Tensile, Quasistatic and Dynamic Fracture Properties of Nano-Al2O3-Modified Epoxy Resin

Abstract

1. Introduction

2. Materials and Sample Preparation

2.1. Materials

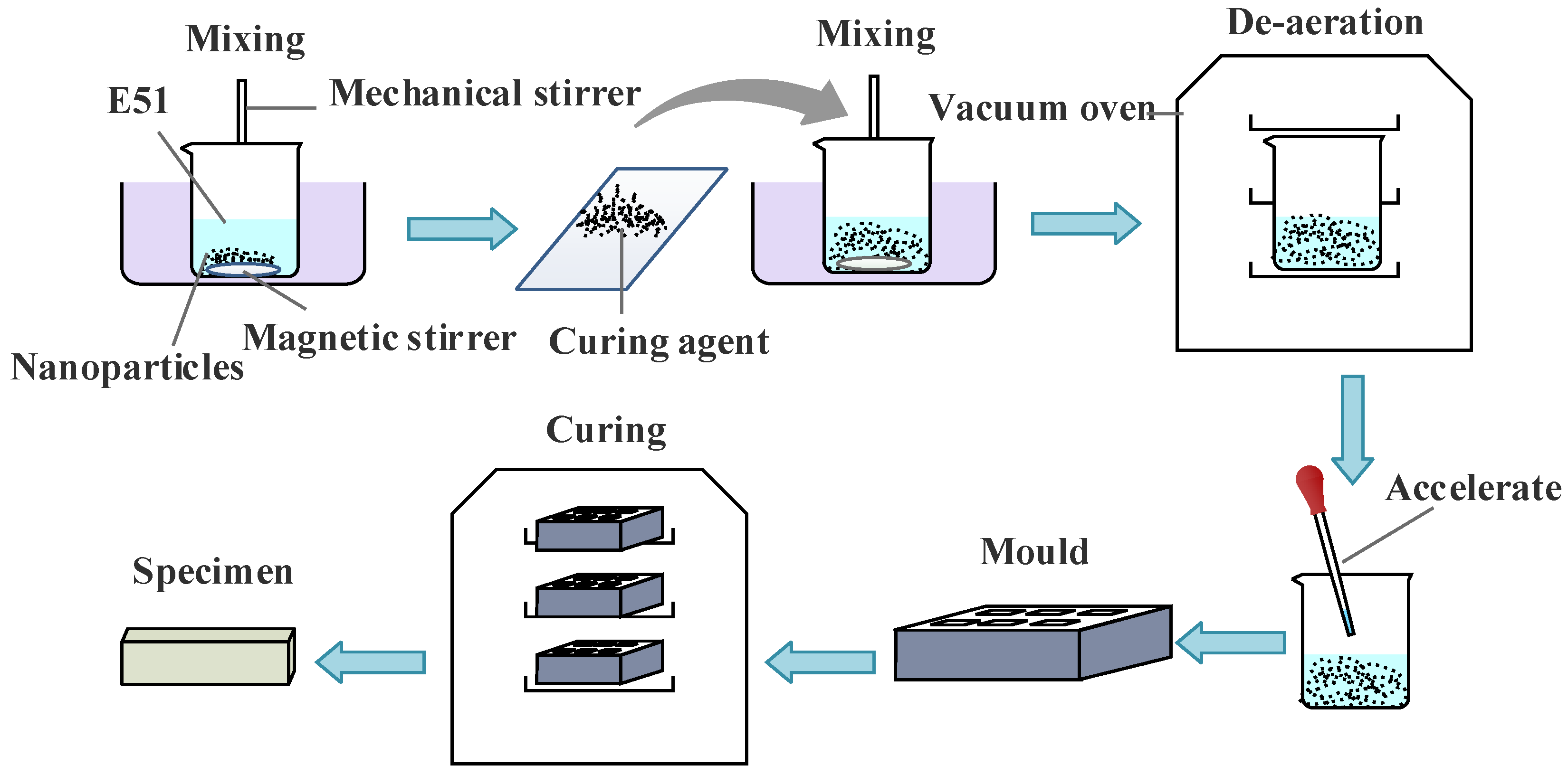

2.2. Samples Preparation

3. Experimental Section

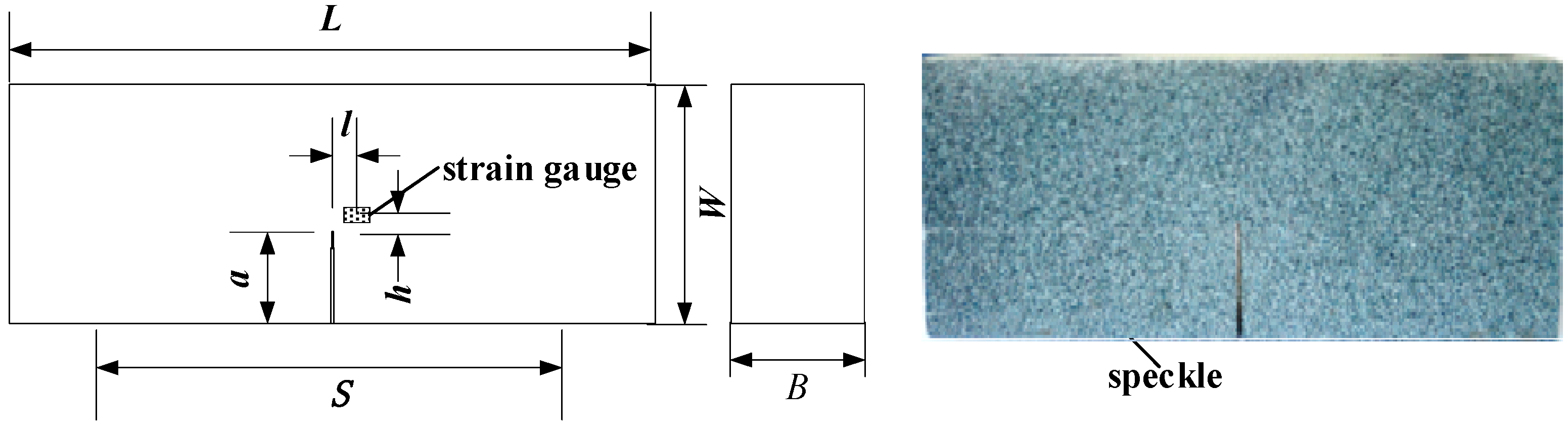

3.1. Tensile and Quasisstatic Mode-I Fracture Toughness Test

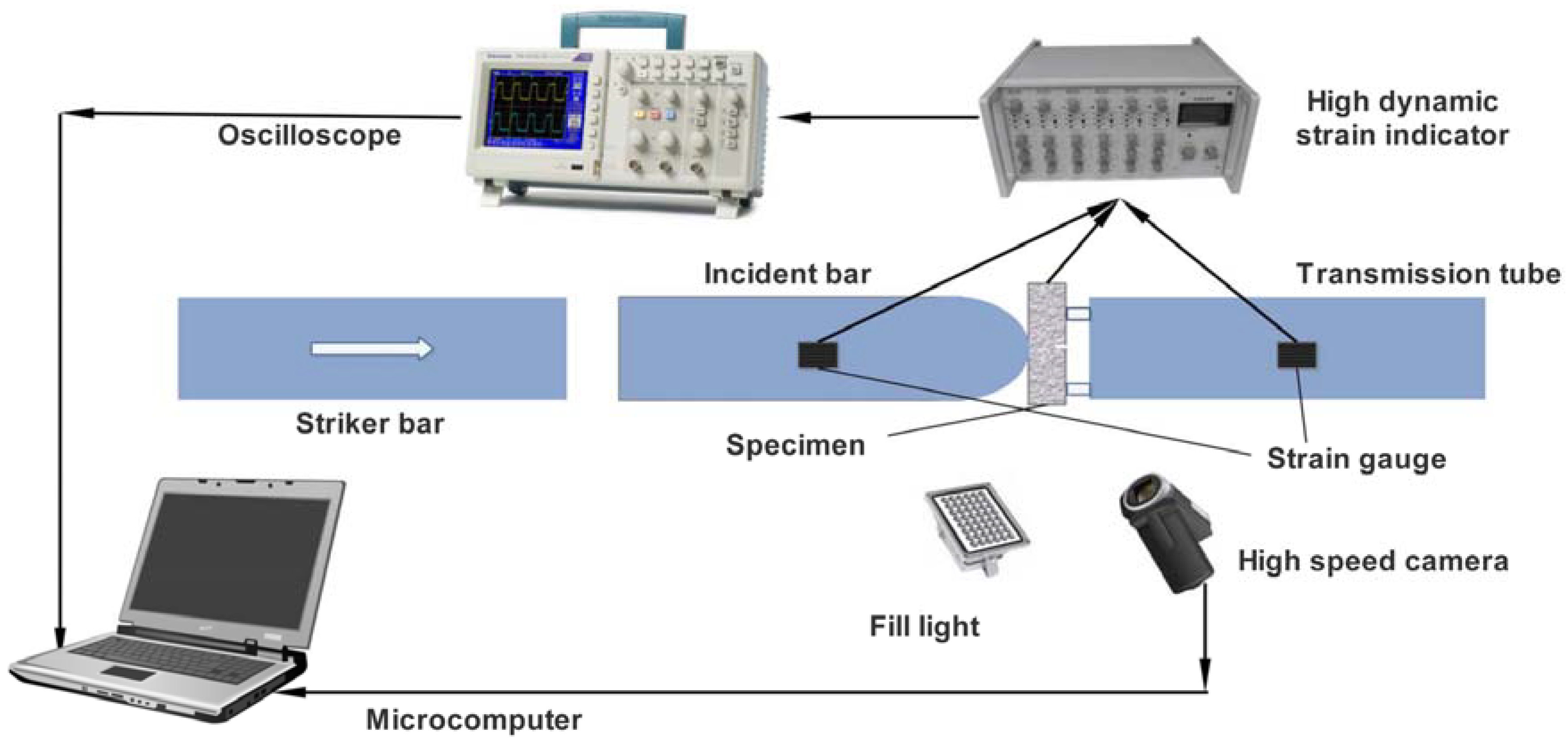

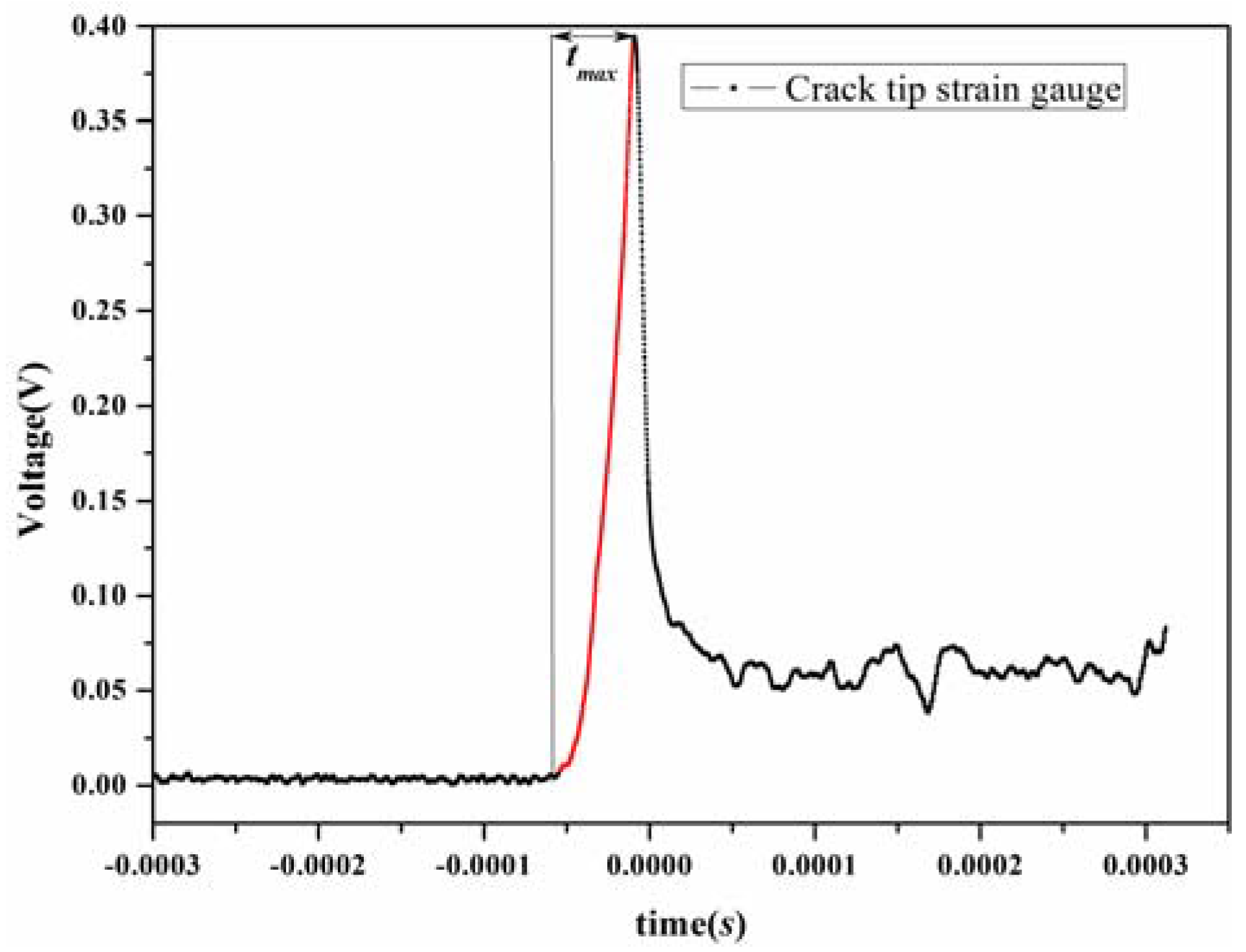

3.2. SHPB Loading System

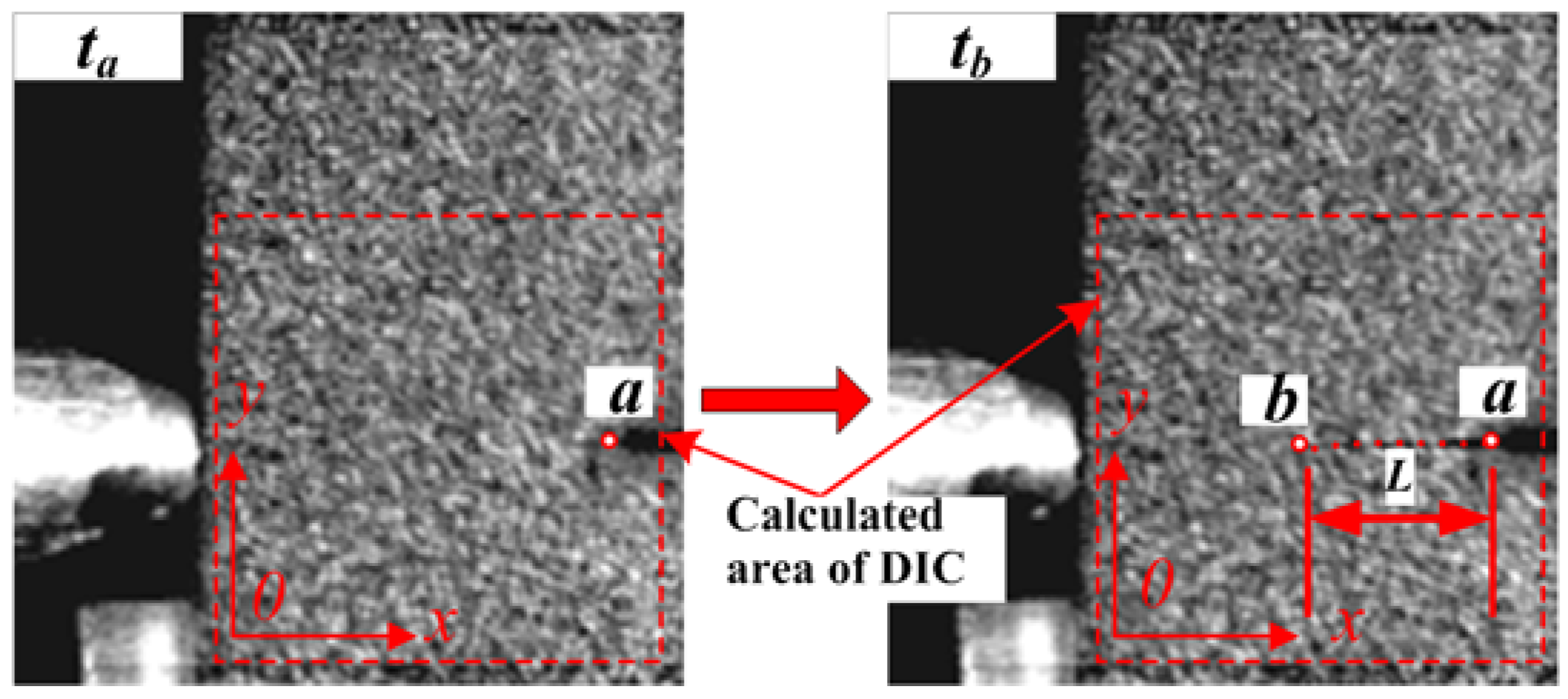

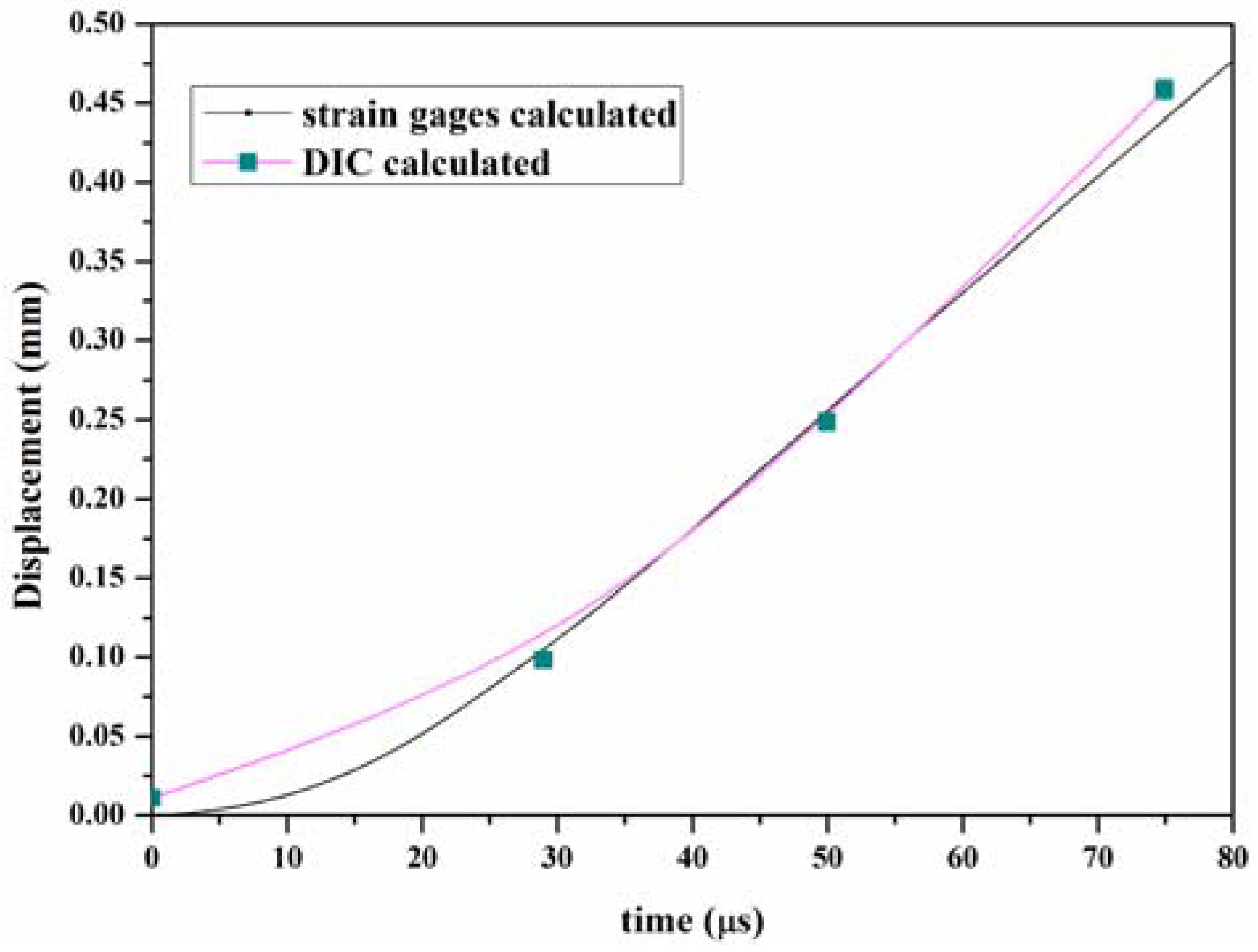

3.3. Data Analysis

4. Results and Discussion

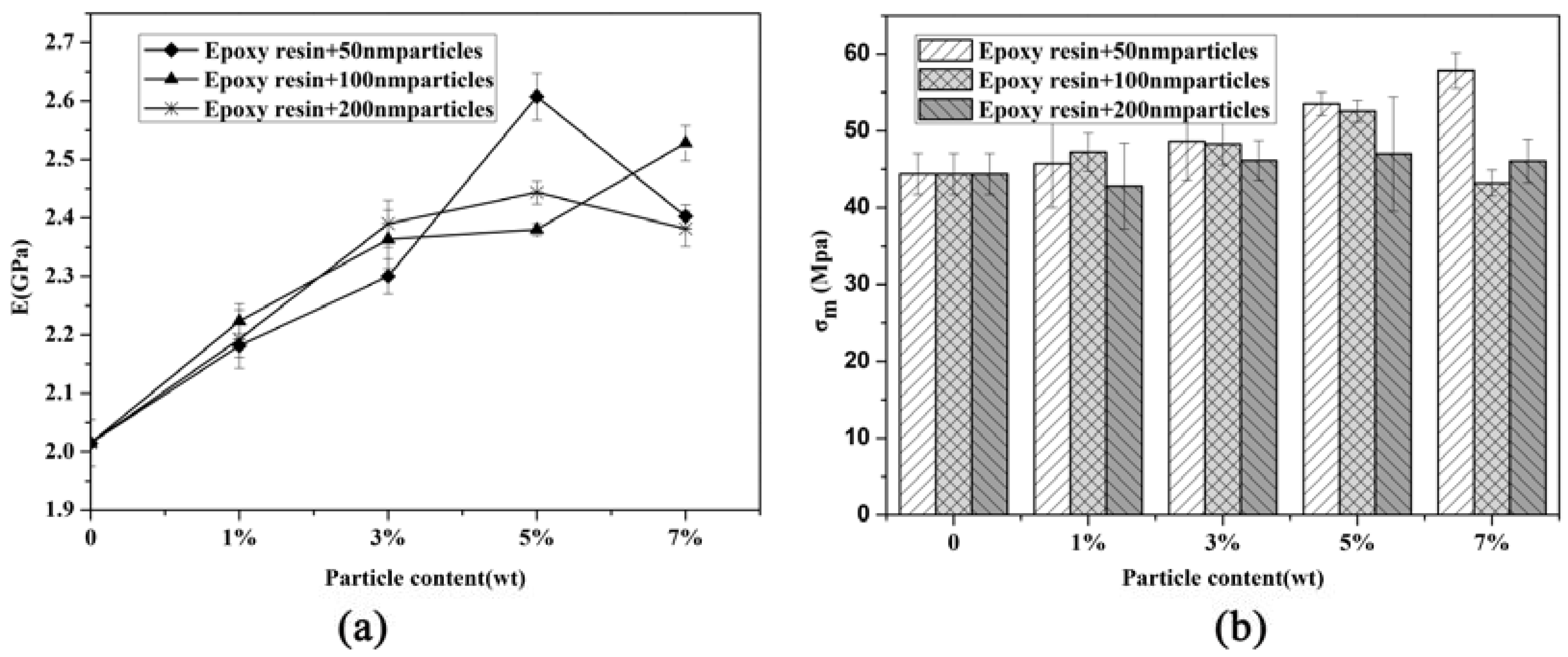

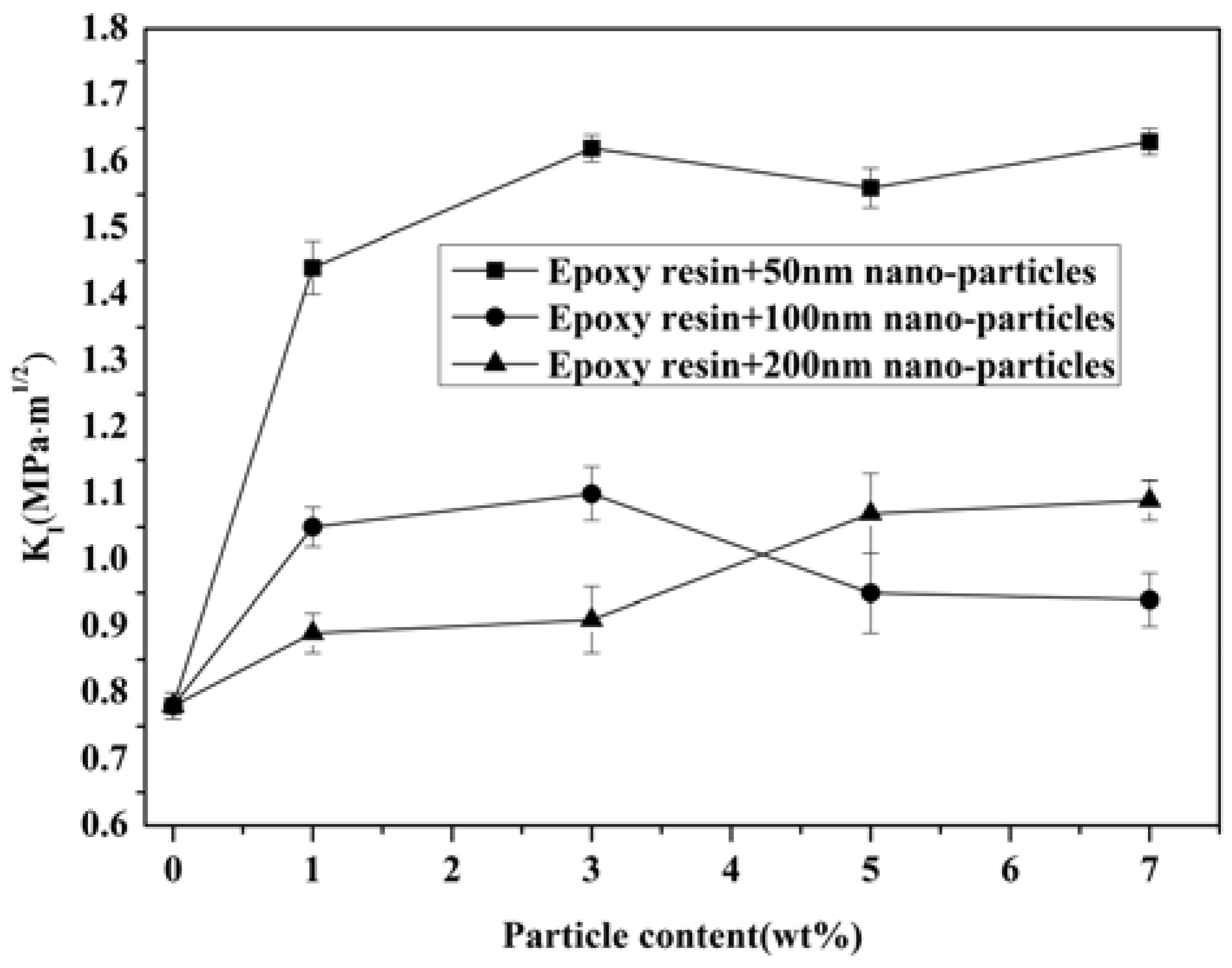

4.1. Tensile and Quasistatic Mode-I Fracture Toughness

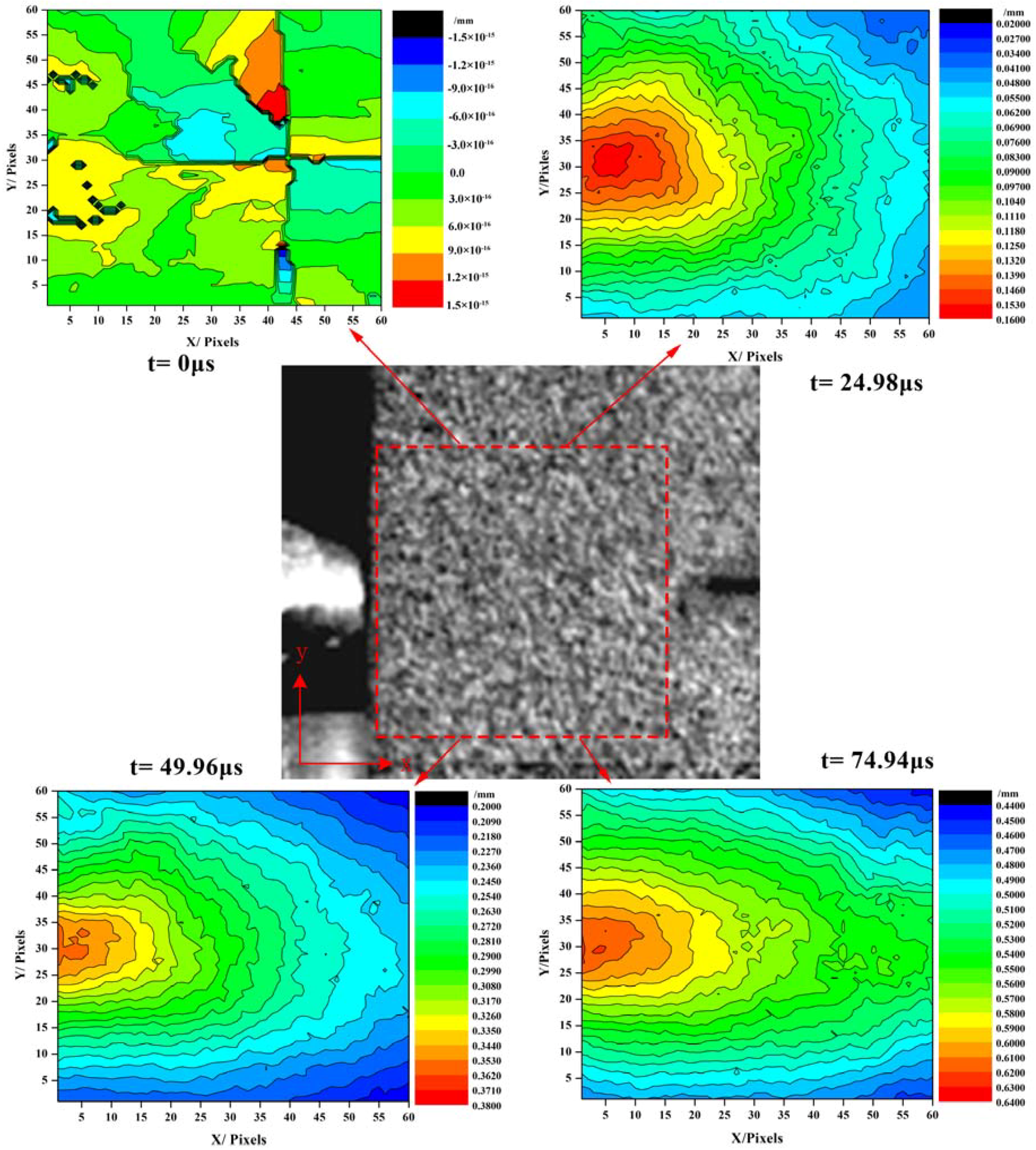

4.2. Effect of Particle Size and Content on the Crack Propagation Velocity

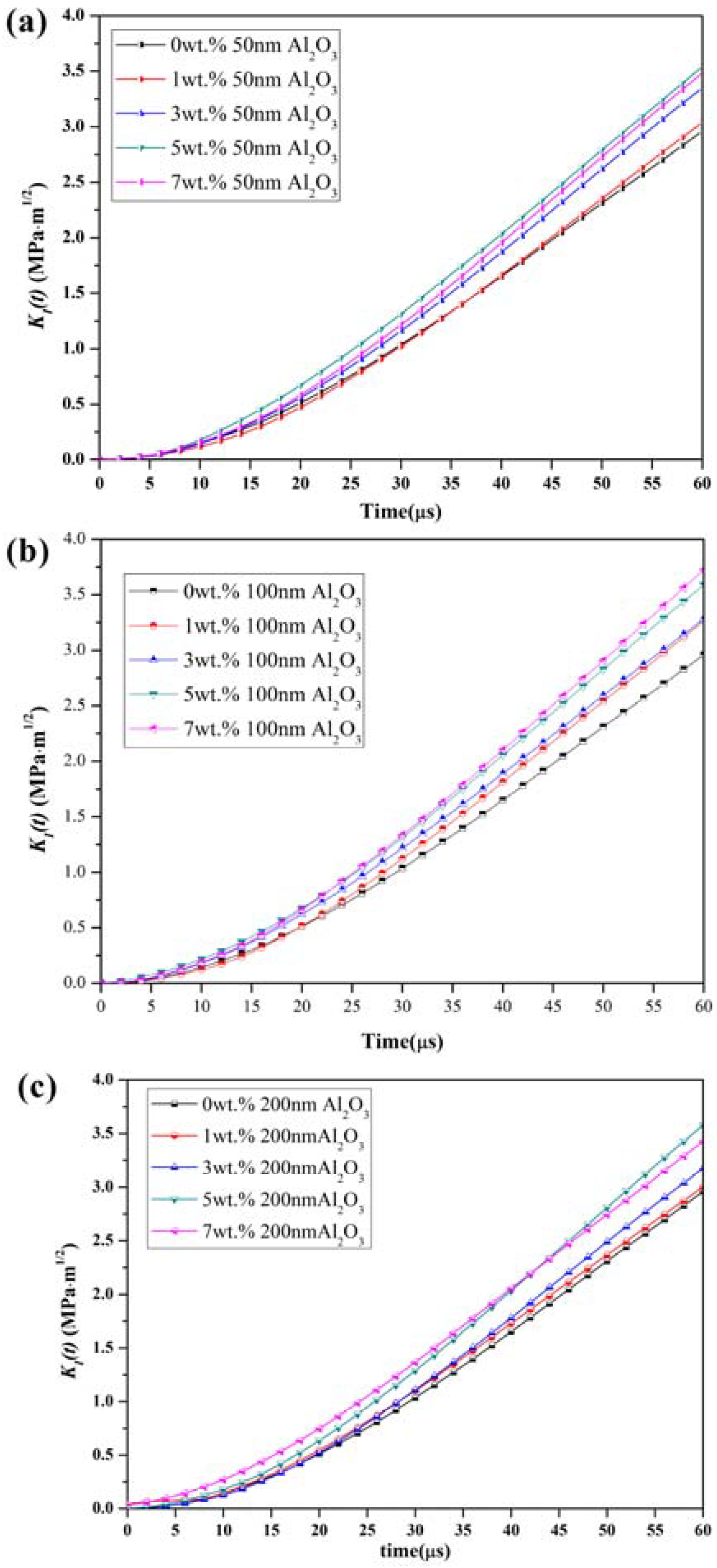

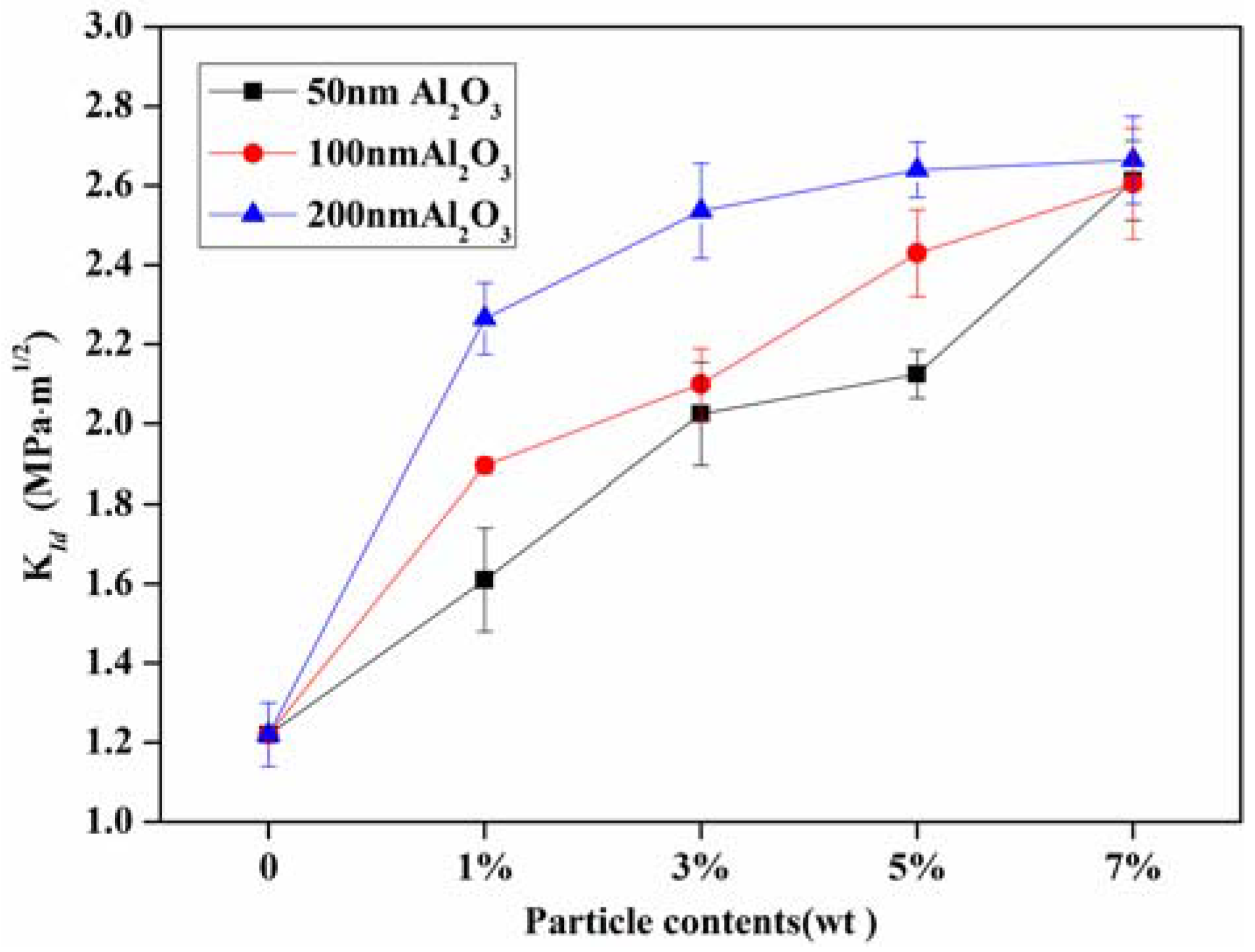

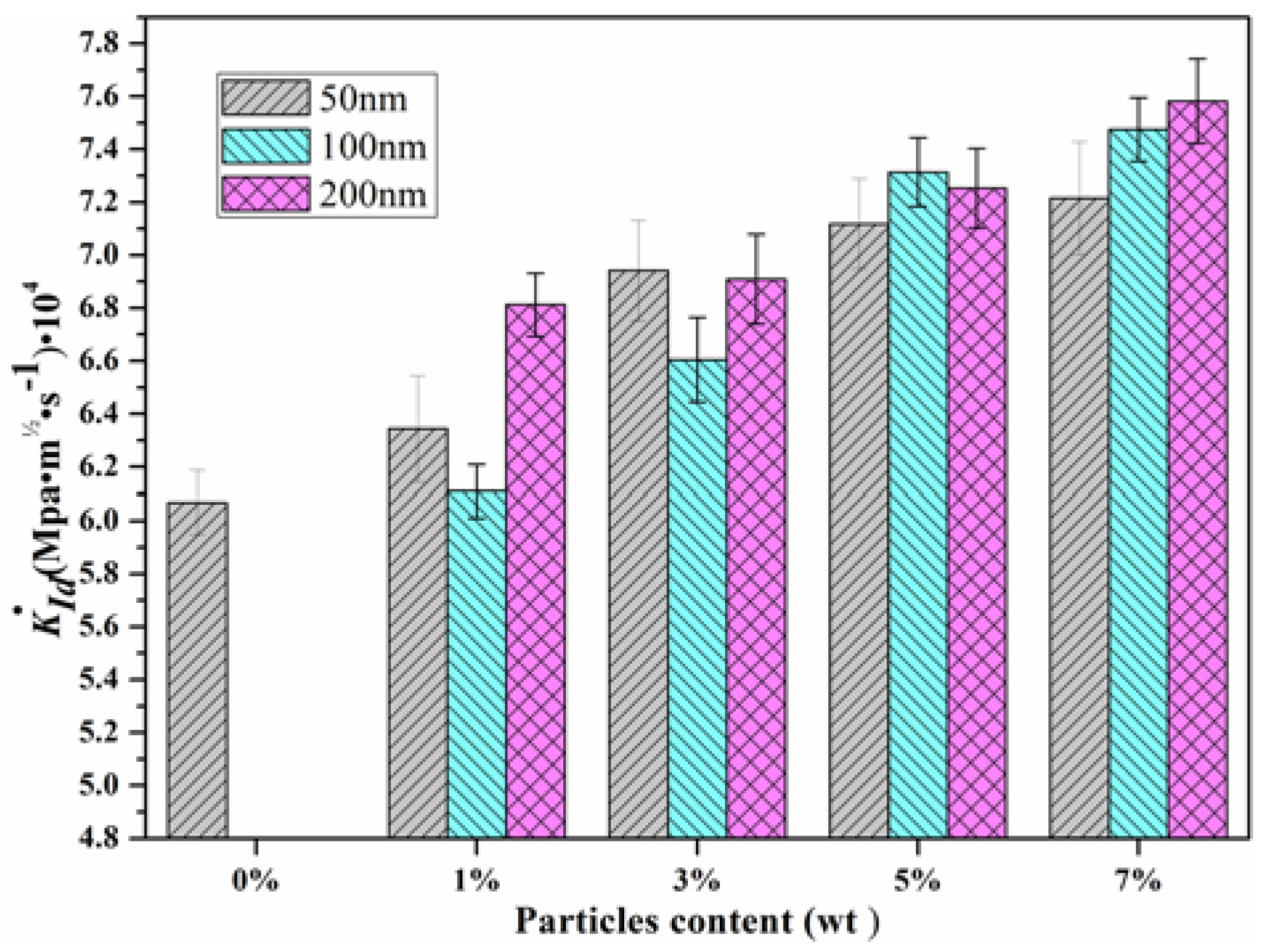

4.3. Effect of Particles Size and Content on the Dynamic SIF

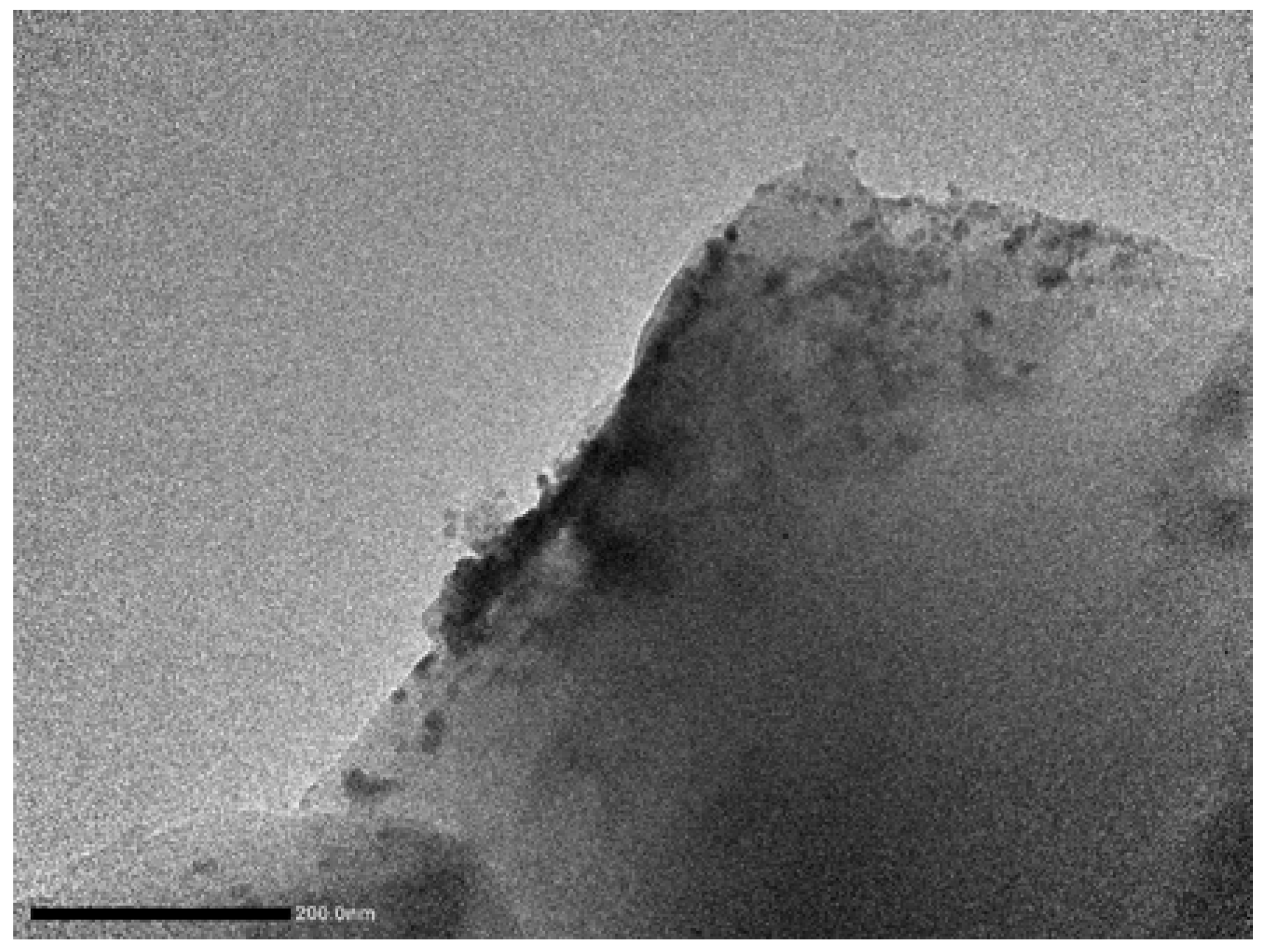

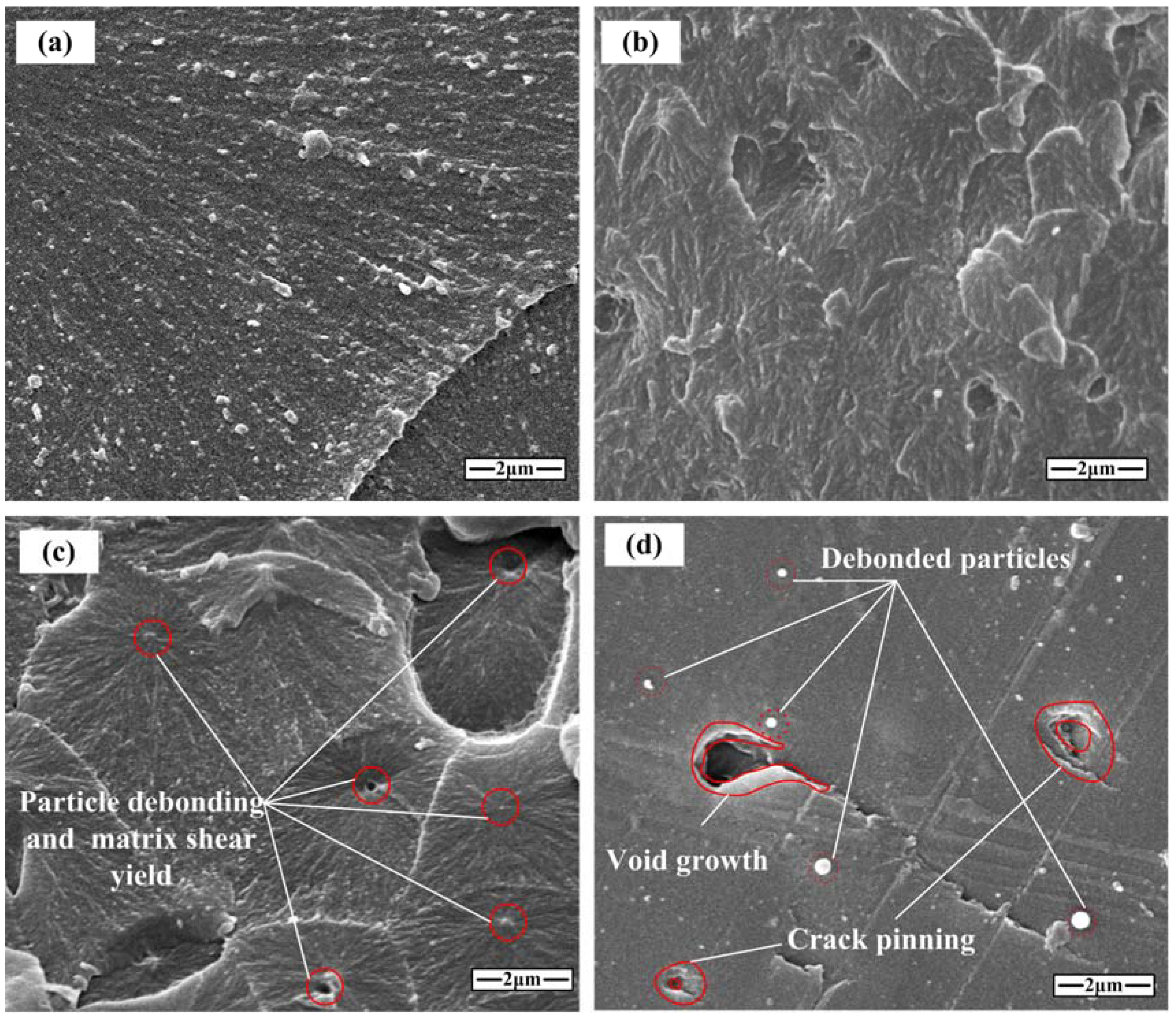

4.4. Toughenning Mechanisms

5. Conclusions

- ◆

- The tensile modulus of epoxy resin modified with three Al2O3 particles of different size increased with particle content, with the highest increase of 29.2% for epoxy resin modified with 5 wt % of 50 nm particles. The tensile strength significantly increased for the epoxy resin modified with 5 wt % and 7 wt % of 50 nm particles, while there were almost no changes for the epoxy resin modified with 100 nm and 200 nm particles with different contents.

- ◆

- The quasistatic fracture toughness KIC had a maximum value of 1.56 MPa·m1/2 for epoxy resin modified with 7 wt % of 50 nm particles, and the KIC increased with particle content. While the toughness did not increase with particle content for the fillers at high content, the agglomeration reduced the effective number of Al2O3 particles in the epoxy resin, thus reversing the trend.

- ◆

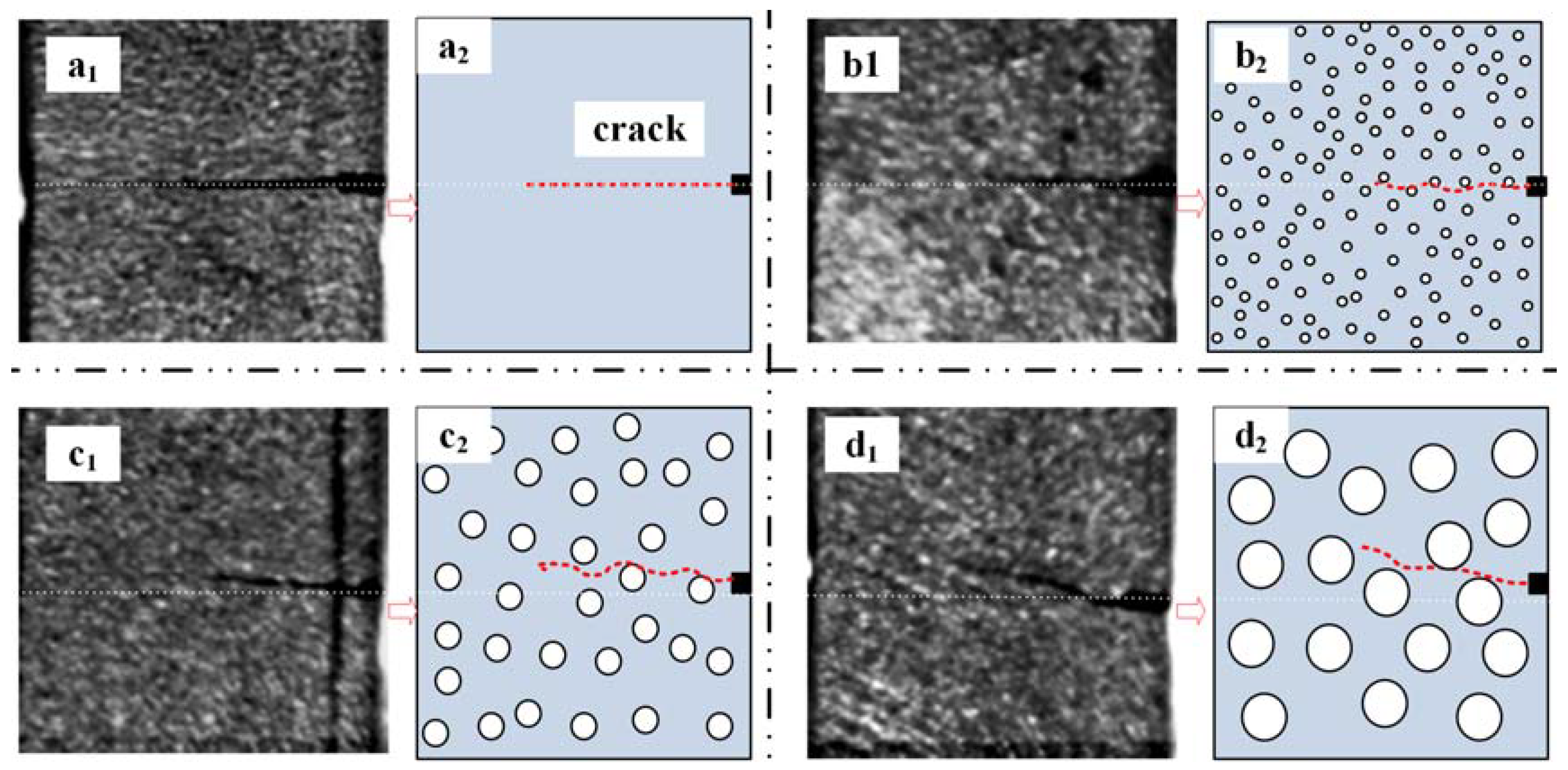

- Crack propagation velocity was evaluated by the DIC method for the composites under dynamic loading condition; the crack path was more easily deflected for large-sized particles than for small-sized particles. Meanwhile, the crack propagation velocity could be reduced with an increase in particle content.

- ◆

- The dynamic initiation fracture toughness KId increased with particle content and size. The dynamic fracture toughness was almost equal for epoxy resin modified with three particle sizes at 7 wt %. For high content fillers, the effect of the particle size could be neglected, and more energy would be expended during the fracture process. The loading rate could be affected by the particle content, while for the epoxy resin modified with low content particles, the effect was obvious; there was no significant size effect for epoxy resin modified with high content particles.

- ◆

- It has been suggested that in particle-modified epoxy resin, the crack deflection processes play an important role in toughening; under dynamic loading and with an increase in particle size, the crack deflection angle became larger. Toughening mechanisms are affected by particle size: for the epoxy resin modified with 50 nm particles, crazed shear band and shear plastic deformation improved the fracture toughness; for the resin modified with 100 nm particles, debonding and plastic void growth were observed; finally, particle debonding and crack pinning were shown to occur in epoxy resin modified with 200 nm particles.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kinloch, A.J.; Kodokian, G.A.; Jamarani, M.B. Impact properties of epoxy polymers. J. Mater. Sci. 1987, 22, 4111–4120. [Google Scholar] [CrossRef]

- Kobayashi, T.; Koide, Y.; Daicho, Y.; Ikeda, R. Dynamic fracture toughness testing of epoxy resin filled with SiO2 particles. Eng. Fract. Mech. 1987, 28, 21–29. [Google Scholar] [CrossRef]

- Ting, R.Y.; Cottington, R.L. Comparison of laboratory techniques for evaluating the fracture toughness of glassy polymers. J. Appl. Polym. Sci. 1980, 25, 1815–1823. [Google Scholar] [CrossRef]

- Guo, L.C.; Kitamura, T.; Yan, Y.B.; Sumigawa, T.; Huang, K. Fracture mechanics investigation on crack propagation in the nano-multilayered materials. Int. J. Solids Struct. 2015, 64–65, 208–220. [Google Scholar] [CrossRef]

- Huang, K.; Guo, L.C.; Yan, Y.B.; Kitamura, T. Investigation on the competitive fracture behavior in nano-multilayered structures. Int. J. Solids Struct. 2016, 92–93, 45–53. [Google Scholar] [CrossRef]

- Nakamura, Y.; Yamaguchi, M.; Okubo, M.; Matsumoto, T. Effect of particle size on impact properties of epoxy resin filled with angular shaped silica particles. Polymer 1991, 32, 2976–2979. [Google Scholar] [CrossRef]

- Nakamura, Y.; Yamaguchi, M.; Okubo, M.; Matsumoto, T. Effects of particle size on mechanical and impact properties of epoxy resin filled with spherical silica. J. Appl. Polym. Sci. 1992, 45, 1281–1289. [Google Scholar] [CrossRef]

- Nakamura, Y.; Yamaguchi, M. Instrumented charpy impact test of epoxy resin filled with irregular-shaped silica particles. Polym. Eng. Sci. 1993, 33, 279–284. [Google Scholar] [CrossRef]

- Day, R.J.; Lovell, P.A.; Pierre, D. Toughening of epoxy resins using particles prepared by emulsion polymerization: Effects of particle surface functionality, size and morphology on impact fracture properties. Polym. Int. 1997, 44, 288–299. [Google Scholar] [CrossRef]

- Evora, V.M.; Shukla, A. Fabrication, characterization, and dynamic behavior of polyester/TiO2 nanocomposites. Mater. Sci. Eng. A 2003, 361, 358–366. [Google Scholar] [CrossRef]

- Zhang, Q.X.; Yu, Z.Z.; Xie, X.L.; Mai, Y.W. Crystallization and impact energy of polypropylene/CaCO3 nanocomposites with nonionic modifier. Polymer 2004, 45, 5985–5994. [Google Scholar] [CrossRef]

- Marur, P.R.; Batra, R.C.; Garcia, G.; Loos, A.C. Static and dynamic fracture toughness of epoxy/alumina composite with submicron inclusions. J. Mater. Sci. 2004, 39, 1437–1440. [Google Scholar] [CrossRef]

- Kitey, R.; Tippur, H.V. Role of particle size and filler–matrix adhesion on dynamic fracture of glass-filled epoxy. I. Macromeasurements. Acta Mater. 2005, 53, 1153–1165. [Google Scholar] [CrossRef]

- Jajam, K.C.; Tippur, H.V. Is Nano Always Better? Static and Dynamic Fracture Study of Particulate Polymer Composites//Dynamic Behavior of Materials; Springer: New York, NY, USA, 2013; Volume 1, pp. 537–544. [Google Scholar]

- Wetzel, B.; Rosso, P.; Haupert, F.; Friedrich, K. Epoxy nanocomposites–fracture and toughening mechanisms. Eng. Fract. Mech. 2006, 73, 2375–2398. [Google Scholar] [CrossRef]

- Zamanian, M.; Mortezaei, M.; Salehnia, B.; Jam, J.E. Fracture toughness of epoxy polymer modified with nanosilica particles: Particle size effect. Eng. Fract. Mech. 2013, 97, 193–206. [Google Scholar] [CrossRef]

- Guo, L.C.; Guo, F.N.; Yu, H.J.; Zhang, L. An interaction energy integral method for nonhomogeneous materials with interfaces under thermal loading. Int. J. Solids Struct. 2012, 49, 355–365. [Google Scholar] [CrossRef]

- Guo, F.N.; Guo, L.C.; Yu, H.J.; Zhang, L. Thermal fracture analysis of nonhomogeneous piezoelectric materials using an interaction energy integral method. Int. J. Solids Struct. 2014, 51, 910–921. [Google Scholar] [CrossRef]

- Guo, F.N.; Guo, L.C.; Huang, K.; Bai, X.M.; Zhong, S.Y.; Yu, H.J. An interaction energy integral method for T-stress evaluation in nonhomogeneous materials under thermal loading. Mech. Mater. 2015, 83, 30–39. [Google Scholar] [CrossRef]

- Guo, L.C.; Noda, N. Modeling method for a crack problem of functionally graded materials with arbitrary properties- piecewise-exponential model. Int. J. Solids Struct. 2007, 44, 6768–6790. [Google Scholar] [CrossRef]

- Blaber, J.; Adair, B.; Antoniou, A. Ncorr: Open-source 2D digital image correlation matlab software. Exp. Mech. 2015, 55, 1105–1122. [Google Scholar] [CrossRef]

- Rubio, L.; Fernández-Sáez, J.; Navarro, C. Determination of dynamic fracture-initiation toughness using three-point bending tests in a modified Hopkinson pressure bar. Exp. Mech. 2003, 43, 379–386. [Google Scholar] [CrossRef]

- Jiang, F.C.; Vecchio, K.S. Hopkinson bar loaded fracture experimental technique: A critical review of dynamic fracture toughness tests. Appl. Mech. Rev. 2009, 62. [Google Scholar] [CrossRef]

- Guinea, G.V.; Pastor, J.Y.; Planas, J. Stress intensity factor, compliance and CMOD for a general three-point-bend beam. Int. J. Fract. 1998, 89, 103–116. [Google Scholar] [CrossRef]

- Jajam, K.C.; Tippur, H.V. Quasi-static and dynamic fracture behavior of particulate polymer composites: A study of nano-vs. micro-size filler and loading-rate effects. Compos. Part B Eng. 2012, 43, 3467–3481. [Google Scholar] [CrossRef]

- Faber, K.T.; Evans, A.G. Crack deflection processes—I. Theory. Acta Metall. 1983, 31, 565–576. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; Friedrich, K.; Eger, C. Property improvements of in situ epoxy nanocomposites with reduced interparticle distance at high nanosilica content. Acta Mater. 2006, 54, 1833–1842. [Google Scholar] [CrossRef]

- Liang, Y.L.; Pearson, R.A. Toughening mechanisms in epoxy–silica nanocomposites (ESNs). Polymer 2009, 50, 4895–4905. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Masania, K.; Taylor, A.C. The mechanisms and mechanics of the toughening of epoxy polymers modified with silica nanoparticles. Polymer 2010, 51, 6284–6294. [Google Scholar] [CrossRef]

- Spanoudakis, J.; Young, R.J. Crack propagation in a glass particle-filled epoxy resin. J. Materi. Sci. 1984, 19, 473–486. [Google Scholar] [CrossRef]

| Particles Size | Particle Content Nano-Al2O3 (wt %) | Density ρ (g/cm3) | Elastic Modulus E (GPa) | Poisson’s Ratio ν |

|---|---|---|---|---|

| 0 | 0 | 1.213 ± 0.004 | 2.02 ± 0.04 | 0.36 |

| 50 nm | 1 | 1.238 ± 0.003 | 2.18 ± 0.02 | 0.35 |

| 3 | 1.256 ± 0.004 | 2.30 ± 0.03 | 0.35 | |

| 5 | 1.247 ± 0.006 | 2.61 ± 0.04 | 0.35 | |

| 7 | 1.295 ± 0.001 | 2.40 ± 0.02 | 0.35 | |

| 100 nm | 1 | 1.234 ± 0.005 | 2.22 ± 0.03 | 0.35 |

| 3 | 1.249 ± 0.002 | 2.36 ± 0.05 | 0.34 | |

| 5 | 1.272 ± 0.004 | 2.38 ± 0.01 | 0.35 | |

| 7 | 1.291 ± 0.003 | 2.52 ± 0.03 | 0.36 | |

| 200 nm | 1 | 1.237 ± 0.001 | 2.19 ± 0.05 | 0.35 |

| 3 | 1.256 ± 0.004 | 2.39 ± 0.04 | 0.35 | |

| 5 | 1.275 ± 0.006 | 2.44 ± 0.02 | 0.34 | |

| 7 | 1.294 ± 0.003 | 2.38 ± 0.03 | 0.35 |

| Particle Size | Content (wt %) | Crack Velocity (m/s) | Crack Initiation Time ti (μs) |

|---|---|---|---|

| 0 | 0 | 286.91 | 33.1 |

| 50 nm | 1 | 277.42 | 38.4 |

| 3 | 270.51 | 40.4 | |

| 5 | 245.92 | 41.0 | |

| 7 | 254.12 | 49.8 | |

| 100 nm | 1 | 229.52 | 41.0 |

| 3 | 213.13 | 43.6 | |

| 5 | 192.34 | 44.9 | |

| 7 | 180.34 | 42.4 | |

| 200 nm | 1 | 213.13 | 50.1 |

| 3 | 204.93 | 54.7 | |

| 5 | 188.54 | 52.9 | |

| 7 | 178.24 | 56.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Z.; He, H.; Liang, W.; Wang, Z.; He, L.; Zhang, X. Tensile, Quasistatic and Dynamic Fracture Properties of Nano-Al2O3-Modified Epoxy Resin. Materials 2018, 11, 905. https://doi.org/10.3390/ma11060905

Duan Z, He H, Liang W, Wang Z, He L, Zhang X. Tensile, Quasistatic and Dynamic Fracture Properties of Nano-Al2O3-Modified Epoxy Resin. Materials. 2018; 11(6):905. https://doi.org/10.3390/ma11060905

Chicago/Turabian StyleDuan, Zhiwei, Hailing He, Wenyan Liang, Zhenqing Wang, Liang He, and Xiaohong Zhang. 2018. "Tensile, Quasistatic and Dynamic Fracture Properties of Nano-Al2O3-Modified Epoxy Resin" Materials 11, no. 6: 905. https://doi.org/10.3390/ma11060905

APA StyleDuan, Z., He, H., Liang, W., Wang, Z., He, L., & Zhang, X. (2018). Tensile, Quasistatic and Dynamic Fracture Properties of Nano-Al2O3-Modified Epoxy Resin. Materials, 11(6), 905. https://doi.org/10.3390/ma11060905