Aging Response and Precipitation Behavior after 5% Pre-Deformation of an Al-Mg-Si-Cu Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

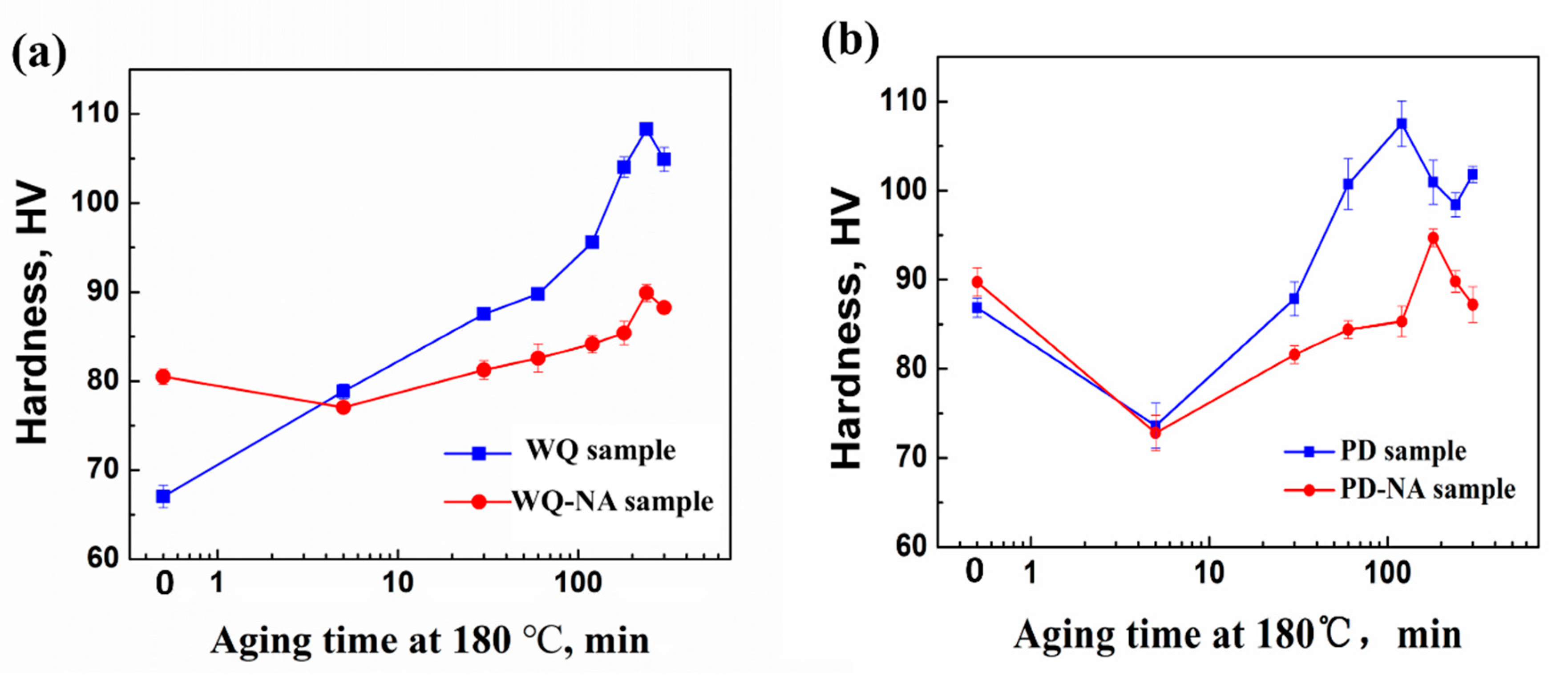

3.1. Age-Hardening Behavior

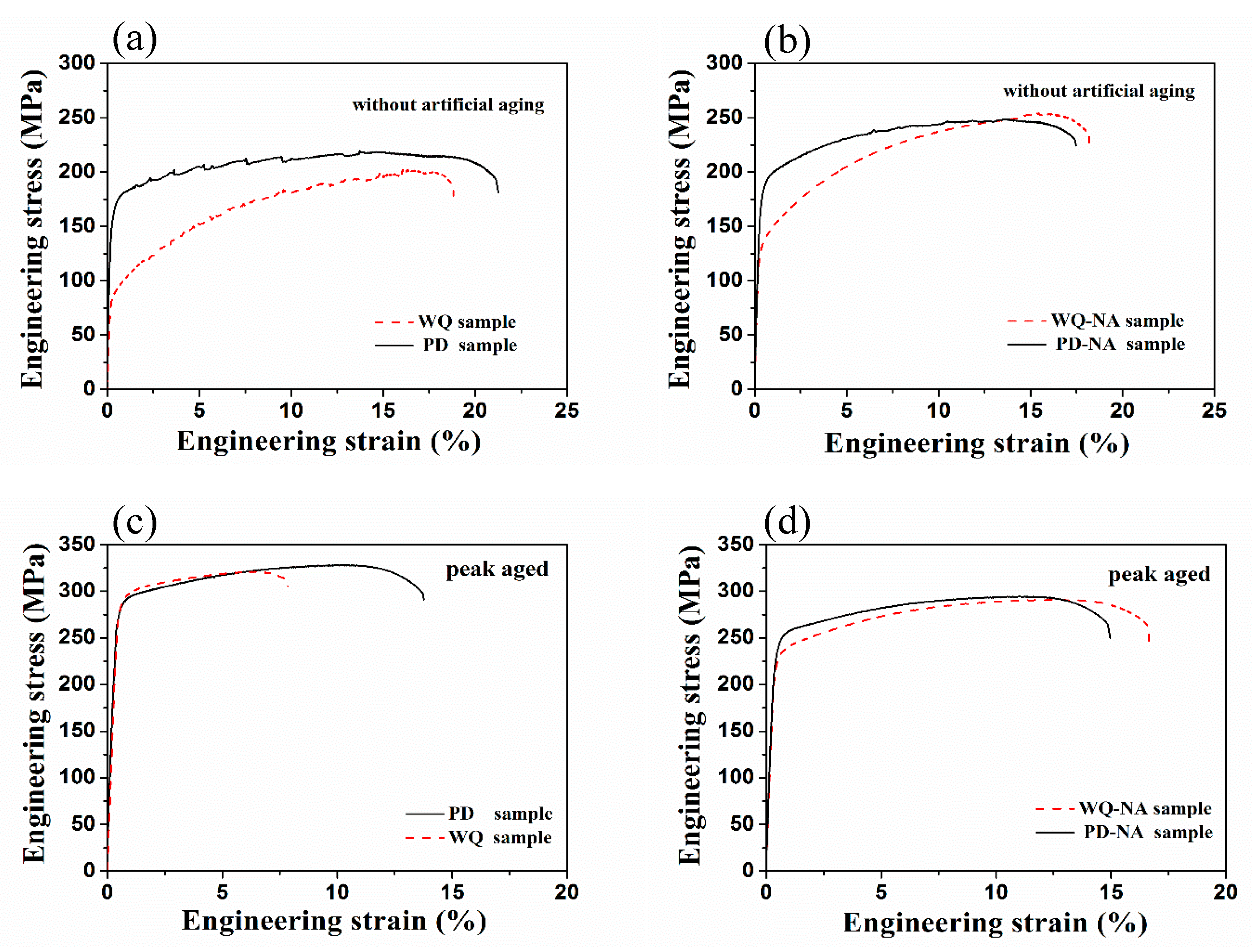

3.2. Tensile Behavior

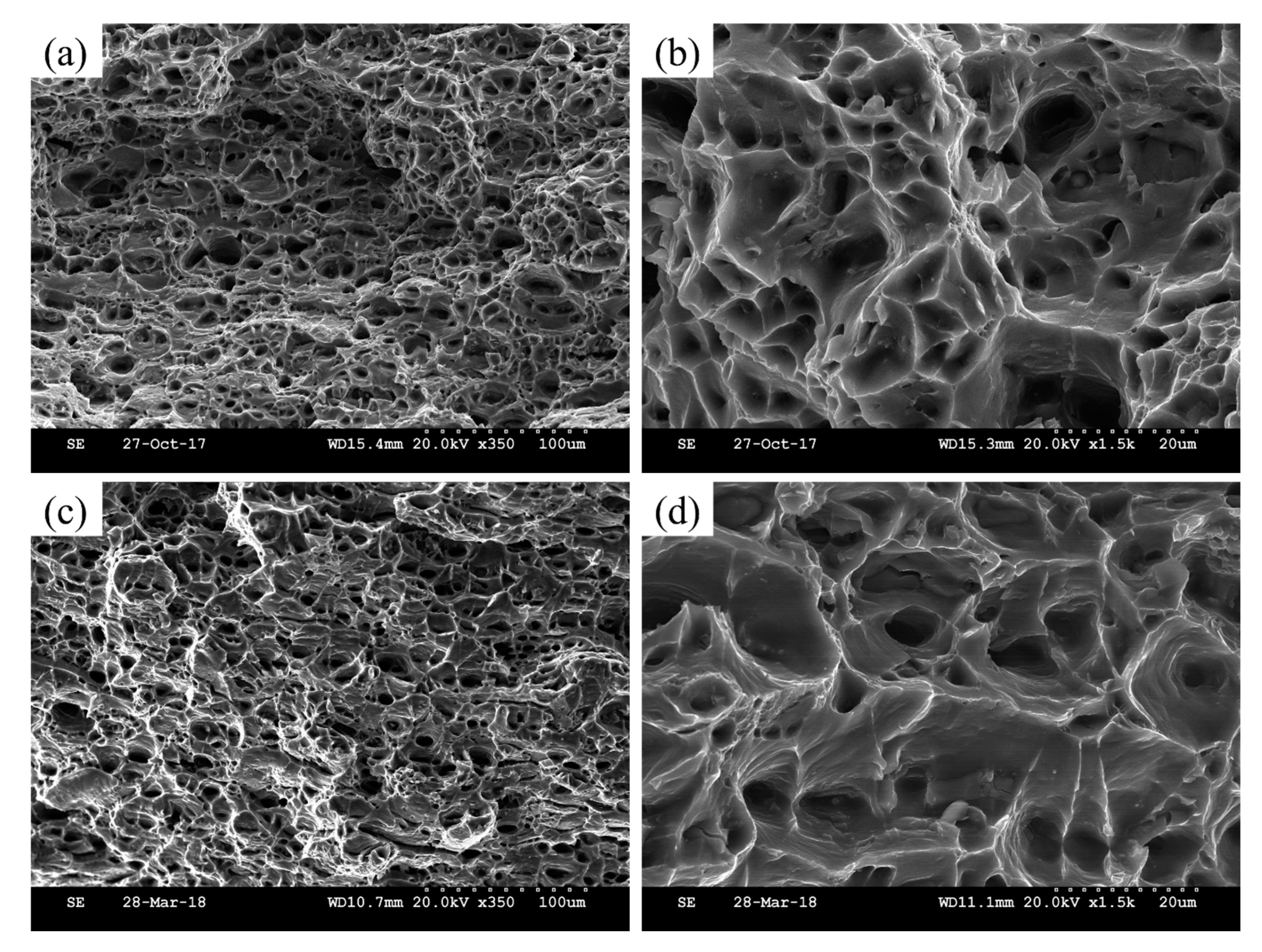

3.3. Fracture Mechanism

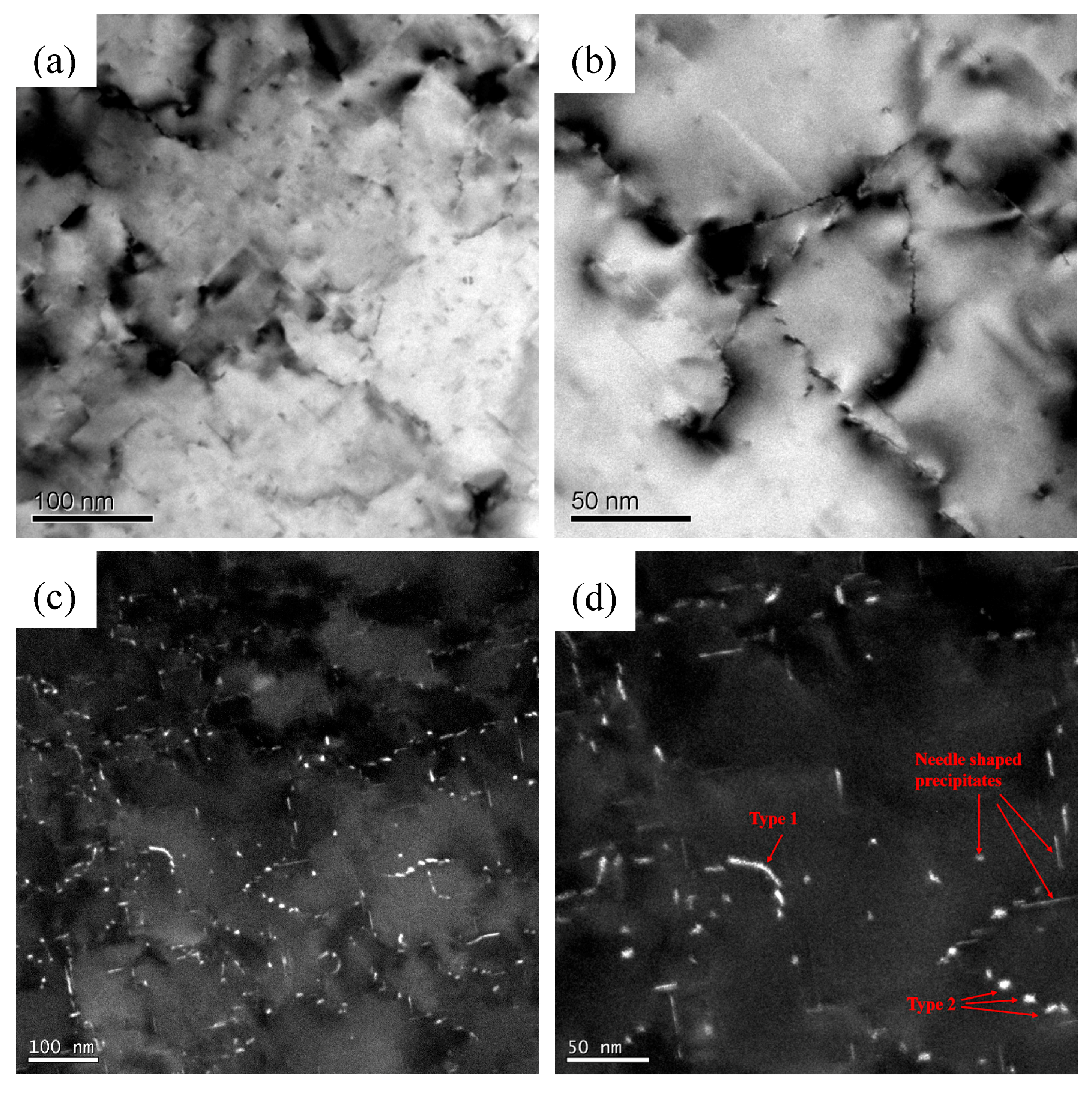

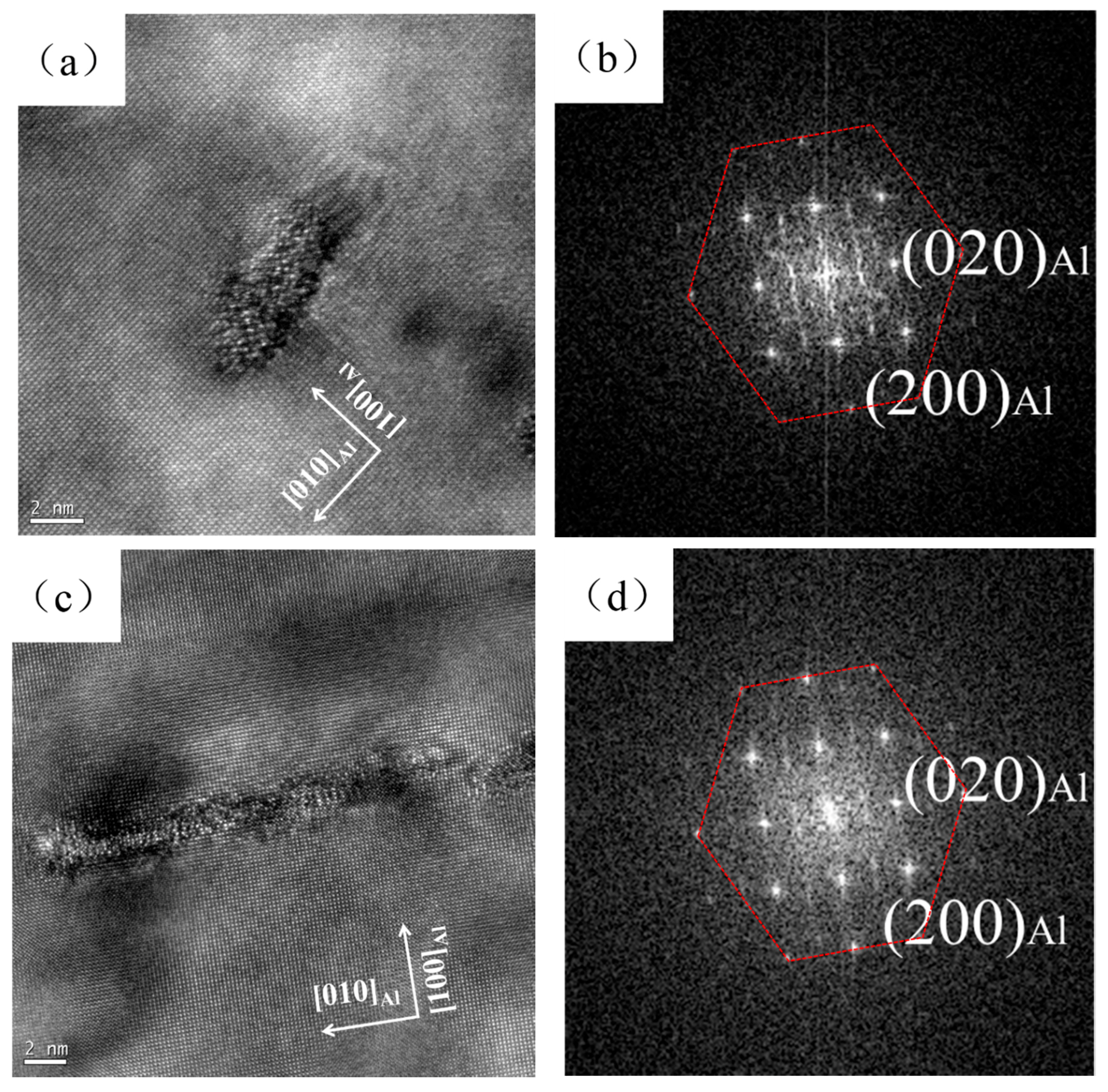

3.4. Precipitation Behavior

4. Discussion

5. Conclusions

- After quenching, 5% pre-deformation cannot increase the peak hardness and yield strength upon subsequent artificial aging compared with the T6 condition. However, the pre-deformation treatment could inhibit the negative influence of natural aging to some degree. After seven days of a natural aging process, the pre-deformed sample has better peak hardness and yield strength upon artificial aging.

- The sample with 5% pre-deformation treatment reaches the peak artificial aging condition after 120 min, compared to 240 min of the sample without pre-deformation.

- The pre-deformation treatment could reduce 50% of the artificial aging time to reach the peak aging condition compared with T6 treatment. The dislocations generated by pre-deformation significantly accelerate the process of precipitation during artificial aging.

- Type 1 and Type 2 precipitates are exhibited along dislocations after pre-deformation, which have disordered atomic arrangements on the ordered subcell (Si network). The disordered precipitates occupied a number of Mg and Si atoms, and result in fewer β" precipitates being formed during subsequent artificial aging.

Author Contributions

Funding

Conflicts of Interest

References

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; Smet, P.D.; Haszler, A.; Vieregge, A. Recent development in aluminum alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Immarigeon, J.-P.; Holt, R.T.; Koul, A.K.; Zhao, L.; Wallace, W.; Beddoes, J.C. Lightweight materials for aircraft applications. Mater. Charact. 1995, 35, 41–67. [Google Scholar] [CrossRef]

- Marioara, C.D.; Nordmark, H.; Andersen, S.J.; Holmestad, R. Post-β″ phases and their influence on microstructure and hardness in 6xxx Al-Mg-Si alloys. J. Mater. Sci. 2006, 41, 471–478. [Google Scholar] [CrossRef]

- Fallah, V.; Langelier, B.; Ofori-Opoku, N.; Raeisinia, B.; Provatas, N.; Esmaeili, S. Cluster evolution mechanisms during aging in Al-Mg-Si alloys. Acta Mater. 2016, 103, 290–300. [Google Scholar] [CrossRef]

- Edwards, G.A.; Stiller, K.; Dunlop, G.L.; Couper, M.J. The precipitation sequence in Al-Mg-Si alloys. Acta Mater. 1998, 46, 3893–3904. [Google Scholar] [CrossRef]

- Fallah, V.; Korinek, A.; Ofori-Opoku, N.; Raeisinia, B.; Gallerneault, M.; Provatas, N.; Esmaeili, S. Atomic-scale pathway of early-stage precipitation in Al-Mg-Si alloys. Acta Mater. 2014, 82, 457–467. [Google Scholar] [CrossRef]

- Jin, S.; Ngai, T.; Zhang, G.; Zhai, T.; Jia, S.; Li, L. Precipitation strengthening mechanisms during natural ageing and subsequent artificial aging in an Al-Mg-Si-Cu alloy. Mater. Sci. Eng. A 2018, 724, 53–59. [Google Scholar] [CrossRef]

- Andersen, S.J.; Zandbergen, H.W.; Jansen, J.; Træholt, C.; Tundal, U.; Reiso, O. The crystal structure of the β″ phase in Al-Mg-Si alloys. Acta Mater. 1998, 46, 3283–3298. [Google Scholar] [CrossRef]

- Chen, J.H.; Costan, E.; Huis, M.A.V.; Xu, Q.; Zandbergen, H.W. Atomic pillar-based nanoprecipitates strengthen AlMgSi Alloys. Science 2006, 312, 416–419. [Google Scholar] [CrossRef] [PubMed]

- Vissers, R.; Huis, M.A.; Jansen, J.; Zanbergen, H.W.; Marioara, C.D.; Andersen, S.J. The crystal structure of the β′ phase in Al-Mg-Si alloys. Acta Mater. 2007, 55, 3815–3823. [Google Scholar] [CrossRef]

- Xiao, Q.; Liu, H.; Yi, D.; Yin, D.; Chen, Y.; Zhang, Y.; Wang, B. Effect of Cu content on precipitation and age-hardening behavior in Al-Mg-Si-xCu alloys. J. Alloys Compd. 2017, 695, 1005–1013. [Google Scholar] [CrossRef]

- Ding, L.; Jia, Z.; Zhang, Z.; Sanders, R.E.; Liu, Q.; Yang, G. The natural aging and precipitation hardening behaviour of Al-Mg-Si-Cu alloys with different Mg/Si ratios and Cu additions. Mater. Sci. Eng. A 2015, 627, 119–126. [Google Scholar] [CrossRef]

- Martinsen, F.A.; Ehlers, F.J.H.; Torsæter, M.; Holmestad, R. Reversal of the negative natural aging effect in Al-Mg-Si alloy. Acta Mater. 2012, 60, 6091–6101. [Google Scholar] [CrossRef]

- Pogatscher, S.; Antrekowitsch, H.; Ebner, T.; Uggowitzer, P.J. The role of co-clusters in the artificial aging of AA6061 and AA6060. Light Metals 2012, 510, 415–420. [Google Scholar]

- Pogatscher, S.; Antrekowitsch, H.; Leitner, H.; Ebner, T.; Uggowitzer, P.J. Mechanisms controlling the artificial aging of Al-Mg-Si alloys. Acta Mater. 2011, 59, 3352–3363. [Google Scholar] [CrossRef]

- Strobel, K.; Lay, M.D.H.; Easton, M.A.; Sweet, L.; Zhu, S.; Parson, N.C.; Hill, A.J. Effects of quench rate and natural aging on the age hardening behavior of aluminum alloy AA6060. Mater. Charact. 2016, 111, 43–52. [Google Scholar] [CrossRef]

- Aruga, Y.; Kozuka, M.; Takaki, Y.; Sato, T. Formation and reversion of clusters during natural aging and subsequent artificial aging in an Al-Mg-Si alloy. Mater. Sci. Eng. A 2015, 631, 86–96. [Google Scholar] [CrossRef]

- Zandbergen, M.W.; Xu, Q.; Cerezo, A.; Smith, G.D.W. Study of precipitation in Al-Mg-Si alloys by Atom Probe Tomography I. Microstructural changes as a function of ageing temperature. Acta Mater. 2015, 101, 136–148. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andesen, S.J.; Jansen, J.; Zandbergen, H.W. The influence of temperature and storage time at RT on nucleation of the β″ phase in a 6082 Al-Mg-Si alloy. Acta Mater. 2003, 51, 789–796. [Google Scholar] [CrossRef]

- Yassar, R.S.; Field, D.P.; Weiland, H. The effect of cold deformation on the kinetics of the β″ precipitates in an Al-Mg-Si alloy. Metall. Mater. Trans. A 2005, 36, 2059–2065. [Google Scholar] [CrossRef]

- Yassar, R.S.; Field, D.P.; Weiland, H. The effect of predeformation on the β″ and β′ precipitates and the role of Q′ phase in an Al-Mg-Si alloy; AA6022. Scr. Mater. 2005, 53, 299–303. [Google Scholar] [CrossRef]

- Teichmann, K.; Marioara, C.D.; Andersen, S.J.; Pedersen, K.O.; Gulbrandsen-Dahl, S.M.; Kolar, M.; Holmestad, R.; Marthinsen, K. HRTEM study of the effect of deformation on the early precipitation behaviour in an AA6060 Al-Mg-Si alloy. Philos. Mag. 2011, 91, 3744–3754. [Google Scholar] [CrossRef]

- Yang, M.; Liu, S.; He, X.; Wang, J.; Kong, Y.; Zhao, P.; Li, K. Effect of stamping deformation on microstructure and properties evolution of an Al-Mg-Si-Cu alloy for automotive panels. J. Mater. Sci. 2017, 52, 5569–5581. [Google Scholar] [CrossRef]

- Reed, J.M.; Walter, M.E. Observations of serration characteristics and acoustic emission during serrated flow of an Al-Mg alloy. Mater. Sci. Eng. A 2003, 359, 1–10. [Google Scholar] [CrossRef]

- Cao, L.; Rometsch, P.A.; Couper, M.J. Clustering behavior in an Al-Mg-Si-Cu alloy during natural ageing and subsequent under-ageing. Mater. Sci. Eng. A 2013, 559, 257–261. [Google Scholar] [CrossRef]

- Andersen, S.J.; Marioara, C.D.; Vissers, R.; Froseth, A.; Zandbergen, H.W. The structural relation between precipitates in Al-Mg-Si alloys, the Al-matrix and diamond silicon, with emphasis on the trigonal phase U1-MgAl2Si2. Mater. Sci. Eng. A 2007, 444, 157–169. [Google Scholar] [CrossRef]

- Liu, C.H.; Li, X.L.; Wang, S.H.; Chen, J.H.; Teng, Q.; Chen, J.; Gu, Y. A tuning nano-precipitation approach for achieving enhanced strength and good ductility in Al alloys. Mater. Des. 2014, 54, 144–148. [Google Scholar] [CrossRef]

- Jin, S.; Ngai, T.; Li, L.; Lai, Y.; Chen, Z.; Wang, A. Influence of natural aging and pre-treatment on the precipitation and age-hardening behavior of Al-1.0Mg-0.65Si-0.24Cu alloy. J. Alloys Compd. 2018, 742, 852–859. [Google Scholar] [CrossRef]

- Quainoo, G.K.; Yannacopoulos, S. The effect of cold work on the precipitation kinetics of AA6111 aluminum. J. Mater. Sci. 2004, 39, 6495–6502. [Google Scholar] [CrossRef]

| Sample | Process of the Sample |

|---|---|

| WQ | Sample solution heat treatment at 540 °C for 1 h, and then water quenched to room temperature |

| WQ-NA | WQ sample then had seven days of natural aging |

| PD | WQ sample immediate cold rolling by 5% (pre-deformation) |

| PD-NA | PD sample then had seven days of natural aging |

| Sample | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| WQ | 84.8 ± 1.8 | 202.0 ± 2.1 | 19.8 ± 2 |

| PD | 166.8 ± 3.8 | 219.9 ± 4.6 | 22.2 ± 1.2 |

| WQ-NA | 131.0 ± 5.1 | 254.4 ± 7.5 | 20.8 ± 1.3 |

| PD-NA | 183.4 ± 6.1 | 248.9 ± 3.2 | 17.2 ± 1.5 |

| Peak aged WQ | 287.5 ± 5.2 | 301.3 ± 7.2 | 7.8 ± 1.2 |

| Peak aged PD | 287.9 ± 4.3 | 318.2 ± 5.1 | 13.6 ± 2.1 |

| Peak aged WQ-NA | 229.6 ± 4.8 | 221.6 ± 5.6 | 16.5 ± 2.0 |

| Peak aged PD-NA | 246.1 ± 5.6 | 230.4 ± 6.2 | 15.4 ± 1.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, S.; Ngai, T.; Li, L.; Jia, S.; Zhai, T.; Ke, D. Aging Response and Precipitation Behavior after 5% Pre-Deformation of an Al-Mg-Si-Cu Alloy. Materials 2018, 11, 1422. https://doi.org/10.3390/ma11081422

Jin S, Ngai T, Li L, Jia S, Zhai T, Ke D. Aging Response and Precipitation Behavior after 5% Pre-Deformation of an Al-Mg-Si-Cu Alloy. Materials. 2018; 11(8):1422. https://doi.org/10.3390/ma11081422

Chicago/Turabian StyleJin, Shuoxun, Tungwai Ngai, Liejun Li, Shian Jia, Tongguang Zhai, and Dongjie Ke. 2018. "Aging Response and Precipitation Behavior after 5% Pre-Deformation of an Al-Mg-Si-Cu Alloy" Materials 11, no. 8: 1422. https://doi.org/10.3390/ma11081422

APA StyleJin, S., Ngai, T., Li, L., Jia, S., Zhai, T., & Ke, D. (2018). Aging Response and Precipitation Behavior after 5% Pre-Deformation of an Al-Mg-Si-Cu Alloy. Materials, 11(8), 1422. https://doi.org/10.3390/ma11081422