1. Introduction

Nowadays, with the intent to improve fatigue strength and to increase the life span of components, several processes are employed. Shot peening is one of the most widespread processes that can improve fatigue behavior. It is widely used and is a low cost and simple method. Its application is still further expanding especially in aeronautic and automotive industries [

1,

2,

3].

Shot peening consists of impacting a flux of spherical shots against a metallic surface, inducing a residual stress field and work hardening on the top layer of the components. Due to the shot impacts, the surface layer of a component yields plastically. The result from the inability of the plastically deformed material to rearrange itself on the elastic subsurface layers generates residual compressive stresses. At the same time, because of the shot marks the surface roughness increases and work hardening is induced a result of the plastic deformation. The beneficial effects of this mechanical surface treatment are mostly related to the compressive residual stress field and the induced strain hardening [

4,

5,

6,

7]. On the surface, residual compressive stresses and work hardening are able to stop difficult crack propagation, reducing the probability of fatigue damage. Thus, the increase in resistance to fatigue, stress corrosion cracking, fretting, galling, erosion, and closing pores are common benefits that result from the shot peening process [

8,

9,

10,

11,

12,

13,

14,

15,

16].

Regarding stainless steels, in recent years it has been found that the corrosion potential becomes nobler with an increase in compressive stresses at the surface layer, since the Cr/Fe ratio in the passive film increases where large compressive stresses are found in the grains under it. Then, thanks to these compressive stresses, this passive surface layer can result in a higher corrosion resistance [

17,

18,

19,

20].

Thanks to their biphasic microstructure and high content of alloying elements, such as chromium and nickel, duplex and super duplex stainless steels feature good pitting corrosion resistance, which promotes their exploitation in oil & gas, chemical, and marine applications where high corrosion resistance is usually required. Thus, in this way, residual stress fields could have a beneficial effect, since they have been found to increase pitting corrosion resistance in stainless steels [

17,

18,

19,

20].

Bearing these ideas in mind, the aim of this work is to perform shot peening treatments to a F55-UNS S32760 super duplex stainless steel, in order to study the influence of this treatment on corrosion resistance.

In detail, the influence of various initial conditions of F55-UNS S32760 super duplex stainless steel specimens prepared through different thermal treatments are evaluated in this work. The investigated thermal paths avoid the precipitation of detrimental intermetallic phases, fulfilling the classical standard requirements. Nonetheless, the physical properties of the target material are strongly affected by its thermal history, both in terms of mechanical properties and microstructure morphology [

21,

22,

23,

24].

Shot peening treatments were performed after the thermal treatments of the samples. Characterization has been made in terms of microstructure morphology, local chemical composition, microhardness of each constituent phase, and energy dissipation modes. The enhanced properties that are a result of the shot peening have been evaluated in terms of residual stress depth profiles, FWHM (Full Width at Half Maximum, related with the work hardening), both by means of X-ray diffraction (XRD), surface hardness, surface roughness, and corrosion resistance through salt spray fog tests. The influence of the initial thermal treatments on the results have been highlighted.

The shot medium employed was Zirshot® Y300, composed of ceramic beads and blasted with a 10A Almen intensity. Then, the microstructure, the surface hardness, the residual stresses field, and the corrosion resistance properties of the shot peened specimens have been evaluated and the differences, generated by the various initial condition of the target material, have been highlighted.

5. Discussion

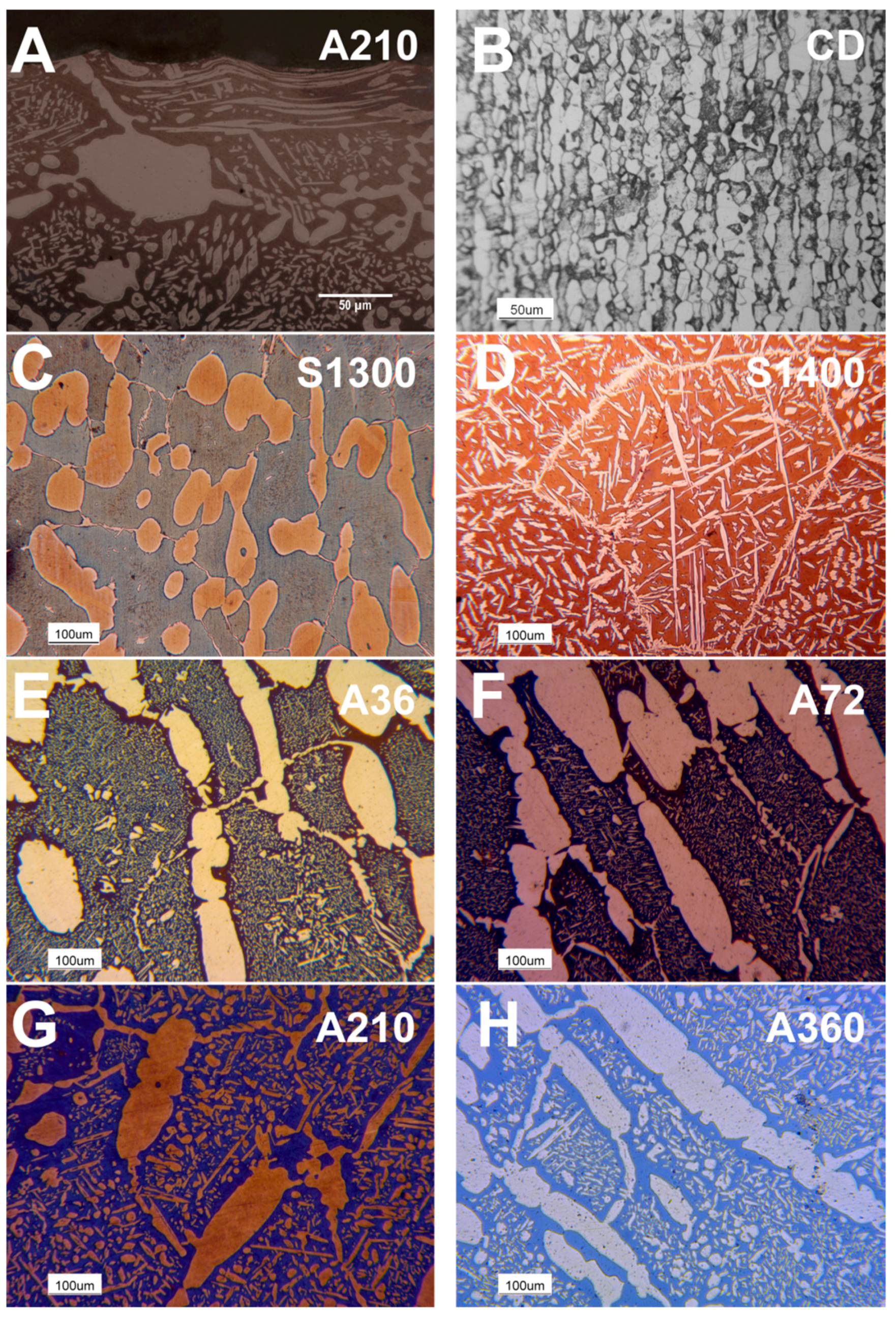

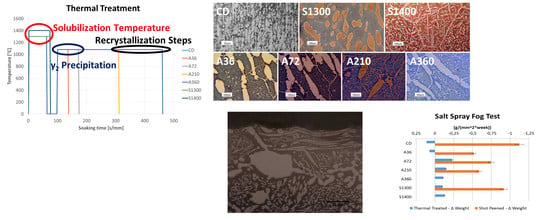

The optical microscopy analysis (

Figure 1) shows the typical complex microstructure of AISI F55-UNS S32760 super duplex stainless steel, including the secondary austenite precipitates present in their morphologies: martensitic-shear precipitation and Widmanstätten structures [

26]. The distortion of the sub-surface austenitic grains demonstrates the deformation induced by the shot peening, which is a purely mechanical surface treatment. The presence of any other phase different from the former ones (austenite and ferrite), especially the most detrimental ones in this kind of steel (σ and χ) [

23,

24,

25], have not been detected by optical microscopy, neither before or after the shot peening treatment [

59].

However, the austenitic content after shot peening treatments, measured via XRD analysis, reveals a large decrease of the austenite content after the shot peening treatment (

Table 4). Thus, the occurrence of a stress/strain-induced microstructural modification has been identified. The martensitic phase can be generated from the austenite by deformation through two mechanisms. At room temperature, the martensitic transformation is ruled by stain-induced mechanisms [

59,

60]. Although it has a low stacking fault energy, austenite in duplex stainless steel is usually not prone to strain-induced martensite formation, since the duplex microstructure modifies the mechanisms of deformation. On the other hand, the decrease in the austenite volume fraction, measured by XRD but not detected by optical microscopy, coupled with the absence of any other phase nucleation, proves the generation of strain-induced martensite through the shot peening treatment [

59,

60,

61].

This strain-induced martensite enhances the austenite work hardening and usually affects the corrosion resistance, since it increases the number of active anodic sites at the surface [

60,

61].

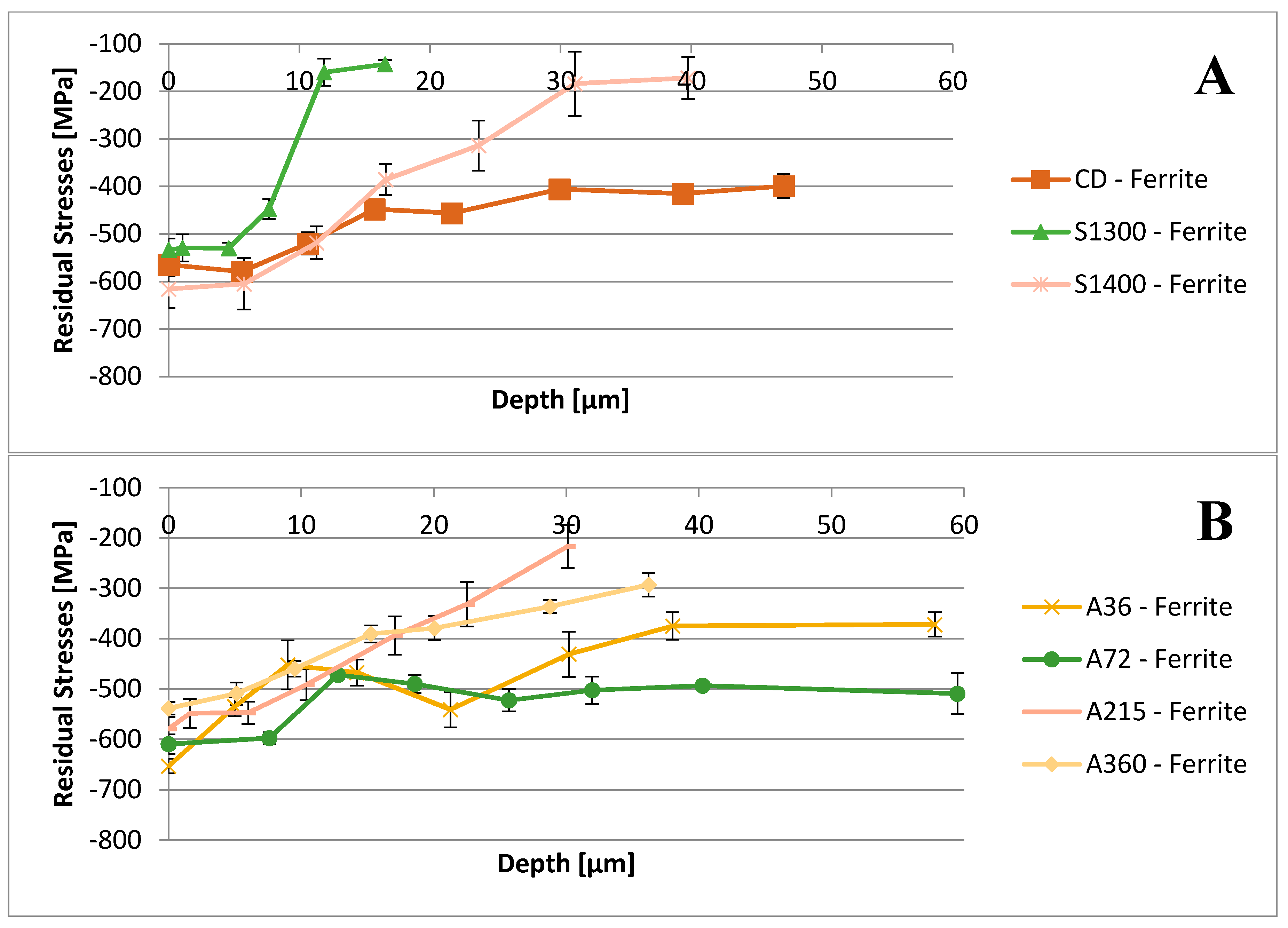

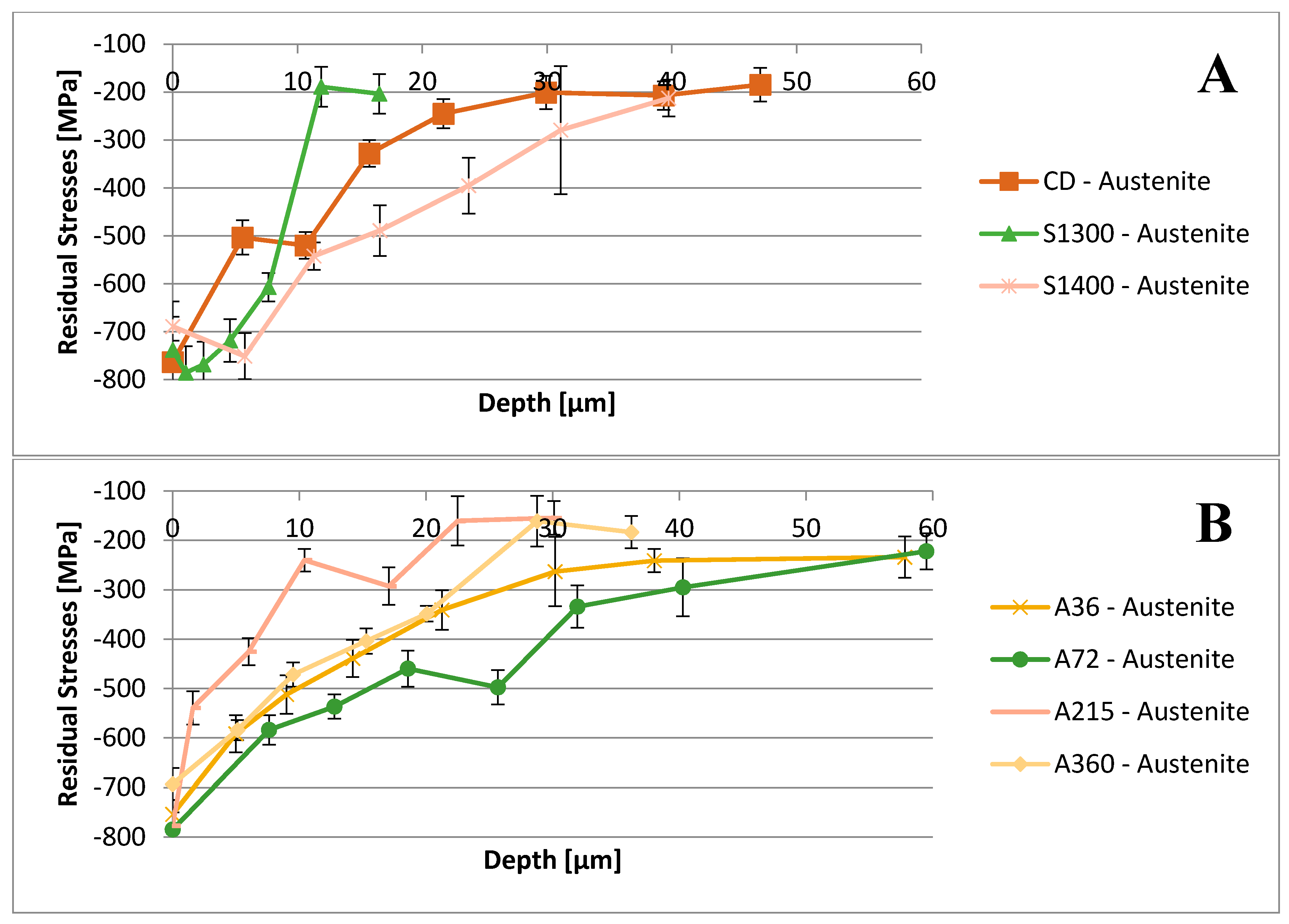

Further, in-depth profiles of the residual stresses measured by XRD have been drawn for each specimen (

Figure 2 and

Figure 3). All the samples show the presence of compressive residual stresses at the surface and in a thin layer under the surface, due to the shot peening treatment.

Residual stresses measured in the inner areas of the samples in the ferritic phase testify also to the presence of the residual stresses given by the previous thermo-mechanical history of the specimens. In detail, the residual stresses of the CD sample are related to the cold-forming processes, featuring this specimen. On the other hand, the residual stresses in the core of the annealed A36, A72, A210, and A360 samples are generated by the secondary austenite precipitation process, which occurred during the thermal treatment. Indeed, this precipitation generates compressive stresses within the ferritic matrix, due to the military character of the martensitic-shear and Widmanstätten precipitation processes. Further, with the ongoing of the annealing treatment, the relaxation of these residual stresses is observed. On the other hand, thermally generated residual stresses have not been detected within austenite, since its low stacking fault energy promotes recrystallization processes and the consequent annihilation of these stresses [

62,

63,

64].

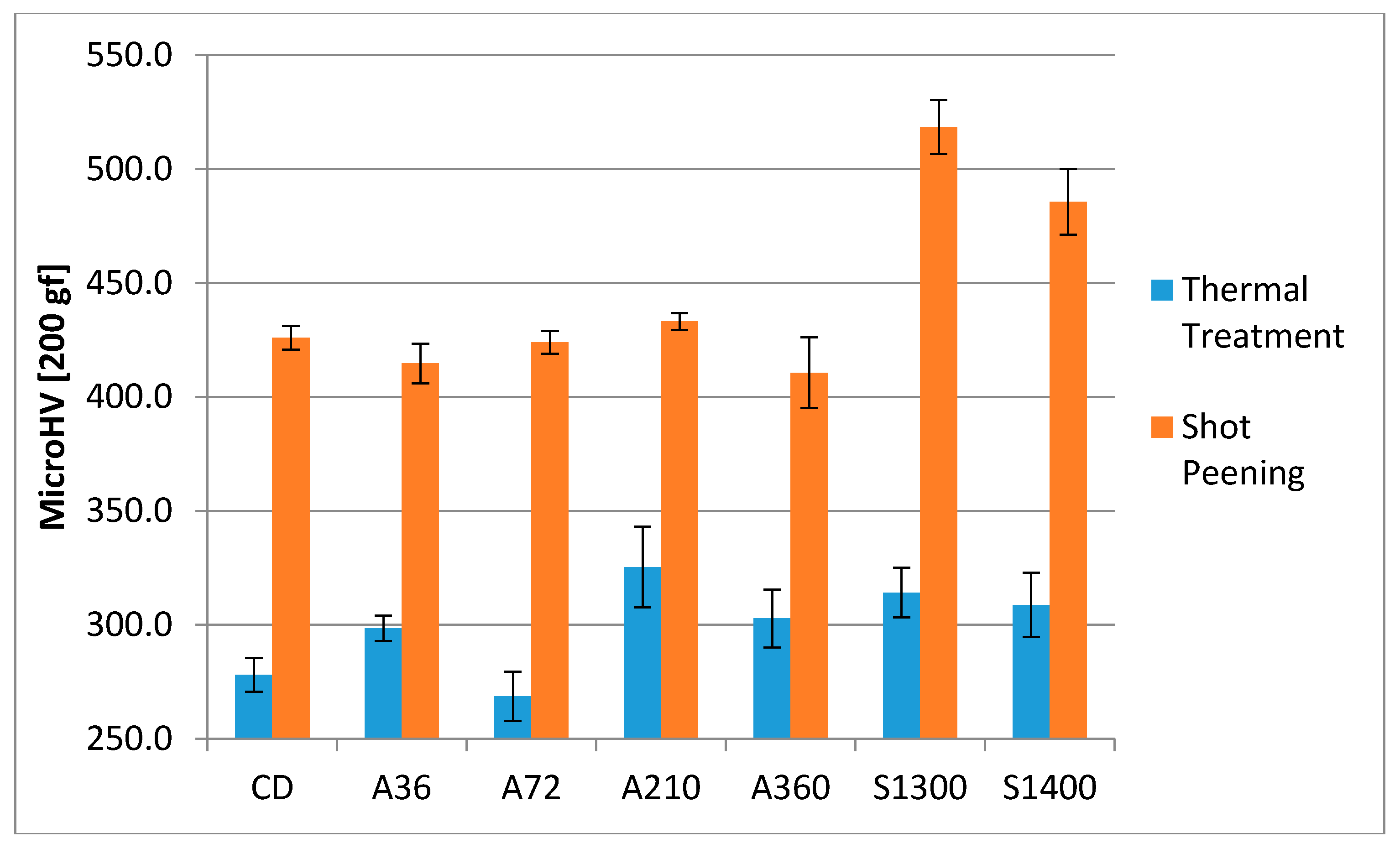

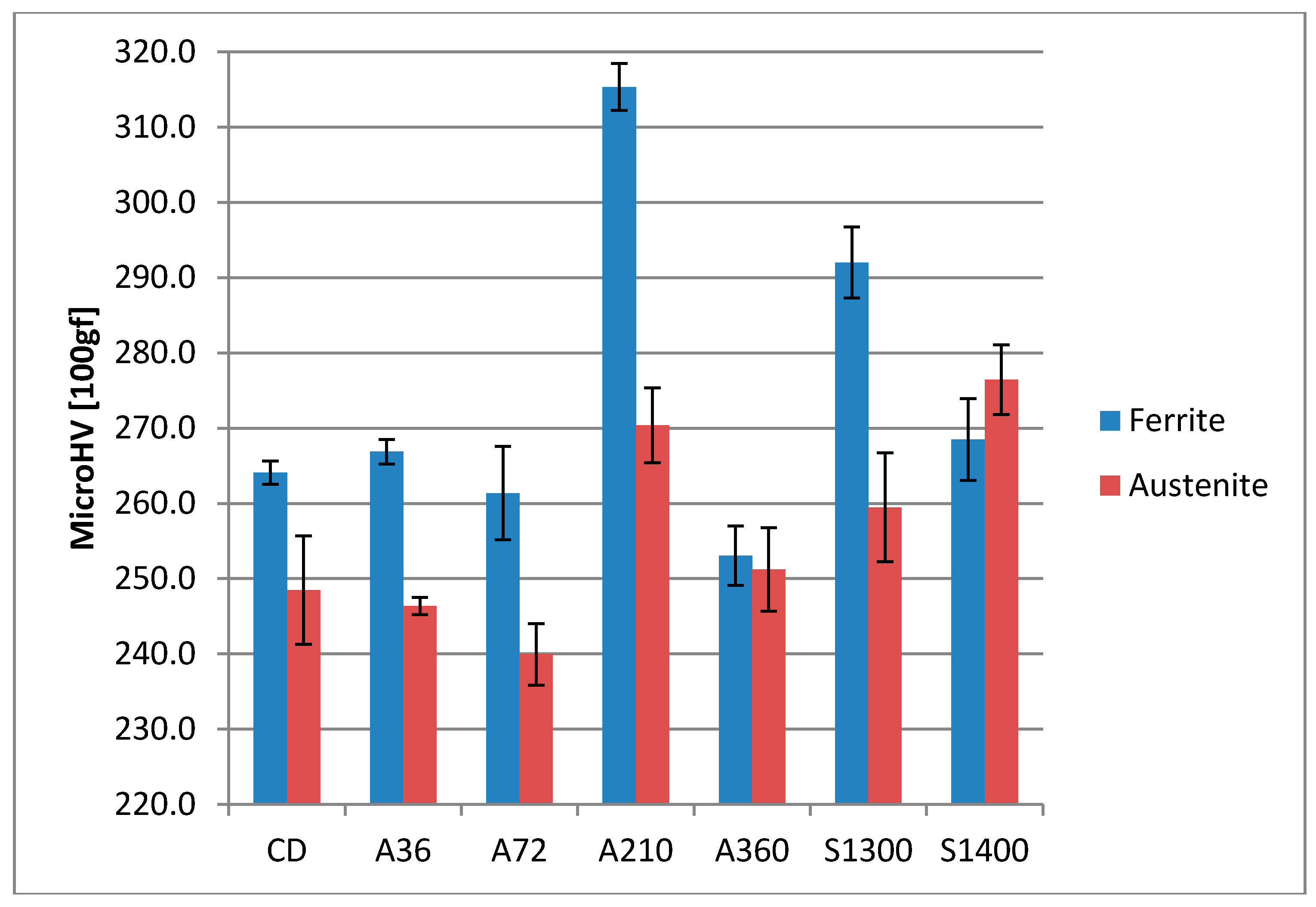

As a result, the samples, which are mainly affected by the shot peening treatment, are solubilized at 1300 °C and at 1400 °C. Indeed, they experience a larger increase in the compressive residual stresses at the surface in the ferritic phase. Consequently, this results in a larger enhancement of the surface hardness in comparison to the other investigated conditions. This consideration should be extrapolated without the contribution of the austenitic phase, since it would result in marginal change, which is expected by micromechanics [

65,

66,

67]. As expected, this trend is observed in the increase in surface hardness (

Figure 4).

Furthermore, these results, which display high surface compressive residual stresses even after an annealing thermal treatment, are related to two main reasons. The first is the thermal path of the treatment. The very high temperature of the treatment followed by the water quench achieves very high cooling rates, generating residual stresses in the material. The second reason is related to the high temperature phase transformations of AISI F55-UNS S32760 Super Duplex Stainless Steel displacive precipitations, the recrystallizations that not occur at the same time for the 2 main constituent phases, and the different stress-strain partitioning that occurs between the two phases. [

21,

25,

26,

65,

66,

67]. In addition to the data presented in this work, two other sets of XRD measurements were made on samples prepared following exactly the same experimental and thermal paths: the first at around 200–300 μm depth and the other one much deeper on the samples sections. These two sets of measures have been made with two different XRD devices, one at Universidad de Oviedo and the other at Politecnico di Milano. Both of the obtained results are in accordance with the data presented in this work. These two sets of results identify the depth measure limits.

Focusing on the penetration depth of the shot peening treatment, it can be observed that this surface mechanical treatment affects a thin superficial layer. In detail, this layer is around 20–30 μm deep, and even less in the sample annealed at 1300 °C (10–12 μm deep).

Regarding the shape of the residual stresses depth profiles, further considerations should be highlighted. The compressive residual stress state induced by the shot peening can be described by two overlaid phenomena. First, Hertzian pressure generates compressive residual stresses with a maximum below the surface. Second, the surface layer undergoes plastic stretching, leading to residual stresses with the maximum at the surface itself. The predominant effect depends upon the strength of the peened material. The substrate material and its microstructure may also contribute to the compressive residual stresses depth profile through a third process: stress/strain induced martensite transformation. The constraint, given by the volume dilation and exerted by the surrounding material, leads to a further deepening of the compressive residual stress values, moving the compressive residual stresses peak within the subsurface region, where the maximum Hertzian pressure is reached [

48,

65,

68,

69].

The compression residual stresses peaks occur in the subsurface region, due to the initial surface hardness of the samples (

Figure 4) at the threshold values of 300–350 HV. The specimens solubilized at 1300 °C and at 1400 °C follow this behavior for both the constituent phases. On the other hand, A210 sample, which has the higher surface hardness, does not display the same behavior. In detail, its austenitic phase clearly shows the maximum of its compressive residual stresses profile located at the surface. This behavior is demonstrated by the very little quantity of strain induced martensitic transformation occurring in this sample, which results not sufficient to shift the maximum of the compressive residual stresses to the subsurface region.

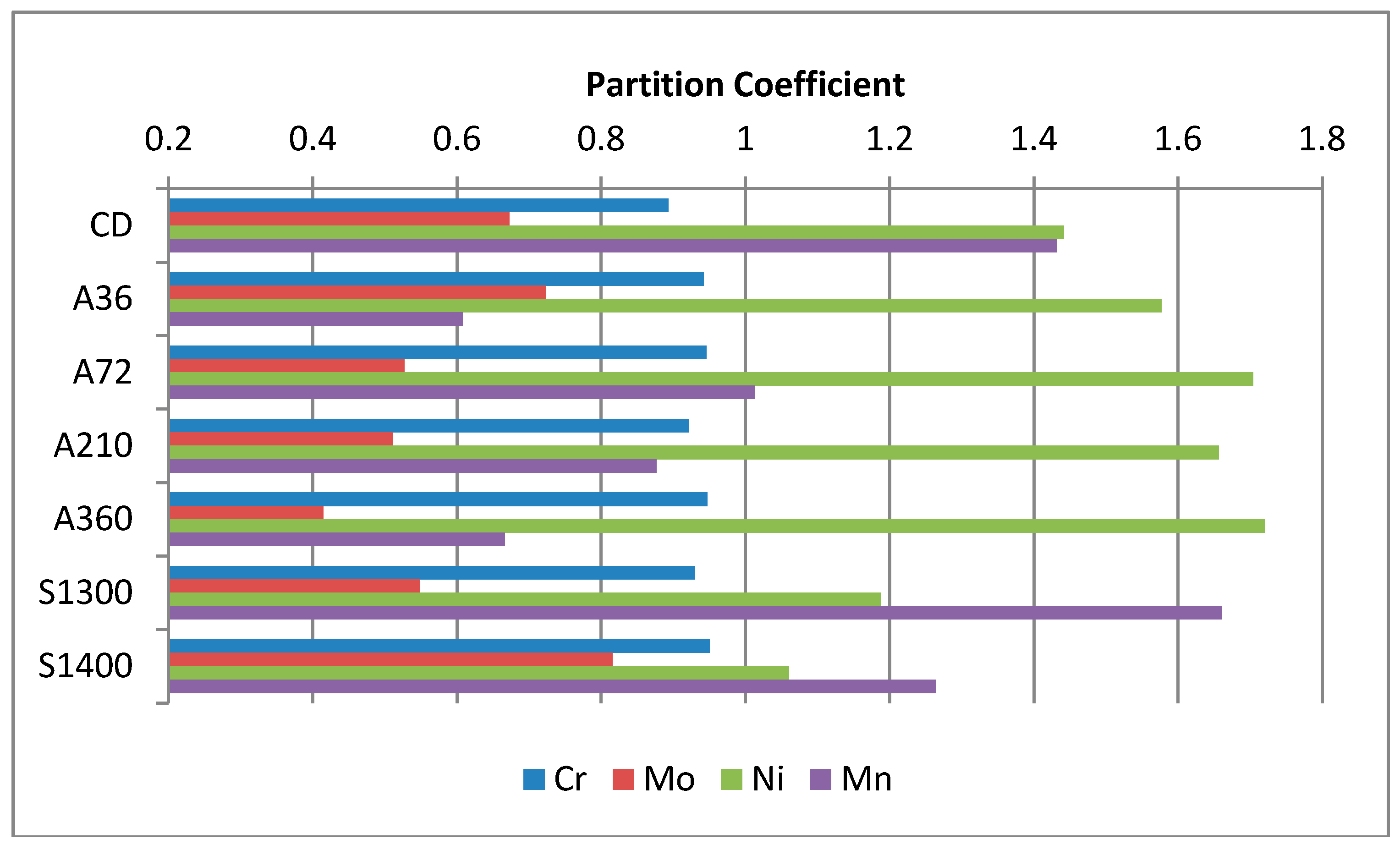

Focusing on the corrosion resistance properties, the experimental results show an evident difference among the tested samples (

Table 7). First, the significant chromium, nickel, and molybdenum content of this alloy (

Table 5) must be underlined, resulting in a strong capability to counteract external degradation attacks, which is typical of the investigated steel grade. Assuming this, in the test environment the surficial degradation of the metallic alloy is caused by three mechanisms: generalized corrosion, pitting corrosion, and galvanic corrosion between the two constituent phases. The collected data describe the overall phenomenon [

70,

71].

Before the shot peening treatment, specimens show a very low corrosion rate and, consequently, a very high pitting corrosion resistance. A slight increment in weight after the salt spray fog test has been recorded by the samples CD and A36. This behavior can be linked to generalized corrosion and the development and the thickening of the surface passive film on the surface. Thus, the pitting phenomena on these samples has not been recorded and has not been identified by visual inspection via optical microscopy. On the other hand, this visual inspection has detected the presence of corrosion products. Then, the projection at one year of exposure for these samples is not meaningful, since over such a long time-interval the pitting corrosion is expected to be trigged.

In general, after the shot peening treatment, the specimens become damaged by the chloride-rich environment, showing a lower pitting corrosion resistance than the thermally treated samples. This can be related to the surface defects generated by the surface mechanical treatment, which would act as initiation sites for the pitting phenomena. The presence of strain-induced martensite increases the number of active anodic sites at the surface. Further, the cold-worked surface layer shifts the corrosion potential of the austenite, which is the nobler phase to the anodic direction, decreasing the overall corrosion resistance of the alloy [

17].

On the other hand, the samples S1400 and A360 are not affected by the degradation phenomena in the gravimetric tests. Also, the visual inspection via optical microscopy does not record the presence of any pitting phenomena on these samples. However, corrosion products have been detected on the surface of the sample annealed for 360 s/mm and shot peened. Again, the projection at one year of exposure for these samples is not meaningful, since over such a long time-interval the pitting corrosion is expected to occur [

19]. Then, the data assigned to the solubilized at 1400 °C and shot peened sample display the best behavior in a chloride-rich environment, appearing in contrast with those collected for all the other shot peened samples. This result can be explained considering different aspects.

First, the solubilized at 1400 °C sample achieved quite a pristine surface after the mechanical surface treatment, as observed by the fractal analysis (

Table 6). Indeed, in this case the absence of cracks and hook-shaped defects prevents the formation of narrow crevices, which actuate as pitting corrosion initiation sites (

Figure 7) [

72,

73].

Further, the compressive residual stresses induced by the shot peening increase the duplex stainless steels pitting corrosion resistance. These three effects may be responsible for the increased corrosion resistance of the samples. First, compressive residual stresses in the surface layer have a beneficial contribution to the generation and growth kinetics of the passive film, improving the electrochemical corrosion resistance. Further, with the increasing compressive stresses, the corrosion potential becomes nobler because the stress field has been proven to enhance the Cr/Fe ratio in the passive film [

17]. Finally, compressive residual stresses lead to the reduction of the derogatory effects of inclusions on the treated surface [

59] and prevent pit initiation on the inclusions at low potential without changing the pitting potential [

59], enhancing the corrosion resistance [

74,

75,

76,

77,

78].

However, these features do not completely explain the good results obtained by the specimen solubilized at 1400 °C also under the mechanical point of view. Micromechanics highlight different aspects, which could have significant results for this aim. First, the austenitic phase is the most attracted by a mechanical treatment. Second, homogeneity at the surface plays a key role for both the mechanical and corrosion resistance properties [

23]. Thus, to obtain it after the shot peening process, the initial microstructure must be as uniform as possible, by focusing mainly on austenite as previously stated [

79,

80]. Taking in account all these aspects, the sample solubilized at 1400 °C displays the most suitable initial microstructure. Indeed, it appears as the most homogeneous in terms of austenite morphology and distribution (

Figure 1), the mechanical properties of the two constituent phases (

Figure 5), and also the chemical element distribution between the two phases (

Table 5 and

Figure 6).

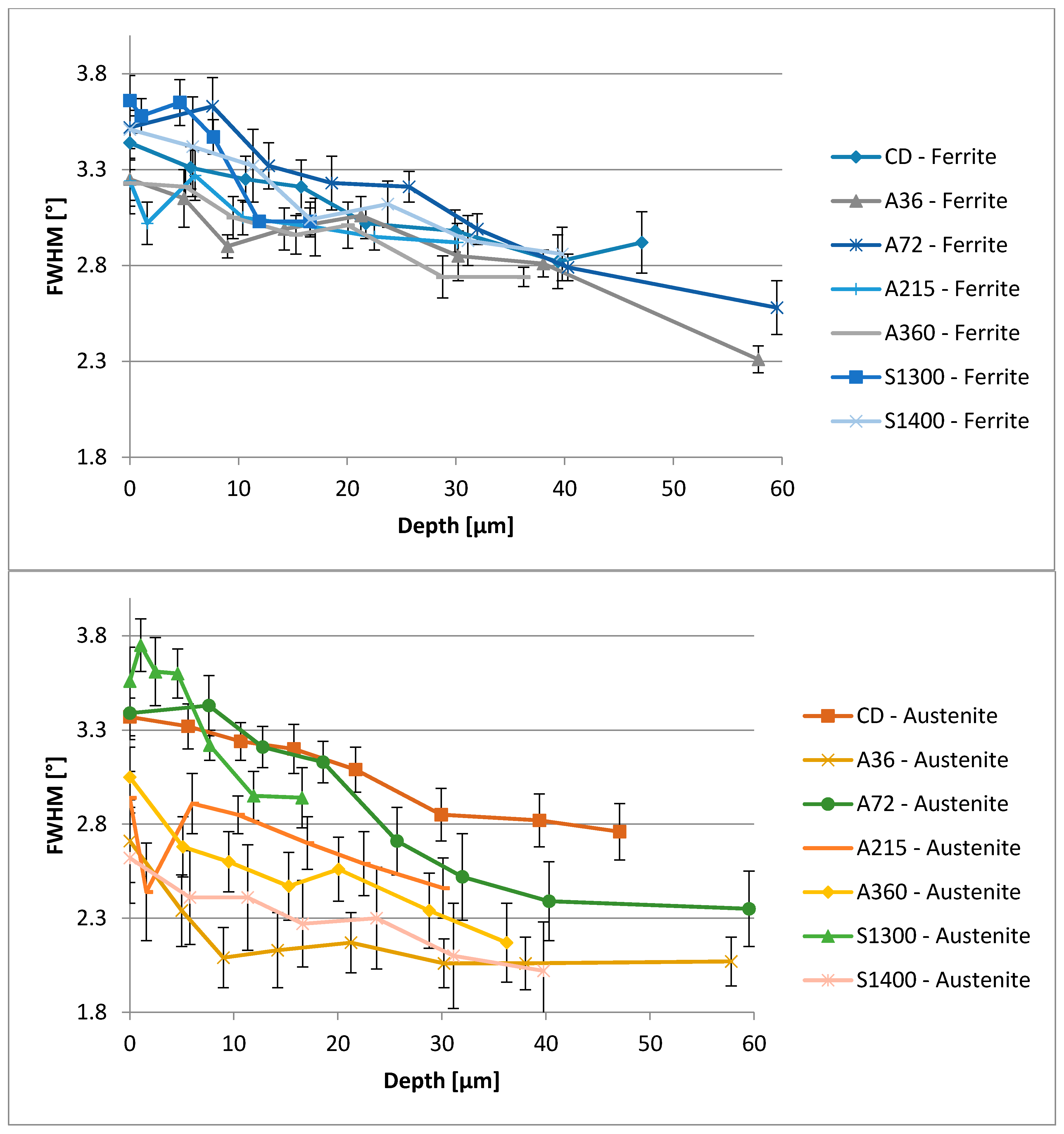

Further, this specimen is also the most homogeneous in the energy dissipation modes, featuring its microstructure and displaying impact energy storage, provided by the shot peening process. Indeed, the materials continuum may store the energy conferred by the blasting medium impact, generating imperfections within the crystal lattice. These imperfections result in microscopic stresses and can be measured through the Full Width at Half Maximum (FWHM) of the XRD spectra. The collected data are grouped in

Figure 8. Microscopic stresses are without direction, but, since they are generated by a directional process such as shot peening, their presence should be limited to achieve the maximum homogeneity within the microstructure. The depth profiles of the FWHM values reflect the trend of the residual stresses, to which are linked [

56,

57]. Microstresses measured at the surface within the ferritic phase are quite similar for all the samples with narrow data scattering. Further, since ferrite is less prone to deformations, these microstresses are less significant [

65,

66,

67]. On the other hand, results from the austenitic phase of the surface samples show a broadening, which increases the significance of the data. The solubilized at 1400 °C sample results are less affected by this phenomenon, demonstrating the tendency of this microstructure to accommodate energy in a different manner.

A further method used by the microstructure to accommodate strains and to store the energy given by the impact of the blasting medium is the generation of staking faults. For face centered cubic (f.c.c.) lattices, such as austenite, one of these mechanisms is the generation of twins. Twins are 2-dimensional defects; they intrinsically create anisotropy in the surrounding microstructure [

81]. Thus, to achieve a homogeneous microstructure their presence should be limited.

However, twins may be thermally generated; thus, benchmark values for each sample should be measured to assess the increase, due to the shot peening process [

82]. The number of twins per area has been counted, using oxalic acid electrochemically etched micrographs, in both regions: near the surface in the mechanically affected layer and in the core of the samples. In

Table 8, the collected data are shown. The increase in twins concentration at the samples surface evinces their “mechanical” nucleation, which is related to the storage of the impact energy of the blasting medium.

The completely different behavior of the sample solubilized at 1400 °C can also be highlighted. This is due to the austenitic grain morphology of these specimens. Indeed, it is composed only by allotriomorph austenite and Widmanstätten austenite plates. In the first morphology, twins cannot be generated because of the presence of grain boundaries, which are too close. In the latter case, twins cannot be generated since the Widmanstätten austenite plates are generated by the surrounding defects and a set of periodic dislocations share the same direction, nearly parallel to the close-packed directions [

83,

84]. This behavior ensures a more uniform and homogeneous microstructure with respect to the other samples, in which these 2-dimensional defects intrinsically create anisotropy.

Finally, the last possible energy dissipation mode featuring these microstructures is the strain induced martensitic transformation. Since it is a 3-dimensional process, it intrinsically results in the most uniform and homogeneous outcome. As reported in

Table 4, the specimens solubilized at 1400 °C widely exploit this energy dissipation phenomenon to store the impact energy provided by the shot peening process. Thus, its microstructure results are the most homogeneous, considering this aspect.