Complexity and Anisotropy of Plastic Flow of α-Ti Probed by Acoustic Emission and Local Extensometry

Abstract

1. Introduction

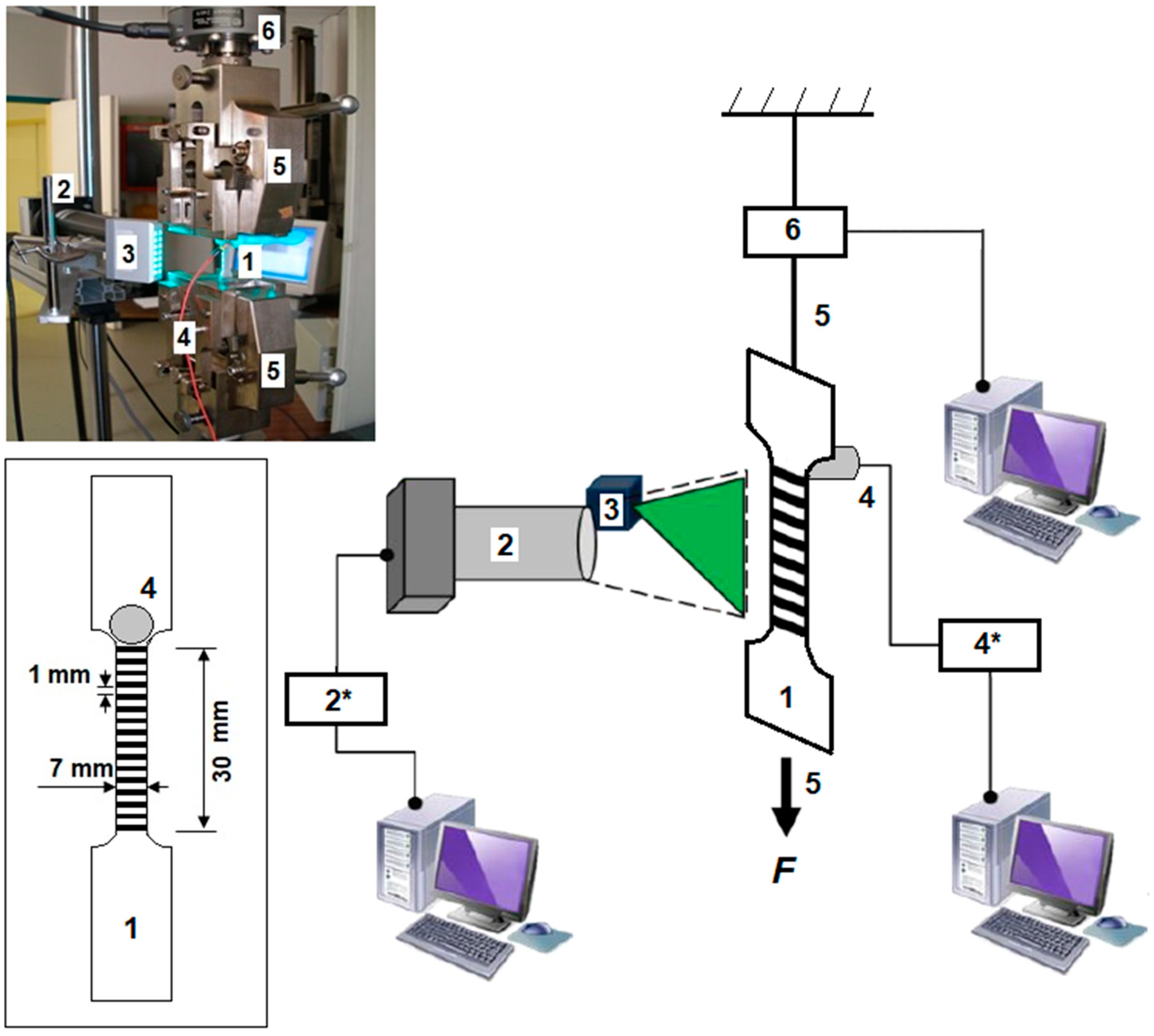

2. Materials and Methods

3. Results

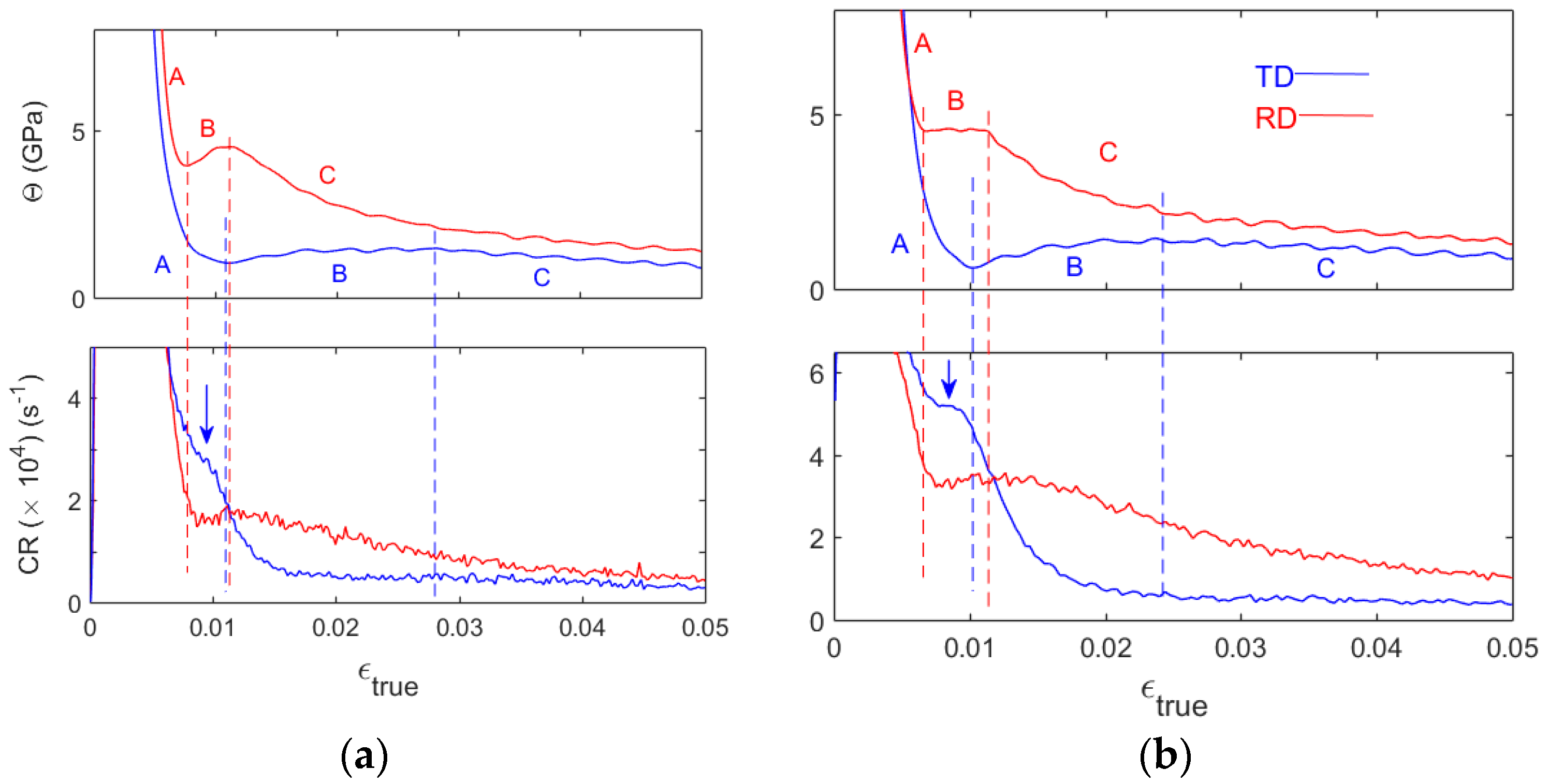

3.1. Three-Stage Work-Hardening Behavior

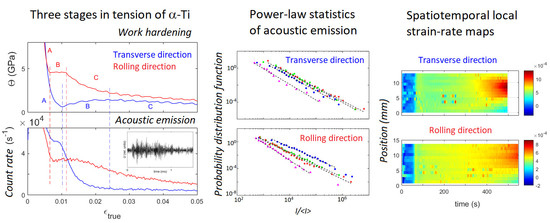

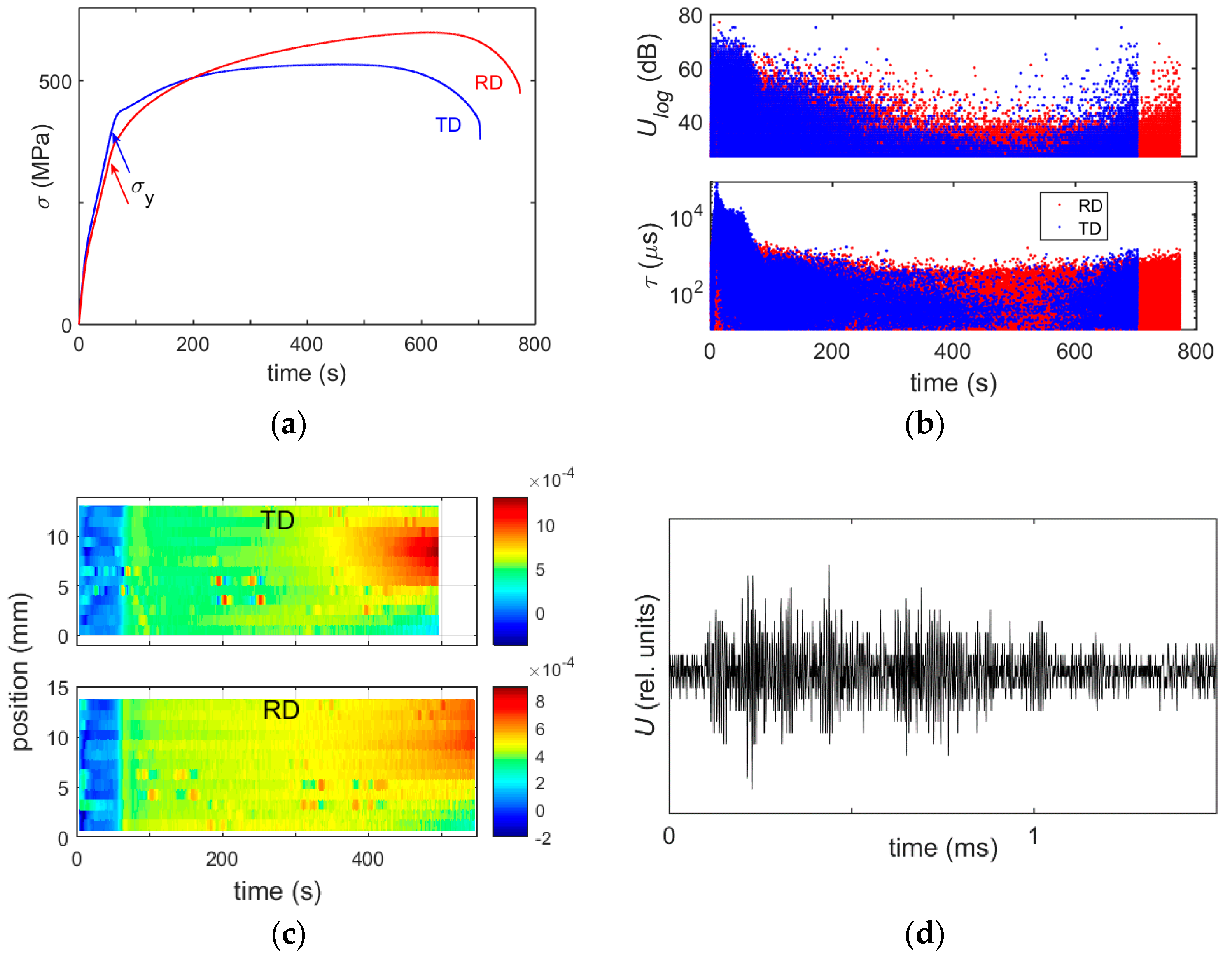

- Both deformation curves (Figure 2a) show a tendency to a concave shape at the elastoplastic transition (it is stronger for the TD orientation at this strain rate). Although the concavity is less pronounced than that reported for compression [3,4,5,6,7,8], the corresponding Θ(ε) curves distinctly display a three-stage character (see Figure 3).

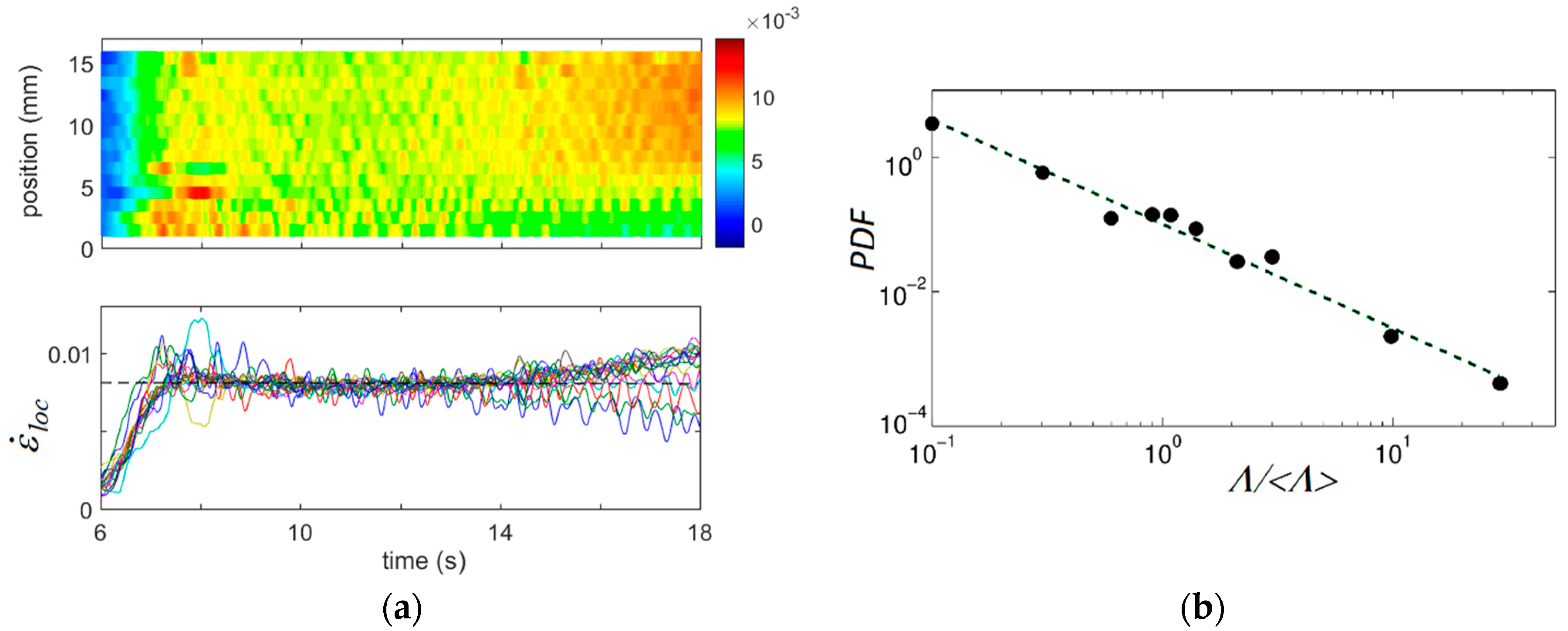

- Figure 2b shows the entire series of AE events recorded for both samples. Each dot in the upper chart represents the logarithmic value Ulog of the amplitude of an AE hit with the duration τ shown in the bottom chart (For clarity, Figure 2d illustrates one of the diverse waveforms corresponding to a hit. The complexity of such waveforms is one of the signatures of collective nature of the dislocation dynamics [26]). The overall evolution of the series of AE events is typical of most materials [15]. The AE occurs virtually immediately after the beginning of loading, is very strong during elastic deformation, and decreases after the elastoplastic transition. The strong AE accompanying the elastic stage is usually ascribed to the microplasticity that is characterized by a fast multiplication of dislocations and large flight distances of dislocations between rare obstacles [15,27]. The further exhaustion of AE during stable plastic flow (before necking) is attributed to the accumulation of barriers to the motion of dislocations. It can also be seen that the AE increases again upon the onset of necking leading to strain localization. The last effect goes beyond the scope of the paper and will only be used hereinafter as a benchmark.

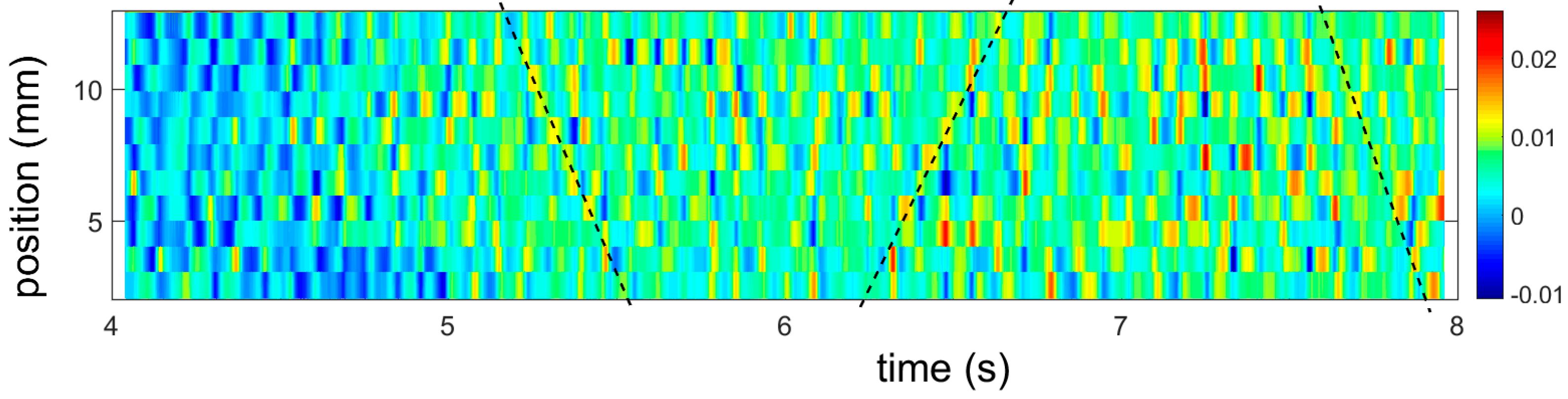

- An important feature of the spatiotemporal maps of Figure 2c is that the local strain-rate values attain during the elastoplastic transition quasi-simultaneously over the entire field of vision [10]. It should be noted that as the sample is stretched during the test, the grid lines located close to the mobile grip gradually leave the field of vision of the CCD camera, so that the overall map only covers about 14 mm of the gage length. However, by restricting the analyzed time interval, it can be recognized that this conclusion is also valid for the other specimen cross-sections. Similar behavior was observed at all strain rates for both orientations. This result allows to invalidate an alternative mechanism of low strain hardening at the stage A [8], based on the suggestion of propagation of a Lüders-like deformation band and requiring conditions favorable for aging of dislocations by solute atoms [28]. Besides the overall pattern, Figure 2c reveals fluctuations both in space and time. Statistical distributions of such fluctuations will be studied in Section 3.2, alongside with the AE statistics.

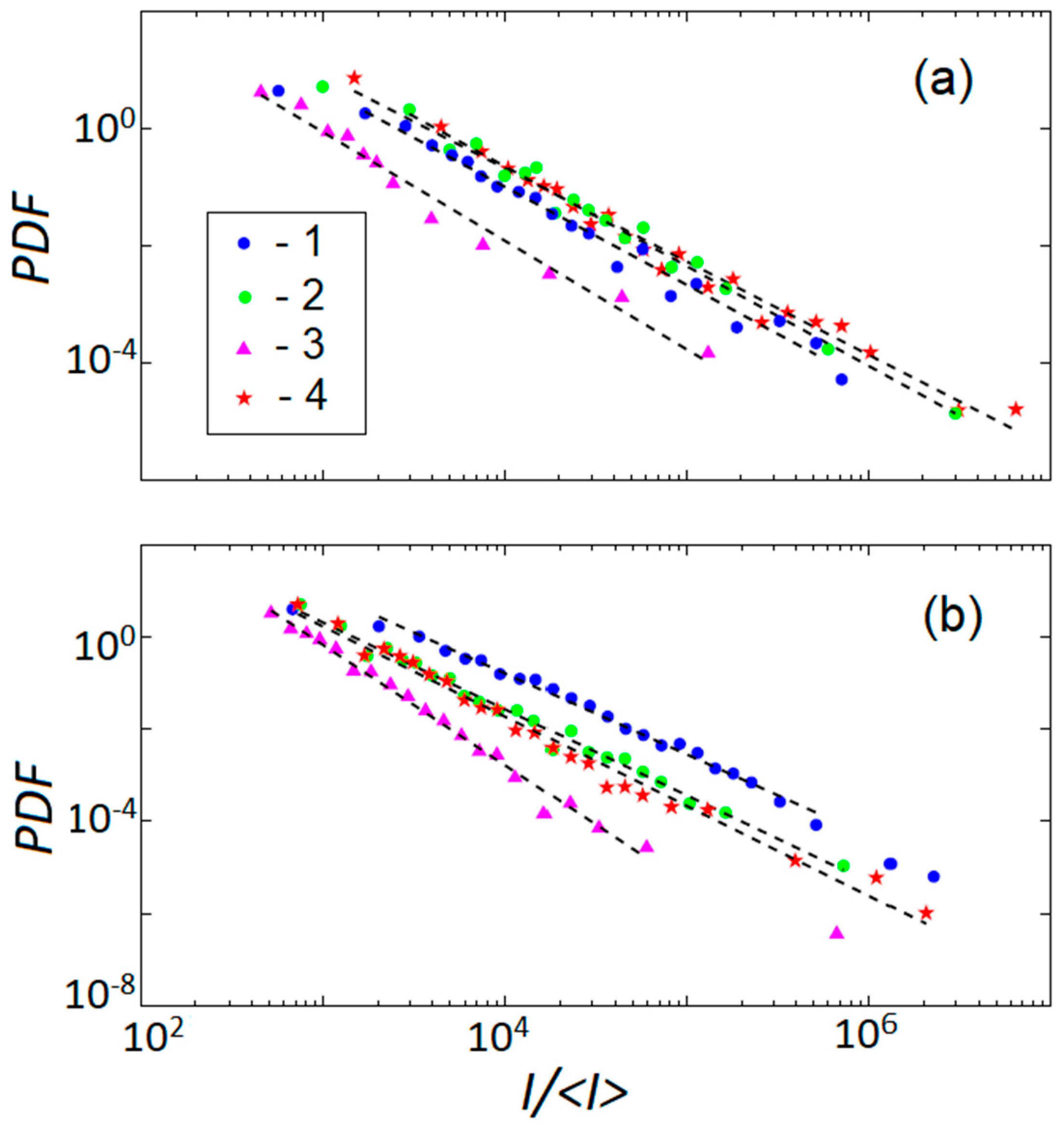

3.2. Statistics of Deformation Processes on a Mesoscopic Scale

4. Discussion

5. Conclusions

- The average activity of the AE accompanying tensile deformation of α-Ti has a non-monotonous character in the strain range corresponding to the three-stage work-hardening behavior characteristic of hcp materials. The totality of data corroborates the recently proposed model predicting that the work-hardening peculiarity can be caused by the dislocation mechanism alone, due to the strong anisotropy of the dislocation glide in different slip systems in hcp crystals [12].

- More specifically, the AE activity detected in the samples cut along the rolling direction shows three stages corresponding rather well to the work-hardening stages. Both AE and deformation behaviors allow for a unique interpretation considering the transition from the initially predominant prismatic glide to the multiple slip. The immediate onset of the multiple slip makes more intricate the qualitative interpretation of such results for samples oriented in the transverse direction and would require a further development of the modeling to couple the mechanisms of plasticity and acoustic emission in the anisotropic material.

- On the mesoscopic scales relevant to either AE or local strain rates, the deformation processes in α-Ti obey power-law statistics characteristic of the avalanche dynamics. Such behavior has recently been established for various materials and first and foremost, for hcp crystals [31]. The values of the power-law exponents found in the present experiments are also close to the seemingly universal exponent (β ~ 1.5) reported in the literature. At the same time, β-values determined for different subsets of large AE datasets testify that the power law may depend on the sample orientation and the strain range. In particular, β was found to increase considerably close to the onset of necking and to decrease again during the neck development. These data indicate that the statistical analysis of the data obtained using high-resolution methods of investigation of the plastic flow may be useful for the further progress in the understanding of the plasticity of hcp materials.

Author Contributions

Funding

Conflicts of Interest

References

- Kocks, U.F. Laws for Work-Hardening and Low-Temperature Creep. J. Eng. Mater. Technol. 1976, 98, 76–85. [Google Scholar] [CrossRef]

- Estrin, Y.; Toth, L.S.; Molinari, A.; Bréchet, Y. A dislocation-based model for all hardening stages in large strain deformation. Acta Mater. 1998, 15, 5509–5522. [Google Scholar] [CrossRef]

- Kailas, S.V.; Prasad, Y.V.R.K.; Biswas, S.K. Influence of initial texture on the microstructural instabilities during compression of commercial α-Titanium at 25 °C to 400 °C. Metall. Mater. Trans. A 1994, 25, 1425–1434. [Google Scholar] [CrossRef]

- Wang, B.; Xin, R.; Huang, G.; Liu, Q. Effect of crystal orientation on the mechanical properties and strain hardening behavior of magnesium alloy AZ31 during uniaxial compression. Mater. Sci. Eng. A 2012, 534, 588–593. [Google Scholar] [CrossRef]

- Salem, A.A.; Kalidindi, S.R.; Doherty, R.D. Strain hardening regimes and microstructure evolution during large strain compression of high purity titanium. Scr. Mater. 2002, 46, 419–423. [Google Scholar] [CrossRef]

- Jiang, J.; Godfrey, A.; Liu, W.; Liu, Q. Microtexture evolution via deformation twinning and slip during compression of magnesium alloy AZ31. Mater. Sci. Eng. A 2008, 483–484, 576–579. [Google Scholar] [CrossRef]

- Sarker, D.; Chen, D.L. Detwinning and strain hardening of an extruded magnesium alloy during compression. Scr. Mater. 2012, 67, 165–168. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Guo, W.G.; Cheng, J.Y. Mechanical properties and deformation mechanisms of a commercially pure titanium. Acta Mater. 1999, 47, 3705–3720. [Google Scholar] [CrossRef]

- Becker, H.; Pantleon, W. Work-hardening stages and deformation mechanism maps during tensile deformation of commercially pure titanium. Comp. Mater. Sci. 2013, 76, 52–59. [Google Scholar] [CrossRef]

- Roth, A.; Lebyodkin, M.A.; Lebedkina, T.A.; Lecomte, J.S.; Richeton, T.; Amouzou, K.E.K. Mechanisms of anisotropy of mechanical properties of a-titanium in tension conditions. Mater. Sci. Eng. A 2014, 596, 236–243. [Google Scholar] [CrossRef]

- Barkia, B.; Doquet, V.; Couzinié, J.P.; Guillot, I.; Héripré, E. In situ monitoring of the deformation mechanisms in titanium with different oxygen contents. Mater. Sci. Eng. A 2015, 636, 91–102. [Google Scholar] [CrossRef]

- Amouzou, K.E.K.; Richeton, T.; Roth, A.; Lebyodkin, M.A.; Lebedkina, T.A. Micromechanical modeling of hardening mechanisms in commercially pure α-titanium in tensile condition. Int. J. Plast. 2016, 80, 222–240. [Google Scholar] [CrossRef]

- Conrad, H. Effect of interstitial solutes on the strength and ductility of titanium. Prog. Mater. Sci. 1981, 26, 123–403. [Google Scholar] [CrossRef]

- Naka, S. Etude des Mécanismes de Déformation Plastique à Basse Température de Monocristaux de Titane Alpha. Ph.D. Thesis, O.N.E.R.A., Palaiseau, France, 1983. [Google Scholar]

- Máthis, K.; Chmelík, F. Exploring plastic deformation of metallic materials by the acoustic emission technique. In Acoustic Emission; Sikorski, W., Ed.; InTech: Rijeka, Croatia, 2012; pp. 23–48. ISBN 978-953-51-0056-0. [Google Scholar]

- Roth, A.; Lebedkina, T.A.; Lebyodkin, M.A. On the critical strain for the onset of plastic instability in an austenitic FeMnC steel. Mater. Sci. Eng. A 2012, 539, 280–284. [Google Scholar] [CrossRef]

- Richeton, T.; Dobron, P.; Chmelik, F.; Weiss, J.; Louchet, F. On the critical character of plasticity in metallic single crystals. Mater. Sci. Eng. A 2006, 424, 190–195. [Google Scholar] [CrossRef]

- Fressengeas, C.; Beaudoin, A.J.; Entemeyer, D.; Lebedkina, T.; Lebyodkin, M.; Taupin, V. Dislocation transport and intermittency in the plasticity of crystalline solids. Phys. Rev. B 2009, 79, 014108. [Google Scholar] [CrossRef]

- Lebyodkin, M.A.; Kobelev, N.P.; Bougherira, Y.; Entemeyer, D.; Fressengeas, C.; Gornakov, V.S.; Lebedkina, T.A.; Shashkov, I.V. On the similarity of plastic flow processes during smooth and jerky flow: Statistical analysis. Acta Mater. 2012, 60, 3729–3740. [Google Scholar] [CrossRef]

- Weiss, J.; Rhouma, W.B.; Richeton, T.; Dechanel, S.; Louchet, F.; Truskinovsky, L. From mild to wild fluctuations in crystal plasticity. Phys. Rev. Lett. 2015, 114, 105504. [Google Scholar] [CrossRef] [PubMed]

- Lebedkina, T.A.; Zhemchuzhnikova, D.A.; Lebyodkin, M.A. Correlation versus randomization of jerky flow in an AlMgScZr alloy using acoustic emission. Phys. Rev. E 2018, 97, 013001. [Google Scholar] [CrossRef] [PubMed]

- Ghaderi, A.; Barnett, M.R. Sensitivity of deformation twinning to grain size in titanium and magnesium. Acta Mater. 2011, 59, 7824–7839. [Google Scholar] [CrossRef]

- Lebyodkin, M.A.; Shashkov, I.V.; Lebedkina, T.A.; Mathis, K.; Dobron, P.; Chmelik, F. Role of superposition of dislocation avalanches in the statistics of acoustic emission during plastic deformation. Phys. Rev. E 2013, 88, 042402. [Google Scholar] [CrossRef] [PubMed]

- Lebedkina, T.A.; Lebyodkin, M.A.; Chateau, J.-P.; Jacques, A.; Allain, S. On the mechanism of unstable plastic flow in an austenitic FeMnC TWIP steel. Mater. Sci. Eng. A 2009, 519, 147–154. [Google Scholar] [CrossRef]

- Weiss, J.; Grasso, J.R.; Miguel, M.C.; Vespignani, A.; Zapperi, S. Complexity in dislocation dynamics: Experiments. Mater. Sci. Eng. A 2001, 309–310, 360–364. [Google Scholar] [CrossRef]

- Lebyodkin, M.A.; Lebedkina, T.A.; Chmelík, F.; Lamark, T.T.; Estrin, Y.; Fressengeas, C.; Weiss, J. Intrinsic structure of acoustic emission events during jerky flow in an Al alloy. Phys. Rev. B 2009, 79, 174114. [Google Scholar] [CrossRef]

- Maaβ, R.; Derlet, P.M. Micro-plasticity and recent insights from intermittent and small-scale plasticity. Acta Mater. 2018, 143, 338–363. [Google Scholar] [CrossRef]

- Klusemann, B.; Fischer, G.; Böhlke, T.; Svendsen, B. Thermomechanical characterization of Portevin–Le Châtelier bands in AlMg3 (AA5754) and modeling based on a modified Estrin–McCormick approach. Int. J. Plast. 2015, 67, 192–216. [Google Scholar] [CrossRef]

- Zhemchuzhnikova, D.; Lebyodkin, M.; Lebedkina, T.; Mogucheva, A.; Yuzbekova, D.; Kaibyshev, R.O. Peculiar Spatiotemporal Behavior of Unstable Plastic Flow in an AlMgMnScZr Alloy with Coarse and Ultrafine Grains. Metals 2017, 7, 325. [Google Scholar] [CrossRef]

- Mudrock, R.N.; Lebyodkin, M.A.; Kurath, P.; Beaudoin, A.J.; Lebedkina, T.A. Strain-rate fluctuations during macroscopically uniform deformation of a solution-strengthened alloy. Scr. Mater. 2011, 65, 1093–1096. [Google Scholar] [CrossRef]

- Zaiser, M. Scale invariance in plastic flow of crystalline solids. Adv. Phys. 2006, 55, 185–245. [Google Scholar] [CrossRef]

- Zuev, L.B. On the waves of plastic flow localization in pure metals and alloys. Ann. Phys. 2007, 16, 286–310. [Google Scholar] [CrossRef]

- Salje, E.K.H.; Dahmen, K.A. Crackling noise in disordered materials. Annu. Rev. Condens. Matter Phys. 2014, 5, 233–254. [Google Scholar] [CrossRef]

- Gu, Y.; Ma, A.; Jiang, J.; Yuan, Y.; Li, H. Deformation structure and mechanical properties of pure titanium produced by rotary-die equal-channel-angular pressing. Metals 2017, 7, 297. [Google Scholar] [CrossRef]

- Cojocaru, V.D.; Serban, N. Effects of solution treating on microstructural and mechanical properties of a heavily deformed new biocompatible Ti-Nb-Zr-Fe alloy. Metals 2018, 8, 297. [Google Scholar] [CrossRef]

- Ji, Z.; Shen, C.; Wei, F.; Li, H. Dependence of macro- and micro-properties on α plates in Ti-6Al-2Zr-1Mo-1V alloy with tri-modal microstructure. Metals 2018, 8, 299. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lebyodkin, M.; Amouzou, K.; Lebedkina, T.; Richeton, T.; Roth, A. Complexity and Anisotropy of Plastic Flow of α-Ti Probed by Acoustic Emission and Local Extensometry. Materials 2018, 11, 1061. https://doi.org/10.3390/ma11071061

Lebyodkin M, Amouzou K, Lebedkina T, Richeton T, Roth A. Complexity and Anisotropy of Plastic Flow of α-Ti Probed by Acoustic Emission and Local Extensometry. Materials. 2018; 11(7):1061. https://doi.org/10.3390/ma11071061

Chicago/Turabian StyleLebyodkin, Mikhail, Kékéli Amouzou, Tatiana Lebedkina, Thiebaud Richeton, and Amandine Roth. 2018. "Complexity and Anisotropy of Plastic Flow of α-Ti Probed by Acoustic Emission and Local Extensometry" Materials 11, no. 7: 1061. https://doi.org/10.3390/ma11071061

APA StyleLebyodkin, M., Amouzou, K., Lebedkina, T., Richeton, T., & Roth, A. (2018). Complexity and Anisotropy of Plastic Flow of α-Ti Probed by Acoustic Emission and Local Extensometry. Materials, 11(7), 1061. https://doi.org/10.3390/ma11071061