Microsegregation Model Including Convection and Tip Undercooling: Application to Directional Solidification and Welding

Abstract

1. Introduction

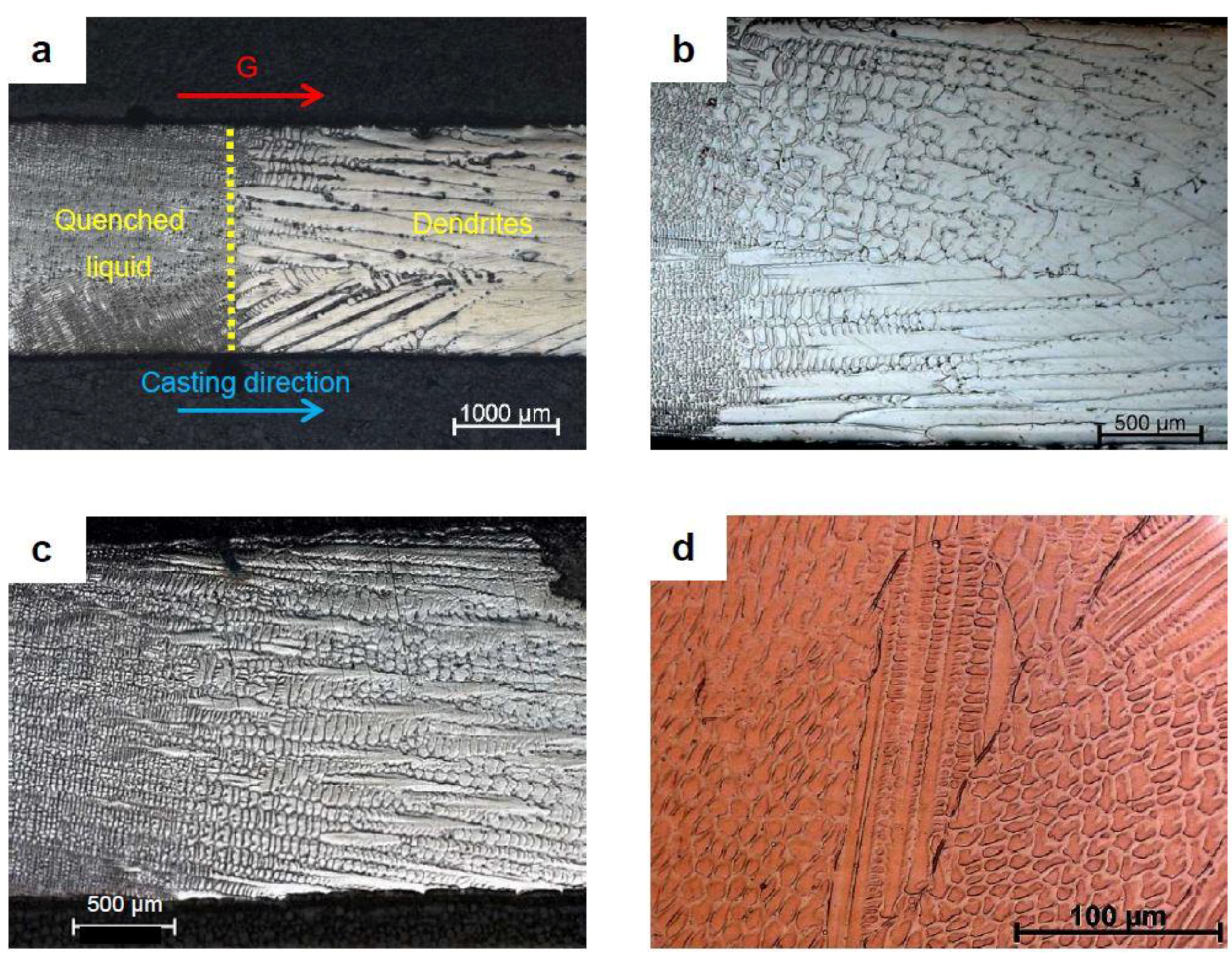

2. Experimental Section

3. Microstructure and Microsegregation

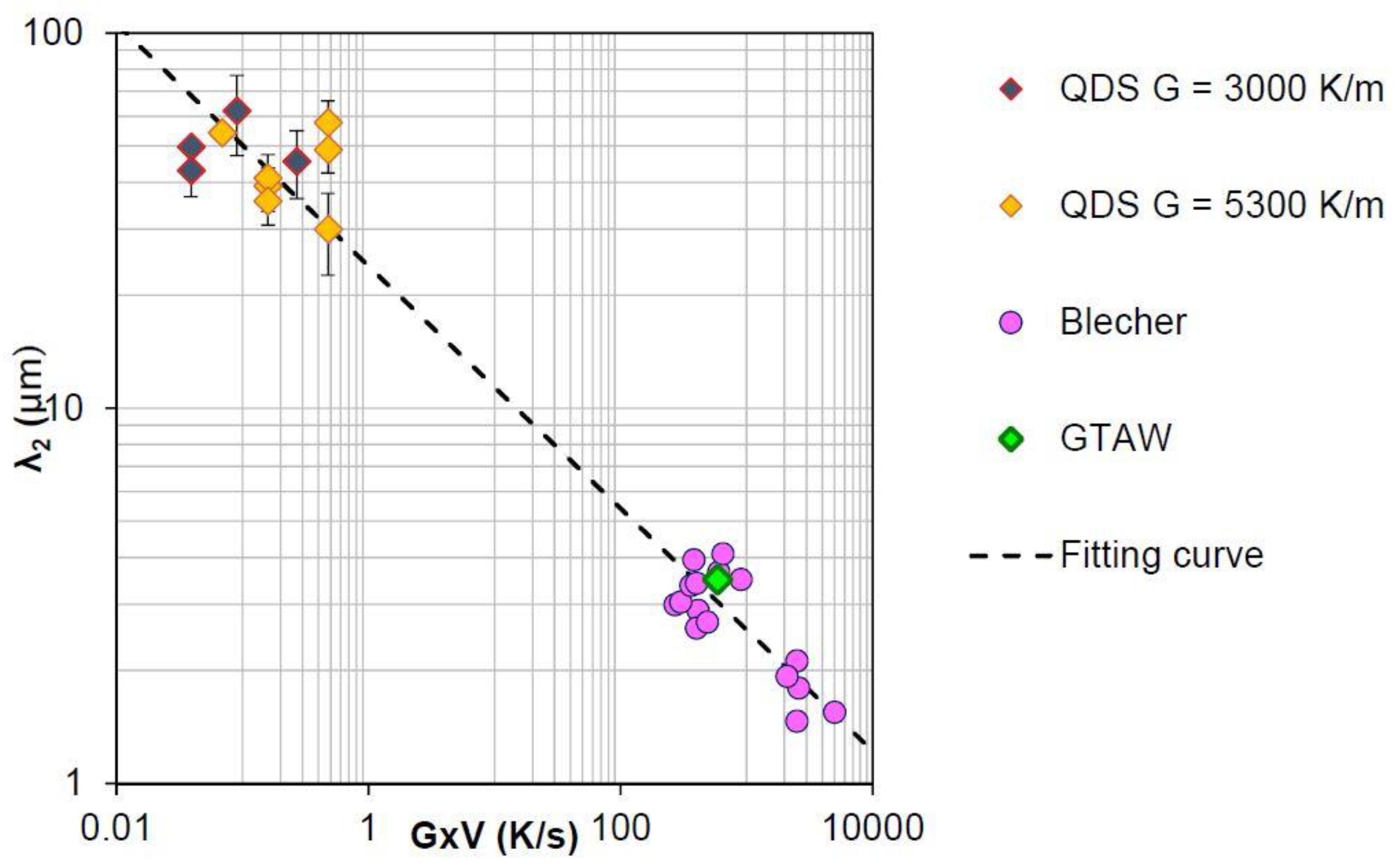

3.1. Secondary Dendrite Arm Spacing (SDAS) Law

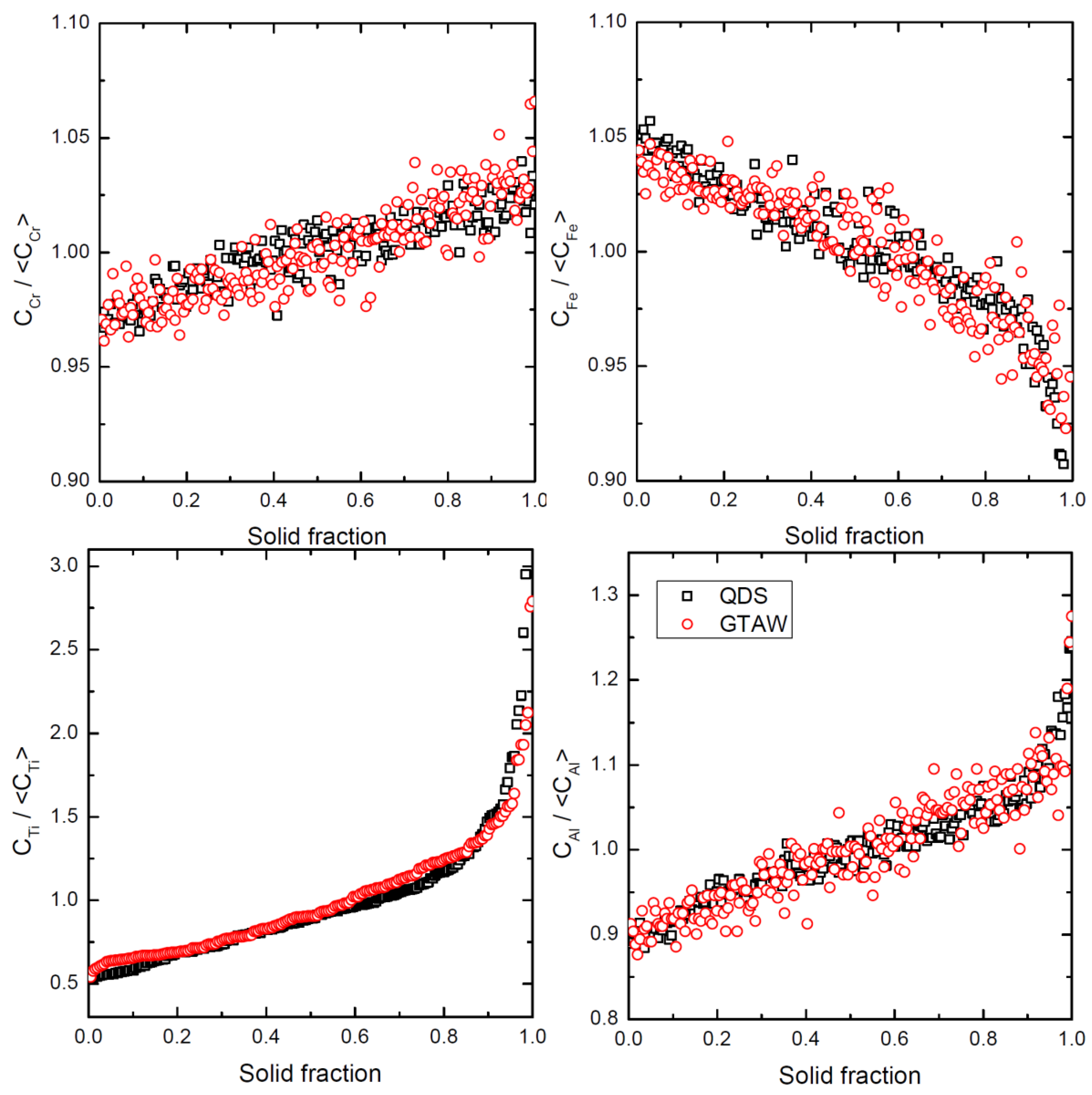

3.2. Microsegregation Results

4. Modelling Microsegregation: Including Fluid Flow

4.1. Microsegregation Model

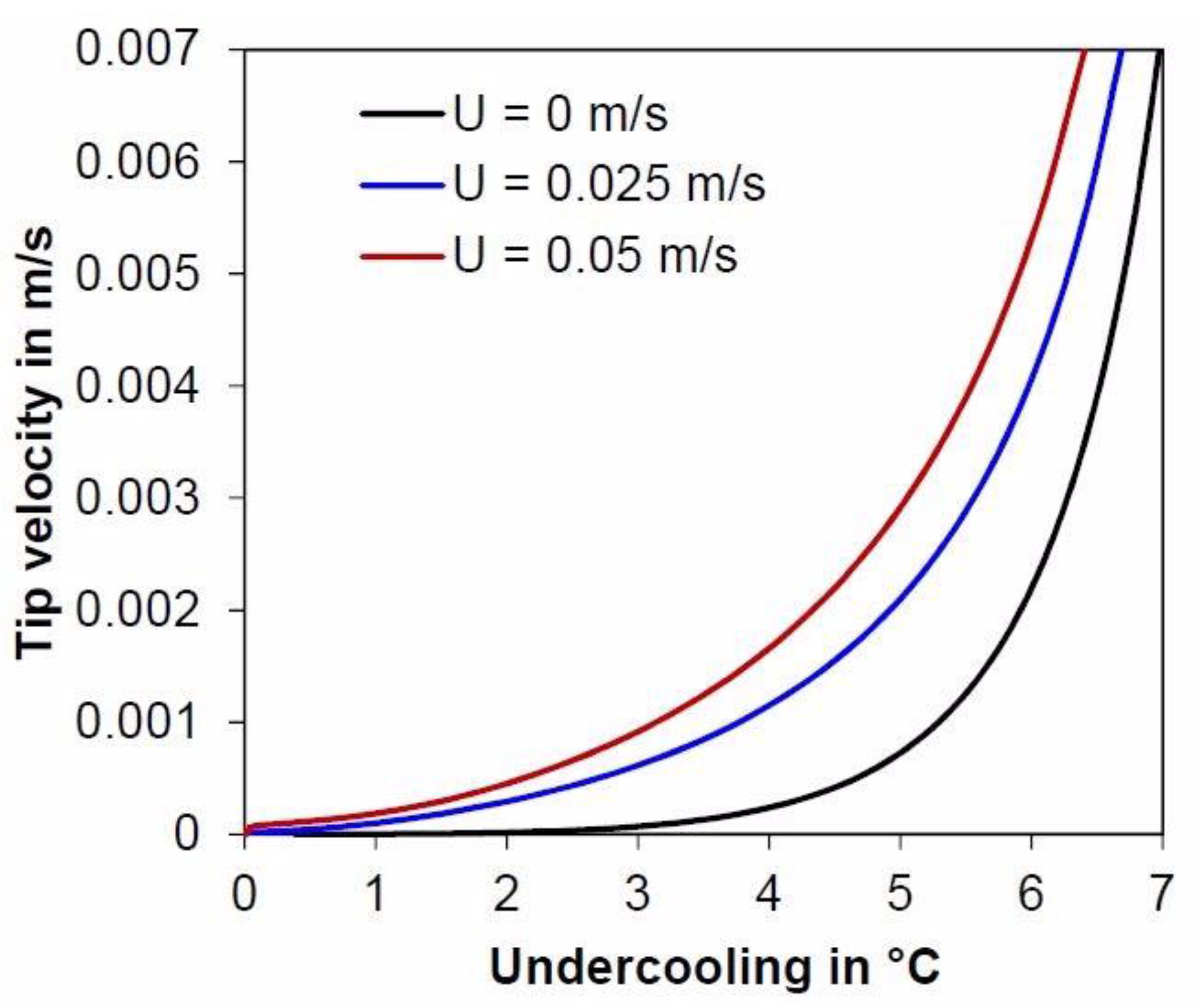

4.2. Tip Undercooling

4.3. Consequence of Convection on Microsegregation

4.4. Evaluation of Tip Undercooling in the Presence of Convection

5. Comparison between Microsegregation Model and Experimental Results

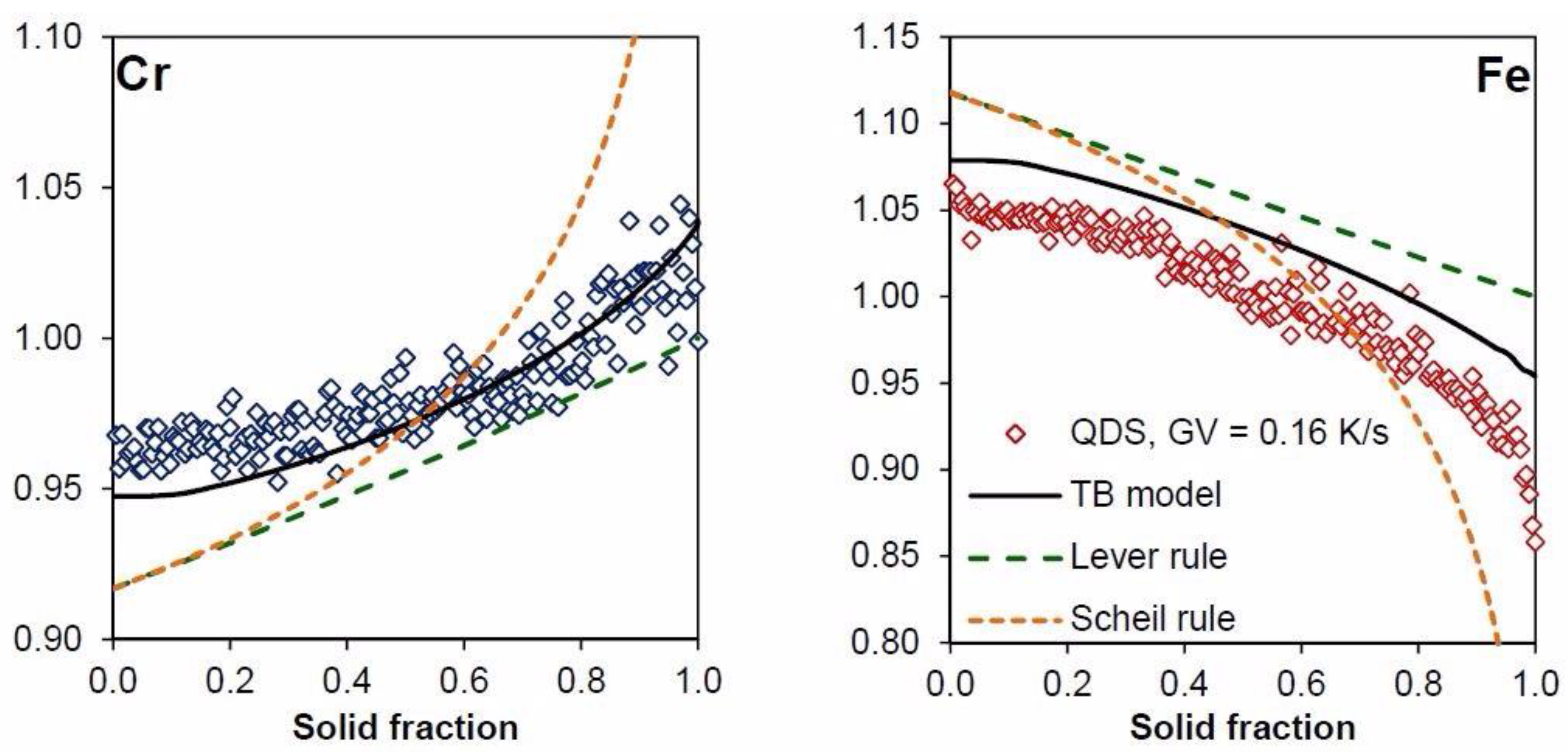

5.1. QDS Experiment

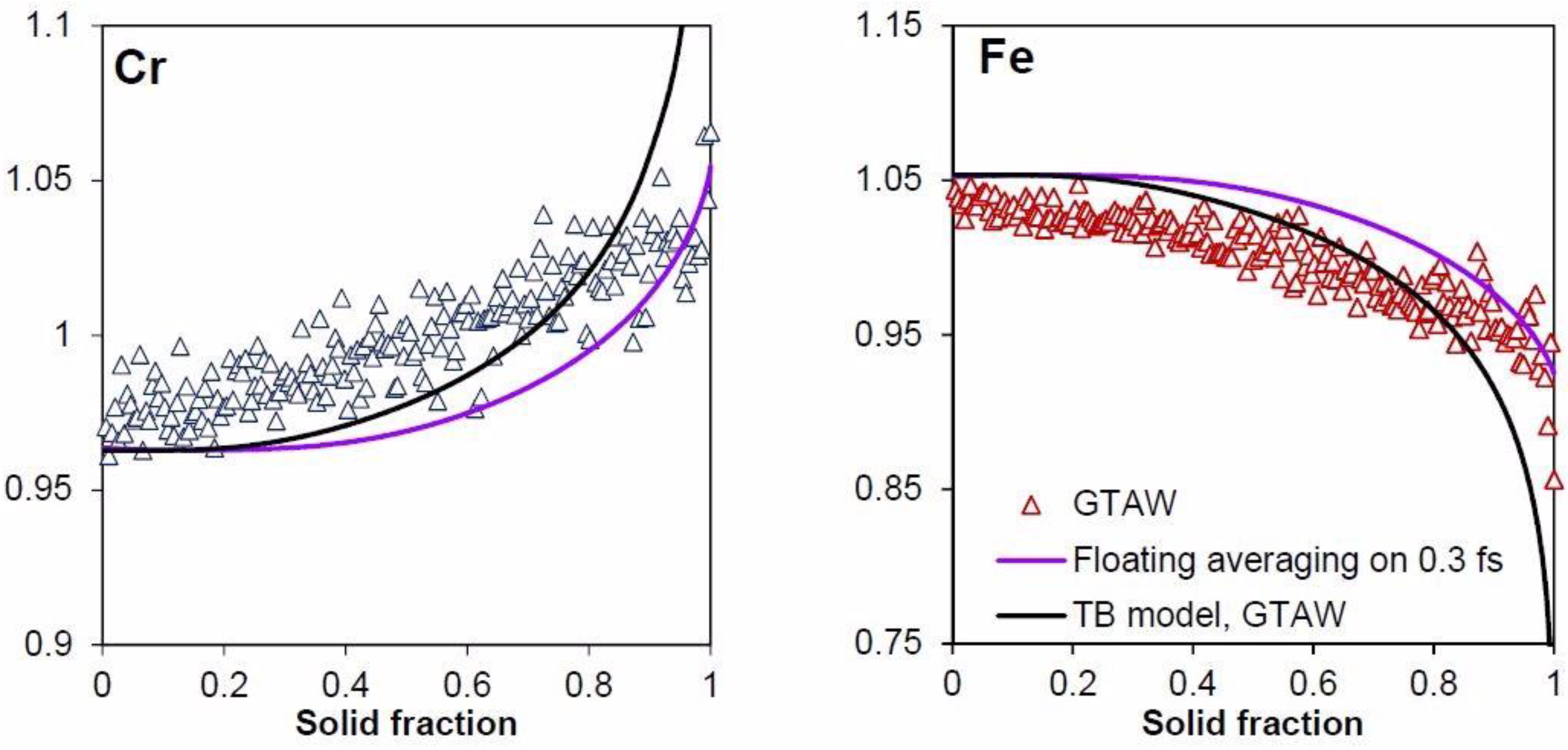

5.2. TB Model and GTAW

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Suh, J.-H.; Shin, J.-K.; Kang, S.-J.L.; Lim, Y.-S.; Kuk, I.-H.; Kim, J.-S. Investigation of IGSCC behaviour of sensitized and laser surface melted Alloy 600. Mater. Sci. Eng. 1998, A254, 67–75. [Google Scholar] [CrossRef]

- Kai, J.J.; Liu, M.N. The effects of heat treatment on the carbide evolution and the chromium depletion along grain boundary of Inconel 690 alloy. Scr. Metall. 1989, 23, 17–22. [Google Scholar] [CrossRef]

- Noecker, F.F.; DuPont, J.N. Metallurgical investigation into ductility dip cracking in Ni-based alloys: Part II. Weld. J. 2009, 88, 62s–77s. [Google Scholar]

- Wang, J.D.; Gan, D. Effects of grain boundary carbides on the mechanical properties of Inconel 600. Mater. Chem. Phys. 2001, 70, 124–128. [Google Scholar] [CrossRef]

- Mo, W.; Lu, S.; Li, D.; Li, Y. Effects of filler metal composition on the microstructure and mechanical properties for ERNiCrFe-7multi-pass weldments. Mater. Sci. Eng. A 2013, 582, 326–337. [Google Scholar] [CrossRef]

- Jeng, S.L.; Lee, H.T.; Rehbach, W.P.; Kuo, T.Y.; Weirich, T.E.; Mayer, J.P. Effects of Nb on the microstructure and corrosive property in the Alloy 690–SUS 304L weldment. Mater. Sci. Eng. A 2005, 397, 229–238. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Sowards, J.W.; Lippold, J.C. Improving the ductility-dip cracking resistance of Ni-base alloys. J. Mater. Process. Technol. 2006, 179, 212–218. [Google Scholar] [CrossRef]

- Meng, F.; Wang, J.; Han, E.-H.; Ke, W. The role of TiN inclusions in stress corrosion crack initiation for alloy 690TT in high-temperature and high-pressure water. Corros. Sci. 2010, 52, 927–932. [Google Scholar] [CrossRef]

- Kuo, T.Y.; Lee, H.T. Effects of filler metal composition on joining properties of alloy 690 weldments. Mater. Sci. Eng. A 2002, 338, 202–212. [Google Scholar]

- Crum, J.R.; Gosnay, S.M.; Kiser, S.D.; Zhang, R. Corrosion acceptance testing of weld metals for nuclear service, Materials Selection and Design. NACE Int. 2011, 50, 70–75. [Google Scholar]

- Young, G.A.; Capobianco, T.E.; Penik, M.A.; Morris, B.W.; McGee, J.J. The mechanism of Ductility Dip cracking in Nickel-Chromium Alloys. Weld. J. 2008, 87, 31s–43s. [Google Scholar]

- Collins, M.G.; Lippold, J.C. An investigation of ductility Dip Cracking in Nickel-Based Filler Materials—Part 1. Weld. J. 2003, 82, 288–295. [Google Scholar]

- Collins, M.G.; Ramirez, A.J.; Lippold, J.C. An investigation of ductility Dip Cracking in Nickel-Based Filler Materials—Part 2. Weld. J. 2003, 82, 348–354. [Google Scholar]

- Collins, M.G.; Ramirez, A.J.; Lippold, J.C. An investigation of ductility Dip Cracking in Nickel-Based Filler Materials—Part 3. Weld. J. 2004, 83, 39–49. [Google Scholar]

- Noecker, F.F.; DuPont, J.N. Metallurgical investigation into ductility dip cracking in Ni-based alloys: Part 1. Weld. J. 2009, 8, 7–20. [Google Scholar]

- Nissley, N.E.; Lippold, J.C. Ductility-Dip Cracking Susceptibility of Nickel-Based Weld Metals: Part 1—Strain to Fracture Testing. Weld. J. 2008, 87, 257–264. [Google Scholar]

- Nissley, N.E.; Lippold, J.C. Ductility-Dip Cracking Susceptibility of Nickel-Based Weld Metals: Part 2—Microstructural Charaterization. Weld. J. 2009, 88, 131–140. [Google Scholar]

- Kiser, S.D.; Zhang, R.; Baker, B.A. A New Welding Material for Improved resistance to Ductility Dip Cracking. 2008. Available online: http://www.specialmetalswelding.com/papers/trend%20paper%20-2008.pdf (accessed on 6 December 2013).

- INCONEL Filler Metal 52M, Special Metals. Available online: http://www.specialmetals.com/assets/smc/documents/smw/fm52m.pdf (accessed on 6 December 2013).

- INCONEL Filler Metal 52MSS, Special Metals. Available online: http://www.specialmetals.com/assets/smc/documents/smw/fm52mss.pdf (accessed on 6 December 2013).

- Lee, H.T.; Jeng, S.L.; Yen, C.H.; Kuo, T.Y. Dissimilar welding of nickel-based Alloy 690 to SUS 304L with Ti addition. J. Nucl. Mater. 2004, 335, 59–69. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Lippold, J.C. High temperature behaviour of Ni-base weld metal Part II—Insight into the mechanism for ductility deep cracking. Mater. Sci. Eng. A 2004, 380, 245–258. [Google Scholar] [CrossRef]

- Campbell, J.; Tiryakioglu, M. Bifilm defects in Ni-based alloy castings. Metall. Mater. Trans. B 2012, 43, 902–914. [Google Scholar] [CrossRef]

- Lachowicz, M.; Dudzinski, W.; Haimann, K.; Podrez-Radziszewska, M. Microstructure transformations and cracking in the matrix of γ-γ’ superalloy Inconel 713C melted with electron beam. Mater. Sci. Eng. A 2008, 479, 269–276. [Google Scholar] [CrossRef]

- Liu, J.; Duarte, H.P.; Kou, S. Evidence of back diffusion reducing cracking during solidification. Acta Mater. 2017, 122, 47–59. [Google Scholar] [CrossRef]

- Srikanth, A.; Manikandan, M. Development of welding technique to avoid the sensitization in the alloy 600 by conventional Gas Tungsten Arc Welding method. J. Manuf. Process. 2017, 30, 452–466. [Google Scholar] [CrossRef]

- Rappaz, M.; Gandin, C.-A.; Desbiolles, J.-L.; Thévoz, P. Prediction of Grain Structures in Various Solidification Processes. Metall. Mater. Trans. A 1996, 27, 695–705. [Google Scholar] [CrossRef]

- Gandin, C.-A.; Desbiolles, J.L.; Rappaz, M.; Thévoz, P. A Three-Dimentional Cellular Automaton-Finite Element Model for the Prediction of Solidification Grain Structures. Metall. Mater. Trans. A 1999, 30, 3153–3165. [Google Scholar] [CrossRef]

- Flood, S.C.; Hunt, J.D. Columnar and equiaxed growth I. A model of a columnar front with a temperature dependent velocity. J. Cryst. Growth 1987, 82, 543–551. [Google Scholar] [CrossRef]

- Chen, S.; Guillemot, G.; Gandin, C.-A. 3D Coupled Cellular Automaton (CA)–Finite Element (FE) Modeling for Solidification Grain Structures in Gas Tungsten Arc Welding (GTAW). ISIJ Int. 2014, 54, 401–407. [Google Scholar] [CrossRef]

- Krauss, H.G. Experimental Measurement of Thin Plate 304 Stainless Steel GTA Weld Pool Surface Temperatures. Weld. J. 1987, 66, 353s–359s. [Google Scholar]

- Tanaka, M.; Yamamoto, K.; Tashiro, S.; Nakata, K.; Yamamoto, E.; Yamazaki, K.; Suzuki, K.; Murphy, A.B.; Lowke, J.J. Time-dependent calculations of molten pool formation and thermal plasma with metal vapour in gas tungsten arc welding. J. Phys. D Appl. Phys. 2010, 43, 1–11. [Google Scholar] [CrossRef]

- Kurz, W.; Giovanola, B.; Trivedi, R. Theory of microstructural development during rapid solidification. Acta Metall. 1985, 34, 823–830. [Google Scholar] [CrossRef]

- Appolaire, B.; Combeau, H.; Lesoult, G. Modeling of equiaxed growth in multicomponent alloys accounting for convection and for the globular/dendritic morphological transition. Mater. Sci. Eng. A 2008, 487, 33–45. [Google Scholar] [CrossRef]

- Tong, X.; Beckermann, C. A diffusion boundary layer model of microsegregation. J. Cryst. Growth 1998, 187, 289–302. [Google Scholar] [CrossRef]

- INCONEL Filler Metal 52, Special Metals. Available online: http://www.specialmetals.com/assets/smc/documents/smw/fm52.pdf (accessed on 6 December 2013).

- Boettinger, W.J.; Kattner, U.R. On Differential Thermal Analyzer Curves for the Melting and Freezing of Alloys. Metall. Mater. Trans. A 2002, 33, 1779–1794. [Google Scholar] [CrossRef]

- Bobadilla, M.; Lacaze, J.; Lesoult, G. Influence des conditions de solidification sur le déroulement de la solidification des aciers inoxydables austénitiques. J. Crist. Growth 1988, 89, 531–544. [Google Scholar] [CrossRef]

- Anderson, J.O.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-calc and Dictra, Computation Tools for Materials Science. Calphad 2002, 26, 273–312. [Google Scholar] [CrossRef]

- Wu, W.; Tsai, C.H. Hot Cracking Susceptibility of Fillers 52 and 82 in Alloy 690 Welding. Metall. Mater. Trans. A 1999, 30, 417–426. [Google Scholar] [CrossRef]

- Charpentier, M.; Daloz, D.; Hazotte, A.; Gautier, E.; Lesoult, G.; Grange, M. Study of Microstructure and Solute Partitioning in a CastTi-48Al-2Cr-2Nb Alloy by Quenching during Directional Solidification Technique. Metall. Mater. Trans. A 2003, 34, 2139–2149. [Google Scholar] [CrossRef]

- Zollinger, J.; Lapin, J.; Daloz, D.; Combeau, H. Influence of oxygen on solidification behaviour of cast TiAl-based alloys. Intermetallics 2007, 15, 1343–1350. [Google Scholar] [CrossRef]

- Lacaze, J.; Lesoult, G. Experimental investigation of the development of microsegregation during solidification of an Al-Cu-Mg-Si aluminium alloy. Mater. Sci. Eng. A 1993, 173, 119–122. [Google Scholar] [CrossRef]

- Zollinger, J.; Daloz, D. On the sampling methodology to characterize microsegregation. Mater. Charact. 2011, 62, 1058–1065. [Google Scholar] [CrossRef]

- Blecher, J.J.; Palmer, T.A.; Debroy, T. Solidification Map of a Nickel-Base Alloy. Metall. Mater. Trans. A 2014, 45, 2142–2151. [Google Scholar] [CrossRef]

- Frenk, A.; Kurz, W. High speed laser cladding: Solidification conditions and microstructure of a cobalt-based alloy. Mater. Sci. Eng. A 1993, 173, 339–342. [Google Scholar] [CrossRef]

- Dantzig, J.A.; Rappaz, M. Solidification, Engineering Sciences, Materials; EPFL Press: Lausanne, Switzerland, 2009. [Google Scholar]

- Ganessan, M.; Dye, D.; Lee, P.D. A Technique for characterizing Microsegregation in Multicomponent Alloys and Its Application to Single-Crystal Superalloy Castings. Metall. Mater. Trans. A 2005, 36, 2191–2204. [Google Scholar] [CrossRef]

- Seo, S.M.; Jeong, H.W.; Ahn, Y.K.; Yun, D.W.; Lee, J.H.; Yoo, Y.S. A comparative study of quantitative microsegregation analyses performed during the solidification of the Ni-base superalloy CMSX-10. Mater. Charact. 2014, 89, 43–55. [Google Scholar] [CrossRef]

- Liang, Y.-J.; Cheng, X.; Wang, H.-U. A new microsegregation model for rapid solidification condition multicomponent alloys and its application to single-crystal nickel-base superalloys of laser rapid directional solidification. Acta Materilia 2016, 118, 17–27. [Google Scholar] [CrossRef]

- Scheil, E. Bemerkungen zur Schichtkristallbildung (Retrograde saturation curves). Z. Metallkunde 1942, 34, 70–72. [Google Scholar]

- Clyne, T.W.; Kurz, W. Solute redistribution during solidification with rapid solid state diffusion. Metall. Trans. A Phys. Metall. Mater. Sci. 1981, 12, 965–971. [Google Scholar] [CrossRef]

- Kobayashi, S. Mathematical analysis of solute redistribution during solidification based in a columnar dendrite model. Trans. ISIJ Int. 1988, 28, 728–735. [Google Scholar] [CrossRef]

- Wang, C.Y.; Beckermann, C. A unified solute diffusion model for columnar and equiaxed dendritic solidification. Mater. Sci. Eng. A 1993, 171, 199–211. [Google Scholar] [CrossRef]

- Appolaire, B.; Albert, V.; Combeau, H.; Lesoult, G. Free growth of equiaxed crystals setting in undercooled NH4Cl-H2O melts. Acta Mater. 1998, 46, 5851–5862. [Google Scholar] [CrossRef]

- Gabathuler, J.P.; Weinberg, F. Fluid Flow into a dendritic Array under Forced Convection. Metall. Trans. B 1983, 14, 733–741. [Google Scholar] [CrossRef]

- Magnin, P.; Trivedi, R. Eutectic growth, a modification of the Jackson and Hunt theory. Acta Metall. Mater. 1991, 39, 453–467. [Google Scholar] [CrossRef]

- Kobatake, H.; Brillo, J. Density and viscosity of ternary Cr-Fe-Ni liquid alloys. J. Mater. Sci. 2013, 48, 6818–6824. [Google Scholar] [CrossRef]

- Gao, Z.; Ojo, O.A. Modeling analysis of hybrid laser arc welding of single criystal nickel-based superalloys. Acta Mater. 2012, 60, 3153–3167. [Google Scholar] [CrossRef]

- Bezençon, C. Recouvrement Monocristallin par procédé laser d’un Superalliage à base Nickel. Ph.D. Thesis, Materials science & Eng. Institut, Ecole Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 2002. [Google Scholar]

- Hamouda, H.B. Modélisation et Simulation de la Structure de Solidification dans les Superalliages Base-Nickel: Application AM1; Autre; Ecole Nationale Supérieure des Mines de Paris: Paris, France, 2012; NNT: 2012ENMP0040. [Google Scholar]

- Castaing, R. Advances in Electronics and Electron Physics, 13th ed.; Masson, C., Ed.; Academic Press: New York, NY, USA, 1960; p. 317. [Google Scholar]

| Ni | Cr | Fe | Al | Ti | Mn | Si | C | |

|---|---|---|---|---|---|---|---|---|

| EPMA | 57.98 | 29.98 | 10.06 | 0.65 | 0.52 | 0.29 | 0.13 | 0.03 |

| Specification [36] | ≈60 | 28–31.5 | 7–11 | <1.1 | <1 | <0.5 | <0.5 | <0.04 |

| DTA (°C) | Thermo-Calc (°C, FM52) | Thermo-Calc (°C, Ni-29.98Cr-10.06Fe) | |

|---|---|---|---|

| Solidus | 1379.2 | 1364 | 1409.4 |

| Liquidus | 1389.8 | 1400 | 1417.8 |

| Test Type | Thermal Gradient (K/m) | V (mm/s) | G/V (K·s/m²) | G·V (K/s) |

|---|---|---|---|---|

| QDS | 5300 | 0.09 | 5.89 × 107 | 0.477 |

| 0.03 | 1.77 × 108 | 0.159 | ||

| 0.013 | 4.08 × 108 | 0.0689 | ||

| 3000 | 0.09 | 3.33 × 107 | 0.27 | |

| 0.03 | 1 × 108 | 0.09 | ||

| 0.013 | 2.31 × 108 | 0.039 | ||

| GTAW | ≈300,000 | 1.66 | 1.81 × 108 | 498 |

| k | Cr | Fe | Al | Ti | Mn | Si | |

|---|---|---|---|---|---|---|---|

| QDS, GV = 0.477 K/s | k1 | 0.96 | 1.05 | 0.87 | 0.5 | 0.75 | 0.59 |

| QDS, GV = 0.16 K/s | k1 | 0.96 | 1.07 | 0.86 | 0.46 | 0.73 | 0.66 |

| QDS, GV = 0.039 K/s | k1 | 0.98 | 1.06 | 0.87 | 0.5 | 0.76 | 0.66 |

| k2 | 0.98 | 1.05 | 0.94 | 0.62 | 0.71 | 0.59 | |

| GTAW | k1 | 0.97 | 1.04 | 0.91 | 0.54 | x | x |

| Thermo-Calc for FM52 alloy | k1 | 0.93 | 1.13 | 0.99 | 0.41 | 0.54 | 0.62 |

| Thermo-Calc for ternary Ni-29.98Cr-10.06Fe | k1 | 0.92 | 1.11 | x | x | x | x |

| Physical Quantities | |

| Gibbs-Thompson coefficient (Km) | Γ = 1.82 × 10−7 |

| Diffusion Coefficient for Fe and Cr in molten nickel (m2/s) | Dl = 1.57 × 10−9 |

| Heat capacity of liquid (J·kg−1·K−1) [59,60] | Cpl = 700 |

| Thermal conductivity of liquid (W·m−1·K−1) [59,61] | λl = 30 |

| Dynamic viscosity of liquid at 1400 °C (N·s·m−2) [58] | μ = 0.00483 |

| Liquid density at Tl (kg·m−3) [58] | ρl = 7160 |

| Latent heat of fusion (J/kg) | L = 1.3 × 105 |

| Thermodynamic Quantities | |

| Liquidus slope for Cr (K·(%w)−1) | mCr = −2.27 |

| Liquidus slope for Fe (K·(%w)−1) | mFe = 4.55 |

| Partition coefficient of Cr | kCr = 0.93 |

| Partition coefficient of Fe | kFe = 1.11 |

| Composition of Cr in weight percent | 29.98 |

| Composition of Fe in weight percent | 10.06 |

| Fictive reference temperature in °C [33] | 1439.5 |

| Solidus temperature | 1409.4 |

| Liquidus temperature | 1417.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Billotte, T.; Daloz, D.; Rouat, B.; Tirand, G.; Kennedy, J.R.; Robin, V.; Zollinger, J. Microsegregation Model Including Convection and Tip Undercooling: Application to Directional Solidification and Welding. Materials 2018, 11, 1252. https://doi.org/10.3390/ma11071252

Billotte T, Daloz D, Rouat B, Tirand G, Kennedy JR, Robin V, Zollinger J. Microsegregation Model Including Convection and Tip Undercooling: Application to Directional Solidification and Welding. Materials. 2018; 11(7):1252. https://doi.org/10.3390/ma11071252

Chicago/Turabian StyleBillotte, Thomas, Dominique Daloz, Bernard Rouat, Guillaume Tirand, Jacob R. Kennedy, Vincent Robin, and Julien Zollinger. 2018. "Microsegregation Model Including Convection and Tip Undercooling: Application to Directional Solidification and Welding" Materials 11, no. 7: 1252. https://doi.org/10.3390/ma11071252

APA StyleBillotte, T., Daloz, D., Rouat, B., Tirand, G., Kennedy, J. R., Robin, V., & Zollinger, J. (2018). Microsegregation Model Including Convection and Tip Undercooling: Application to Directional Solidification and Welding. Materials, 11(7), 1252. https://doi.org/10.3390/ma11071252