Impact-Sliding Tribology Behavior of TC17 Alloy Treated by Laser Shock Peening

Abstract

1. Introduction

2. Experimental Details

2.1. Materials

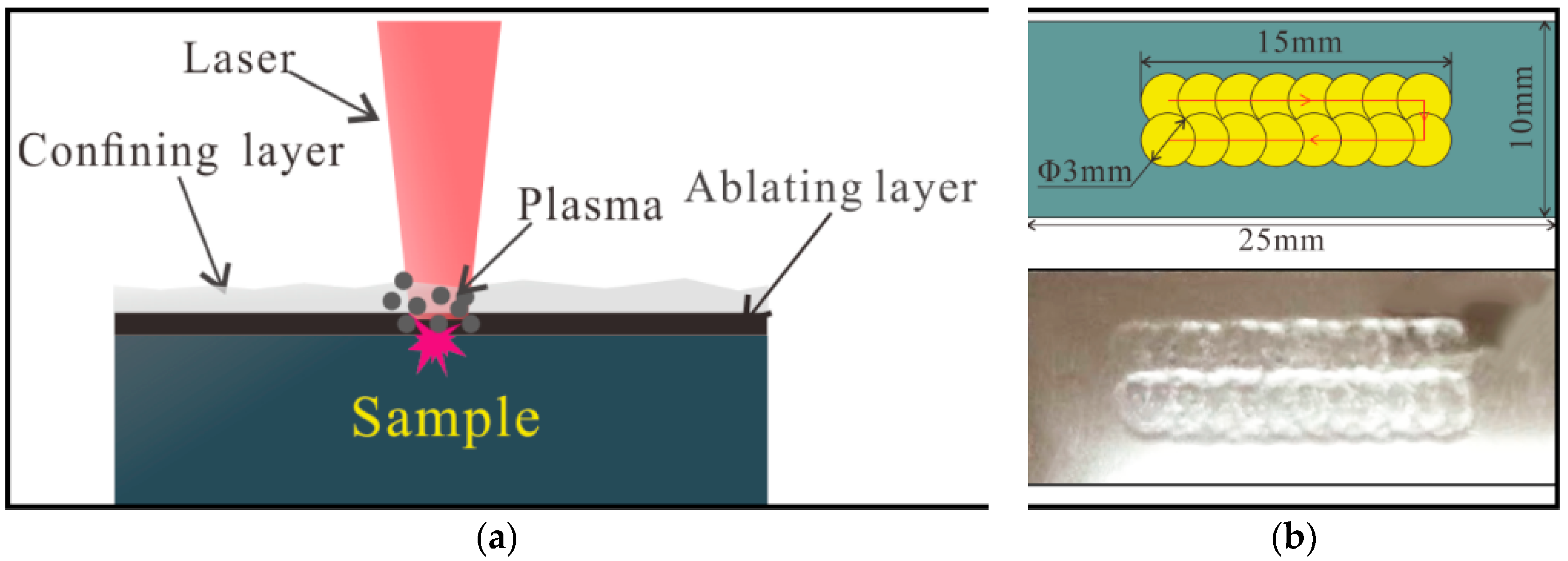

2.2. LSP

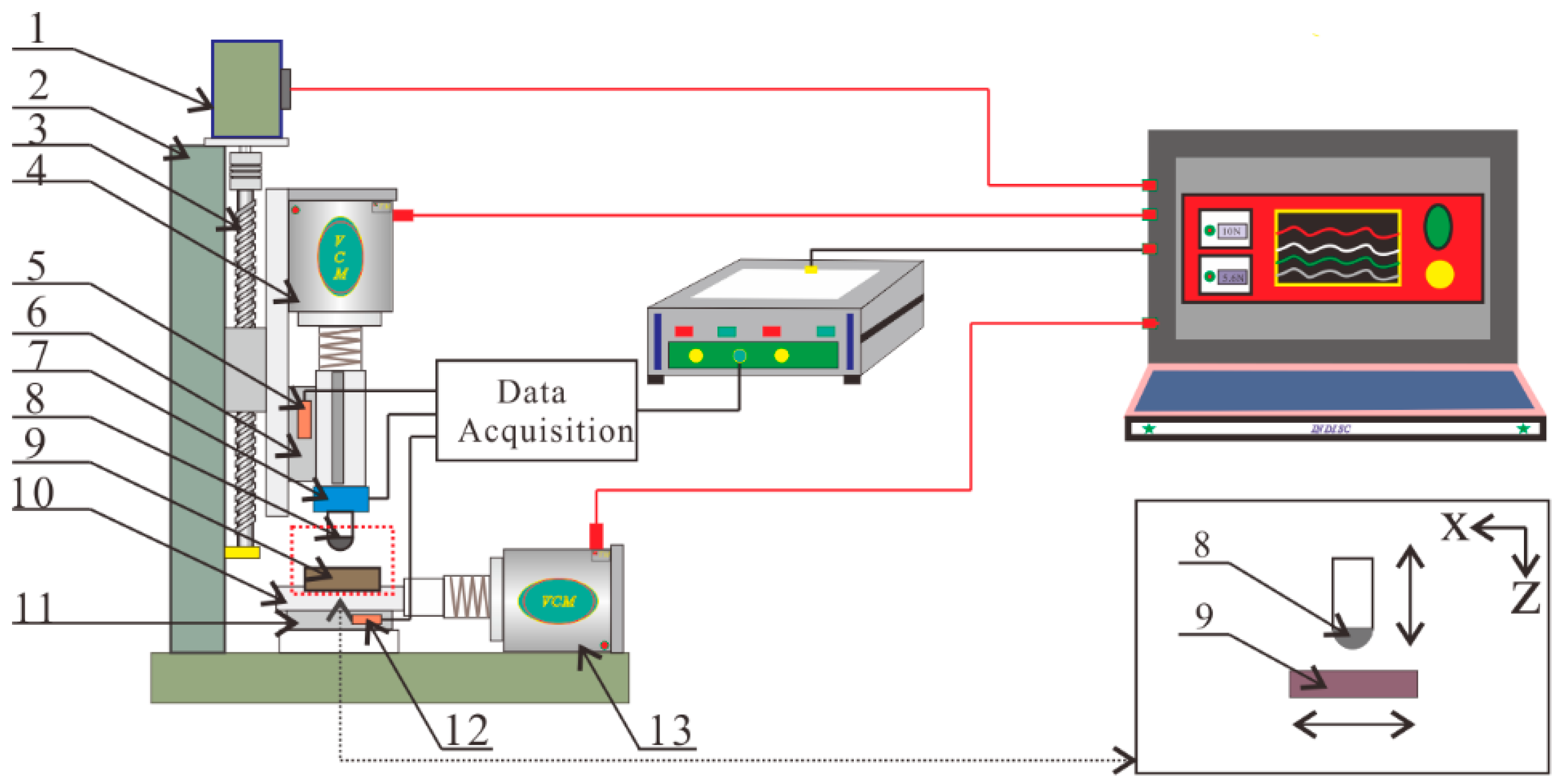

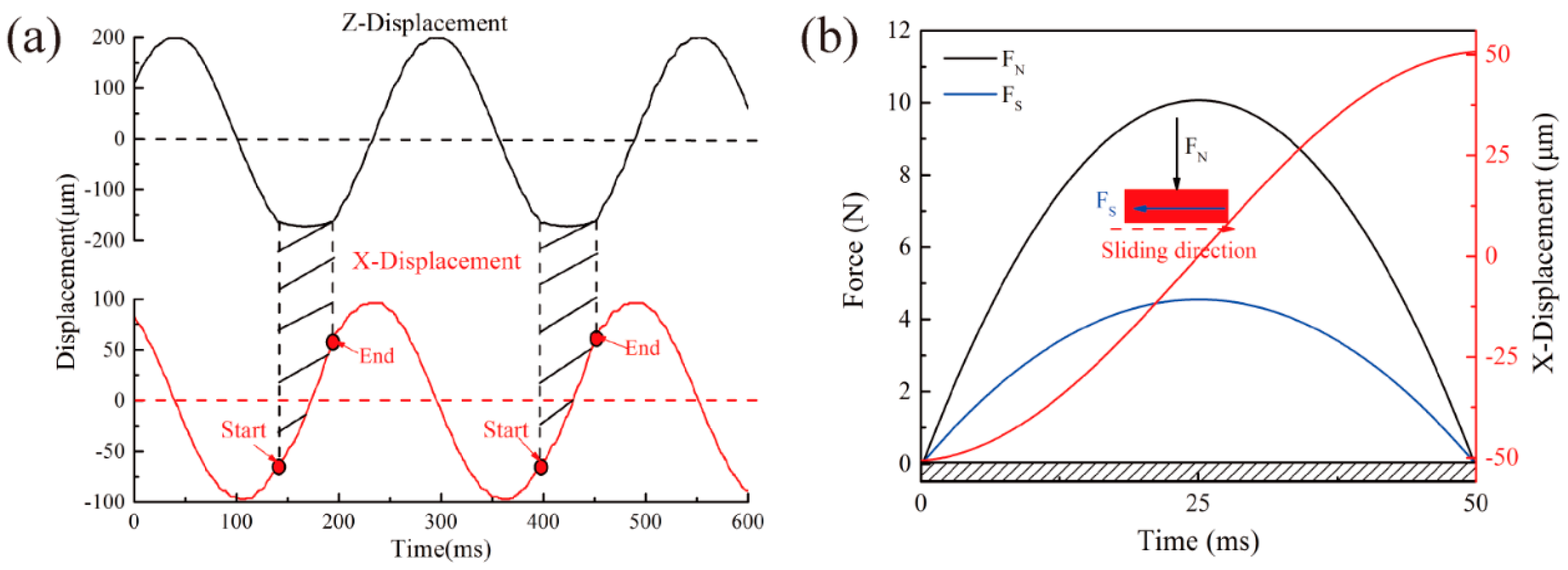

2.3. Impact-Sliding Fretting Wear Test Method

3. Results

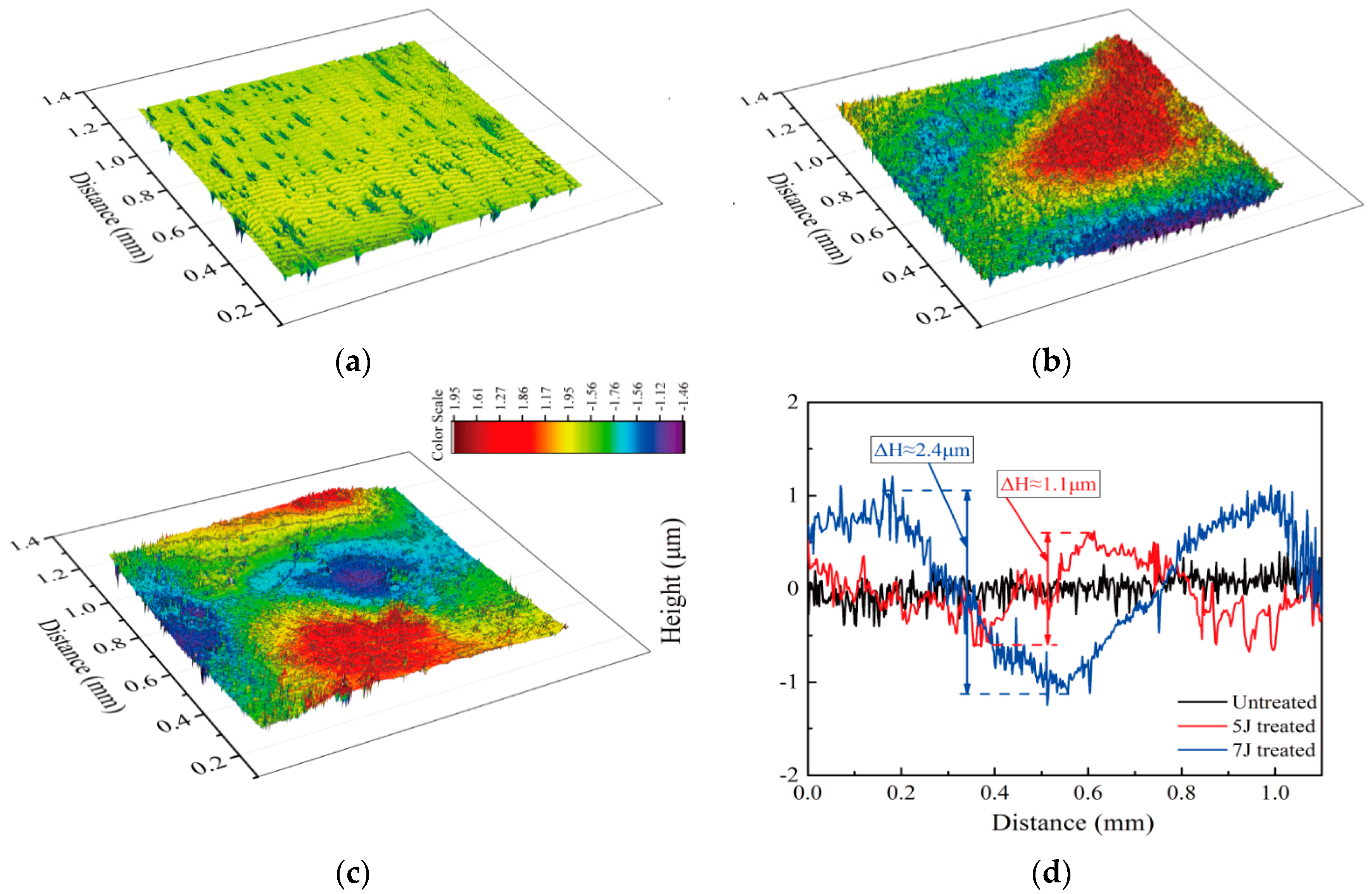

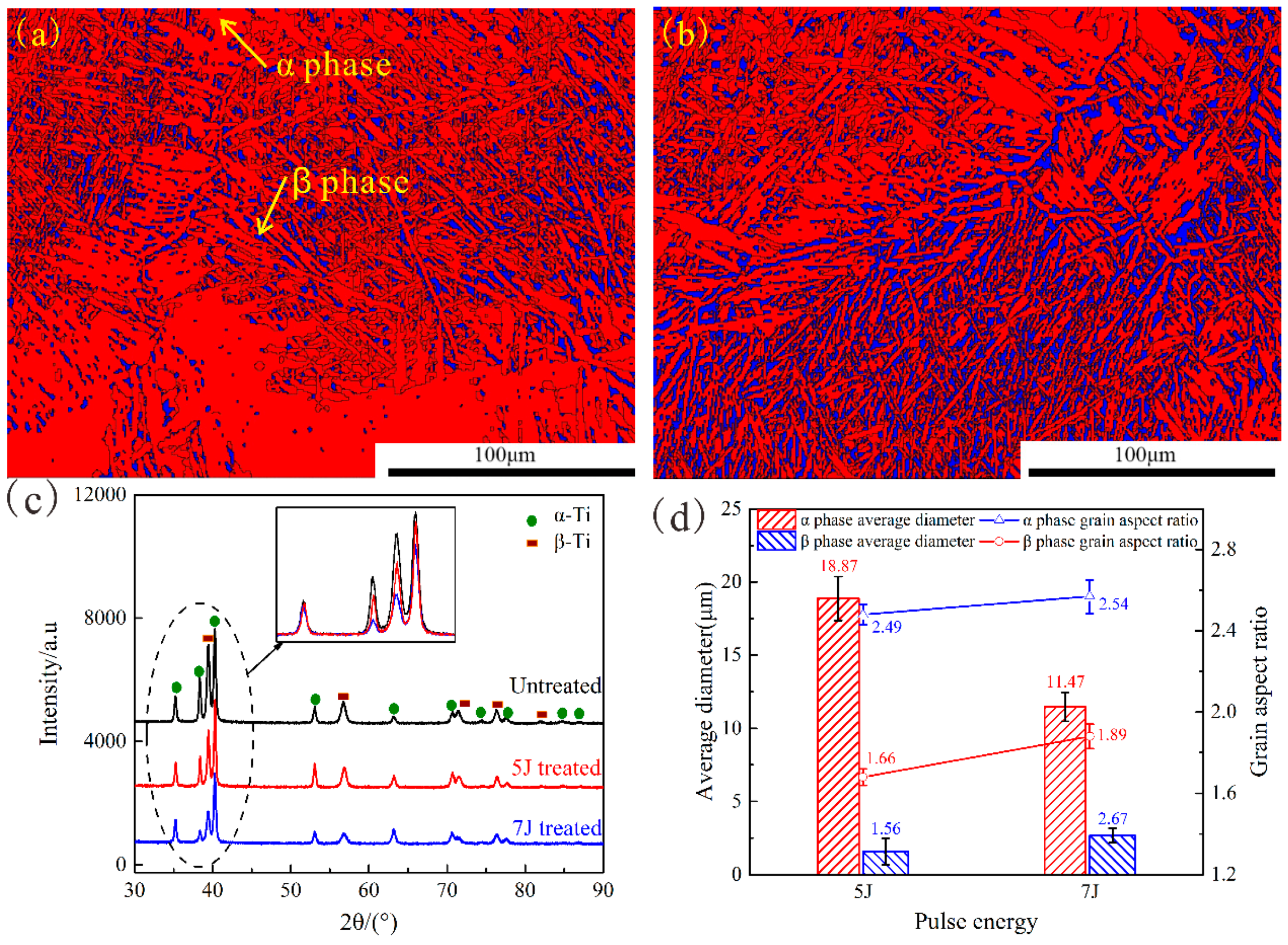

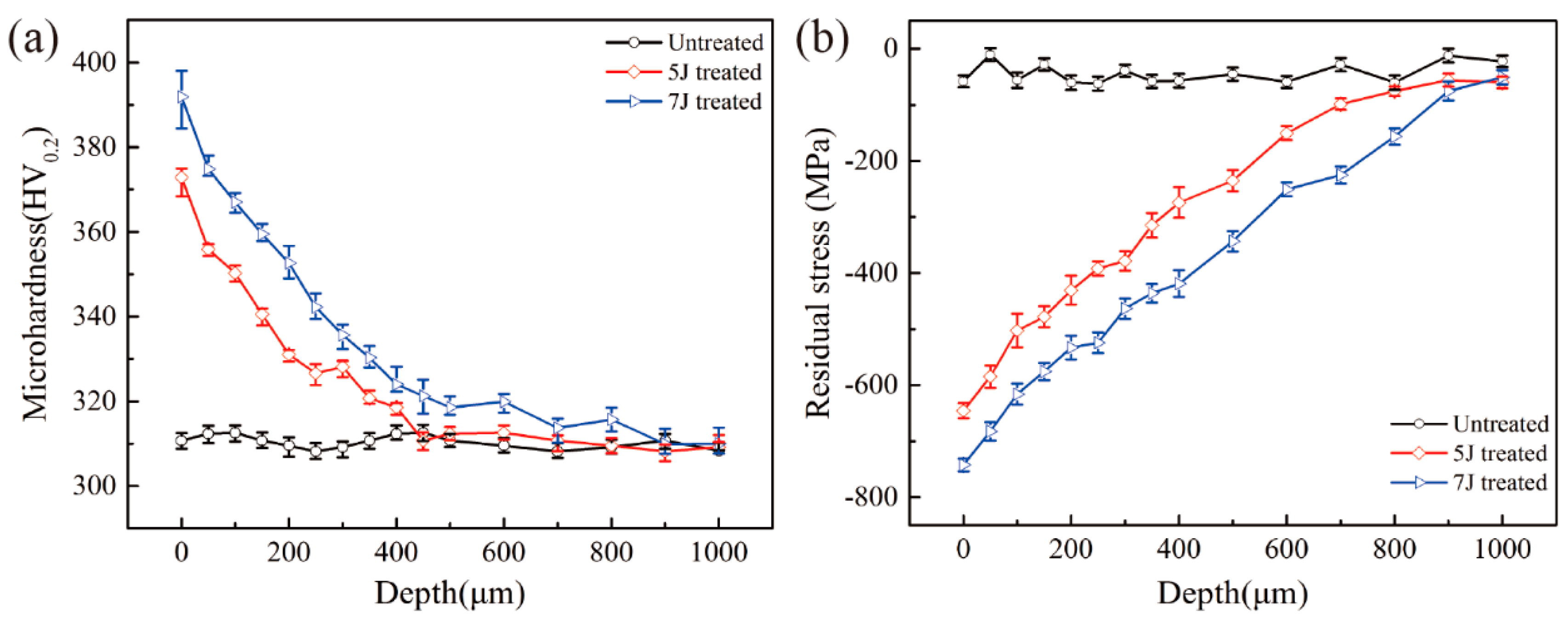

3.1. Characteristics of Materials

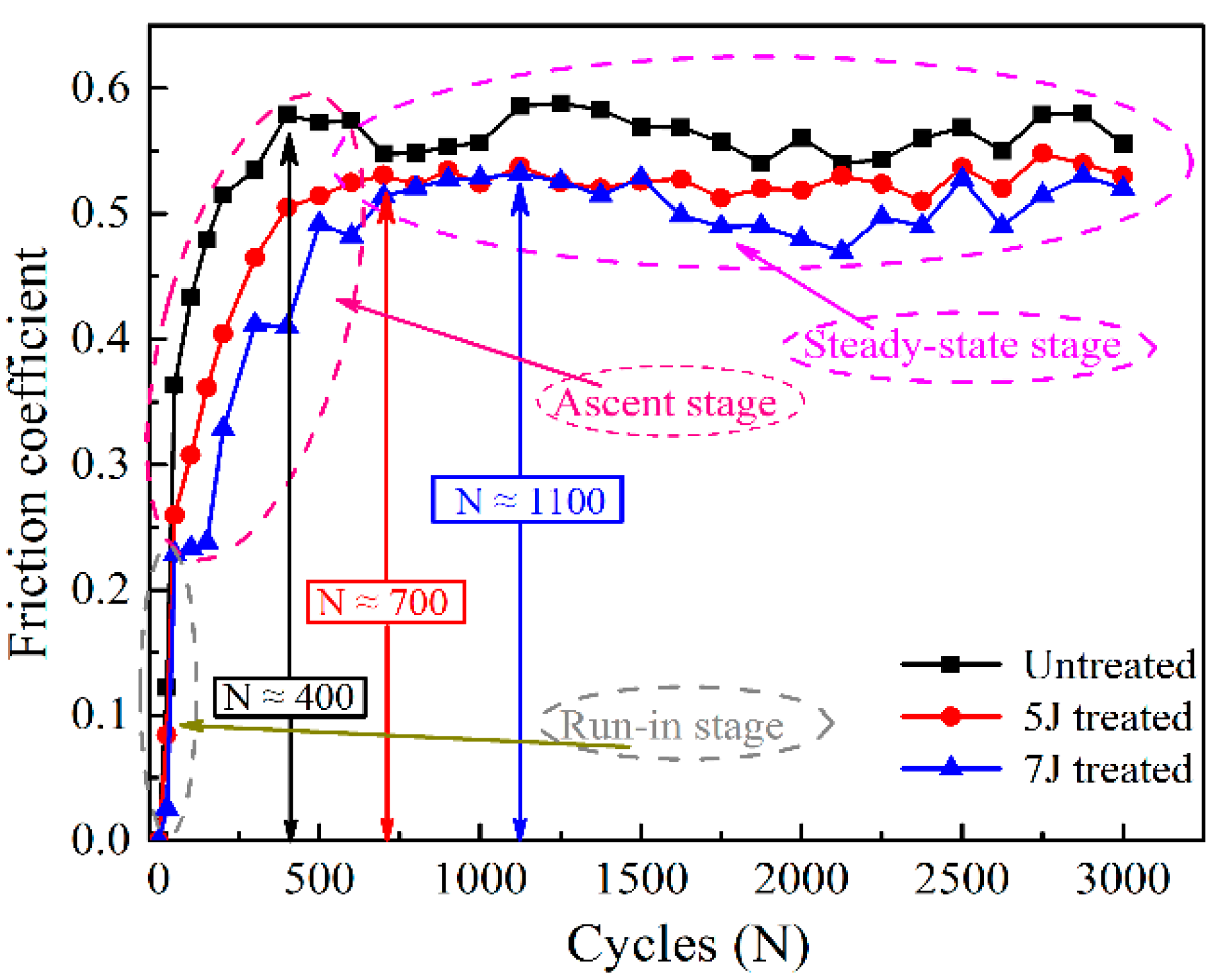

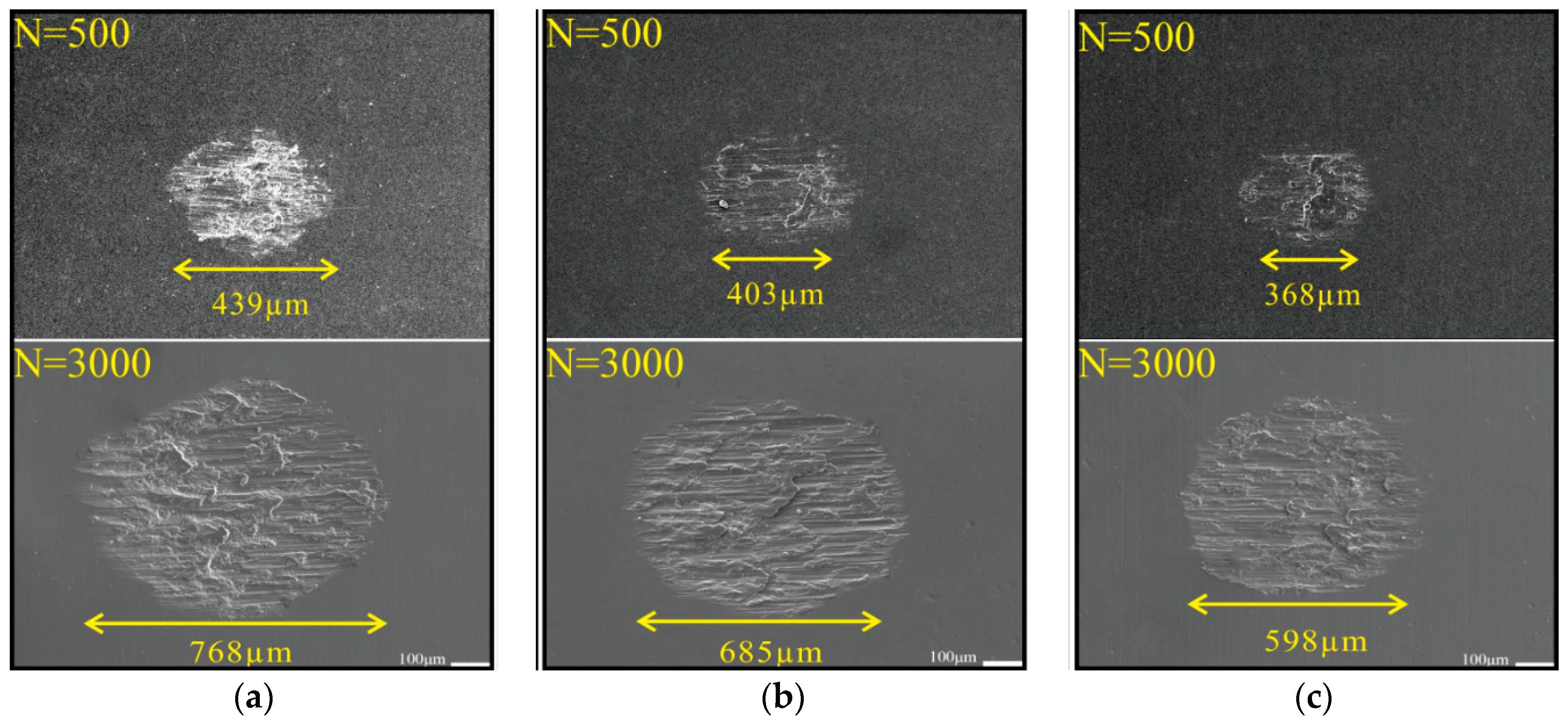

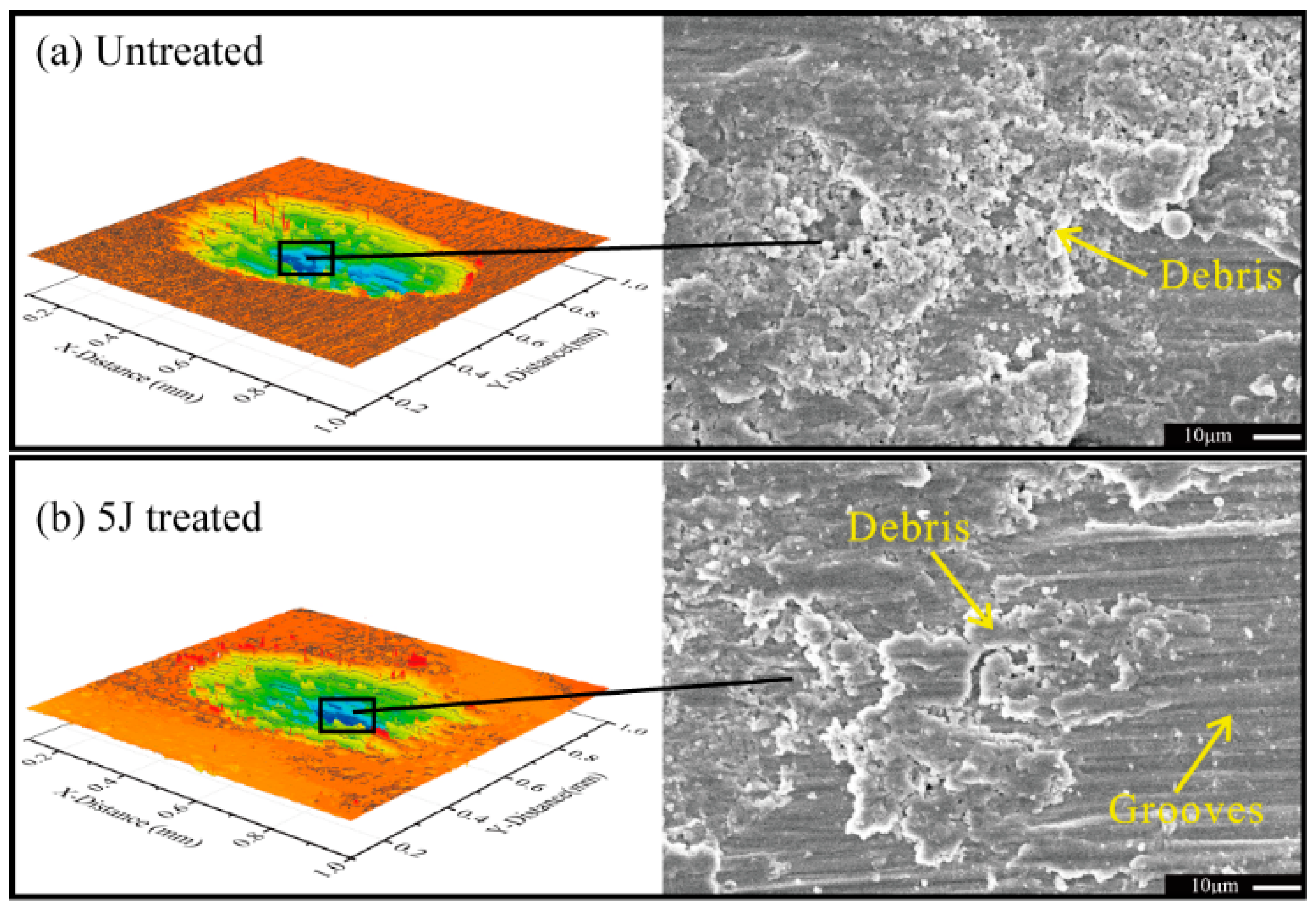

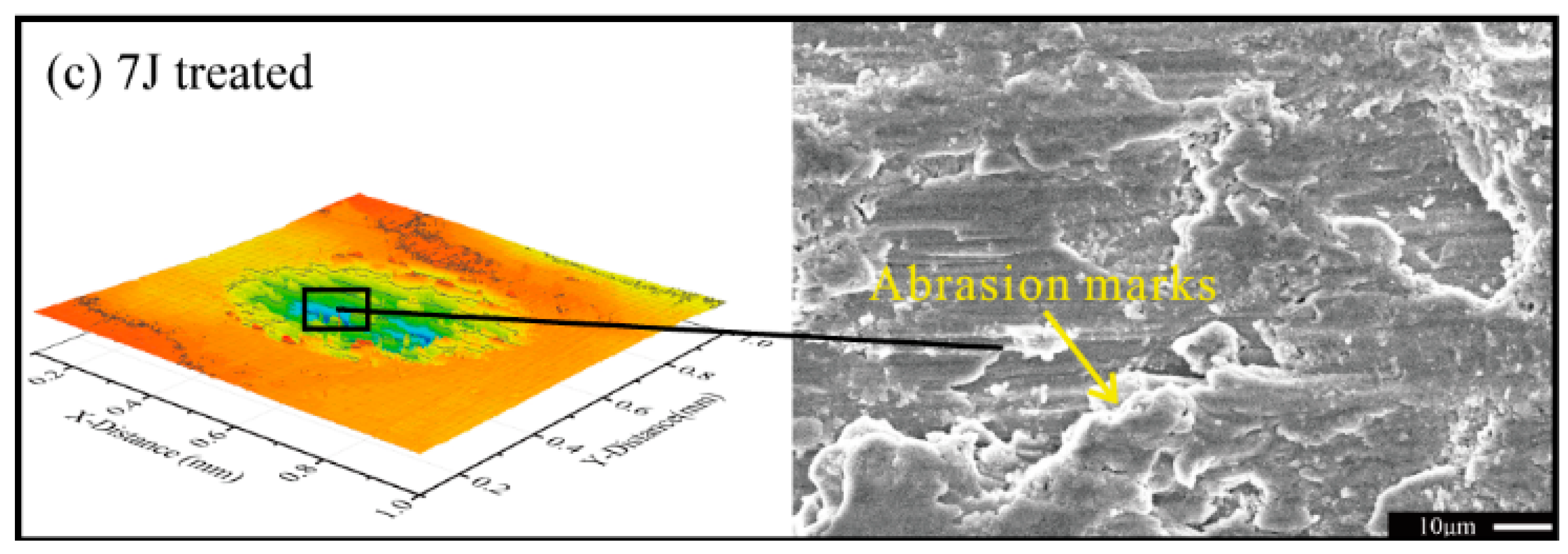

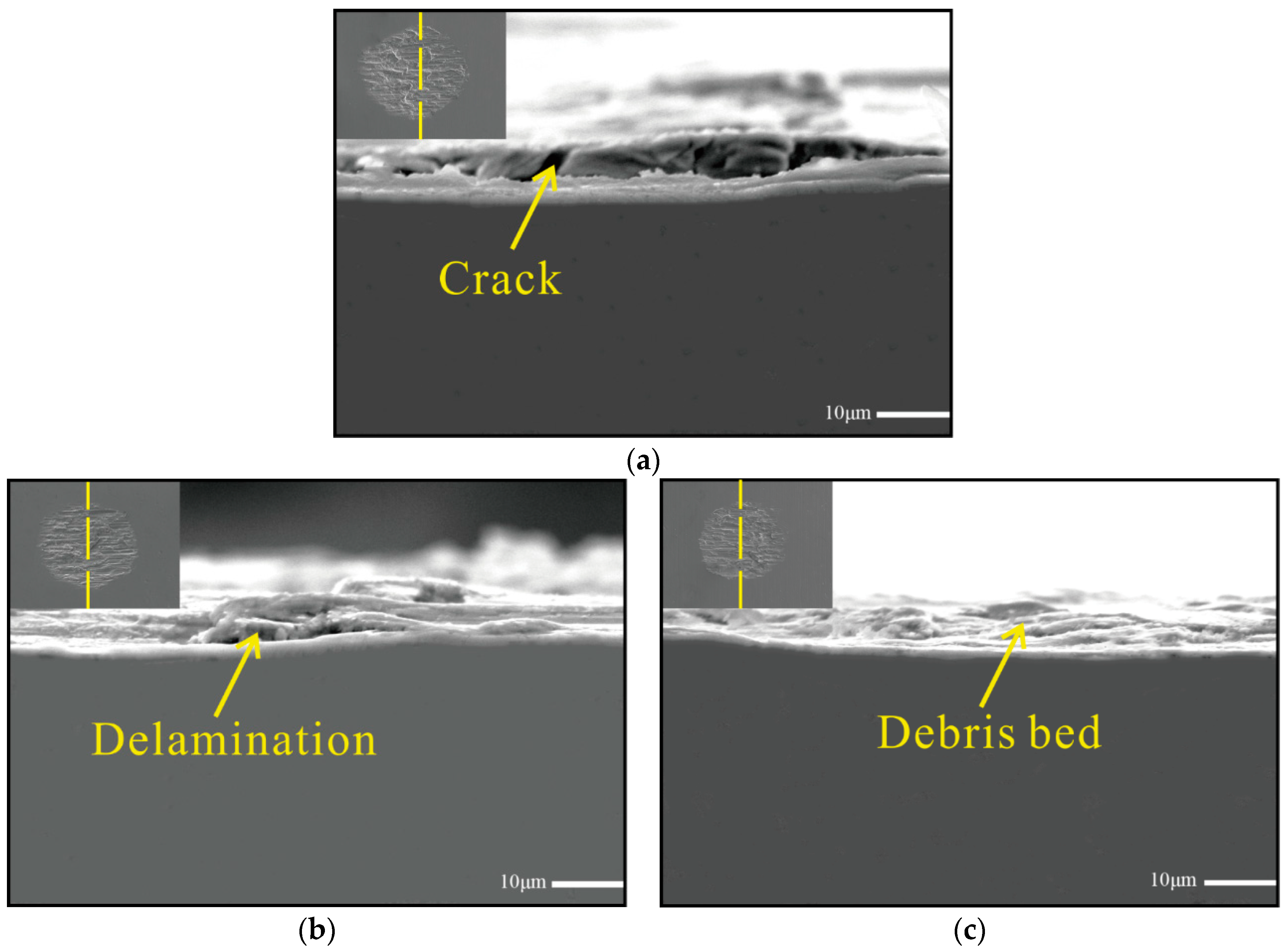

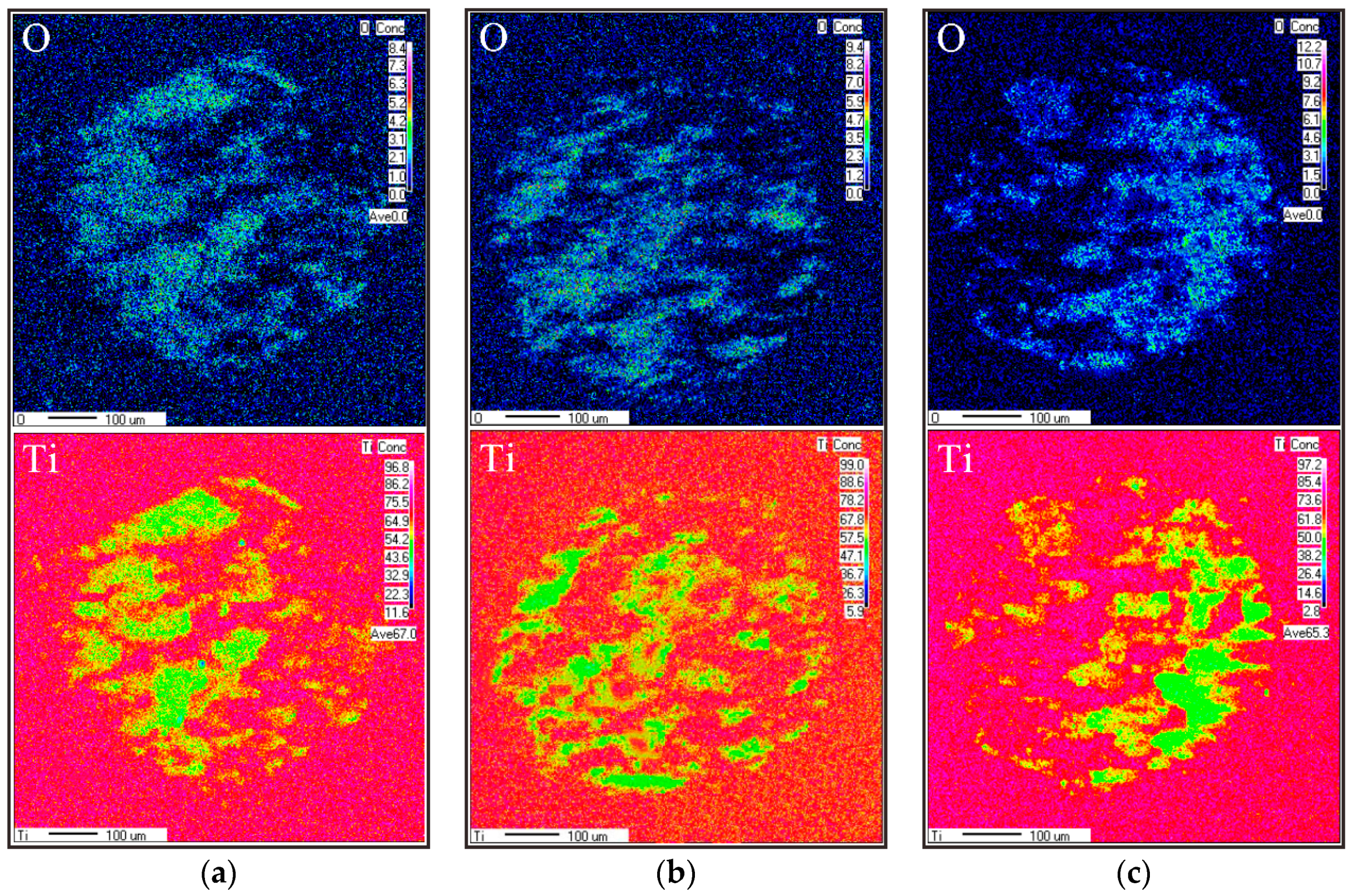

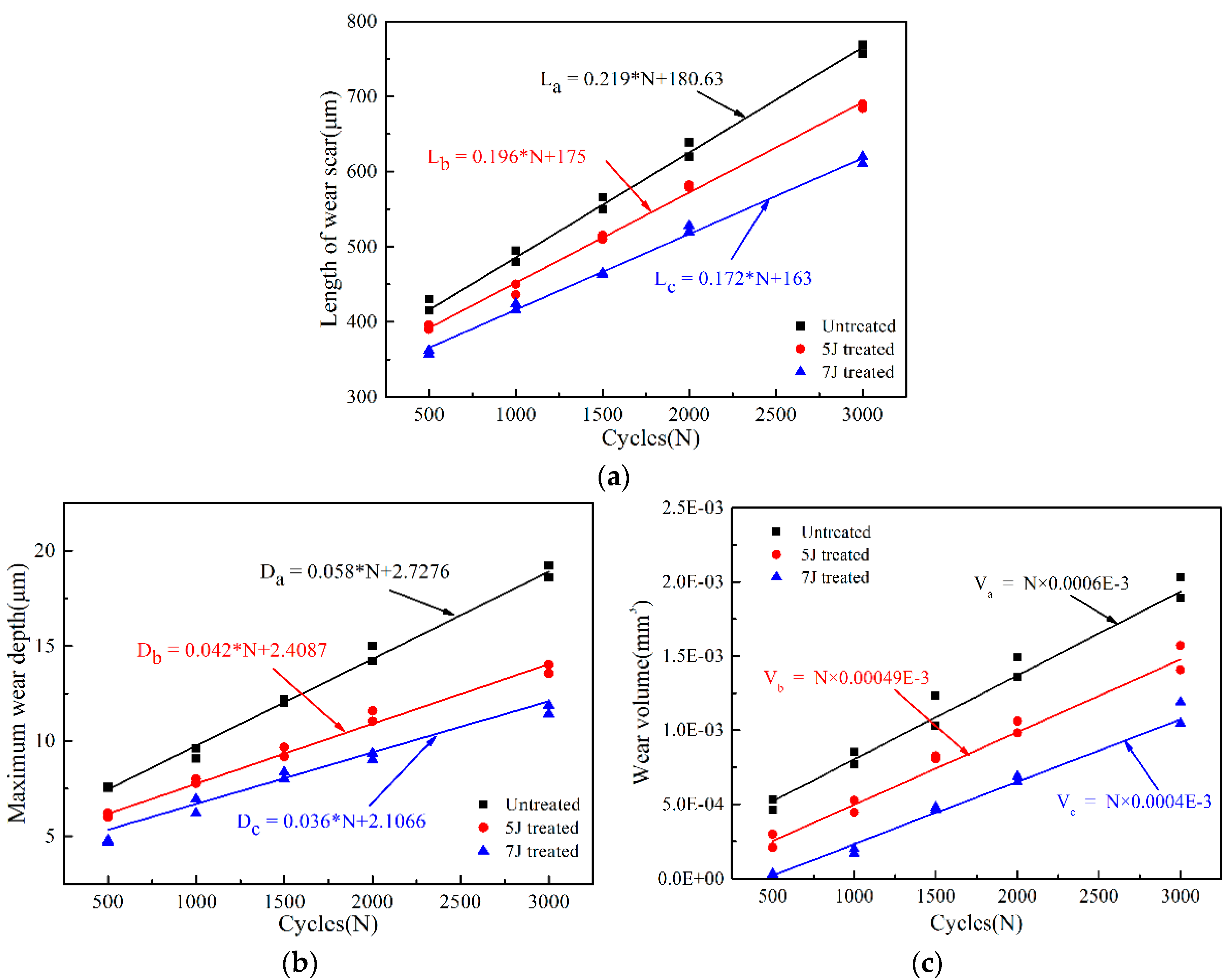

3.2. Wear Analysis

3.3. Summary

4. Conclusions

- (a)

- LSP generated microdents on the surface of TC17 titanium alloy which induced plastic deformation and residual compressive stress on this material. The improvement in the impact-sliding wear resistance of TC17 titanium alloy after LSP was caused by the increased surface hardness and compressive residual stress.

- (b)

- Under the same impact-sliding wear condition, the test sample treated by 7J pulse energy exhibited the best wear resistance, whereas the untreated sample showed the poorest results. As impact-sliding cycles increased, growth rates of wear area, wear depth, and wear volume of the three test samples varied. Therefore, lower growth rate was obtained when pulse energy was higher. The main wear mechanisms of the three test samples included delamination and abrasive wear.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, B.L. Study on the Mechanical Properties of Titanium Alloy TC17 and Characteristics in Machining. Ph.D. Thesis, Shandong University, Jinan, China, 2013. [Google Scholar]

- Zhou, W.; Ren, X.; Liu, F.; Ren, Y.; Li, L. Nanocrystallization in the duplex Ti-6Al-4V alloy processed by multiple laser shock peening. Metals 2016, 6. [Google Scholar] [CrossRef]

- Sun, J.Z.; Li, M.Q.; Li, H. Deformation behavior of TC17 titanium alloy with basket weave microstructure during isothermal compression. J. Alloys Compd. 2018, 730, 533–543. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Liu, H.Q.; Wang, H.M.; Wagner, D. Effect of stress ratio on VHCF behavior for a compressor blade titanium alloy. Int. J. Fatigue 2016, 93, 232–237. [Google Scholar] [CrossRef]

- Zhang, X.H.; Liu, D.X.; Tan, H.B.; Wang, X.F. Effect of TiN/Ti composite coating and shot peening on fretting fatigue behavior of TC17 alloy at 350 °C. Surf. Coat. Technol. 2009, 203, 2315–2321. [Google Scholar] [CrossRef]

- Ayed, Y.; Germain, G.; Ammar, A.; Furet, B. Tool wear analysis and improvement of cutting conditions using the high-pressure water-jet assistance when machining the Ti17 titanium alloy. Precis. Eng. 2015, 42, 294–301. [Google Scholar] [CrossRef]

- Wei, X.; Zhang, P.; Wei, D.; Zhao, H.; Liskiewicz, T. Niobium coated Ti-Al alloy: Improvement of tribological behavior, oxidation resistance and flame retardancy. Int. J. Surf. Sci. Eng. 2016, 10, 559–569. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, Z.B.; Sun, Y.; Peng, J.F.; Zhu, M.H. Low velocity impact wear behavior of MoS2/Pb nanocomposite coating under controlled kinetic energy. Surf. Coat. Technol. 2017, 326, 53–62. [Google Scholar] [CrossRef]

- Liu, Y.G.; Li, H.M.; Li, M.Q. Characterization of surface layer in TC17 alloy treated by air blast shot peening. Mater. Des. 2015, 65, 120–126. [Google Scholar] [CrossRef]

- Wu, J.F.; Zou, S.K.; Zhang, Y.K.; Gong, S.L.; Sun, G.F.; Ni, Z.H.; Cao, Z.W.; Che, Z.G.; Feng, A.X. Microstructures and mechanical properties of β forging Ti17 alloy under combined laser shock processing and shot peening. Surf. Coat. Technol. 2017, 328, 3–291. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.S.; Zhang, Q.; Zhao, Y.H.; Zhu, Y.T. Gradient Structured Copper by Rotationally Accelerated Shot Peening. J. Mater. Sci. Technol. 2017, 33, 758–761. [Google Scholar] [CrossRef]

- Guo, L.; Fan, X.; Yu, G.; Yang, H. Microstructure control techniques in primary hot working of titanium alloy bars: A review. Chin. J. Aeronaut. 2016, 29, 30–40. [Google Scholar] [CrossRef]

- Wang, K.; Zeng, W.; Zhao, Y.; Lai, Y.; Zhou, Y. Hot working of Ti-17 titanium alloy with lamellar starting structure using 3-D processing maps. J. Mater. Sci. 2010, 45, 5883–5891. [Google Scholar] [CrossRef]

- Qiao, H.C.; Zhao, J.B.; Gao, Y. Experimental investigation of laser peening on TiAl alloy microstructure and properties. Chin. J. Aeronaut. 2015, 28, 609–616. [Google Scholar] [CrossRef]

- Qiao, H.C. Experimental investigation of laser peening on Ti17 titanium alloy for rotor blade applications. Appl. Surf. Sci. 2015, 351, 524–530. [Google Scholar]

- Ren, X.D.; Zhou, W.F.; Ren, Y.P.; Xu, S.D.; Liu, F.F.; Yuan, S.Q.; Ren, N.F.; Huang, J.J. Dislocation evolution and properties enhancement of GH2036 by laser shock processing: Dislocation dynamics simulation and experiment. Mater. Sci. Eng. A 2016, 654, 184–192. [Google Scholar] [CrossRef]

- Zhou, D.C.; Hua, G.R.; Zhu, J. Rsearxh on laser shock processing and its application in aeroengine blade. Hot. Work. Tec. 2016, 20, 17–19. [Google Scholar]

- Rahmati, B.; Sarhan, A.A.; Basirun, W.J.; Abas, W.A.B.W. Ceramic tantalum oxide thin film coating to enhance the corrosion and wear characteristics of Ti-6Al-4V alloy. J. Alloys Compd. 2016, 676, 369–376. [Google Scholar] [CrossRef]

- Guan, H.D.; Cai, Z.B.; Ren, Y.P.; Jing, J.Y.; Wang, W.J.; Zhu, M.H. Impact-fretting wear behavior of Inconel 690 alloy tubes effected by pre-compressive stress. J. Alloys Compd. 2017, 724, 910–920. [Google Scholar] [CrossRef]

- Cai, Z.B.; Peng, J.F.; Qian, H.; Tang, L.C.; Zhu, M.H. Impact fretting wear behavior of alloy 690 tubes in dry and deionized water conditions. Chin. J. Mech. Eng. 2017, 30, 819–828. [Google Scholar] [CrossRef]

- Messaadi, M.; Kapsa, P. Wear behavior of high chromium sintered steel under dynamic impact-sliding: Effect of temperature. Tribol. Int. 2016, 100, 380–387. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, T.; Nie, X. Wear failure behaviour of titanium-based oxide coatings on a titanium alloy under impact and sliding forces. J. Alloys Compd. 2013, 578, 336–344. [Google Scholar] [CrossRef]

- Korashy, A.; Attia, H.; Thomson, V.; Oskooei, S. Characterization of fretting wear of cobalt-based superalloys at high temperature for aero-engine combustor components. Wear 2015, 330, 327–337. [Google Scholar] [CrossRef]

- Sato, Y.; Iwabuchi, A.; Uchidate, M.; Yashiro, H. Dynamic corrosion properties of impact-fretting wear in high-temperature pure water. Wear 2015, 330, 182–192. [Google Scholar] [CrossRef]

- Ren, X.D.; Zhou, W.F.; Liu, F.F.; Ren, Y.P.; Yuan, S.Q.; Ren, N.F.; Xu, S.D.; Yang, T. Microstructure evolution and grain refinement of Ti-6Al-4V alloy by laser shock processing. Appl. Surf. Sci. 2016, 363, 44–49. [Google Scholar] [CrossRef]

- Huang, S.; Zhu, Y.; Guo, W.; Peng, P.; Diao, X.G. Impact toughness and microstructural response of Ti-17 titanium alloy subjected to laser shock peening. Surf. Coat. Technol. 2017, 327, 32–41. [Google Scholar] [CrossRef]

- Rigney, D.A. Comments on the sliding wear of metals. Tribol. Int. 1997, 30, 361–367. [Google Scholar] [CrossRef]

| Number of cycles (N) | 500, 1000, 1500, 2000, 3000 |

| Maximum impact force (N) | 10 |

| Amplitude in x-direction (μm) | 100 |

| Amplitude in z-direction (μm) | 200 |

| Frequency (Hz) | x: 4, z: 4 |

| Temperature (°C) | 25 |

| Number of experiments | 3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, M.; Wang, W.; He, W.; Cai, Z. Impact-Sliding Tribology Behavior of TC17 Alloy Treated by Laser Shock Peening. Materials 2018, 11, 1229. https://doi.org/10.3390/ma11071229

Yin M, Wang W, He W, Cai Z. Impact-Sliding Tribology Behavior of TC17 Alloy Treated by Laser Shock Peening. Materials. 2018; 11(7):1229. https://doi.org/10.3390/ma11071229

Chicago/Turabian StyleYin, Meigui, Wenjian Wang, Weifeng He, and Zhenbing Cai. 2018. "Impact-Sliding Tribology Behavior of TC17 Alloy Treated by Laser Shock Peening" Materials 11, no. 7: 1229. https://doi.org/10.3390/ma11071229

APA StyleYin, M., Wang, W., He, W., & Cai, Z. (2018). Impact-Sliding Tribology Behavior of TC17 Alloy Treated by Laser Shock Peening. Materials, 11(7), 1229. https://doi.org/10.3390/ma11071229