Fabrication and Mechanical Properties of Tungsten Inert Gas Welding Ring Welded Joint of 7A05-T6/5A06-O Dissimilar Aluminum Alloy

Abstract

1. Introduction

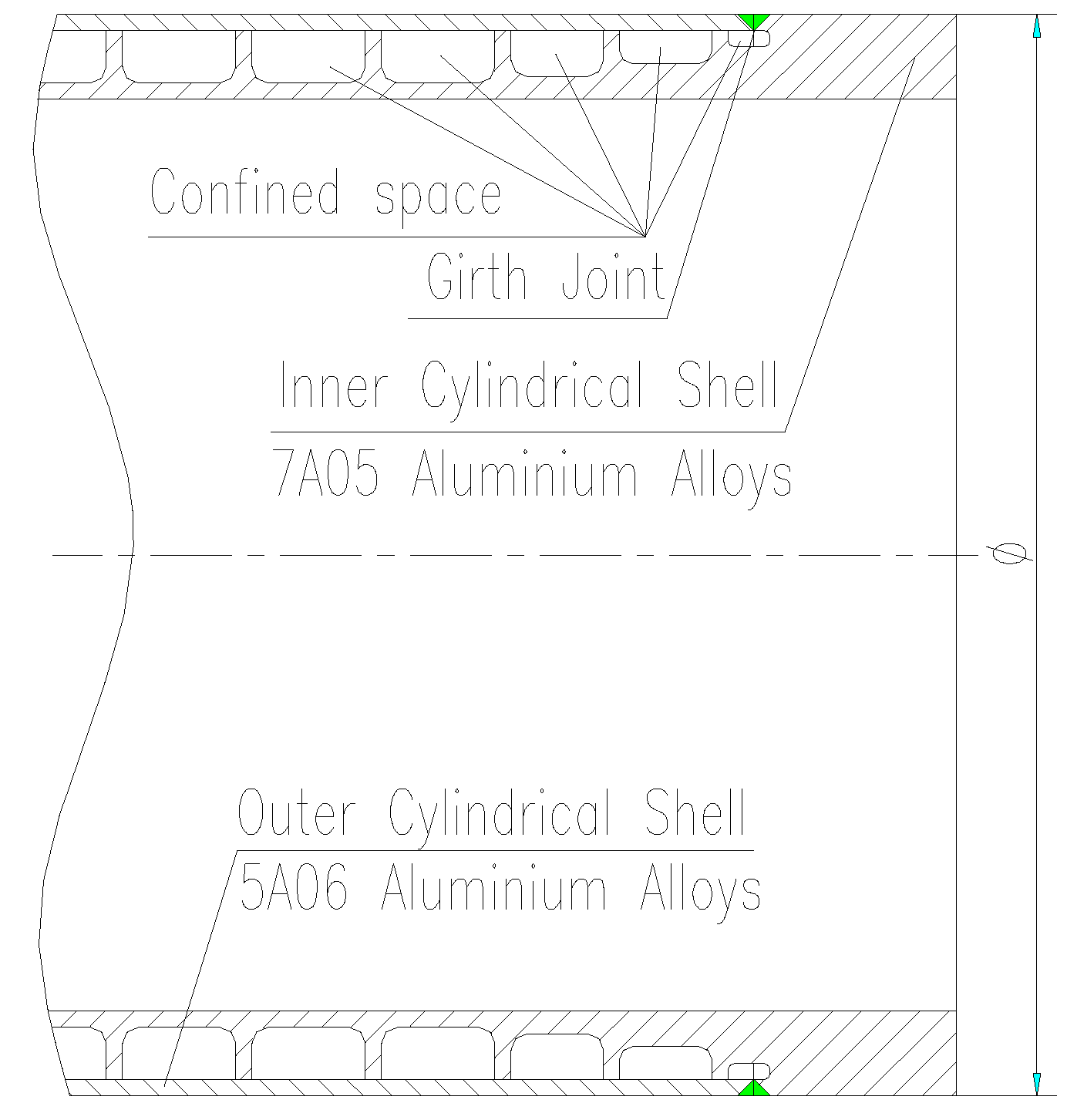

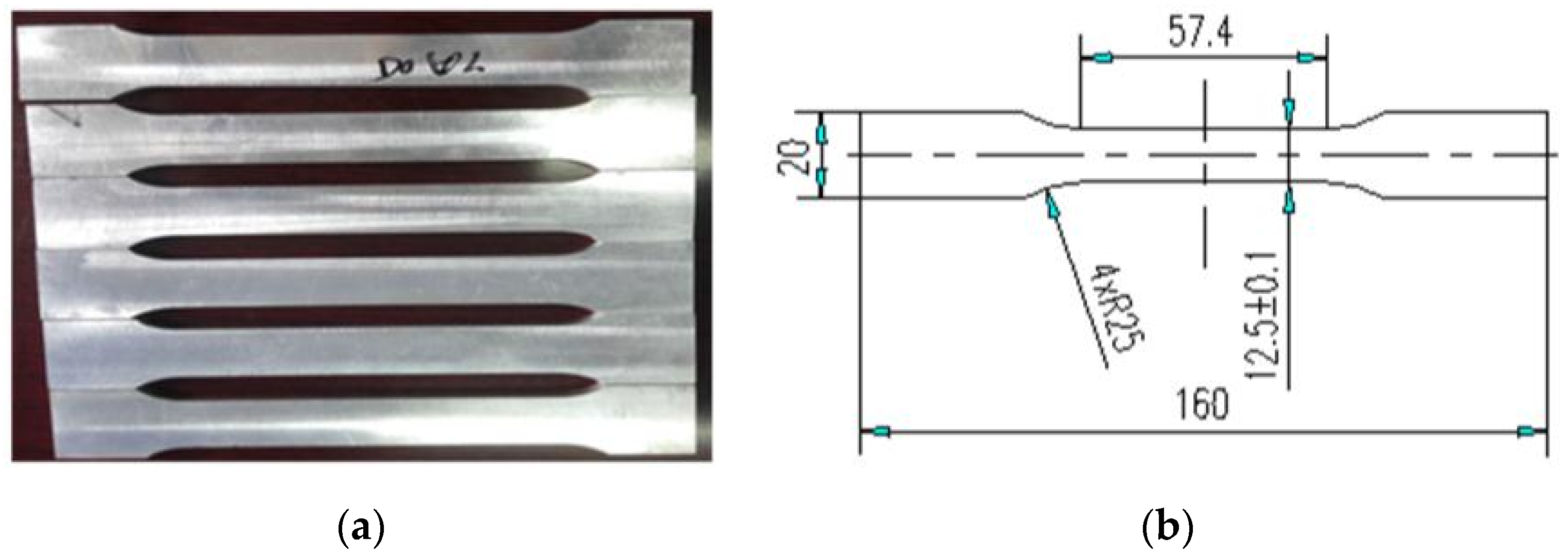

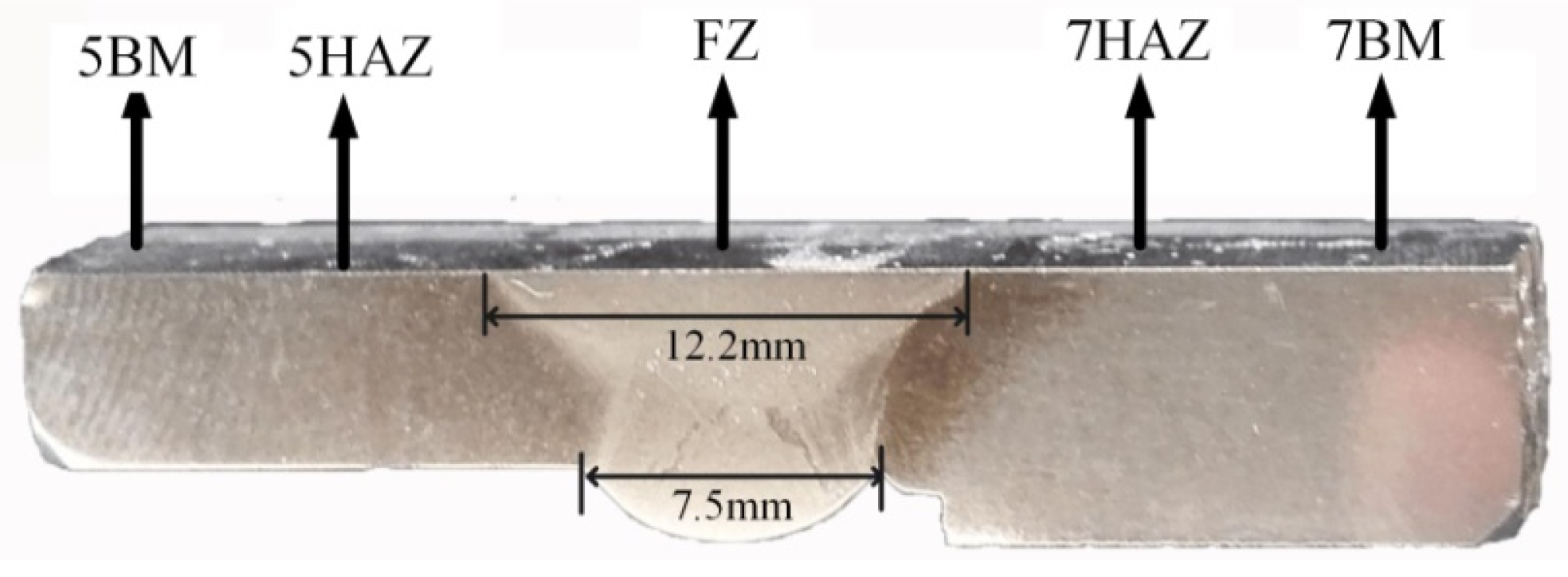

2. Materials and Methods

3. Results

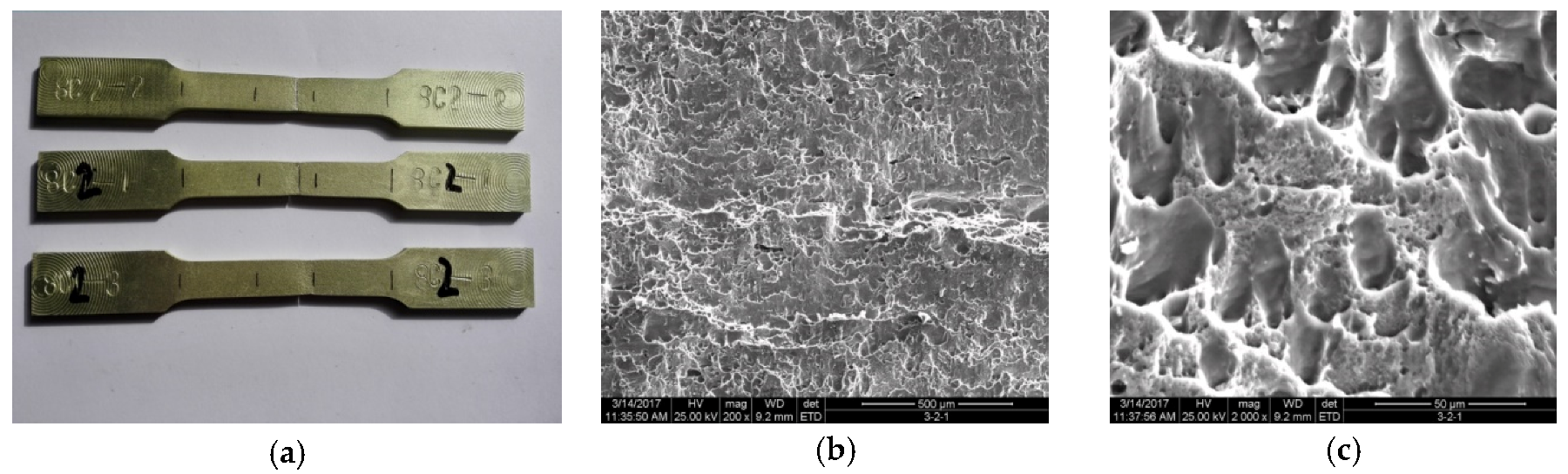

3.1. Mechanical Properties of the Welded Joints

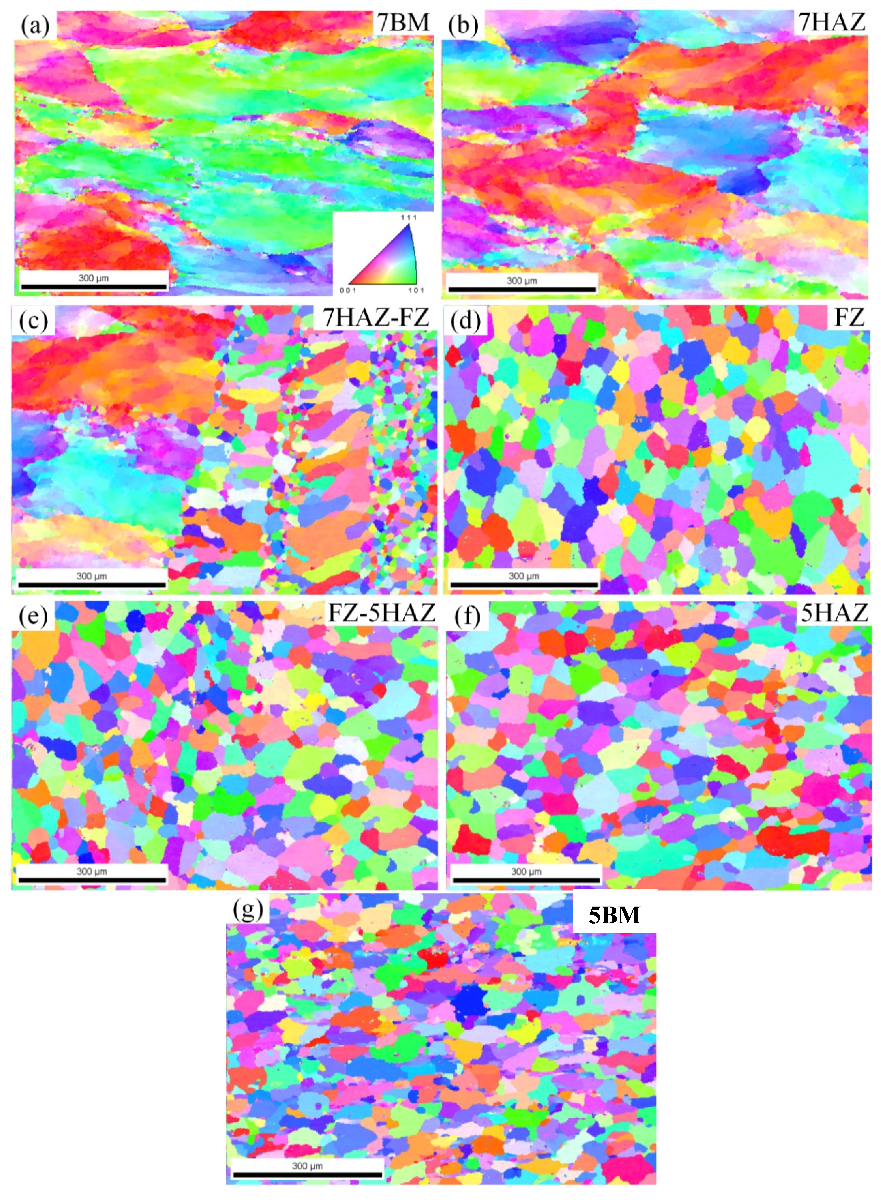

3.2. EBSD Analysis of the Grain Structure

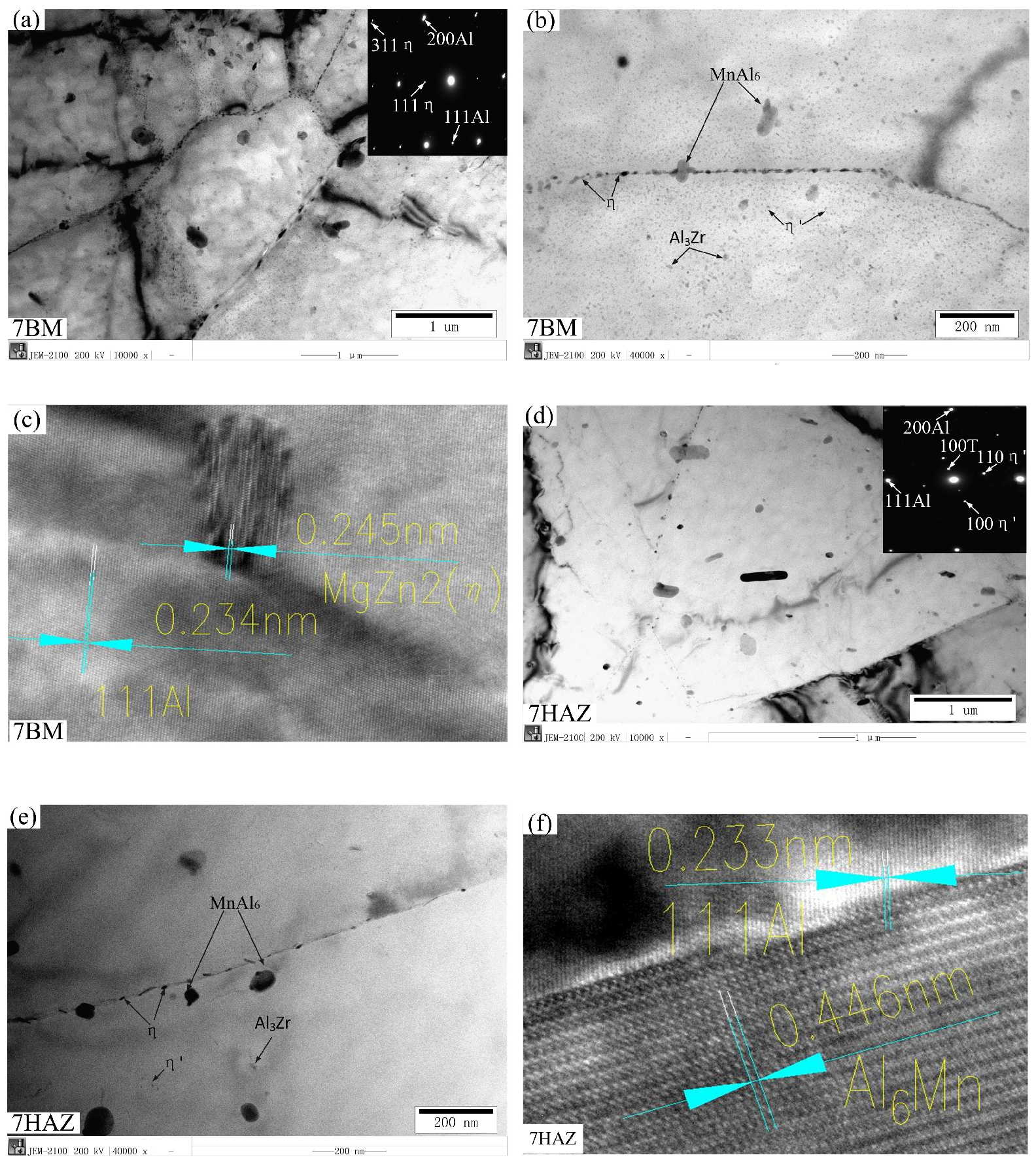

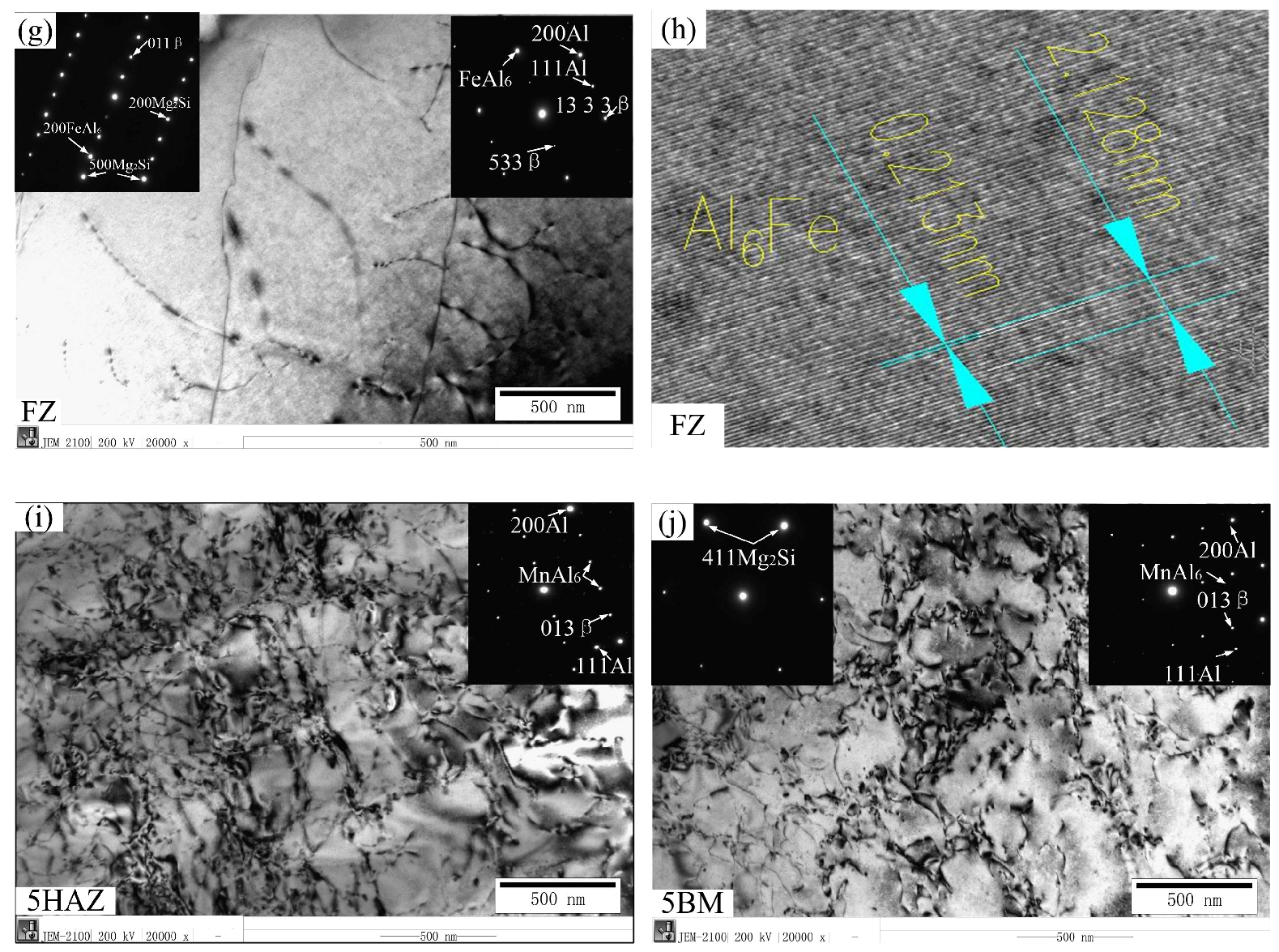

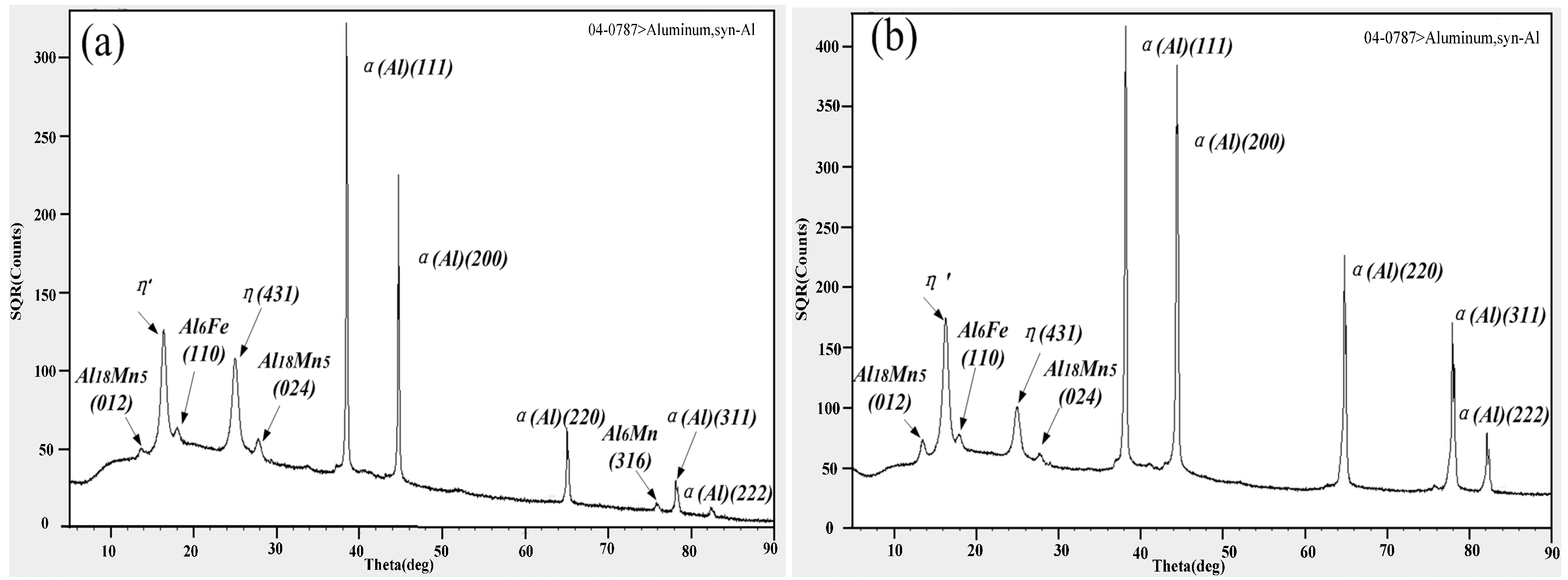

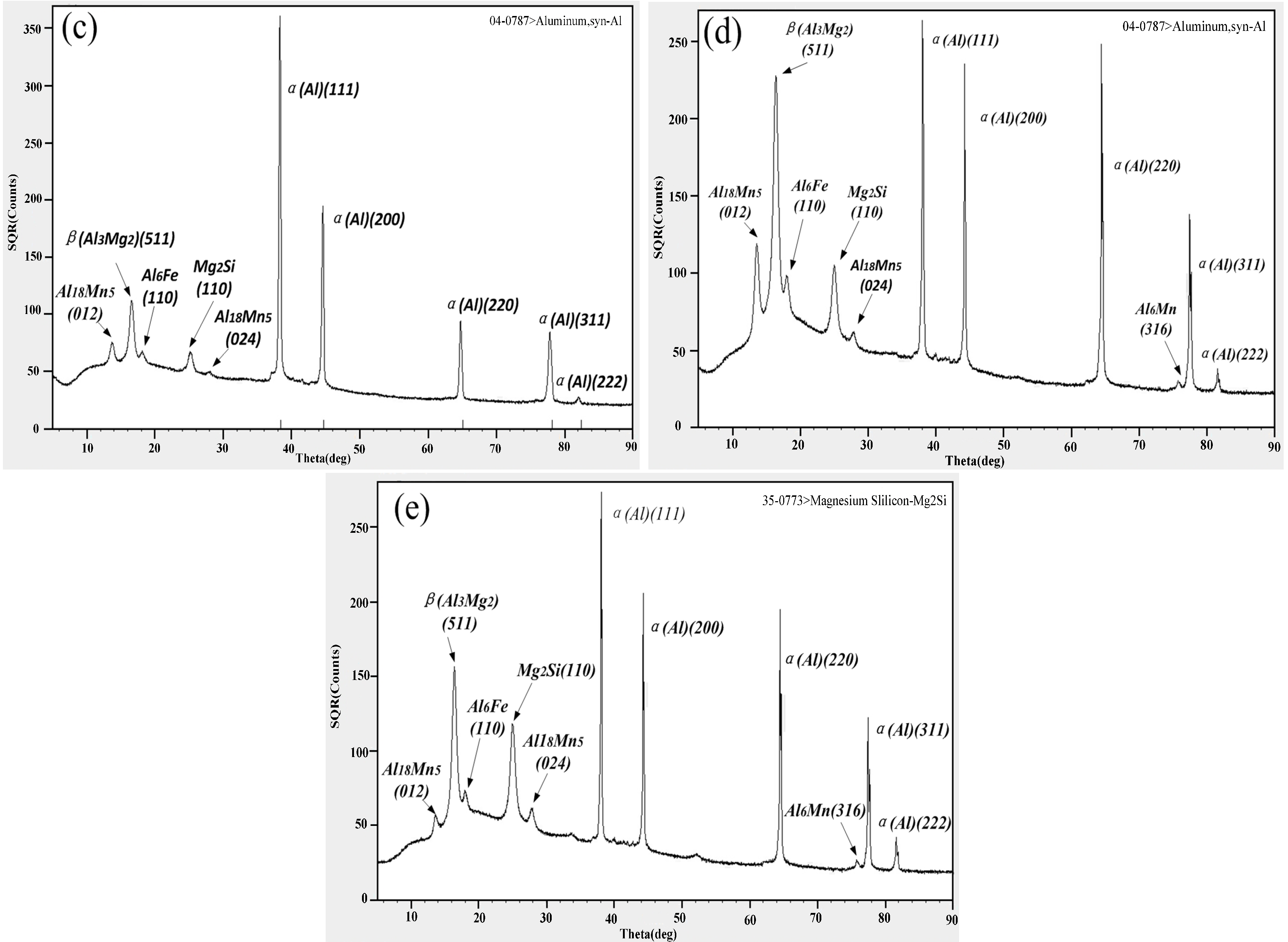

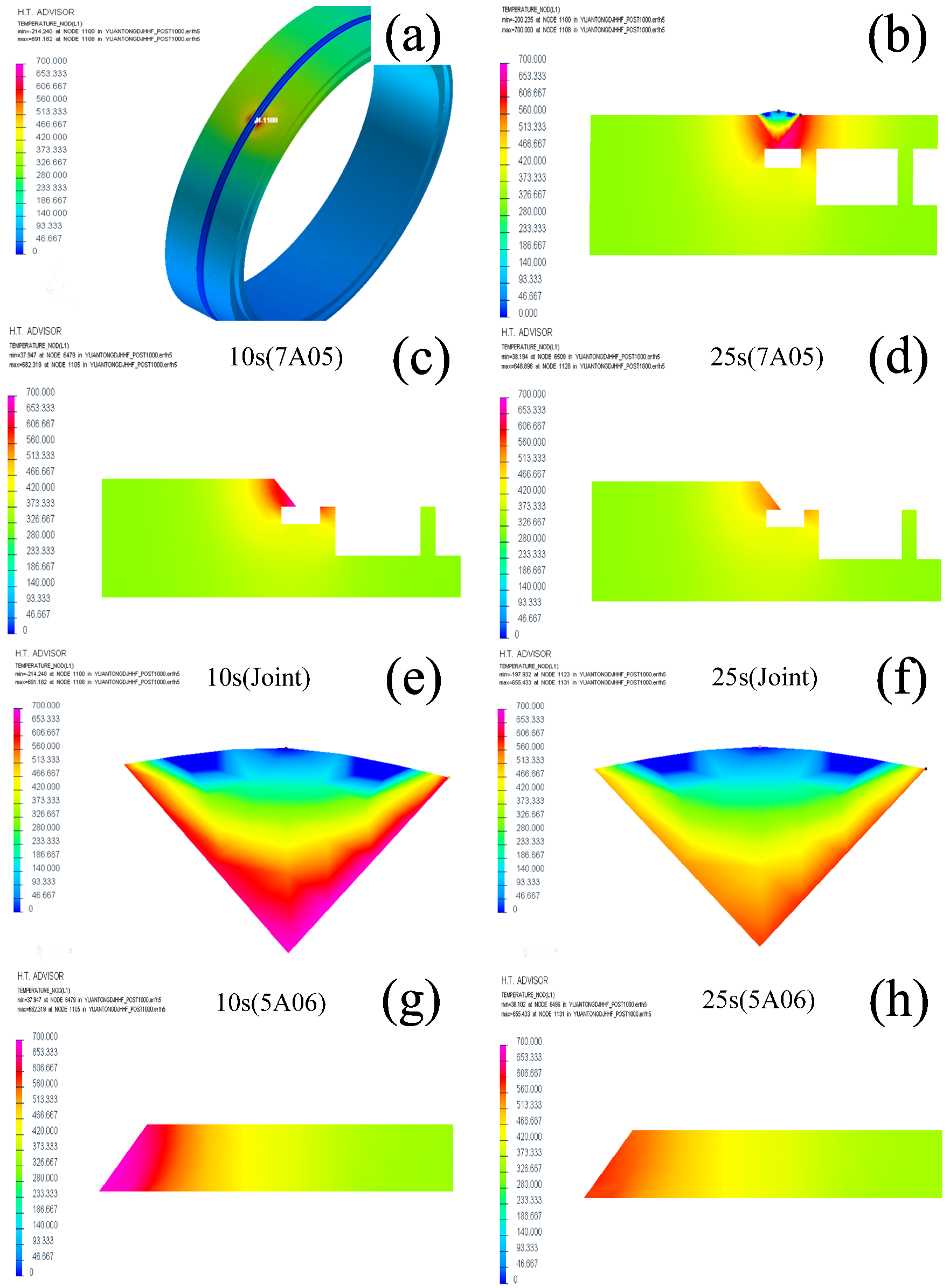

3.3. TEM and XRD Analysis of the Precipitate Structure

4. Discussion

5. Conclusions

- The tensile strength and yield strength of the welded joint reached 78.87% and 97.24% of the 5A06 base metal, respectively, and the elongation reached 84.29% of the 7A05-T6 base metal. Its mechanical properties after external hydraulic test and lifting test were verified to meet engineering requirements.

- The main reason for the weakest area of the weld zone is that the grain is coarsened in the region. The enhanced amount of precipitates is less or the strengthening phase dissolves during long periods of quenching, moreover, there are more iron-containing impurity phases.

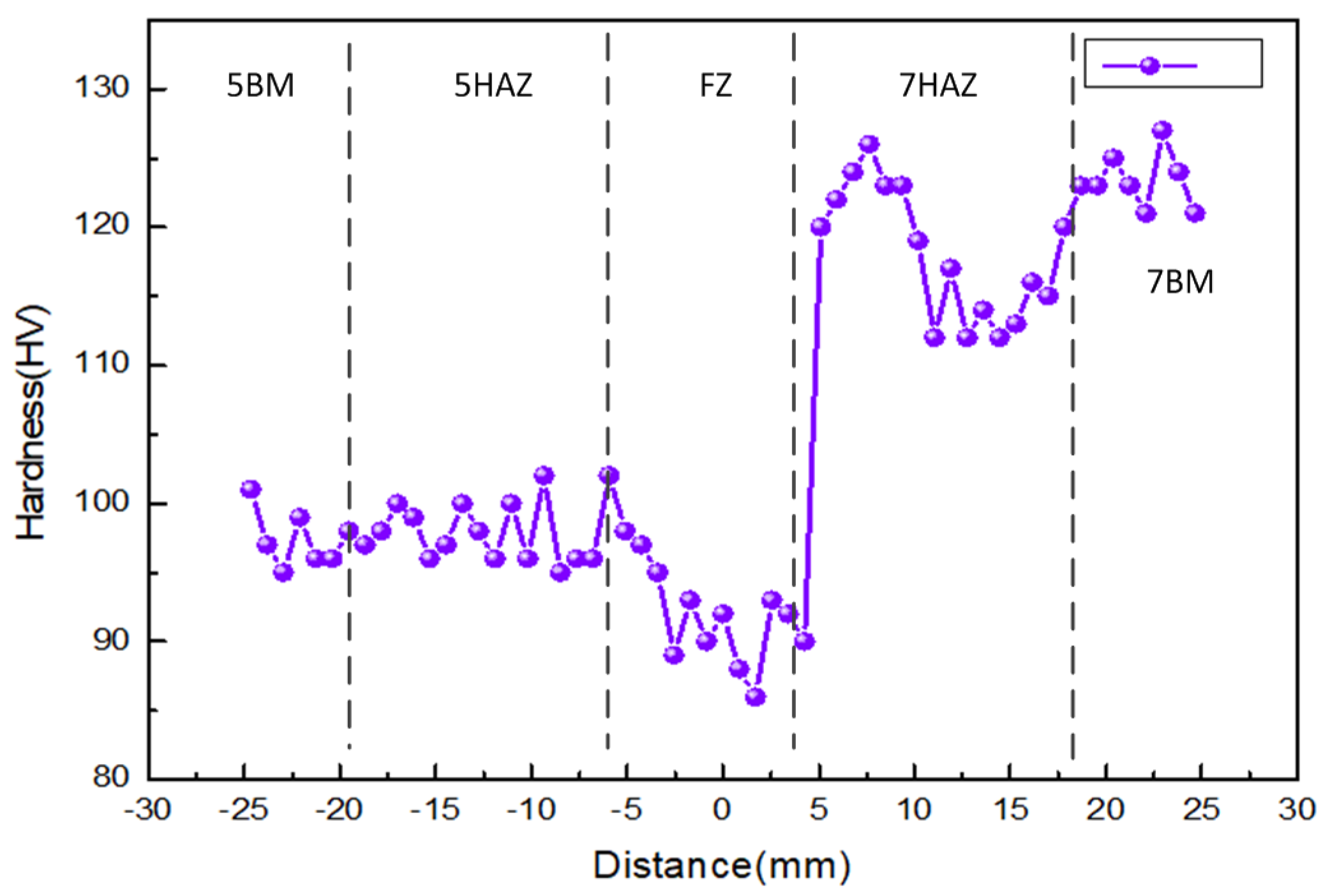

- The hardness curve of the welded joint is asymmetrical. The width of the weld is approximately 12 mm, and the hardness of the weld center is the lowest (about 86 HV). 7HAZ is divided into the quench zone and over-aging zone. The original precipitated phase of the quenching zone is dissolved in the aluminum matrix to form a supersaturated solid solution. After a period, the solid solution will precipitate η′ (MgZn2) phase, resulting in natural aging strengthening, and achieving a higher hardness. The hardness reduction occurred in the distance from the center of the weld 10–18 mm range, which is the over-aging area with a minimum value of about 110 HV. The reason is that over-aging area is far from the weld, and the temperature is higher than the aging temperature. 7A05, however, is lower than the solution treatment temperature of 7A05, resulting in η′ phase aggregation growing and coarsening. Moreover, η′ (MgZn2) enhanced phase dissolved fully and the dislocation density decreased rapidly, resulting in softening of the over-aging area due to the long quenching effect of 7HAZ area. However, the hardness of the softening area is higher than the weld zone, and the weld zone is still the weakest position of the welded joint.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fan, H.; Fang, D.; Chen, L.; Dai, Z.; Yang, W. Manufacturing and testing of a CFRC sandwich cylinder with Kagome cores. Compos. Sci. Technol. 2009, 69, 2695–2700. [Google Scholar] [CrossRef]

- Vasiliev, V.V.; Barynin, V.A.; Razin, A.F. Anisogrid composite lattice structures—Development and aerospace applications. Compos. Struct. 2012, 94, 1117–1127. [Google Scholar] [CrossRef]

- Vasiliev, V.V.; Razin, A.F. Anisogrid composite lattice structures for spacecraft and aircraft application. Compos. Struct. 2006, 76, 182–189. [Google Scholar] [CrossRef]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Sielski, R.A. Research needs in aluminum structure Ships. Offshore Struct. 2008, 3, 57–65. [Google Scholar] [CrossRef]

- Davis, J.R. Aluminum and Aluminum Alloys; ASM International: Almere, The Netherlands, 1993. [Google Scholar]

- Yang, B.; Yan, J.; Sutton, M.A.; Reynolds, A.P. Banded microstructure in AA2024-T351 and AA2524-T351 aluminum friction stir welds: Part I. Metallurgical studies. Mater. Sci. Eng. 2004, 364, 55–65. [Google Scholar] [CrossRef]

- Sutton, M.A.; Yang, B.; Reynolds, A.P.; Yan, J. Banded microstructure in 2024-T351 and 2524-T351 aluminum friction stir welds: Part II. Mechanical characterization. Mater. Sci. Eng. 2004, 364, 66–74. [Google Scholar] [CrossRef]

- Genevois, C.; Deschamps, A.; Vacher, P. Comparative study on local and global mechanical properties of 2024 T351,2024 T6 and 5251 O friction stir welds. Mater. Sci. Eng. 2006, 415, 162–170. [Google Scholar] [CrossRef]

- Giri, A.; Mahapatra, M.M. On the measurement of sub-surface residual stresses in SS 304L welds by dry ring core technique. Measurement 2017, 106, 152–160. [Google Scholar] [CrossRef]

- Kainuma, S.; Jeong, Y.S.; Yang, M.; Inokuchi, S. Welding residual stress in roots between deck plate and U-rib in orthotropic steel decks. Measurement 2016, 92, 475–482. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Nieslony, P.; Krolczyk, J.B.; Samardzic, I.; Legutko, S.; Hloch, S.; Barrans, S.; Maruda, R.W. Influence of argon pollution on the weld Surface Morphology. Measurement 2015, 70, 203–213. [Google Scholar] [CrossRef]

- Krolczyk, J.B.; Gapinski, B.; Krolczyk, G.M.; Samardzic, I.; Maruda, R.W.; Soucek, K.; Stas, L. Topographic Inspection as a Method of Weld Joint Diagnostic. Teh. Vjesn. 2016, 23, 301–306. [Google Scholar]

- Kumar, R.; Chattopadhyaya, S.; Hloch, S.; Krolczyk, G.; Legutko, S. Wear characteristics and defects analysis of friction stir welded joint of aluminium alloy 6061-T6. Eksploat. Niezawodn. 2016, 18, 128–135. [Google Scholar] [CrossRef]

- Cavaliere, P.; Cerri, E.; Squillace, A. Mechanical response of 2024-7075 aluminium alloys joined by Friction Stir Welding. J. Mater. Sci. 2005, 40, 3669–3676. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Casalino, G.; Casavola, C.; Moramarco, V. Analysis and comparison of friction stir welding and laser assisted friction stir welding of aluminum alloy. Materials 2013, 6, 5923–5941. [Google Scholar] [CrossRef] [PubMed]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Church, M.G.; Templesmith, P.; Dawes, C.J. Friction Stir Butt Welding. International Patent Application No. PCT/GB92/02203, 1 December 1991. [Google Scholar]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding—Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Katayama, S. Laser welding of aluminium alloys and dissimilar metals. Weld. Int. 2004, 18, 618–625. [Google Scholar] [CrossRef]

- Luijendijk, T. Welding of dissimilar aluminium alloys. J. Mater. Process. Tech. 2000, 103, 29–35. [Google Scholar] [CrossRef]

- Moreira, P.M.G.P.; Figueiredo, M.A.V.D.; Castro, P.M.S.T.D. Fatigue behavior of FSW and MIG weldments for two aluminium alloys. Theor. Appl. Fract. Mech. 2007, 48, 169–177. [Google Scholar] [CrossRef]

- Kumagai, M. Recent technological developments in welding of Aluminium and its alloys. Weld. Int. 2003, 17, 173–181. [Google Scholar] [CrossRef]

- Kumar, T.S.; Balasubramanian, V.; Sanavullah, M.Y. Influences of pulsed current tungsten inert gas welding parameters on the tensile properties of AA6061 aluminium alloy. Mater. Des. 2007, 28, 2080–2092. [Google Scholar] [CrossRef]

- Barnes, T.A.; Pashby, I.R. Joining techniques for aluminium spaceframes used in automobiles: Part I—Solid and liquid phase welding. J. Mater. Process. Technol. 2000, 99, 62–71. [Google Scholar] [CrossRef]

- Gou, G.; Zhang, M.; Chen, H.; Chen, J.; Li, P.; Yang, Y.P. Effect of humidity on porosity, microstructure, and fatigue strength of A7N01S-T5 aluminum alloy welded joints in high-speed trains. Mater. Des. 2015, 85, 309–317. [Google Scholar] [CrossRef]

- Welding Handbook, Materials and Applications, 8th ed.; American Welding Society: Miami, FL, USA, 1996; Part 1; Volume 3, ISBN 0-87171-470-1.

- Kim, H.T.; Nam, S.W. Solidification cracking susceptibility of high strength aluminum alloy weldment. Scr. Mater. 1996, 34, 1139–1145. [Google Scholar] [CrossRef]

- Hermann, R.; Birley, S.S.; Holdway, P. Liquation cracking in aluminium alloy welds. Mater. Sci. Eng. 1996, 212, 247–255. [Google Scholar] [CrossRef]

- Mathers, G. The Welding of Aluminium and Its Alloys; Woodhead Publishing: Boca Raton, FL, USA, 2002. [Google Scholar]

- Çam, G.; İpekoğlu, G. Recent developments in joining of aluminum alloys. Int. J. Adv. Manuf. Technol. 2017, 91, 1851–1866. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Behnagh, R.A.; Akbari, M.; Givi, M.K.B.; Farhani, F. Modelling and Pareto optimization of mechanical properties of friction stir welded AA7075/AA5083 butt joints using neural network and particle swarm algorithm. Mater. Des. 2013, 44, 190–198. [Google Scholar] [CrossRef]

- Dong, J.; Zhang, D.; Zhang, W.; Qiu, C. Microstructure Evolution during Dissimilar Friction Stir Welding of AA7003-T4 and AA6060-T4. Materials 2018, 11, 342. [Google Scholar] [CrossRef] [PubMed]

- Shigematsu, I.; Kwon, Y.J.; Suzuki, K.; Imai, T.; Saito, N. Joining of 5083 and 6061 aluminum alloys by friction stir welding. J. Mater. Sci. Lett. 2003, 22, 353–356. [Google Scholar] [CrossRef]

- Zhu, D.; Chen, J.; Liu, C.; Huang, C.; Wang, S.; Chen, J.; Gu, Y. Relationship between mechanical properties and microstructure of Al-Mg-Si and Al-Zn-Mg. Chin. J. Nonferr. Met. 2014, 24, 293–301. [Google Scholar]

- Liao, C.; Su, G.; Gao, Y.; Song, W.; Bao, H.; Gao, J. Microstructure and mechanical properties of 7075/5A06 dissimilar aluminum alloy joints made by TIG welding. Chin. J. Nonferr. Met. 2015, 25, 43–48. [Google Scholar]

- Welding—Recommendations for Welding of Metallic Material; BS EN 1011-1:1998; European Committee for Standardization: Brussels, Belgium, 1998.

- Process Parameters Optimization Method, JB/T 7510-94; China Machine Press: Beijing, China, 1994.

- Test Piece and Tensile Test Method for Tensile Test of Forged Aluminum and Magnesium Alloy Products; GB/T 16865-2013; Standards Press of China: Beijing, China, 2013.

- Metal Material Vickers Hardness Test Part 1: Test Method; GB/T 4340.1-2009; Standards Press of China: Beijing, China, 2009.

- Guo, Z.; Ou, X.; Shuai, G.; Chen, Y. Numerical simulation of temperature field for TIG welding of aluminum alloy sheet based on the SYSWELD. Adv. Mater. Res. 2012, 472, 1945–1949. [Google Scholar] [CrossRef]

- Wang, X.; Mao, S.; Chen, P.; Liu, Y.; Ning, J.; Li, H.; Zang, K.; Zhang, Z.; Han, X. Evolution of microstructure and mechanical properties of a dissimilar aluminum alloy weldment. Mater. Des. 2016, 90, 230–237. [Google Scholar] [CrossRef]

- Degischer, H.P.; Lacom, W.; Zahra, A.; Zahra, C.Y. Decomposition processes in an Al-5% Zn-1% Mg alloy.—2. Electronmicroscopic investigation. Z. MetaIlkd. 1980, 71, 231–238. [Google Scholar]

- Löffler, H.; Kovacs, I.; Lendvai, J. Decomposition processes in Al-Zn-Mg alloys. Mater. Sci. 1983, 18, 2215–2240. [Google Scholar] [CrossRef]

- Ringer, S.P.; Hono, K. Microstructural evolution and age hardening in aluminium alloys: Atom probe field-ion microscopy and transmission electron microscopy studies. Mater. Charact. 2000, 44, 101–131. [Google Scholar] [CrossRef]

- Berg, L.K.; Gjønnes, J.; Hansen, V.; Li, X.Z.; Knutson-Wedel, M.; Waterloo, G.; Schryvers, D.; Wallenberg, L.R. GP-zones in Al-Zn-Mg alloys and their role in artificial aging. Acta Mater. 2001, 49, 3443–3451. [Google Scholar] [CrossRef]

- Starink, M.; Zahra, A.M. Low-temperature decomposition of Al-Mg alloys: Guinier-Preston zones and L12 ordered precipitates. Philos. Mag. A 1997, 76, 701–714. [Google Scholar] [CrossRef]

- Starink, M.J.; Zahra, A.M. β′ and β precipitation in an Al-Mg alloy studied by DSC and TEM. Acta Mater. 1998, 46, 3381–3397. [Google Scholar] [CrossRef]

- Nebti, S.; Hamana, D.; Cizeron, G. Calorimetric study of pre-precipitation and precipitation in Al-Mg alloy. Acta Metall. Mater. 1995, 43, 3583–3588. [Google Scholar] [CrossRef]

- Chen, M.; Li, Y.; Tang, Y.; Ma, M.; Wang, X.; Liu, W. Comparison study of microstructure by metallographic on the polarized light and texture by XRD of CC5083 and CC5182 aliuminium alloy after cold rolling and recrystallization. Spectrosc. Spectr. Anal. 2015, 35, 814–819. [Google Scholar]

- Mourik, P.V.; Maaswinkel, M.N.; Keijser, T.H.D.; Mittemeijer, E.J. Precipitation in liquid-quenched Al-Mg alloys; A study using X-ray diffraction line shift and line broadening. J. Mater. Sci. 1989, 24, 3779–3786. [Google Scholar] [CrossRef]

- Goswami, R.; Spanos, G.; Pao, P.S.; Holtz, R.L. Precipitation behavior of the β phase in Al-5083. Mater. Sci. Eng. A 2010, 527, 1089–1095. [Google Scholar] [CrossRef]

| Base Metal | Si | Fe | Mg | Mn | Cr | Zn | Cu | Zr | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 7A05 | 0.077 | 0.15 | 1.37 | 0.22 | 0.09 | 4.58 | 0.0078 | 0.15 | 0.044 | Balance |

| 5A06 | 0.12 | 0.13 | 6.2 | 0.62 | ----- | 0.232 | 0.11 | ----- | 0.034 | Balance |

| ER5356 | 0.037 | 0.13 | 4.59 | 0.12 | 0.11 | 0.007 | 0.001 | ----- | 0.1 | Balance |

| Base Metal | Yield Strength (MPa) | Tensile Strength (MPa) | Rupture Strain (%) |

|---|---|---|---|

| 7A05-T6 | 414.4 | 311.6 | 13.56 |

| 5A06-O | 356.4 | 161.8 | 21.14 |

| 7A05/5A06 | 281.08 | 157.33 | 11.43 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Cao, Z.; Liu, K.; Zhang, X.; Zhou, K.; Ou, P. Fabrication and Mechanical Properties of Tungsten Inert Gas Welding Ring Welded Joint of 7A05-T6/5A06-O Dissimilar Aluminum Alloy. Materials 2018, 11, 1156. https://doi.org/10.3390/ma11071156

Wang W, Cao Z, Liu K, Zhang X, Zhou K, Ou P. Fabrication and Mechanical Properties of Tungsten Inert Gas Welding Ring Welded Joint of 7A05-T6/5A06-O Dissimilar Aluminum Alloy. Materials. 2018; 11(7):1156. https://doi.org/10.3390/ma11071156

Chicago/Turabian StyleWang, Wukun, Zengqiang Cao, Kai Liu, Xianglong Zhang, Kewen Zhou, and Peng Ou. 2018. "Fabrication and Mechanical Properties of Tungsten Inert Gas Welding Ring Welded Joint of 7A05-T6/5A06-O Dissimilar Aluminum Alloy" Materials 11, no. 7: 1156. https://doi.org/10.3390/ma11071156

APA StyleWang, W., Cao, Z., Liu, K., Zhang, X., Zhou, K., & Ou, P. (2018). Fabrication and Mechanical Properties of Tungsten Inert Gas Welding Ring Welded Joint of 7A05-T6/5A06-O Dissimilar Aluminum Alloy. Materials, 11(7), 1156. https://doi.org/10.3390/ma11071156