The Evaluation of Physio-Mechanical and Tribological Characterization of Friction Composites Reinforced by Waste Corn Stalk

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Corn Stalk Fibers

2.2. Fabrication of Friction Composites

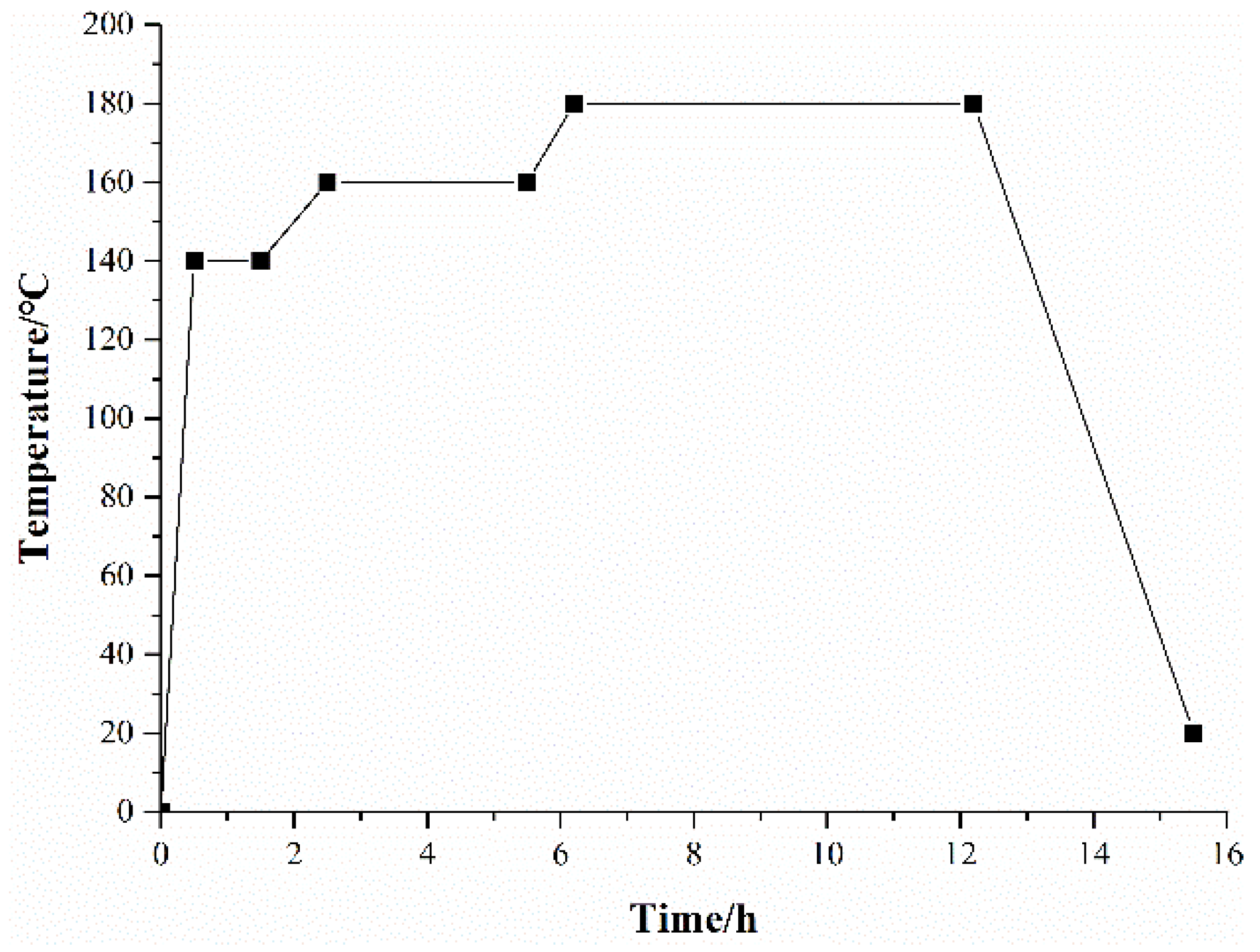

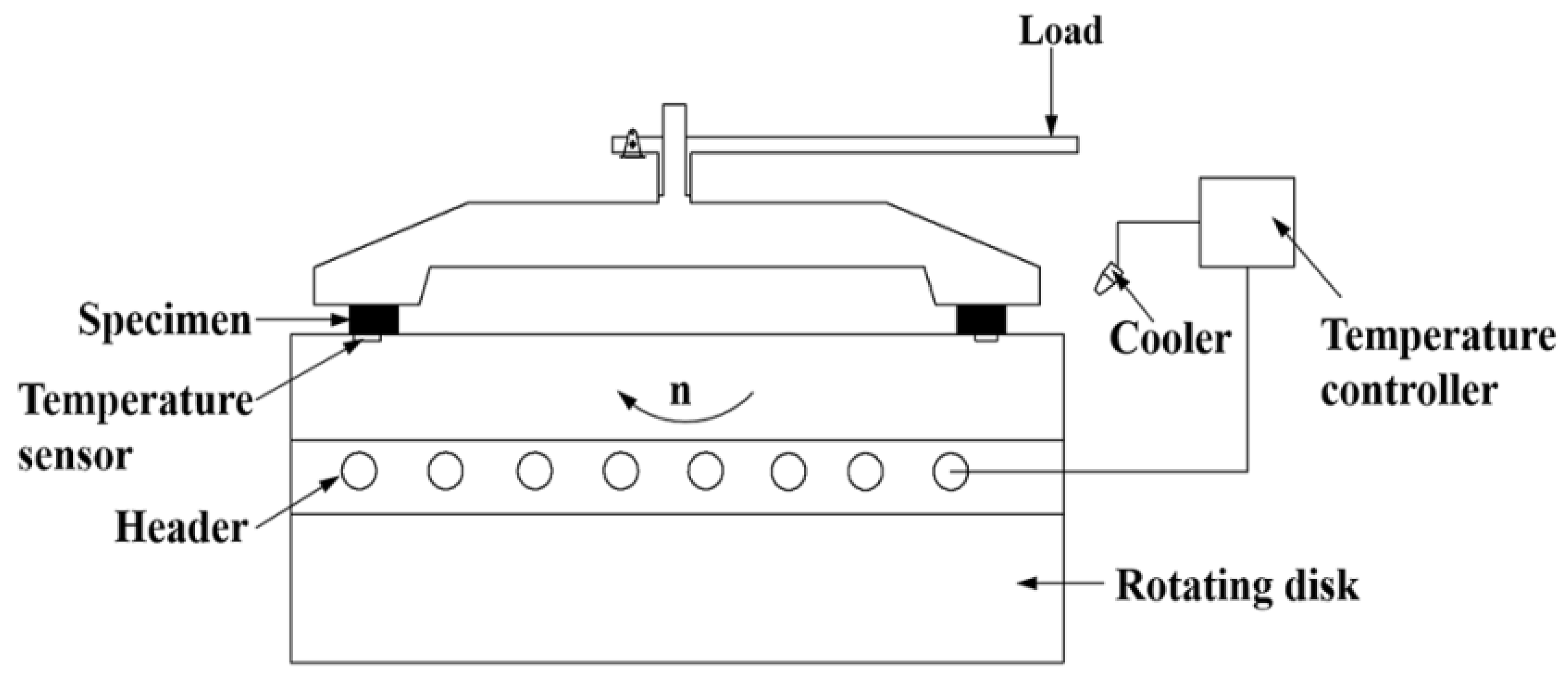

2.3. Testing Methods and Equipment

3. Results and Discussion

3.1. Surface Morphology of Corn Stalk Fibers

3.2. Physio-Mechanical Performances

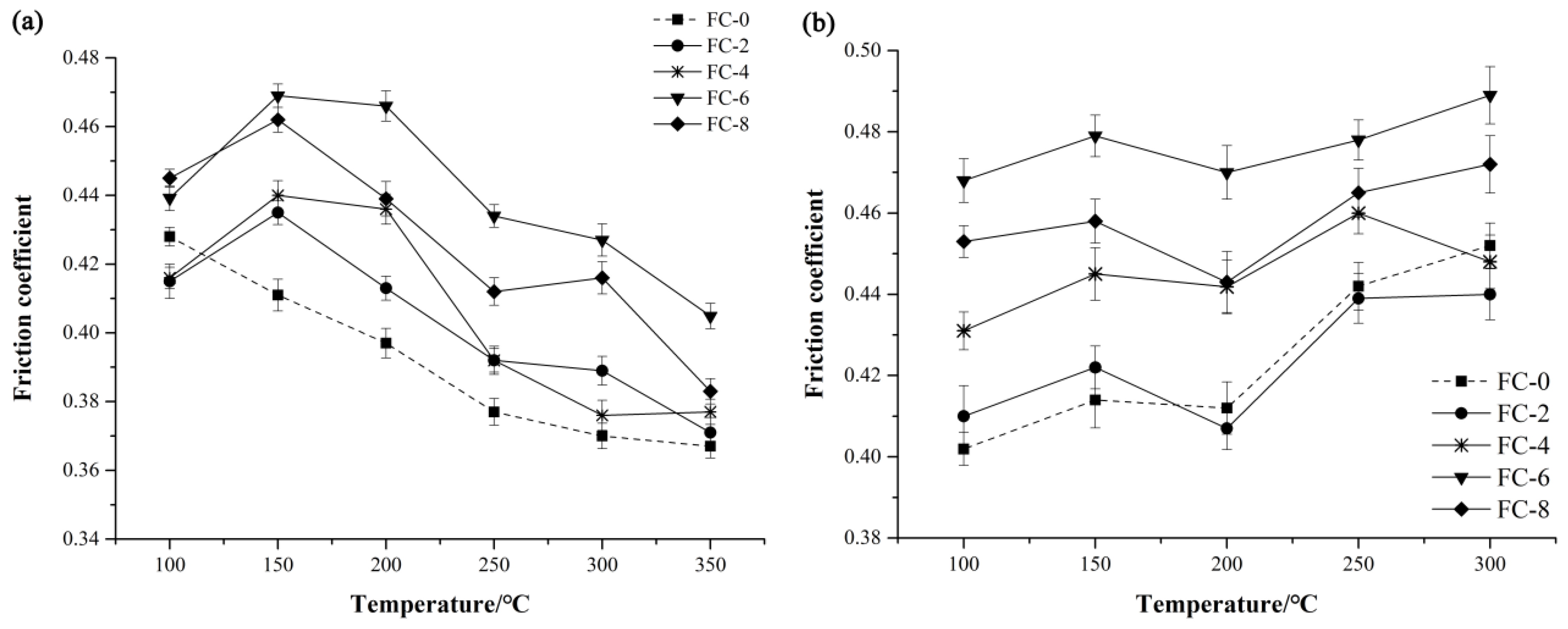

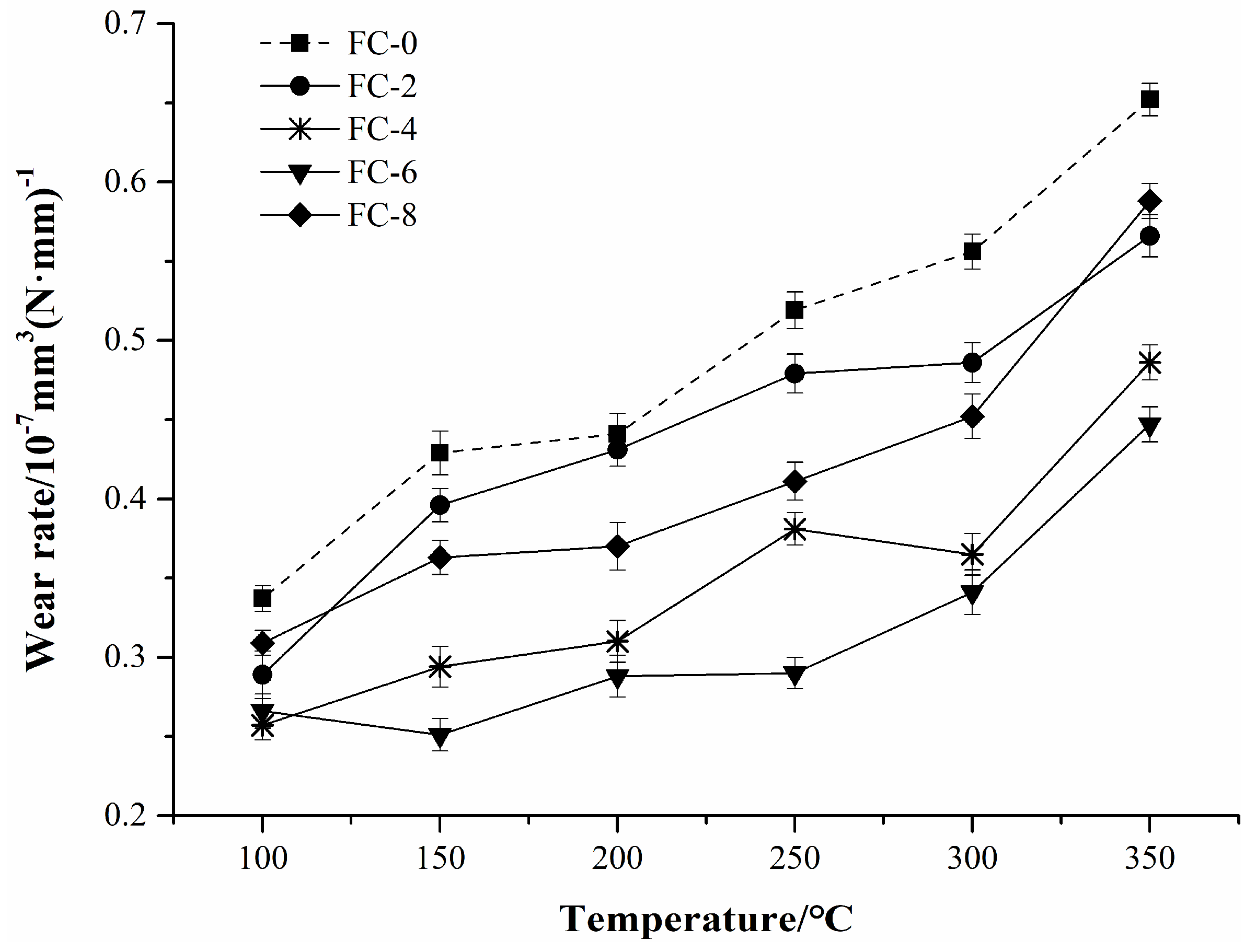

3.3. Friction and Wear Behaviors

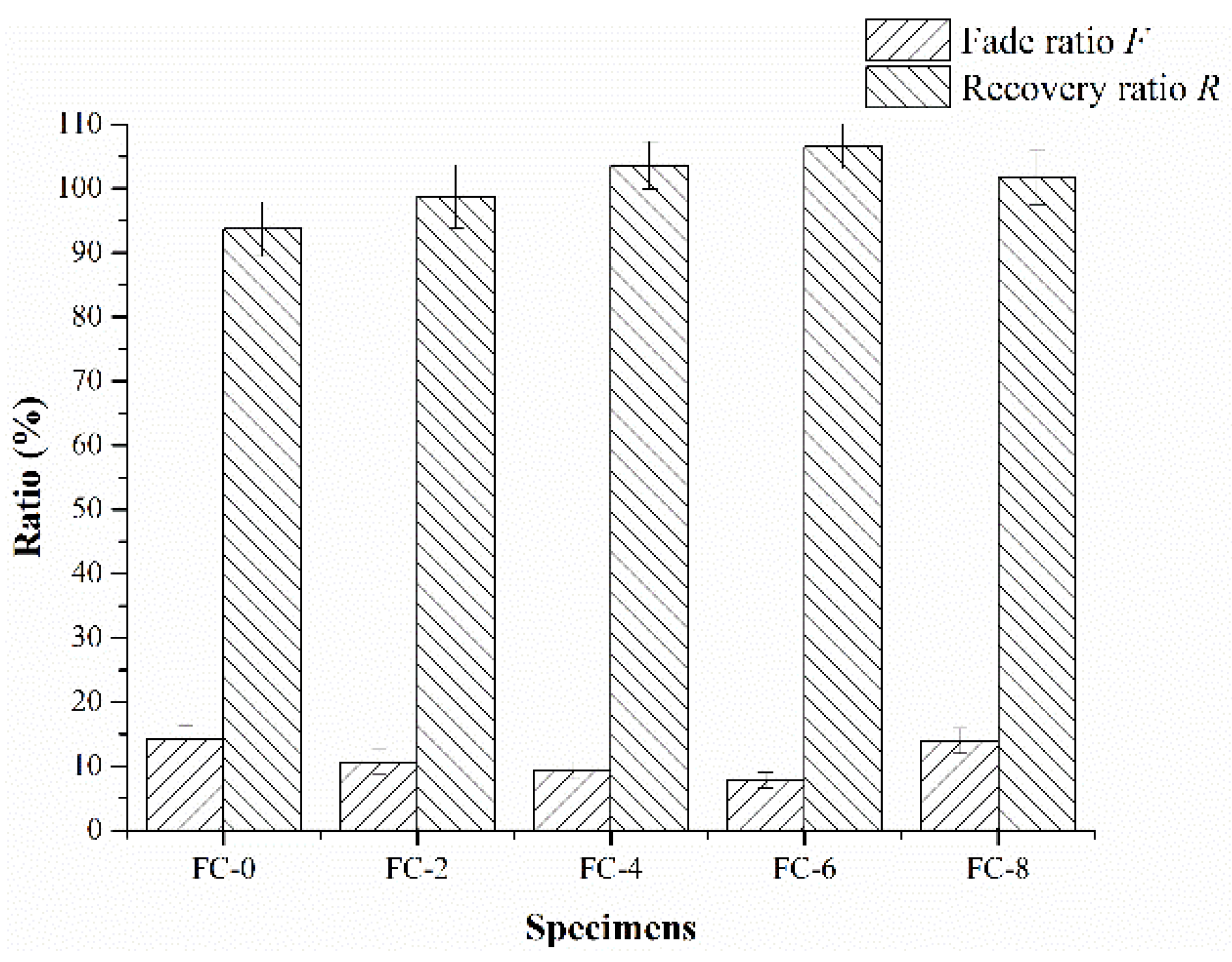

3.4. Fade Resistance and Recovery Properties

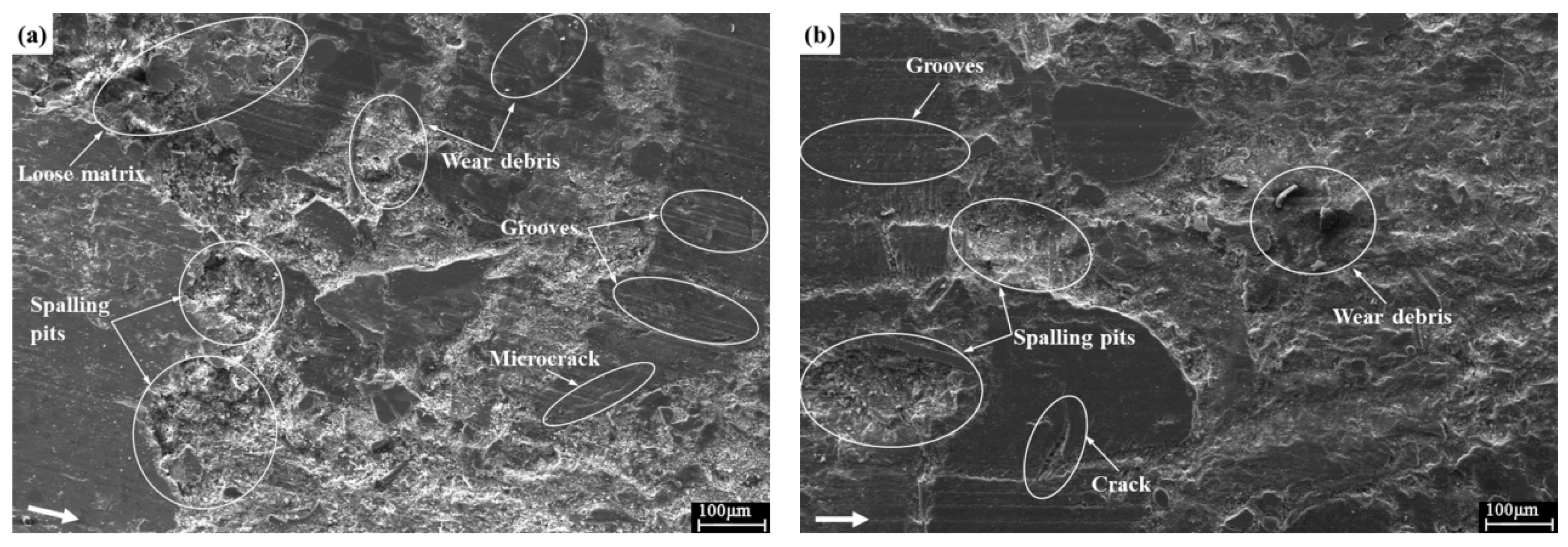

3.5. Analysis of Worn Surface

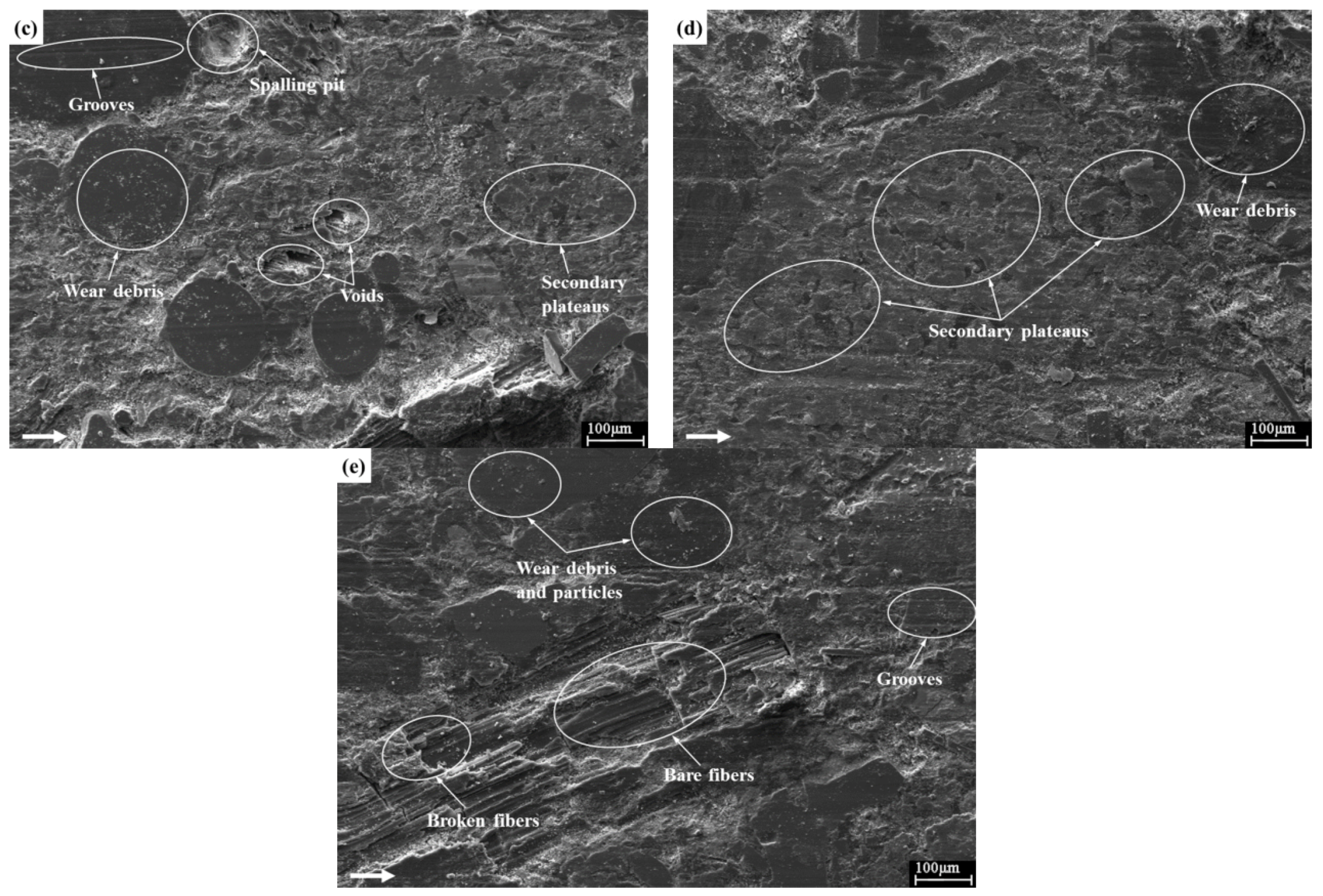

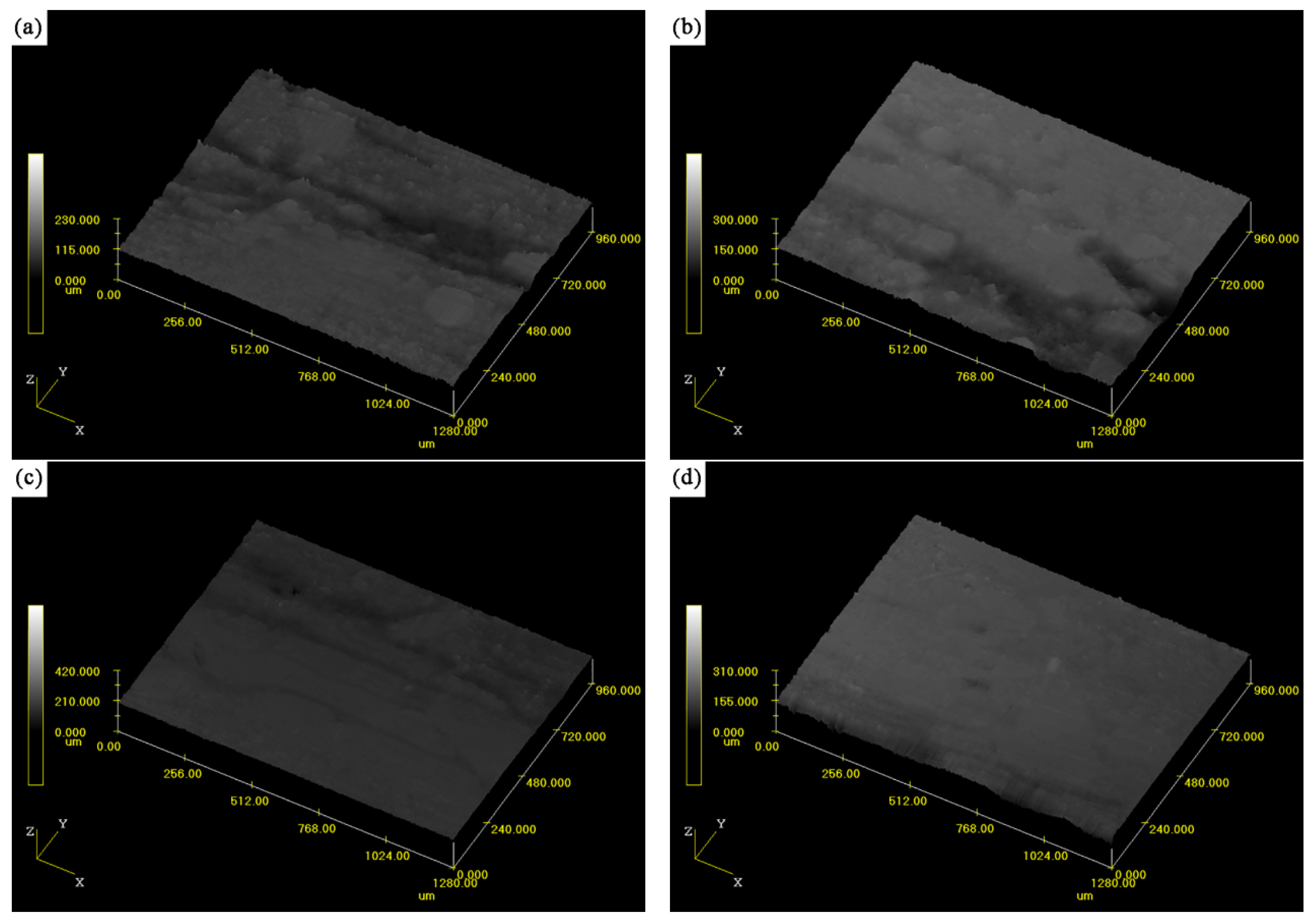

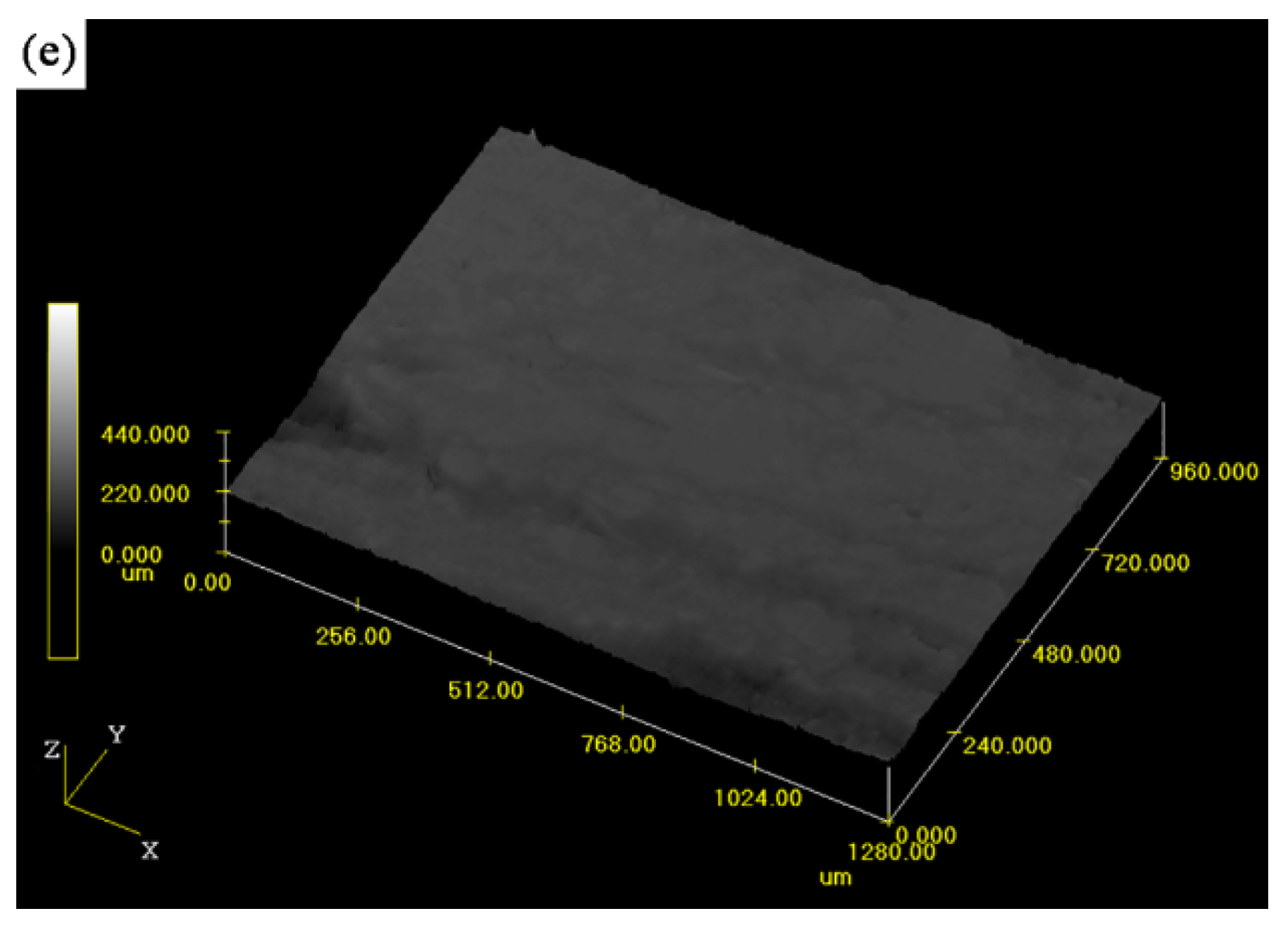

3.6. Analysis of Worn Surface Roughness

4. Conclusions

- The density and hardness of friction composites decreased with the increasing content of corn stalk fibers. At the same time, the impact strength of specimen FC-4 was the highest in comparison with that of other composites.

- The friction coefficients of the composites generally increased first and then decreased with the temperature increase. Compared with specimen FC-0, the corn stalk fiber-reinforced friction composites showed higher friction coefficients except for the case at 100 °C.

- The specimen FC-6 showed a fade ratio of 7.8% and recovery ratio of 106.5%, suggesting superior fade resistance and recovery performances.

- The wear rates of all composites were significantly influenced by the test temperature and increased with temperature rise. The specimen FC-6 exhibited the lowest wear rate, except for that when the temperatures were about 100–150 °C.

- The micrographs of worn surface morphology showed that the tribological performances of friction composites were closely associated with the formation of secondary contact plateaus on the surfaces. The specimen FC-6 had a smoother worn surface (Ra = 1.746 μm) than other friction composites and was covered with a great number of secondary plateaus and few shallow grooves, which explained the higher wear resistance.

Author Contributions

Funding

Conflicts of Interest

References

- Ingram, M.; Spikes, H.; Noles, J.; Watts, R.F. Contact properties of wet clutch friction material. Tribol. Int. 2010, 43, 815–821. [Google Scholar] [CrossRef]

- Cai, P.; Li, Z.; Wang, T.; Wang, Q. Effect of aspect ratios of aramid fiber on mechanical and tribological behaviors of friction materials. Tribol. Int. 2015, 92, 109–116. [Google Scholar] [CrossRef]

- Wang, Z.H.; Hou, G.H.; Yang, Z.R.; Jiang, Q.; Zhang, F.; Xie, M.H.; Yao, Z.J. Influence of slag weight fraction on mechanical, thermal and tribological properties of polymer based friction materials. Mater. Des. 2016, 90, 76–83. [Google Scholar] [CrossRef]

- Kumar, M.; Bijwe, J. Composite friction materials based on metallic fillers: sensitivity of μ to operating variables. Tribol. Int. 2011, 44, 106–113. [Google Scholar] [CrossRef]

- Kuroe, M.; Tsunoda, T.; Kawano, Y.; Takahashi, A. Application of lignin-modified phenolic resins to brake friction material. J. Appl. Polym. Sci. 2013, 129, 310–315. [Google Scholar] [CrossRef]

- Kim, S.J.; Cho, M.H.; Lim, D.S.; Jang, H. Synergistic effects of aramid pulp and potassium titanate whiskers in the automotive friction material. Wear 2001, 251, 1484–1491. [Google Scholar] [CrossRef]

- Kim, S.J.; Jang, H. Friction and wear of friction materials containing two different phenolic resins reinforced with aramid pulp. Tribol. Int. 2000, 33, 477–484. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Chan, D. Review of automotive brake friction materials. Proc. Inst. Mech. Eng. Part D 2004, 218, 953–966. [Google Scholar]

- Etemadi, H.; Shojaei, A.; Jahanmard, P. Effect of alumina nanoparticle on the tribological performance of automotive brake friction materials. J. Reinf. Plast. Compos. 2014, 33, 166–178. [Google Scholar] [CrossRef]

- Öztürk, B.; Öztürk, S. Effects of resin type and fiber length on the mechanical and tribological properties of brake friction materials. Tribol. Lett. 2011, 42, 339–350. [Google Scholar]

- Aranganathan, N.; Mahale, V.; Bijwe, J. Effects of aramid fiber concentration on the friction and wear characteristics of non-asbestos organic friction composites using standardized braking tests. Wear 2016, 354, 69–77. [Google Scholar] [CrossRef]

- Jang, H.; Ko, K.; Kim, S.J.; Basch, R.H.; Fash, J.W. The effect of metal fibers on the friction performance of automotive brake friction materials. Wear 2004, 256, 406–414. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant fibre based bio-composites: Sustainable and renewable green materials. Renewable Sustainable Energy Rev. 2017, 79, 558–584. [Google Scholar] [CrossRef]

- Ray, D.; Sengupta, S.; Sengupta, S.P.; Mohanty, A.K.; Misra, M. A Study of the Mechanical and Fracture Behavior of Jute-Fabric-Reinforced Clay-Modified Thermoplastic Starch-Matrix Composites. Macromol. Mater. Eng. 2007, 292, 1075–1084. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Influence of fiber orientation and fiber content on properties of sisal-jute-glass fiber-reinforced polyester composites. J. Appl. Polym. Sci. 2016, 133, 42968. [Google Scholar] [CrossRef]

- Chand, N.; Dwivedi, U.K. Effect of coupling agent on abrasive wear behaviour of chopped jute fibre-reinforced polypropylene composites. Wear 2006, 261, 1057–1063. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Tribological behavior of natural fiber reinforced PLA composites. Wear 2013, 297, 829–840. [Google Scholar] [CrossRef]

- Nirmal, U.; Yousif, B.F.; Rilling, D.; Brevern, P.V. Effect of betelnut fibres treatment and contact conditions on adhesive wear and frictional performance of polyester composites. Wear 2010, 268, 1354–1370. [Google Scholar] [CrossRef] [Green Version]

- Fu, Z.; Suo, B.; Yun, R.; Lu, Y.; Wang, H.; Qi, S.; Jiang, S.; Lu, Y.; Matejka, V. Development of eco-friendly brake friction composites containing flax fibers. J. Reinf. Plast. Compos. 2012, 31, 681–689. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.; Zhao, Z.; Wang, M.; Jia, W. Effects of corn stalk fiber content on properties of biomass brick. Constr. Build. Mater. 2016, 127, 11–17. [Google Scholar] [CrossRef]

- Husseien, M.; Amer, A.A.; El-Maghraby, A.; Hamedallah, N. A comprehensive characterization of corn stalk and study of carbonized corn stalk in dye and gas oil sorption. J. Anal. Appl. Pyrolysis. 2009, 86, 360–363. [Google Scholar] [CrossRef]

- Cai, D.; Li, P.; Luo, Z.; Qin, P.; Chen, C.; Wang, Y.; Wang, Z.; Tan, T. Effect of dilute alkaline pretreatment on the conversion of different parts of corn stalk to fermentable sugars and its application in acetone-butanol-ethanol fermentation. Bioresour. Technol. 2016, 211, 117–124. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Chen, C.; Li, J.; Zhou, B.; Xie, M.; Hu, S.; Kawamura, K.; Chen, Y. Molecular composition and size distribution of sugars, sugar-alcohols and carboxylic acids in airborne particles during a severe urban haze event caused by wheat straw burning. Atmos. Environ. 2011, 45, 2473–2479. [Google Scholar] [CrossRef]

- Luo, Z.; Li, P.; Cai, D.; Chen, Q.; Qin, P.; Tan, T.; Cao, H. Comparison of performances of corn fiber plastic composites made from different parts of corn stalk. Ind. Crops. Prod. 2017, 95, 521–527. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Fan, M.; McVicar, B. Interfacial properties with bonding and failure mechanisms of wheat straw node and internode. Composites Part A 2017, 99, 102–112. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Kokan, S.J.; Raja, R.N.; Sathyanarayanan, R.; Elanchezhian, C.; Prasad, A.R.; Manickavasagam, V.M. Evaluation of mechanical properties of abaca-jute-glass fibre reinforced epoxy composite. Mater. Des. 2013, 51, 357–366. [Google Scholar] [CrossRef]

- Corrales, F.; Vilaseca, F.; Llop, M.; Gironès, J.; Méndez, J.A.; Mutjè, P. Chemical modification of jute fibers for the production of green-composites. J. Hazard. Mater. 2007, 144, 730–735. [Google Scholar] [CrossRef] [PubMed]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Composites Part B 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Merlini, C.; Soldi, V.; Barra, G.M.O. Influence of fiber surface treatment and length on physico-chemical properties of short random banana fiber-reinforced castor oil polyurethane composites. Polym. Test. 2011, 30, 833–840. [Google Scholar] [CrossRef]

- Goriparthi, B.K.; Suman, K.N.S.; Rao, N.M. Effect of fiber surface treatments on mechanical and abrasive wear performance of polylactide/jute composites. Composites Part A 2012, 43, 1800–1808. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y.; Wang, L.; Tong, J.; Zhuang, J.; Jia, H. Performance assessment of hybrid fibers reinforced friction composites under dry sliding conditions. Tribol. Int. 2018, 119, 262–269. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y.; Menon, C.; Tong, J. Evaluation of Wear Resistance of Friction Materials Prepared by Granulation. ACS Appl. Mater. Interfaces 2015, 7, 22814–22820. [Google Scholar] [CrossRef] [PubMed]

- Satapathy, B.K.; Bijwe, J. Performance of friction materials based on variation in nature of organic fibres: Part I. Fade and recovery behaviour. Wear 2004, 257, 573–584. [Google Scholar] [CrossRef]

- Fu, H.; Fu, L.; Zhang, G.L.; Wang, R.M.; Liao, B.; Sun, B.C. Abrasion mechanism of stainless steel/carbon fiber-reinforced polyether-ether-ketone (PEEK) composites. J. Mater. Eng. Perform 2009, 18, 973–979. [Google Scholar] [CrossRef]

- Rahman, M.M.; Khan, M.A. Surface treatment of coir (Cocos nucifera) fibers and its influence on the fibers’ physico-mechanical properties. Compos. Sci. Technol. 2007, 67, 2369–2376. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y.; Shang, W.; Gao, Z.; Wang, H.; Guo, L.; Tong, J. Tribological and mechanical properties of pine needle fiber reinforced friction composites under dry sliding conditions. RSC Adv. 2014, 4, 36777–36783. [Google Scholar] [CrossRef]

- Matějka, V.; Fu, Z.; Kukutschová, J.; Qi, S.; Jiang, S.; Zhang, X.; Yun, R.; Vaculík, M.; Heliová, M.; Lu, Y. Jute fibers and powderized hazelnut shells as natural fillers in non-asbestos organic non-metallic friction composites. Mater. Des. 2013, 51, 847–853. [Google Scholar] [CrossRef]

- Fei, J.; Luo, W.; Huang, J.F.; Ouyang, H.B.; Xu, Z.W.; Yao, C.Y. Effect of carbon fiber content on the friction and wear performance of paper-based friction materials. Tribol. Int. 2015, 87, 91–97. [Google Scholar] [CrossRef]

- Ji, Z.; Jin, H.; Luo, W.; Cheng, F.; Chen, Y.; Ren, Y.; Wu, Y.; Hou, S. The effect of crystallinity of potassium titanate whisker on the tribological behavior of NAO friction materials. Tribol. Int. 2017, 107, 213–220. [Google Scholar] [CrossRef]

- Cai, P.; Wang, Y.; Wang, T.; Wang, Q. Effect of resins on thermal, mechanical and tribological properties of friction materials. Tribol. Int. 2015, 87, 1–10. [Google Scholar] [CrossRef]

- Silvestre, N. State-of-the-art review on carbon nanotube reinforced metal matrix composites. Int. J. Compos. Mater. 2013, 3, 28–44. [Google Scholar]

- Patnaik, A.; Kumar, M.; Satapathy, B.K.; Tomar, B.S. Performance sensitivity of hybrid phenolic composites in friction braking: effect of ceramic and aramid fibre combination. Wear 2010, 269, 891–899. [Google Scholar] [CrossRef]

- Satapathy, B.K.; Bijwe, J. Fade and recovery behavior of non-asbestos organic (NAO) composite friction materials based on combinations of rock fibers and organic fibers. J. Reinf. Plast. Compos. 2005, 24, 563–577. [Google Scholar] [CrossRef]

- Einset, E.O. Analysis of reactive melt infiltration in the processing of ceramics and ceramic composites. Chem. Eng. Sci. 1998, 53, 1027–1039. [Google Scholar] [CrossRef]

- Straffelini, G.; Maines, L. The relationship between wear of semimetallic friction materials and pearlitic cast iron in dry sliding. Wear 2013, 307, 75–80. [Google Scholar] [CrossRef]

- Kumar, M.; Satapathy, B.K.; Patnaik, A.; Kolluri, D.K.; Tomar, B.S. Hybrid composite friction materials reinforced with combination of potassium titanate whiskers and aramid fibre: assessment of fade and recovery performance. Tribol. Int. 2011, 44, 359–367. [Google Scholar] [CrossRef]

- Kim, S.H.; Jang, H. Friction and vibration of brake friction materials reinforced with chopped glass fibers. Tribol. Lett. 2013, 52, 341–349. [Google Scholar] [CrossRef]

- Prabhu, T.R.; Varma, V.K.; Vedantam, S. Tribological and mechanical behavior of multilayer Cu/SiC+ Gr hybrid composites for brake friction material applications. Wear 2014, 317, 201–212. [Google Scholar] [CrossRef]

| Raw Materials (by wt %) | Specimens | ||||

|---|---|---|---|---|---|

| FC-0 | FC-2 | FC-4 | FC-6 | FC-8 | |

| Corn stalk fibers | 0 | 2 | 4 | 6 | 8 |

| Compound mineral fibers | 25 | 24.42 | 23.84 | 23.26 | 22.68 |

| Vermiculite powder | 5 | 4.88 | 4.76 | 4.64 | 4.52 |

| Calcium carbonate | 10 | 9.77 | 9.54 | 9.31 | 9.08 |

| Coke | 5 | 4.88 | 4.76 | 4.64 | 4.52 |

| Graphite | 8 | 7.81 | 7.62 | 7.43 | 7.24 |

| Friction powder | 1 | 0.98 | 0.96 | 0.94 | 0.92 |

| Zirconium silicate | 4 | 3.91 | 3.82 | 3.73 | 3.64 |

| Alumina | 6 | 5.86 | 5.72 | 5.58 | 5.44 |

| Barium sulfate | 20 | 19.54 | 19.08 | 18.62 | 18.16 |

| Zinc stearate | 2 | 1.95 | 1.90 | 1.85 | 1.80 |

| Phenolic resin | 14 | 14 | 14 | 14 | 14 |

| Specimens | Density (g·cm−3) | Hardness (HRR) | Impact Strength (MPa) |

|---|---|---|---|

| FC-0 | 2.33 | 103.6 | 0.461 ± 0.009 |

| FC-2 | 2.23 | 101.4 | 0.424 ± 0.012 |

| FC-4 | 2.20 | 98.9 | 0.486 ± 0.007 |

| FC-6 | 2.18 | 97.2 | 0.473 ± 0.013 |

| FC-8 | 2.11 | 95.8 | 0.422 ± 0.015 |

| Specimens | Average Roughness | Root-Mean-Square Roughness | Maximum Valley Depth | Maximum Peak Height |

|---|---|---|---|---|

| Ra (μm) | Rq (μm) | Rv (μm) | Rp (μm) | |

| FC-0 | 2.786 | 3.883 | 71.305 | 34.012 |

| FC-2 | 2.506 | 3.429 | 38.974 | 26.658 |

| FC-4 | 1.838 | 2.661 | 75.024 | 30.059 |

| FC-6 | 1.746 | 2.574 | 42.031 | 25.824 |

| FC-8 | 2.407 | 3.401 | 48.576 | 35.839 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Wu, S.; Zhuang, J.; Tong, J.; Xiao, Y.; Qi, H. The Evaluation of Physio-Mechanical and Tribological Characterization of Friction Composites Reinforced by Waste Corn Stalk. Materials 2018, 11, 901. https://doi.org/10.3390/ma11060901

Ma Y, Wu S, Zhuang J, Tong J, Xiao Y, Qi H. The Evaluation of Physio-Mechanical and Tribological Characterization of Friction Composites Reinforced by Waste Corn Stalk. Materials. 2018; 11(6):901. https://doi.org/10.3390/ma11060901

Chicago/Turabian StyleMa, Yunhai, Siyang Wu, Jian Zhuang, Jin Tong, Yang Xiao, and Hongyan Qi. 2018. "The Evaluation of Physio-Mechanical and Tribological Characterization of Friction Composites Reinforced by Waste Corn Stalk" Materials 11, no. 6: 901. https://doi.org/10.3390/ma11060901