Micromechanical Modeling of the Elasto-Viscoplastic Behavior and Incompatibility Stresses of β-Ti Alloys

Abstract

1. Introduction

2. Micromechanical Model

2.1. Fields Equations

2.2. Single Crystal’s Constitutive Behavior

2.3. Self-Consistent Approximation Based on Affine Translated Field Method

3. Results and Discussions

3.1. Model Parameters

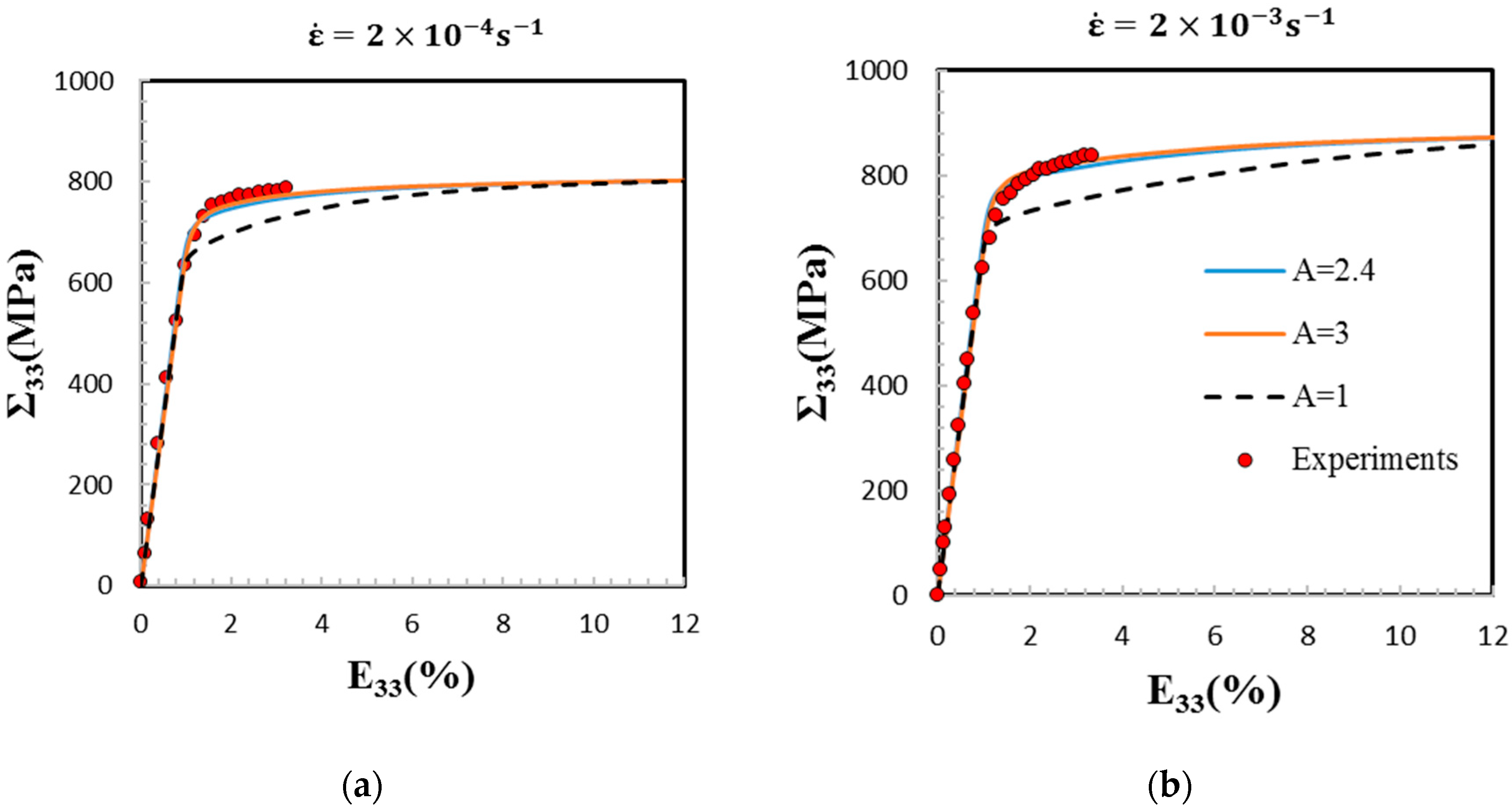

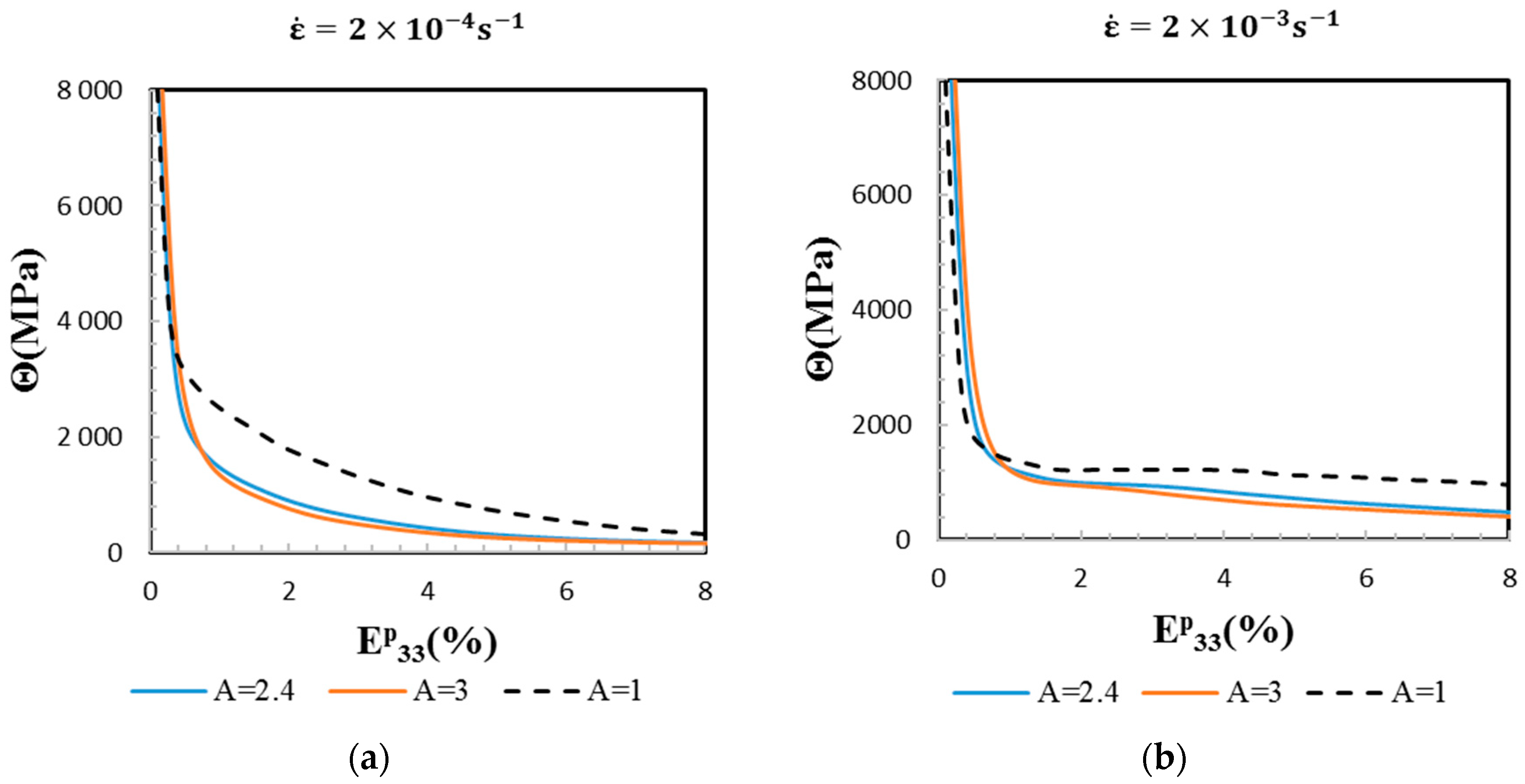

3.2. Macroscopic Stress–Strain Responses and Strain-Hardening Behavior

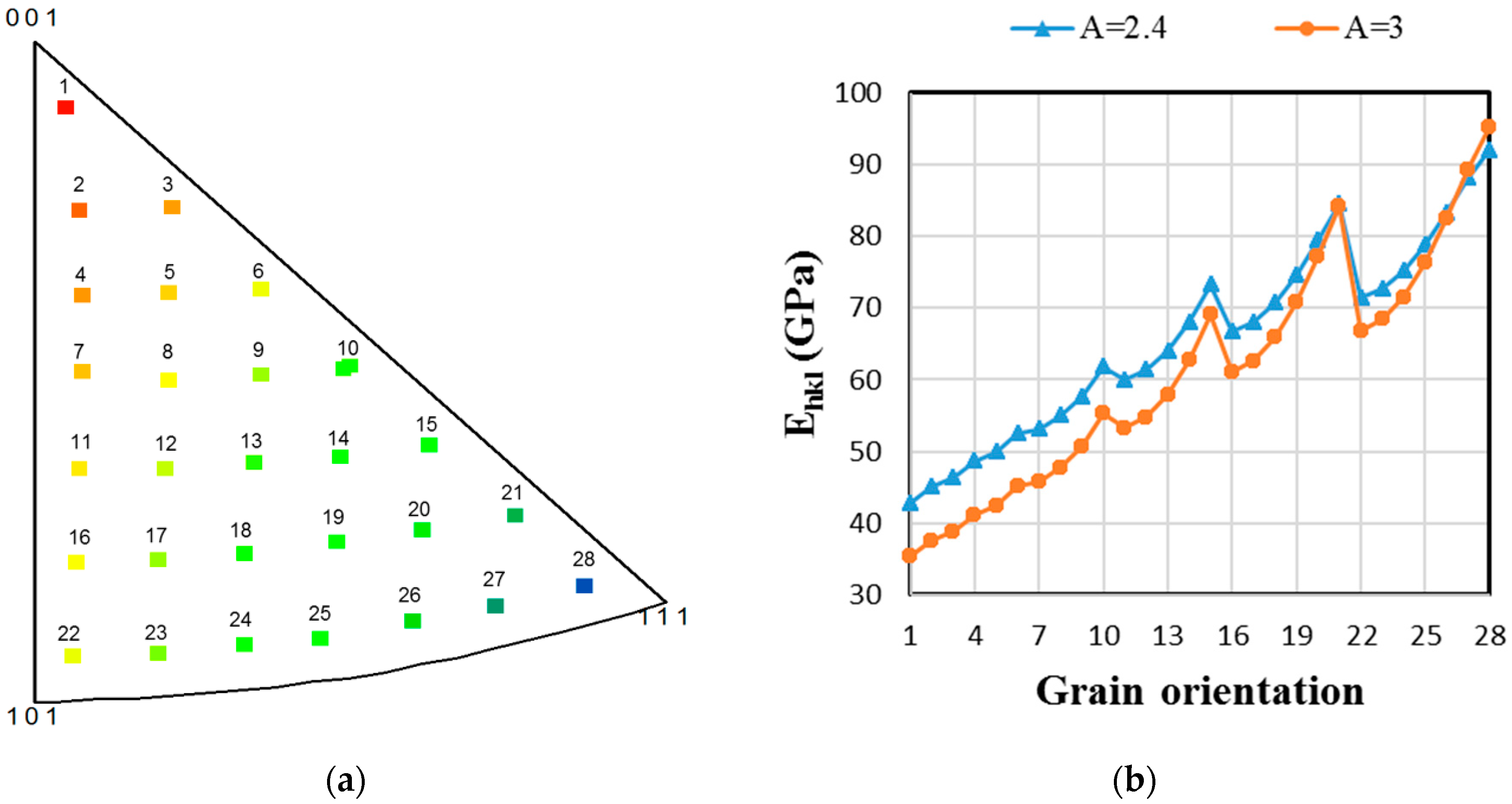

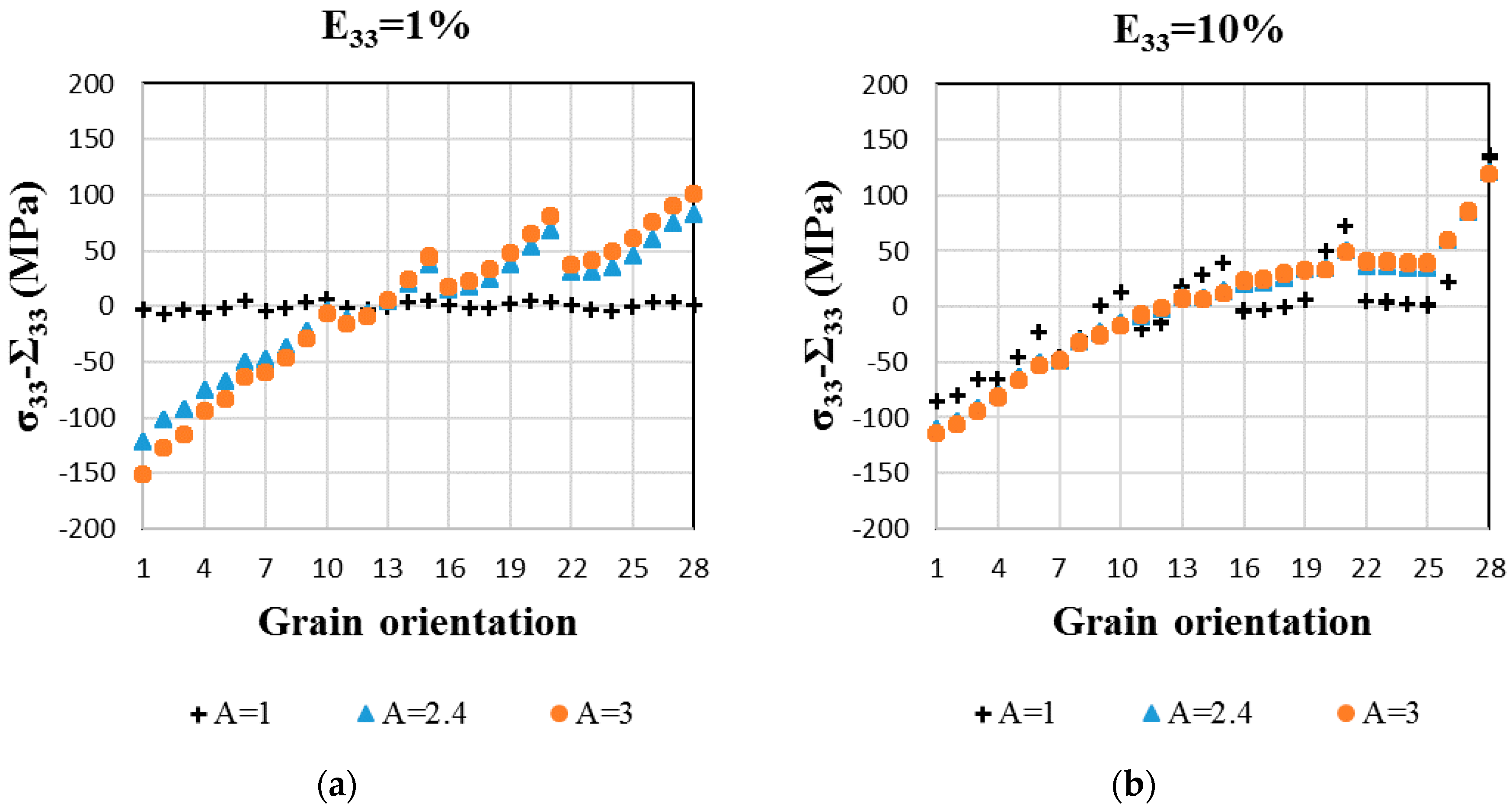

3.3. Local Mechanical Fields Analysis

3.4. Effect of Anisotropic Elasticity on Relative Slip Activities in 100% β-Ti

4. Conclusions

- At the macroscopic scale, the two sets of β-phase SEC well predict the tensile elasto-viscoplastic behavior of a randomly oriented and equiaxed β Ti-17 at two strain rates by the EVPSC model. This shows the relevancy of the model for the prediction of the material’s hardening and strain rate sensitivity;

- In contrast, at the grain scale, the two sets of SEC lead to the scattered incompatibility of stresses and strains. These incompatibilities increase in magnitude with the Zener factor A and depend on the grain orientation. The grains oriented with their <100> direction parallel to the tensile axis are more sensitive to the anisotropy factor A (Figure 5). The local mechanical fields analysis demonstrates that considering only the macroscopic behavior is not sufficient to evaluate the effect of the elastic anisotropy of the β-phase;

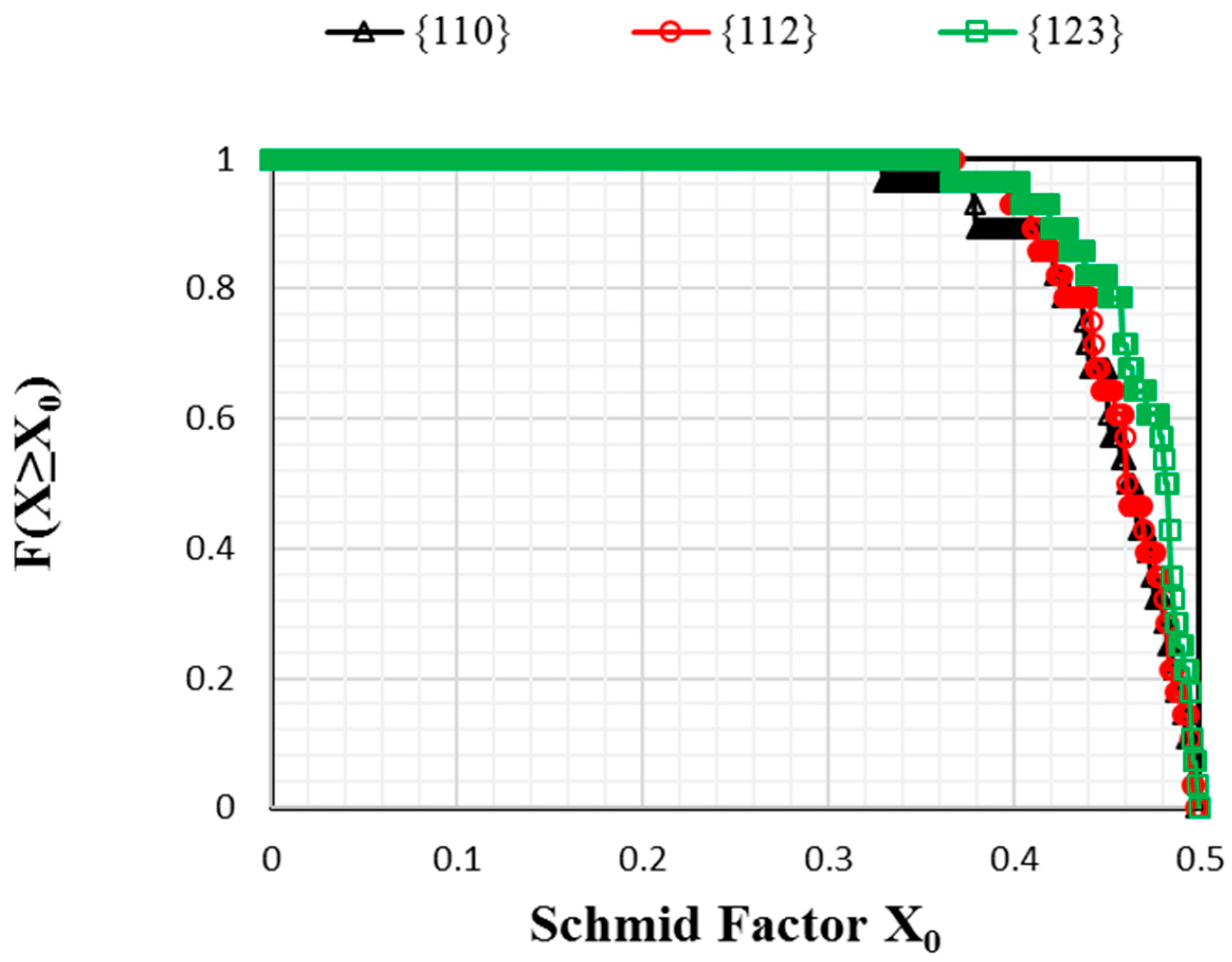

- Lastly, it is shown that the elastic anisotropy of the β-phase can affect the slip activities of a fully β-phase microstructure. Contrary to the isotropic elastic case, {112} <111> slip systems are clearly predominant at the onset of plasticity in the simulations with A = 2.4 and 3 (Figure 6).

Author Contributions

Funding

Conflicts of Interest

References

- Chini, M.R.; Germain, L.; Gey, N.; Andrieu, S.; Duval, T. Advanced Microtexture Analysis of A Ti 10-2-3 Product for Better Understanding of Local Variations in Mechanical Behavior. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 1943–1948. [Google Scholar]

- Chung, D.H.; Buessem, W.R. The Elastic Anisotropy of Crystals. J. Appl. Phys. 1967, 38, 2010–2012. [Google Scholar] [CrossRef]

- Zener, C.M.; Siegel, S. Elasticity and Anelasticity of Metals. J. Phys. Colloid Chem. 1949, 53, 1468. [Google Scholar] [CrossRef]

- Martin, G. Simulation Numérique Multi-Échelles du Comportement Mécanique des Alliages de Titane Bêta-Métastable Ti5553 et Ti17. Ph.D. Thesis, Ecole Nationale Supérieure des Mines de Paris, Paris, France, 2012. [Google Scholar]

- Raghunathan, S.L.; Stapleton, A.M.; Dashwood, R.J.; Jackson, M.; Dye, D. Micromechanics of Ti–10V–2Fe–3Al: In situ synchrotron characterisation and modelling. Acta Mater. 2007, 55, 6861–6872. [Google Scholar] [CrossRef]

- Petry, W.; Heiming, A.; Trampenau, J.; Alba, M.; Herzig, C.; Schober, H.R.; Vogl, G. Phonon dispersion of the bcc phase of group-IV metals. I. bcc titanium. Phys. Rev. B 1991, 43, 10933–10947. [Google Scholar] [CrossRef]

- Ledbetter, H.; Ogi, H.; Kai, S.; Kim, S.; Hirao, M. Elastic constants of body-centered-cubic titanium monocrystals. J. Appl. Phys. 2004, 95, 4642–4644. [Google Scholar] [CrossRef]

- Fréour, S.; Lacoste, E.; François, M.; Guillén, R. Determining Ti-17 β-phase single-crystal elasticity constants through X-ray diffraction and inverse scale transition model. Mater. Sci. Forum 2011, 681, 97–102. [Google Scholar] [CrossRef]

- Fréour, S.; Gloaguen, D.; François, M.; Perronnet, A.; Guillén, R. Determination of single-crystal elasticity constants in a cubic phase within a multiphase alloy: X-ray diffraction measurements and inverse-scale transition modelling. J. Appl. Crystallogr. 2005, 38, 30–37. [Google Scholar] [CrossRef]

- Fisher, E.S.; Dever, D. Relation of the c′ elastic modulus to stability of b.c.c. transition metals. Acta Metall. 1970, 18, 265–269. [Google Scholar] [CrossRef]

- Reid, C.N.; Routbort, J.L.; Maynard, R.A. Elastic constants of Ti–40 at.% Nb at 298 °K. J. Appl. Phys. 1973, 44, 1398–1399. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Rokhlin, S.I. Determination of elastic constants of generally anisotropic inclined lamellar structure using line-focus acoustic microscopy. J. Acoust. Soc. Am. 2009, 126, 2998–3007. [Google Scholar] [CrossRef] [PubMed]

- Nejezchlebová, J.; Janovská, M.; Seiner, H.; Sedlák, P.; Landa, M.; Šmilauerová, J.; Stráský, J.; Harcuba, P.; Janeček, M. The effect of athermal and isothermal ω phase particles on elasticity of β-Ti single crystals. Acta Mater. 2016, 110, 185–191. [Google Scholar] [CrossRef]

- Richeton, T.; Wagner, F.; Chen, C.; Toth, L.S. Combined Effects of Texture and Grain Size Distribution on the Tensile Behavior of α-Titanium. Materials 2018, 11, 1088. [Google Scholar] [CrossRef] [PubMed]

- Ji, Z.; Shen, C.; Wei, F.; Li, H. Dependence of Macro- and Micro-Properties on α Plates in Ti-6Al-2Zr-1Mo-1V Alloy with Tri-Modal Microstructure. Metals 2018, 8, 299. [Google Scholar] [CrossRef]

- Cojocaru, V.D.; Șerban, N. Effects of Solution Treating on Microstructural and Mechanical Properties of a Heavily Deformed New Biocompatible Ti–Nb–Zr–Fe Alloy. Metals 2018, 8, 297. [Google Scholar] [CrossRef]

- Li, J.; van Vliet, K.J.; Zhu, T.; Yip, S.; Suresh, S. Atomistic mechanisms governing elastic limit and incipient plasticity in crystals. Nature 2002, 418, 307–310. [Google Scholar] [CrossRef] [PubMed]

- Martin, G.; Naźe, L.; Cailletaud, G. Numerical multi-scale simulations of the mechanical behavior of β-metastable titanium alloys Ti5553 and Ti17. Procedia Eng. 2011, 10, 1803–1808. [Google Scholar] [CrossRef]

- Hounkpati, V.; Fréour, S.; Gloaguen, D.; Legrand, V.; Kelleher, J.; Kockelmann, W.; Kabra, S. In situ neutron measurements and modelling of the intergranular strains in the near-β titanium alloy Ti-β21S. Acta Mater. 2016, 109, 341–352. [Google Scholar] [CrossRef]

- Lhadi, S.; Berbenni, S.; Gey, N.; Richeton, T.; Germain, L. Micromechanical modeling of the effect of elastic and plastic anisotropies on the mechanical behavior of beta-Ti alloys. Int. J. Plast. 2018. [Google Scholar] [CrossRef]

- Settefrati, A. Étude Expérimentale et Modélisation par Champ de Phase de la Formation de Alpha dans les Alliages de Titane Bêta-Métastable. Ph.D. Thesis, Université de Lorraine, Lorraine, France, 2012. [Google Scholar]

- Duval, T. Analyse Multi-Échelles des Relations Microstructure/Propriétés Mécaniques sous Sollicitation Monotone et Cyclique des Alliages de Titane β-Métastable. Ph.D. Thesis, Ecole Nationale Supérieure de Mécanique et d’Aérotechnique, Chasseneuil-du-Poitou, France, 2013. [Google Scholar]

- Mareau, C.; Berbenni, S. An affine formulation for the self-consistent modeling of elasto-viscoplastic heterogeneous materials based on the translated field method. Int. J. Plast. 2015, 64, 134–150. [Google Scholar] [CrossRef]

- Amouzou, K.E.K.; Richeton, T.; Roth, A.; Lebyodkin, M.A.; Lebedkina, T.A. Micromechanical modeling of hardening mechanisms in commercially pure α-titanium in tensile condition. Int. J. Plast. 2016, 80, 222–240. [Google Scholar] [CrossRef]

- Méric, L.; Poubanne, P.; Cailletaud, G. Single Crystal Modeling for Structural Calculations: Part 1—Model Presentation. J. Eng. Mater. Technol. 1991, 113, 162–170. [Google Scholar] [CrossRef]

- Méric, L.; Cailletaud, G. Single Crystal Modeling for Structural Calculations: Part 2—Finite Element Implementation. J. Eng. Mater. Technol. 1991, 113, 171–182. [Google Scholar] [CrossRef]

- Paquin, A.; Sabar, H.; Berveiller, M. Integral formulation and self-consistent modelling of elastoviscoplastic behavior of heterogeneous materials. Arch. Appl. Mech. 1999, 69, 14–35. [Google Scholar] [CrossRef]

- Sabar, H.; Berveiller, M.; Favier, V.; Berbenni, S. A new class of micro–macro models for elastic–viscoplastic heterogeneous materials. Int. J. Solids Struct. 2002, 39, 3257–3276. [Google Scholar] [CrossRef]

- Berbenni, S.; Favier, V.; Lemoine, X.; Berveiller, M. Micromechanical modeling of the elastic-viscoplastic behavior of polycrystalline steels having different microstructures. Mater. Sci. Eng. A 2004, 372, 128–136. [Google Scholar] [CrossRef]

- Masson, R.; Zaoui, A. Self-consistent estimates for the rate-dependentelastoplastic behaviour of polycrystalline materials. J. Mech. Phys. Solids 1999, 47, 1543–1568. [Google Scholar] [CrossRef]

- Clément, N. Phase Transformations and Mechanical Properties of the Ti-5553 Beta-Metastable Titanium Alloy. Ph.D. Thesis, Université Catholique de Louvain (UCL), Louvain-la-Neuve, Belgium, 2010. [Google Scholar]

- Hershey, A.V. The elasticity of an isotropic aggregate of anisotropic cubic crystals. J. Appl. Mech.-Trans. ASME 1954, 21, 236–240. [Google Scholar]

- Kröner, E. Computation of the elastic constants of polycrystals from constants of single crystals. Z. Phys. 1958, 151, 504–518. [Google Scholar] [CrossRef]

- Weinberger, C.R.; Boyce, B.L.; Battaile, C.C. Slip planes in bcc transition metals. Int. Mater. Rev. 2013, 58, 296–314. [Google Scholar] [CrossRef]

- Sauzay, M. Cubic elasticity and stress distribution at the free surface of polycrystals. Acta Mater. 2007, 55, 1193–1202. [Google Scholar] [CrossRef]

- Tiba, I.; Richeton, T.; Motz, C.; Vehoff, H.; Berbenni, S. Incompatibility stresses at grain boundaries in Ni bicrystalline micropillars analyzed by an anisotropic model and slip activity. Acta Mater. 2015, 83, 227–238. [Google Scholar] [CrossRef]

| Ti-Based Alloy | SEC (GPa) | A | EYM (GPa) of 100% β (Calculated) | ||

|---|---|---|---|---|---|

| C11 | C12 | C44 | |||

| Ti-17 [4] | 100 | 70 | 36 | 2.4 | 69.4 |

| Pure [6] | 134 | 110 | 36 | 3 | 66.6 |

| Slip Family | n | K(MPa·s1/n) | r0(MPa) | c(MPa) |

|---|---|---|---|---|

| {110} <111> 12 slip systems | 20 | 300 | 113 | 200 |

| {112} <111> 12 slip systems | 20 | 300 | 113 | 200 |

| {123} <111> 24 slip systems | 20 | 300 | 123 | 400 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lhadi, S.; Chini, M.-R.; Richeton, T.; Gey, N.; Germain, L.; Berbenni, S. Micromechanical Modeling of the Elasto-Viscoplastic Behavior and Incompatibility Stresses of β-Ti Alloys. Materials 2018, 11, 1227. https://doi.org/10.3390/ma11071227

Lhadi S, Chini M-R, Richeton T, Gey N, Germain L, Berbenni S. Micromechanical Modeling of the Elasto-Viscoplastic Behavior and Incompatibility Stresses of β-Ti Alloys. Materials. 2018; 11(7):1227. https://doi.org/10.3390/ma11071227

Chicago/Turabian StyleLhadi, Safaa, Maria-Rita Chini, Thiebaud Richeton, Nathalie Gey, Lionel Germain, and Stéphane Berbenni. 2018. "Micromechanical Modeling of the Elasto-Viscoplastic Behavior and Incompatibility Stresses of β-Ti Alloys" Materials 11, no. 7: 1227. https://doi.org/10.3390/ma11071227

APA StyleLhadi, S., Chini, M.-R., Richeton, T., Gey, N., Germain, L., & Berbenni, S. (2018). Micromechanical Modeling of the Elasto-Viscoplastic Behavior and Incompatibility Stresses of β-Ti Alloys. Materials, 11(7), 1227. https://doi.org/10.3390/ma11071227