Delamination Study in Edge Trimming of Basalt Fiber Reinforced Plastics (BFRP)

Abstract

:1. Introduction

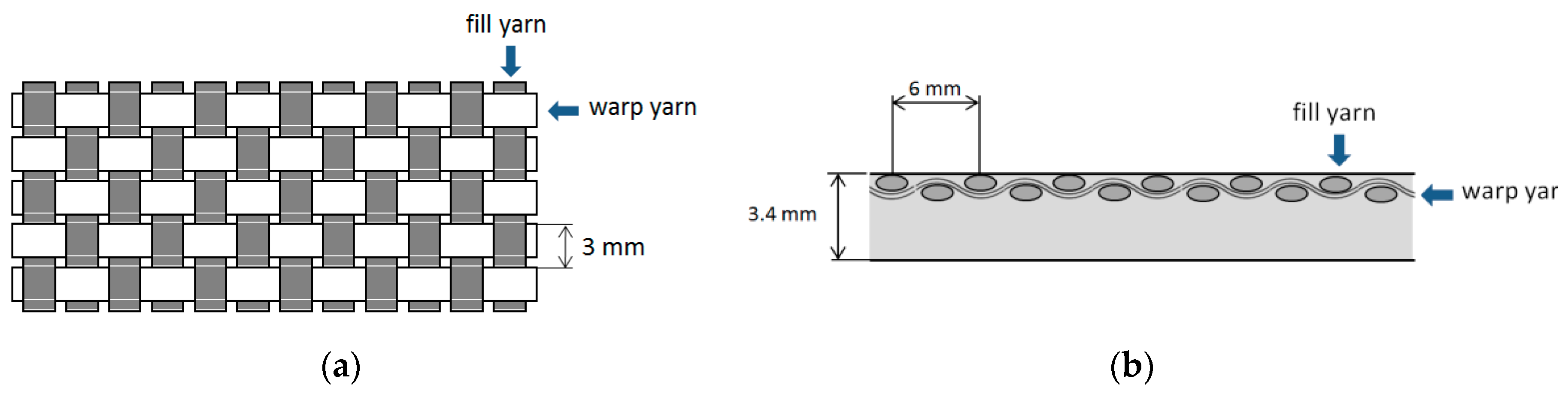

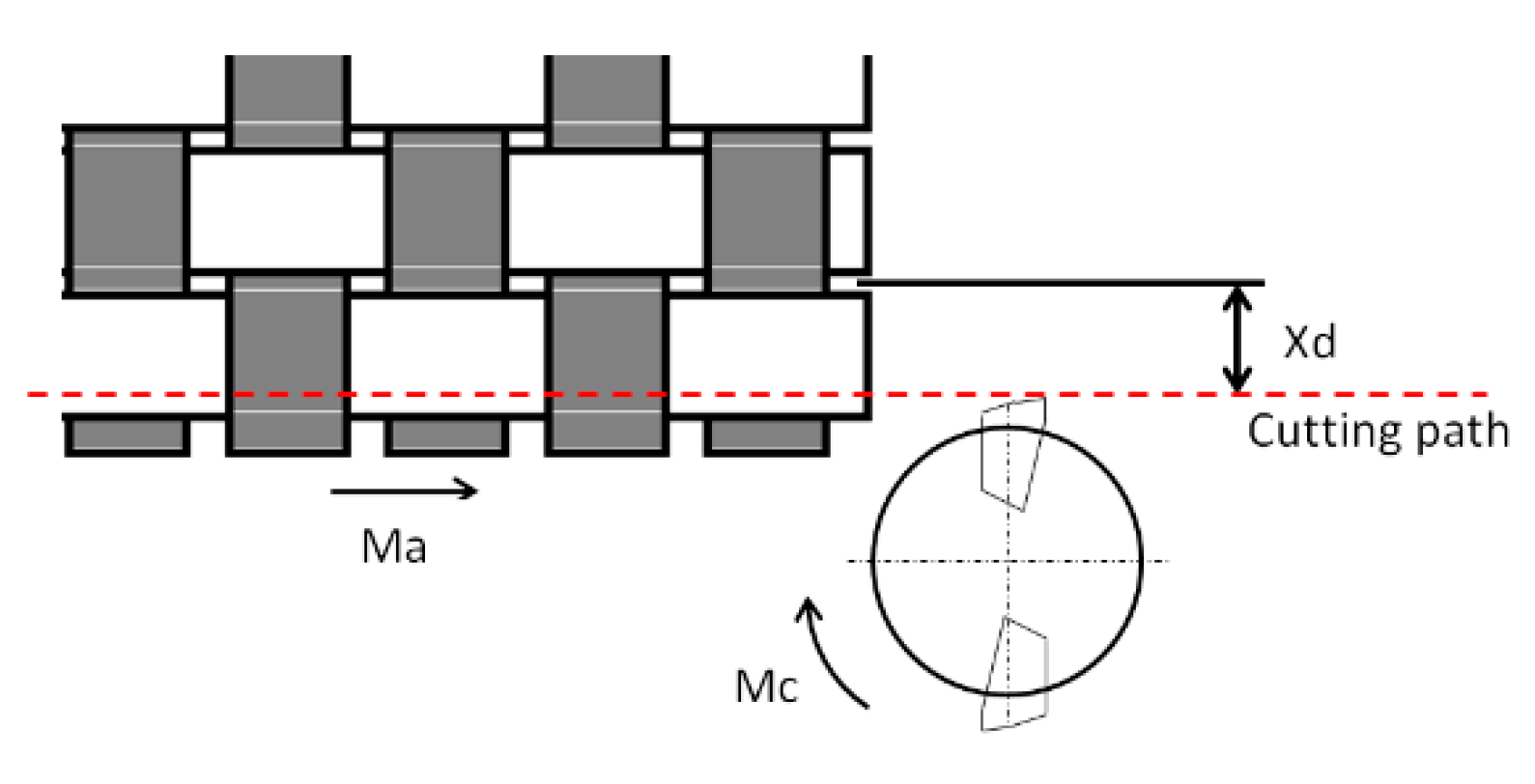

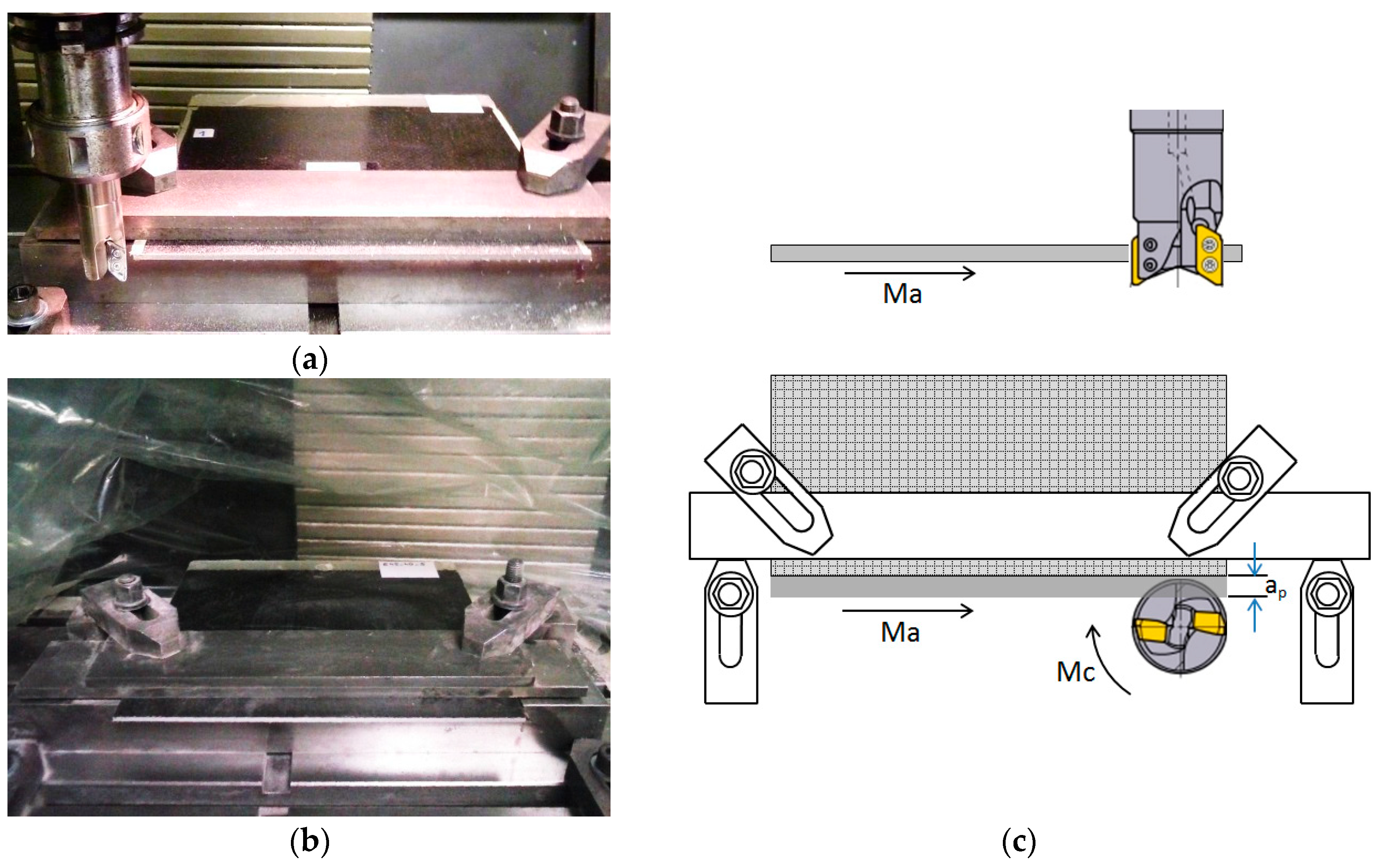

2. Materials and Methods

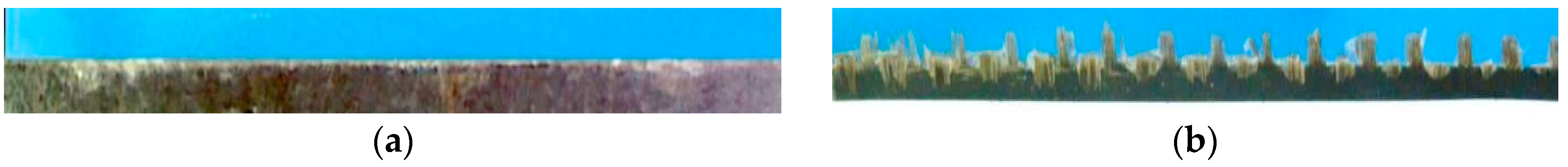

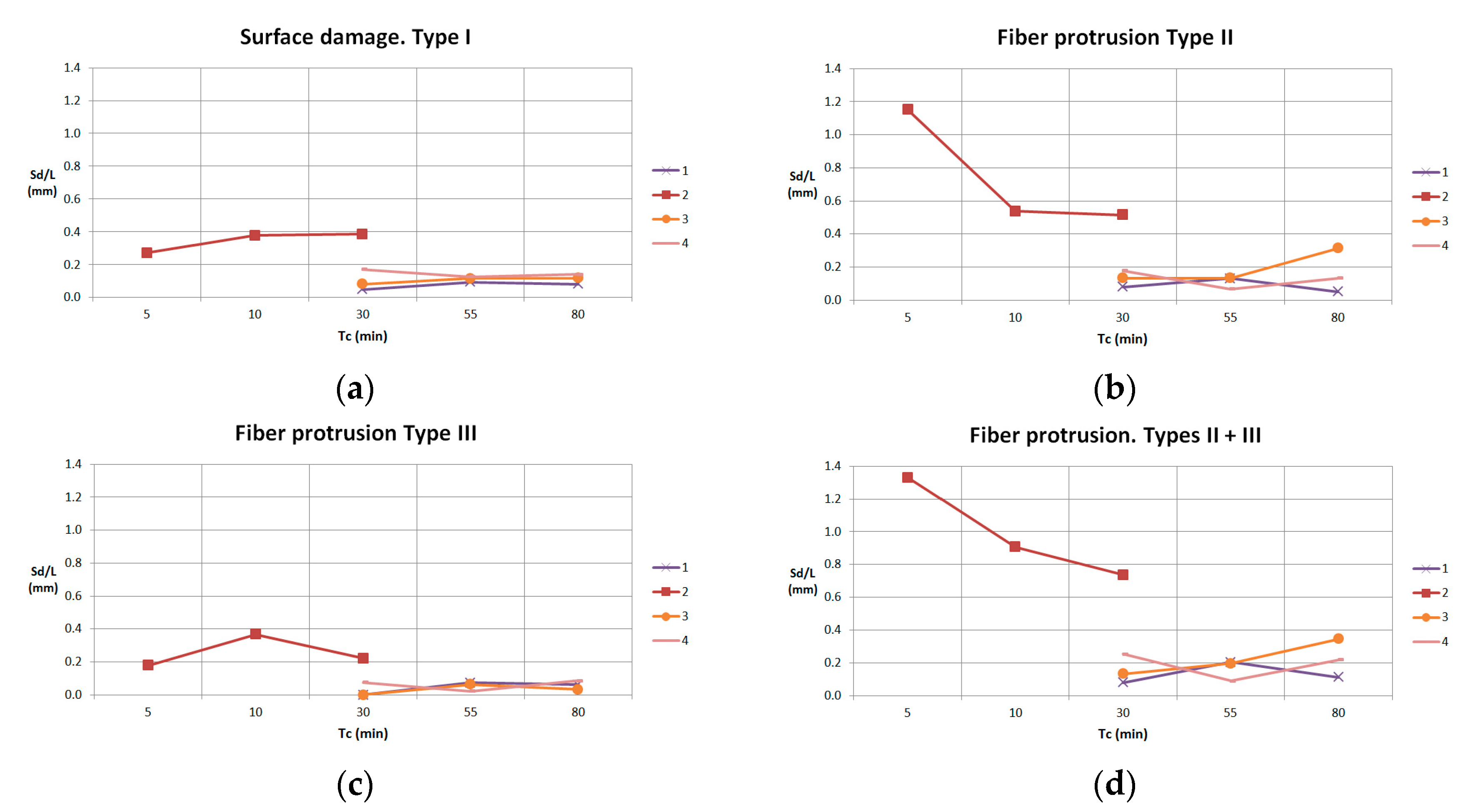

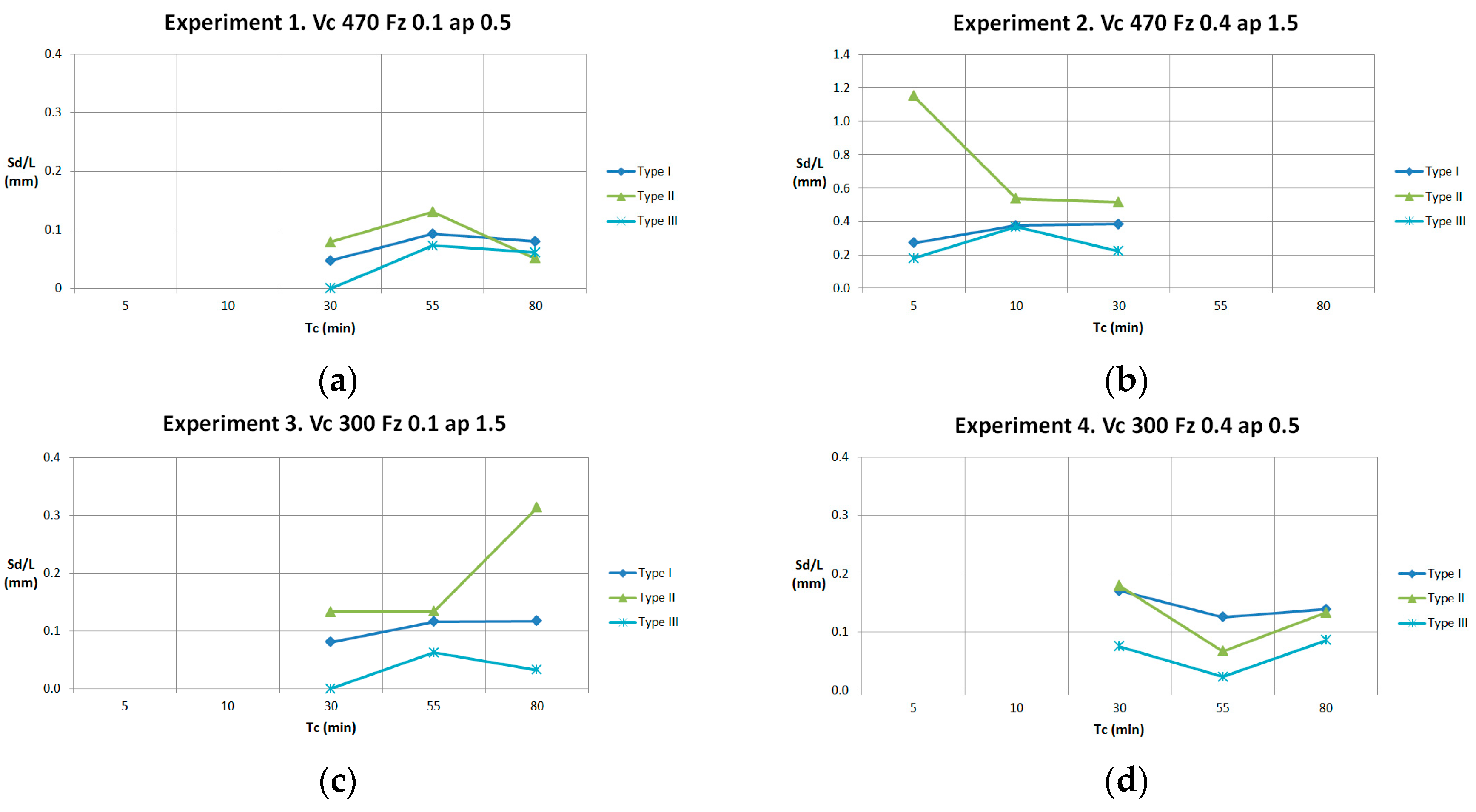

3. Results and Discussion

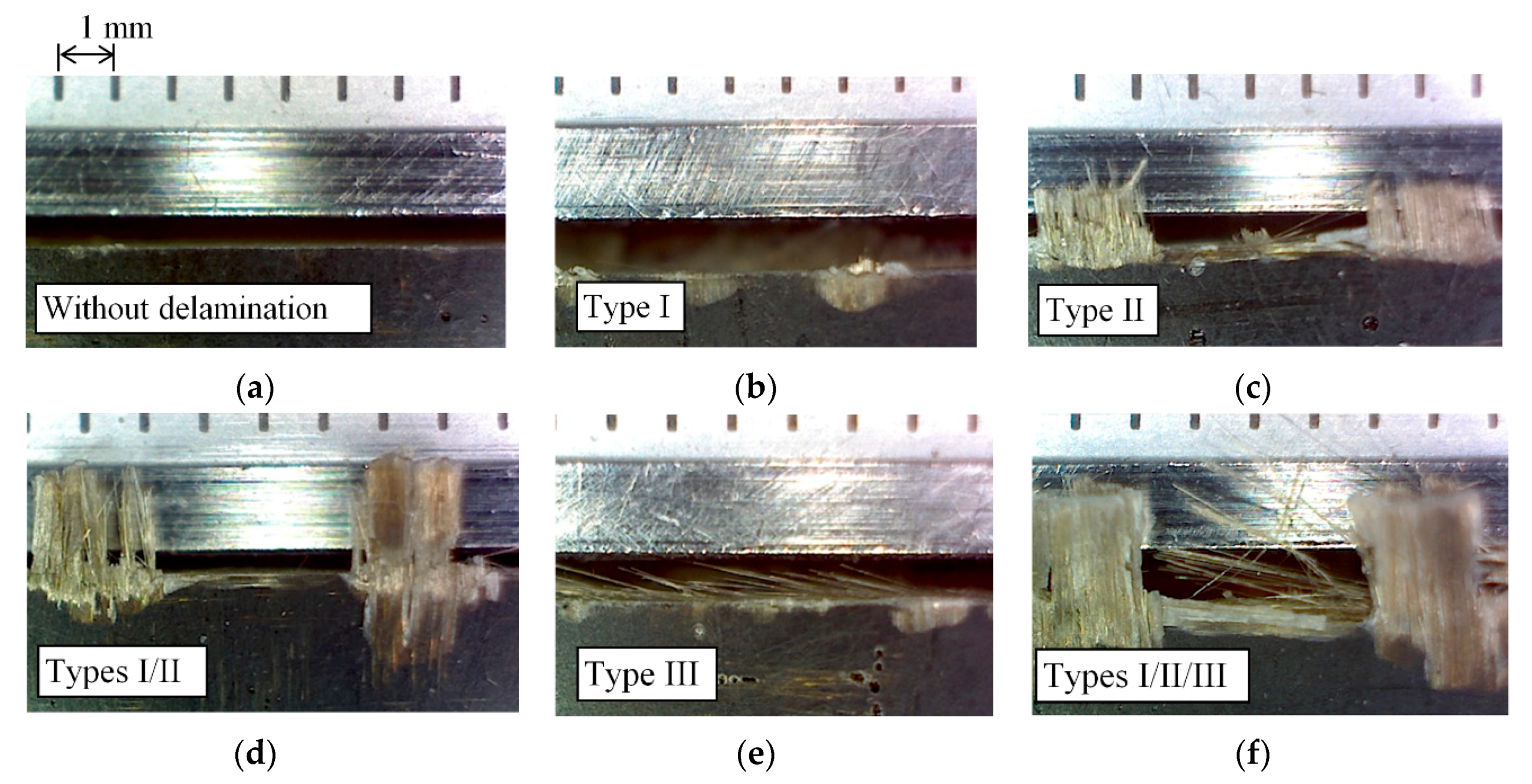

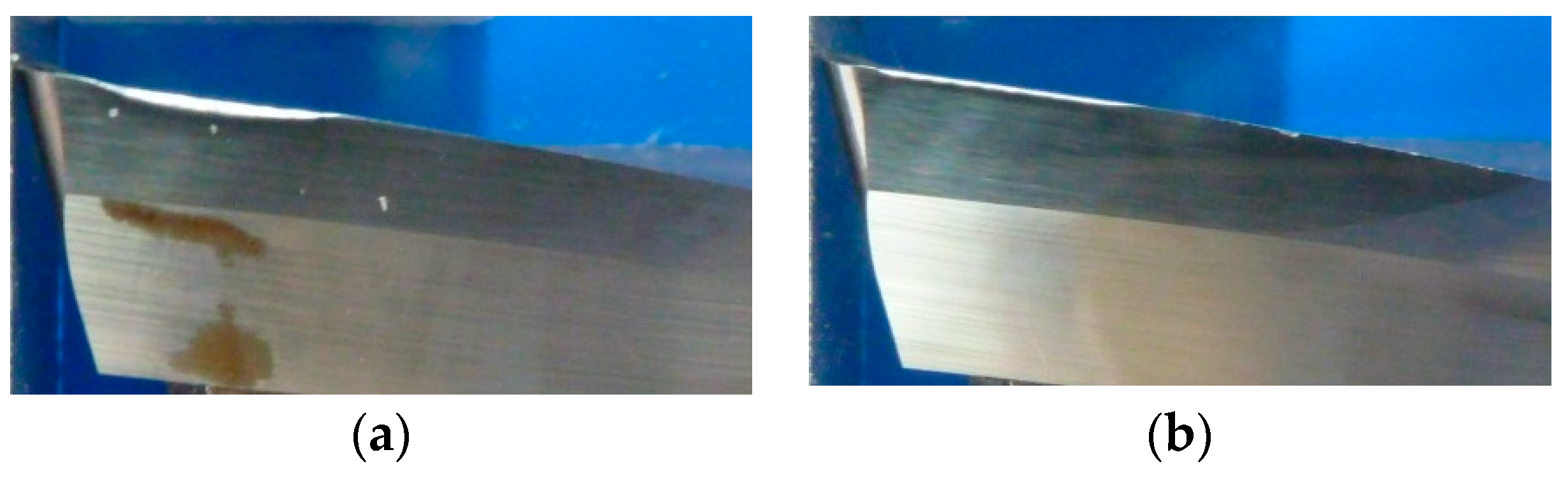

3.1. Types of Delamination

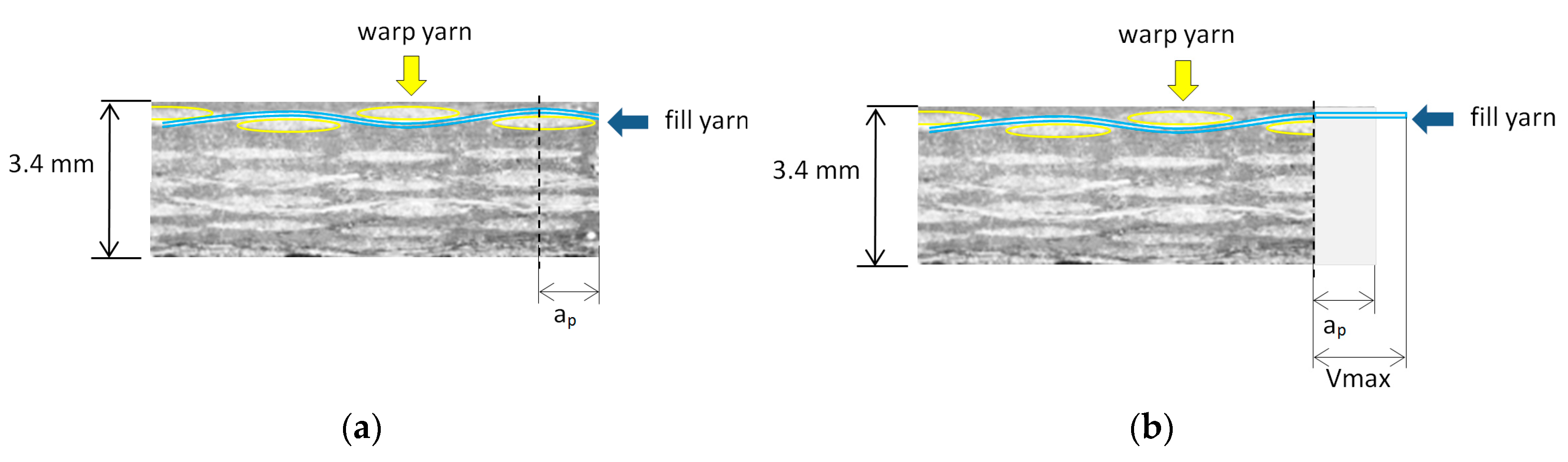

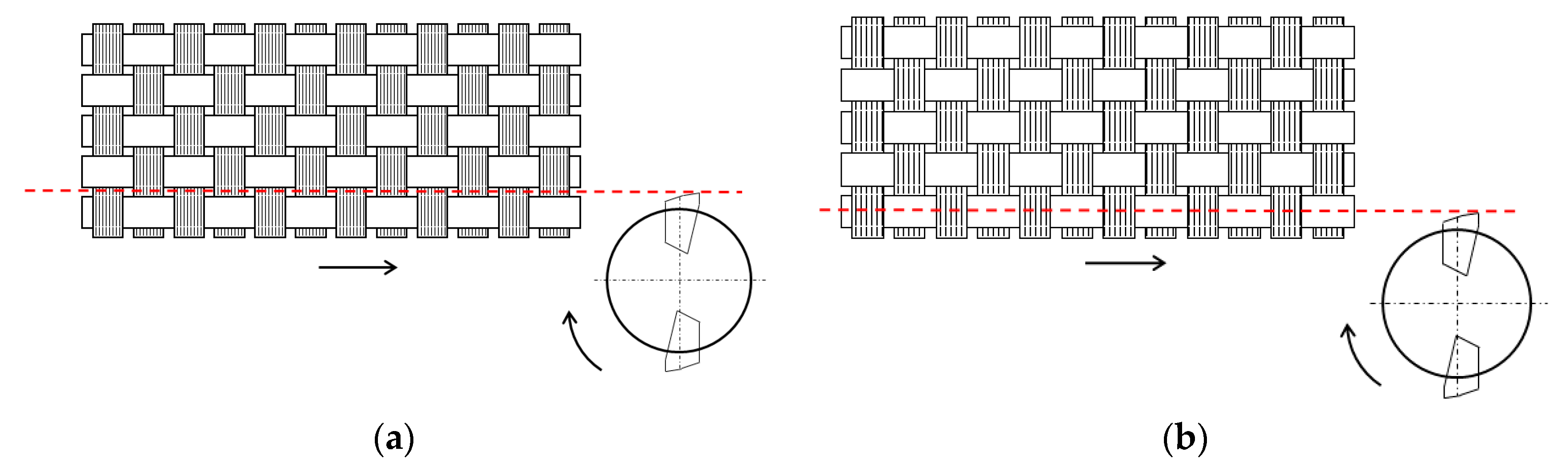

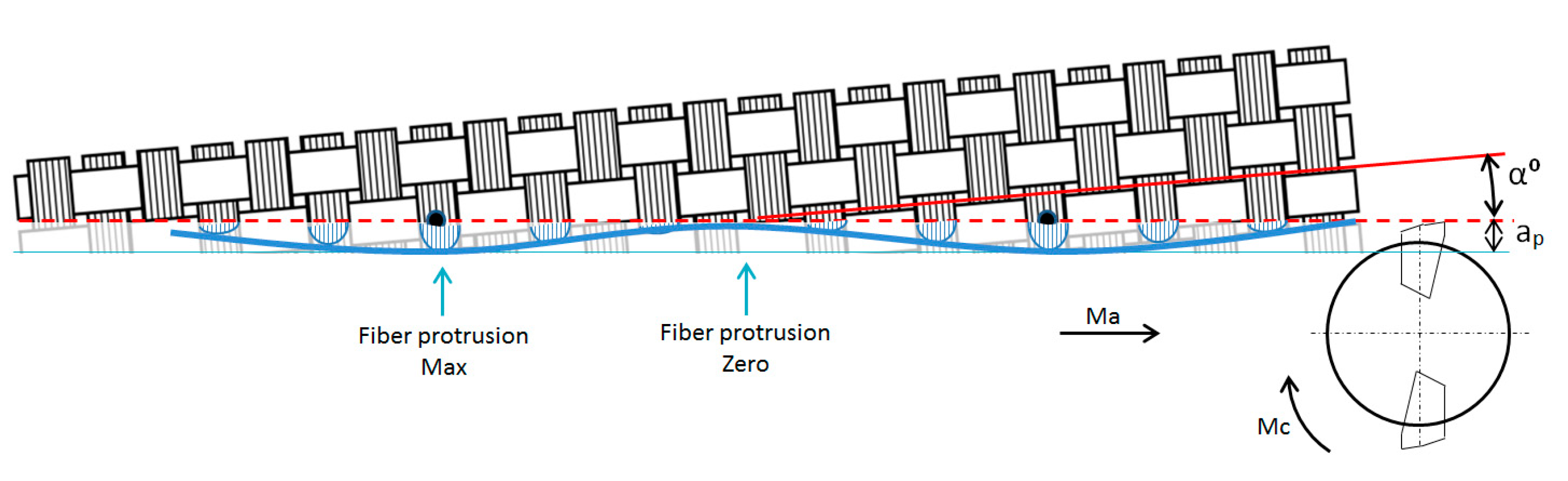

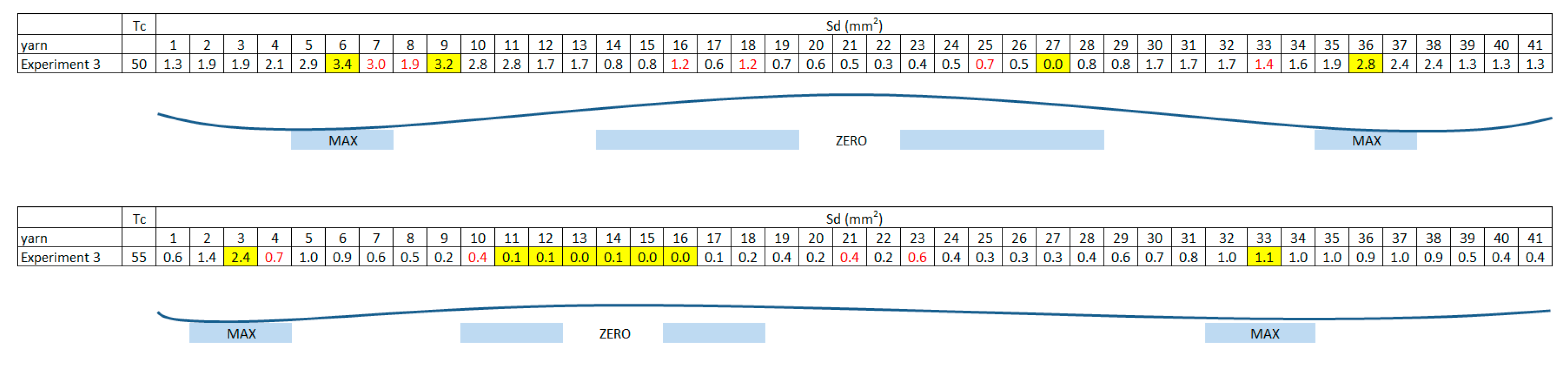

3.2. Relation between Fiber Orientation and Fiber Position in Laminate Respect to Machining Direction

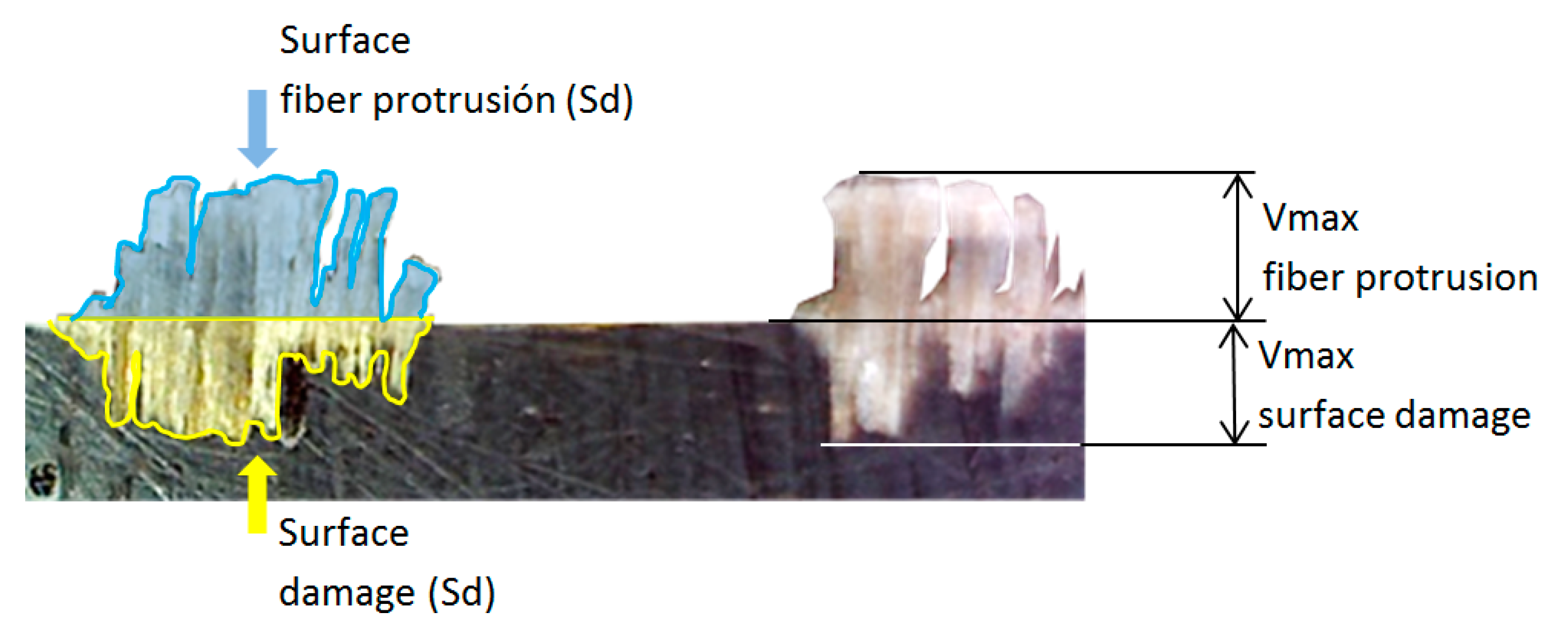

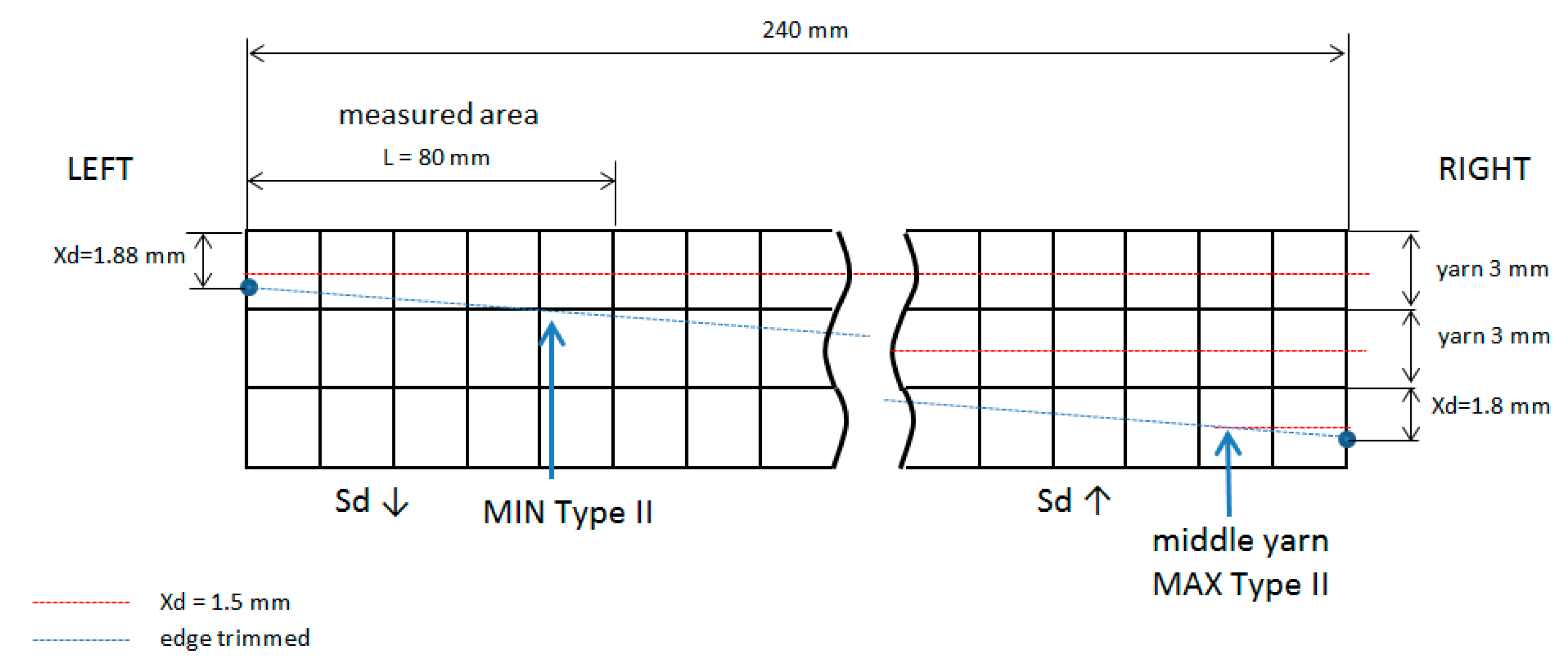

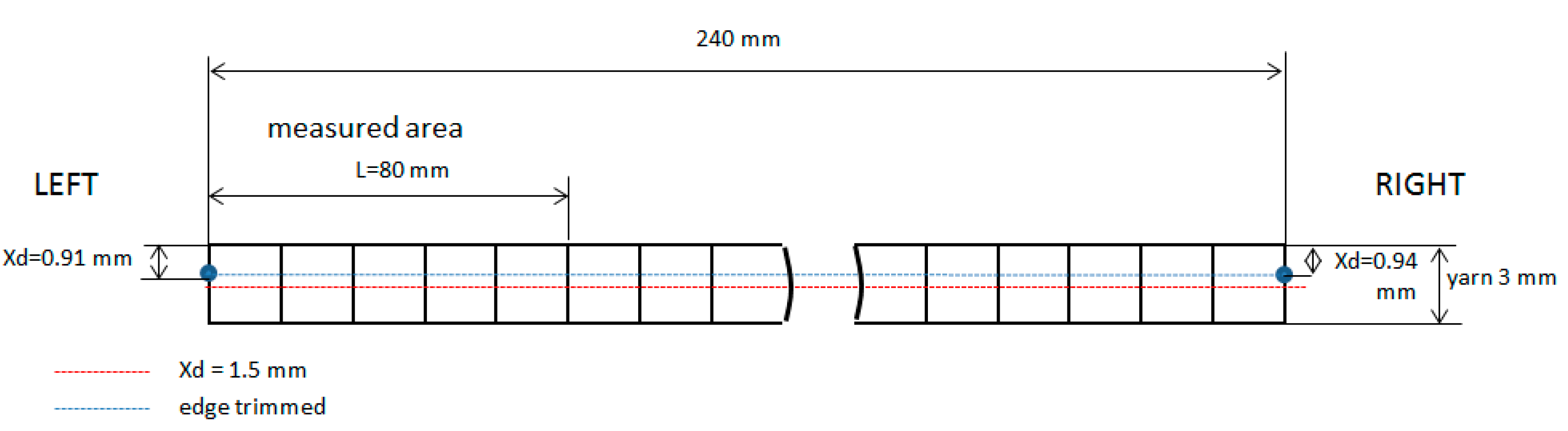

3.3. Definition of Sd/L Parameter to Compare Delamination Values

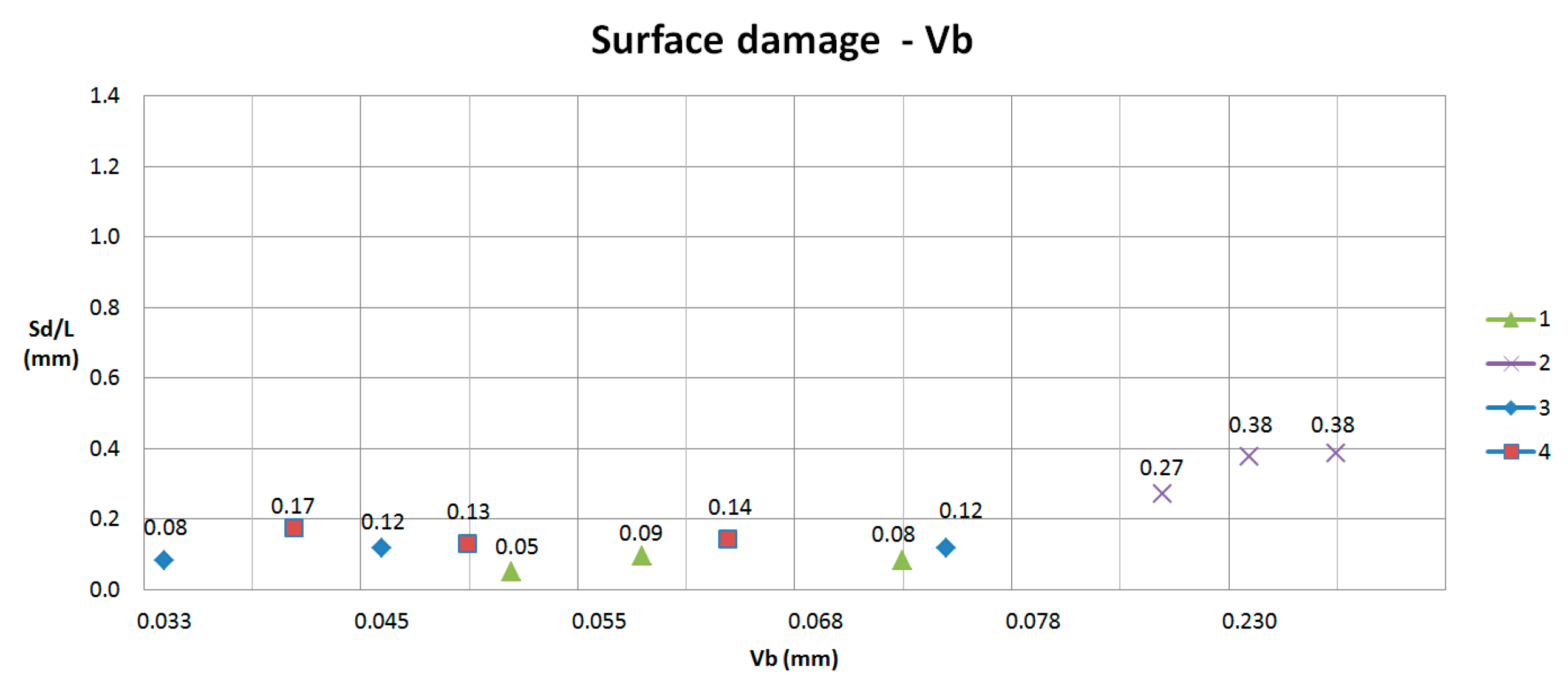

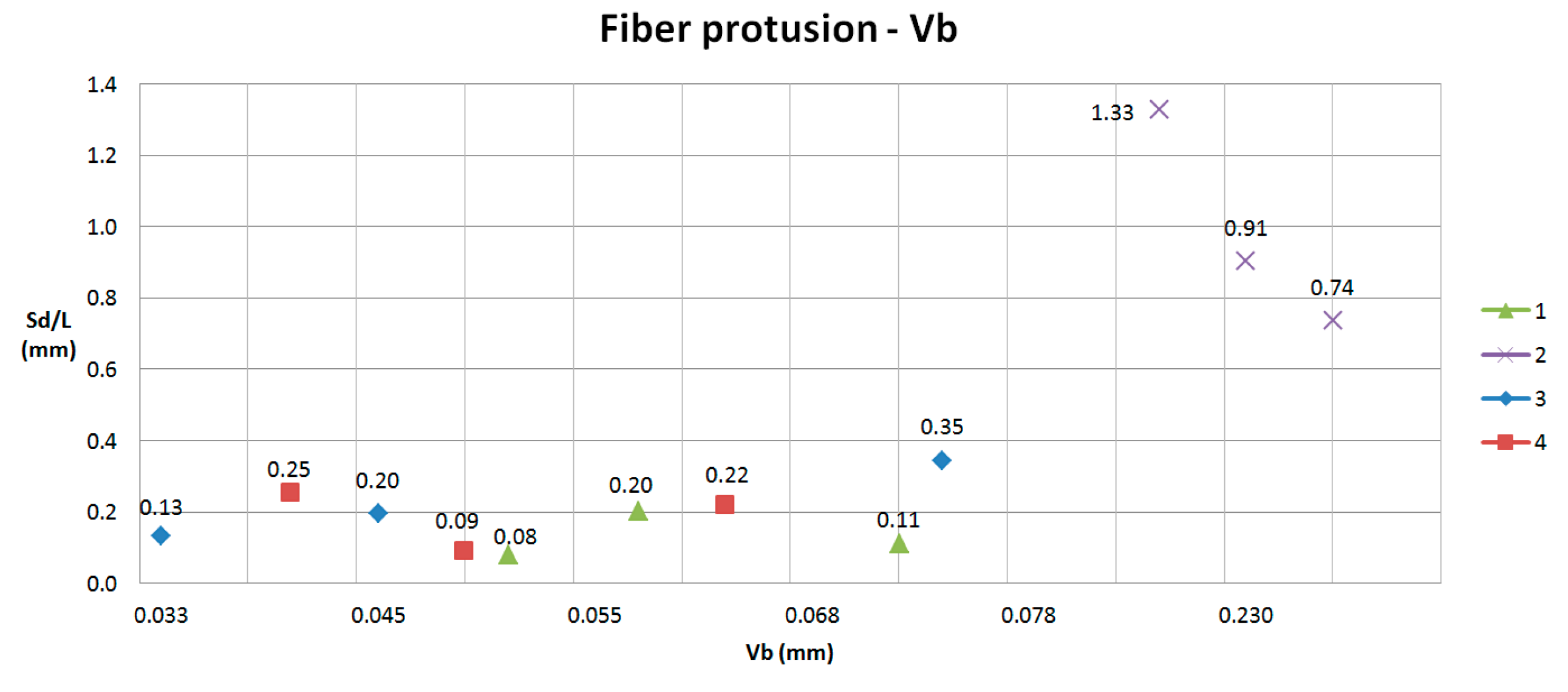

3.4. Relation between Tool Wear and Delamination Parameters

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Teti, R. Machining of composite materials. CIRP Ann. Manuf. Technol. 2002, 51, 611–634. [Google Scholar] [CrossRef]

- Voss, R.; Seeholzer, L.; Kuster, F.; Wegener, K. Influence of fibre orientation, tool geometry and process parameters on surface quality in milling of CFRP. CIRP J. Manuf. Sci. Technol. 2017, 18, 75–91. [Google Scholar] [CrossRef]

- Lopresto, V.; Caggiano, A.; Teti, R. High Performance Cutting of Fiber Reinforced Plastic Composite Materials. Proc. CIRP 2016, 46, 71–82. [Google Scholar] [CrossRef]

- König, W.; Grass, P. Quality definition and assessment in drilling of fibre reinforced thermosets. CIRP Ann. Manuf. Technol. 1989, 38, 119–124. [Google Scholar] [CrossRef]

- Colligan, K.; Ramulu, M. The effect of edge trimming on composite surface plies. Manuf. Rev. (USA) 1992, 5, 274–283. [Google Scholar]

- Azmi, A.I.; Lin, R.J.T.; Bhattacharyya, D. Machinability study of glass fibre-reinforced polymer composites during end milling. Int. J. Adv. Manuf. Technol. 2013, 64, 247–261. [Google Scholar] [CrossRef]

- Davim, J.P.; Reis, P. Damage and dimensional precision on milling carbon fiber-reinforced plastic using design experiments. J. Mater. Process. Technol. 2005, 160, 160–167. [Google Scholar] [CrossRef]

- Davim, J.P.; Campos Rubio, J.; Abrao, A. A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminate. Compos. Sci. Technol. 2007, 67, 1939–1945. [Google Scholar] [CrossRef]

- Gaitonde, V.N.; Karnik, S.R.; Campos Rubio, J.; Esteves Correia, A.; Abrão, A.M.; Davime, J.P. Analysis of parametric influence on delamination in high-speed drilling of carbon fiber reinforced plastic composites. J. Mater. Process. Technol. 2008, 1–3, 431–438. [Google Scholar] [CrossRef]

- Hintze, W.; Hartmann, D.; Schütte, C. Occurrence and propagation of delamination during the machining of carbon fibre reinforced plastics (CFRPs)–An experimental study. Compos. Sci. Technol. 2011, 71, 1719–1726. [Google Scholar] [CrossRef]

- Hintze, W.; Cordes, M.; Koerkel, G. Influence of wear structure on delamination when milling CFRP. J. Mater. Process. Technol. 2015, 216, 199–205. [Google Scholar] [CrossRef]

- Razfar, M.R.; Zanjani Zadeh, M.R. Optimum damage and surface roughness prediction in end milling glass fibre-reinforced plastics, using neural network and genetic algorithm. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 653–664. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.Y.; Dhuttargaon, M.; Cheraghi, H. New tool life criterion for delamination free milling of CFRP. Int. J. Adv. Manuf. Technol. 2017, 92, 2131–2143. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.Y.; Urban, N.; Cheraghi, H. Machining Damage in Edge Trimming of CFRP. Mater. Manuf. Process. 2012, 27, 802–808. [Google Scholar] [CrossRef]

- Navarro, M.D.; Meseguer, M.D.; Sánchez, A.I.; Gutiérrez, S.C. Tool wear study in edge trimming on basalt fibres reinforced plastics. Proced. Manuf. 2017, 13, 259–266. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical characterisation of basalt fibre reinforced plastic. Compos. Part B 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. Glass-basalt/epoxy hybrid composites for marine applications. Mater. Des. 2011, 32, 2091–2099. [Google Scholar] [CrossRef]

| Level | Cutting Speed Vc (m/min) | Feed per Tooth Fz (mm) | Depth of Cut ap (mm) | Fiber Volume Fv (%) |

|---|---|---|---|---|

| 1 | 300 | 0.1 | 0.5 | 40 |

| 2 | 470 | 0.4 | 1.5 | 60 |

| Test | Cutting Speed Vc (m/min) | Feed per Tooth Fz (mm) | Depth of Cut ap (mm) | Fiber Volume Fv (%) |

|---|---|---|---|---|

| 1 | 470 | 0.1 | 0.5 | 60 |

| 2 | 470 | 0.4 | 1.5 | 60 |

| 3 | 300 | 0.1 | 1.5 | 60 |

| 4 | 300 | 0.4 | 0.5 | 60 |

| 5 | 470 | 0.1 | 1.5 | 40 |

| 6 | 470 | 0.4 | 0.5 | 40 |

| 7 | 300 | 0.1 | 0.5 | 40 |

| 8 | 300 | 0.4 | 1.5 | 40 |

| Test | Vc | Fz | ap | Fv % | Tc (min) | Vb (mm) | Type I | ||

|---|---|---|---|---|---|---|---|---|---|

| Sd (mm2) | % L | Vmax (mm) | |||||||

| 1 | 470 | 0.1 | 0.5 | 60 | 30 | 0.049 | 3.80 | 41% | 0.30 |

| 55 | 0.057 | 7.48 | 69% | 0.61 | |||||

| 80 | 0.072 | 6.43 | 58% | 0.74 | |||||

| 2 | 470 | 0.4 | 1.5 | 60 | 5 | 0.211 | 21.68 | 95% | 0.96 |

| 10 | 0.232 | 30.11 | 99% | 2.29 | |||||

| 30 | 0.247 | 30.79 | 94% | 2.28 | |||||

| 3 | 300 | 0.1 | 1.5 | 60 | 30 | 0.032 | 6.46 | 45% | 0.68 |

| 55 | 0.047 | 9.26 | 73% | 0.81 | |||||

| 80 | 0.073 | 9.36 | 95% | 0.49 | |||||

| 4 | 300 | 0.4 | 0.5 | 60 | 30 | 0.041 | 13.65 | 65% | 1.83 |

| 55 | 0.048 | 10.03 | 53% | 1.43 | |||||

| 80 | 0.063 | 11.14 | 81% | 1.14 | |||||

| Test | Vc | Fz | ap | Fv % | Tc (min) | Vb (mm) | Type II | Type III | Total | II and III | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sd (mm2) | % L | Vmax | Sd (mm2) | % L | Sd (mm2) | % L | |||||||

| 1 | 470 | 0.1 | 0.5 | 60 | 30 | 0.049 | 6.35 | 41% | 0.614 | 0 | 0% | 6.35 | 41% |

| 55 | 0.057 | 10.44 | 42% | 0.611 | 5.89 | 43% | 16.33 | 85% | |||||

| 80 | 0.072 | 4.12 | 35% | 0.655 | 4.94 | 38% | 9.06 | 73% | |||||

| 2 | 470 | 0.4 | 1.5 | 60 | 5 | 0.211 | 92.17 | 48% | 2.110 | 14.29 | 52% | 106.46 | 100% |

| 10 | 0.232 | 43.04 | 45% | 2.584 | 29.41 | 54% | 72.45 | 99% | |||||

| 30 | 0.247 | 41.21 | 39% | 2.468 | 17.77 | 55% | 58.98 | 94% | |||||

| 3 | 300 | 0.1 | 1.5 | 60 | 30 | 0.032 | 10.64 | 72% | 1.487 | 0 | 0% | 10.64 | 72% |

| 55 | 0.047 | 10.66 | 70% | 0.993 | 5.00 | 22% | 15.66 | 92% | |||||

| 80 | 0.073 | 25.07 | 68% | 2.104 | 2.59 | 30% | 27.66 | 98% | |||||

| 4 | 300 | 0.4 | 0.5 | 60 | 30 | 0.041 | 14.34 | 55% | 1.201 | 6.01 | 20% | 20.35 | 75% |

| 55 | 0.048 | 5.35 | 40% | 0.715 | 1.84 | 16% | 7.19 | 56% | |||||

| 80 | 0.063 | 10.66 | 55% | 0.634 | 6.85 | 32% | 17.51 | 87% | |||||

| Test | Vc | Fz | ap | Tc | Vb | CL (m) | Sd/L (mm) | Xd (mm) | Trend Type II | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TypeI | II | III | II + III | Left | Right | ||||||||

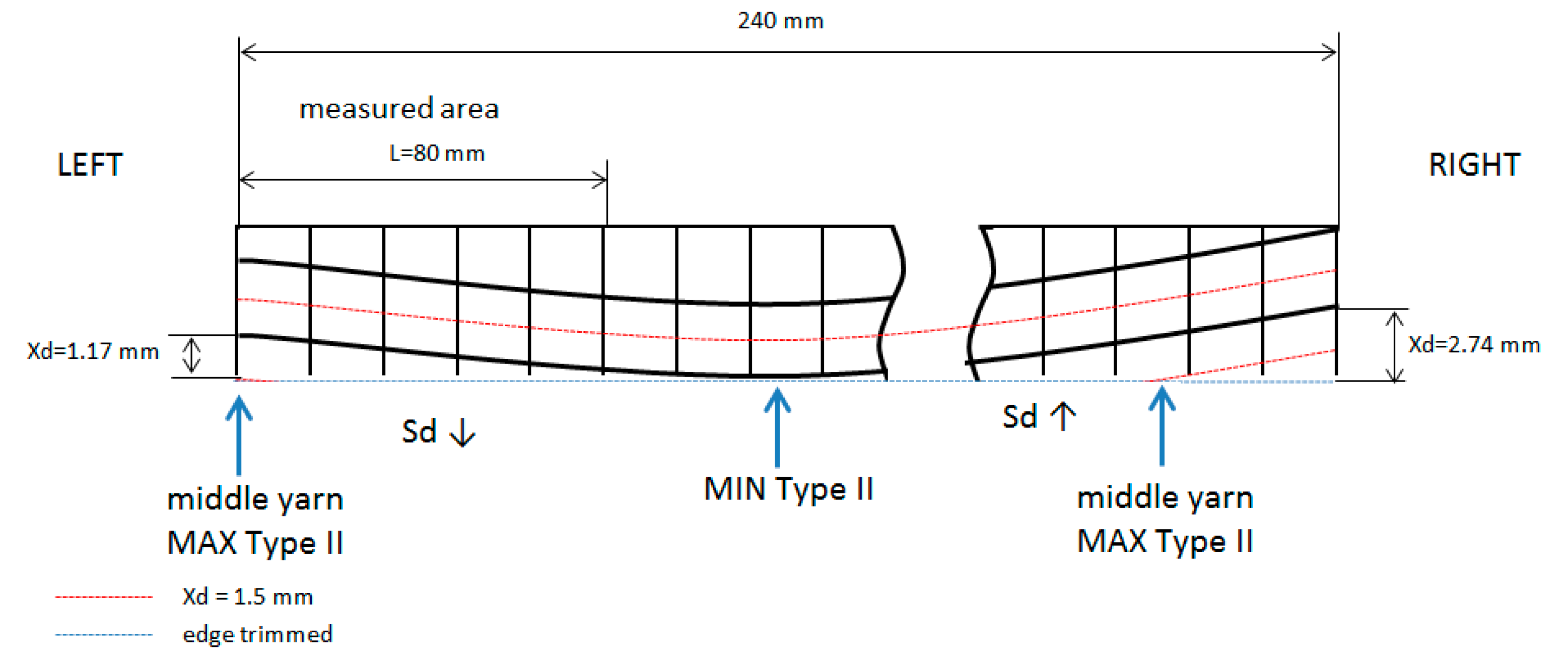

| 1 | 470 | 0.1 | 0.5 | 30 | 0.049 | 35.9 | 0.05 | 0.08 | 0.00 | 0.08 | 1.88 | 1.8 | Sd ↓ |

| 55 | 0.057 | 65.8 | 0.09 | 0.13 | 0.07 | 0.20 | 0.91 | 0.94 | uniform | ||||

| 80 | 0.072 | 95.7 | 0.08 | 0.05 | 0.06 | 0.11 | 1.17 | 2.74 | Sd ↓ | ||||

| 2 | 470 | 0.4 | 1.5 | 5 | 0.211 | 23.9 | 0.27 | 1.15 | 0.18 | 1.33 | - | - | - |

| 10 | 0.232 | 47.9 | 0.38 | 0.54 | 0.37 | 0.91 | - | - | - | ||||

| 30 | 0.247 | 143.6 | 0.38 | 0.52 | 0.22 | 0.74 | - | - | - | ||||

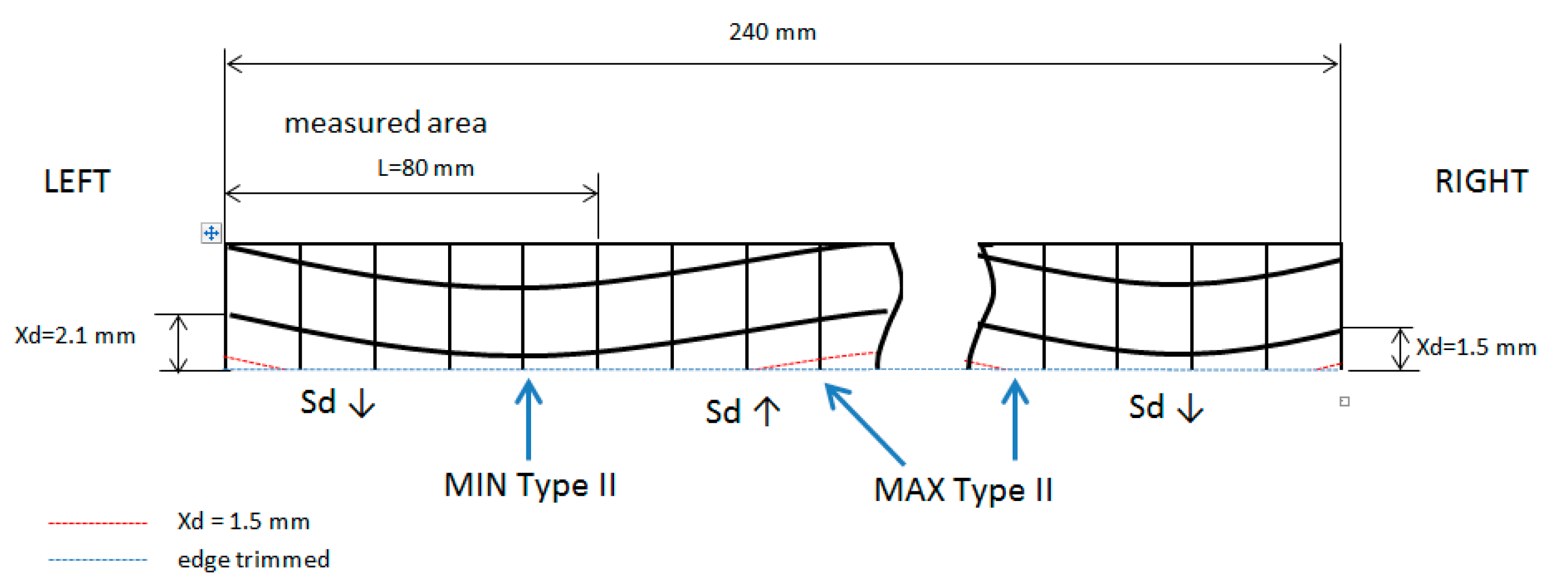

| 3 | 300 | 0.1 | 1.5 | 30 | 0.032 | 22.9 | 0.08 | 0.13 | 0.00 | 0.13 | 0.9 | 0.95 | uniform |

| 55 | 0.047 | 42.0 | 0.12 | 0.13 | 0.06 | 0.20 | 1.1 | 1.16 | Sd ↓ | ||||

| 80 | 0.073 | 61.1 | 0.12 | 0.31 | 0.03 | 0.35 | 2.1 | 1.5 | Sd ↑ | ||||

| 4 | 300 | 0.4 | 0.5 | 30 | 0.041 | 91.7 | 0.17 | 0.18 | 0.08 | 0.25 | 2.11 | 2.3 | uniform |

| 55 | 0.048 | 168.1 | 0.13 | 0.07 | 0.02 | 0.09 | 2.35 | 1.57 | Sd ↓ | ||||

| 80 | 0.063 | 244.5 | 0.14 | 0.13 | 0.09 | 0.22 | 2.71 | 1.93 | Sd ↓ | ||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navarro-Mas, M.D.; García-Manrique, J.A.; Meseguer, M.D.; Ordeig, I.; Sánchez, A.I. Delamination Study in Edge Trimming of Basalt Fiber Reinforced Plastics (BFRP). Materials 2018, 11, 1418. https://doi.org/10.3390/ma11081418

Navarro-Mas MD, García-Manrique JA, Meseguer MD, Ordeig I, Sánchez AI. Delamination Study in Edge Trimming of Basalt Fiber Reinforced Plastics (BFRP). Materials. 2018; 11(8):1418. https://doi.org/10.3390/ma11081418

Chicago/Turabian StyleNavarro-Mas, Maria Dolores, Juan Antonio García-Manrique, Maria Desamparados Meseguer, Isabel Ordeig, and Ana Isabel Sánchez. 2018. "Delamination Study in Edge Trimming of Basalt Fiber Reinforced Plastics (BFRP)" Materials 11, no. 8: 1418. https://doi.org/10.3390/ma11081418

APA StyleNavarro-Mas, M. D., García-Manrique, J. A., Meseguer, M. D., Ordeig, I., & Sánchez, A. I. (2018). Delamination Study in Edge Trimming of Basalt Fiber Reinforced Plastics (BFRP). Materials, 11(8), 1418. https://doi.org/10.3390/ma11081418