Virtual Extensometer Analysis of Martensite Band Nucleation, Growth, and Strain Softening in Pseudoelastic NiTi Subjected to Different Load Cases

Abstract

1. Introduction

2. Materials and Methods

2.1. Optical Strain Measurements Using DIC

2.2. Determination of Nominal Uniaxial Stresses and Strains

3. Results and Discussion

4. Summary and Conclusions

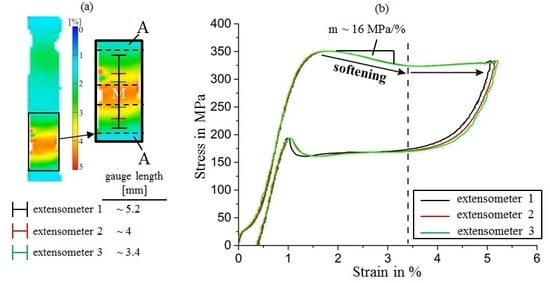

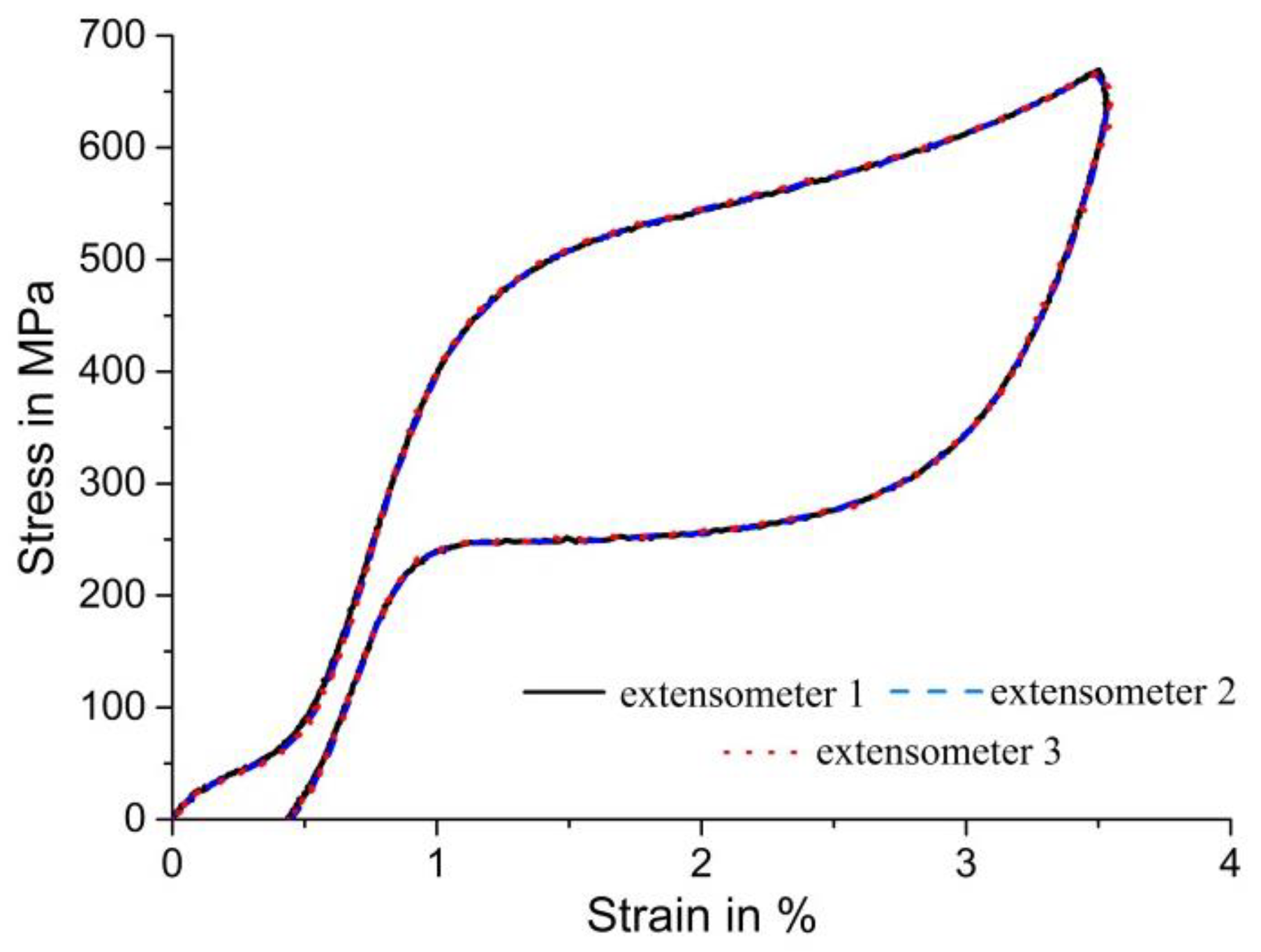

- Under uniaxial tension, characteristics of the stress–strain curves in terms of the absolute length of the pseudoelastic plateau, and especially in terms of the shape of the nucleation peak, can be considerably affected by the position of a (virtual) extensometer with respect to the nucleation site of distinct martensite bands. In the case of a localized deformation, which primarily occurs in tension in NiTi, the positioning of the extensometer used for the strain analysis is highly important when analyzing subtle features of the resulting stress–strain curves. We show, for the first time, that the specific softening behavior of NiTi SMAs under uniaxial tensile loading can, to some extent, be directly analyzed experimentally by locating an extensometer in post-experimental DIC data analysis directly onto the region where a martensite band is nucleated. The amount of strain softening (slope of the resulting stress–strain curve: 16 MPa/%) may form an experimental basis for advanced mechanical modeling studies.

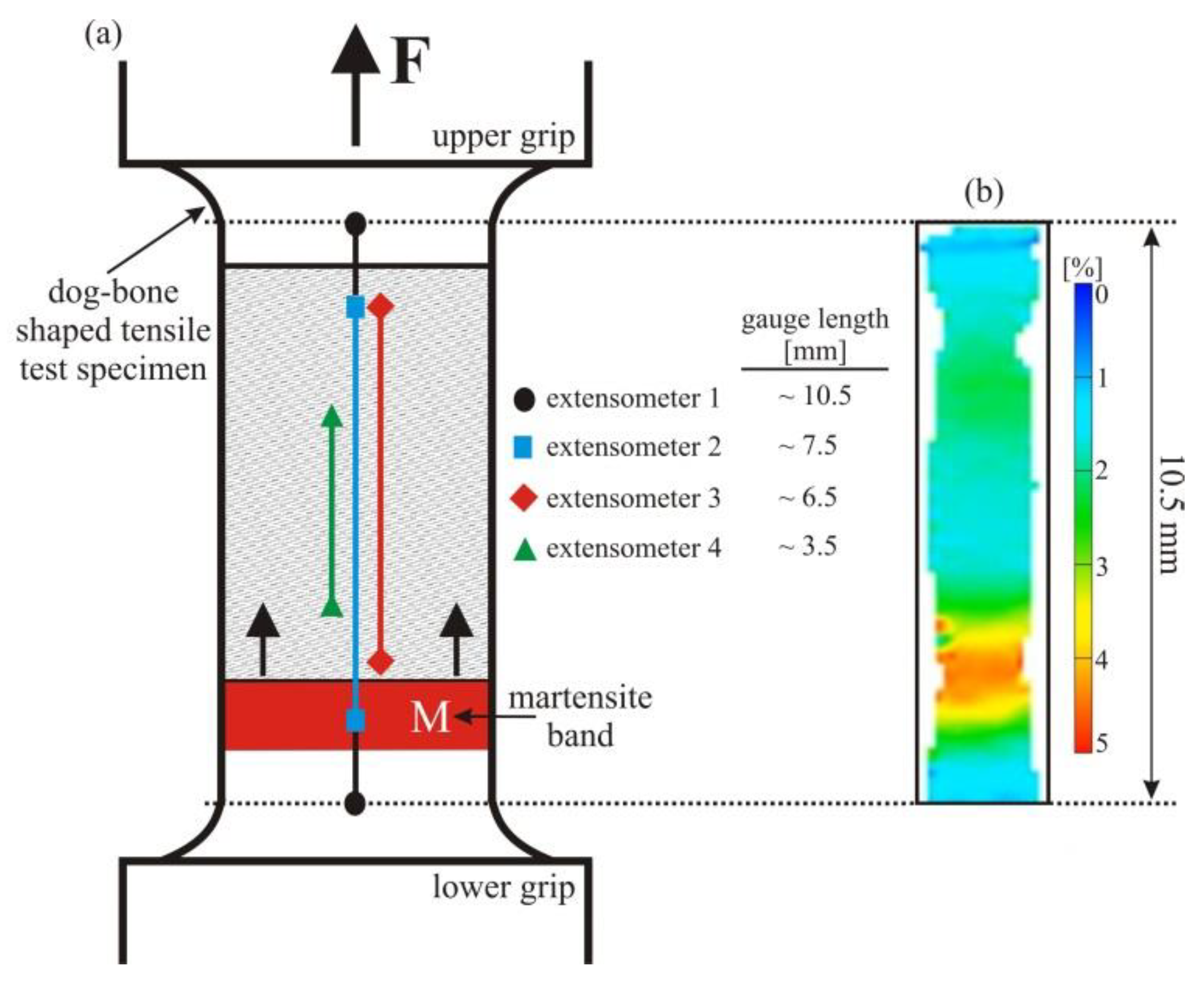

- The mechanical response of pseudoelastic NiTi associated with the stress-induced martensitic transformation exhibits a strong difference in tension and compression. This can be attributed to the different macroscopic modes of deformation. Under tension, the stress-induced martensitic transformation proceeds in a localized manner (via formation and growth of martensite bands). Under simple compression, the deformation proceeds homogeneously (without distinct martensite bands/strain localization. Therefore, the position and total gauge length of a (virtual) extensometer has no influence on the stress–strain curves in compression.

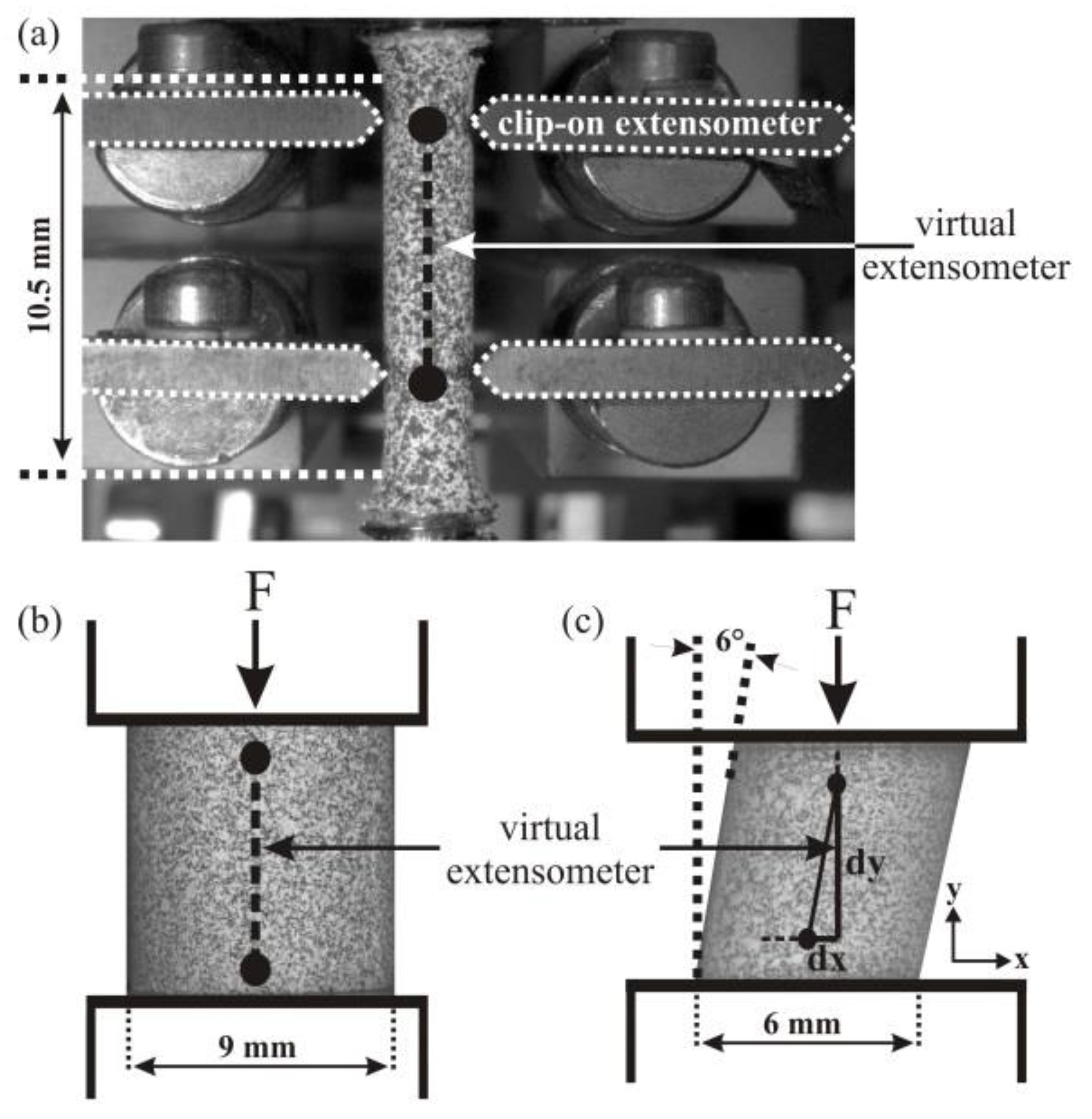

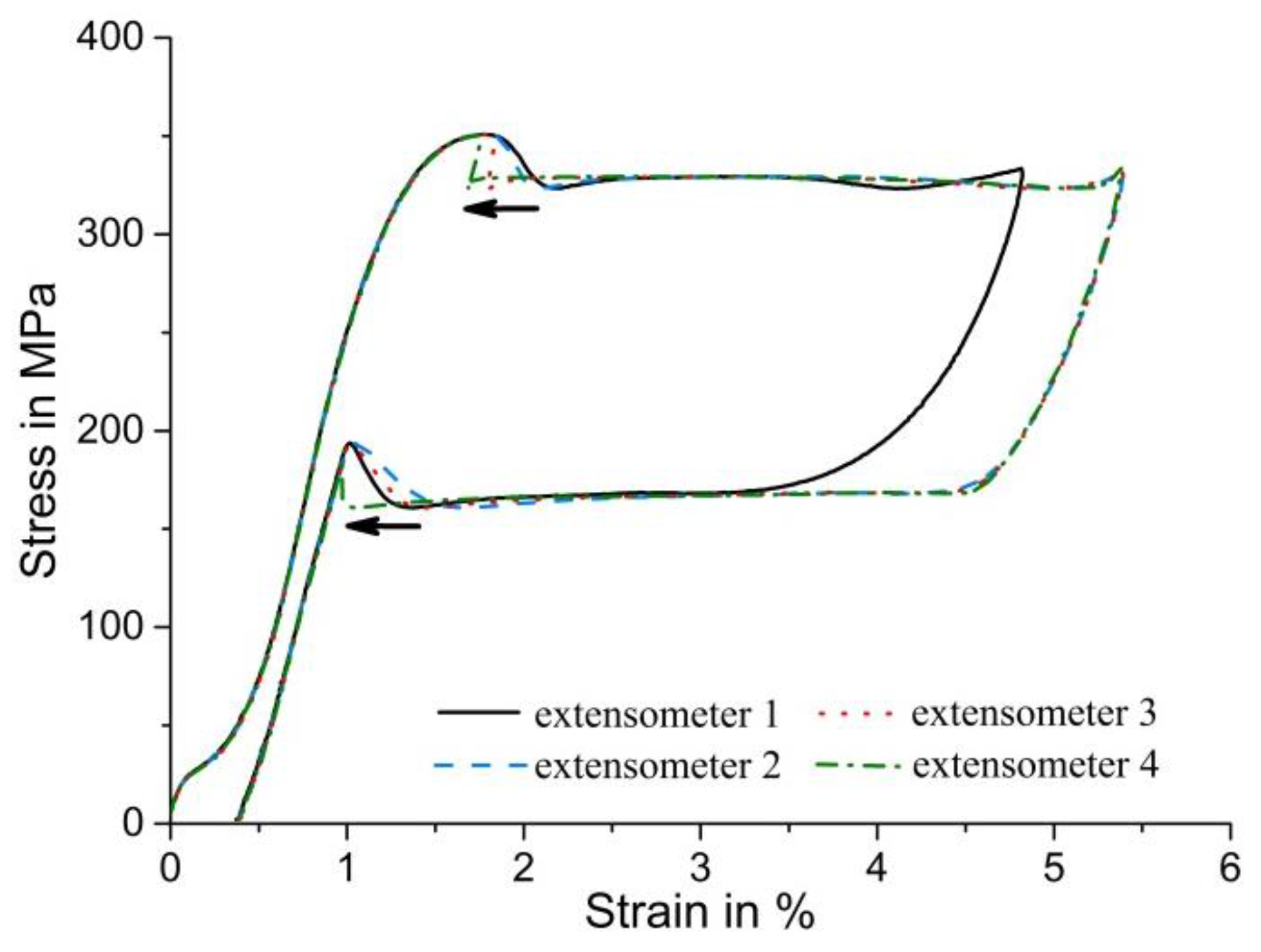

- In the multi-axial load case created by the special geometry of compression-shear specimens, the material exhibits a strong inhomogeneity of the transformation. However, no lateral growth of distinct martensite bands (as observed under uniaxial tension) occurs, and therefore the macroscopic stress–strain behavior closely resembles the behavior under simple compression. However, there is a small but systematic effect of the virtual extensometer’s gauge length on the resulting stress–strain curves in this special load case. While it is less pronounced when compared to tensile loading, it clearly highlights the inhomogeneous deformation mode of NiTi when subjected to compression-shear loading.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Duerig, T.; Pelton, A.; Stöckel, D. An overview of nitinol medical applications. Mater. Sci. Eng. A 1999, 273–275, 149–160. [Google Scholar] [CrossRef]

- Wagner, M.F.-X.; Eggeler, G. New aspects of bending rotation fatigue in ultra-fine-grained pseudo-elastic NiTi wires. Int. J. Mater. Res. 2006, 97, 1687–1696. [Google Scholar] [CrossRef]

- Wagner, M.; Richter, J.; Frenzel, J.; Grönemeyer, D.; Eggeler, G. Design of a Medical Non-Linear Drilling Device: The Influence of Twist and Wear on the Fatigue Behaviour of NiTi Wires Subjected to Bending Rotation. Mater. Werkst. 2004, 35, 320–325. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Shape Memory Alloys: A Material and a Technology. Adv. Eng. Mater. 2001, 3, 837–850. [Google Scholar] [CrossRef]

- Elibol, C.; Wagner, M.F.-X. Investigation of the stress-induced martensitic transformation in pseudoelastic NiTi under uniaxial tension, compression and compression–shear. Mater. Sci. Eng. A 2015, 621, 76–81. [Google Scholar] [CrossRef]

- Elibol, C.; Wagner, M.F.-X. Strain rate effects on the localization of the stress-induced martensitic transformation in pseudoelastic NiTi under uniaxial tension, compression and compression-shear. Mater. Sci. Eng. A 2015, 643, 194–202. [Google Scholar] [CrossRef]

- Shaw, J.A.; Kyriakides, S. Initiation and propagation of localized deformation in elasto-plastic strips under uniaxial tension. Int. J. Plast. 1998, 13, 837–871. [Google Scholar] [CrossRef]

- Wagner, M.F.-X.; Schaefer, A. Macroscopic versus local strain rates during tensile testing of pseudoelastic NiTi. Scr. Mater. 2010, 63, 863–866. [Google Scholar] [CrossRef]

- Azadi, B.; Rajapakse, R.K.N.D.; Maijer, D.M. Multi-dimensional constitutive modeling of SMA during unstable pseudoelastic behavior. Int. J. Solids Struct. 2007, 44, 6473–6490. [Google Scholar] [CrossRef]

- Feng, P.; Sun, Q.P. Experimental investigation on macroscopic domain formation and evolution in polycrystalline NiTi microtubing under mechanical force. J. Mech. Phys. Solids 2006, 54, 1568–1603. [Google Scholar] [CrossRef]

- Grossmann, C.; Schaefer, A.; Wagner, M.F.-X. A finite element study on localized deformation and functional fatigue in pseudoelastic NiTi strips. Mater. Sci. Eng. A 2010, 527, 1172–1178. [Google Scholar] [CrossRef]

- Šittner, P.; Sedlák, P.; Seiner, H.; Sedmák, P.; Pilch, J.; Delville, R.; Heller, L.; Kadeřávek, L. On the coupling between martensitic transformation and plasticity in NiTi: Experiments and continuum based modelling. Prog. Mater. Sci. 2018, 98, 249–298. [Google Scholar] [CrossRef]

- Orgéas, L.; Favier, D. Stress-induced martensitic transformation of a NiTi alloy in isothermal shear, tension and compression. Acta Mater. 1998, 46, 5579–5591. [Google Scholar] [CrossRef]

- Orgéas, L.; Favier, D.; Liu, Y.; Rio, G. Mechanical instability of NiTi in tension, compression and shear. In IUTAM Symposium on Mechanics of Martensitic Phase Transformation in Solids; Sun, Q.P., Ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002; pp. 205–212. ISBN 978-94-017-0069-6. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Z.; van Humbeeck, J.; Dealey, L. Asymmetry of stress–strain curves under tension and compression for NiTi shape memory alloys. Acta Mater. 1998, 46, 4325–4338. [Google Scholar] [CrossRef]

- Mao, S.C.; Luo, J.F.; Zhang, Z.; Wu, M.H.; Liu, Y.; Han, X.D. EBSD studies of the stress-induced B2–B19′ martensitic transformation in NiTi tubes under uniaxial tension and compression. Acta Mater. 2010, 58, 3357–3366. [Google Scholar] [CrossRef]

- Reedlunn, B.; Churchill, C.B.; Nelson, E.E.; Shaw, J.A.; Daly, S.H. Tension, compression, and bending of superelastic shape memory alloy tubes. J. Mech. Phys. Solids 2014, 63, 506–537. [Google Scholar] [CrossRef]

- Bechle, N.J.; Kyriakides, S. Localization in NiTi tubes under bending. Int. J. Solids Struct. 2014, 51, 967–980. [Google Scholar] [CrossRef]

- Jiang, D.; Kyriakides, S.; Bechle, N.J.; Landis, C.M. Bending of pseudoelastic NiTi tubes. Int. J. Solids Struct. 2017, 124, 192–214. [Google Scholar] [CrossRef]

- Wagner, M.F.-X.; Eggeler, G. Stress and strain states in a pseudoelastic wire subjected to bending rotation. Mech. Mater. 2006, 38, 1012–1025. [Google Scholar] [CrossRef]

- He, Y.J.; Sun, Q.P. Effects of structural and material length scales on stress-induced martensite macro-domain patterns in tube configurations. Int. J. Solids Struct. 2009, 46, 3045–3060. [Google Scholar] [CrossRef]

- He, Y.J.; Sun, Q.P. Scaling relationship on macroscopic helical domains in NiTi tubes. Int. J. Solids Struct. 2009, 46, 4242–4251. [Google Scholar] [CrossRef]

- Wagner, M.F.-X.; Dey, S.; Gugel, H.; Frenzel, J.; Somsen, C.; Eggeler, G. Effect of low-temperature precipitation on the transformation characteristics of Ni-rich NiTi shape memory alloys during thermal cycling. Intermetallics 2010, 18, 1172–1179. [Google Scholar] [CrossRef]

- Shaw, J.A.; Kyriakides, S. Thermomechanical aspects of NiTi. J. Mech. Phys. Solids 1995, 43, 1243–1281. [Google Scholar] [CrossRef]

- Reedlunn, B.; Daly, S.; Hector, L., Jr.; Zavattieri, P.; Shaw, J. Tips and Tricks for Characterizing Shape Memory Wire Part 5: Full-Field Strain Measurement by Digital Image Correlation. Exp. Tech. 2013, 37, 62–78. [Google Scholar] [CrossRef]

- Lu, H.; Cary, P.D. Deformation measurements by digital image correlation: Implementation of a second-order displacement gradient. Exp. Mech. 2000, 40, 393–400. [Google Scholar] [CrossRef]

- Delpueyo, D.; Grediac, M.; Balandraud, X.; Badulescu, C. Investigation of martensitic microstructures in a monocrystalline Cu–Al–Be shape memory alloy with the grid method and infrared thermography. Mech. Mater. 2012, 45, 34–51. [Google Scholar] [CrossRef]

- Young, M.L.; Wagner, M.F.-X.; Frenzel, J.; Schmahl, W.W.; Eggeler, G. Phase volume fractions and strain measurements in an ultrafine-grained NiTi shape-memory alloy during tensile loading. Acta Mater. 2010, 58, 2344–2354. [Google Scholar] [CrossRef]

- Khalil-Allafi, J.; Hasse, B.; Klönne, M.; Wagner, M.; Pirling, T.; Predki, W.; Schmahl, W.W. In-situ diffraction investigation of superelastic NiTi shape memory alloys under mechanical stress with neutrons and with synchrotron radiation. Mater. Werkst. 2004, 35, 280–283. [Google Scholar] [CrossRef]

- Hsu, W.N.; Polatidis, E.; Smid, M.; Casati, N.; Petegem, S.V.; Swygenhoven, H.V. Load path change on superelastic NiTi alloys: In situ synchrotron XRD and SEM DIC. Acta Mater. 2018, 144, 874–883. [Google Scholar] [CrossRef]

- Pan, B.; Qian, K.; Xie, H.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas. Sci. Technol. 2009, 20, 062001. [Google Scholar] [CrossRef]

- GOM (Gesellschaft für Optische Messtechnik mbH). Software “ARAMIS” v6.3.1 Optical Deformation Analysis; Gesellschaft für Optische Messtechnik mbH: Braunschweig, Germany, 2010. [Google Scholar]

- Pfeiffer, S.; Frint, P.; Wagner, M.F.-X. Analysis of the complex stress state during early loading in cylindrical compression-shear specimens. Mater. Sci. Eng. 2017, 181, 012025. [Google Scholar] [CrossRef]

- Elibol, C. Lokalisierungs- und Relaxationsphänomene in Pseudoelastischen und Martensitischen NiTi-Formgedächtnislegierungen. Ph.D. Thesis, University of Technology Chemnitz, Chemnitz, Germany, 20 February 2018. [Google Scholar]

- Liu, Y.; Liu, Y.; Humbeeck, J.V. Lüders-like deformation associated with martensite reorientation in NiTi. Scr. Mater. 1998, 39, 1047–1055. [Google Scholar] [CrossRef]

- Shaw, J.A.; Kyriakides, S. On the nucleation and propagation of phase transformation fronts in a NiTi alloy. Acta Mater. 1997, 45, 683–700. [Google Scholar] [CrossRef]

- Sun, Q.-P.; Li, Z.-Q. Phase transformation in superelastic NiTi polycrystalline micro-tubes under tension and torsion––From localization to homogeneous deformation. Int. J. Solids Struct. 2002, 39, 3797–3809. [Google Scholar] [CrossRef]

- Liu, Y. On the nucleation and propagation of stress-induced martensitic transformation in NiTi. Mater. Sci. Eng. A 1999, 271, 506–508. [Google Scholar]

- Li, Z.-Q.; Sun, Q.-P. The initiation and growth of macroscopic martensite band in nano-grained NiTi microtube under tension. Int. J. Plast. 2002, 18, 1481–1498. [Google Scholar] [CrossRef]

- Kim, J.I.; Liu, Y.; Miyazaki, S. Ageing-induced two-stage R-phase transformation in Ti-50.9at.%Ni. Acta Mater. 2004, 52, 487–499. [Google Scholar] [CrossRef]

- Hallai, J.F.; Kyriakides, S. Underlying material response for Lüders-like instabilities. Int. J. Plast. 2013, 47, 1–12. [Google Scholar] [CrossRef]

- Sedmak, P.; Pilch, J.; Heller, L.; Kopecek, J.; Wright, J.; Sedlak, P.; Frost, M.; Sittner, P. Grain-resolved analysis of localized deformation in nickel-titanium wire under tensile load. Science 2016, 353, 559–562. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elibol, C.; Wagner, M.F.-X. Virtual Extensometer Analysis of Martensite Band Nucleation, Growth, and Strain Softening in Pseudoelastic NiTi Subjected to Different Load Cases. Materials 2018, 11, 1458. https://doi.org/10.3390/ma11081458

Elibol C, Wagner MF-X. Virtual Extensometer Analysis of Martensite Band Nucleation, Growth, and Strain Softening in Pseudoelastic NiTi Subjected to Different Load Cases. Materials. 2018; 11(8):1458. https://doi.org/10.3390/ma11081458

Chicago/Turabian StyleElibol, Cagatay, and Martin F.-X. Wagner. 2018. "Virtual Extensometer Analysis of Martensite Band Nucleation, Growth, and Strain Softening in Pseudoelastic NiTi Subjected to Different Load Cases" Materials 11, no. 8: 1458. https://doi.org/10.3390/ma11081458

APA StyleElibol, C., & Wagner, M. F.-X. (2018). Virtual Extensometer Analysis of Martensite Band Nucleation, Growth, and Strain Softening in Pseudoelastic NiTi Subjected to Different Load Cases. Materials, 11(8), 1458. https://doi.org/10.3390/ma11081458