Influence of Pre-Stress Magnitude on Fatigue Crack Growth Behavior of Al-Alloy

Abstract

1. Introduction

2. Material and Experiments

3. Results

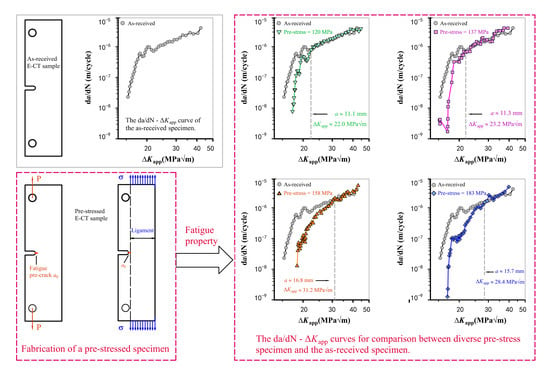

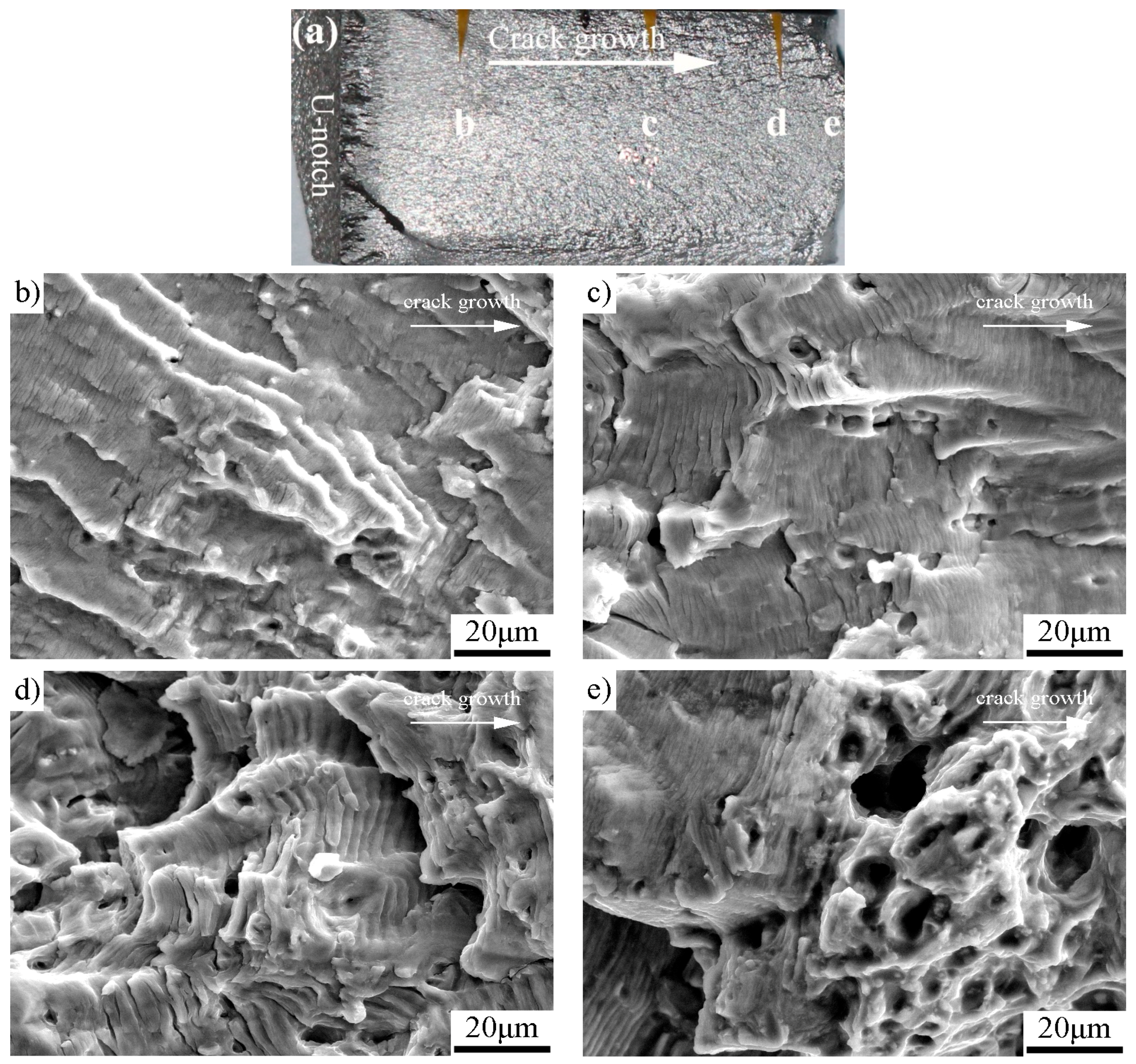

3.1. Effect of Pre-Stress Magnitude on Fatigue Property

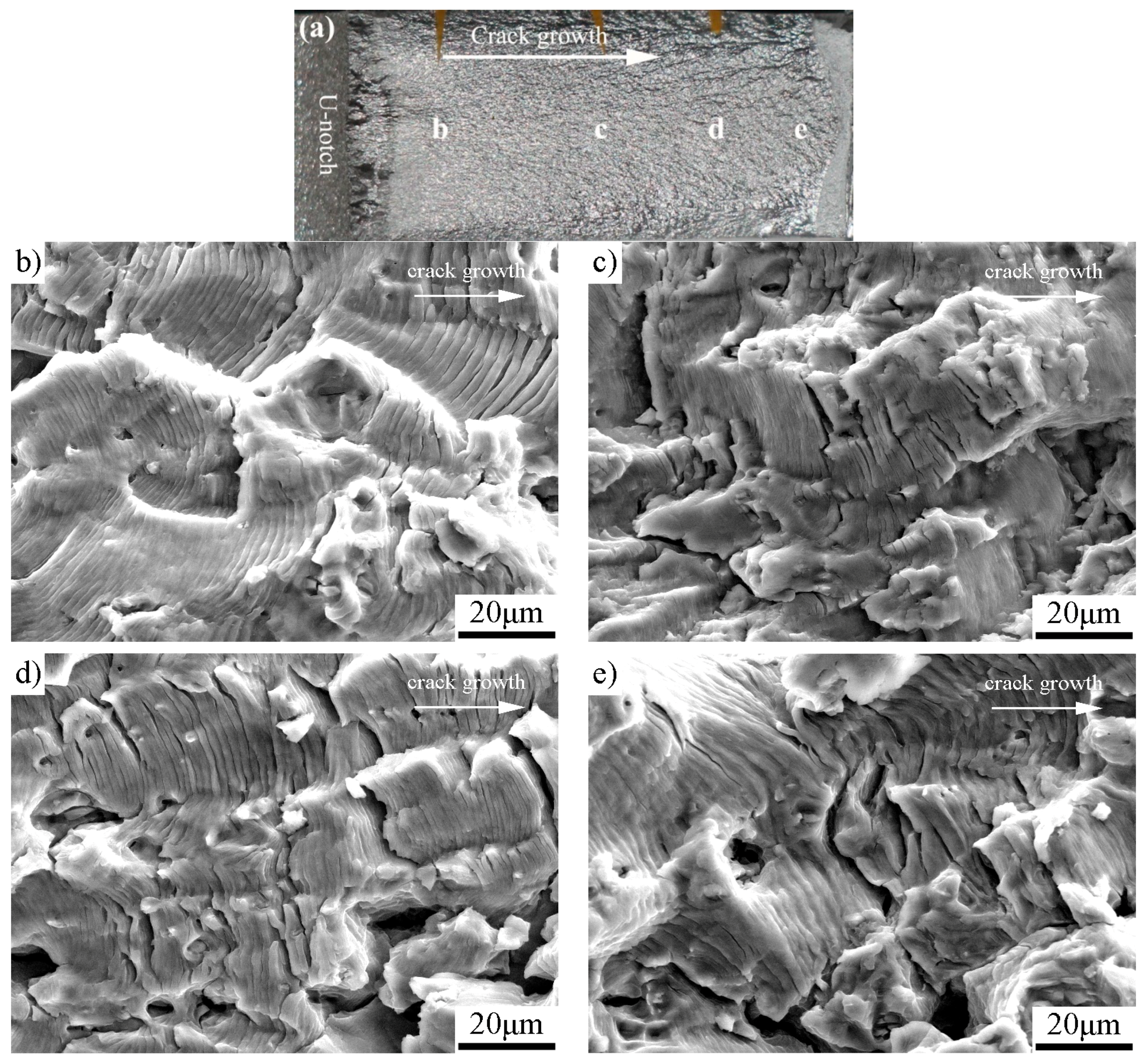

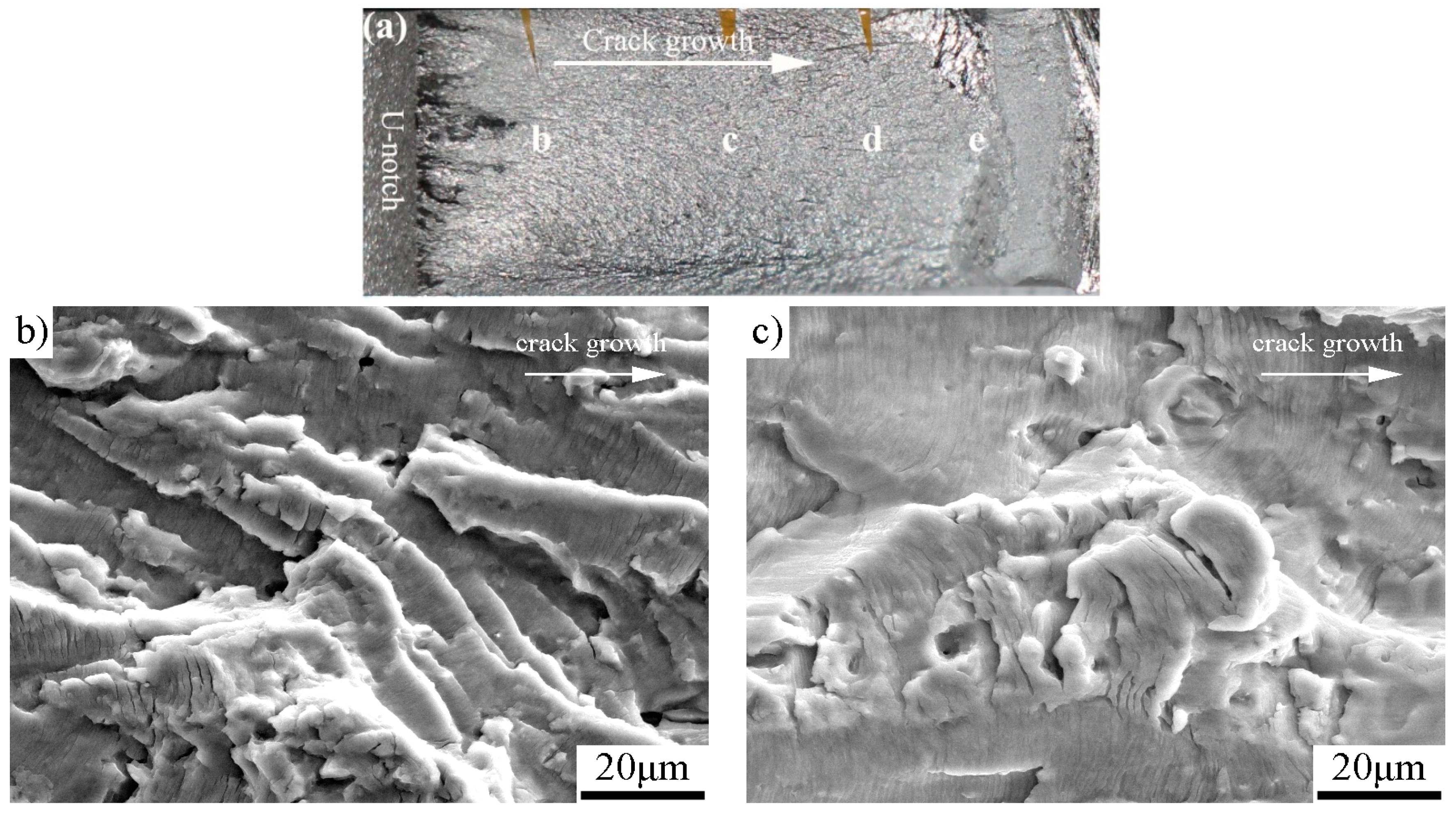

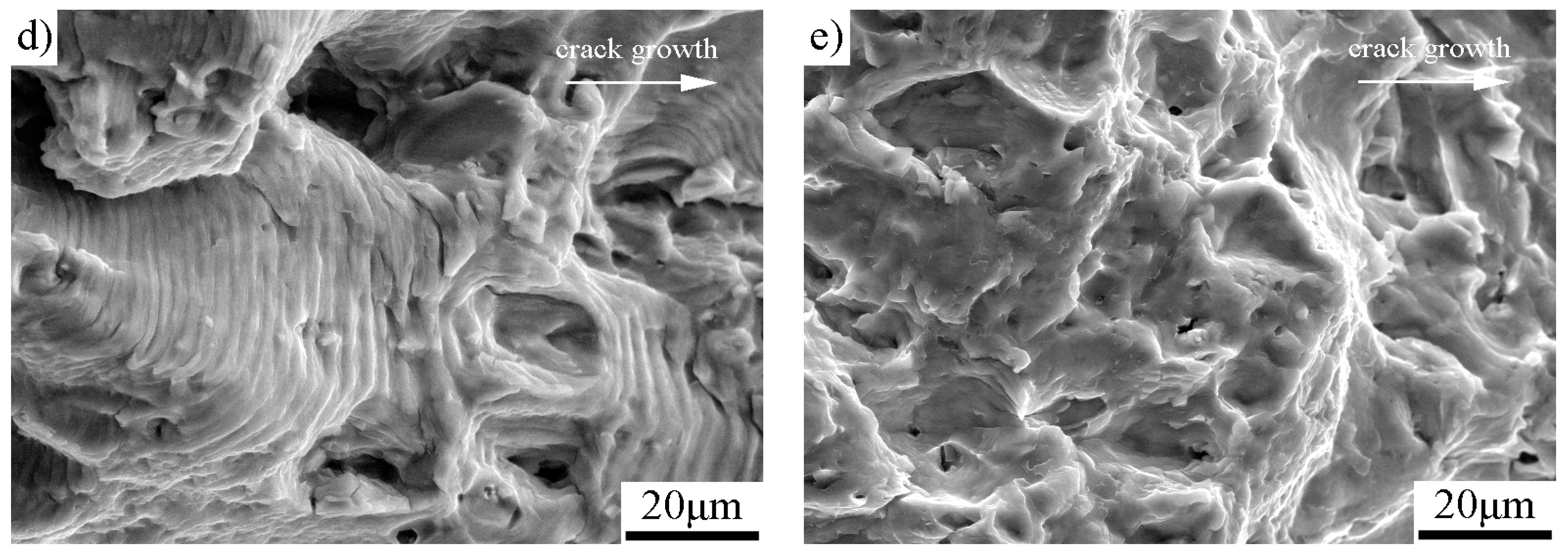

3.2. Observations of Fatigue-Fractured Surfaces

4. Discussions

5. Conclusions

- (1)

- The fatigue crack growth property of the Al-alloy after the introduction of pre-stress subjected to cycle loading was developed by two stages: the initial improvement stage and subsequent normal stage.

- (2)

- Various pre-stress significantly improved the fatigue performance of Al-alloy, and no adverse factor was observed for increasing fatigue property. Pre-stress does not change the fatigue fracture characteristic (i.e., fatigue striation), but obviously reduces the fatigue striations spacing.

- (3)

- At the stage of initial improvement, the fatigue life and crack growth resistance of a specimen increases firstly, reaches a peak value at a pre-stress of approximate 158 MPa, and then decreases, with the increasing pre-stress magnitude. This is because excessive pre-stress generates the phenomenon of strain hardening.

- (4)

- Paris curves of the as-received and each pre-stress specimen intersect at a point, which is the turning point from the improvement stage to normal stage. The occurrence of the normal stage after incorporation of pre-stress is due to the relaxation of pre-stress with the increasing number of fatigue cycling and/or crack length.

Author Contributions

Funding

Conflicts of Interest

References

- Carle, D.; Blount, G. The suitability of aluminium as an alternative material for car bodies. Mater. Des. 1999, 20, 267–272. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Zhan, K.; Jiang, C.H.; Ji, V. Effect of prestress stateon surface layer characteristic of S30432 austenitic stainless steel in shot peening process. Mater. Des. 2012, 42, 89–93. [Google Scholar] [CrossRef]

- Ramos, R.; Ferreira, N.; Ferreira, J.A.M.; Capela, C.; Batista, A.C. Improvement in fatigue life of Al 7475-T7351 alloy specimens by applying ultrasonic and microshot peening. Int. J. Fatigue 2016, 92, 87–95. [Google Scholar] [CrossRef]

- Sepe, R.; Armentani, E.; Caputo, F.; Lamanna, G. Numerical evaluation and experimental comparison of elasto-plastic stress-strain distribution around the corner cracks of a notched specimen. Procedia Eng. 2015, 109, 285–295. [Google Scholar] [CrossRef]

- Sepe, R.; Laiso, M.; Luca, A.D.; Caputo, F. Evaluation of residual stresses in butt welded joint of dissimilar material by FEM. Key Eng. Mater. 2017, 754, 268–271. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, C.; Gan, X.; Chen, Y.; Ji, V. Influence of shot peening on the fatigue life of laser hardened 17-4PH steel. Int. J. Fatigue 2011, 33, 549–556. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, C.; Gan, X.; Chen, Y. Effect of shot peening on the microstructure of laser hardened 17-4PH. Appl. Surf. Sci. 2010, 257, 1154–1160. [Google Scholar] [CrossRef]

- Zhang, X.C.; Zhang, Y.K.; Lu, J.Z.; Xuan, F.Z.; Wang, Z.D.; Tu, S.T. Improvement of fatigue life of Ti-6Al-4V alloy by laser shock peening. Mater. Sci. Eng. A 2010, 527, 3411–3415. [Google Scholar] [CrossRef]

- Montross, C.S.; Wei, T.; Ye, L.; Clark, G.; Mai, Y.W. Laser shock processing and its effects on microstructure and properties of metal alloys: A review. Int. J. Fatigue 2002, 24, 1021–1036. [Google Scholar] [CrossRef]

- Rousseau, T.; Hoc, T.; Gilles, P.; Nouguier-Lehon, C. Effect of bead quantity in ultrasonic shot peening: Surface analysis and numerical simulations. J. Mater. Process. Technol. 2015, 225, 413–420. [Google Scholar] [CrossRef]

- Lu, J.Z.; Luo, K.Y.; Zhang, Y.K.; Sun, G.F.; Gu, Y.Y.; Zhou, J.Z.; Ren, X.D.; Zhang, X.C.; Zhang, L.F.; Chen, K.M.; et al. Grain refinement mechanism of multiple laser shock processing impacts on ANSI 304 stainless steel. Acta Mater. 2010, 58, 5354–5362. [Google Scholar] [CrossRef]

- Muñoz-Cubillos, J.; Coronado, J.J.; Rodriguez, S.A. Deep rolling effect on fatigue behavior of austenitic stainless steels. Int. J. Fatigue 2017, 95, 120–131. [Google Scholar] [CrossRef]

- Zhao, J.; Dong, Y.; Ye, C. Laser shock peening induced residual stresses and the effect on crack propagation behavior. Int. J. Fatigue 2017, 100, 407–417. [Google Scholar] [CrossRef]

- Kattoura, M.; Mannava, S.R.; Dong, Q.; Vasudevan, V.K. Effect of laser shock peening on residual stress, microstructure and fatigue behavior of ATI 718Plus alloy. Int. J. Fatigue 2017, 102, 121–134. [Google Scholar] [CrossRef]

- Kalainathan, S.; Prabhakaran, S. Recent development and future perspectives of low energy laser shock peening. Opt. Laser Technol. 2016, 81, 137–144. [Google Scholar] [CrossRef]

- Miková, K.; Bagherifard, S.; Bokuvka, O.; Guagliano, M.; Trsko, L. Fatigue behavior of X70 microalloyed steel after severe shot peening. Int. J. Fatigue 2013, 55, 33–42. [Google Scholar] [CrossRef]

- Kikuchi, S.; Nakamura, Y.; Nambu, K.; Ando, M. Effect of shot peening using ultra-fine particles on fatigue properties of 5056 aluminum alloy under rotating bending. Mater. Sci. Eng. A 2016, 652, 279–286. [Google Scholar] [CrossRef]

- Mahmoudi, A.H.; Ghasemi, A.; Farrahi, G.H.; Sherafatnia, K. A comprehensive experimental and numerical study on redistribution of residual stresses by shot peening. Mater. Des. 2016, 90, 478–487. [Google Scholar] [CrossRef]

- Llaneza, V.; Belzunce, F.J. Study of the effects produced by shot peening on the surface of quenched and tempered steels: Roughness, residual stresses and work hardening. Appl. Surf. Sci. 2015, 356, 475–485. [Google Scholar] [CrossRef]

- Bichler, C.; Pippan, R. Effect of single overloads in ductile metals: A reconsideration. Eng. Fract. Mech. 2007, 74, 1344–1359. [Google Scholar] [CrossRef]

- Vasco-Olmo, J.M.; Díaz, F.A. Experimental evaluation of the effect of overloads on fatigue crack growth by analysing crack tip displacement fields. Eng. Fract. Mech. 2016, 166, 82–96. [Google Scholar] [CrossRef]

- Vasco-Olmo, J.M.; Díaz, F.A.; Patterson, E.A. Experimental evaluation of shielding effect on growing fatigue cracks under overloads using ESPI. Int. J. Fatigue 2015, 83, 117–126. [Google Scholar] [CrossRef]

- Tsukuda, H.; Ogiyama, H.; Shiraishi, T. Transient fatigue crack growth behavior following single overloads at high stress ratios. Fatigue Fract. Eng. Mater. Struct. 2010, 19, 879–891. [Google Scholar] [CrossRef]

- Zhang, C.G.; Hu, X.; Lu, P.; Zhang, G. Tensile overload-induced plastic deformation and fatigue behavior in weld-repaired high-strength low-alloy steel. J. Mater. Process. Technol. 2013, 213, 2005–2014. [Google Scholar] [CrossRef]

- Piascik, R.S.; Newman, J.C. An extended compact tension specimen for fatigue crack growth and fracture testing. Int. J. Fract. 1996, 76, R43–R48. [Google Scholar] [CrossRef]

- Jones, R.E. Fatigue crack growth retardation after single-cycle peak overload in ti-6al-4v titanium alloy. Eng. Fract. Mech. 1973, 5, 585–588. [Google Scholar] [CrossRef]

- Carlson, R.L.; Kardomateas, G.A.; Bates, P.R. The effects of overloads in fatigue crack growth. Int. J. Fatigue 1991, 13, 453–460. [Google Scholar] [CrossRef]

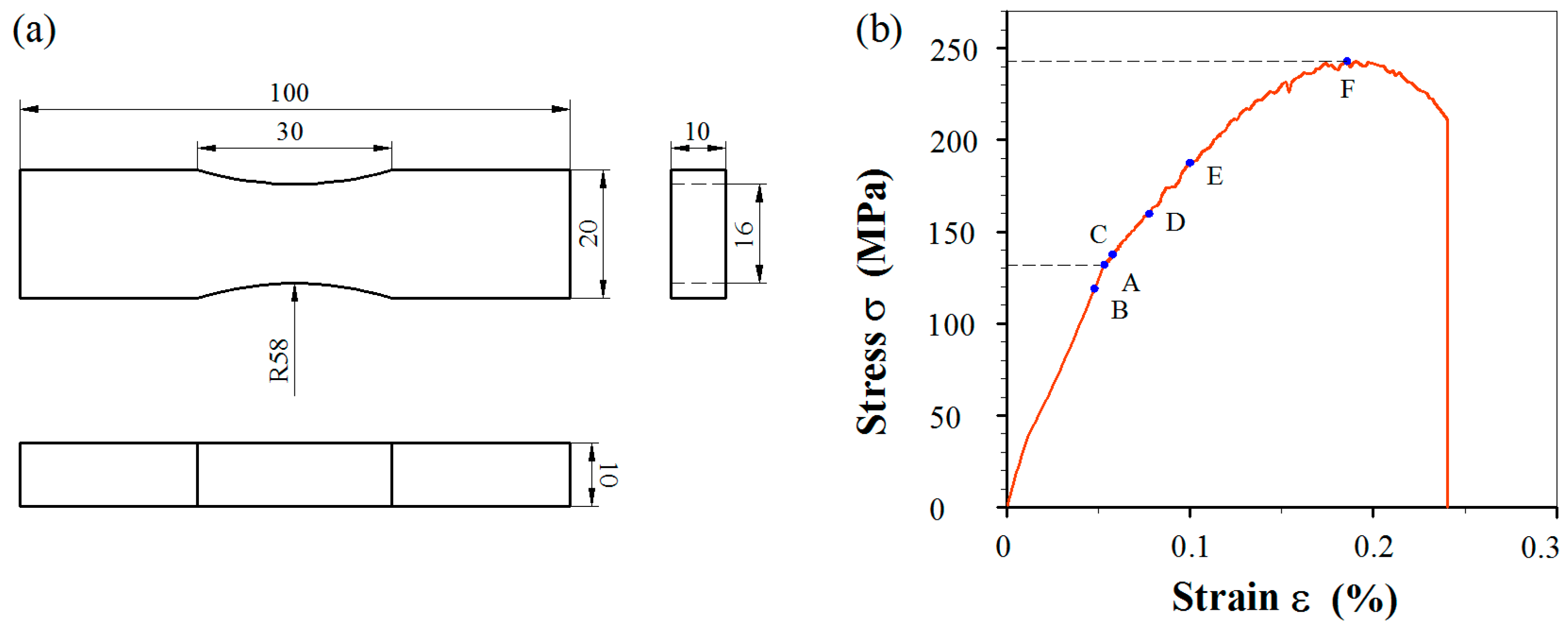

| Material | State | Yield Strength σy | Ultimate Tensile Strength σUTS | Young Modulus |

|---|---|---|---|---|

| Al5052 | H32 | 132 MPa | 243 MPa | 69.3–70.7 GPa |

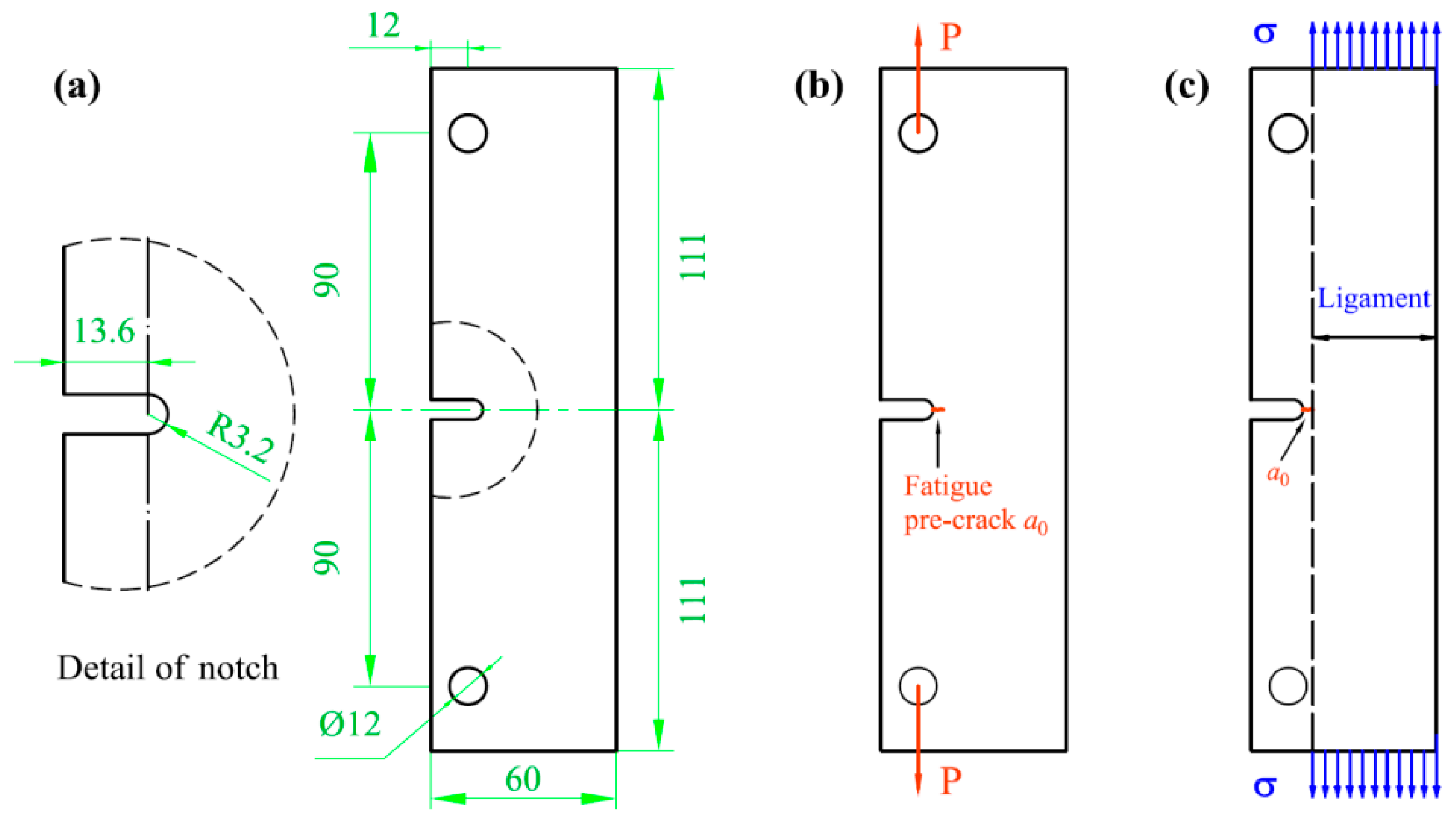

| Sample | Fatigue Pre-Crack (mm) | Ligament (mm2) (Length × Thickness) | Applied Load (kN) | Pre-Stress (MPa) (Point in Figure 2b) |

|---|---|---|---|---|

| 1 | 0.9 | 42.3 × 10 | - | - |

| 2 | 1.4 | 41.8 × 10 | 50 | 120 (B) |

| 3 | 1 | 42.2 × 10 | 58 | 137 (C) |

| 4 | 1.9 | 41.3 × 10 | 65.2 | 158 (D) |

| 5 | 0.9 | 42.3 × 10 | 77.3 | 183 (E) |

| Pre-Stress (MPa) | 120 | 137 | 158 | 183 |

|---|---|---|---|---|

| Length of pre-stress affected zone (mm) | 4.9 | 5.5 | 9.9 | 10.1 |

| Fatigue pre-crack (mm) | 1.4 | 1.0 | 1.9 | 0.9 |

| Crack length recovering to normal da/dN | 6.3 | 6.5 | 11.8 | 11.0 |

| Number of fatigue cycles elapsed | 109,055 | 209,857 | 333,650 | 242,905 |

| ΔKapp () ↔ normal da/dN | 22.0 | 23.2 | 31.5 | 28.4 |

| The applied maximum load Pmax (kN) | 12.0 | 12.0 | 12.5 | 12.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Song, W.; Wang, Q.; Liu, W. Influence of Pre-Stress Magnitude on Fatigue Crack Growth Behavior of Al-Alloy. Materials 2018, 11, 1267. https://doi.org/10.3390/ma11081267

Zhang C, Song W, Wang Q, Liu W. Influence of Pre-Stress Magnitude on Fatigue Crack Growth Behavior of Al-Alloy. Materials. 2018; 11(8):1267. https://doi.org/10.3390/ma11081267

Chicago/Turabian StyleZhang, Chunguo, Weizhen Song, Qitao Wang, and Wen Liu. 2018. "Influence of Pre-Stress Magnitude on Fatigue Crack Growth Behavior of Al-Alloy" Materials 11, no. 8: 1267. https://doi.org/10.3390/ma11081267

APA StyleZhang, C., Song, W., Wang, Q., & Liu, W. (2018). Influence of Pre-Stress Magnitude on Fatigue Crack Growth Behavior of Al-Alloy. Materials, 11(8), 1267. https://doi.org/10.3390/ma11081267