Anisotropy of Transport Properties Correlated to Grain Boundary Density and Quantified Texture in Thick Oriented Ca3Co4O9 Ceramics

Abstract

1. Introduction

2. Fabrication of Textured Ca3Co4O9 Ceramic Stacks

- (i)

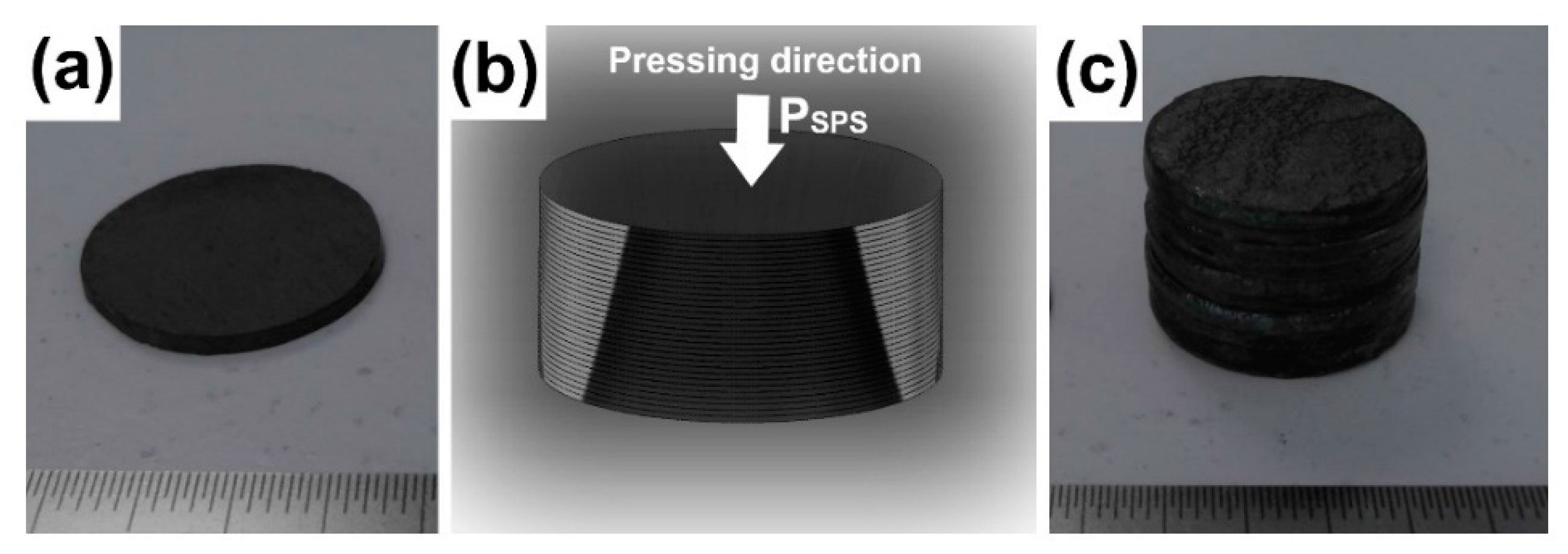

- A 2 mm-thick pellet (Figure 1a) was prepared using the SPS process as follows: The Ca3Co4O9 powder was poured into a graphite mould with an inner diameter of 13 mm. A pulsed electric current (2500 A, 4 V) was injected through the mould to heat the material up to the dwell temperature TSPS = 1173 K while keeping it under a uniaxial pressure PSPS = 50 MPa for tSPS = 2 min under vacuum (10−3 bar).

- (ii)

- Using the SPT process, a 0.7 mm-thick sample was elaborated similarly to the SPS one but with an edge-free mould. First, the Ca3Co4O9 powder was cold-compacted in a 13 mm-diameter mould and naturally sintered at 1173 K for 2 h. The obtained preform was then placed in the centre of a graphite mould with a larger diameter of 20 mm and was made to undergo the same experimental conditions (TSPS, PSPS, tSPS) applied in the case of the single SPS samples. The idea here was to allow free deformation and orientation of the grains with the purpose of inducing a prominent grain growth and texture, respectively.A batch of single SPT-processed pellets were mirror-polished and also stacked along their mean c*-axis before being treated in the same conditions as the SPS stack.

- (iii)

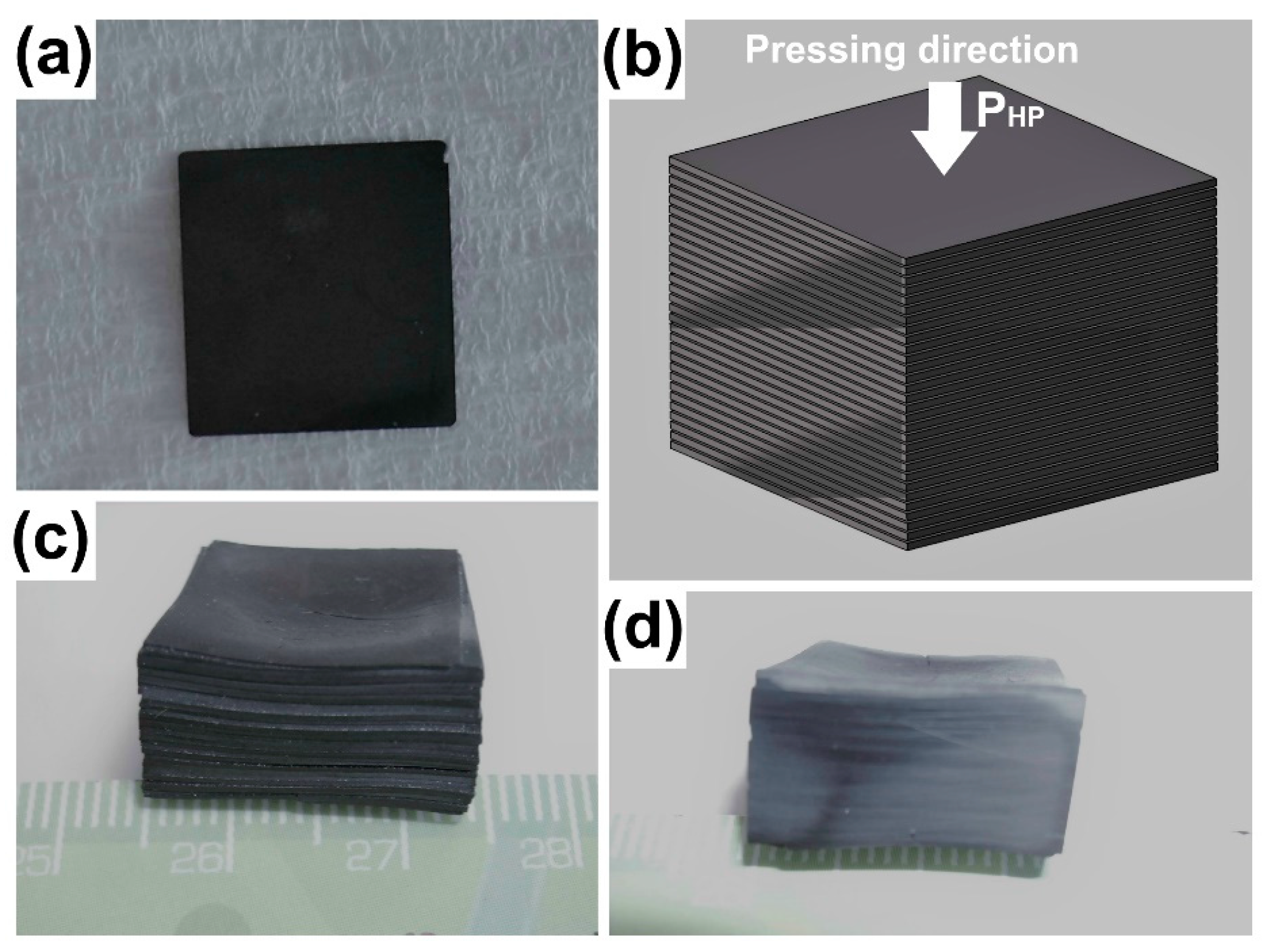

- On the other hand, 0.5 mm-thick samples were prepared using the HP process. The Ca3Co4O9 powder was first cold-compacted into 4 mm-thick and 25-mm diameter pellets. The pellet was set in a homemade furnace between two silver foils to avoid an undesirable reaction with the alumina bearing plates. The sample was then heated to the dwell temperature of PHP = 1193 K and maintained for tHP = 24 h under a uniaxial pressure PHP = 30 MPa under air atmosphere.

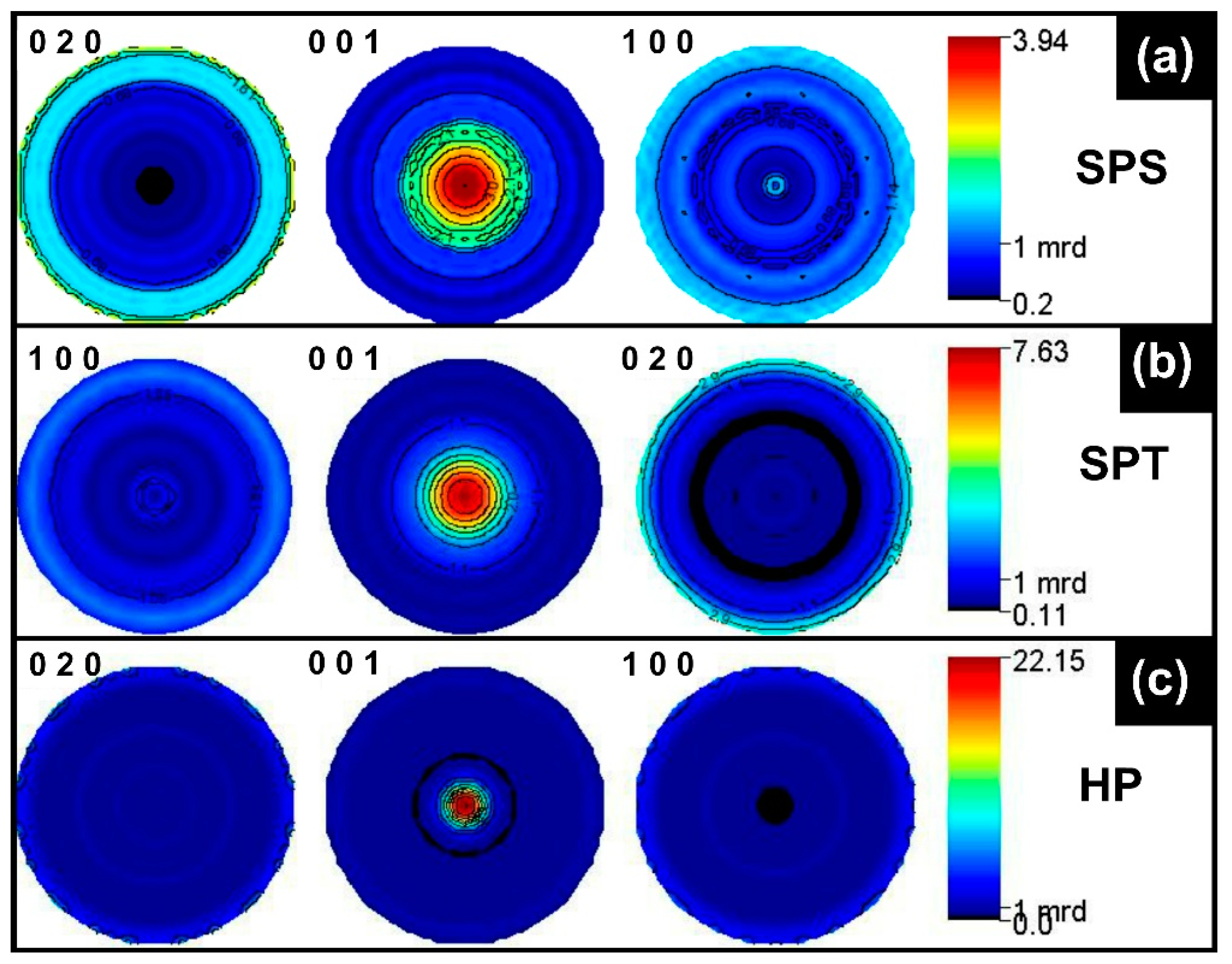

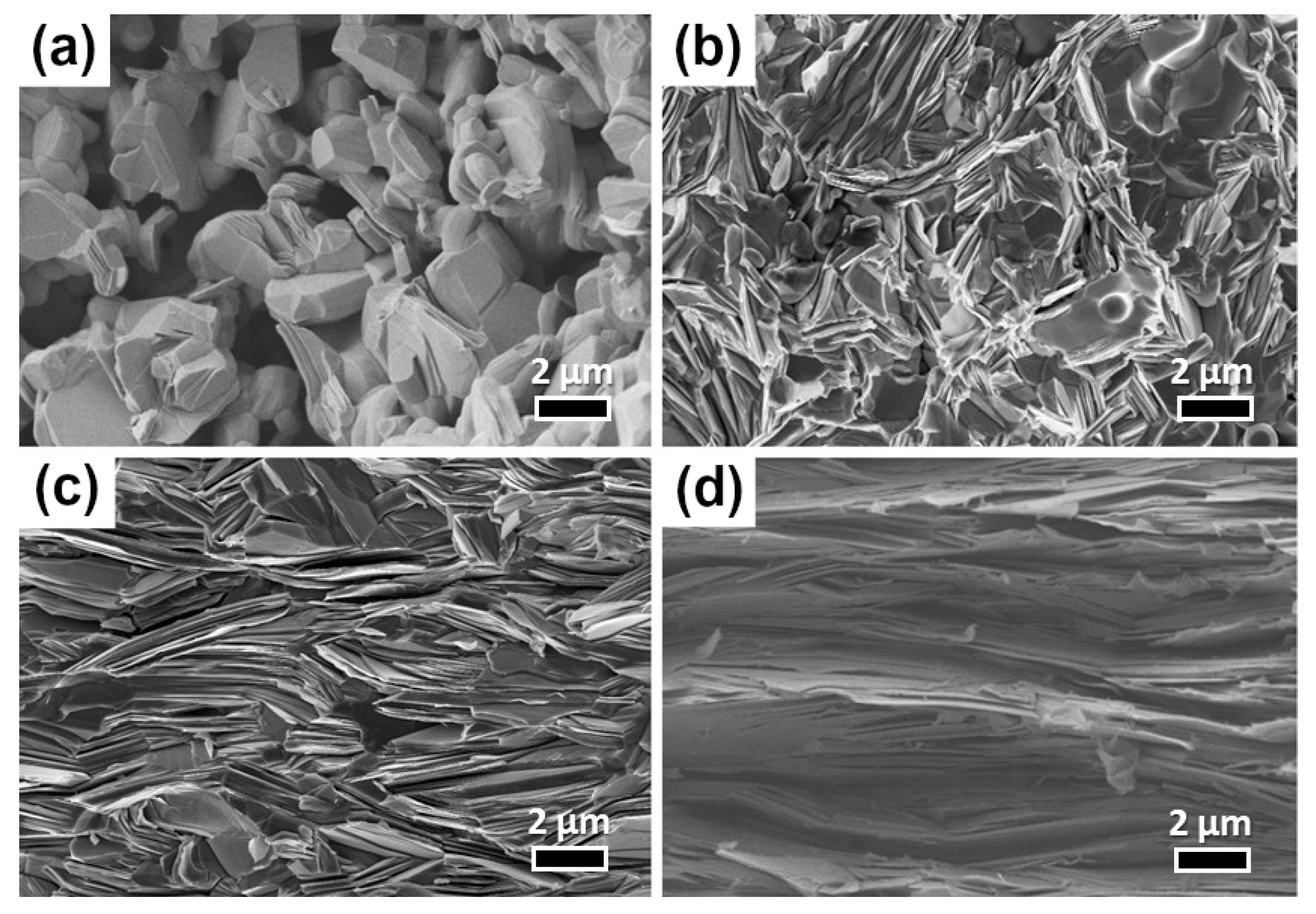

3. Quantified Crystallographic Texture and Microstructure

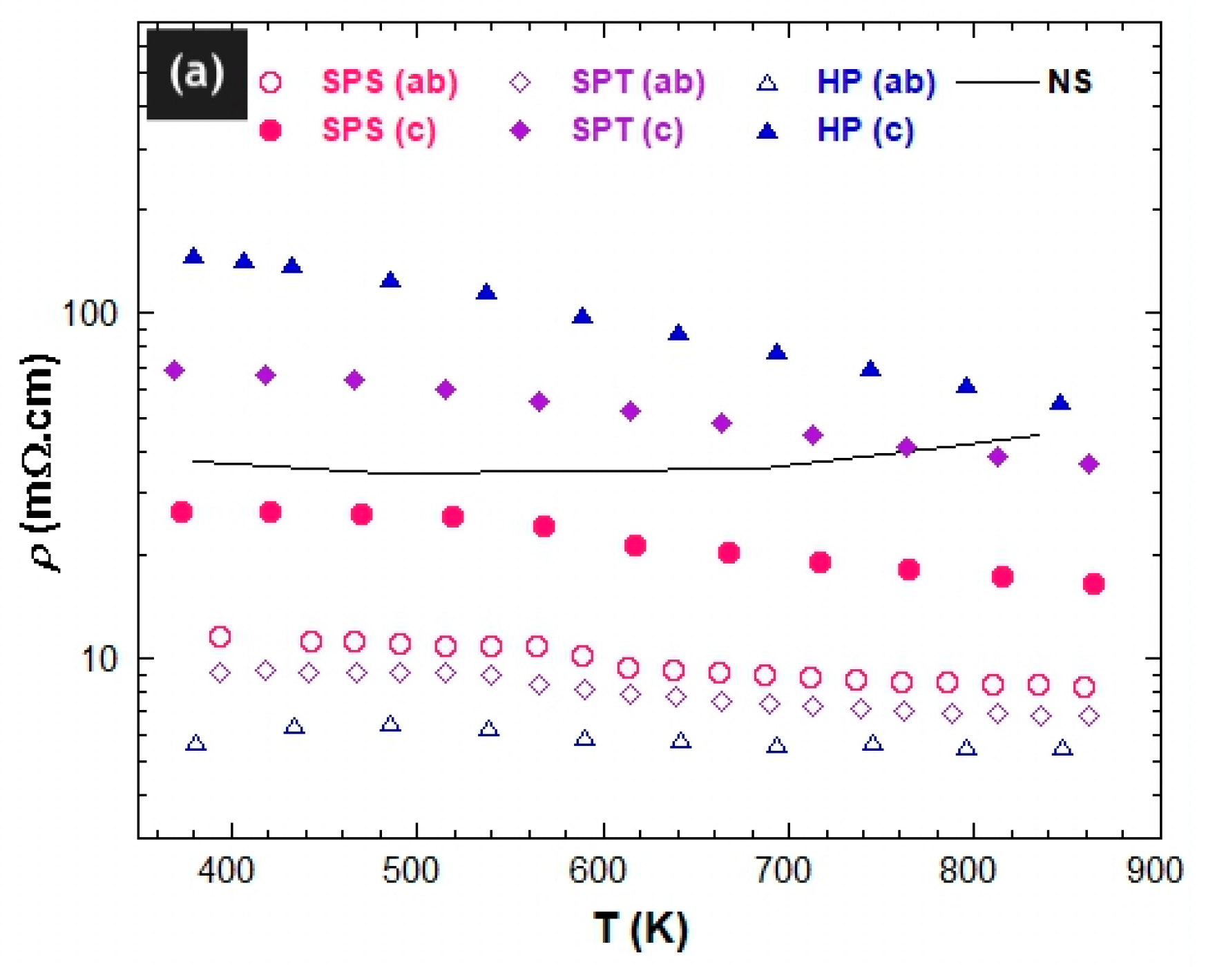

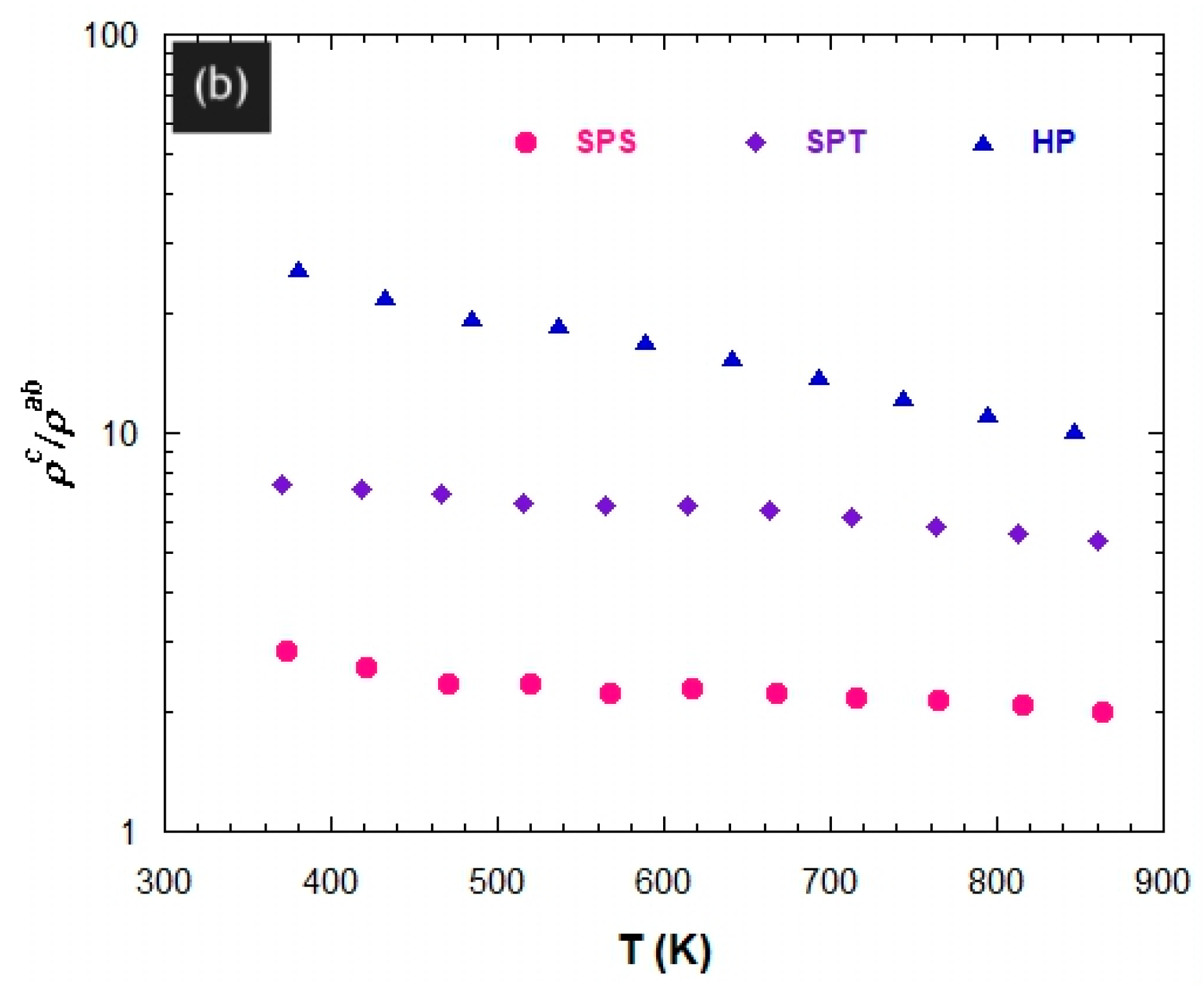

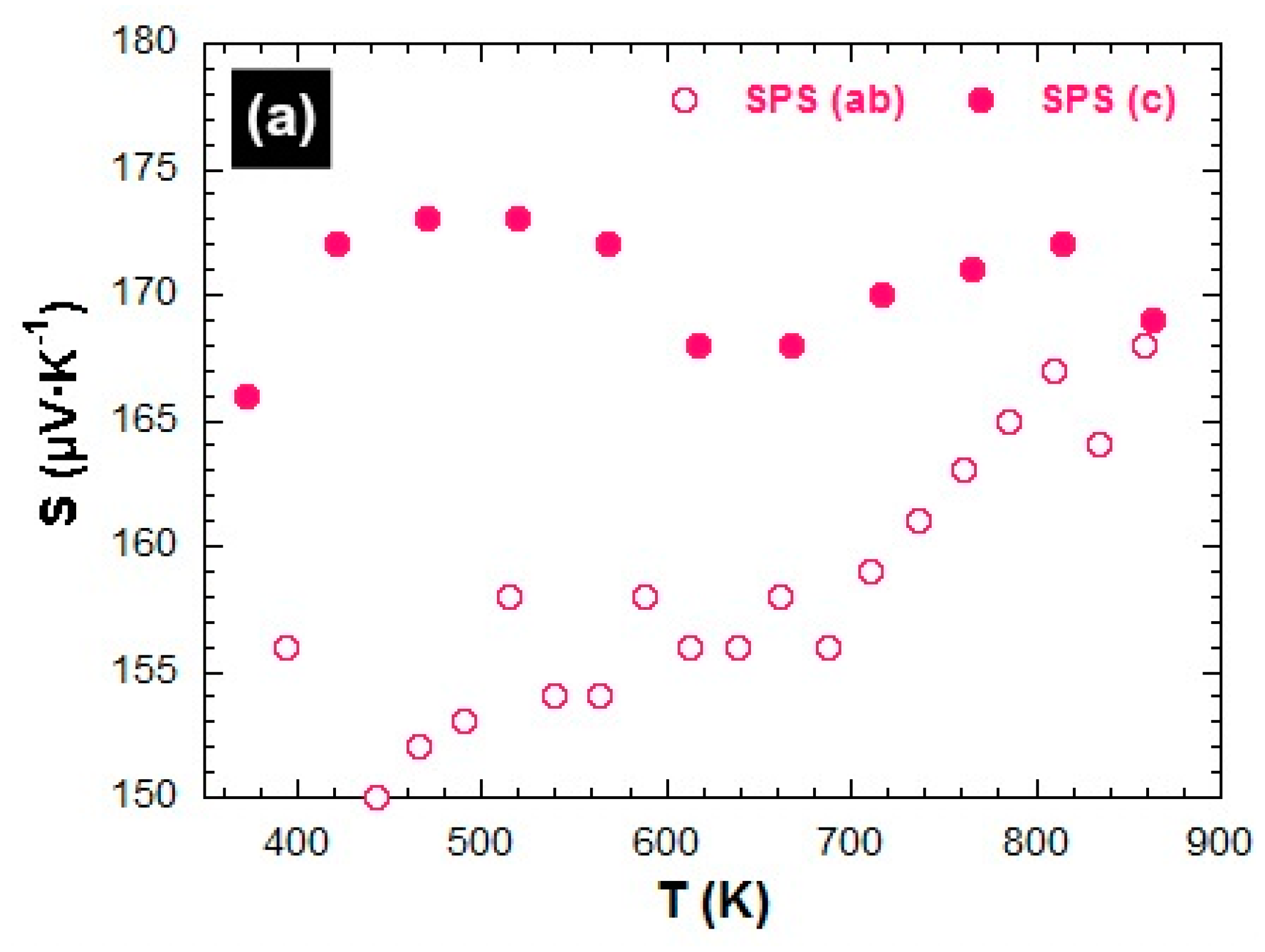

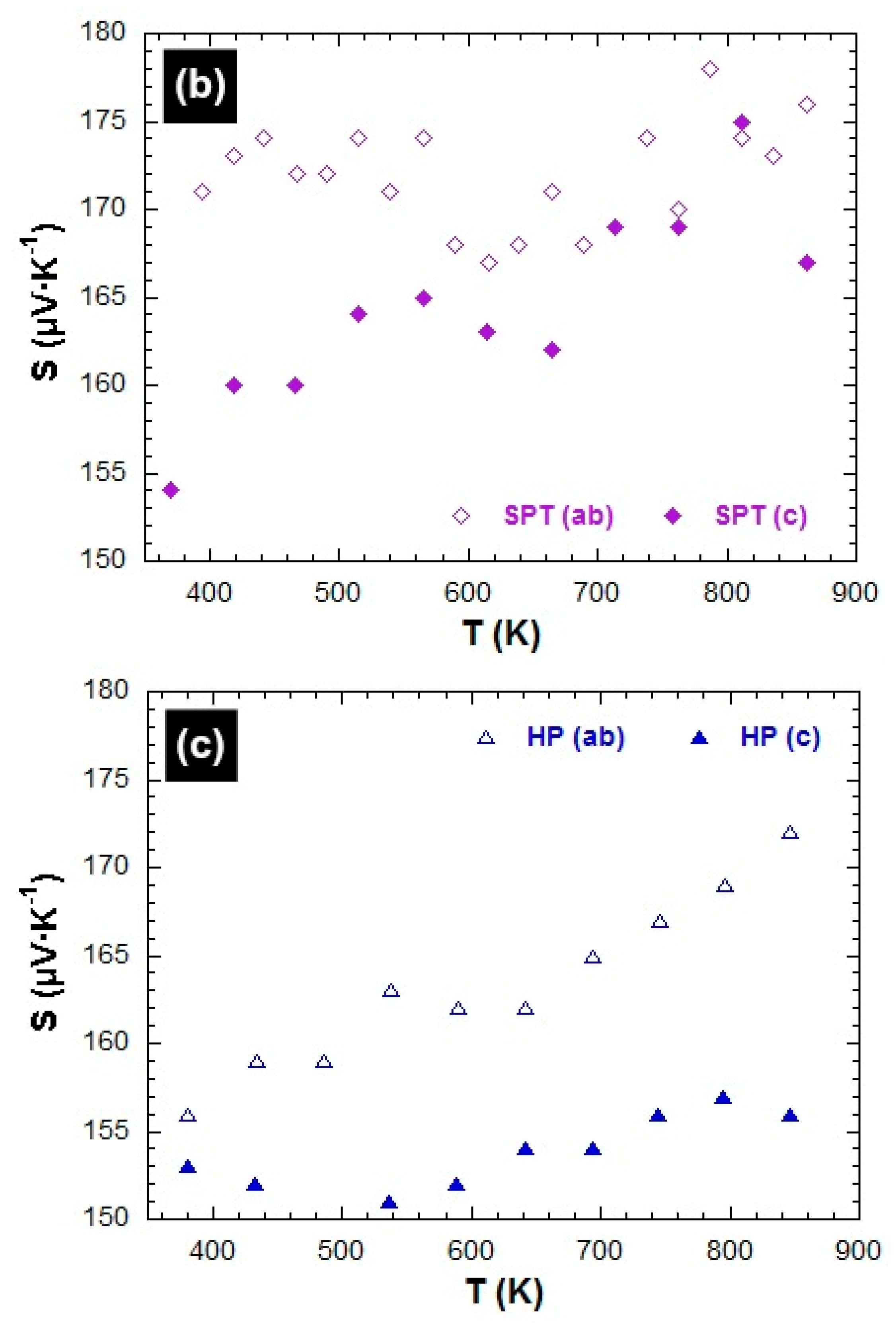

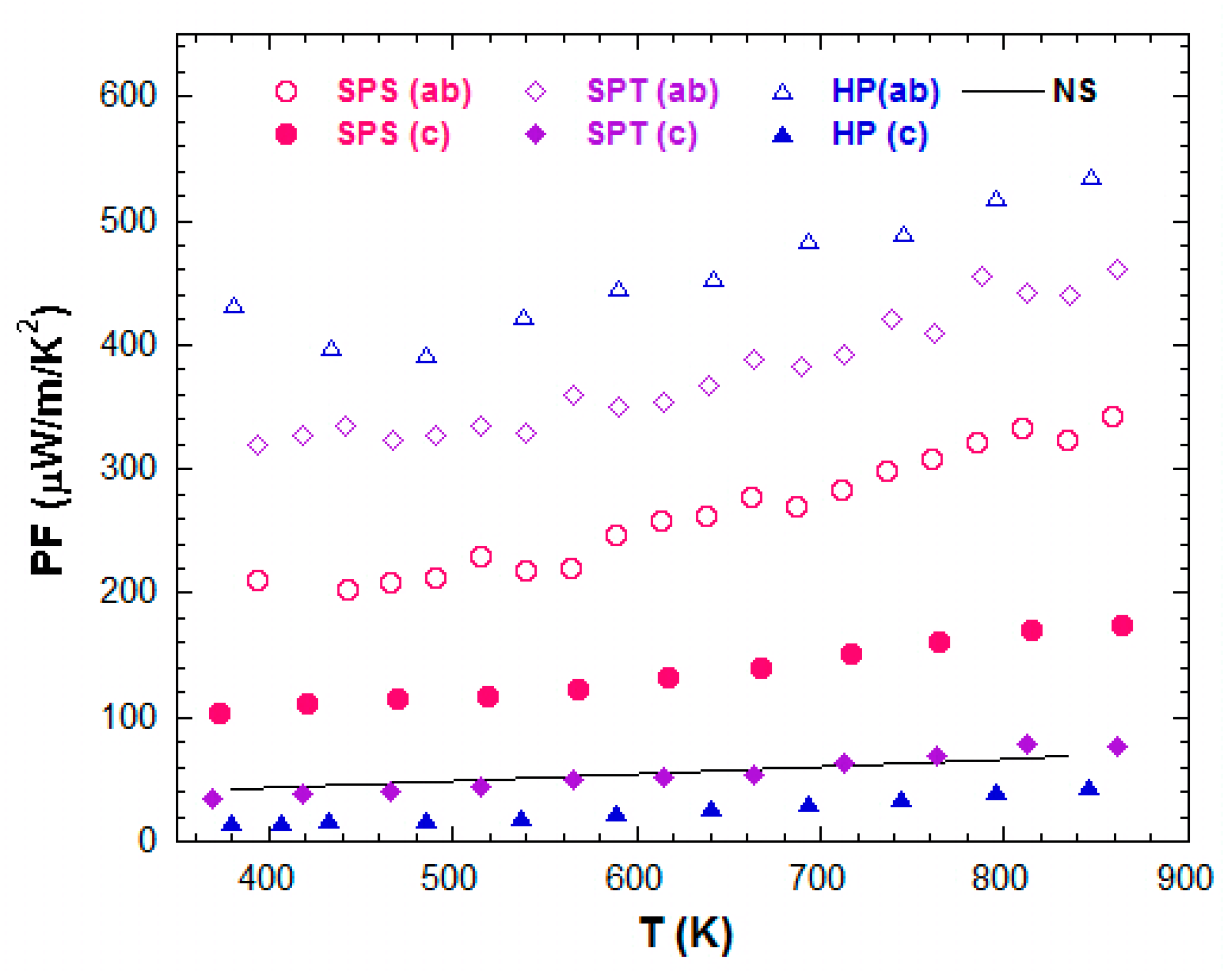

4. Anisotropy of Transport Properties

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- LeBlanc, S. Thermoelectric generators: Linking material properties and systems engineering for waste heat recovery applications. Sustain. Mater. Technol. 2014, 1, 26–35. [Google Scholar] [CrossRef]

- Bell, L.E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 2008, 321, 1457–1461. [Google Scholar] [CrossRef] [PubMed]

- Slack, G.A. CRC Handbook of Thermoelectrics; Rowe, D.M., Ed.; CRC Press: New York, NY, USA, 1995; pp. 407–440. [Google Scholar]

- Biswas, K.; He, J.Q.; Blum, I.D.; Wu, C.I.; Hogan, T.; Seidman, D.N.; Dravid, V.P.; Kanatzidis, M.G. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 2012, 489, 414. [Google Scholar] [CrossRef] [PubMed]

- Heremans, J.P.; Wiendlocha, B.; Chamoire, A.M. Resonant levels in bulk thermoelectric semiconductors. Energy Environ. Sci. 2012, 5, 5510–5530. [Google Scholar] [CrossRef]

- Kanatzidis, M.G. Nanostructured Thermoelectrics: The New Paradigm? Chem. Mater. 2010, 22, 648–659. [Google Scholar] [CrossRef]

- Vineis, C.J.; Shakouri, A.; Majumdar, A.; Kanatzidis, M.G. Nanostructured Thermoelectrics: Big Efficiency Gains from Small Features. Adv. Mater. 2010, 22, 3970–3980. [Google Scholar] [CrossRef] [PubMed]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed]

- Zebarjadi, M.; Esfarjani, K.; Dresselhaus, M.S.; Ren, Z.F.; Chen, G. Perspectives on thermoelectrics: From fundamentals to device applications. Energy Environ. Sci. 2012, 5, 5147–5162. [Google Scholar] [CrossRef]

- Harnwunggmoung, A.; Kurosaki, K.; Muta, H.; Yamanaka, S. High-temperature thermoelectric properties of thallium-filled skutterudites. Appl. Phys. Lett. 2010, 96, 202107. [Google Scholar] [CrossRef]

- Cook, B.A.; Kramer, M.J.; Wei, X.; Harringa, J.L.; Levin, E.M. Nature of the cubic to rhombohedral structural transformation in (AgSbTe2)15(GeTe)85 thermoelectric material. J. Appl. Phys. 2007, 101, 053715. [Google Scholar] [CrossRef]

- Hsu, K.F.; Loo, S.; Guo, F.; Chen, W.; Dyck, J.S.; Uher, C.; Hogan, T.; Polychroniadis, E.K.; Kanatzidis, M.G. Cubic AgPbmSbTe2+m: Bulk Thermoelectric Materials with High Figure of Merit. Science 2004, 303, 818–821. [Google Scholar] [CrossRef] [PubMed]

- Caillat, T.; Fleurial, J.; Borshchevsk, A. Preparation and thermoelectric properties of semiconducting Zn4Sb3. J. Phys. Chem. Solids 1997, 58, 1119–1125. [Google Scholar] [CrossRef]

- Terasaki, I.; Sasago, Y.; Uchinokura, K. Large thermoelectric power in NaCo2O4 single crystals. Phys. Rev. B 1997, 56, R12685–R12687. [Google Scholar] [CrossRef]

- Masset, A.C.; Michel, C.; Maignan, A.; Hervieu, M.; Toulemonde, O.; Studer, F.; Raveau, B.; Hejtmanek, J. Misfit-layered cobaltite with an anisotropic giant magnetoresistance: Ca3Co4O9. Phys. Rev. B 2000, 62, 166–175. [Google Scholar] [CrossRef]

- Fujita, K.; Mochida, T.; Nakamura, K. High-temperature thermoelectric properties of NaxCoO2−δ Single Crystals. Jpn. J. Appl. Phys. 2001, 40, 4644–4647. [Google Scholar] [CrossRef]

- Koumoto, K.; Terasaki, I.; Funahashi, R. Complex oxide materials for potential thermoelectric applications. Mater. Res. Soc. Bull. 2006, 31, 206–210. [Google Scholar] [CrossRef]

- Ohta, S.; Nomura, T.; Ohta, H.; Hirano, M.; Hosono, H.; Koumoto, K. Large thermoelectric performance of heavily Nb-doped SrTiO3 epitaxial film at high temperatura. Appl. Phys. Lett. 2005, 87, 092108. [Google Scholar] [CrossRef]

- Ohtaki, M.; Tsubota, T.; Eguchi, K.; Arai, H. High-temperature thermoelectric properties of (Zn1−xAlx)O. J. Appl. Phys. 1996, 79, 1816–1818. [Google Scholar] [CrossRef]

- Bérardan, D.; Guilmeau, E.; Maignan, A.; Raveau, B. In2O3: Ge, a promising n-type thermoelectric oxide composite. Solid State Commun. 2008, 146, 97–101. [Google Scholar] [CrossRef]

- Fergus, J.W. Oxide materials for high thermoelectric energy conversion. J. Eur. Ceram. Soc. 2012, 32, 525–540. [Google Scholar] [CrossRef]

- Wang, Y.; Sui, Y.; Cheng, J.; Wang, X. Efficient room temperature thermoelectric characteristics of Ca3−xAgxCo4O9+δ/Agy composites. J. Phys. D Appl. Phys. 2008, 41, 045406. [Google Scholar] [CrossRef]

- Masuda, Y.; Nagahama, D.; Itahara, H.; Tani, T.; Seoc, W.S.; Koumotoa, K. Thermoelectric performance of Bi- and Na-substituted Ca3Co4O9 improved through ceramic texturing. J. Mater. Chem. 2003, 13, 1094–1099. [Google Scholar] [CrossRef]

- Kenfaui, D.; Chateigner, D.; Gomina, M.; Noudem, J.G. Anisotropy of the mechanical and thermoelectric properties of hot-pressed single-layer and multilayer thick Ca3Co4O9 ceramics. Int. J. Appl. Ceram. Technol. 2011, 8, 214–226. [Google Scholar] [CrossRef]

- Kenfaui, D.; Bonnefont, G.; Chateigner, D.; Fantozzi, G.; Gomina, M.; Noudem, J.G. Ca3Co4O9 ceramics consolidated by SPS process: Optimization of mechanical and thermoelectric properties. Mater. Res. Bull. 2010, 45, 1240–1249. [Google Scholar] [CrossRef]

- Noudem, J.G.; Kenfaui, D.; Chateigner, D.; Gomina, M. Granular and lamellar thermoelectric oxides consolidated by spark plasma sintering. J. Electron. Mater. 2011, 40, 1100–1106. [Google Scholar] [CrossRef]

- Kenfaui, D.; Chateigner, D.; Gomina, M.; Noudem, J. Texture, mechanical and thermoelectric properties of Ca3Co4O9 ceramics. J. Alloy. Comp. 2010, 490, 472–479. [Google Scholar] [CrossRef]

- Kenfaui, D.; Gomina, M.; Chateigner, D.; Noudem, J.G. Mechanical properties of Ca3Co4O9 bulk oxides intended to be used in thermoelectric generators. Ceram. Int. 2014, 40, 10237–10246. [Google Scholar] [CrossRef]

- Noudem, J.G.; Kenfaui, D.; Chateigner, D.; Gomina, M. Toward the enhancement of thermoelectric properties of lamellar Ca3Co4O9 by edge-free spark plasma texturing. Scr. Mater. 2012, 66, 258–260. [Google Scholar] [CrossRef]

- Ricote, J.; Chateigner, D. Quantitative texture analysis applied to the study of preferential orientations in ferroelectric thin films, Bol. Soc. Esp. Ceram. Vidrio. 1999, 38, 587–591. [Google Scholar] [CrossRef]

- Chateigner, D. Combined Analysis; Wiley-ISTE: London, UK, 2010; 496p. [Google Scholar]

- Lutterotti, L.; Matthies, S.; Wenk, H. MAUD (Material Analysis Using Diffraction): A User Friendly Java Program for Rietveld Texture Analysis and More; Spunar, J.A., Ed.; National Research Council of Canada: Ottawa, ON, Canada, 1999; pp. 1599–1604. [Google Scholar]

- Lutterotti, L.; Chateigner, D.; Ferrari, S.; Ricote, J. Texture, residual stress and structural analysis of thin films using a combined X-ray analysis. Thin Solid Films 2004, 450, 34–41. [Google Scholar] [CrossRef]

- Guilmeau, E.; Chateigner, D.; Noudem, J.; Funahashi, R.; Horii, S.; Ouladdiaf, B. Rietveld texture analysis of complex oxides: examples of polyphased Bi2223 superconducting and Co349 thermoelectric textured ceramics characterization using neutron and X-ray diffraction. J. Appl. Cryst. 2005, 38, 199–210. [Google Scholar] [CrossRef]

- Muguerra, H.; Grebille, D. An original disorder-order transition related to electronic and magnetic properties in the thermoelectric misfit phase [Ca2CoO3][CoO2]1.62. Acta Cryst. B 2008, 64, 676–683. [Google Scholar] [CrossRef] [PubMed]

- Ohta, H.; Sugiura, K.; Koumoto, K. Recent progress in oxide thermoelectric materials: p-type Ca3Co4O9 and n-type SrTiO3. Inorg. Chem. 2008, 47, 8429–8436. [Google Scholar] [CrossRef] [PubMed]

- Sugiura, K.; Ohta, H.; Nomura, K.; Hirano, M.; Hosono, H.; Koumoto, K. High electrical conductivity of layered cobalt oxide Ca3Co4O9 epitaxial films grown by topotactic ion-exchange method. Appl. Phys. Lett. 2006, 89, 032111. [Google Scholar] [CrossRef]

- Sugiura, K.K.; Ohta, H.; Nomura, K.; Saito, T.; Ikuhara, Y.; Hirano, M.; Hosono, H.; Koumoto, K. Thermoelectric Properties of the Layered Cobaltite Ca3Co4O9 Epitaxial Films Fabricated by Topotactic Ion-Exchange Method. Mater. Trans. 2007, 48, 2104–2107. [Google Scholar] [CrossRef]

- Sakai, A.; Kanno, T.; Yotsuhashi, S.; Odagawa, A.; Adachi, H. Control of Epitaxial Growth Orientation and Anisotropic Thermoelectric Properties of Misfit-Type Ca3Co4O9 Thin Films. Jpn. J. Appl. Phys. 2005, 44, L966. [Google Scholar] [CrossRef]

- Tang, G.D.; Guo, H.H.; Yang, T.; Zhang, D.W.; Xu, X.N.; Wang, L.Y.; Wang, Z.H.; Wen, H.H.; Zhang, Z.D.; Du, Y.W. Anisotropic thermopower and magnetothermopower in a misfit-layered calcium cobaltite. Appl. Phys. Lett. 2011, 98, 202109. [Google Scholar] [CrossRef]

- Schrade, M.; Fjeld, H.; Norby, T.; Finstad, T.G. Versatile apparatus for thermoelectric characterization of oxides at high temperatures. Rev. Sci. Inst. 2014, 85, 103906. [Google Scholar] [CrossRef] [PubMed]

- Nye, J.F. Physical Properties of Crystals: Their Representation by Tensors and Matrices; Lavoisier: Paris, France, 1985. [Google Scholar]

- Grimmer, H. General relations for transport properties in magnetically ordered crystals. Acta Cryst. 1993, 49, 763–771. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Lu, Q. Synthesis of highly textured Ca3Co4O9 ceramics by spark plasma sintering. Ceram. Int. 2007, 33, 1305–1308. [Google Scholar] [CrossRef]

- Tani, T.; Itahara, H.; Xia, C.; Sugiyama, J. Topotactic synthesis of highly-textured thermoelectric cobaltites. J. Mater. Chem. 2003, 13, 1865–1867. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kenfaui, D.; Gomina, M.; Noudem, J.G.; Chateigner, D. Anisotropy of Transport Properties Correlated to Grain Boundary Density and Quantified Texture in Thick Oriented Ca3Co4O9 Ceramics. Materials 2018, 11, 1224. https://doi.org/10.3390/ma11071224

Kenfaui D, Gomina M, Noudem JG, Chateigner D. Anisotropy of Transport Properties Correlated to Grain Boundary Density and Quantified Texture in Thick Oriented Ca3Co4O9 Ceramics. Materials. 2018; 11(7):1224. https://doi.org/10.3390/ma11071224

Chicago/Turabian StyleKenfaui, Driss, Moussa Gomina, Jacques Guillaume Noudem, and Daniel Chateigner. 2018. "Anisotropy of Transport Properties Correlated to Grain Boundary Density and Quantified Texture in Thick Oriented Ca3Co4O9 Ceramics" Materials 11, no. 7: 1224. https://doi.org/10.3390/ma11071224

APA StyleKenfaui, D., Gomina, M., Noudem, J. G., & Chateigner, D. (2018). Anisotropy of Transport Properties Correlated to Grain Boundary Density and Quantified Texture in Thick Oriented Ca3Co4O9 Ceramics. Materials, 11(7), 1224. https://doi.org/10.3390/ma11071224