Evaluation of the Functional Performance in Turned Workpieces: Methodology and Application to UNS A92024-T3

Abstract

:1. Introduction

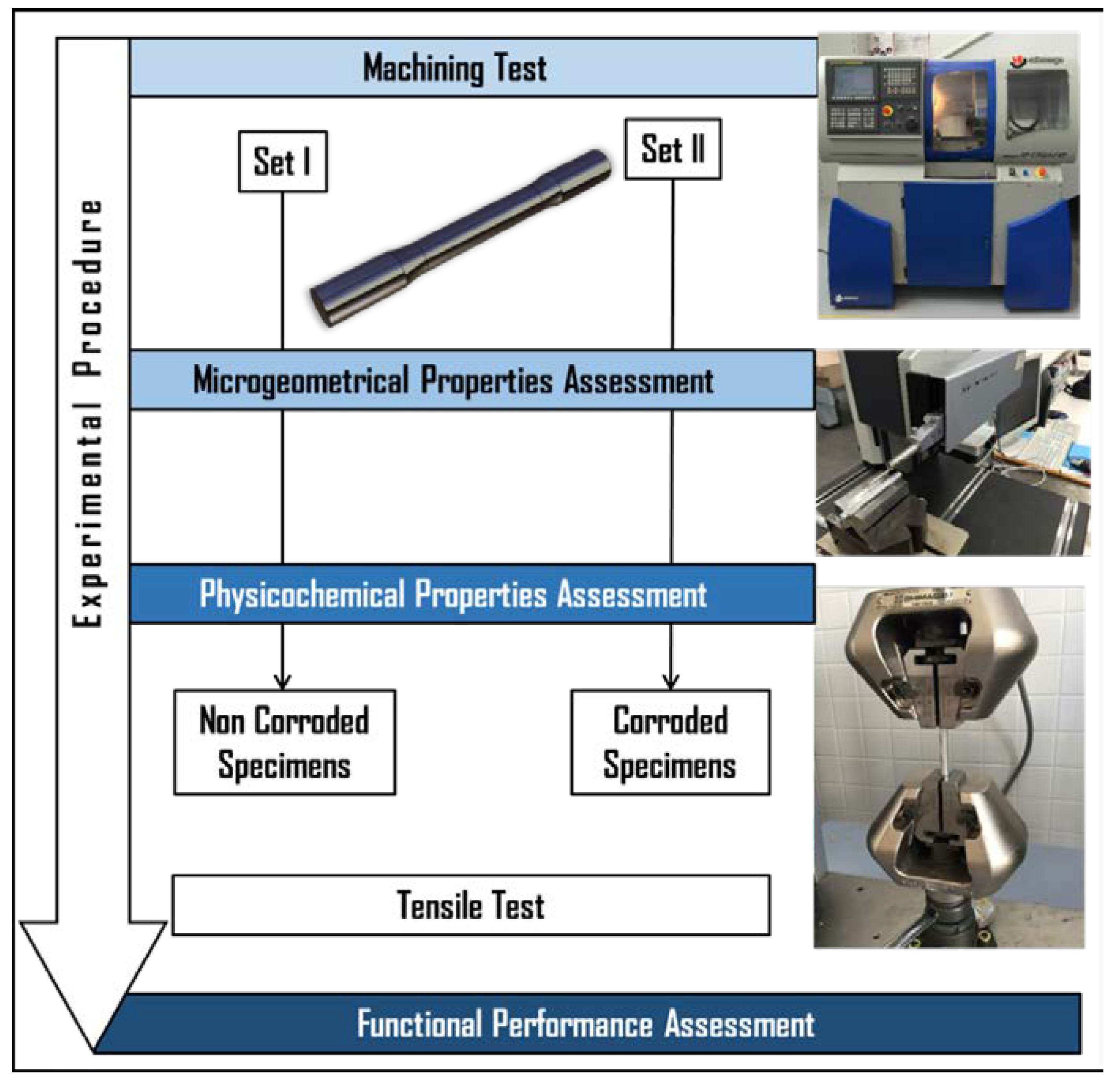

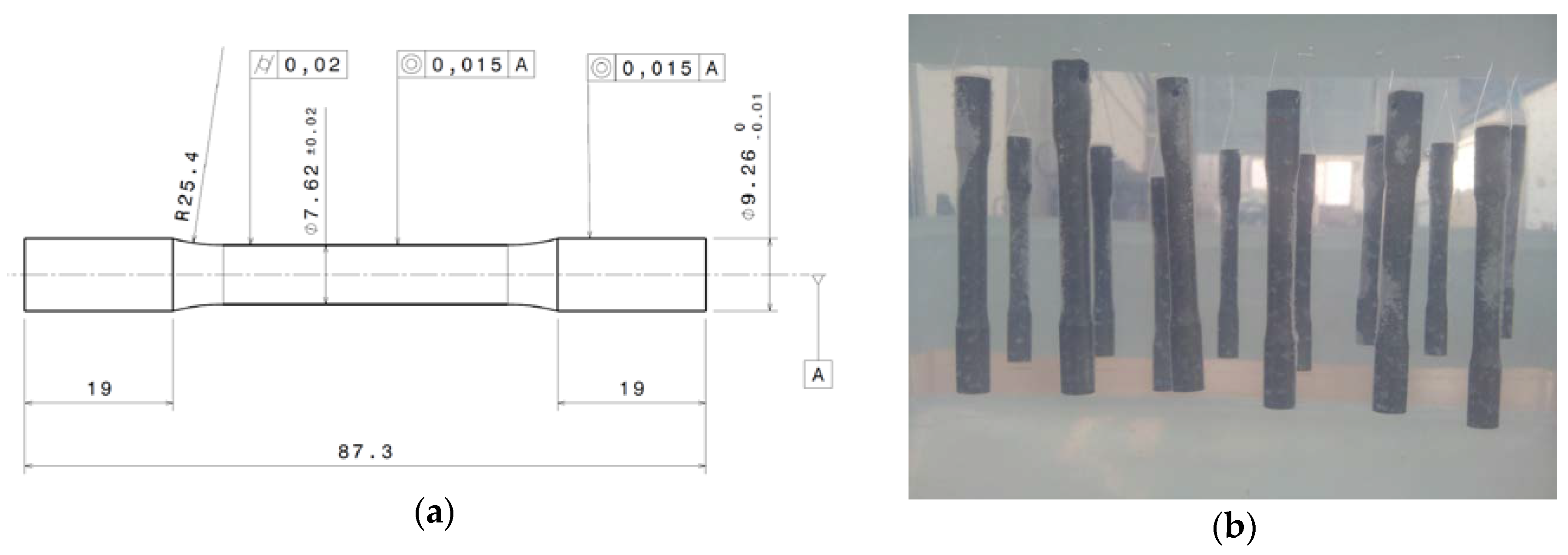

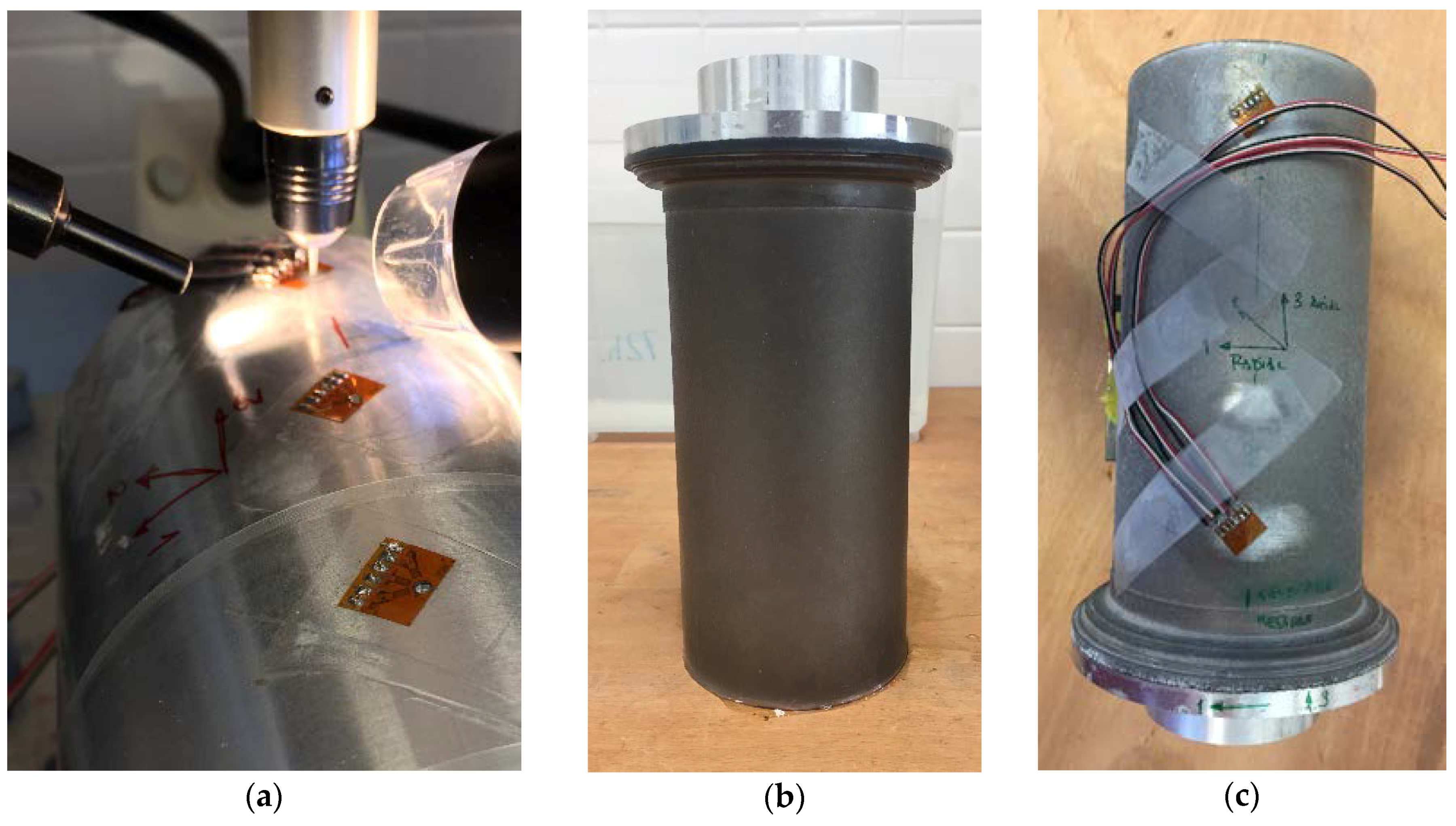

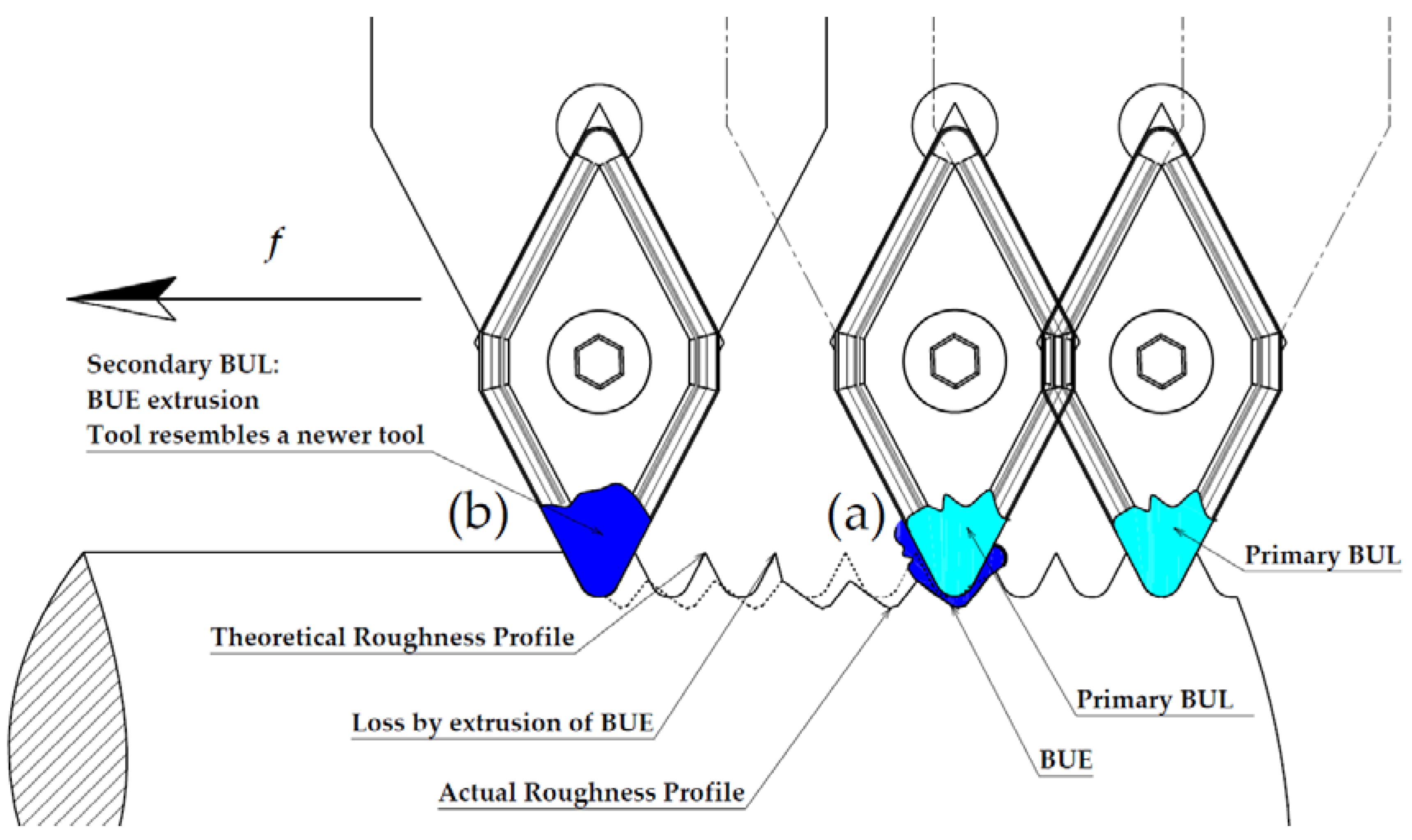

2. Materials and Methods

3. Results and Discussion

4. Conclusions

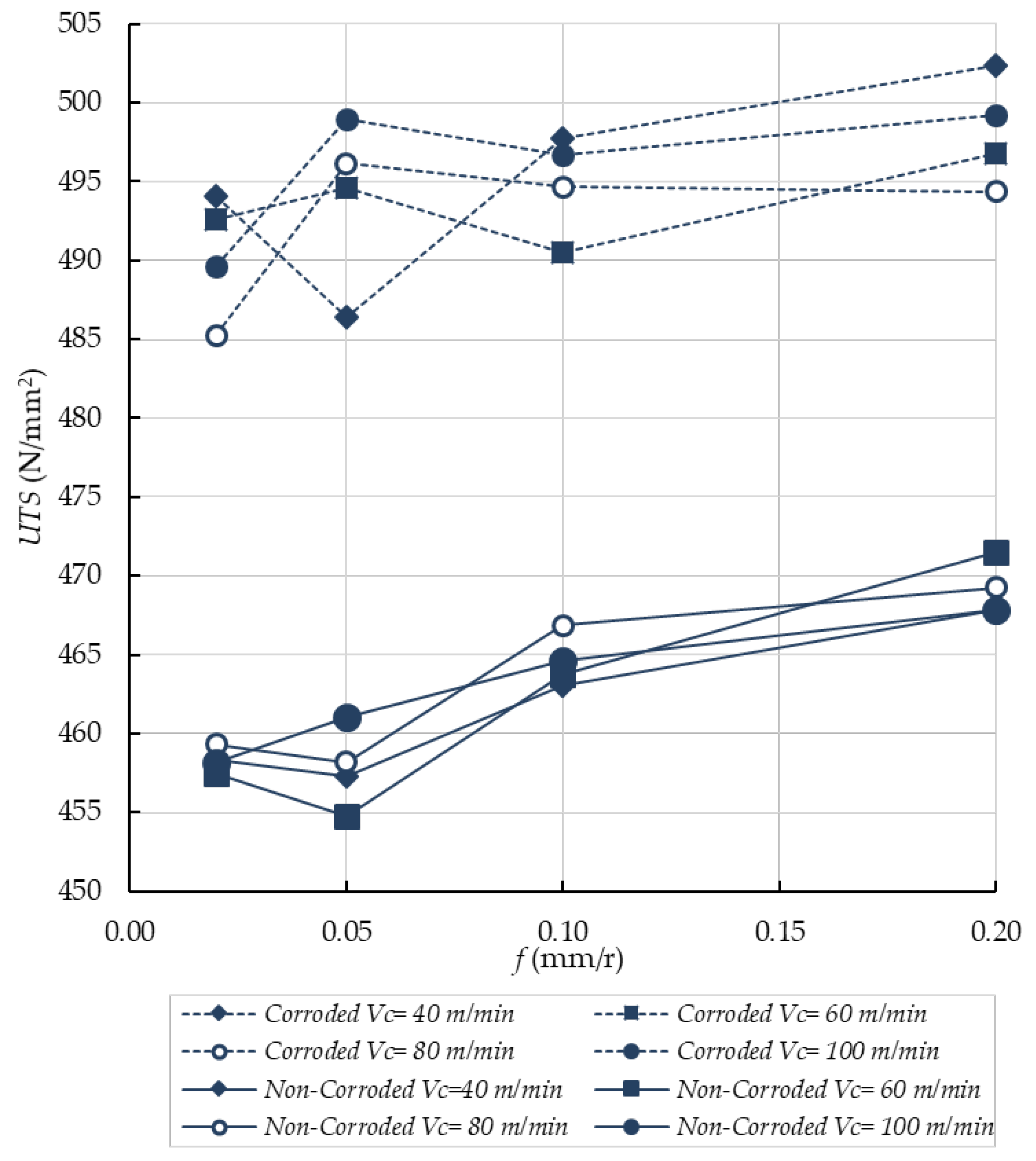

- Machining process can improve the tensile strength of horizontal dry turned samples of aeronautical alloy UNS A92024-T3. In this limited context, functional performance is favored by machining. Physicochemical properties are responsible for improving the mechanical properties and hence the functional performance.

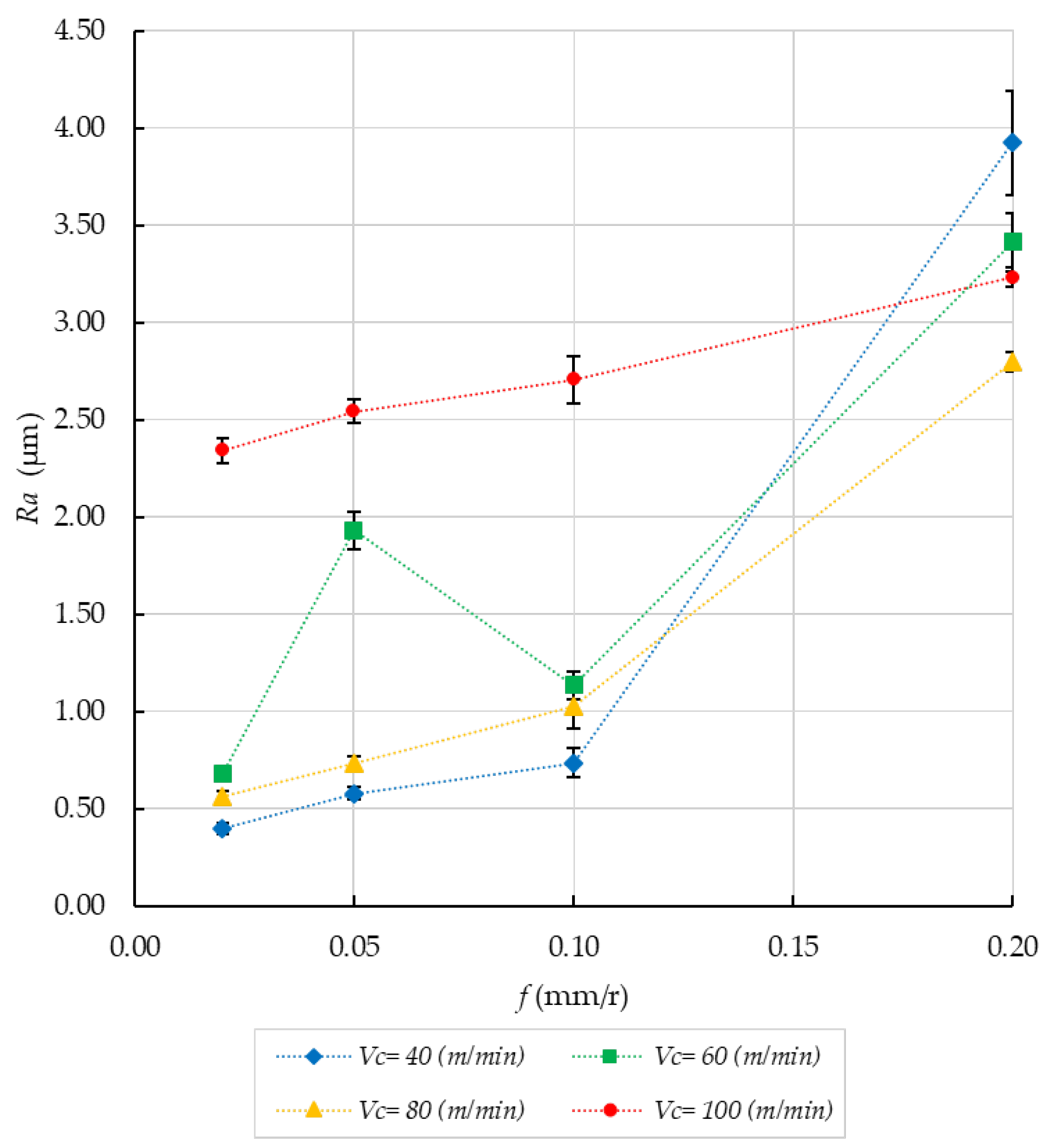

- Generally speaking, the UTS increases with the feed. Thus, there is no predominant influence of the microgeometrical properties acquired after machining over the UTS. In this sense, tensile residual stress taking place on the surface after machining is not large enough to generate a decrease of UTS value.

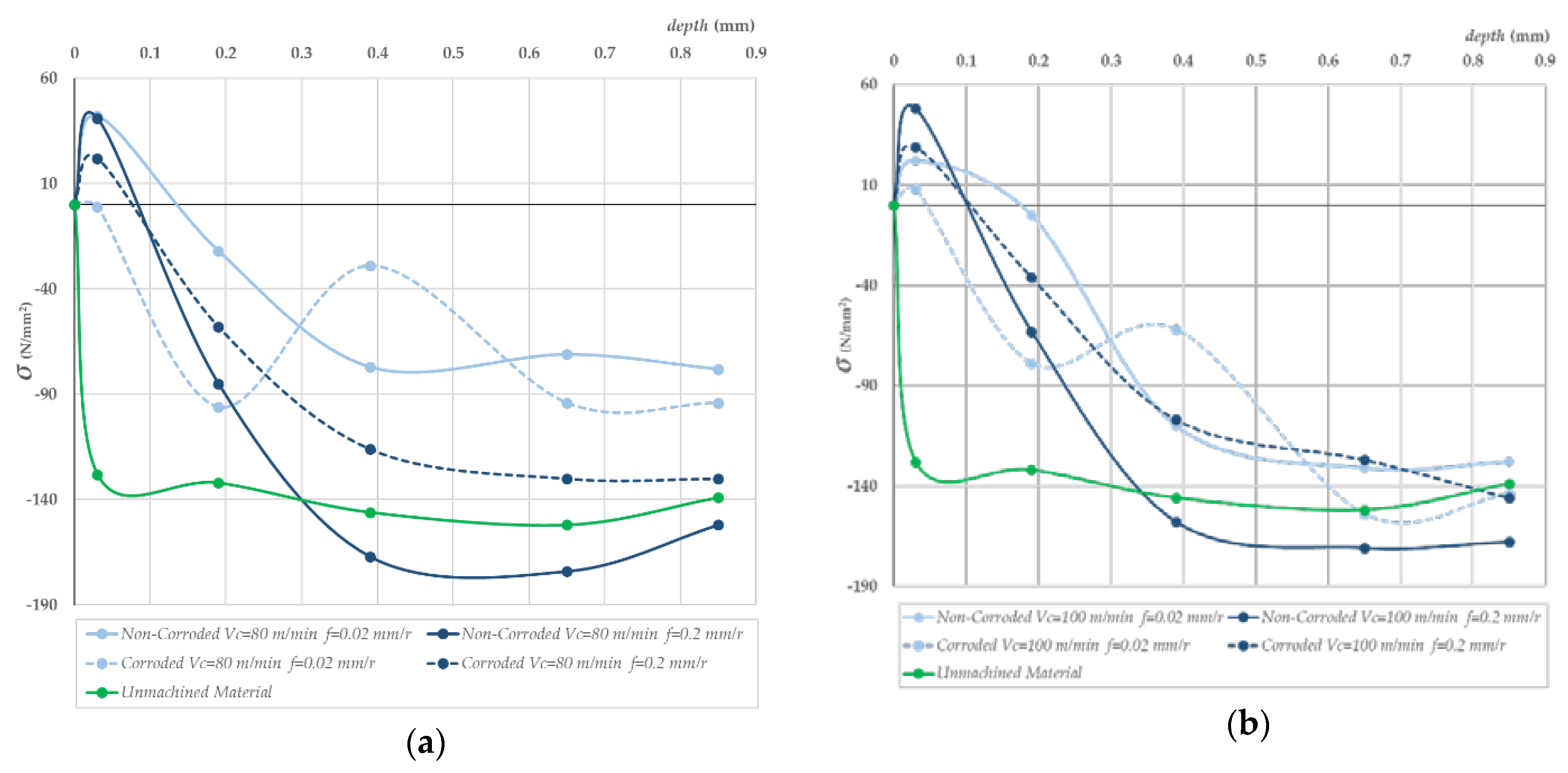

- The compressive residual stress after machining is responsible for the best results of UTS. Furthermore, as the feed increases, the compressive residual stress increases too, thereby improving the value of compressive residual stress of the unmachined material. Thus, the higher the compressive residual stress, the higher the UTS value.

- The results of the test of tensile stress after corrosion show a generalized improvement of the UTS value. The corrosion process removes the first layers of material. These layers, as shown in the results, carry a tensile residual stress and are softer than the unmachined material.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gómez-Parra, A.; Álvarez-Alcón, M.; Salguero, J.; Batista, M.; Marcos, M. Analysis of the evolution of the Built-Up Edge and Built-Up Layer formation mechanisms in the dry turning of aeronautical aluminium alloys. Wear Mater. 2013, 302, 1209–1218. [Google Scholar] [CrossRef]

- Jayal, A.D.; Badurdeen, F.; Dillon, O.W., Jr.; Jawahir, I.S. Sustainable manufacturing: Modeling and optimization challenges at the product, process and system levels. Sustain. Dev. Manuf. Syst. 2010, 2, 144–152. [Google Scholar] [CrossRef]

- Pusavec, F.; Krajnik, P.; Kopac, J. Transitioning to sustainable production—Part I: Application on machining technologies. J. Clean. Prod. 2010, 18, 174–184. [Google Scholar] [CrossRef]

- Pusavec, F.; Kramar, D.; Krajnik, P.; Kopac, J. Transitioning to sustainable production—Part II: Evaluation of sustainable machining technologies. J. Clean. Prod. 2010, 18, 1211–1221. [Google Scholar] [CrossRef]

- Akhavan Niaki, F.; Mears, L. A comprehensive study on the effects of tool wear on surface roughness, dimensional integrity and residual stress in turning IN718 hard-to-machine alloy. J. Manuf. Process. 2017, 30, 268–280. [Google Scholar] [CrossRef]

- Salguero, J.; Batista, M.; Carrilero, M.S.; Álvarez, M.; Marcos, M. Sustainable manufacturing in aerospace industry. Analysis of the viability of intermediate stages elimination in sheet processing. Adv. Mater. Res. 2010, 107, 9–14. [Google Scholar] [CrossRef]

- Marksberry, P.W.; Jawahir, I.S. A comprehensive tool-wear/tool-life performance model in the evaluation of NDM (near dry machining) for sustainable manufacturing. Int. J. Mach. Tools Manuf. 2008, 48, 878–886. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Outeiro, J.C.; Chandrasekaran, H.; Dillon Jr, O.W.; Jawahir, I.S. A review of surface integrity in machining and its impact on functional performance and life of machined products. Int. J. Sustain. Manuf. 2008, 1, 203–236. [Google Scholar] [CrossRef]

- Carrilero, M.S.; Bienvenido, R.; Sánchez, J.M.; Álvarez, M.; González, A.; Marcos, M. A SEM and EDS insight into the BUL and BUE differences in the turning processes of AA2024 Al–Cu alloy. Int. J. Mach. Tools Manuf. 2002, 42, 215–220. [Google Scholar] [CrossRef]

- Fullen, W.J.; Deheck, J. Aluminum Surface Finishing Corrosion Causes and Troubleshooting. NASF Surf. Technol. White Pap. 2014, 79, 1–15. [Google Scholar]

- Bienvenido, R.; Díaz Vázquez, J.E.; Botana, J.; Cano, M.J.; Marcos, M.; Díaz-Vázquez, J.E.; Botana, J.; Cano-Iglesias, M.J.; Marcos, M. Preliminary Study of the Influence of Machining Conditions in the Response to Corrosion of UNS-A92024 Alloy. Adv. Mater. Res. 2010, 107, 117–121. [Google Scholar] [CrossRef]

- UNE-EN 573-3:2014. Aluminium and Aluminium Alloys—Chemical Composition and Form of Wrought Products—Part 1: Numerical Designation System; AENOR: Madrid, Spain, 2014. [Google Scholar]

- ISO 6892-1:2016. Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- ISO 4288:1996. Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture; ISO: Geneva, Switzerland, 1996. [Google Scholar]

- ASTM ASTM NACE/ASTMG31-12a. Standard Guide for Laboratory Immersion Corrosion Testing of Metals; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM ASTM E837-13a. Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Schajer, G.S. Practical Residual Stress Measurement Methods; John Wiley & Sons: West Sussex, UK, 2013; ISBN 978-1-11-834237-4. [Google Scholar]

- H-DRILL Hole-Drilling Residual Stress Calculation Program 2009. Available online: http://www.schajer.org/index.htm (accessed on 20 June 2018).

- Sánchez, J.M.; Rubio, E.; Álvarez, M.; Sebastián, M.A.; Marcos, M. Microstructural characterisation of material adhered over cutting tool in the dry machining of aerospace aluminium alloys. J. Mater. Process. Technol. 2005, 164, 911–918. [Google Scholar] [CrossRef]

- Sánchez, J.M.; Sebastián Pérez, M.A.; González, J.M.; Carrilero, M.S.; Marcos Bárcena, M. Microstructural Differences of Adhered Material in the Tool Edge and Tool Rake Face. Application to the Machining of Al Alloys. Mater. Sci. Forum 2005, 480–481, 181–186. [Google Scholar] [CrossRef]

- Salguero, J.; Carrilero, M.S.; Batista, M.; Álvarez, M.; Marcos, M.; Segui, V.J. Analysis of the Influence of Thermal Treatment on the Dry Turning of Al-Cu Alloys. AIP Conf. Proc. 2009, 1181, 594–602. [Google Scholar]

- Iskra, P.; Tanaka, C.; Ohtani, T. Energy balance of the orthogonal cutting process. Holz als roh-und Werkstoff 2005, 63, 358–364. [Google Scholar] [CrossRef]

- Rubio, E.M.; Camacho, A.M.; Sánchez-Sola, J.M.; Marcos, M. Surface roughness of AA7050 alloy turned bars: Analysis of the influence of the length of machining. J. Mater. Process. Technol. 2005, 162–163, 682–689. [Google Scholar] [CrossRef]

- Trujillo Vilches, F.J. Análisis Paramétrico del Mecanizado en Seco de la Aleación UNS A97075. Ph.D. Thesis, University of Malaga, Málaga, Spain, 2013. [Google Scholar]

- UNE 38314:2000. Wrought Aluminium and Aluminium Alloys. 2000 Series. AlCu. Alloy EN AW-2024, EN AW-AlCu4Mg1; AENOR: Madrid, Spain, 2000. [Google Scholar]

- ASTM ASTM B211—03. Standard Specification for Aluminum and Aluminum-Alloy Bar, Rod, and Wire; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Gómez-Parra, A.; Puerta, F.J.; Rosales, E.I.; González-Madrigal, J.M.; Marcos, M. Study of the Influence of Cutting Parameters on the Ultimate Tensile Strength (UTS) of UNS A92024 Alloy Dry Turned Bars. Procedia Eng. 2013, 63, 796–803. [Google Scholar] [CrossRef]

- Gómez-Parra, Á.; Puerta, F.J.; Rosales, E.I.; García-Jurado, D.; Mainé, J.M.; Marcos, M. Influence of the Dry Turning Parameters on the Ultimate Tensile Strength (UTS) of UNS A92024 Samples. Mater. Sci. Forum 2014, 797, 65–70. [Google Scholar] [CrossRef]

- Novovic, D.; Dewes, R.C.C.; Aspinwall, D.K.K.; Voice, W.; Bowen, P. The effect of machined topography and integrity on fatigue life. Int. J. Mach. Tools Manuf. 2004, 44, 125–134. [Google Scholar] [CrossRef]

- Dahlman, P.; Gunnberg, F.; Jacobson, M. The influence of rake angle, cutting feed and cutting depth on residual stresses in hard turning. J. Mater. Process. Technol. 2004, 147, 181–184. [Google Scholar] [CrossRef]

- Choi, Y. Influence of feed rate on surface integrity and fatigue performance of machined surfaces. Int. J. Fatigue 2015, 78, 46–52. [Google Scholar] [CrossRef]

- Hua, J.; Shivpuri, R.; Cheng, X.; Bedekar, V.; Matsumoto, Y.; Hashimoto, F.; Watkins, T.R. Effect of feed rate, workpiece hardness and cutting edge on subsurface residual stress in the hard turning of bearing steel using chamfer + hone cutting edge geometry. Mater. Sci. Eng. A 2005, 394, 238–248. [Google Scholar] [CrossRef]

- Bethencourt, M.; Botana, F.J.; Cano, M.J.; Marcos, M.; Sánchez-Amaya, J.M.; González-Rovira, L. Behaviour of the alloy AA2017 in aqueous solutions of NaCl. Part I: Corrosion mechanisms. Corros. Sci. 2009, 51, 518–524. [Google Scholar] [CrossRef]

- Jeelani, S.; Musial, M. Effect of cutting speed and tool rake angle on the fatigue life of 2024-T351 aluminium alloy. Int. J. Fatigue 1984, 6, 169–172. [Google Scholar] [CrossRef]

| Cu | Mg | Mn | Si | Fe | Zn | Ti | Cr | Al |

|---|---|---|---|---|---|---|---|---|

| 4.0 | 1.5 | 0.6 | 0.5 | 0.5 | 0.25 | 0.15 | 0.10 | Rest |

| Vc (m/min) | f (mm/r) | d (mm) |

|---|---|---|

| 40 | 0.02 | 0.50 |

| 60 | 0.05 | 0.50 |

| 80 | 0.10 | 0.50 |

| 100 | 0.20 | 0.50 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez-Parra, Á.; Sanz, A.; Gámez, A.J. Evaluation of the Functional Performance in Turned Workpieces: Methodology and Application to UNS A92024-T3. Materials 2018, 11, 1264. https://doi.org/10.3390/ma11081264

Gómez-Parra Á, Sanz A, Gámez AJ. Evaluation of the Functional Performance in Turned Workpieces: Methodology and Application to UNS A92024-T3. Materials. 2018; 11(8):1264. https://doi.org/10.3390/ma11081264

Chicago/Turabian StyleGómez-Parra, Álvaro, Alfredo Sanz, and Antonio J. Gámez. 2018. "Evaluation of the Functional Performance in Turned Workpieces: Methodology and Application to UNS A92024-T3" Materials 11, no. 8: 1264. https://doi.org/10.3390/ma11081264

APA StyleGómez-Parra, Á., Sanz, A., & Gámez, A. J. (2018). Evaluation of the Functional Performance in Turned Workpieces: Methodology and Application to UNS A92024-T3. Materials, 11(8), 1264. https://doi.org/10.3390/ma11081264