The Effect of the Morphology of Coarse Aggregate on the Properties of Self-Compacting High-Performance Fibre-Reinforced Concrete

Abstract

1. Introduction

2. Materials and Methods

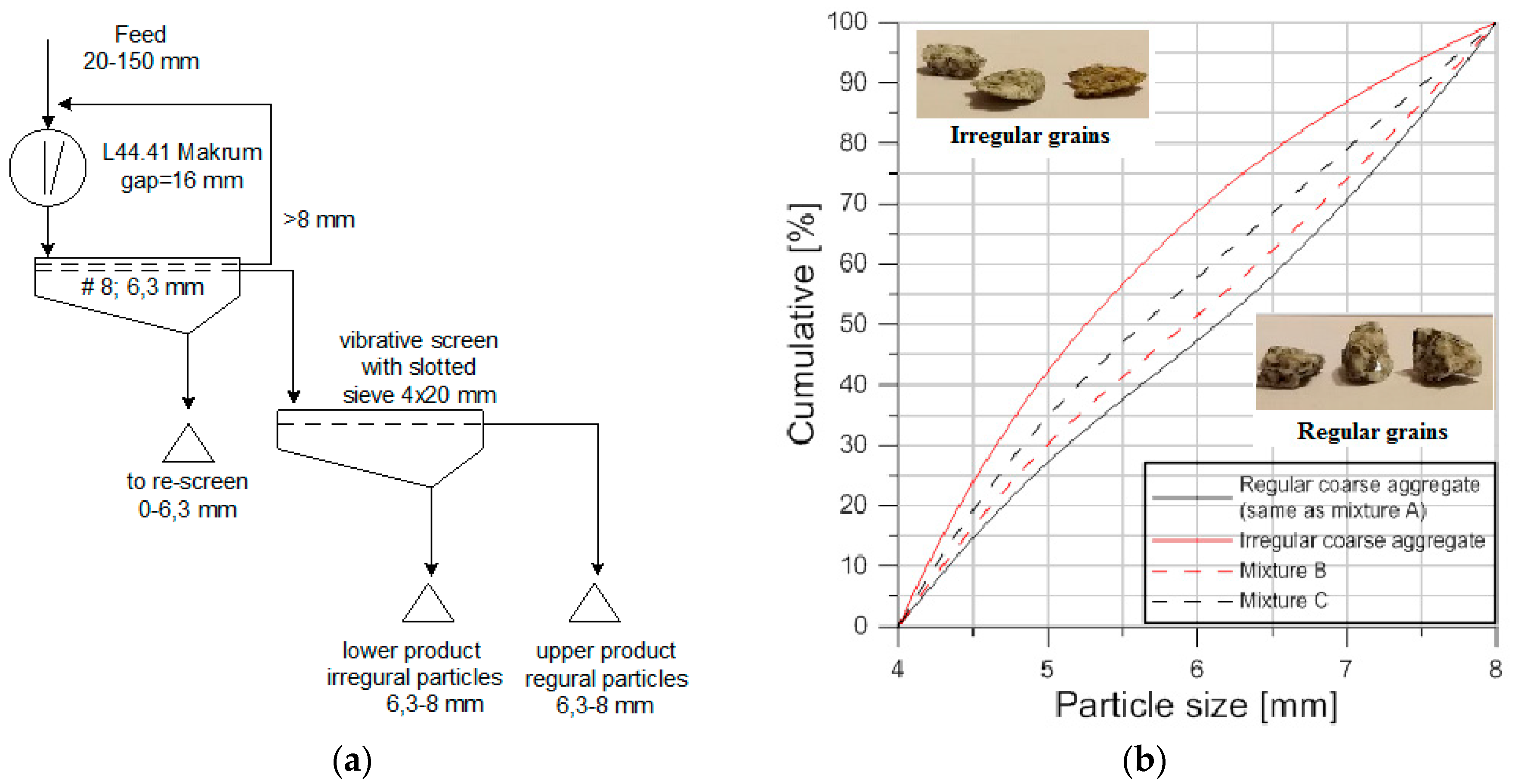

2.1. Preparation of Coarse Aggregate

2.2. Experimental Setup

- regular coarse aggregate (same as mixture A),

- irregular coarse aggregate,

- mixture B (80% of regular and 20% of irregular coarse aggregate, this ratio is most commonly found in concrete aggregates and results from the widespread crushing systems), and

- mixture C (50% of regular and 50% of irregular coarse aggregate).

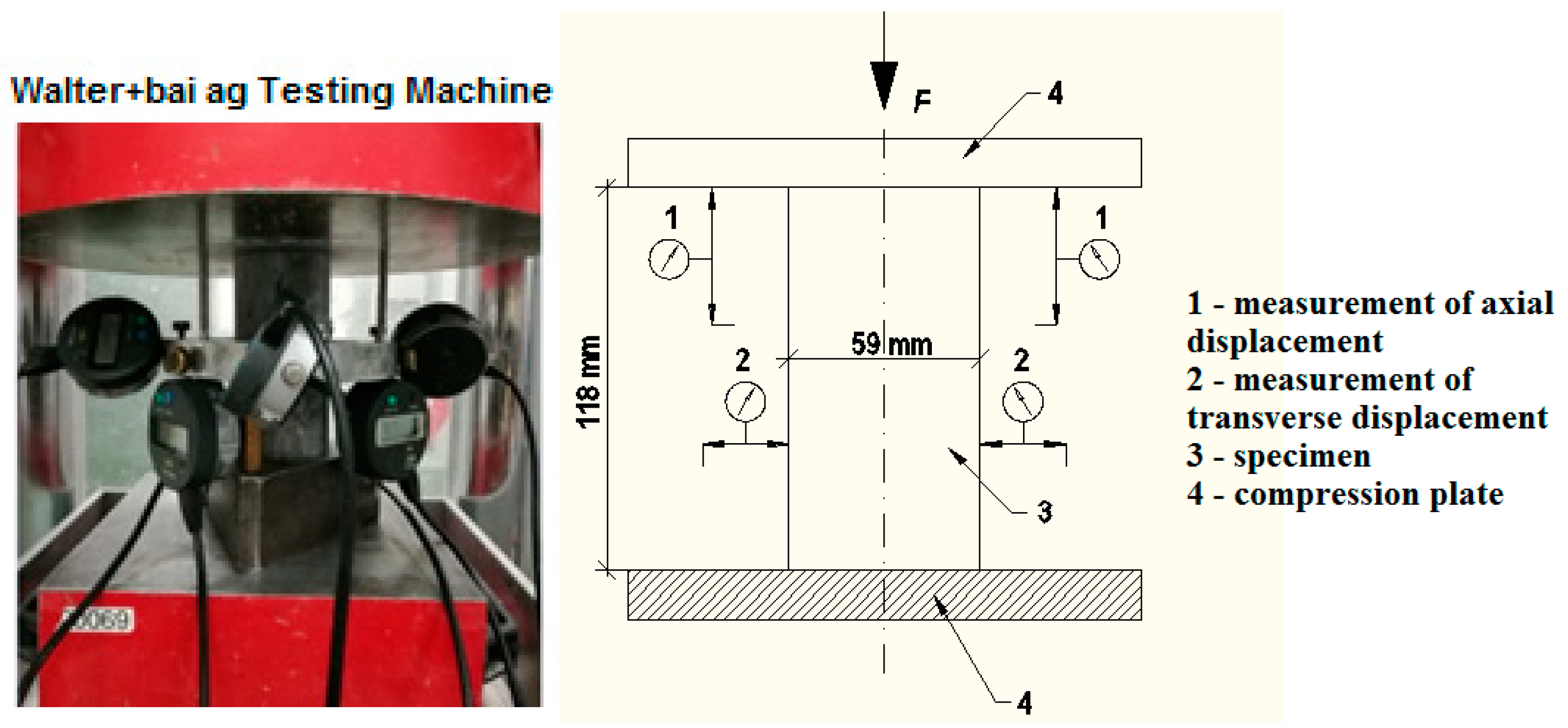

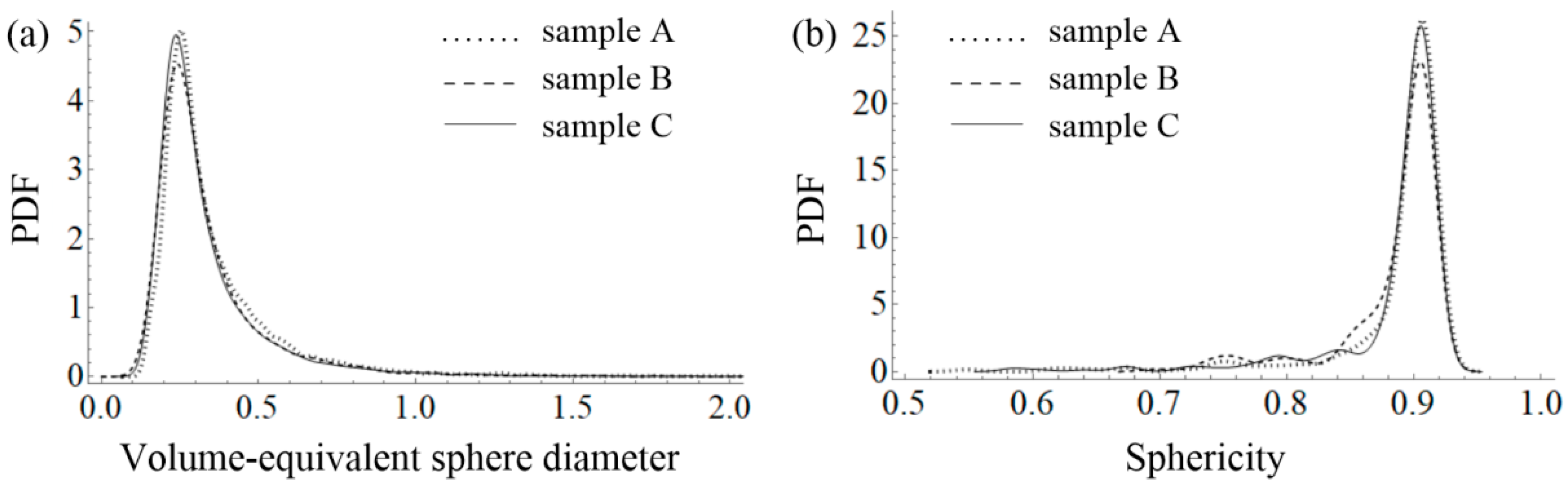

2.3. Microscale Laboratory Test

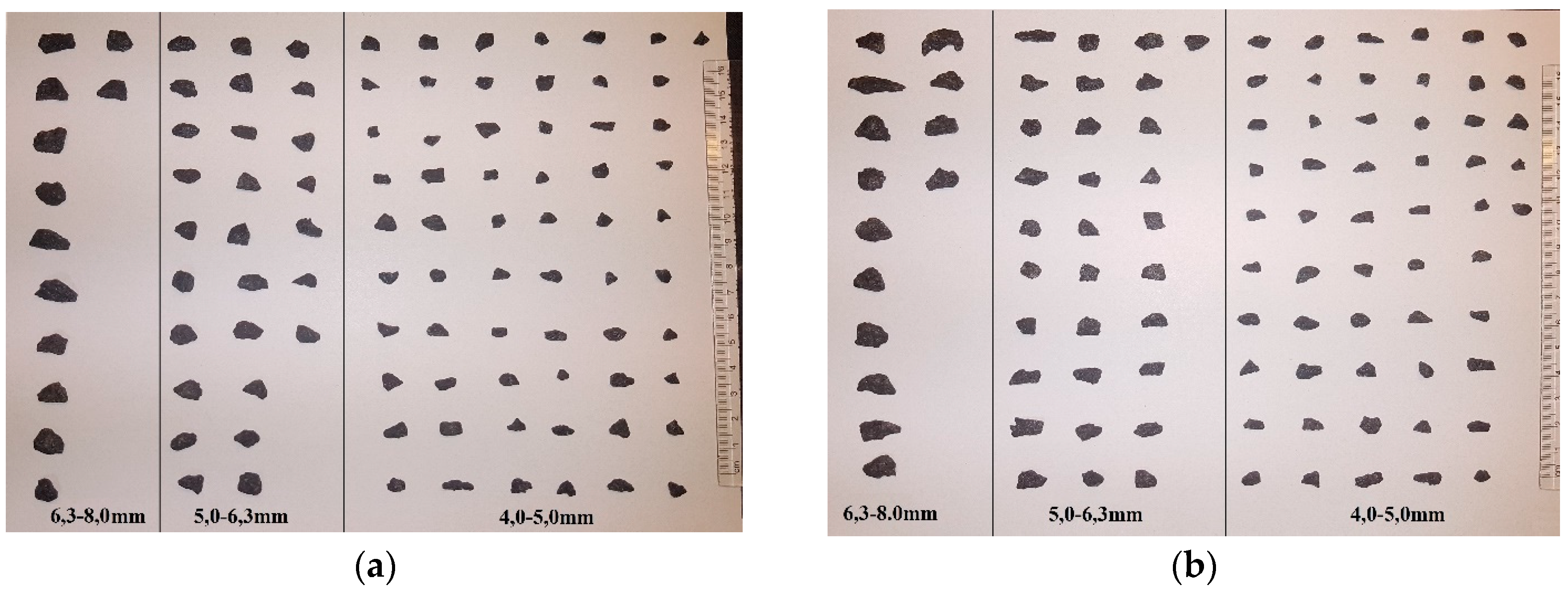

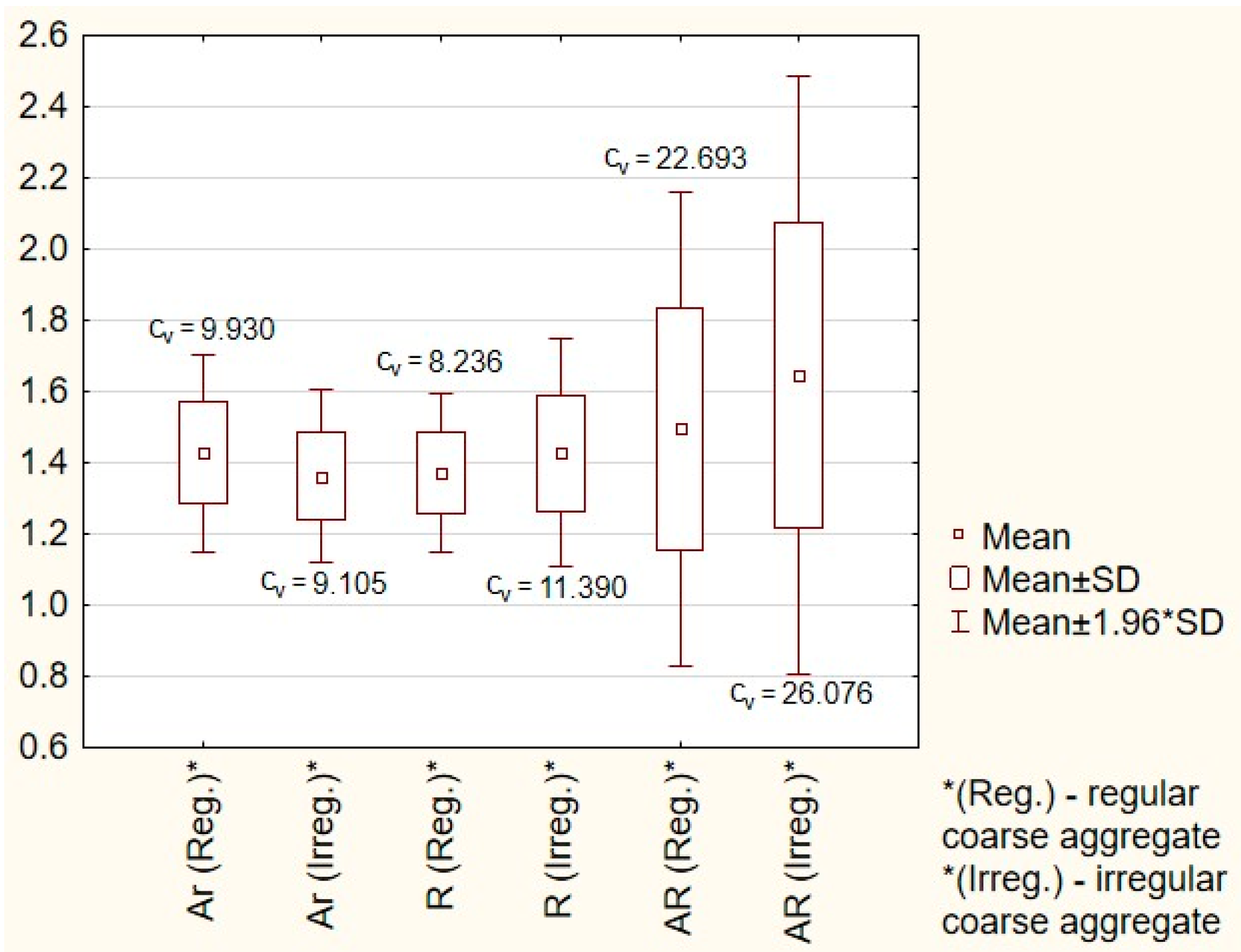

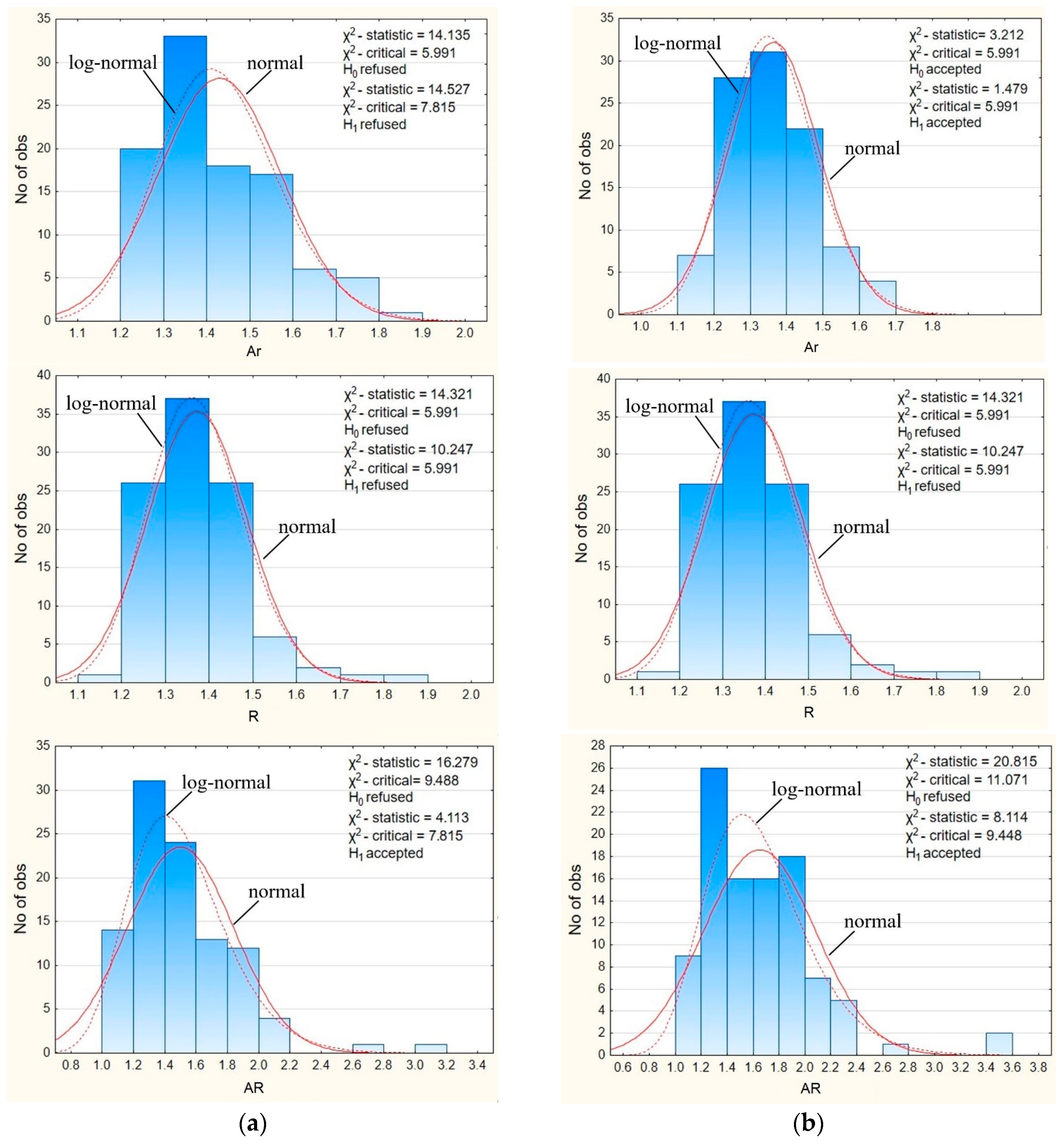

3. Morphological Characterization of Coarse Aggregate

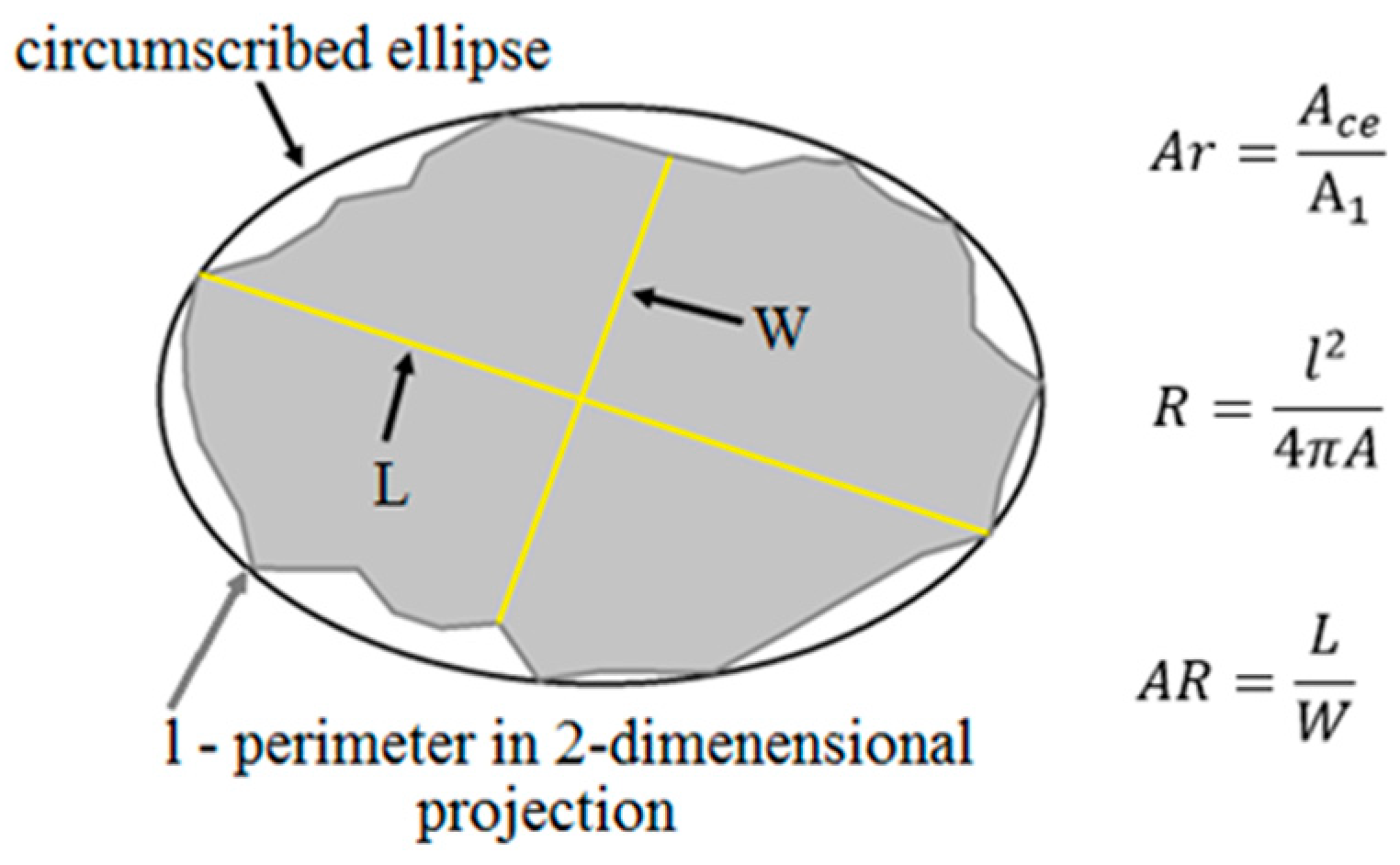

- Area ratio (Ar) describes the form of particles in a 2-dimensional system. It is defined as the ratio of the area of a circumscribing ellipse (Ace) to the area of a particle (A1). The value of the area ratio for a circle or elliptical image of a particle is equal to 1.

- Roundness (R) describes how closely the morphology of the particle approaches the circle. The value of roundness is equal to or greater than 1.

- The aspect ratio (AR) of a particle is used to describe the form of particles in a two-dimensional system. It is defined as the ratio of the particle’s length (L) to its width (W). The aspect ratio of a circle and equilateral polygon is equal to 1.

4. Results and Discussion

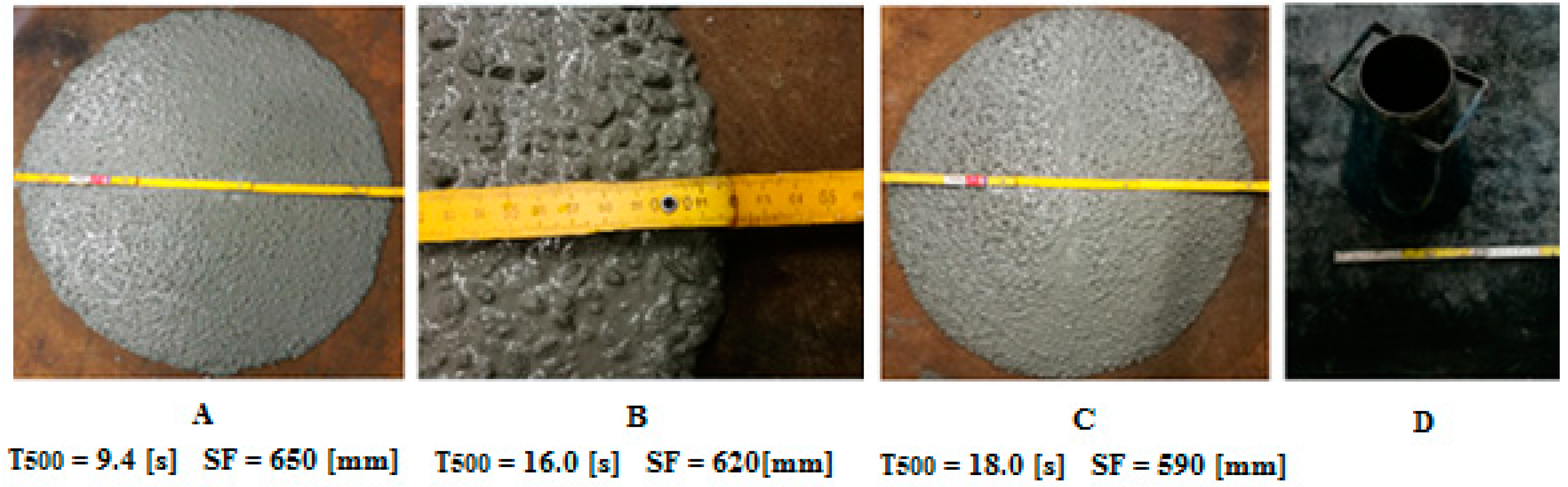

4.1. Properties of Fresh Concrete Mixture

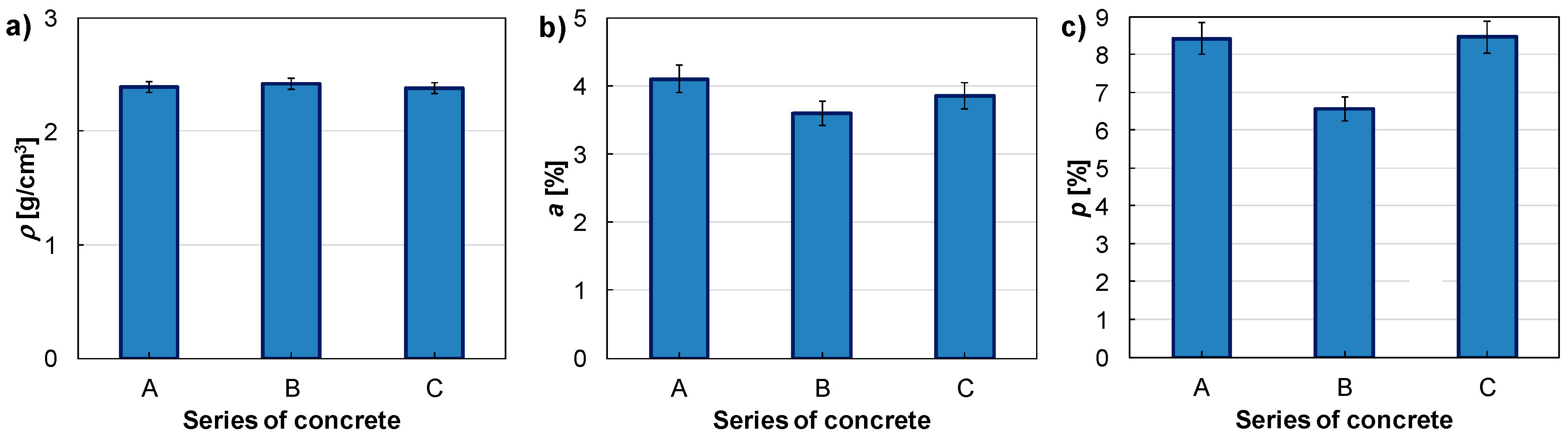

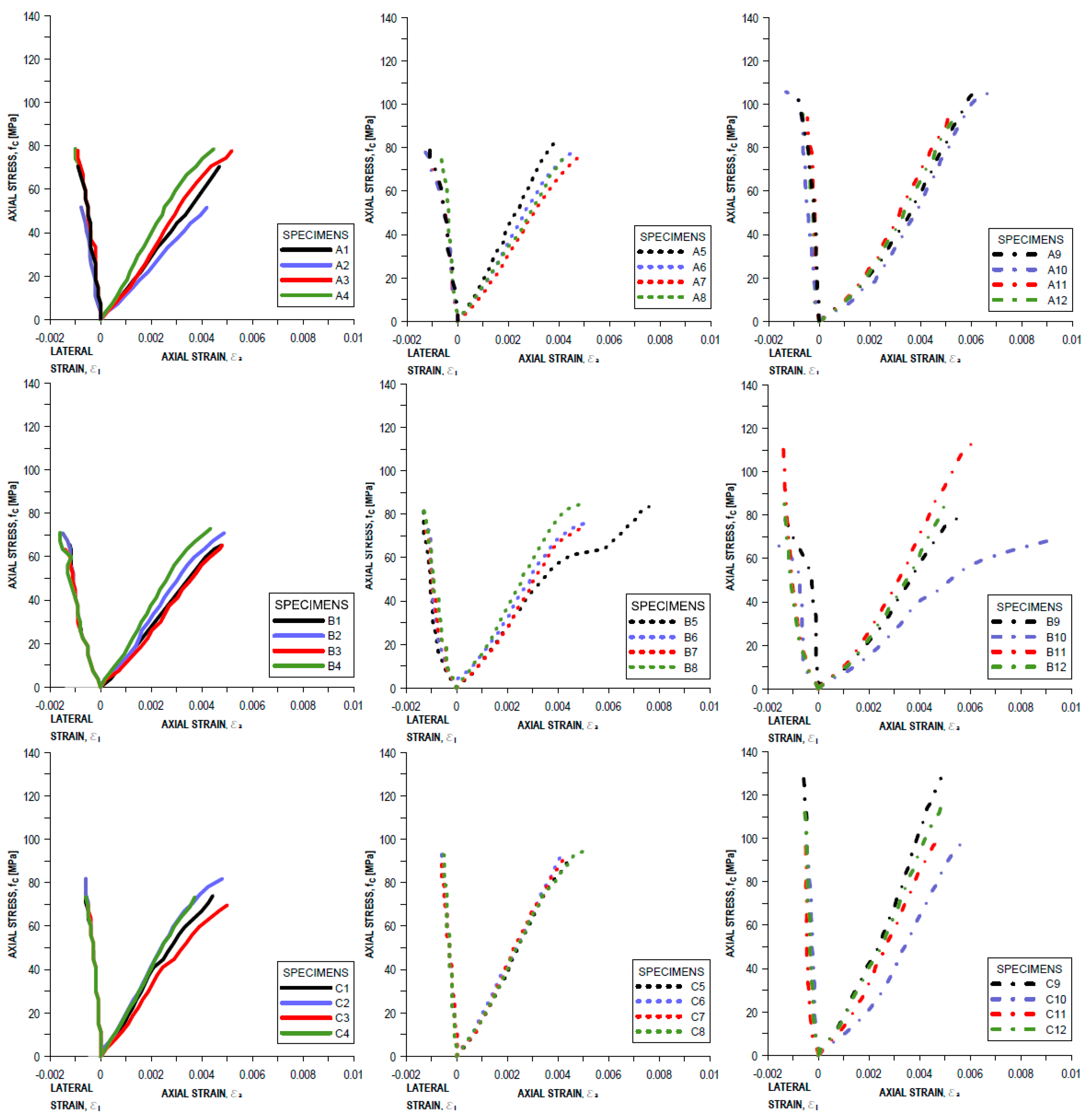

4.2. Selected Physical and Mechanical Properties of Hardened Concrete

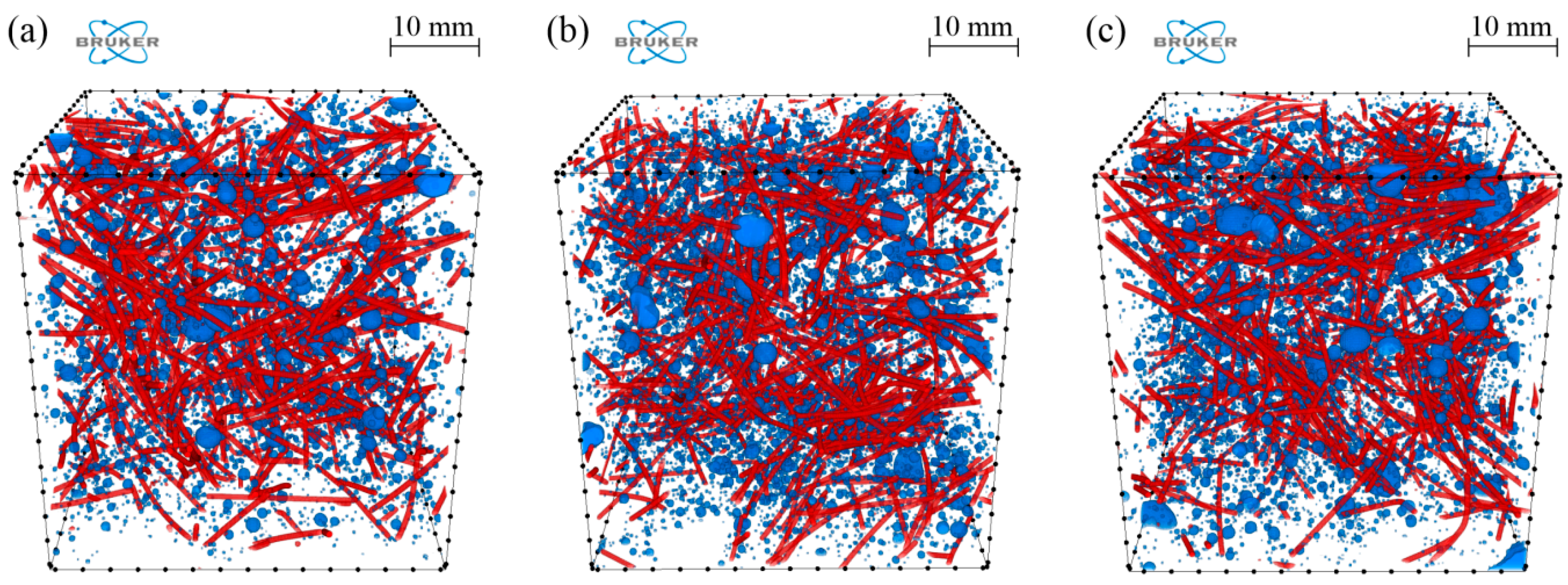

4.3. Microscale Investigation

5. Conclusions

- It has been proven that the morphology of the grains of coarse aggregate has an enormous effect on the compressive strength and stiffness of the tested concretes. This may be due to the different friction angle and better filling of the grain skeleton by the mix of aggregate containing regular and irregular grains when compared to the regular grain aggregate,

- The sharper edges of the irregular aggregates may induce more pronounced stress concentrations. In this case, it would actually lead to an improved compressive strength. The lowest transverse strains occur in the case of concrete C, which contains the highest amount of irregular aggregate,

- The morphology of the grain aggregate also has an effect on the rheological early age properties of fresh concrete mixes. Based on the presented research, it can be concluded that the appropriate selection of the morphology of the grains of coarse aggregate can affect the rheological parameters of concrete. The research will be continued in order to reduce the proportion of water and cement in relation to the share of aggregates of various morphologies,

- Digital analysis of coarse aggregate showed that the values of the aspect ratio and roundness are closer to 1 for the regular coarse aggregate than for irregular coarse aggregate, which indicates that the morphology of regular coarse aggregate is closer to the shape of a circle than to the morphology of irregular coarse aggregate,

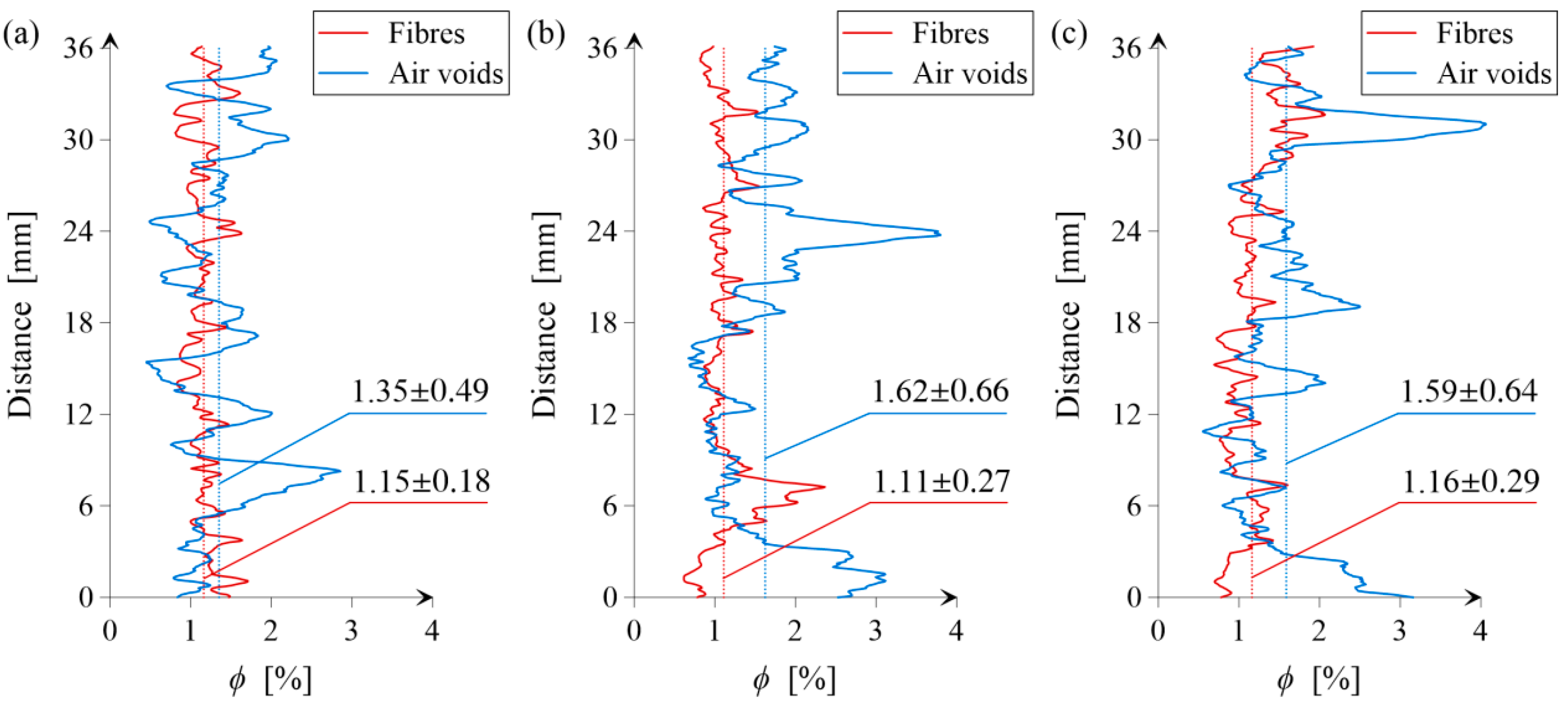

- The morphology of the grain aggregate also has an effect on the air voids and steel fibre distribution along the height of sample. It was observed that this distribution is more homogeneous for the sample with only regular grains in the concrete mixture,

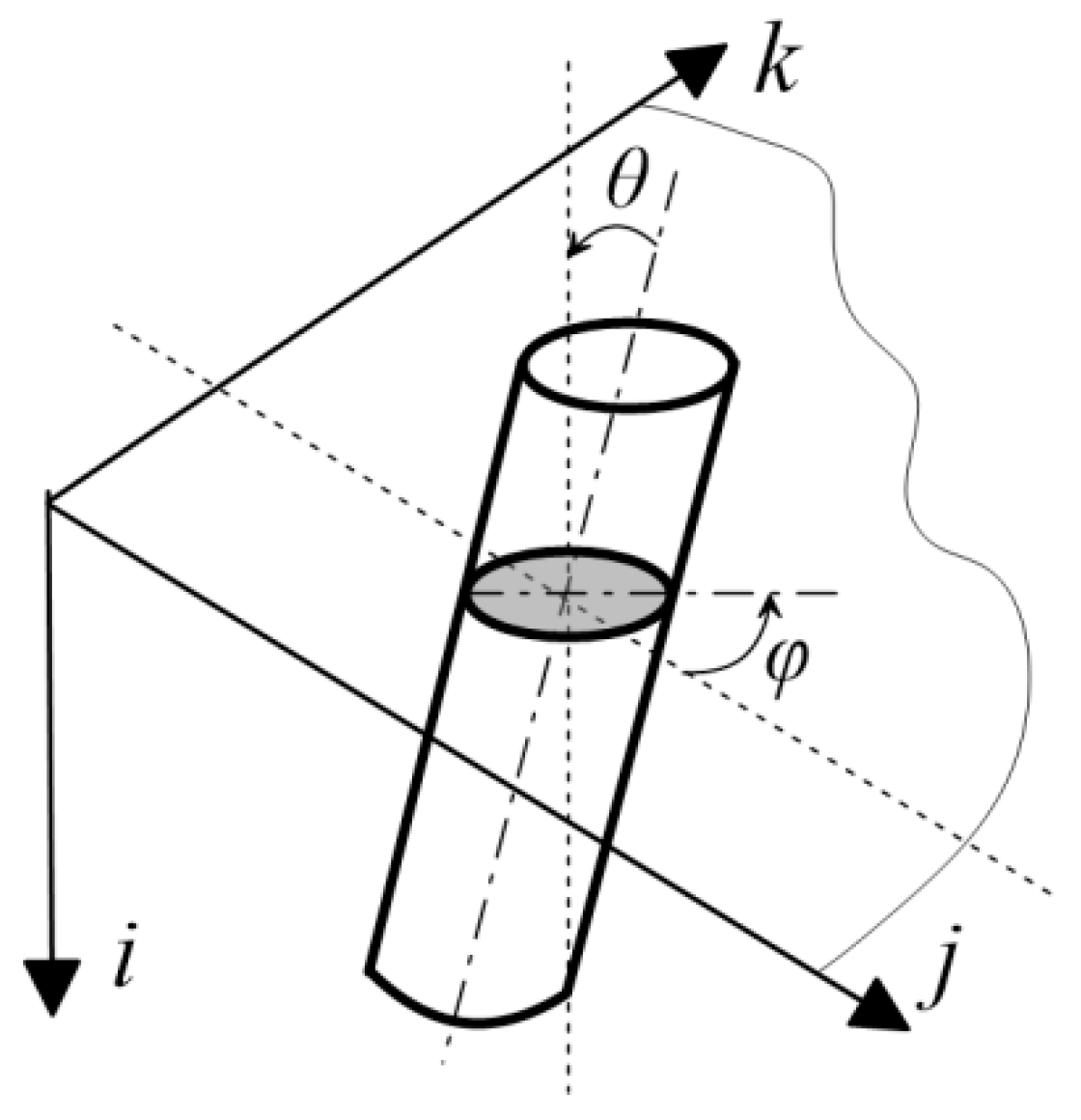

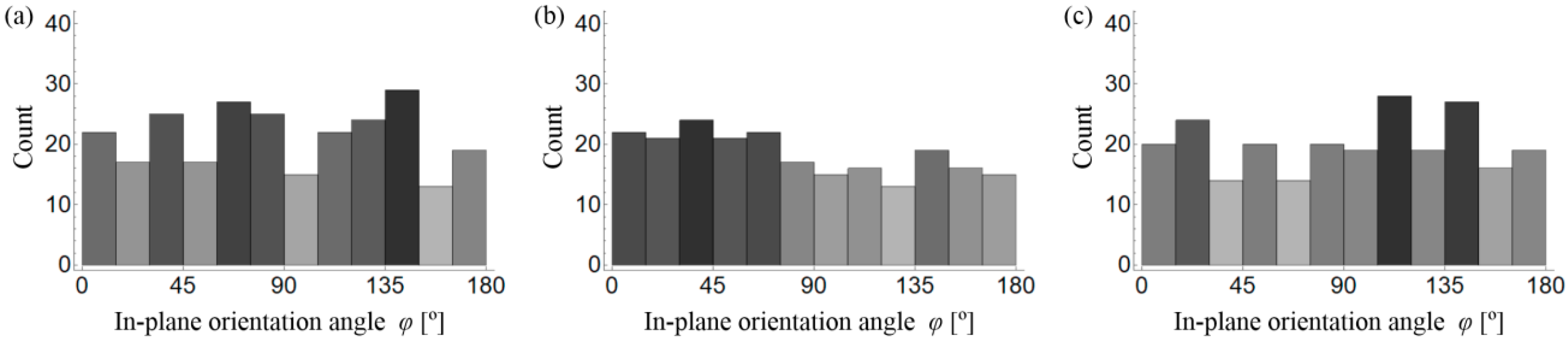

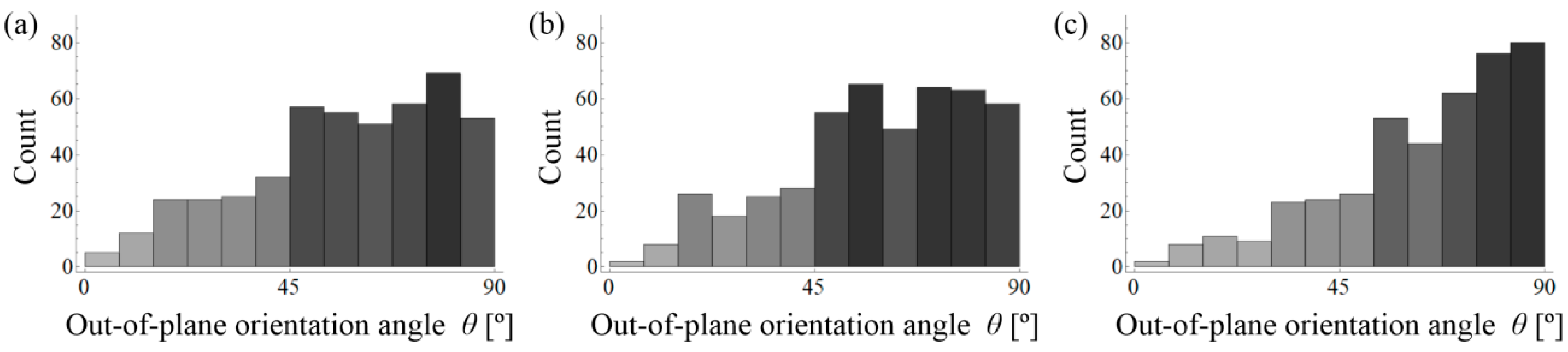

- The morphology of the grain aggregate also has an effect on the orientation of steel fibres. It was observed that a small volume of irregular aggregate grains results in a reduction of the number of fibres oriented horizontally, and as a consequence, a reduction of the anisotropy effect that is caused by gravity.

- In the future work, the effect of coarse aggregate morphology on the behavior of normal concrete and for self-compacting high-performance concrete without steel fibres will be performed. It will allow for determining the essence of this parameter in the design of this type of concretes.

Author Contributions

Funding

Conflicts of Interest

Nomenclature & Symbols

| ρ | density, [kg/m3] |

| ρa | bulk density of coarse aggregate, [kg/m3] |

| dmax | maximum size of a certain fraction’s particle, [mm] |

| a | absorptivity, [%] |

| p | total porosity, [%] |

| Rm | tensile strength of steel fibres, [MPa] |

| AR | aspect ratio, [-] |

| L | length of particle, [mm] |

| W | width of particle, [mm] |

| R | roundness, [-] |

| l | perimeter in a 2-dimensional projection, [mm] |

| A | area in a 2-dimensional projection, [mm2] |

| Ar | area ratio, [-] |

| Ace | ratio of area of a circumscribing ellipse, [mm2] |

| A1 | area of particle, [mm2] |

| , , | average compressive strength at 3, 7, 28 days, [MPa] |

| E | modulus of elasticity, [GPa] |

| , , | average Young modulus at 3, 7, 28 days, [GPa] |

| Rc | nominal compressive strength, [MPa] |

| s | standard deviation, [-] |

| cV | coefficient of variation, [%] |

| axial strain during fracture, [‰] | |

| transverse strain during fracture, [‰] |

References

- Kostrzanowska-Siedlarz, A.; Gołaszewski, J. Rheological Properties of High Performance Self-Compacting Concrete: Effects of Composition and Time. Constr. Build. Mater. 2016, 115, 705–715. [Google Scholar] [CrossRef]

- Han, S.; Cui, Y.; Huang, H.; An, M.; Yu, Z. Effect of Curing Conditions on the Shrinkage of Ultra High-Performance Fiber-Reinforced Concrete. Adv. Civ. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Xue, W.; Chen, J.; Xie, F.; Feng, B. Orientation of Steel Fibers in Magnetically Driven Concrete and Mortar. Materials 2018, 11, 170. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Khayat, K.H.; Shi, C. How do fiber shape and matrix composition affect fiber pullout behavior and flexural properties of UHPC? Cem. Concr. Compos. 2018, 90, 193–201. [Google Scholar] [CrossRef]

- Rajan, B.; Singh, D. Understanding influence of crushers on shape characteristics of fine aggregates based on digital image and conventional techniques. Constr. Build. Mater. 2017, 150, 833–843. [Google Scholar] [CrossRef]

- Zieliński, Z. Correlation of Technological Parameters of Mechanical Crushing and Screening of Rock Materials used in Road Construction; Wyd Uczelniane Politechniki Szczecińskiej: Szczecin, Poland, 1983. (In Polish) [Google Scholar]

- Gu, X.; Tran, Y.; Hong, L. Quantification of Coarse Aggregate Shape in Concrete. Front. Struct. Civ. Eng. 2014, 8, 308–321. [Google Scholar] [CrossRef]

- Navarrete, I.; Lopez, M. Understanding the relationship between the segregation of concrete and coarse aggregate density and size. Constr. Build. Mater. 2017, 149, 741–748. [Google Scholar] [CrossRef]

- Ostrowski, K. The influence of coarse aggregate shape on the properties of high-performance, self-compacting concrete. Tech. Trans. Civ. Eng. 2017. [Google Scholar] [CrossRef]

- Smarzewski, P.; Barnat-Hunek, D.; Jezierski, W. The Possibility of Using Boiler Slag as Coarse Aggregate in High Strength Concrete. KSCE J. Civ. Eng. 2018, 22, 1816–1826. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, Y.; Sun, W.; Nair, H.; Lane, D.S.; Wang, L. Effect of coarse aggregate morphology on the mechanical properties of stone matrix asphalt. Constr. Build. Mater. 2017, 152, 48–56. [Google Scholar] [CrossRef]

- Akçaoğlu, T. Determining aggregate size & shape effect on concrete microcracking under compression by means of a degree of reversibility method. Constr. Build. Mater. 2017, 143, 376–386. [Google Scholar] [CrossRef]

- Qian, Z.; Garboczi, E.J.; Ye, G.; Schlangen, E. Anm: A geometrical model for the composite structure of mortar and concrete using real-shape particles. Mater. Struct. 2016, 49, 149–158. [Google Scholar] [CrossRef]

- Han, J.; Wang, K.; Wang, X.; Monteiro, P.J.M. 2D image analysis method for evaluating coarse aggregate characteristic and distribution in concrete. Constr. Build. Mater. 2016, 127, 30–42. [Google Scholar] [CrossRef]

- Cepuritis, R.; Garboczi, E.J.; Jacobsen, S. Three dimensional shape analysis of concrete aggregate fines produced by VSI crushing. Powder Technol. 2017, 308, 410–421. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, X.; Zhao, Y. Numerical study on the effect of coarse-aggregate morphology on shear performance. J. Test. Eval. 2015, 43. [Google Scholar] [CrossRef]

- Bairagi, N.K.; Ravande, K.; Pareek, V.K. Behaviour of concrete with different proportions of natural and recycled aggregates. Resour. Conserv. Recyc. 1993, 9, 109–126. [Google Scholar] [CrossRef]

- De Larrard, F. Concrete Mixture Proportioning: A Scientific Approach; CRC Press: London, UK, 1999; p. 448. [Google Scholar]

- De Brito, J.; Kurda, R.; Raposeiro da Silva, P. Can We Truly Predict the Compressive Strength of Concrete without Knowing the Properties of Aggregates? Appl. Sci. 2018, 8, 1095. [Google Scholar] [CrossRef]

- Özturan, T.; Çeçen, C. Effect of coarse aggregate type on mechanical properties of concretes with different strengths. Cem. Concr. Res. 1997, 27, 165–170. [Google Scholar] [CrossRef]

- Brandt, M. Optimization Methods for Material Design of Cement-Based Composites; CRC Press: Boca Raton, FL, USA, 2014; p. 328. [Google Scholar]

- Zhu, W.; Wei, J.; Li, F.; Zhang, T.; Chen, Y.; Hu, J.; Yu, Q. Understanding restraint effect of coarse aggregate on the drying shrinkage of self-compacting concrete. Constr. Build. Mater. 2016, 114, 458–463. [Google Scholar] [CrossRef]

- Gawenda, T. Principles for Selection of Crushers and Technological Crushing Circuits in Crushed-Stone Aggregate Production; Wyd AGH: Kraków, Poland, 2015. (In Polish) [Google Scholar]

- Gawenda, T. Set of devices for the production of regular aggregates, AGH w Krakowie, Zgłoszenie nr P.408045 z dn. 2014-04-28. Biuletyn Urzędu Patentowego 2015, 4. Available online: http://patenty.bg.agh.edu.pl/pelneteksty/PL408045A1.pdf (accessed on 6 August 2018). (In Polish).

- Katzer, J. The Influence of Steel Fibers on the Properties of Selected Composites. 2008. Available online: https://www.arkady.info/wplyw-wlokien-stalowych-na-wlasciwosci-wybranych-kompozytow-cementowych.pdf (accessed on 6 August 2018).

- Polish Committee for Standardization. PN-EN 933-4:2008, Tests for Geometrical Properties of Aggregates. Determination of Particle Shape. Shape Index; Polish Committee for Standardization: Warszawa, Poland, 2008. (In Polish)

- Polish Committee for Standardization. PN-EN 12390-3:2009, Testing Hardened Concrete. Compressive Strength of Test Specimens; Polish Committee for Standardization: Warszawa, Poland, 2009. (In Polish)

- Polish Committee for Standardization. PN-EN 12350-8:2009, Testing Fresh Concrete—Part 8: Self-Compacting Concrete—Slump Flow Test; Polish Committee for Standardization: Warszawa, Poland, 2009. (In Polish)

- Polish Committee for Standardization. PN-EN 12390-13:2013, Testing Hardened Concrete, Part 13: Determination of Secant Modulus of Elasticity in Compression; Polish Committee for Standardization: Warszawa, Poland, 2013. (In Polish)

- Różański, A.; Rajczakowska, M.; Serwicki, A. The influence of microstructure geometry on the scale effect in mechanical behaviour of heterogeneous materials. Sci. Eng. Compos. Mater. 2017, 24, 557–571. [Google Scholar] [CrossRef]

- Nunes, S.; Pimentel, M.; Ribeiro, F.; Milheiro-Oliveira, P.; Carvalho, A. Estimation of the tensile strength of UHPFRC layers based on non-destructive assessment of the fibre content and orientation. Cem. Concr. Compos. 2017, 83, 222–238. [Google Scholar] [CrossRef]

- Benjamin, J.R.; Cornell, C.A. Probability Statistics and Decision for Civil Engineers; McGraw Hill: New York, NY, USA, 1970. [Google Scholar]

| Mix Type | Cement [kg/m3] | Fine Aggregate [kg/m3] | Regular Coarse Aggregate [kg/m3] | Irregular Coarse Aggregate [kg/m3] | Water [kg/m3] | Sika Fume [kg/m3] | Super-Plasti-Ciser [kg/m3] | Steel Fibres [kg/m3] |

|---|---|---|---|---|---|---|---|---|

| A | 550 | 850 | 950 | - | 173 | 66 | 19.25 | 78 |

| B | 550 | 850 | 760 | 190 | 173 | 66 | 19.25 | 78 |

| C | 550 | 850 | 475 | 475 | 173 | 66 | 19.25 | 78 |

| Mix Type | Average Compressive Strength at 3 Days [Mpa] | Average Compressive Strength at 7 Days [Mpa] | Average Compressive Strength at 28 Days [Mpa] | Average Young Modulus at 3 Days [Gpa] | Average Young Modulus at 7 Days [Gpa] | Average Young Modulus at 28 Days [Gpa] |

|---|---|---|---|---|---|---|

| A | 69.90 | 78.73 | 100.91 | 16.55 | 19.31 | 18.82 |

| B | 68.47 | 79.24 | 87.28 | 15.05 | 15.85 | 15.50 |

| C | 74.75 | 93.43 | 110.94 | 20.03 | 23.53 | 24.09 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ostrowski, K.; Sadowski, Ł.; Stefaniuk, D.; Wałach, D.; Gawenda, T.; Oleksik, K.; Usydus, I. The Effect of the Morphology of Coarse Aggregate on the Properties of Self-Compacting High-Performance Fibre-Reinforced Concrete. Materials 2018, 11, 1372. https://doi.org/10.3390/ma11081372

Ostrowski K, Sadowski Ł, Stefaniuk D, Wałach D, Gawenda T, Oleksik K, Usydus I. The Effect of the Morphology of Coarse Aggregate on the Properties of Self-Compacting High-Performance Fibre-Reinforced Concrete. Materials. 2018; 11(8):1372. https://doi.org/10.3390/ma11081372

Chicago/Turabian StyleOstrowski, Krzysztof, Łukasz Sadowski, Damian Stefaniuk, Daniel Wałach, Tomasz Gawenda, Konrad Oleksik, and Ireneusz Usydus. 2018. "The Effect of the Morphology of Coarse Aggregate on the Properties of Self-Compacting High-Performance Fibre-Reinforced Concrete" Materials 11, no. 8: 1372. https://doi.org/10.3390/ma11081372

APA StyleOstrowski, K., Sadowski, Ł., Stefaniuk, D., Wałach, D., Gawenda, T., Oleksik, K., & Usydus, I. (2018). The Effect of the Morphology of Coarse Aggregate on the Properties of Self-Compacting High-Performance Fibre-Reinforced Concrete. Materials, 11(8), 1372. https://doi.org/10.3390/ma11081372