1. Introduction

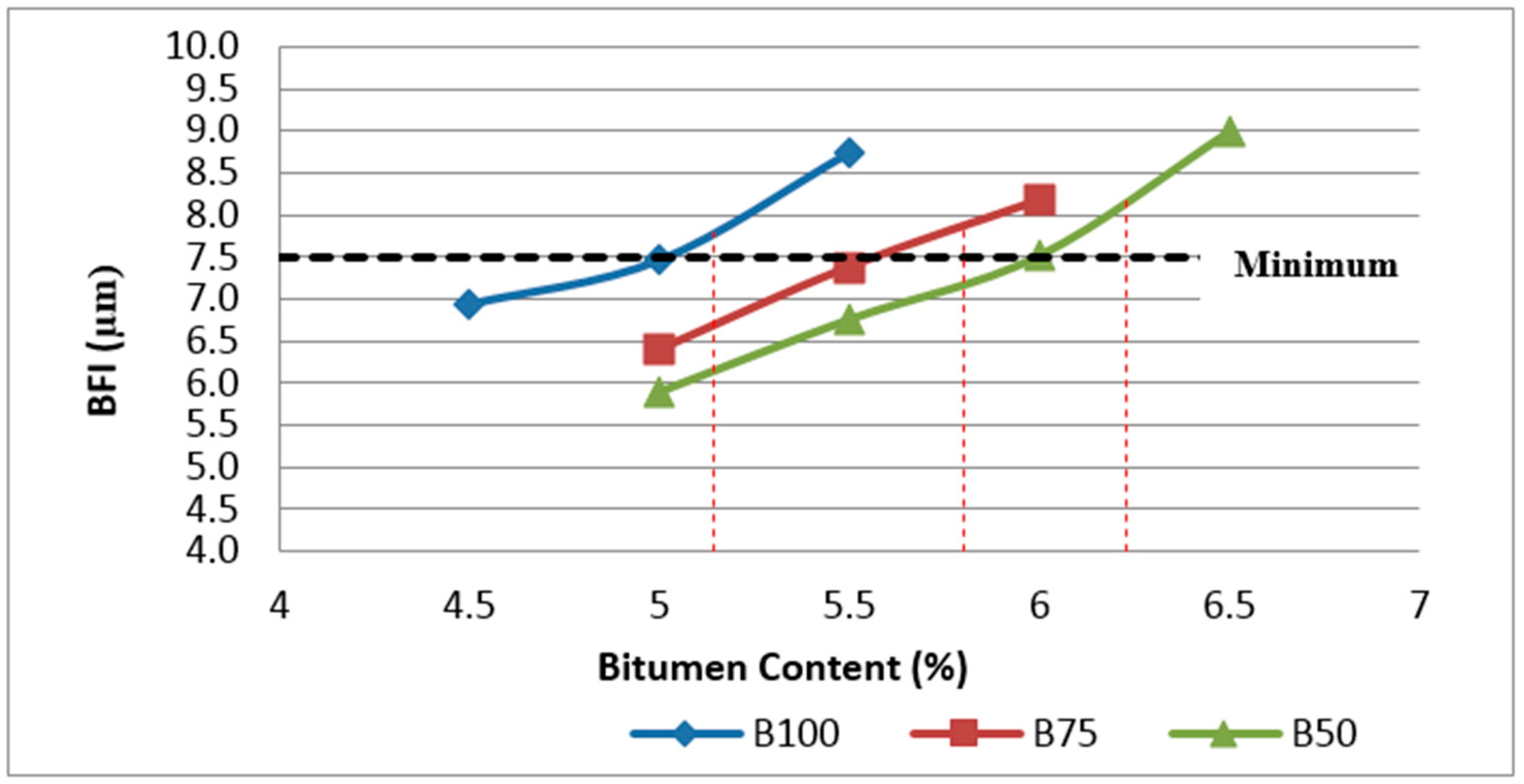

Waste materials are generated increasingly with the continuous growth in the economy and as consumption increases. The growing quantities of waste materials, lack of natural resources and shortage of landfill spaces represent the importance of finding innovative ways of reusing and recycling waste materials. Due to the large quantities of construction and demolition waste (CDW), recycling and utilization of Recycled Construction Aggregates (RCA) obtained from CDW in construction projects, including asphalt pavement construction, can be the most promising solution to this problem. Utilization of RCA in asphalt mixtures is a sustainable technology due to the important role and high portion of aggregates in asphalt mixtures. In addition, RCA has better characteristics for Flakiness Index and Particle Shape compared to basalt [

1]. Since these two characteristics substantially influence the stability and strength of asphalt mixture [

2], they can be considered as one of the strong points of RCA.

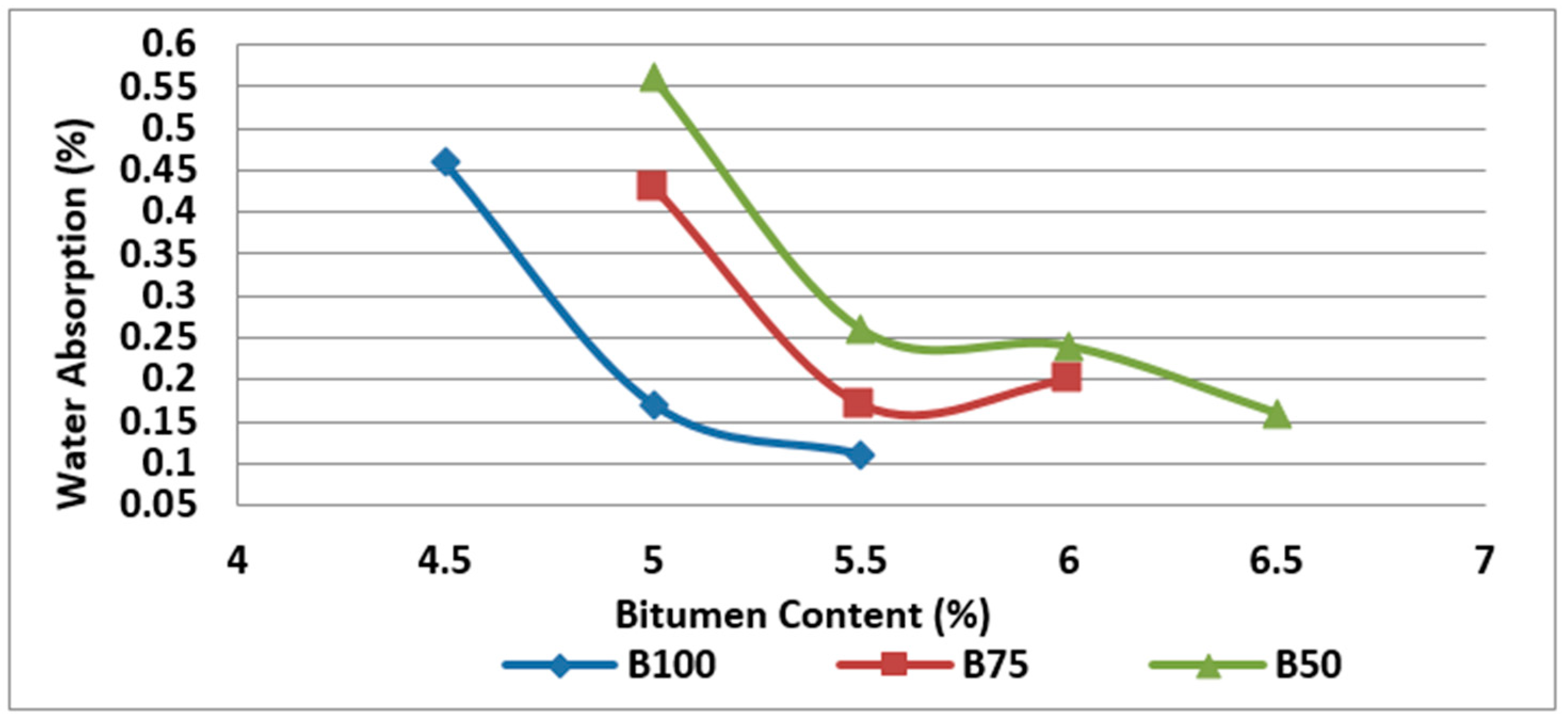

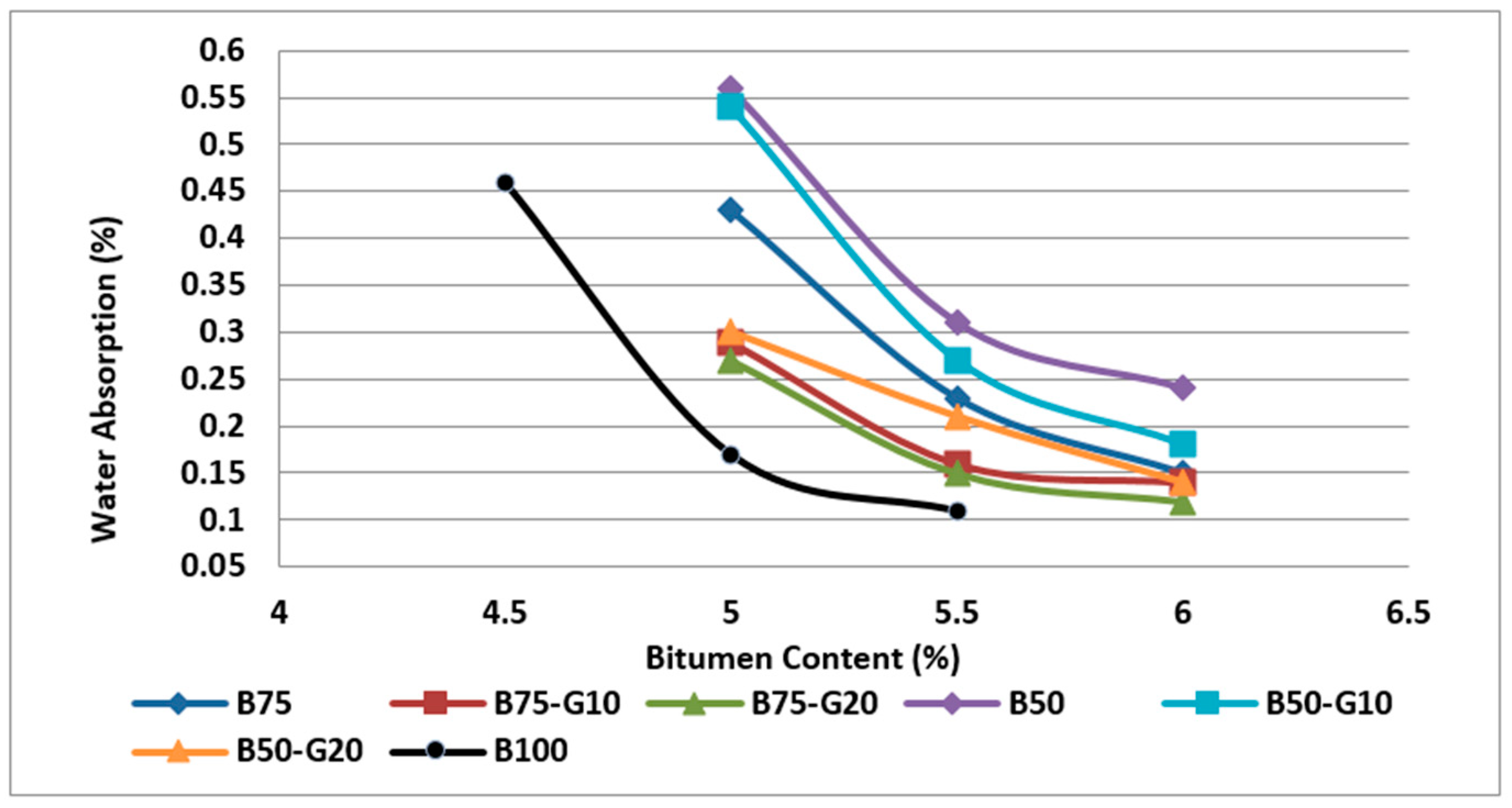

However, the major drawback of RCA is its high water absorption compared to conventional aggregates which subsequently results in high bitumen absorption of asphalt mixtures containing RCA. By combining materials with low absorption, such as glass, the high bitumen absorption of asphalt mixtures containing RCA can be compensated. Using waste glass in RCA-contained asphalt mixtures reduces not only bitumen absorption but also the adverse environmental impacts associated with waste glass disposal due to the nonmetallic and inorganic nature of glass waste, which makes it impossible to be disposed in incinerators or sanitary landfills. In addition, the demand reduction for virgin aggregates is another advantage resulting in subsequent economic advantages.

However, developing a suitable mix design containing RCA and glass is necessary before employing this technology in asphalt mixture production. The purpose of the present work is to study the benefit of glass addition on the bitumen absorption of asphalt mixtures containing RCA in order to optimize the RCA-contained asphalt mix design. In that sense, as discussed in the following sections, several tests were conducted on individual aggregates in order to obtain further knowledge on the recycled aggregate properties as well as to compare them with the corresponding properties of the virgin aggregate and the standards requirements. Based on the results of the aggregate specification tests, different tests were conducted on asphalt mixtures containing various combinations of natural and recycled aggregates in order to investigate their performance in asphalt mixture and to characterize the effects of glass on the bitumen absorption and volumetric properties of asphalt mixtures containing different percentages of RCA. The findings of the experimental work are given in three main sections including the mechanical and physical properties of coarse aggregates (i.e., RCA and basalt), the physical characteristics of fine aggregates (i.e., glass and basalt) and volumetric performance of Hot Mix Asphalt (HMA) containing RCA in combination with glass and without glass.

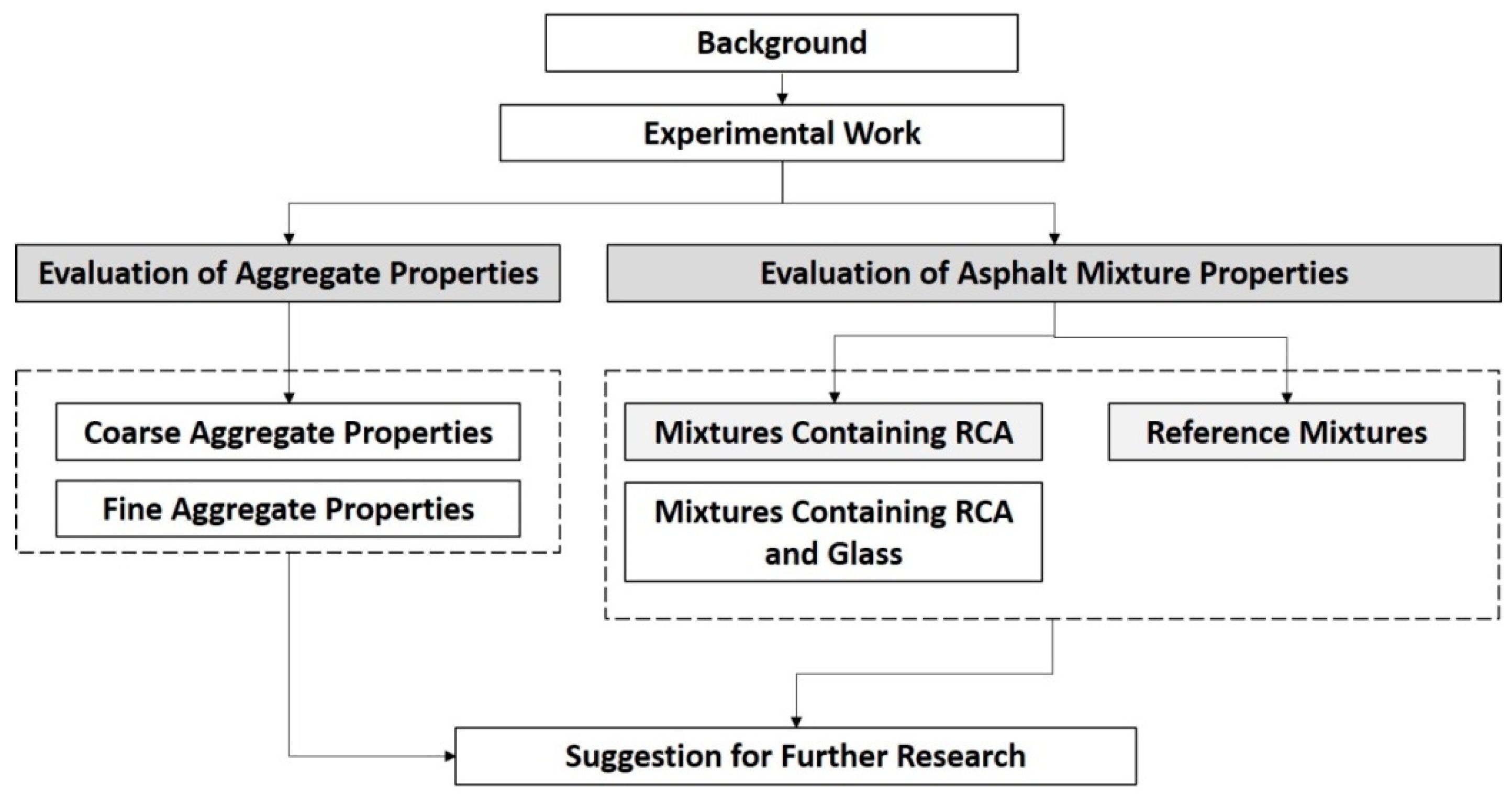

Figure 1 illustrates the flowchart of discussion in this research work.

2. Background

Today, many waste materials such as tyres, plastics, waste glass, etc. are used for construction of different layers of pavements including the asphalt surface layer [

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14]. Utilization of solid wastes in the asphalt layer not only reduces the adverse impacts of waste disposal but also the demand for natural materials which will subsequently results in cost savings and economic advantages. Moreover, using the recycled materials in the asphalt surface layer can contribute to more improvement of engineering characteristics of the asphalt pavement materials, representing a value-added application for solid wastes. However, the selection of waste materials used for road construction, particularly the surface course, is of high importance as the incorporation of wastes should not affect the functional and structural aspects of the pavements [

15,

16,

17].

In addition, due to the importance of the aggregates in asphalt concrete, the studies on the utilization of the recycled aggregates such as reclaimed asphalt pavement (RAP), recycled construction aggregate (RCA), recycled glass, etc. have increased worldwide over the past two decades [

18,

19,

20]. Among the recycled aggregates, the large amount of construction and demolition waste generation worldwide justifies the idea of using RCA in new asphalt mixtures. Referring to available literature e.g., [

21,

22,

23,

24,

25,

26,

27,

28], RCA has been used in the base course and subbase course of pavements over the last two decades. However, few research studies [

29,

30,

31,

32,

33,

34,

35,

36] have reported the utilization of RCA in HMA.

According to comprehensive aggregate specification tests on RCA, RCA cannot satisfy aggregate requirements for asphalt mixtures for two properties of water absorption and wet/dry strength variation [

37]. Accordingly, the application of RCA without any virgin aggregates may result in asphalt mixtures with less efficiency. Therefore, it is required to consider the combination of RCA with other aggregates in certain percentages for the asphalt mixture design. Accordingly, some other materials such as recycled glass can be considered to compensate RCA for some of its shortcomings, and this research will seek for the optimum combination of these materials.

In Australia, about 850,000 tonnes of glass are consumed, of which only 350,000 tonnes are recycled [

38]. This means that approximately 500,000 tonnes of glass are disposed into the landfill every year. The Australian example is indicative of the glass waste disposal throughout the world.

Using waste glass in combination with RCA in asphalt mixture provides substantial environmental and economic advantages since glass waste is one of the most important and particularly troublesome components of solid waste because it cannot be incinerated or degraded. Therefore, it is required to consider a proper approach for its management. Recycling is the most common method for handling glass wastes. In fact, glass can be recycled without any loss in the product quality. Recycling the glass wastes will result in substantial savings of energy as well as mineral resources. In addition, the recycling of glass helps to alleviate the increasing cost of landfill disposal [

39]. However, the variations in glass colour have encouraged the authorities to seek alternative approaches to glass waste management.

Many countries such as the United States, Japan, and several European countries have used glass waste as a substitution for fine aggregate in asphalt mixtures [

40]. However, glass as aggregate in asphalt concrete should meet some technical specifications. Accordingly, many researchers [

41,

42,

43] have studied the utilization of glass as aggregate for asphalt mixtures. Arabani and Azarhoosh (2011) studied the behaviour of asphalt mixtures containing glass (glassphalt) at different temperatures and by using different sizes of glass at different rates. The results of this investigation revealed that adding glass will improve the dynamic behaviour of and the stiffness of asphalt mixtures. In addition, asphalt mixtures containing glass have less temperature sensitivity compared to conventional mixtures [

44]. In another study by Jony et al. (2011), the effect of utilizing different fillers (including glass powder) at different rates in asphalt mixtures was investigated. The results of this investigation indicated that using glass powder as filler improves the Marshall Stability of asphalt mixtures in comparison with the asphalt mixtures made with Portland cement or limestone powder as filler [

45]. Pereira et al. (2010) conducted research on the utilization of waste flat glass as filler in asphalt mixtures. This research concluded that waste glass can be effectively used as filler in asphalt mixtures. In another field study, two sections of road using two sizes of crushed glass were constructed in Minnesota [

46]. Referring to Marti et al. (2002), the results of a rutting test on these roads revealed that the incorporation of waste glass with a size of 9.5 mm in asphalt mixtures provides asphalt mixtures with less dynamic stability compared to asphalt mixtures containing waste glass with a maximum size of 4.75 mm [

47].

Other research by Arnold et al. (2008) showed that the addition of up to 30% glass waste by mass of aggregates will not significantly change the aggregates performance [

48]. Shafabakhsh and Sajed (2014) concluded that asphalt mixtures containing 10 to 15% crushed glass perform satisfactorily [

49]. Finkle and Ksaibati (2007) reported that waste glass can be used as an alternative to the virgin road base materials. However, the glass content of up to 20% and maximum size of 12 mm was recommended based on this research [

50]. Wu et al. (2013) investigated the performance of asphalt mixtures containing waste glass as fine aggregate. The maximum size of 4.75 mm and the optimum content of 10% were recommended by this research [

34]. In a report published by Australian Road Research Board (ARRB) Group for the Packaging Stewardship Forum (PSF) of the Australian food and grocery council (2012), the glass content of up to 20% was recommended for the utilization in asphalt mixtures as fine aggregate. This report limits the utilization of waste glass to 30% by mass of the total fine aggregate in asphalt mixture [

51].

Referring to Su and Chen (2002), in a research program in Taiwan, the engineering properties of the asphalt mixtures incorporating the crushed glass waste were studied through the laboratory and field tests. The result of this research revealed that the utilization of glass waste in asphalt mixtures provides substantial economical and engineering advantages [

52]. Pioneer Road Services carried out the first glass mix trials in Australia in 2003. The roads were compared with conventional asphalt roads for skid resistance properties. The investigation showed that the skid resistance of the asphalt mixtures containing glass waste is similar to conventional asphalt mixtures [

53]. Based on research by Viswanathan (1996), the waste glass can be used in highway construction [

54].

In general, glass is typically brittle and has very low impact resistance. This physical property of glass has been used positively in crushing the waste glass in desirable sizes with low energy consumption. Furthermore, glass shows high volumetric stability under high temperatures of up to 700 °C. The thermal expansion coefficient and softening point of glass are in the range of 8.8 to 9.2 × 10−6 cm/°C and 718 to 738 °C, respectively.

According to available literature, it can be concluded that the application of glass in asphalt mixtures has both advantages and disadvantages, as summarized in

Table 1, which introduces some limits on the utilization of glass in asphalt mixture as follows:

The use of recycled glass is recommended to be limited to 20% as the maximum replacement rate in asphalt mixture

In case of glass content of more than 15% of the total mixture, it is required to add 1 to 2% antistripping agent to the asphalt mixture in order to avoid the stripping problems. Hydrated lime is an effective antistripping agent which can be used in asphalt mixtures containing glass.

Suitable particle size of glass as aggregates in asphalt mixture is 4.75 mm or smaller.

Through this information, it can be easily understood that the application of waste materials in asphalt mixtures directly affects the behaviour of the asphalt mixtures, leading to both advantages and disadvantages of overall asphalt mixture performance. Recognizing this fact, having knowledge about the properties of individual components in asphalt mixtures and their combination will result in selecting the best combination of aggregates for designing an optimum asphalt mixture.

3. Experimental Work

3.1. Materials

In the present study, RCA, glass and basalt have been used as aggregates and the original bitumen studied in this research corresponds to C320, which is the most common binder for wearing courses subjected to heavy loading and/or in hot climates. The typical characteristics of Bitumen C320 are presented in

Table 2.

The virgin aggregate (basalt) was obtained from Nepean Quarries which is a local quarry in Sydney. RCA was obtained from the Revesby Recycling Centre located in Revesby, NSW, Australia. This centre is a transfer station accepting residential and commercial wastes. Based on a statistical study on RCA samples collected over one year, it was observed that there are different construction wastes in RCA, which is mostly (about 64%) composed of sandstone or an agglomerate of sand and cement paste. In addition, a matrix of portland cement concrete will vary between basalt (i.e., Basic Igneous) and granite (i.e., Acidic Igneous) depending on the source of material and the age of the building from which it came makes 17% of RCA. Also, ceramic, glass and brick make about 19% of RCA. The result of the statistical study on RCA is reported in a separate paper.

Recycled glass used in this research was clear crushed glass made from recycled glass and passed through 4.75 mm sieve size and was obtained from Schneppa Glass (Burwood, VIC, Australia).

The fillers considered in this research are hydrated lime and Portland cement. Using the correct amount of hydrated lime, approximately 2% by weight, in mix designs will improve the durability of mixtures and will minimize the problem of stripping, particularly in asphalt mixtures made with partial glass substitution.

3.2. Laboratory Tests on Coarse Aggregates

As presented in the previous sections, in this research project, attempts are made to evaluate the suitability of RCA as part of coarse aggregate in asphalt mixture. Since the basic properties of materials are essential factors in any asphalt mixture design, the fundamental properties of RCA are investigated through conducting different specification tests on different coarse aggregates used in this research (i.e., RCA and basalt).

3.3. Laboratory Tests on Fine Aggregates

To achieve the goals of this research, the study of properties of recycled glass as part of fine aggregate in combination with basalt has been considered as part of this research work. In light of this, different tests have been conducted on recycled glass and basalt (passed 4.75 mm sieve size).

3.4. Laboratory Tests on Asphalt Mixtures Containing Recycled Materials

3.4.1. Sample Preparation

In this study, the asphalt specimens were made from materials mixed in the Centre for Infrastructure Engineering (CIE) laboratory at Western Sydney University. About 4 kg of materials were used to produce three batches of laboratory asphalt mixtures for a finished specimen of diameter 100 ± 2 mm and height of 65 ± 5 mm, in accordance with AS2891.2.1 [

60] and AS2891.2.2 [

61] using an IPC gyratory compactor.

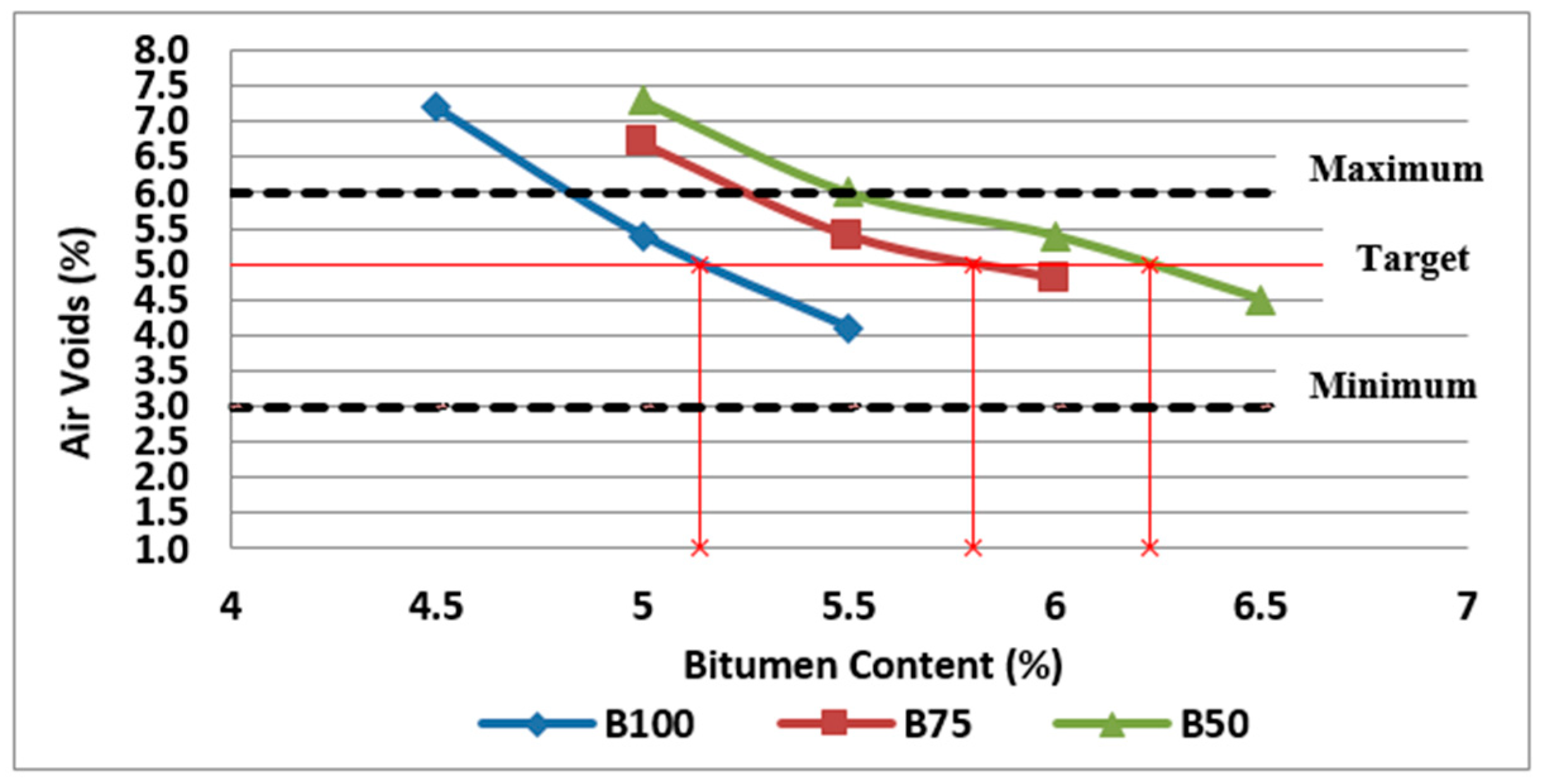

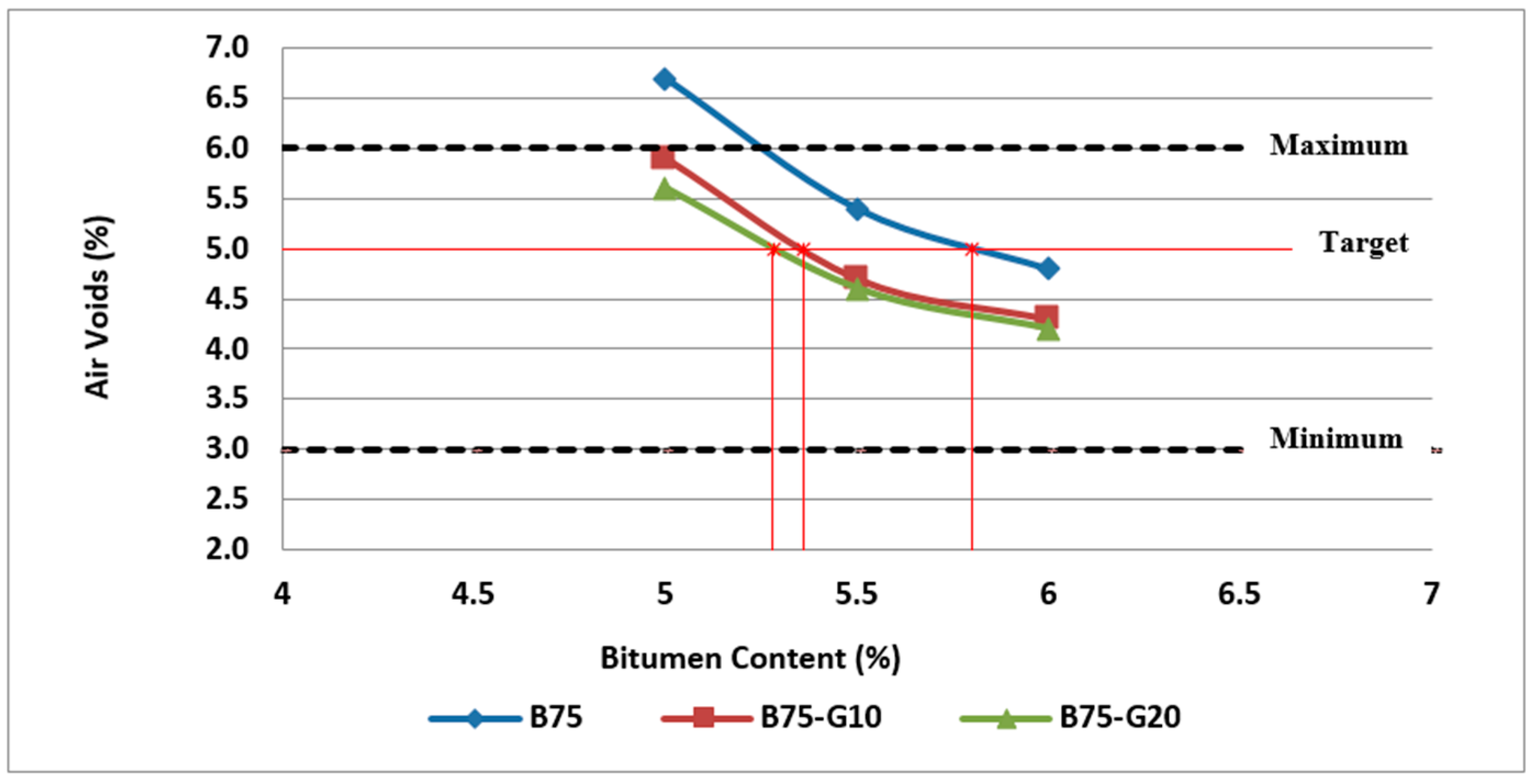

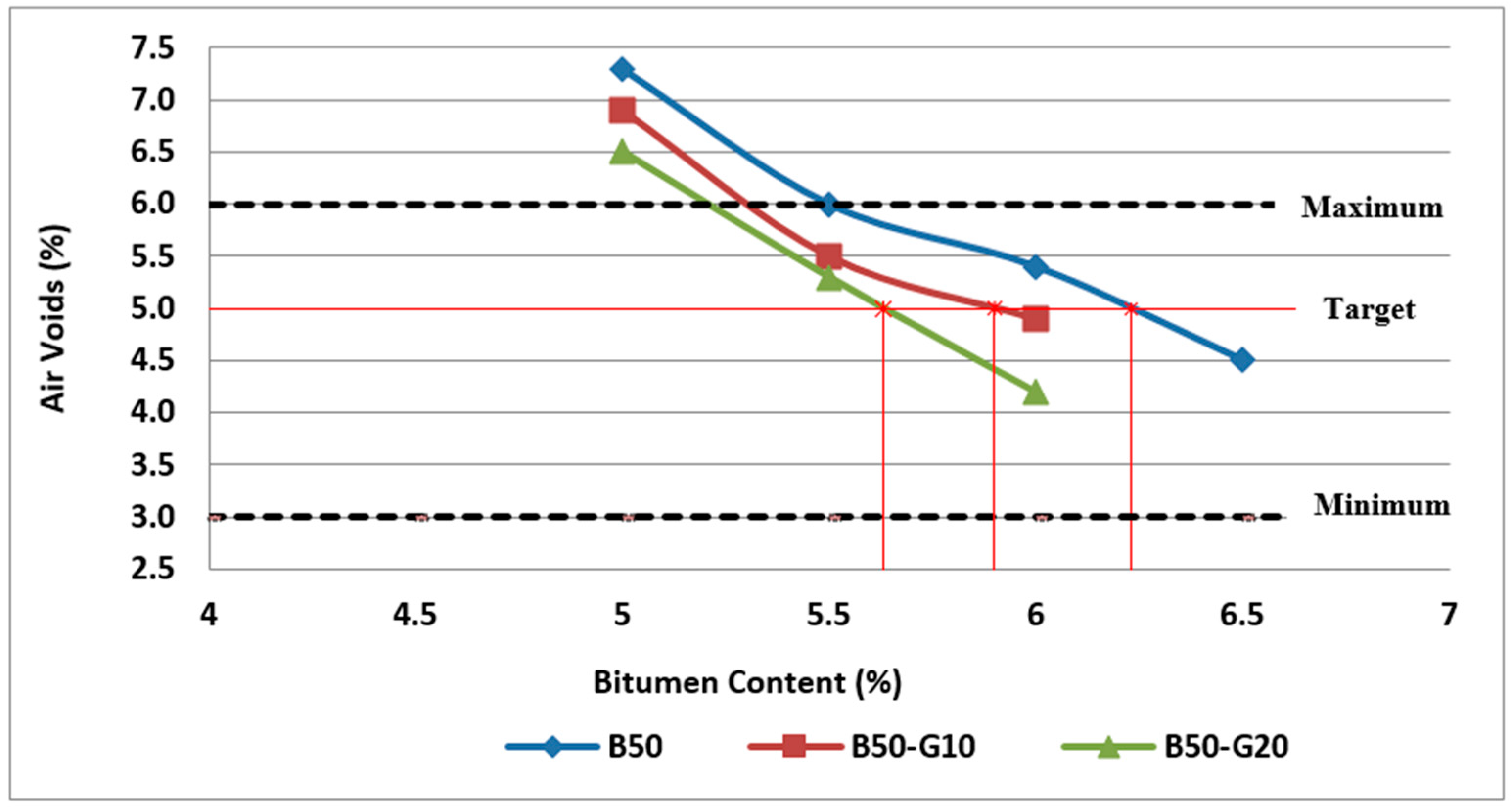

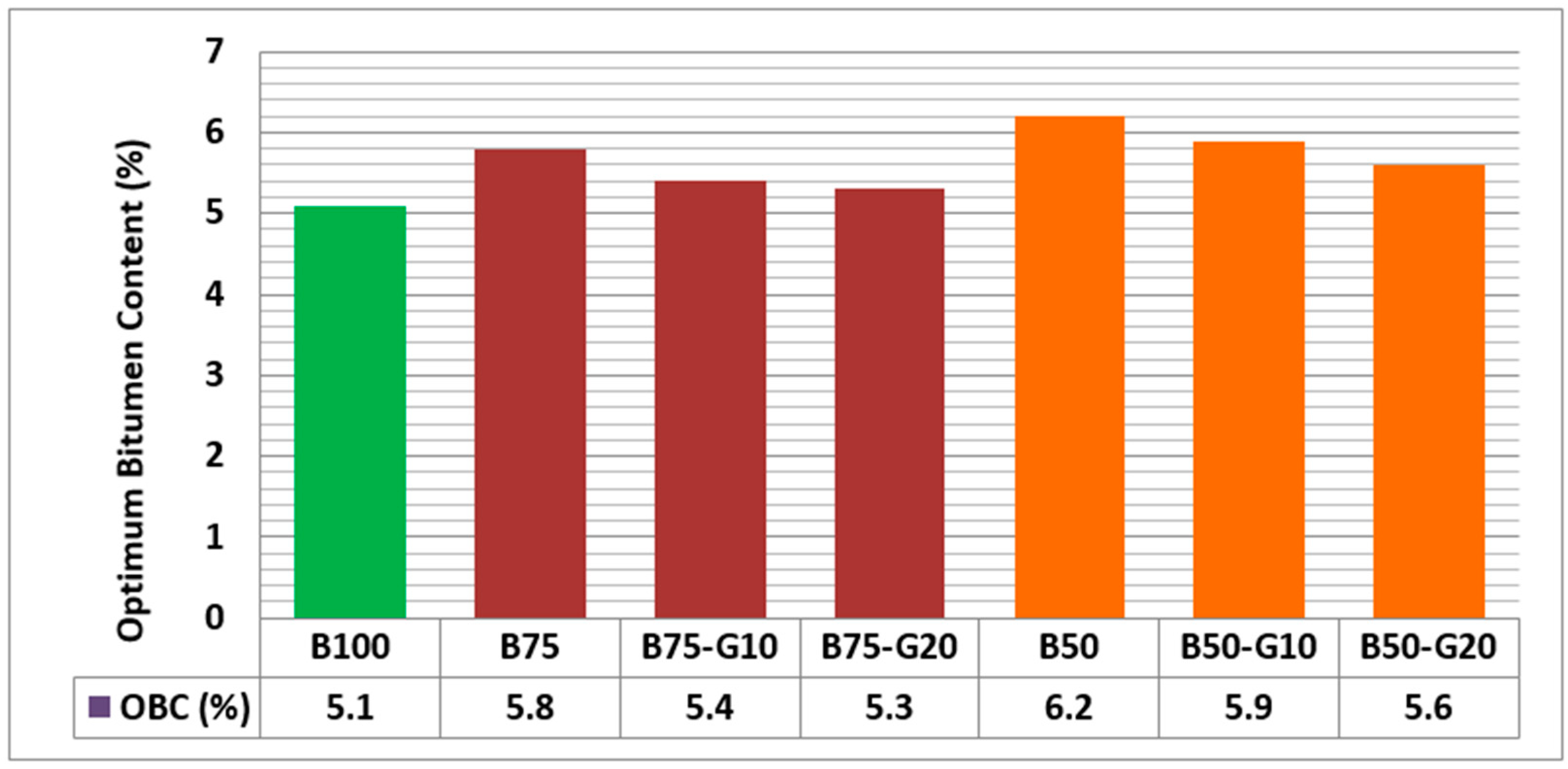

For this experimental work, a group of specimens were prepared without recycled materials (0%) as reference to specimens made with 25% and 50% RCA and 0% glass substitution. In addition, in order to assess the effect of glass on the bitumen absorption of asphalt mixtures containing RCA, two groups of specimens were also prepared with 25% and 50% RCA and glass at the rates of 10% and 20%. The glass substitution was made on each sieve from #4 down to #8. Therefore, 66 samples of the following asphalt mixtures were prepared for this study, as indicated in

Table 3.

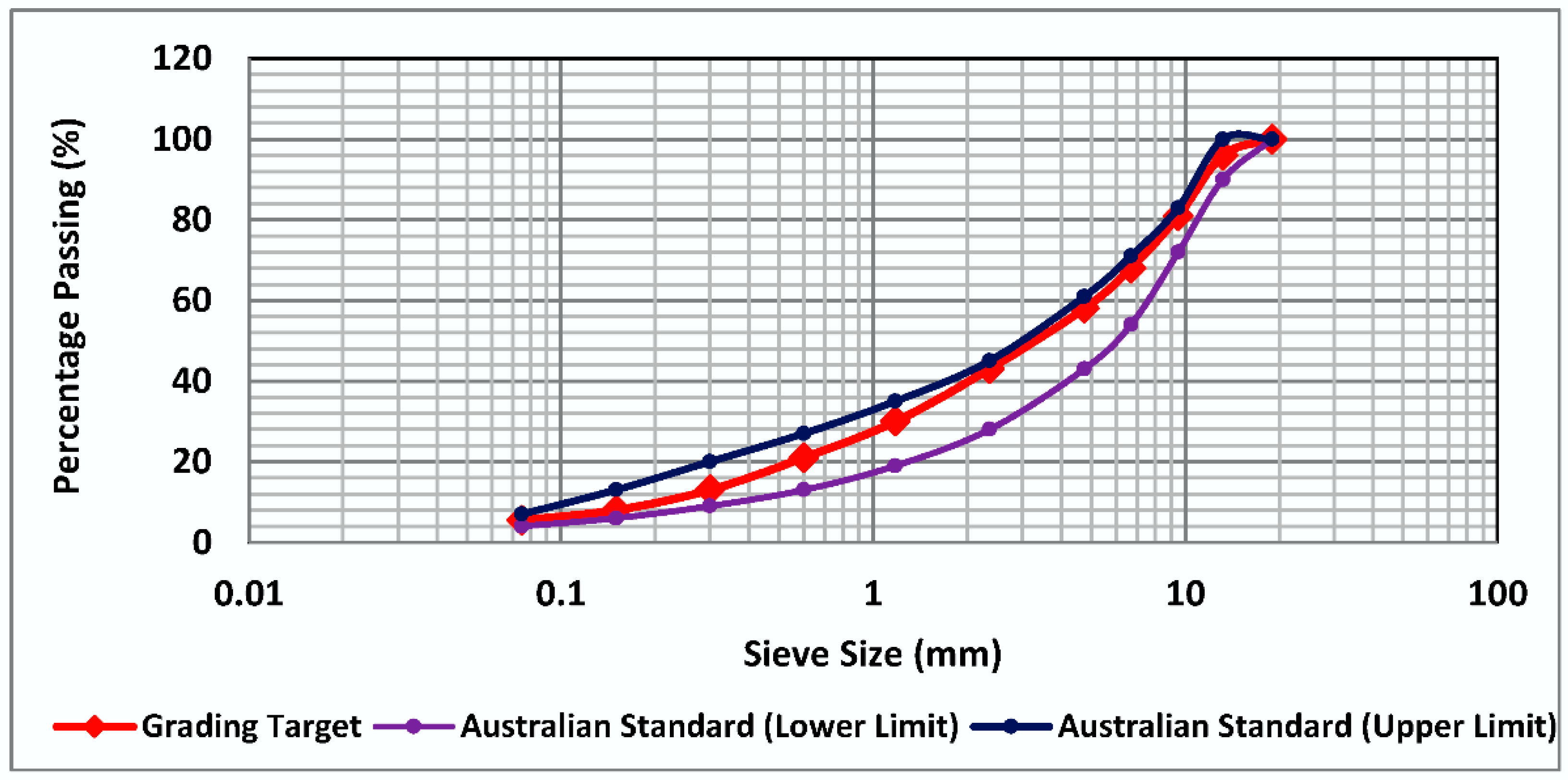

Figure 2 illustrates the design gradation curve used for the preparation of mixtures. It should be noted that portland cement and hydrated lime were used in all asphalt mixtures as filler (passing 0.075 mm sieve).

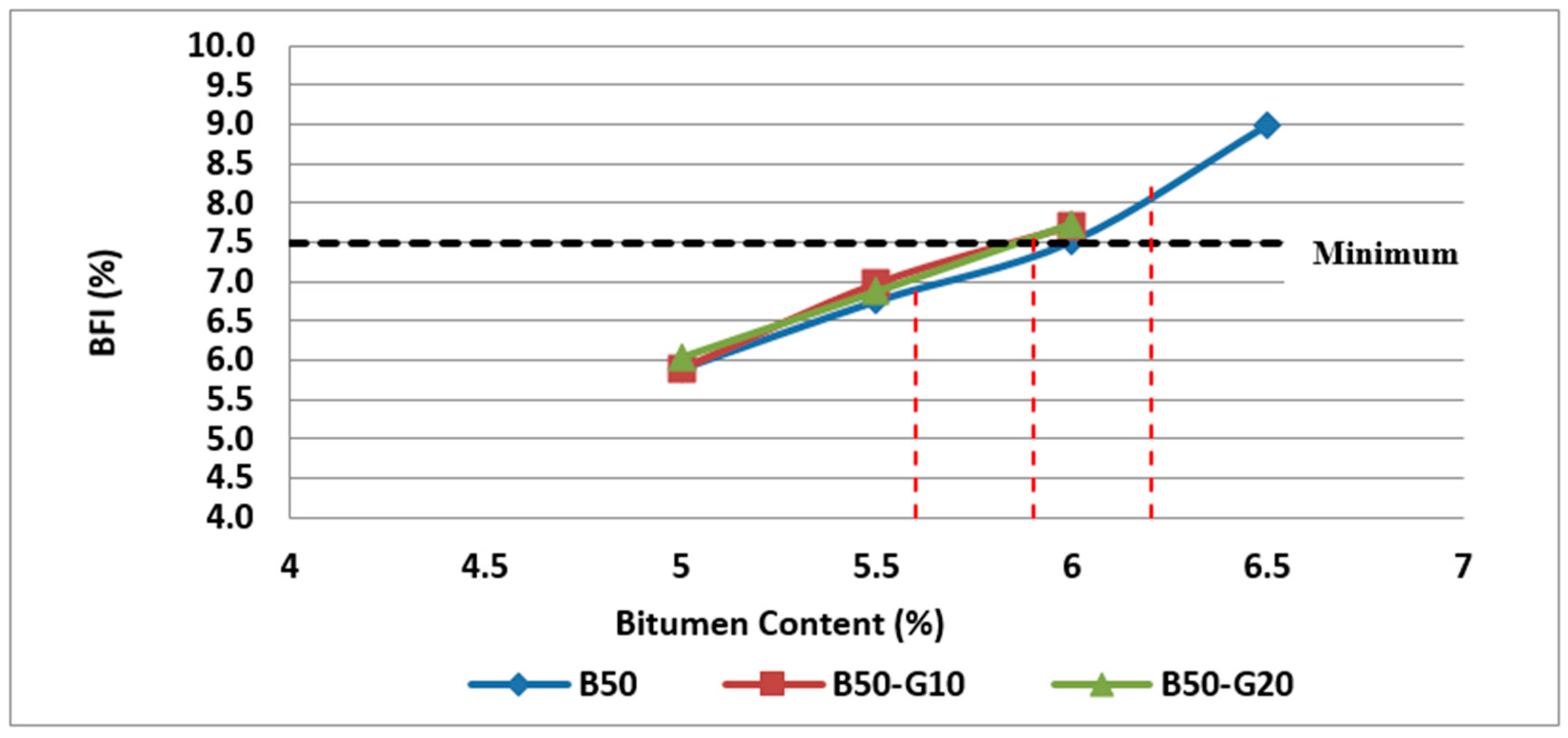

3.4.2. Evaluation of Volumetric Properties of Asphalt Mixtures

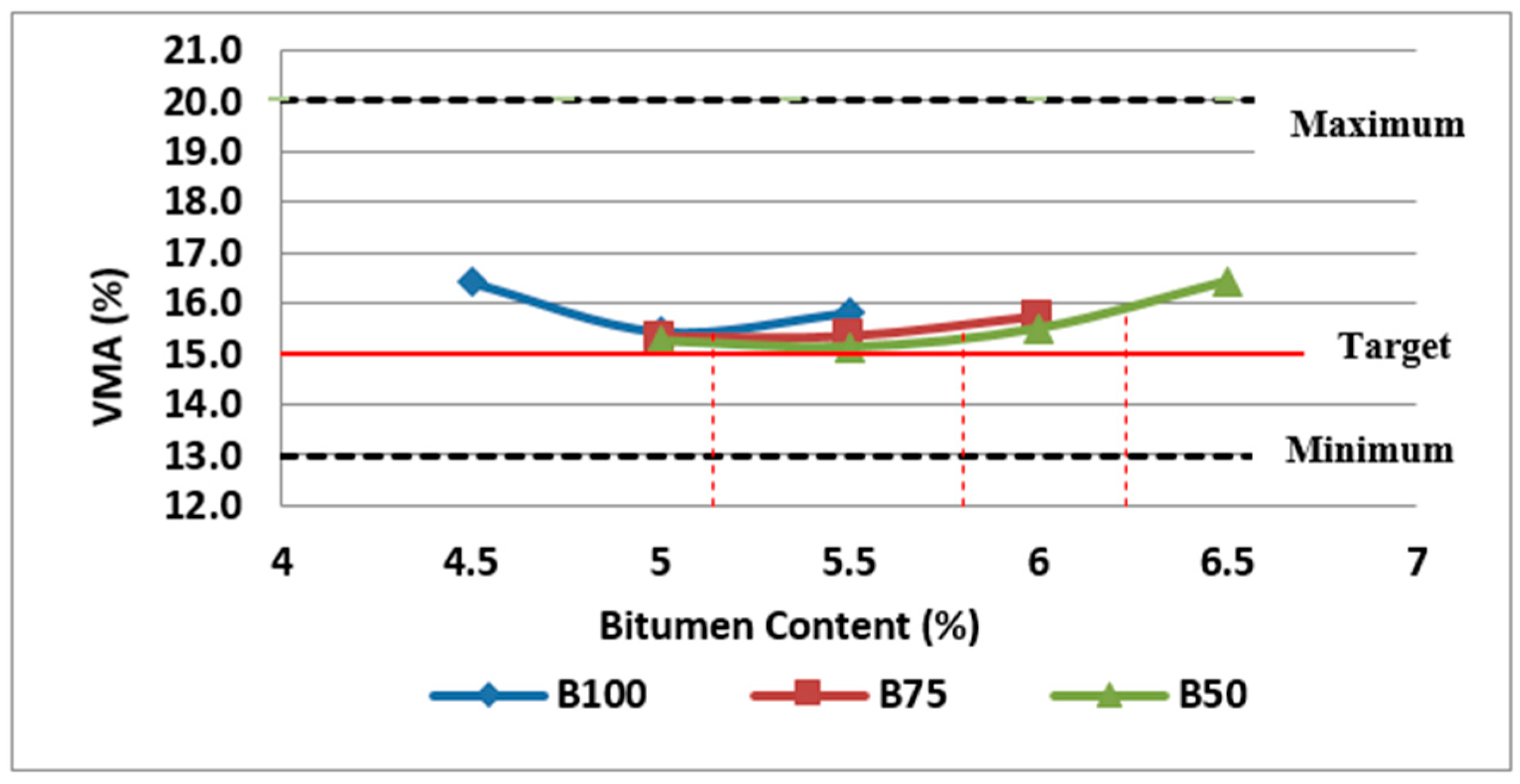

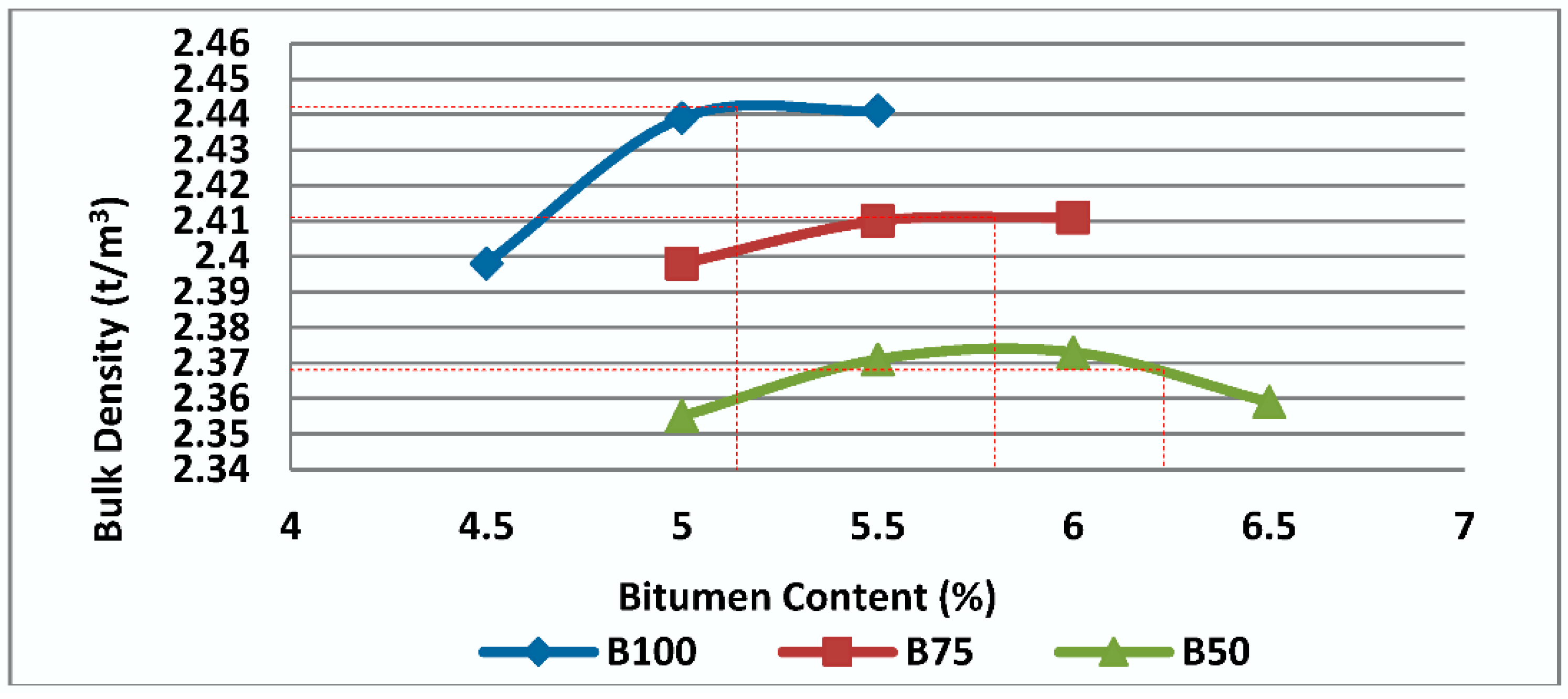

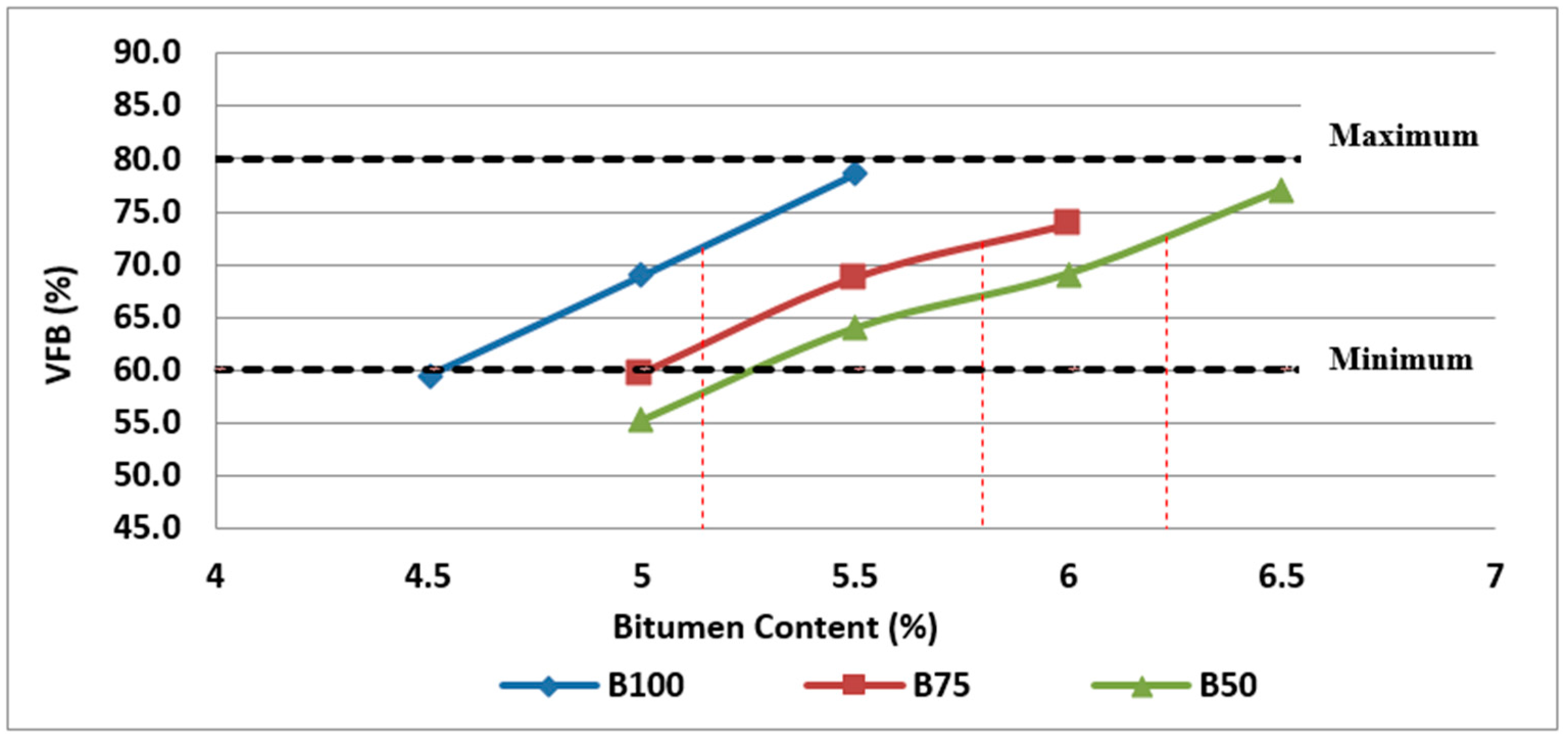

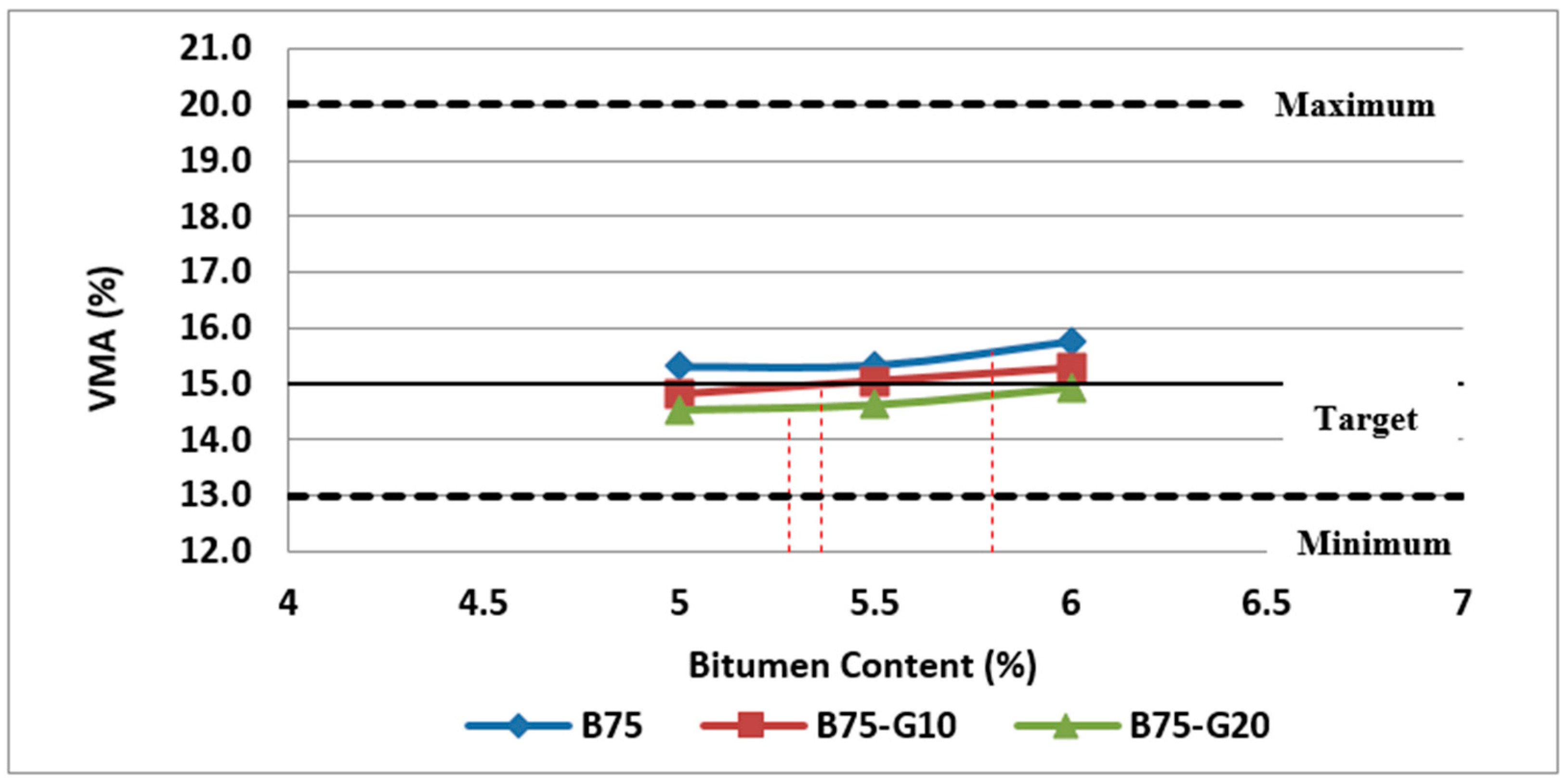

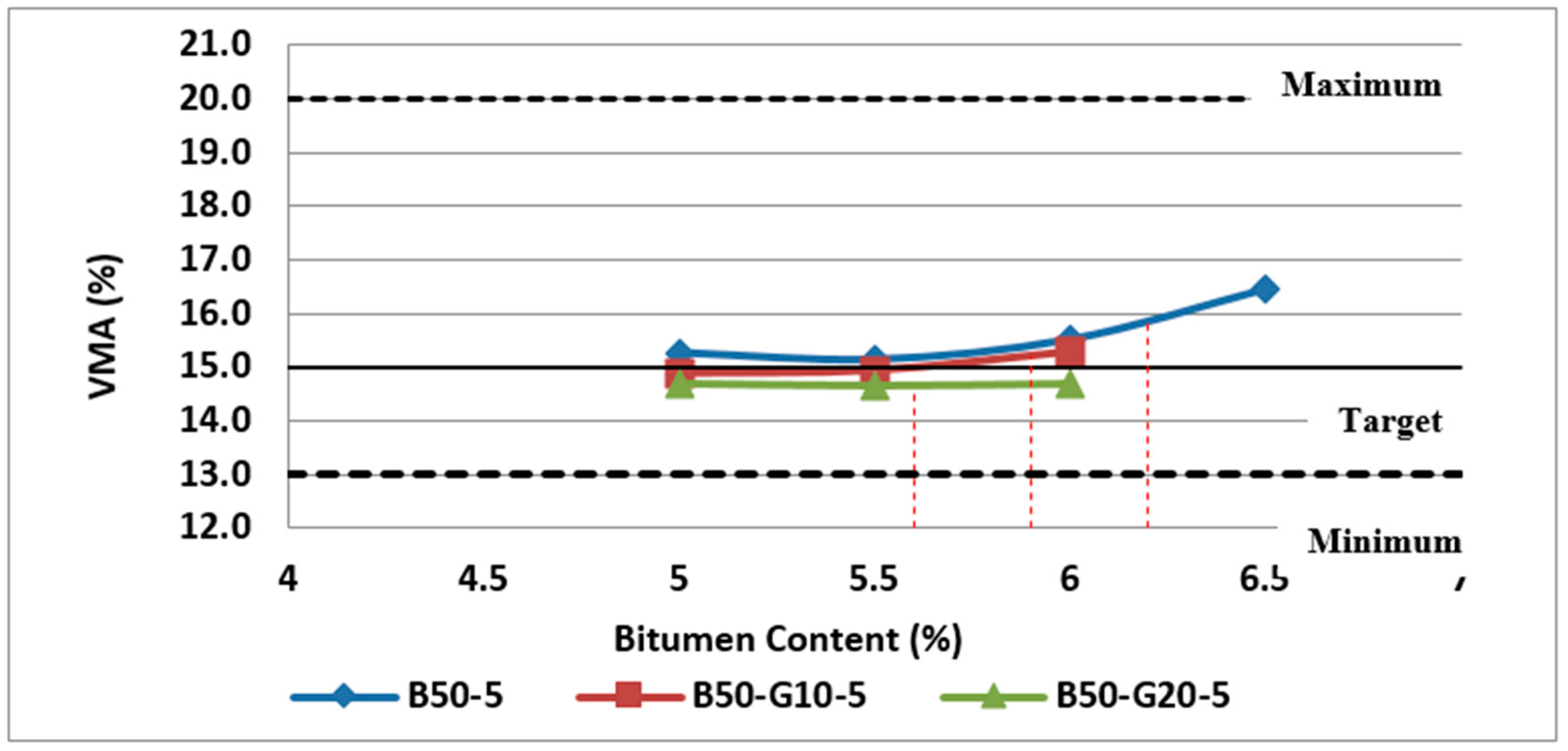

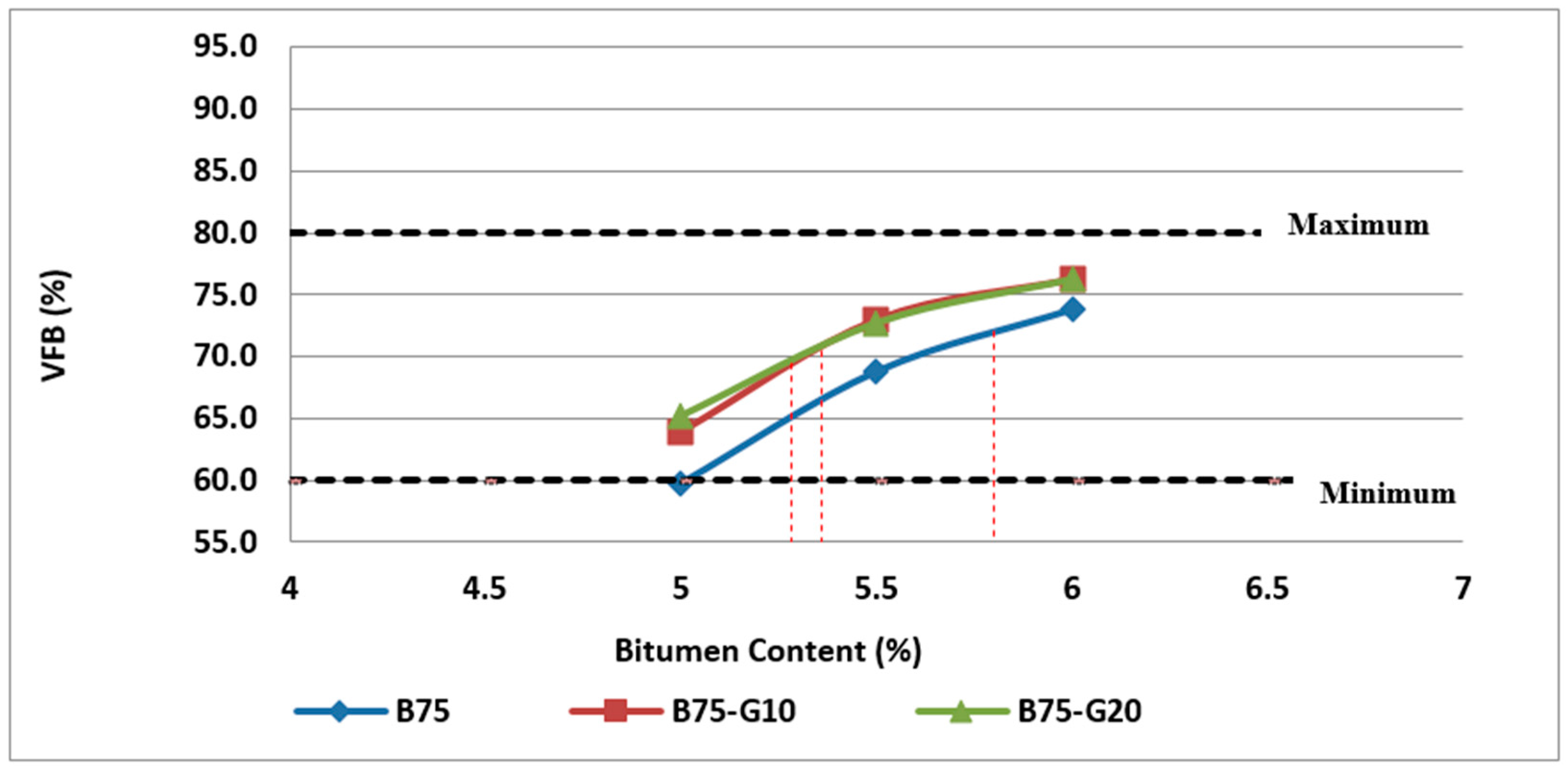

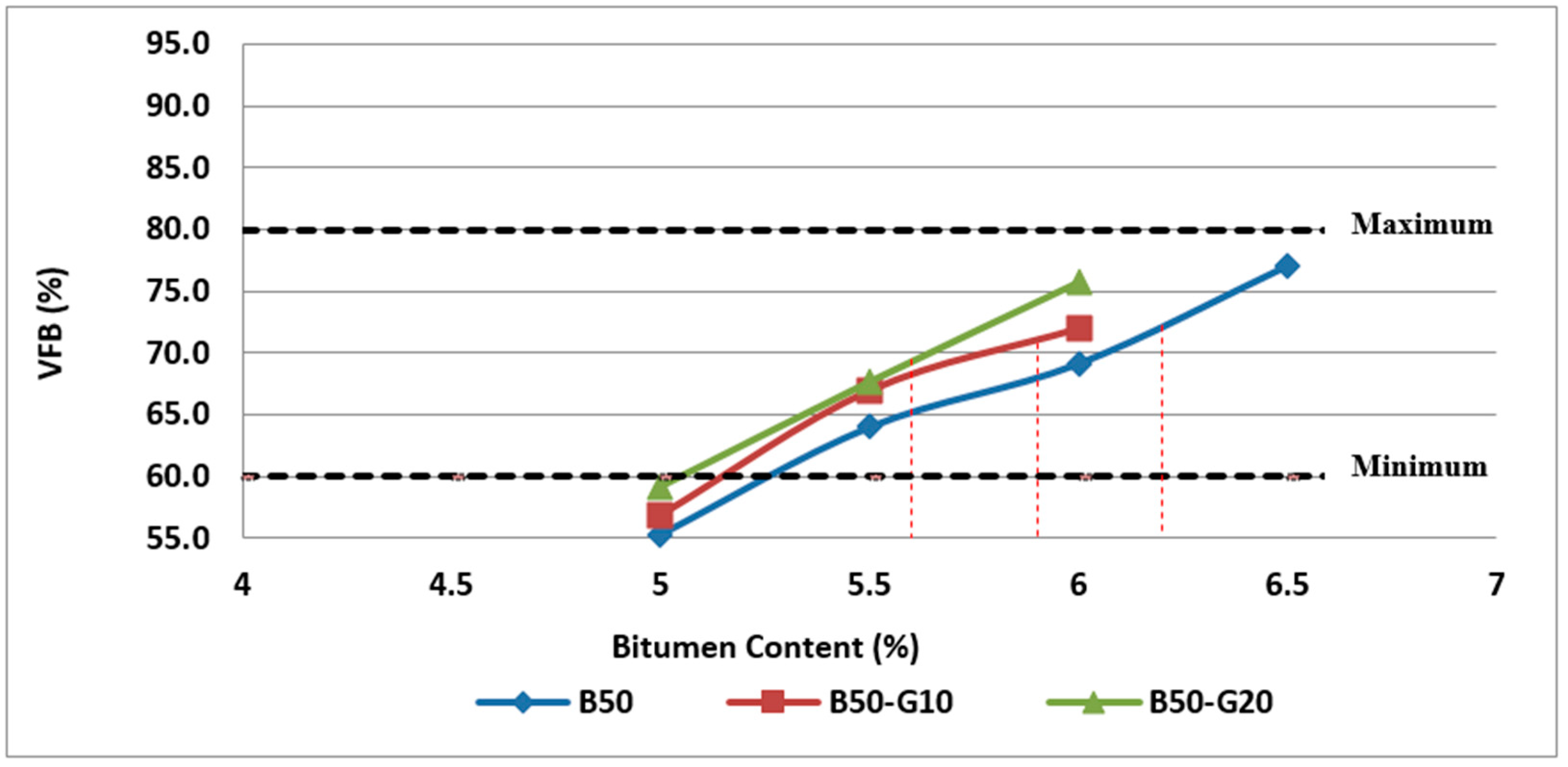

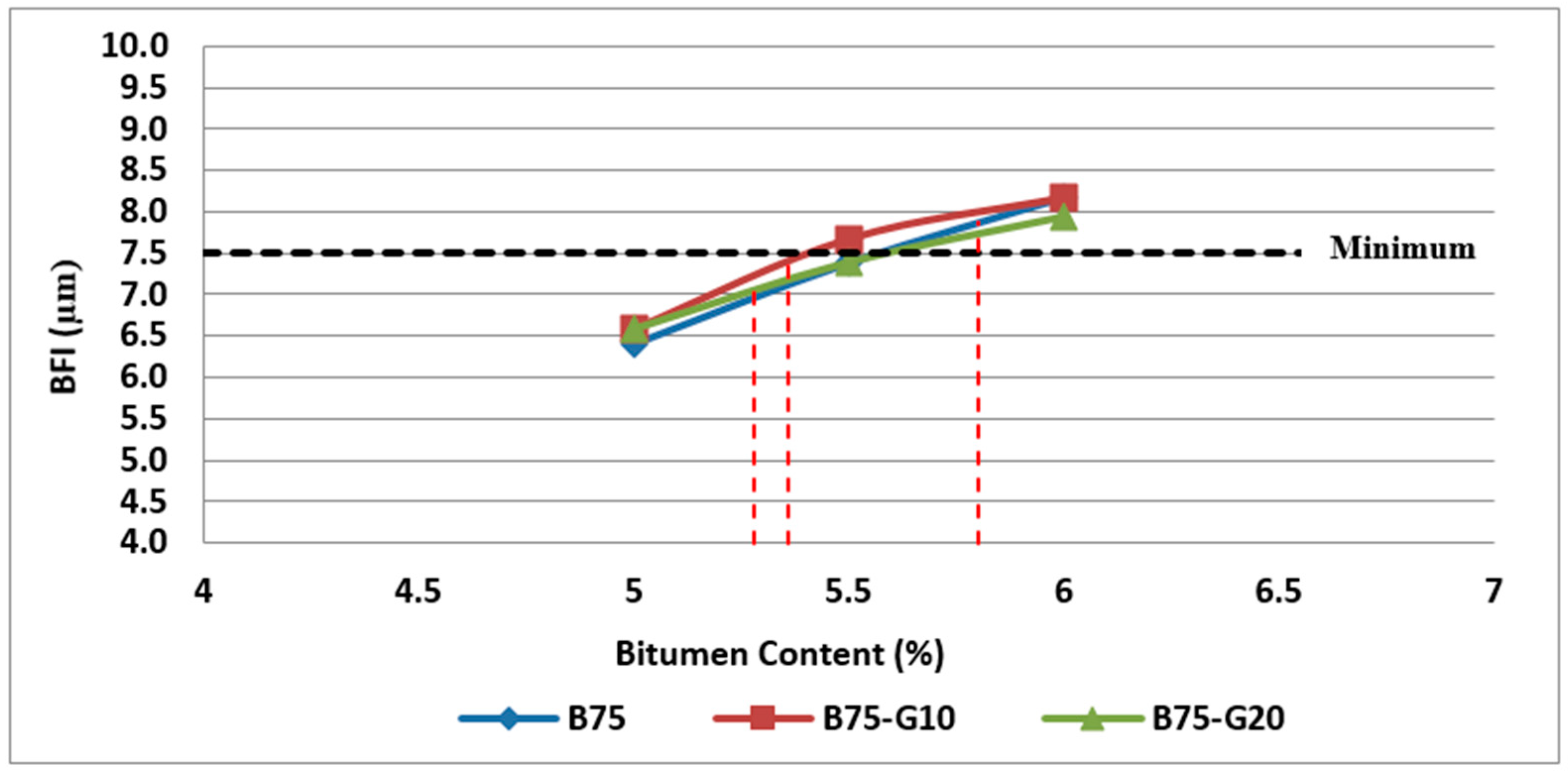

It is generally recognized that the volumetric composition of mixtures greatly influence their performance. The volumetric properties evaluation of asphalt mixtures is the fundamental of asphalt mix design, determining the performance of asphalt mixture. The asphalt mixture volumetric properties including void content, voids filled with binder (VFB) and voids in mineral aggregate (VMA) have been recognized as important parameters affecting the durability and performance of asphalt pavements [

62]. The minimum values are typically required for volumetric parameters depending on the asphalt mixture type.

As mentioned previously, all asphalt mixes in this research are dense-graded asphalt (DGA) with a nominal size of 14 (AC14), which are prepared in accordance with Test Method RMS T661 [

63] and RMS T662 [

64] (120 cycles of compaction) which are identical to AS2891.2.1 [

60] and AS2891.2.2 [

61], respectively. The requirements for volumetric parameters of this type of mixture are summarized in

Table 4. In addition, a summary of the tests carried out to study the mixtures properties is explained in the following sections.

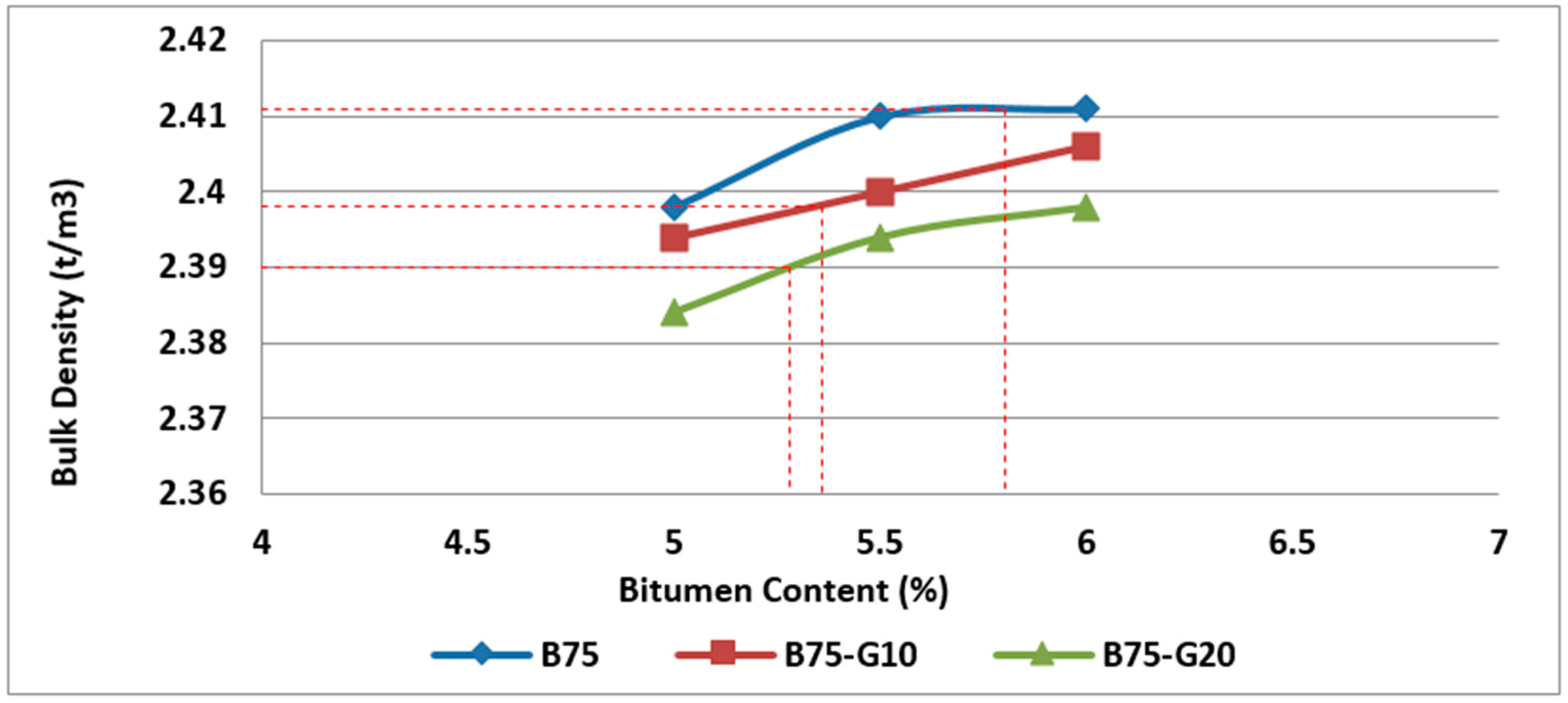

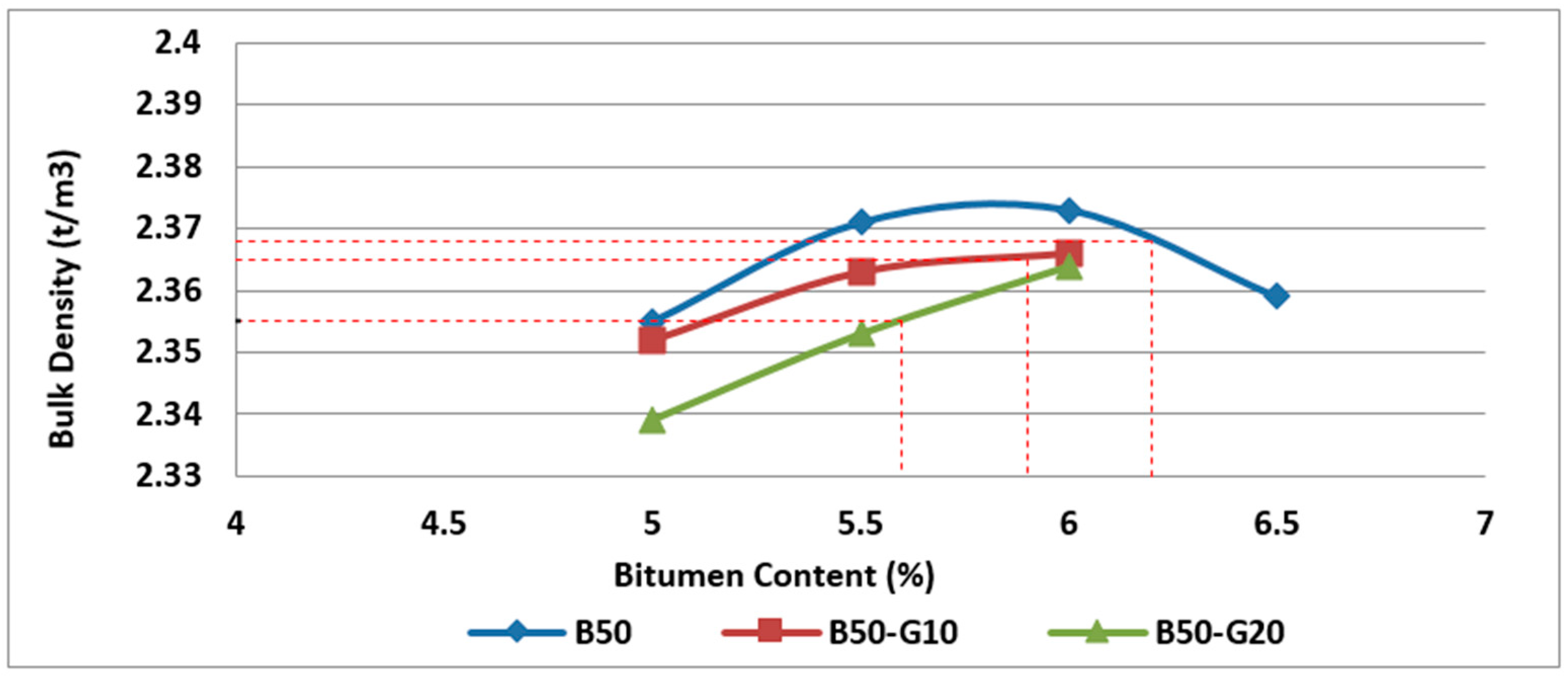

Bulk Density Test

In this research, the bulk density of compacted samples is determined using the presaturation procedure in accordance with AS/NZS 2891.9.2 [

65]. This method is suitable for dense-graded mixtures with internal air voids that are largely inaccessible to moisture resulting in low permeability.

Maximum Density Test

In this study, the maximum density of a loose sample of mix is determined using the methylated spirits displacement procedure, in accordance with AS/NZS 2891.7.3 [

66]. Based on this test method, firstly, the density of methylated spirit (

) was determined as 0.789 t/m

3.

Voids and Volumetric Properties

The voids and volumetric properties of asphalt mixtures are determined, in this research, in accordance with AS/NZS 2891.8 [

67].

3.4.3. Evaluation of Resilient Modulus of Asphalt Mixtures

The stiffness of asphalt mixtures is a fundamental property and plays an important role in determining the performance of asphalt pavement under traffic loading. The resilient modulus is the measure of stiffness of asphalt mixtures. In addition, the resilient modulus of asphalt mixtures is useful in determination of layer thickness through estimation of the relative strength coefficient and calculation of Structural Number (SN).

In this study, resilient modulus test was considered for evaluation of the stiffness of some specimens selected based on the results of a primary test to assess the effect of the RCA amount as well as the asphalt mixture composition on resilient modulus. To this point, the asphalt mixtures were prepared using different combinations but with the same gradation. Subsequently, the asphalt mixtures were compacted with GyroPac at the same level of compaction to make cylindrical specimens of 100 mm in diameter and 65 mm in height.

The resilient modulus, in this research, was determined through an indirect tensile strength test in accordance with AS/NZS 2891.13.1 [

68]. In this test, firstly, the diameter and height of specimens were measured. The specimen was placed in the temperature-controlled cabinet at the temperature of 25 °C to allow the temperature in the specimen to reach equilibrium prior to the test. Then, the machine and Linear Variable Differential Transformers (LVDT) were calibrated to conduct the test.

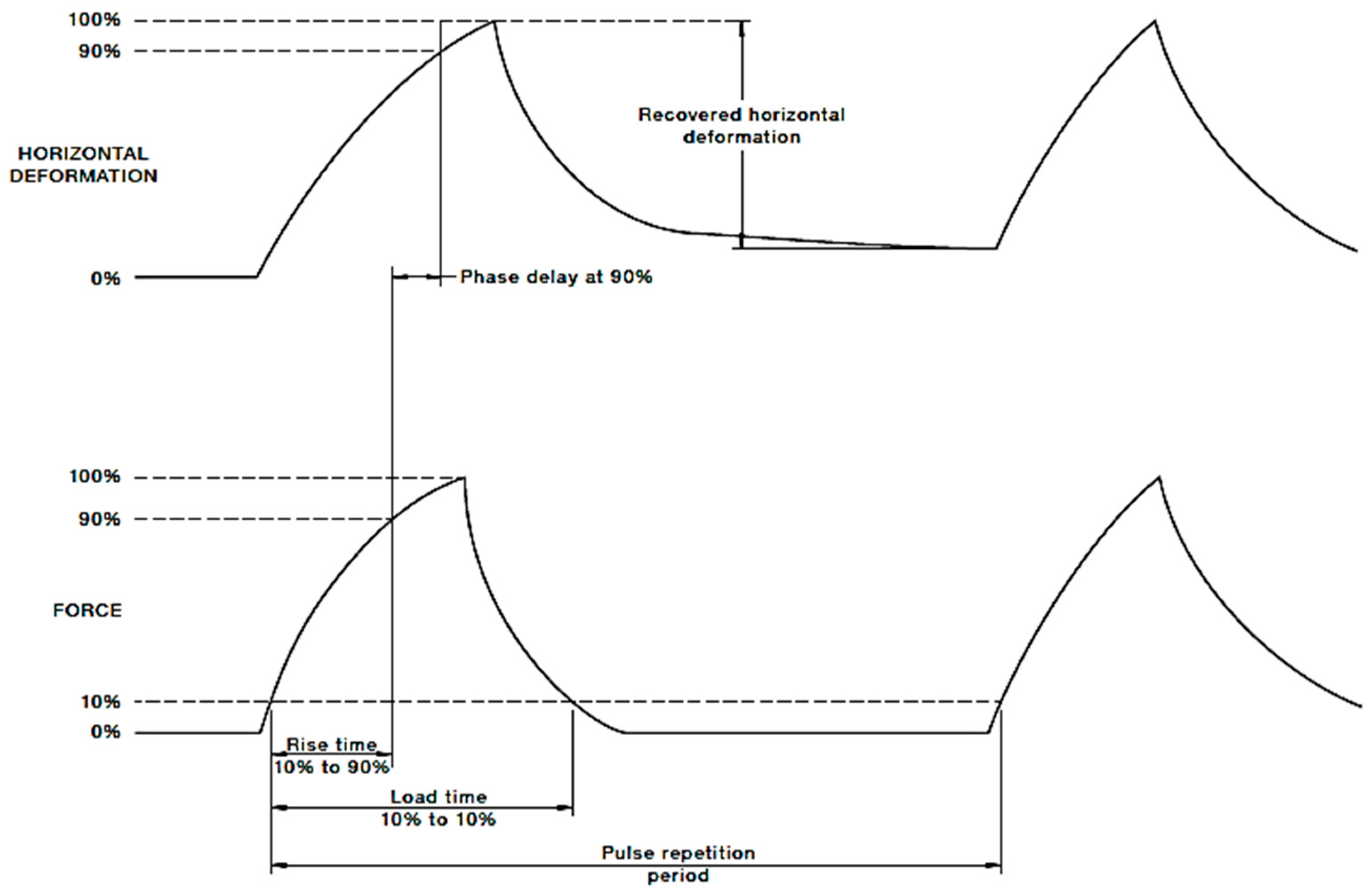

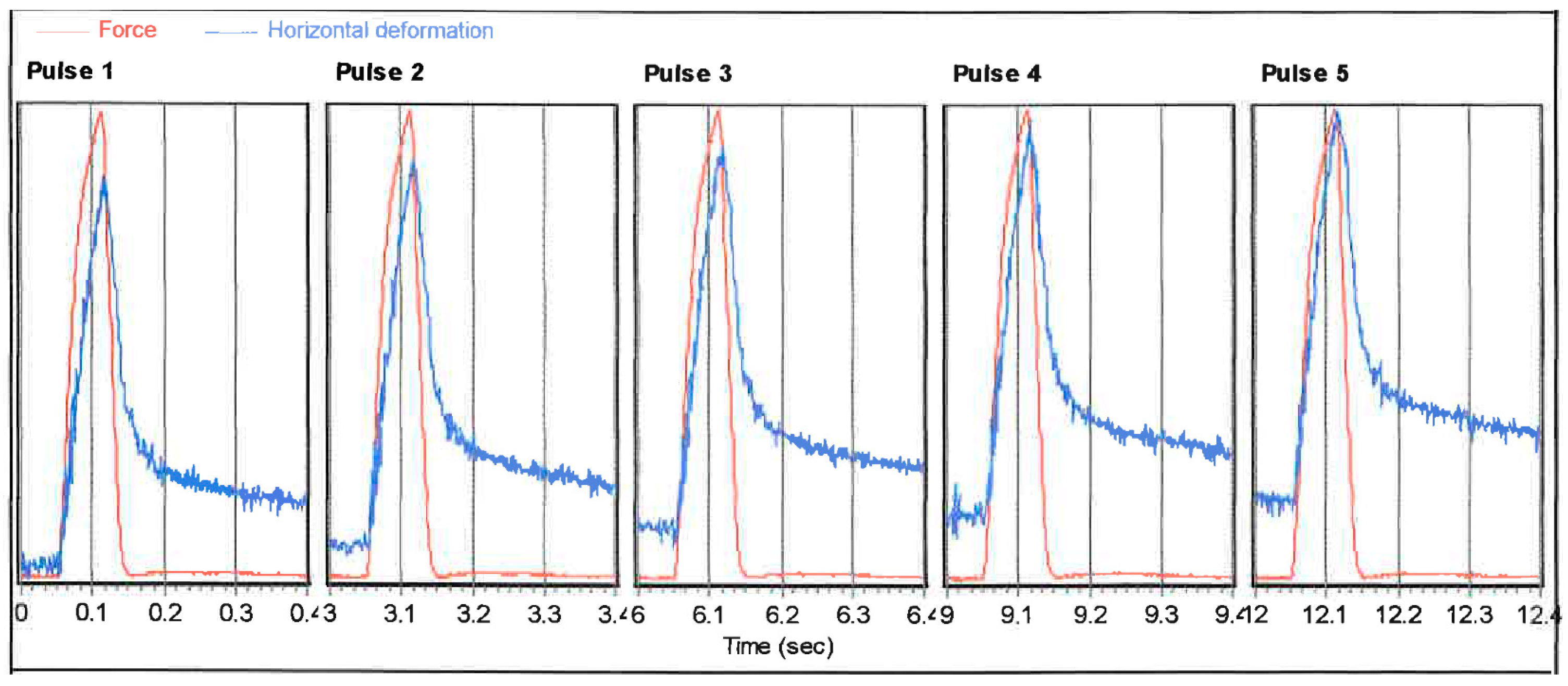

During the test, repeated haversine loading is applied to the specimen at the frequency of 0.1 Hz considering 0.1 s loading and 0.9 s rest period (

Figure 3).

Following the preconditioning, five load pulses were applied with a certain rise time to the peak load at a certain pulse repetition period. The recovered horizontal deformation of the specimen after application of each load pulse was recorded. The Poisson’s ratio is considered as 0.4 in accordance with AS 2891.13.1 [

68]. The resilient modulus

in MPa for each specimen for each load pulse during the resilient modulus test were obtained from the following equation:

where

is peak load (N),

is Poisson ratio,

is recovered horizontal deformation of the specimen after load pulse (mm), and

is the height of specimen (mm).

5. Further Research

Although many laboratory and field investigations have been already performed on the performance of asphalt mixtures made with recycled materials such as RCA and recycled glass, more studies are still required to deal with the challenges of this sustainable approach for further use. In this regard, a set of recommendations are provided for researching the engineering properties and other aspects of this technology, as follows:

The incorporation of waste glass in asphalt mixtures affects the bitumen absorption of mixtures, and therefore can compensate for the high bitumen-absorbing RCA. This research investigated the effect of glass on asphalt mixtures containing RCA considering three different percentages. However, it is recommended to investigate the effect of glass size, colours of glass and the glass content in asphalt mixtures.

Further investigation is required on the fatigue behaviour and also the ageing of asphalt mixtures containing RCA and glass.