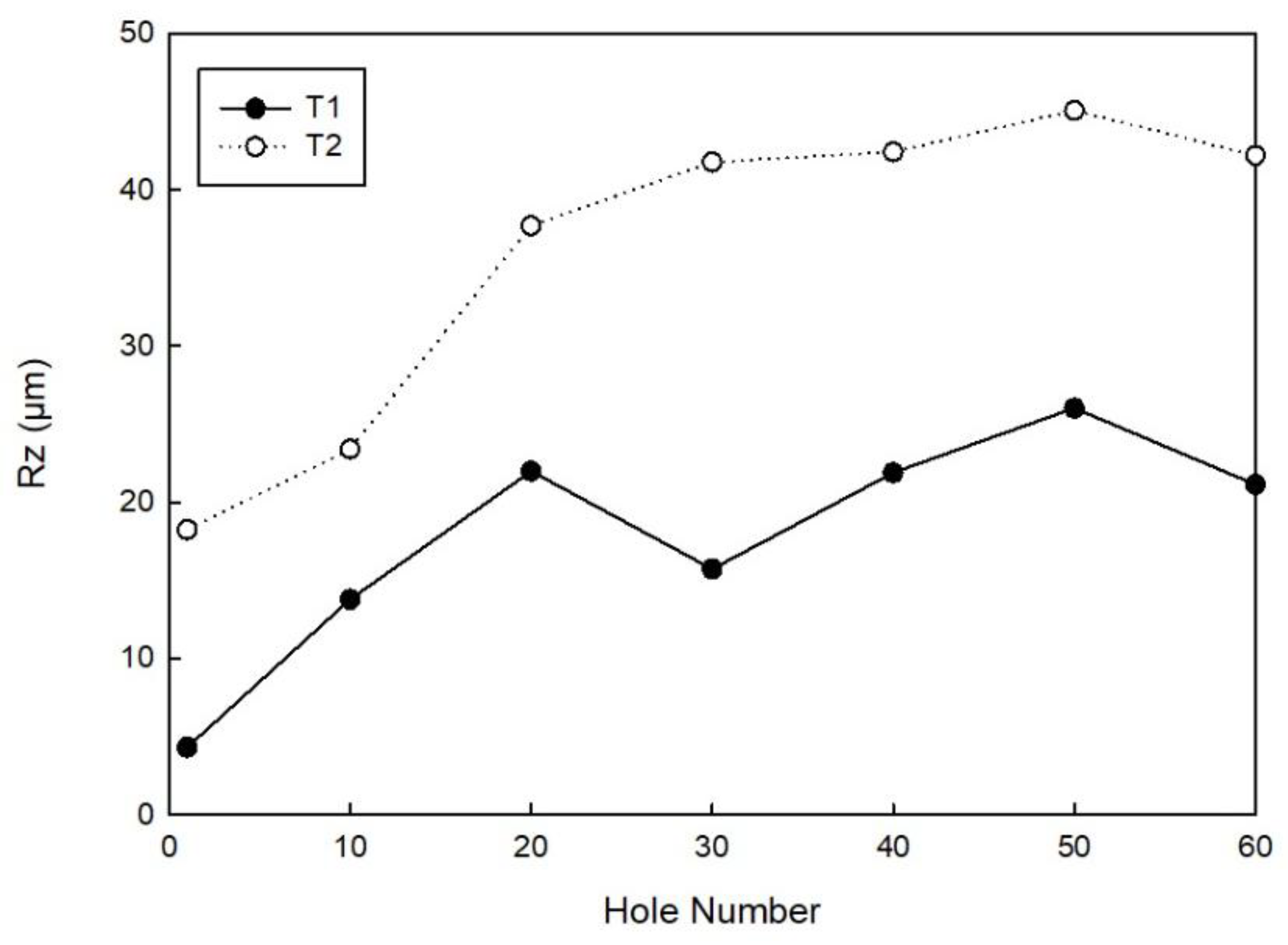

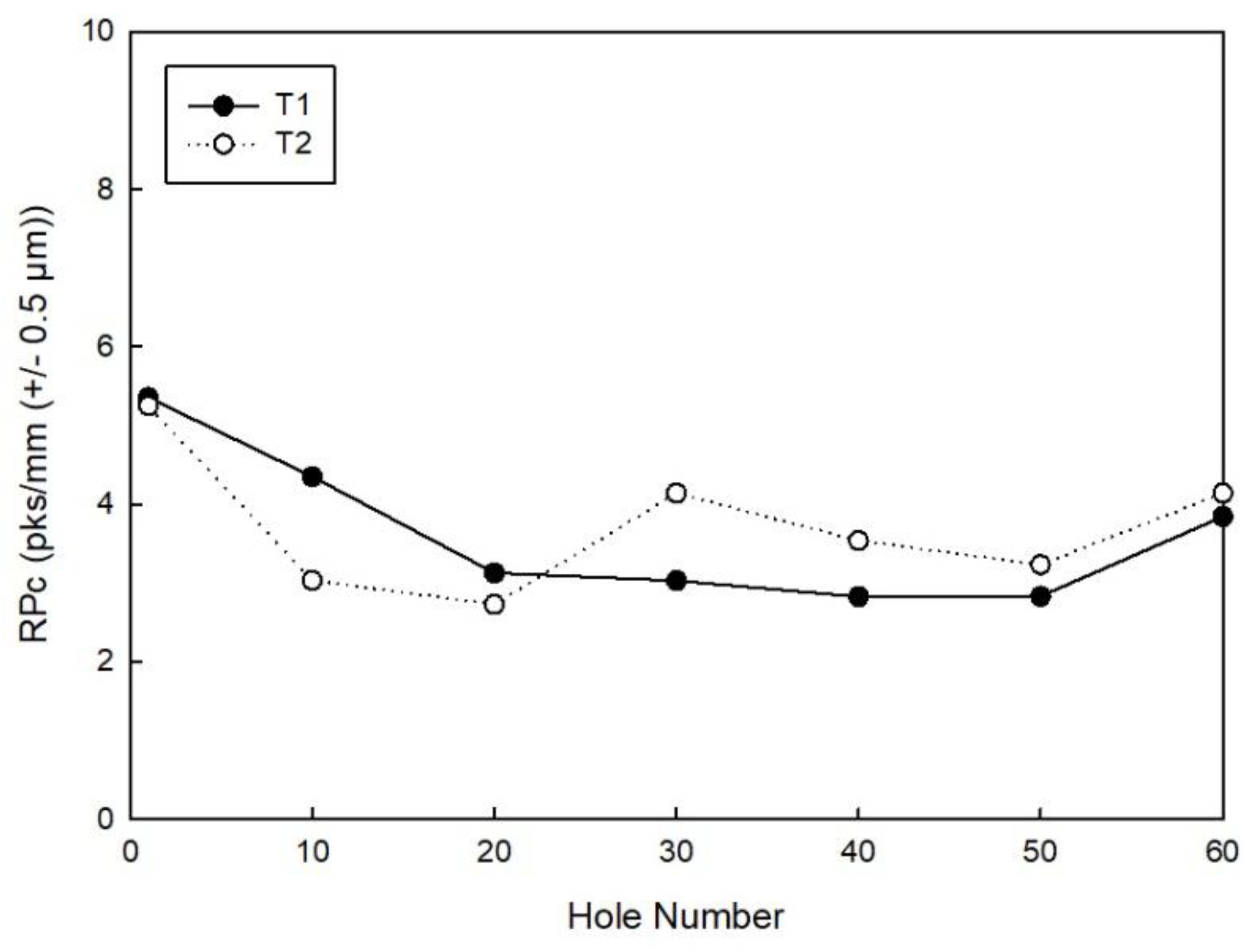

4.3. Surface Roughness

5. Conclusions

- The maximum values of the thrust cutting force, Fzmax, occurring during the drilling phase are consistent with those obtained in the experimental testing campaigns of traditional drilling.

- In terms of the cutting forces, the results obtained with tool T1 are better than those obtained with tool T2, as lower forces were recorded.

- In both tools, a rapid reduction in the diameter of the hole was observed, due to speedy tool wear growth, and also because the selected WC tools were uncoated.

- Tool T1 responded better in terms of a decrease in the hole diameter, and the use of a coated WC tool could lead to further improvement; it was also observed that the roundness of the hole is maintained with the increasing hole number.

- By comparing the measured roughness parameter values, the trends display a growing tendency with an increasing hole number in all of the cases. Moreover, the Ra roughness values are similar for both tools.

- The Rz roughness parameter values are better for tool T1. From this result, it can be inferred that tool T1 induces a lower fibre pull-out phenomenon in the CFRP.

- The RPc roughness parameter values indicate that the number of peaks per mm inside the CFRP is low, suggesting that the surface finish is good, except for the points where the voids caused by the pull-out phenomenon appear.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Caprino, G.; Santo, L.; Nele, L. On the origin of cutting forces in machining unidirectional composite materials. Am. Soc. Mech. Eng. Pet. Div. 1996, 75, 83–87. [Google Scholar]

- Caggiano, A. Machining of fibre reinforced plastic composite materials. Materials 2018, 11, 442. [Google Scholar] [CrossRef] [PubMed]

- Teti, R. Machining of composite materials. CIRP Ann. Manuf. Technol. 2002, 51, 611–634. [Google Scholar] [CrossRef]

- König, W.; Wulf, C.; Grass, P.; Willerscheid, H. Machining of fibre reinforced plastics. CIRP Ann. Manuf. Technol. 1985, 34, 537–548. [Google Scholar] [CrossRef]

- Chen, W.C. Some experimental investigations in the drilling of carbon fiber-reinforced plastic (CFRP) composite laminates. Int. J. Mach. Tools Manuf. 1997, 37, 1097–1108. [Google Scholar] [CrossRef]

- Kumar, D.; Singh, K.K.; Zitoune, R. Experimental investigation of delamination and surface roughness in the drilling of GFRP composite material with different drills. Adv. Manuf. Polym. Compos. Sci. 2016, 2, 47–56. [Google Scholar] [CrossRef]

- Jain, S.; Yang, D.C.H. Delamination-free drilling of composite laminates. J. Eng. Ind. 1994, 116, 475–481. [Google Scholar] [CrossRef]

- Lin, S.C.; Chen, I.K. Drilling carbon fiber-reinforced composite material at high speed. Wear 1996, 194, 156–162. [Google Scholar] [CrossRef]

- Ho-Cheng, H.; Dharan, C.H.K. Delamination during drilling in composite laminates. J. Eng. Ind. 1990, 112, 236–239. [Google Scholar] [CrossRef]

- Davim, J.P.; Reis, P. Study of delamination in drilling carbon fiber reinforced plastics (CFRP) using design experiments. Compos. Struct. 2003, 59, 481–487. [Google Scholar] [CrossRef]

- Hocheng, H.; Tsao, C.C. The path towards delamination-free drilling of composite materials. J. Mater. Process. Technol. 2005, 167, 251–264. [Google Scholar] [CrossRef]

- Durão, L.M.P.; Gonçalves, D.J.S.; Tavares, J.M.R.S.; de Albuquerque, V.H.C.; Aguiar Vieira, A.; Torres Marques, A. Drilling tool geometry evaluation for reinforced composite laminates. Compos. Struct. 2010, 92, 1545–1550. [Google Scholar] [CrossRef]

- Piquet, R.; Ferret, B.; Lachaud, F.; Swider, P. Experimental analysis of drilling damage in thin carbon/epoxy plate using special drills. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1107–1115. [Google Scholar] [CrossRef]

- Feito, N.; Díaz-Álvarez, J.; Díaz-Álvarez, A.; Cantero, J.L.; Miguélez, M.H. Experimental analysis of the influence of drill point angle and wear on the drilling of woven CFRPs. Materials 2014, 7, 4258–4271. [Google Scholar] [CrossRef] [PubMed]

- Gaitonde, V.N.; Karnik, S.R.; Rubio, J.C.; Correia, A.E.; Abrão, A.M.; Davim, J.P. Analysis of parametric influence on delamination in high-speed drilling of carbon fiber reinforced plastic composites. J. Mater. Process. Technol. 2008, 203, 431–438. [Google Scholar] [CrossRef]

- Saoudi, J.; Zitoune, R.; Gururaja, S.; Salem, M.; Mezleni, S. Analytical and experimental investigation of the delamination during drilling of composite structures with core drill made of diamond grits: X-ray tomography analysis. J. Compos. Mater. 2018, 52. [Google Scholar] [CrossRef]

- Cadorin, N.; Zitoune, R.; Seitier, P.; Collombet, F. Analysis of damage mechanism and tool wear while drilling of 3D woven composite materials using internal and external cutting fluid. J. Compos. Mater. 2015, 49, 2687–2703. [Google Scholar] [CrossRef]

- Zitoune, R.; Cadorin, N.; Collombet, F.; Šíma, M. Temperature and wear analysis in function of the cutting tool coating when drilling of composite structure: In situ measurement by optical fiber. Wear 2017, 376–377, 1849–1858. [Google Scholar] [CrossRef]

- Lindqvist, R.; Eriksson, I.; Wolf, M. Orbital drilling of sandwich constructions for space applications. In SAE Technical Paper 2001-01-2571; SAE: Warrendale, PA, USA, 2001; p. 10. [Google Scholar]

- Sadek, A.; Meshreki, M.; Attia, M.H. Characterization and optimization of orbital drilling of woven carbon fiber reinforced epoxy laminates. CIRP Ann. Manuf. Technol. 2012, 61, 123–126. [Google Scholar] [CrossRef]

- Ozturk, O.M.; Kilic, Z.M.; Altintas, Y. Mechanics and dynamics of orbital drilling operations. Int. J. Mach. Tools Manuf. 2018, 129, 37–47. [Google Scholar] [CrossRef]

- Babu, P.R.; Pradhan, B. Effect of damage levels and curing stresses on delamination growth behaviour emanating from circular holes in laminated FRP composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2412–2421. [Google Scholar] [CrossRef]

- Durão, L.; Tavares, J.; de Albuquerque, V.; Marques, J.; Andrade, O. Drilling damage in composite material. Materials 2014, 7, 3802–3819. [Google Scholar] [CrossRef] [PubMed]

- Hocheng, H.; Tsao, C.C. Comprehensive analysis of delamination in drilling of composite materials with various drill bits. J. Mater. Process. Technol. 2003, 140, 335–339. [Google Scholar] [CrossRef]

- Caggiano, A.; Angelone, R.; Teti, R. Image analysis for CFRP drilled hole quality assessment. Procedia CIRP 2017, 62, 440–445. [Google Scholar] [CrossRef]

- UNI ISO EN 4288–2000. Geometrical Product Specifications (gps)-Surface Texture: Profile Method-Rules and Procedures for the Assessment of Surface Texture; International Organization for Standardization: Geneva, Switzerland, 2000. [Google Scholar]

- Gaitonde, V.N.; Karnik, S.R.; Rubio, J.C.; Abrão, A.M.; Correia, A.E.; Davim, J.P. Surface roughness analysis in high-speed drilling of unreinforced and reinforced polyamides. J. Compos. Mater. 2012, 46, 2659–2673. [Google Scholar] [CrossRef]

- Li, S.; Qin, X.; Jin, Y.; Sun, D.; Li, Y. A comparative study of hole-making performance by coated and uncoated WC/Co cutters in helical milling of Ti/CFRP stacks. Int. J. Adv. Manuf. Technol. 2018, 94, 2645–2658. [Google Scholar] [CrossRef]

- Park, K.-H.; Beal, A.; (Dae-Wook) Kim, D.; Kwon, P.; Lantrip, J. A comparative study of carbide tools in drilling of CFRP and CFRP-Ti stacks. J. Manuf. Sci. Eng. 2013, 136, 014501. [Google Scholar] [CrossRef]

- Ramirez, C.; Poulachon, G.; Rossi, F.; Saoubi, R.M. Tool wear monitoring and hole surface quality during CFRP drilling. Procedia CIRP 2014, 13, 163–168. [Google Scholar] [CrossRef]

- Eneyew, E.D.; Ramulu, M. Experimental study of surface quality and damage when drilling unidirectional CFRP composites. J. Mater. Res. Technol. 2014, 3, 354–362. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Young Modulus 0° | 145 GPa |

| Tensile strength 0° | 220 MPa |

| Young Modulus 90° | 8.50 GPa |

| Tensile strength 90° | 75 MPa |

| Revolution | Area of Material Removed (mm2) |

|---|---|

| 1 | 0.46 |

| 2 | 0.86 |

| 3 | 0.88 |

| 4 | 0.90 |

| 5 | 0.93 |

| 6 | 0.96 |

| 7 | 1.00 |

| 8 | 1.04 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caggiano, A.; Improta, I.; Nele, L. Characterization of a New Dry Drill-Milling Process of Carbon Fibre Reinforced Polymer Laminates. Materials 2018, 11, 1470. https://doi.org/10.3390/ma11081470

Caggiano A, Improta I, Nele L. Characterization of a New Dry Drill-Milling Process of Carbon Fibre Reinforced Polymer Laminates. Materials. 2018; 11(8):1470. https://doi.org/10.3390/ma11081470

Chicago/Turabian StyleCaggiano, Alessandra, Ilaria Improta, and Luigi Nele. 2018. "Characterization of a New Dry Drill-Milling Process of Carbon Fibre Reinforced Polymer Laminates" Materials 11, no. 8: 1470. https://doi.org/10.3390/ma11081470

APA StyleCaggiano, A., Improta, I., & Nele, L. (2018). Characterization of a New Dry Drill-Milling Process of Carbon Fibre Reinforced Polymer Laminates. Materials, 11(8), 1470. https://doi.org/10.3390/ma11081470