Processing Techniques for Bioresorbable Nanoparticles in Fabricating Flexible Conductive Interconnects

Abstract

1. Introduction

2. Materials and Methods

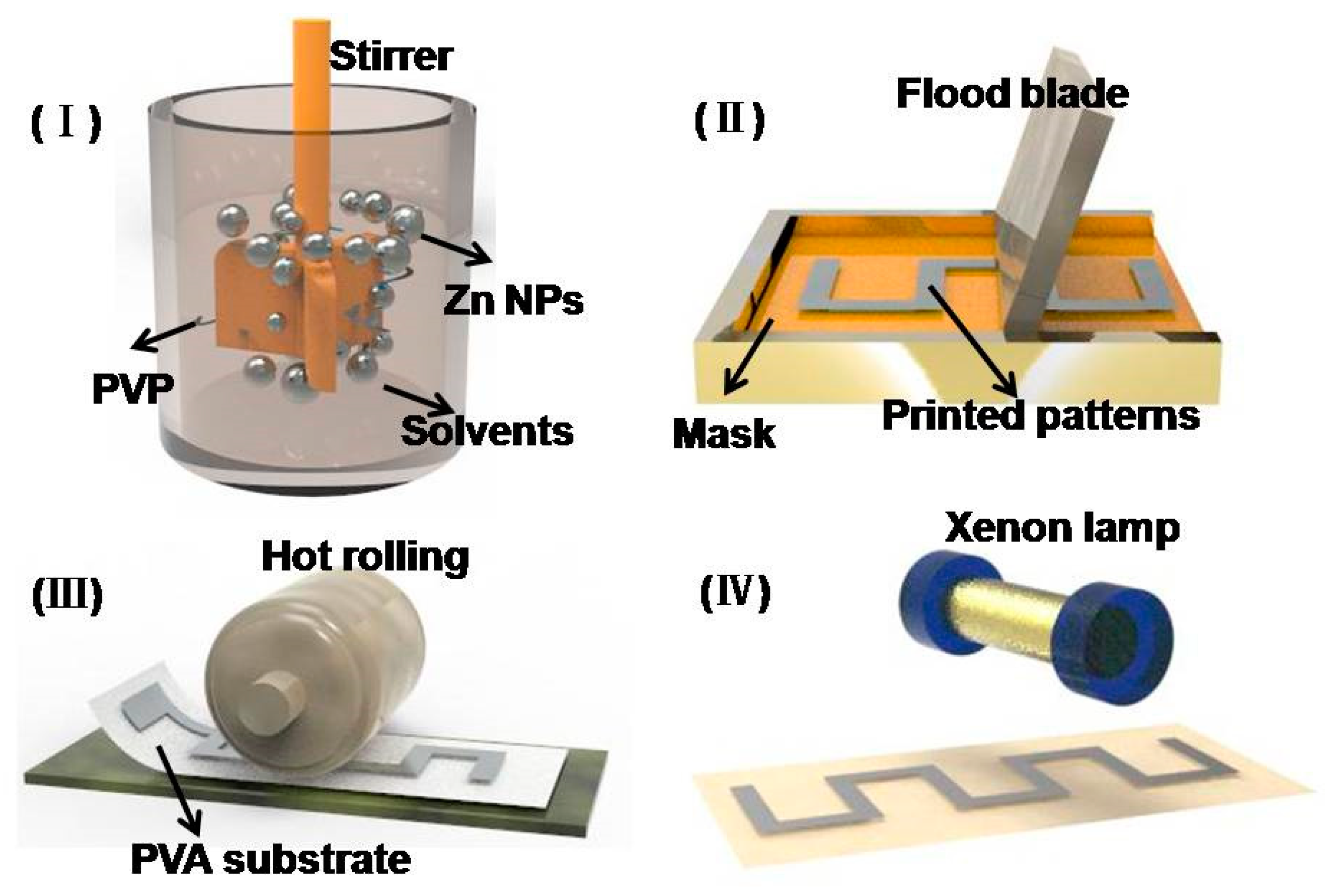

2.1. Preparation of Conductive Inks and Bioresorbable Substrates

2.2. Fabrication of Conductive Patterns

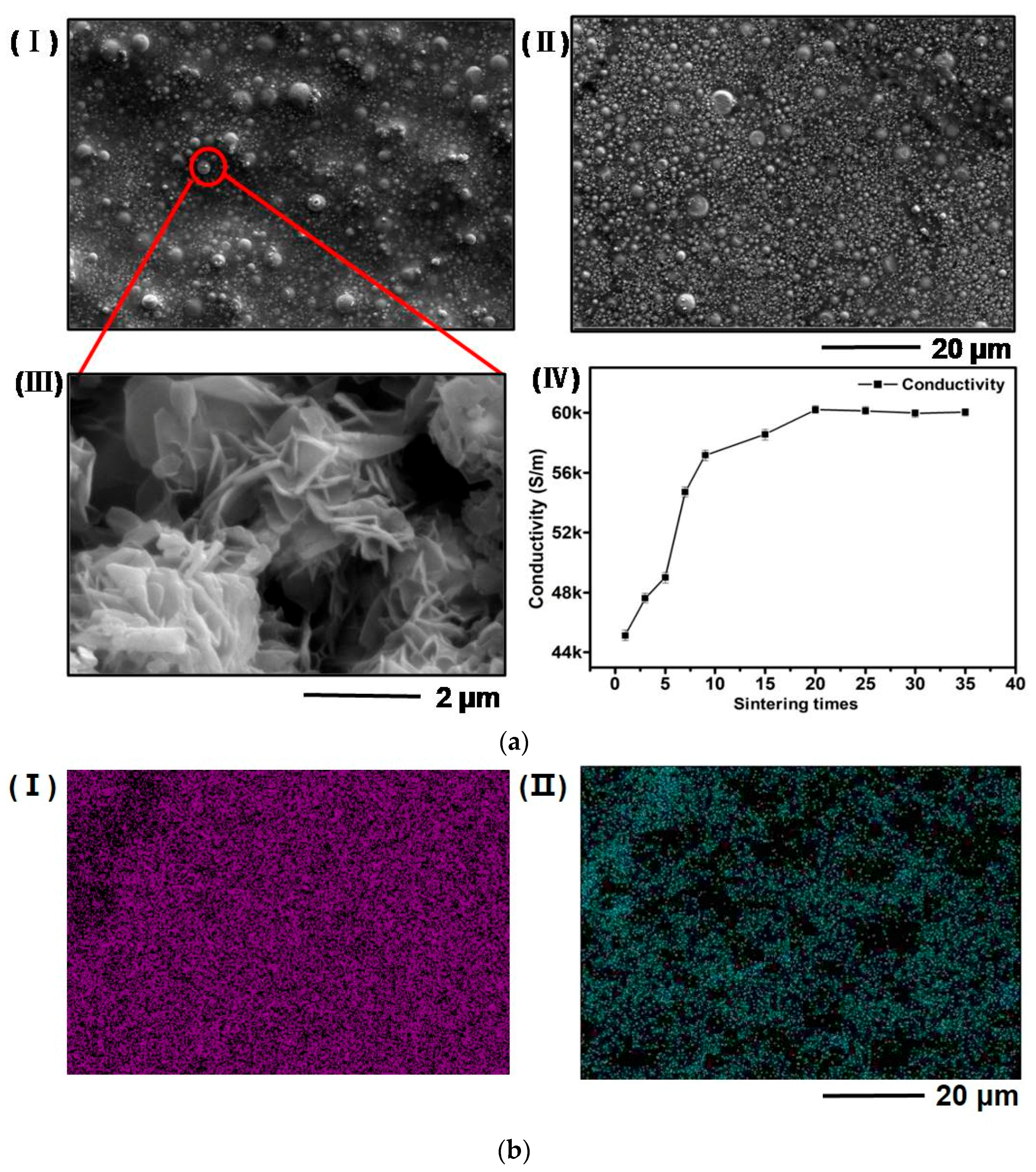

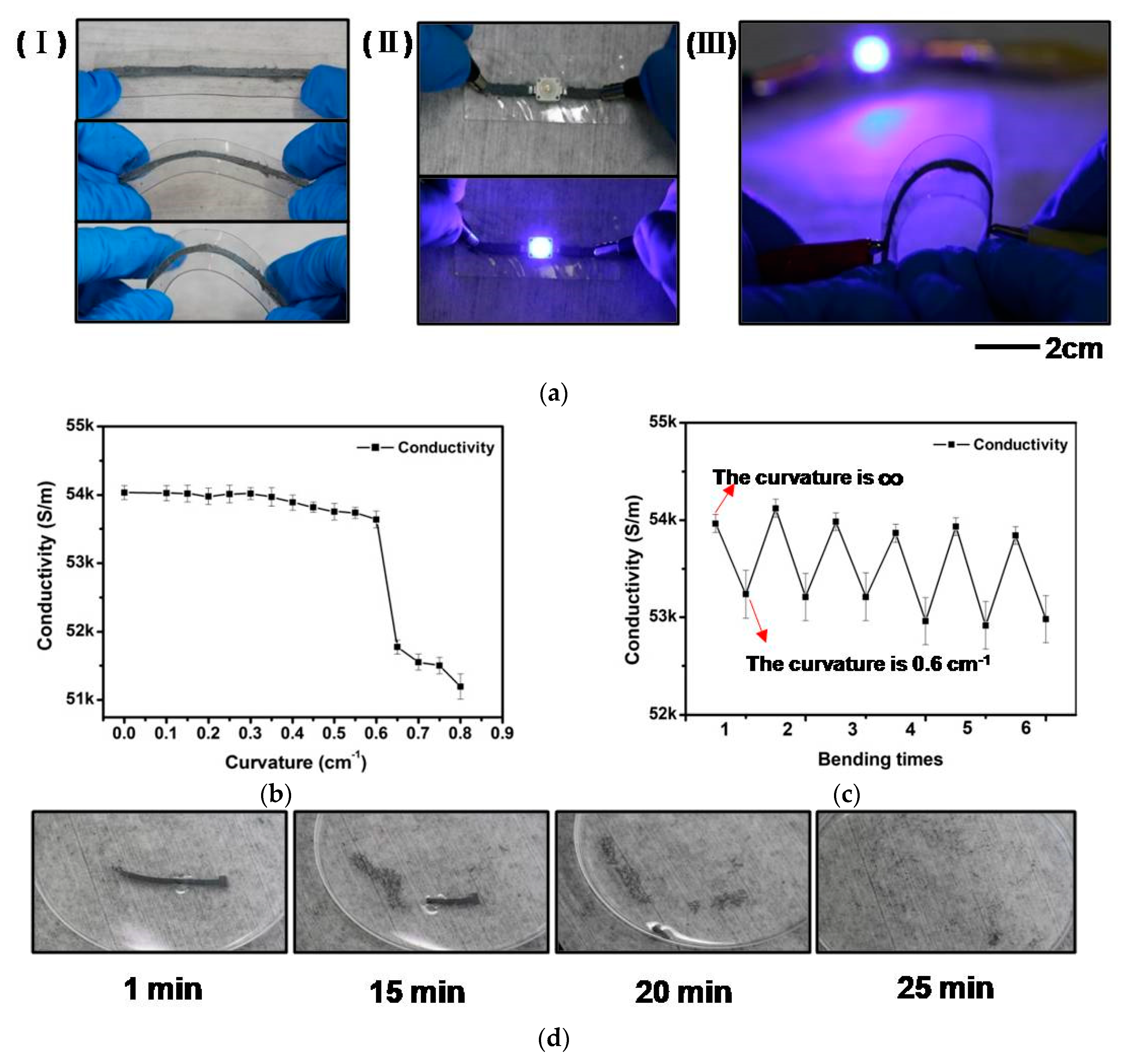

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pramila, S.; Fulekar, M.H.; Bhawana, P. E-waste—A challenge for tomorrow. Res. J. Recent. Sci. 2012, 1, 86–93. [Google Scholar]

- Kumar, U.; Singh, D.N. Electronic waste: Concerns & hazardous threats. Int. J. Curr. Eng. Technol. 2014, 4, 802–811. [Google Scholar]

- Robinson, B.H. E-waste: An assessment of global production and environmental impacts. Sci. Total Environ. 2009, 408, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Aizawa, H.; Yoshida, H.; Sakai, S.-I. Current results and future perspectives for japanese recycling of home electrical appliances. Resour. Conserv. Recycl. 2008, 52, 1399–1410. [Google Scholar] [CrossRef]

- Cui, J.; Zhang, L. Metallurgical recovery of metals from electronic waste: A review. J. Hazard. Mater. 2008, 158, 228–256. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Shou, W.; Mahajan, B.K.; Huang, X.; Pan, H. Materials, processes, and facile manufacturing for bioresorbable electronics: A review. Adv. Mater. 2018. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.H.; Kim, J.-H.; Persano, L.; Hwang, S.-W.; Lee, S.; Lee, J.; Yu, Y.; Kang, Y.; Won, S.M.; Koo, J.; et al. Dry transient electronic systems by use of materials that sublime. Adv. Funct. Mater. 2017, 27, 1606008. [Google Scholar] [CrossRef]

- Yoon, J.; Lee, J.; Choi, B.; Lee, D.; Kim, D.H.; Kim, D.M.; Moon, D.; Lim, M.; Kim, S.; Choi, S.-J. Flammable carbon nanotube transistors on a nitrocellulose paper substrate for transient electronics. Nano Res. 2016, 10, 87–96. [Google Scholar] [CrossRef]

- Hernandez, H.L.; Kang, S.-K.; Lee, O.P.; Hwang, S.-W.; Kaitz, J.A.; Inci, B.; Park, C.W.; Chung, S.; Sottos, N.R.; Moore, J.S.; et al. Triggered transience of metastable poly(phthalaldehyde) for transient electronics. Adv. Mater. 2014, 26, 7637–7642. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Zhang, Y.; Wang, X.; Sim, K.; Liu, J.; Chen, J.; Feng, X.; Xu, H.; Yu, C. M oisture-triggered physically transient electronics. Sci. Adv. 2017, 3, e1701222. [Google Scholar] [CrossRef] [PubMed]

- Bauer, S.; Kaltenbrunner, M. Built to disappear. ACS Nano 2014, 8, 5380–5382. [Google Scholar] [CrossRef] [PubMed]

- Jia, X.; Wang, C.; Ranganathan, V.; Napier, B.; Yu, C.; Chao, Y.; Forsyth, M.; Omenetto, F.G.; MacFarlane, D.R.; Wallace, G.G. A biodegradable thin-film magnesium primary battery using silk fibroin–ionic liquid polymer electrolyte. ACS Energy Lett. 2017, 2, 831–836. [Google Scholar] [CrossRef]

- Wang, Z.; Fu, K.; Liu, Z.; Yao, Y.; Dai, J.; Wang, Y.; Liu, B.; Hu, L. Design of high capacity dissoluble electrodes for all transient batteries. Adv. Funct. Mater. 2017, 27, 1605724. [Google Scholar] [CrossRef]

- Xi, H.; Chen, D.; Lv, L.; Zhong, P.; Lin, Z.; Chang, J.; Wang, H.; Wang, B.; Ma, X.; Zhang, C. High performance transient organic solar cells on biodegradable polyvinyl alcohol composite substrates. RSC Adv. 2017, 7, 52930–52937. [Google Scholar] [CrossRef]

- Salvatore, G.A.; Sülzle, J.; Valle, F.D.; Cantarella, G.; Robotti, F.; Jokic, P.; Knobelspies, S.; Daus, A.; Büthe, L.; Petti, L.; et al. Biodegradable and highly deformable temperature sensors for the internet of things. Adv. Funct. Mater. 2017, 27, 1702390. [Google Scholar] [CrossRef]

- Kang, S.K.; Murphy, R.K.J.; Hwang, S.-W.; Lee, S.M.; Harburg, D.V.; Krueger, N.A.; Shin, J.; Gamble, P.; Cheng, H.; Yu, S.; et al. Bioresorbable silicon electronic sensors for the brain. Nature 2016, 530, 71–76. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.; Kang, S.-K.; Won, S.M.; Gutruf, P.; Jeong, Y.R.; Koo, J.; Lee, S.-S.; Rogers, J.A.; Ha, J.S. Fully biodegradable microsupercapacitor for power storage in transient electronics. Adv. Energy Mater. 2017, 7, 1700157. [Google Scholar] [CrossRef]

- Mahajan, B.K.; Yu, X.; Shou, W.; Pan, H.; Huang, X. Mechanically milled irregular zinc nanoparticles for printable bioresorbable electronics. Small 2017, 13, 1700065. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Kang, S.K.; Salvatore, G.A.; Ma, Y.; Kim, B.H.; Jiang, Y.; Kim, J.S.; Yan, L.; Wie, D.S.; Banks, A.; et al. Wireless microfluidic systems for programmed, functional transformation of transient electronic devices. Adv. Funct. Mater. 2015, 25, 5100–5106. [Google Scholar] [CrossRef]

- Mahajan, B.K.; Ludwig, B.; Shou, W.; Yu, X.; Fregene, E.; Xu, H.; Pan, H.; Huang, X. Aerosol printing and photonic sintering of bioresorbable zinc nanoparticle ink for transient electronics manufacturing. Sci. China Inf. Sci. 2018, 61, 060412. [Google Scholar] [CrossRef]

- Lee, Y.K.; Kim, J.; Kim, Y.; Kwak, J.W.; Yoon, Y.; Rogers, J.A. Room temperature electrochemical sintering of zn microparticles and its use in printable conducting inks for bioresorbable electronics. Adv. Mater. 2017, 29, 1702665. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Liu, Y.; Hwang, S.-W.; Kang, S.-K.; Patnaik, D.; Cortes, J.F.; Rogers, J.A. Biodegradable materials for multilayer transient printed circuit boards. Adv. Mater. 2014, 26, 7371–7377. [Google Scholar] [CrossRef] [PubMed]

- Shou, W.; Mahajan, B.K.; Ludwig, B.; Yu, X.; Staggs, J.; Huang, X.; Pan, H. Low-cost manufacturing of bioresorbable conductors by evaporation-condensation-mediated laser printing and sintering of Zn nanoparticles. Adv. Mater. 2017, 29, 1700172. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Luo, S.; Liu, J.; Xu, H.; Huang, X. Processing Techniques for Bioresorbable Nanoparticles in Fabricating Flexible Conductive Interconnects. Materials 2018, 11, 1102. https://doi.org/10.3390/ma11071102

Li J, Luo S, Liu J, Xu H, Huang X. Processing Techniques for Bioresorbable Nanoparticles in Fabricating Flexible Conductive Interconnects. Materials. 2018; 11(7):1102. https://doi.org/10.3390/ma11071102

Chicago/Turabian StyleLi, Jiameng, Shiyu Luo, Jiaxuan Liu, Hang Xu, and Xian Huang. 2018. "Processing Techniques for Bioresorbable Nanoparticles in Fabricating Flexible Conductive Interconnects" Materials 11, no. 7: 1102. https://doi.org/10.3390/ma11071102

APA StyleLi, J., Luo, S., Liu, J., Xu, H., & Huang, X. (2018). Processing Techniques for Bioresorbable Nanoparticles in Fabricating Flexible Conductive Interconnects. Materials, 11(7), 1102. https://doi.org/10.3390/ma11071102