1. Introduction

One-point-three billion people still live in off-grid areas [

1], and natural disasters often cut off the electricity supply in developed countries and regions. Providing a minimum amount of electricity in an off-grid area and under emergency conditions is vital for communications, medical electronic devices, lighting and other basic needs. A primary battery is the best choice, yet it has a limited life and the risk of unavailable resupply. Solar power generators and wind power generators are major solutions for the off-grid regions, yet they are weather dependent. Hand generators could be the ultimate solution, but depend on manpower. Therefore, other technologies should be developed to provide a minimum amount of electricity. Generating electricity from biomass stoves has attracted much attention in recent years [

2]. This has been achieved by adopting TE modules so that combustion inside the stove can power the thermoelectric generator, while cooking and heating still work simultaneously. Over two billion people burn biomass for cooking and heating [

3], which means that the stove-powered thermoelectric generator (STEG) has good prospects. Further, a well-designed STEG can power a blower to improve the combustion inside the stove, reducing CO and particle pollution [

4], which are known to be harmful.

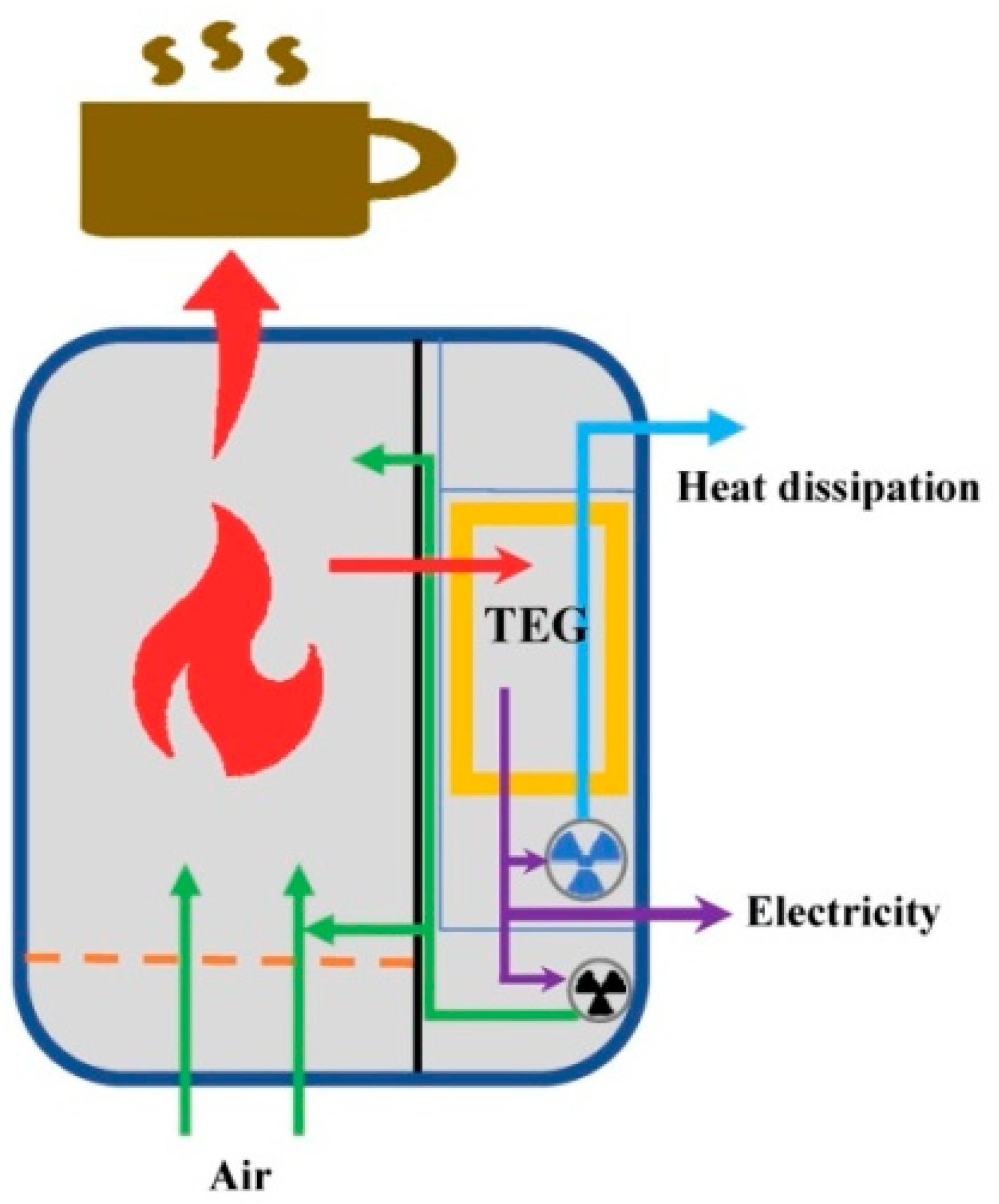

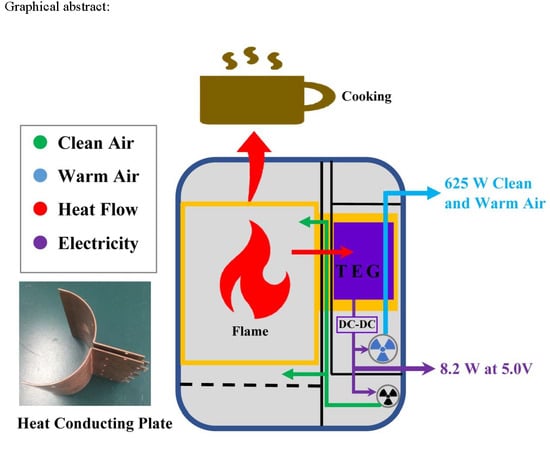

Figure 1 shows a basic STEG in diagram form.

The STEG utilizes the Seebeck effect, i.e., the temperature difference forces electrons to move in one direction between two different metals or semiconductors [

5]. The major advantages of a STEG are little maintenance and weather independence, whereas its drawback is low efficiency [

6,

7], a problem that may be solved by new technologies based on future research [

7]. Many previous studies have focused on STEG, but only a few selected experimental studies are reviewed in the present work. Experimental work on STEG falls into three groups: water-cooled STEG, natural draft air-cooled (NDAC) STEG and forced draft air-cooled (FDAC) STEG.

For the water-cooled STEG, Rinalde et al. [

8] obtained a total of 10 W of electricity. No DC-DC converter was used, and the power consumed by the water pump was not considered. Champier et al. [

9,

10] designed a STEG to produce electricity and to improve the combustion efficiency. The cold end was cooled by a water tank, and an output of electricity of 6 W was recorded [

9]. In this work, a DC-DC converter was used, and the TE efficiency was found to be about 2% for a temperature difference of 200 °C. For the optimized STEG, the same cooling method was used, but the output power increased to 7.6 W [

10]. Montecucco et al. [

11,

12] designed another type of water-cooled STEG, producing a net output of electricity of 19 W with a TE efficiency of about 4–5% for a temperature difference of 150 °C–200 °C. A DC-DC converter was employed here.

For NDAC STEG, Nuwayhid et al. demonstrated that the combination of a TE module and a stove can produce electricity [

2,

13,

14]. The STEG was optimized several times to increase the output power from 1 W [

2] to 3.4 W [

13], and then to 4.2 W [

14]. The cooling method was natural air convection, using ordinary finned heat sinks or heat pipes, and no DC-DC converter was employed. Lertsatitthanakorn [

15] developed a STEG with a maximum of 2.4 W recorded. The power load feature and the TE efficiency for various temperature differences were studied, indicating that the load resistance should be optimized to maximize output power, while the TE efficiency ranged from 1%–3.2% when the temperature difference varied from 44 °C–150 °C. Najjar and Kseibi tested a novel STEG to produce hot water and electricity [

16,

17]. A maximum power output of 7.8 W was recorded with no DC-DC converter. Detail temperature distributions were measured in different positions, and the influence of different fuel types was explored in these works. Moreover, a detailed comparison of previous STEGs was presented in their work [

17].

For FDAC STEG, Mal et al. [

4] tested a STEG, improving the exhaust gas quality (CO and particles) by adding a blowing fan. It was found that the CO and particle concentration decreased significantly when using a blowing fan; while the STEG produced electricity between 2 W and 4 W. O’Shaughnessy et al. [

18] distributed several STEGs in off-grid regions and ran a field test for 80 days. It was found that 3 Wh of electricity power met the basic need. Recently, the BioLite CampStove and BaseCamp, designed for outdoor activities and emergency conditions, can provide 2–5 W of electricity [

19]. Batteries are incorporated and should be charged before first use.

All the above works conclude that the STEG offers a suitable and economical alternative way to produce electricity in off-grid areas and under emergency conditions. However, different opinions should not be ignored, e.g., Sornek et al. [

20] concluded that it is not an economical method of producing electricity using TE modules, and the payback period is too long.

Surveying the above literature, while many aspects of various types of STEG were studied, indicating that the STEG is a potential method of obtaining electricity in off-grid areas and under emergency conditions, as of yet, it is far from fully understood. Several conclusions can be drawn based on the above literature.

- (1)

Water-cooled STEGs have larger output power than air-cooled ones. However, water is not always available everywhere at all times.

- (2)

NDAC STEGs were mostly used in previous studies, resulting in relatively large volumes and weights.

- (3)

FDAC STEGs have attracted attention recently, yet studies are limited.

- (4)

For FDAC STEGs, only a limited number of TE modules can be installed, which restricts their application.

In the present work, an FDAC STEG was designed with a novel type of heat collector allowing the installation of as many as eight TE modules. For safety and ease of use, no battery was incorporated. The maximum electricity power output is 60% larger than that of the available commercial product under comparable weight [

19]. First, the structure of the STEG and the experimental system are discussed. Second, the results of the startup performance, power load feature and TE efficiency are presented and discussed in detail. Third, the heat-conducting plate thickness, cooling fan selection, heat sink dimensions and TE module configuration are optimized. Finally, several conclusions are drawn. The present study offers new experimental data on FDAC STEGs and presents a new type of STEG.

2. Experimental System

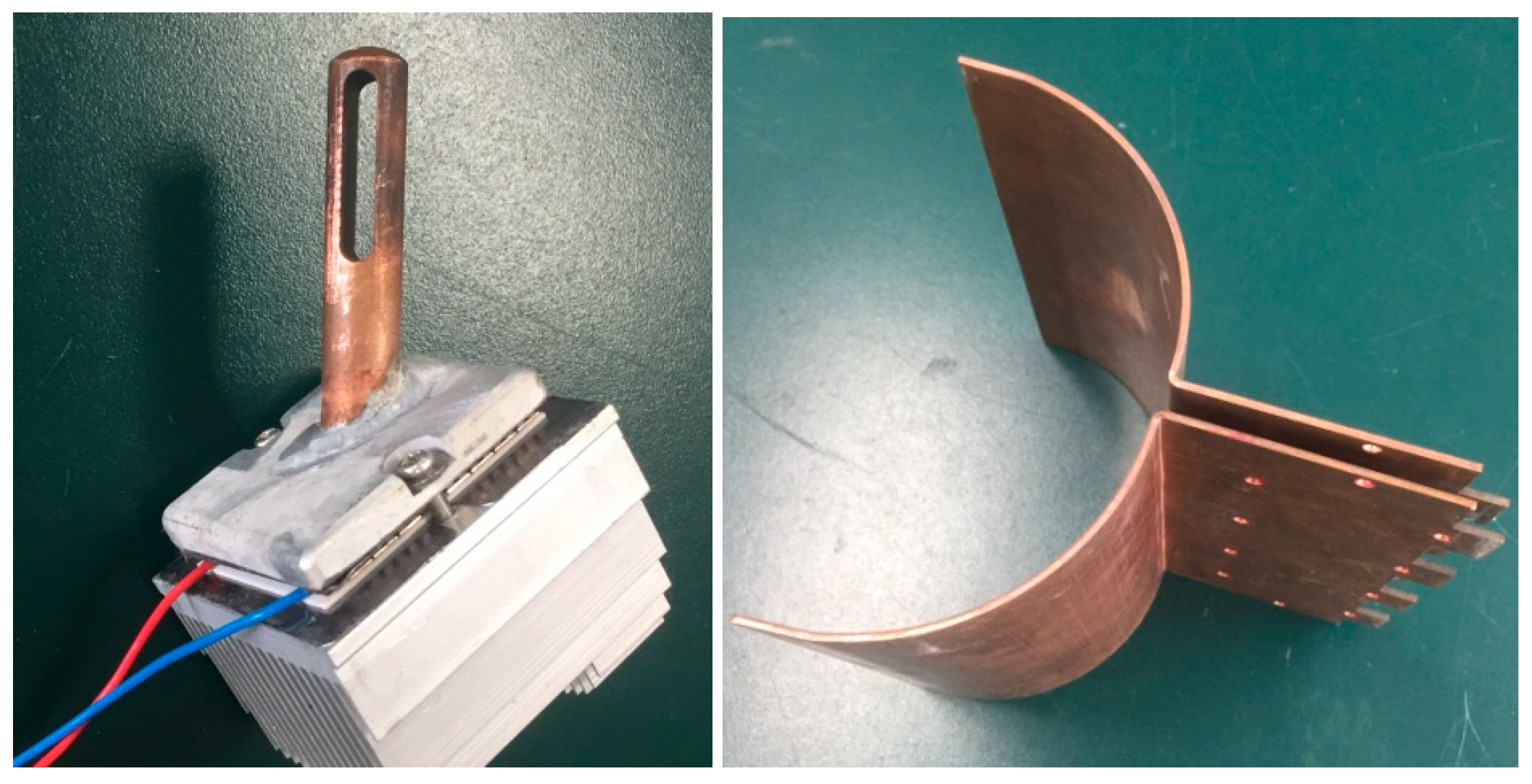

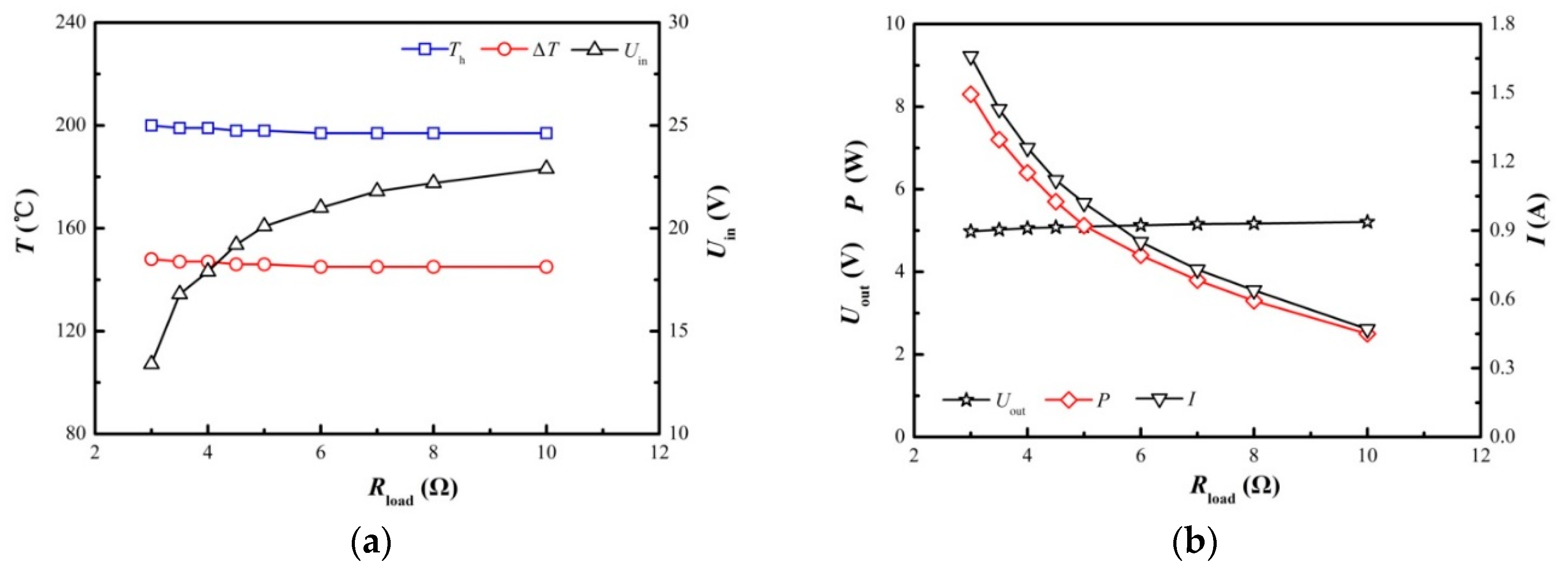

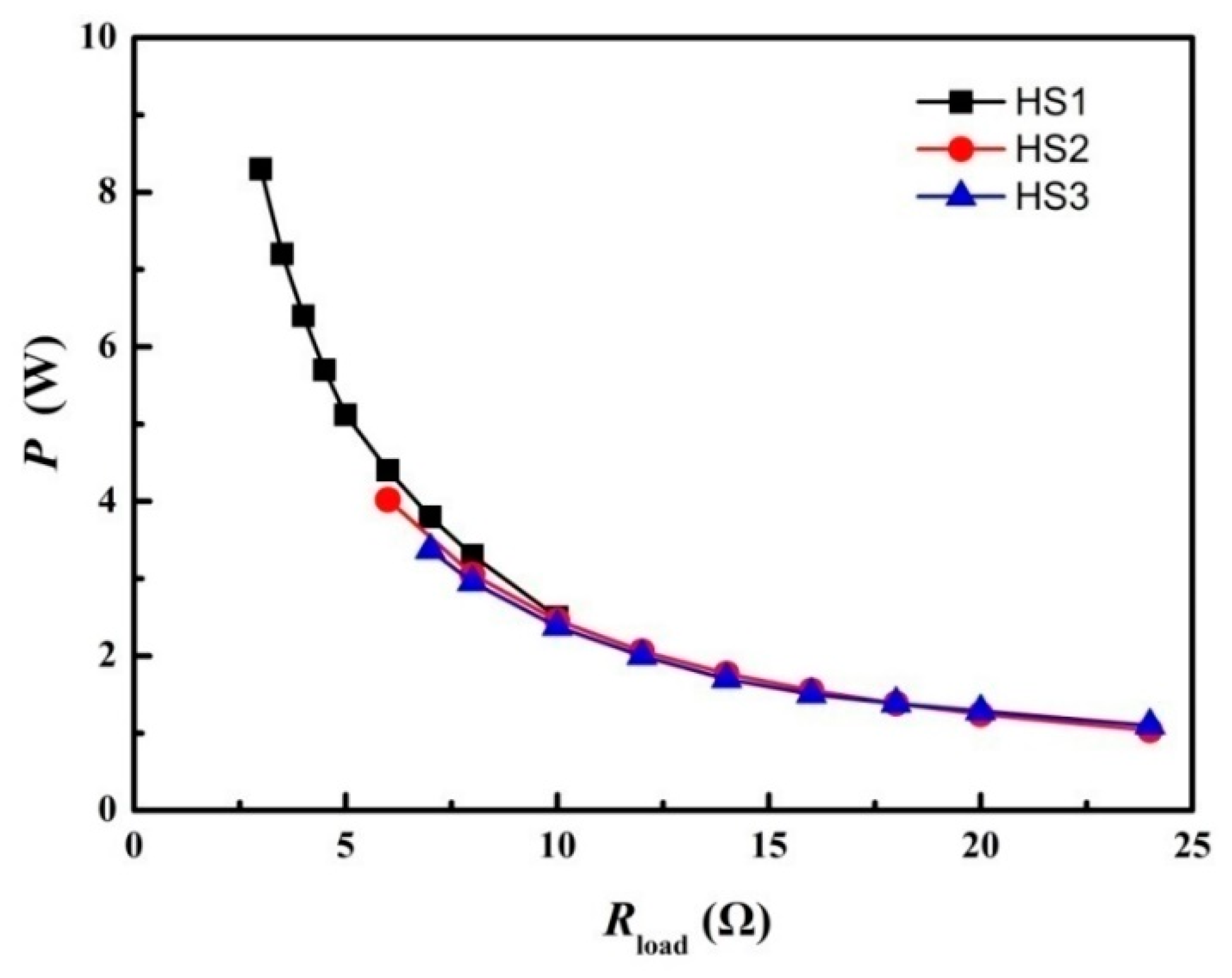

The experimental setup and the electricity circuit are shown in

Figure 2. The STEG consists of a semi-circular steel plate with a porous fuel holder, two quarter circle copper heat-conducting plates, eight TE modules, two aluminum alloy heat sinks, two cooling fans and two DC-DC converters. The semi-circular steel plate and the two quarter circle heat-conducting plates are installed together to form a circular combustion chamber, while a 30 mm-thick layer of fiber glass insulation is wrapped round the outside of the combustion chamber. The diameter and the height of the combustion chamber are 140 mm and 220 mm, respectively, and a porous fuel holder is installed 30 mm above the bottom surface of the combustion chamber. The copper heat-conducting plate has a “Z” shape, and two plates are installed together in opposing direction to form a semi-circle to provide part of the combustion chamber and to form a flat plate for the installation of the TE modules. Eight TE modules, type “TEP1-126T200” with dimensions of 40 mm (length) × 40 mm (width) × 3.8 mm (thickness), are installed on the opposing surfaces of the right-hand side of the heat-conducting plate, equally spaced. The TE material is Bi

2Te

3, and the dimensions of the thermo-element (leg) are 1.3 mm × 1.3 mm × 1.55 mm (length). Typically, the TE module produces 2.8 watts under a temperature difference of 150 °C, and the working temperature of the TE module does not exceed 250 °C. Two aluminum alloy heat sinks are bolted above the TE modules. Two DC air fans are installed on the top surface of the heat sinks, blowing outside air into them, while aluminum foil was used to seal the top surface of the other heat sinks. In order to determine the TE efficiency, an extensible aluminum tube with a diameter of 120 mm was installed to connect the outlet of the heat sinks, so as to form an air duct. This extensible aluminum tube can be used to supply clean and warm air to tents, and heat insulations should be employed when the distance between the tent and the STEG is far away. Two DC-DC converters (type MP1583) were adopted to stabilize the output voltage at 5.0 V. One DC-DC converter was used to supply electricity to the cooling fans, and the other one was used to provide electricity for the external load.

A sketch map of the experimental system is shown in

Figure 2b,c. Four thermocouples with a diameter of 1 mm are installed. The first thermocouple is installed at the center point of the top end of the heat-conducting plate, measuring the hot end temperature. The second one is installed at the center point of the top end of the heat sink, measuring the cold end temperature. The third thermocouple is installed at the outlet of the heat sink, while the fourth one is installed at the exhaust exit of the extensible aluminum tube. The distance from the outlet of the heat sink to the exhaust exit is 800 mm, and screens are installed to ensure uniform air flow. The measuring range and the accuracy of the thermocouples are −200–400 °C and ±0.5%, respectively. The temperature signals were recorded by an Agilent-34,970 A data acquisition instrument combined with a Benchlink Data Logger program. The average air velocity was measured with a Peakmeter MS6252B turbo type anemometer. The measuring range and the accuracy of the thermo-anemometer are 0.8–30.0 m/s and ±2.0%, respectively. The average air velocity and the exhaust air temperature (

T4) are used to calculate the mass flow rate of the cooling air. The power load feature was measured using Prodigit 3311F electronic load. Its measuring range and accuracy are 0–60 V (300 W) and ±0.5%, respectively. Charcoal is used as the fuel in the present experiment. The net calorific power and the density of the charcoal is 31.2 MJ/kg and 1322 kg/m

3, respectively, and the ash mass fraction is 4.87%. The errors of the parameters are shown in

Table 1, where the efficiency of the DC-DC converter was found to be 77.3% using two electric energy testers installed before and after the DC-DC converter. The operation procedure of a running of the present STEG test includes several steps. e.g., Step 1: Put a certain amount of dry branches into the combustion chamber, then put a certain amount of charcoal above the dry branches. Turn on the data acquisition instruments, and initialize the data recording programs. Step 2: Ignite the dry branches. Step 3: Carry out the power load tests when the STEG reaches the steady state. Step 4: Hard charcoal is added into the combustion chamber if necessary. Step 5: Measure the parameters of the exhaust flue gas. On the other hand, the typical running of the pilot product based on the present STEG shown in

Figure 2a is much more user-friendly. First, ignite the branches or any other combustible solid fuels. Second, the clean-and-warm air and electricity can be used when the indicator is above 15 within minutes (an indicator was designed in the pilot product).

Figure 3 shows the heat collector. Copper rods are installed in earlier FDAC STEGs [

4,

18,

19], inserted into the fame zone. This design may be inconvenient when adding fuels, and gaps between the copper rods and the plate where TE modules are fitted may cause the failure of the STEG [

18]. In the present unit, copper plates are used as the heat conductor. This avoids possible gaps. This type of heat collector has several advantages: (1) It is easier to install several TE modules. (2) There is no intrusion into the combustion chamber. (3) It works with various types of fuel, i.e., flaming fuels such as dried twigs, and flameless fuels, such as charcoal. The disadvantage is the weight of the heat collector. A pilot product with dimensions of 265 mm × 173 × 320 mm, based on the present STEG, is shown on the right side of

Figure 2a, and it has all functions indicated in

Figure 1. The mass weight of the pilot product is 8.42 kg, which is 0.26 kg heavier than the BioLite BaseCamp [

19].