Fabrication and Characteristics of Sintered Cutting Stainless Steel Fiber Felt with Internal Channels and an Al2O3 Coating

Abstract

1. Introduction

2. Experimental Procedures

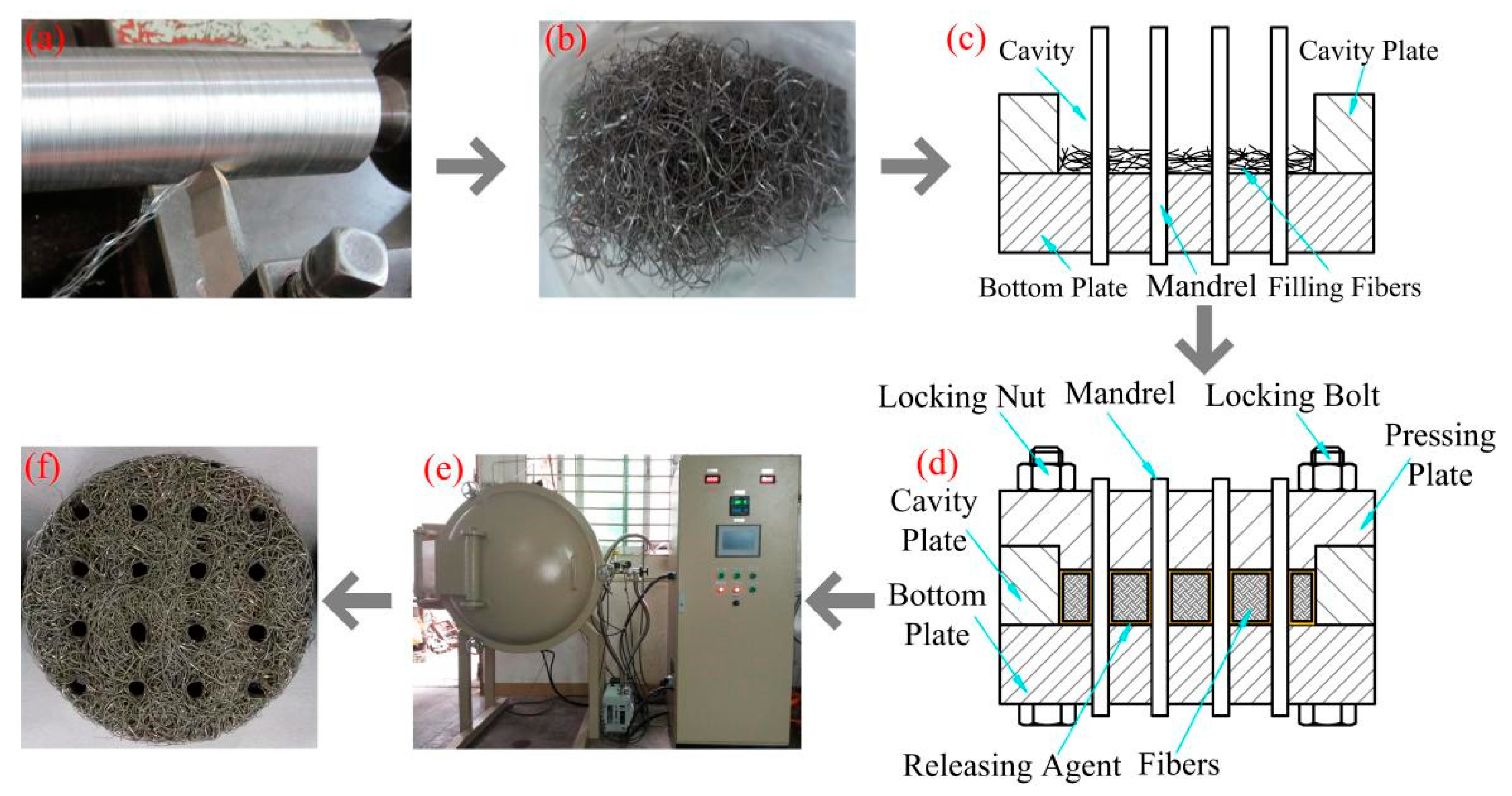

2.1. Fabrication of the SCSSFFC with Al2O3 Coating

2.2. Adhesive Strength Test for SCSSFFC/Al2O3

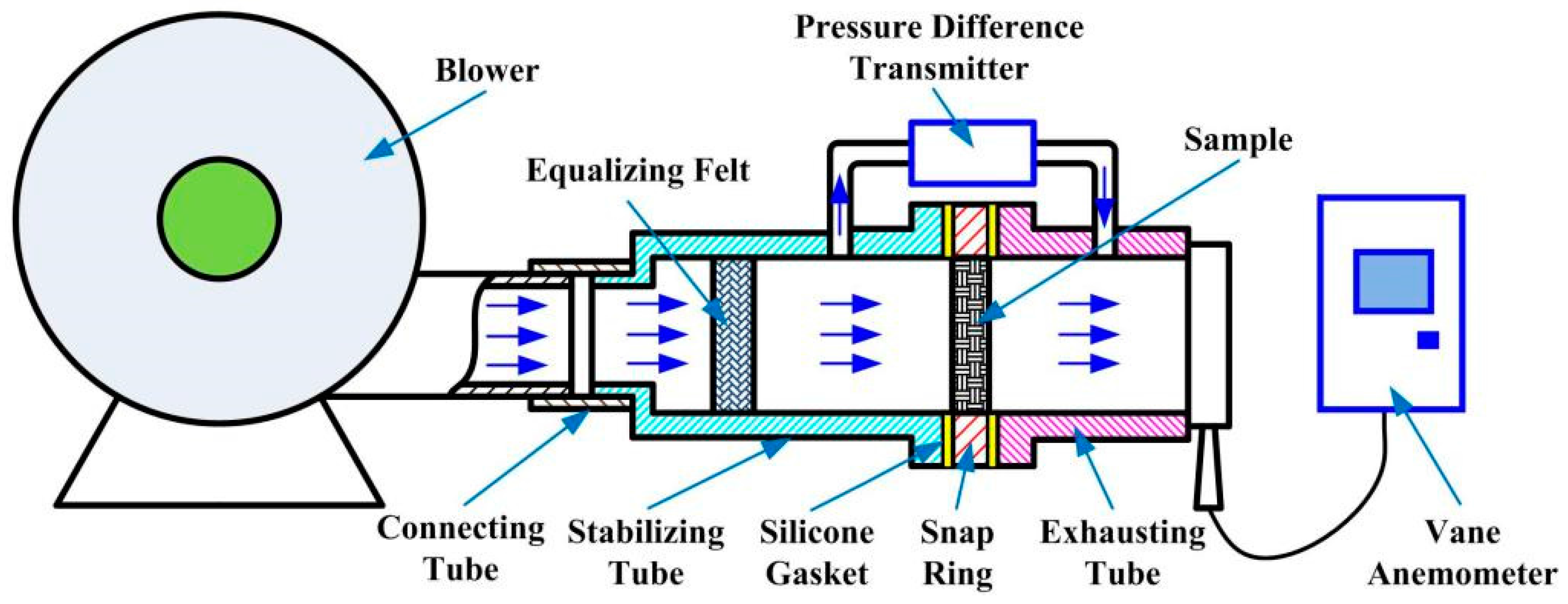

2.3. Permeability Test for SCSSFFC/Al2O3

2.4. Uncertainty Analysis

3. Results

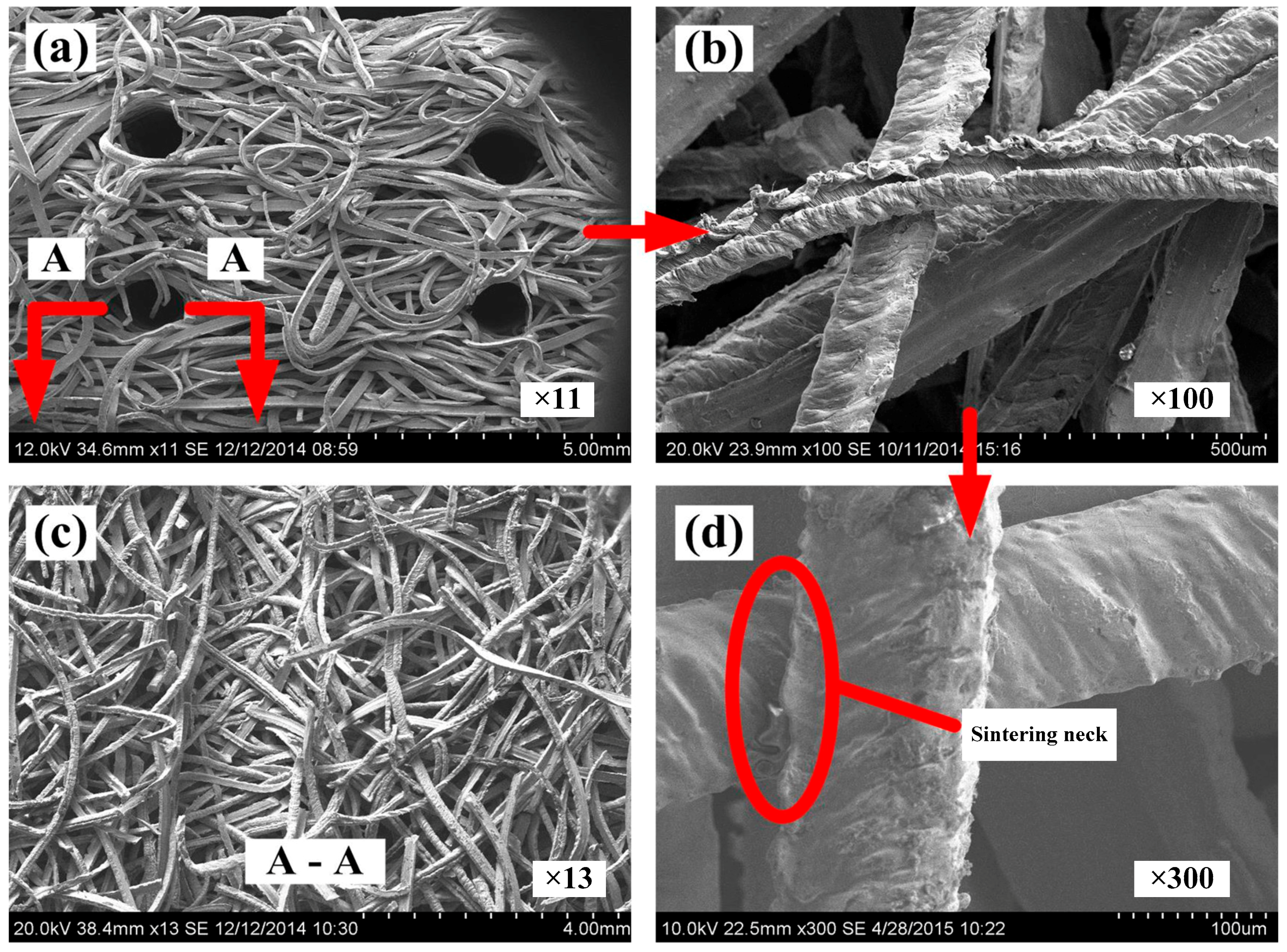

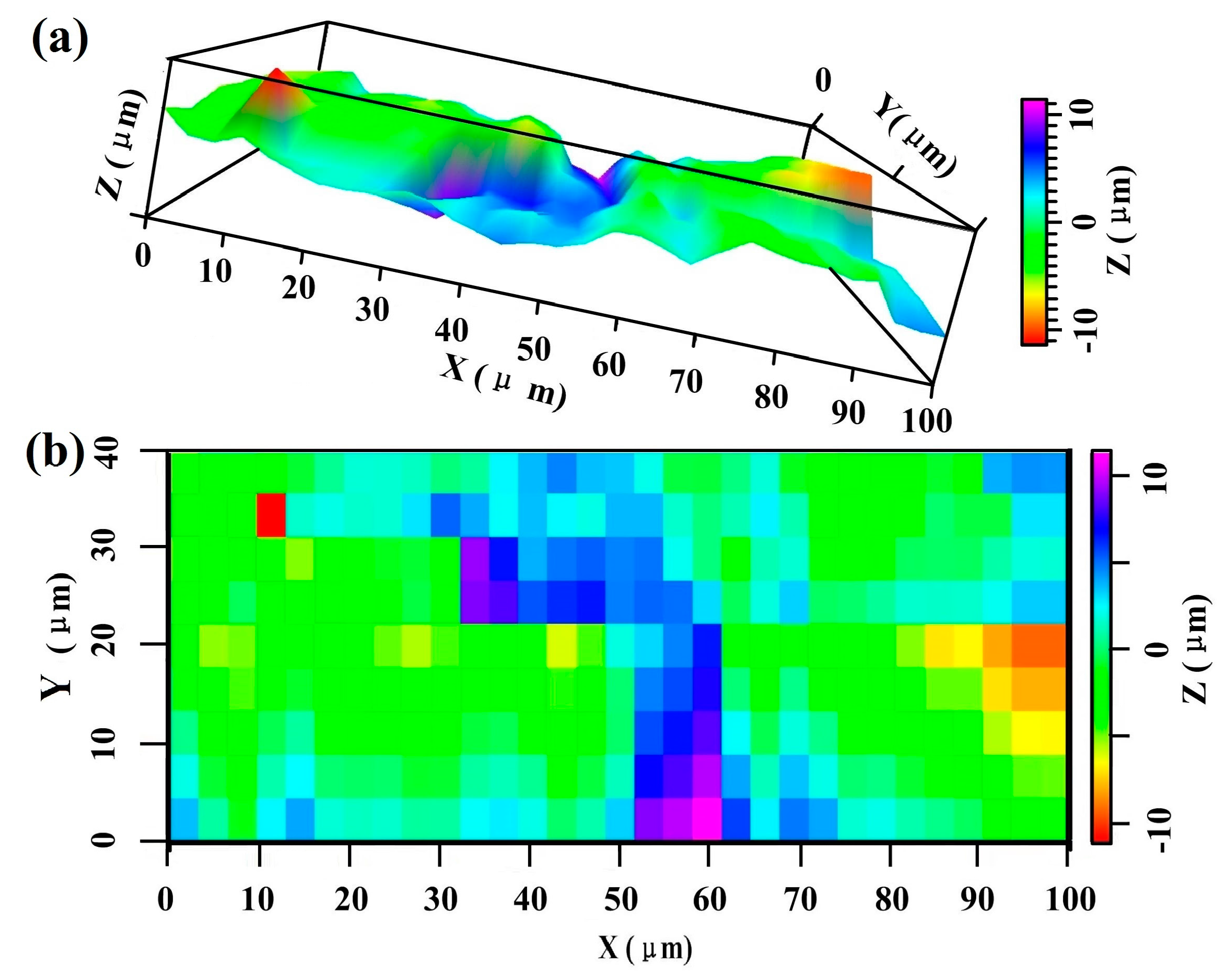

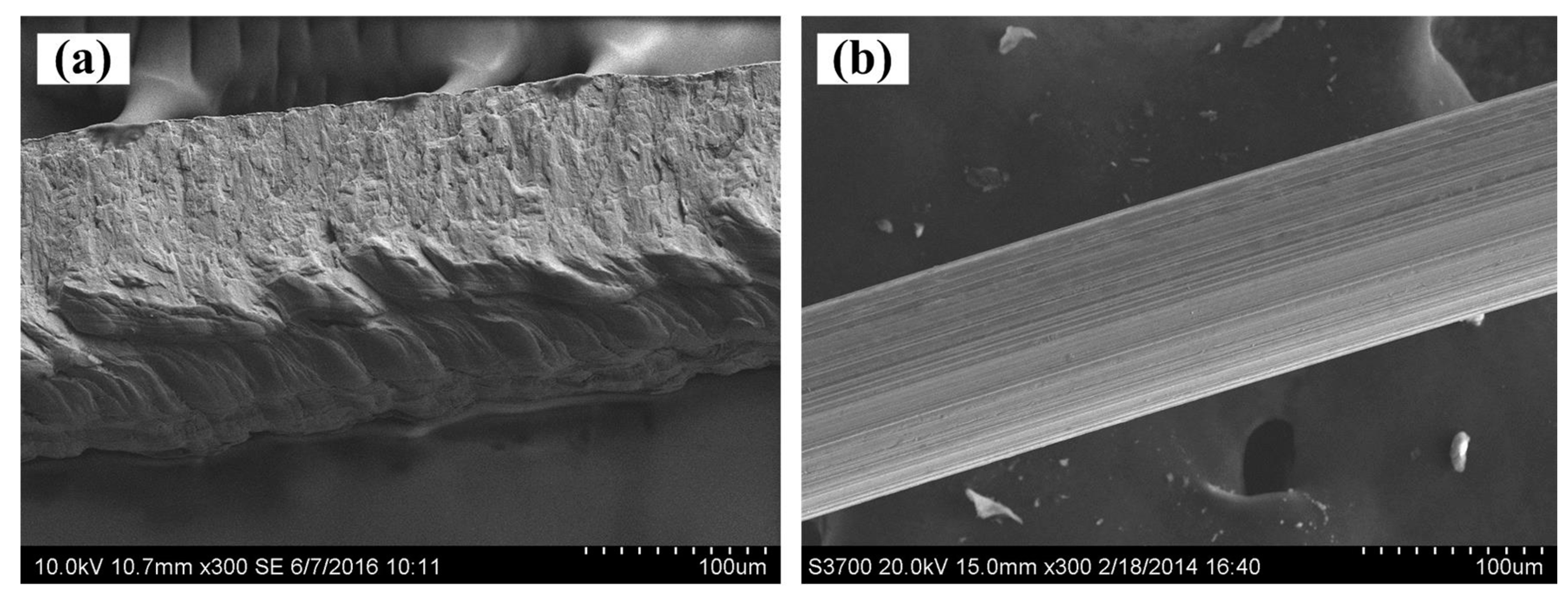

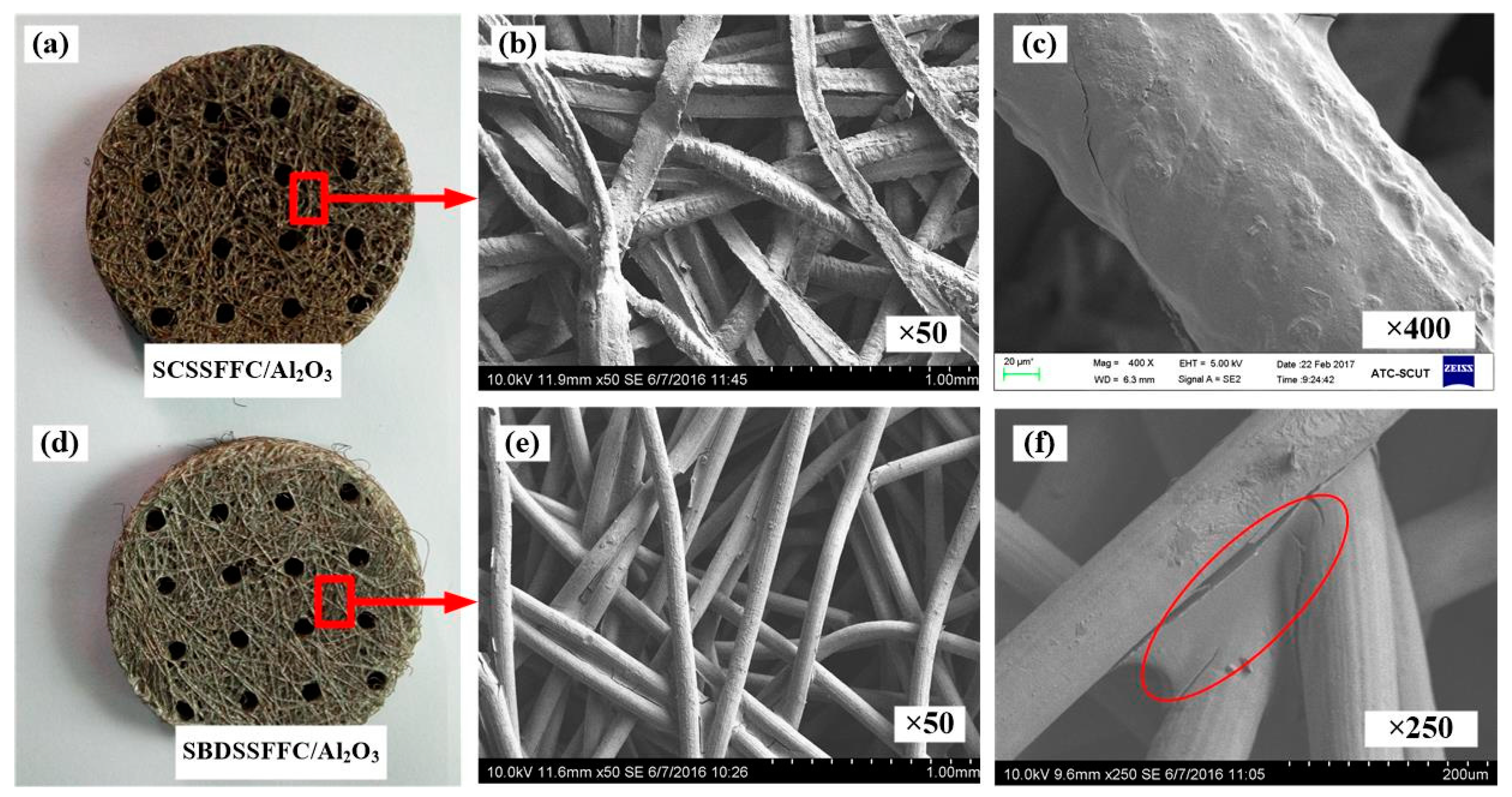

3.1. Characteristics of SCSSFFC/Al2O3

3.2. Adhesive Strength of SCSSFFC/Al2O3

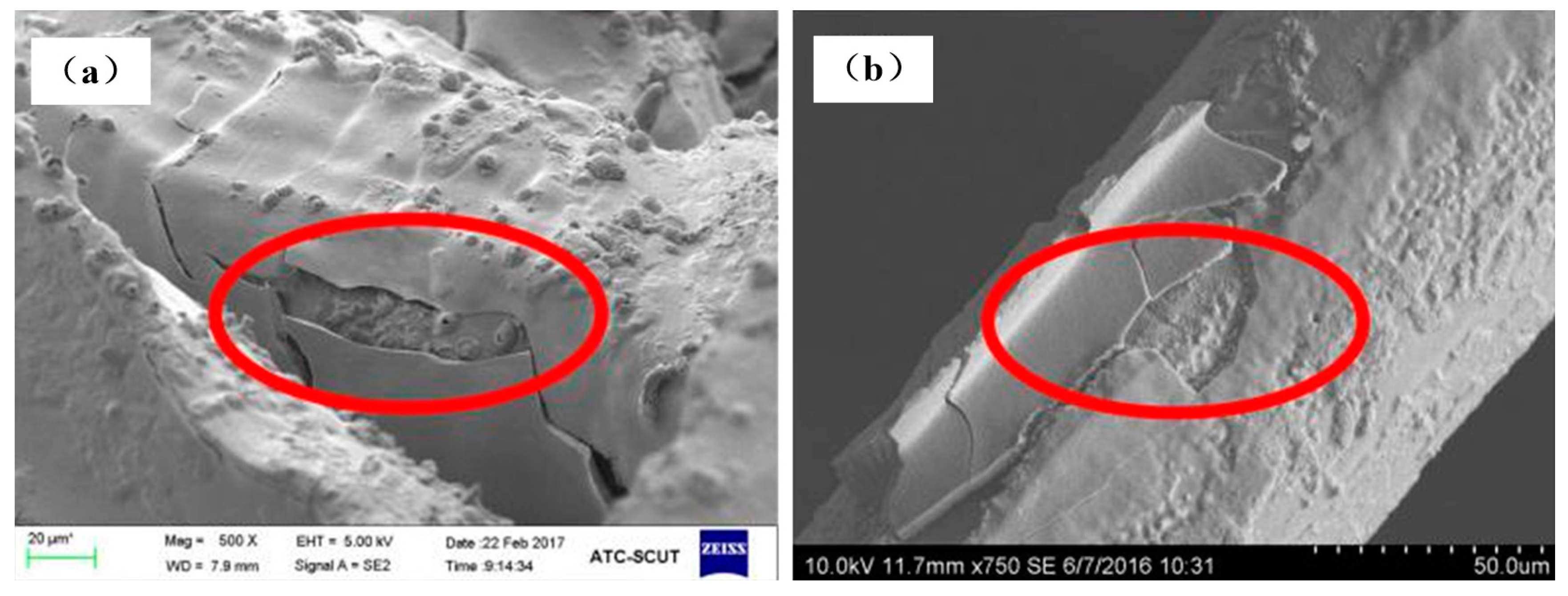

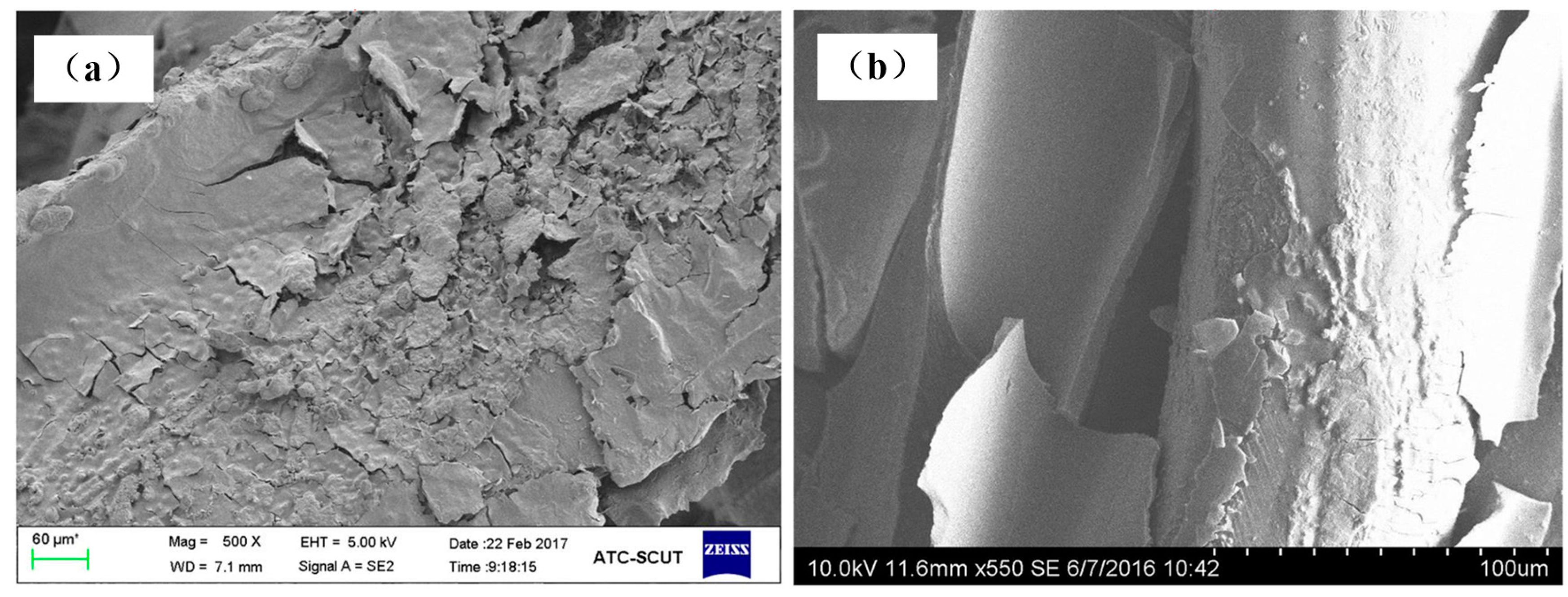

3.2.1. Mechanical Shock Performance of SCSSFFC/Al2O3

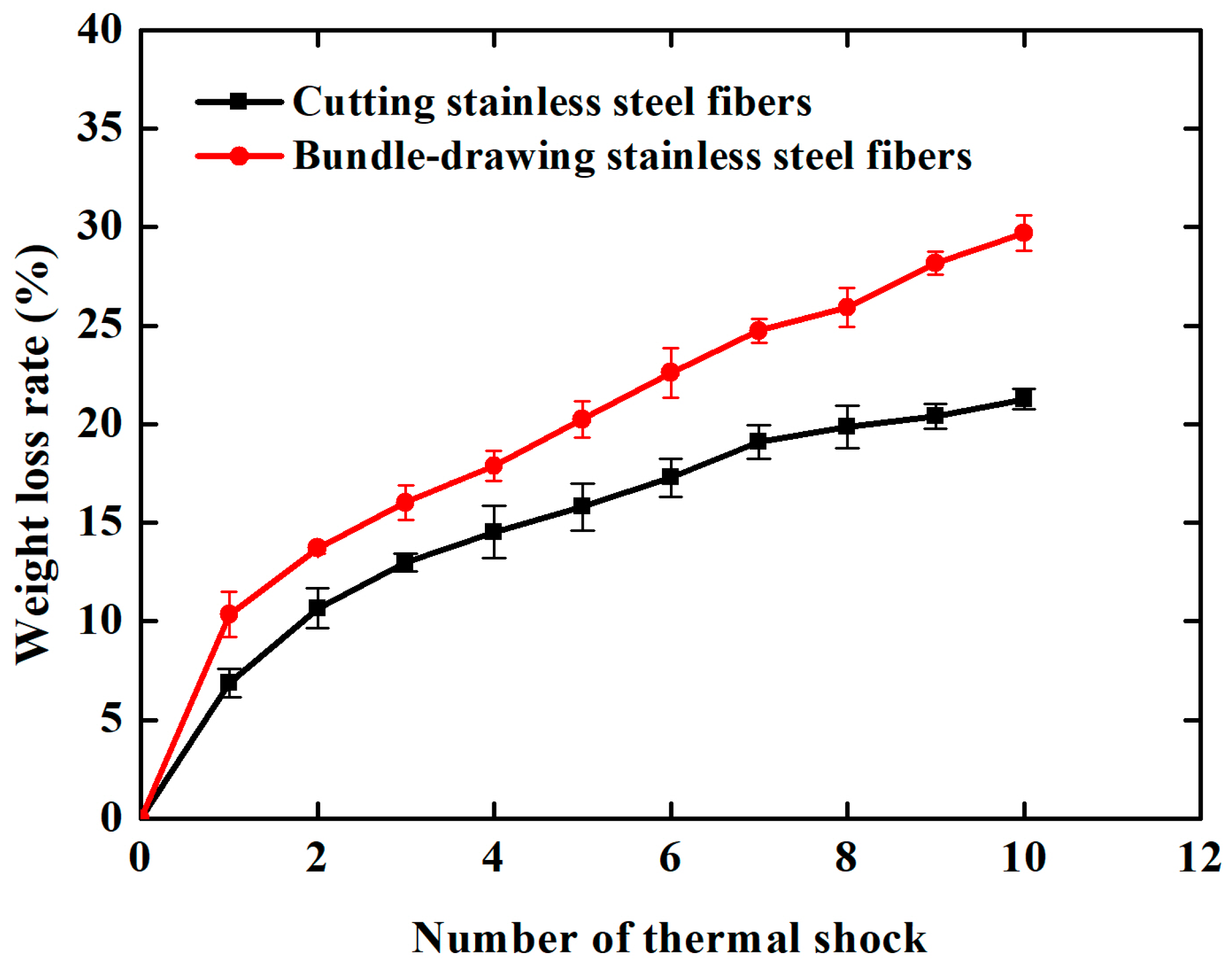

3.2.2. Thermal Shock Performance of SCSSFFC/Al2O3

3.3. Flow Characteristics of SCSSFFC/Al2O3

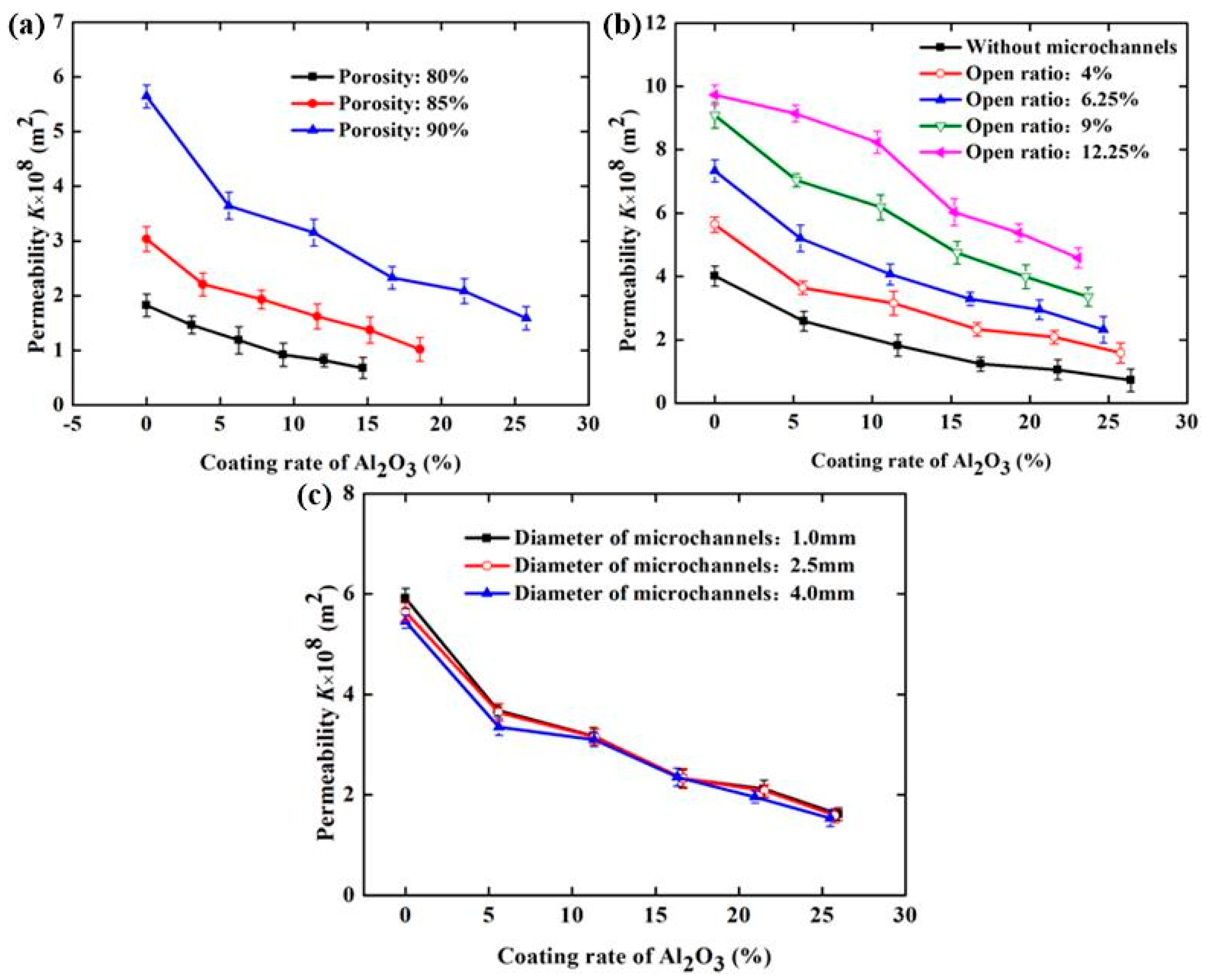

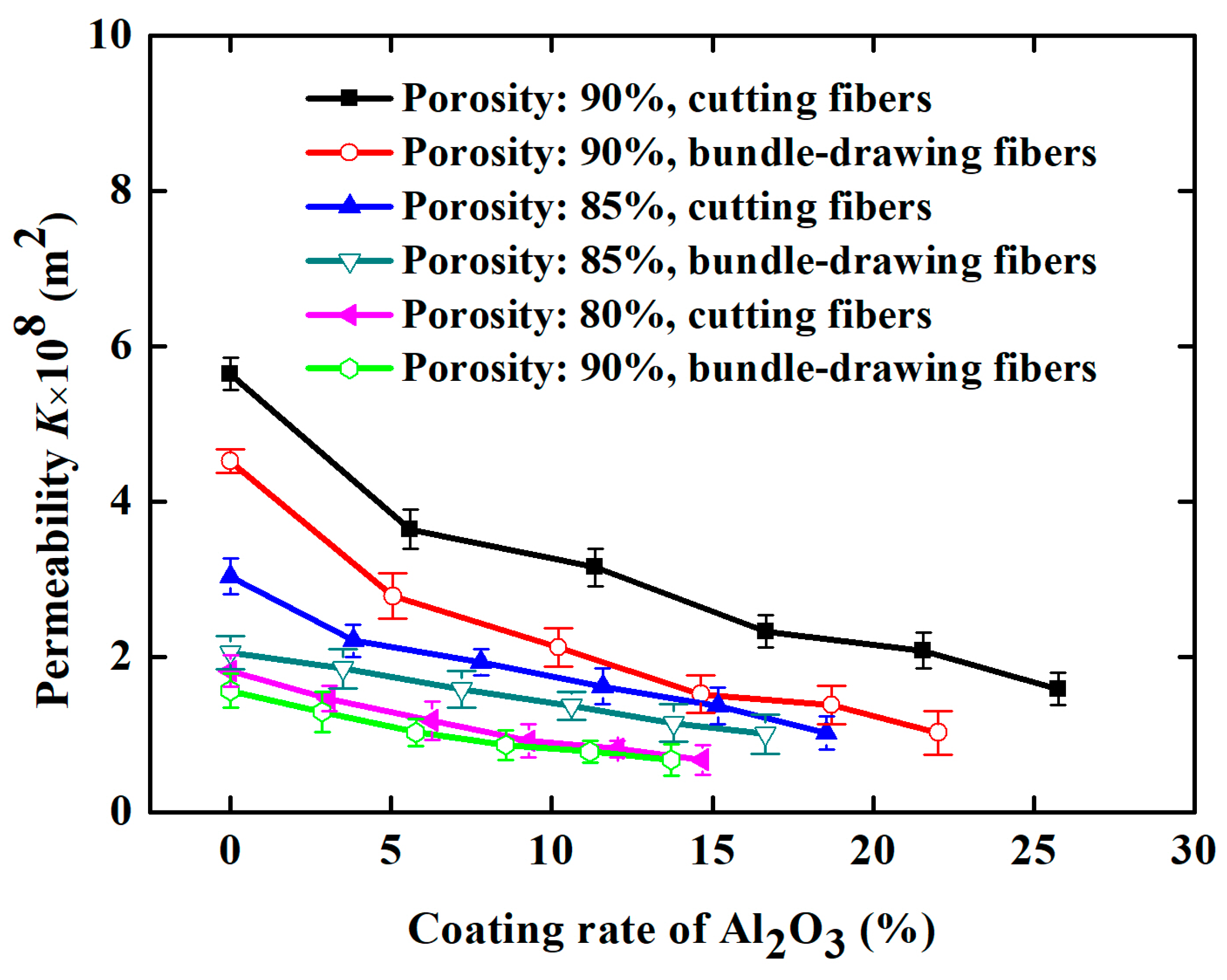

3.3.1. Permeability

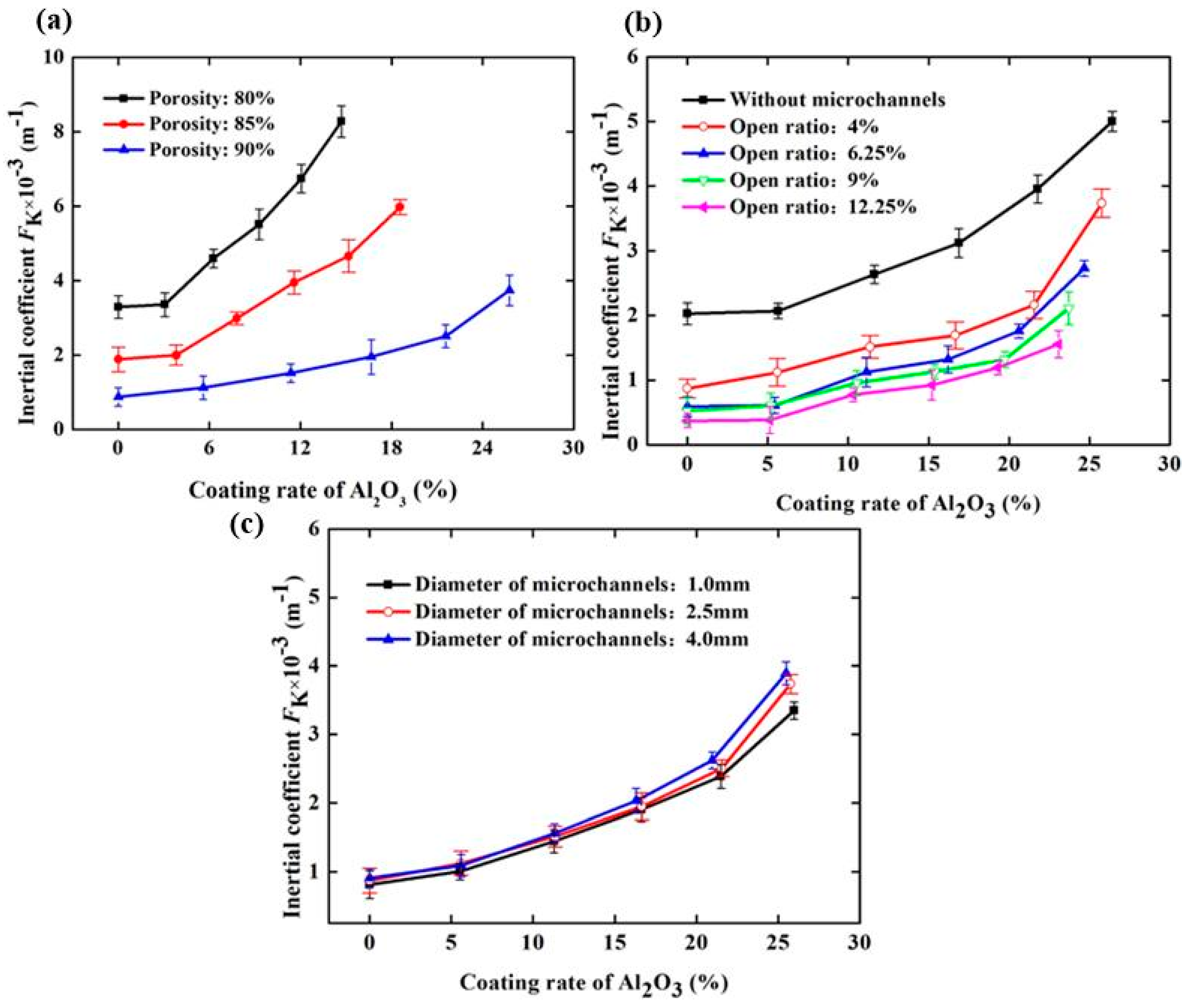

3.3.2. Inertial Coefficient

4. Discussion

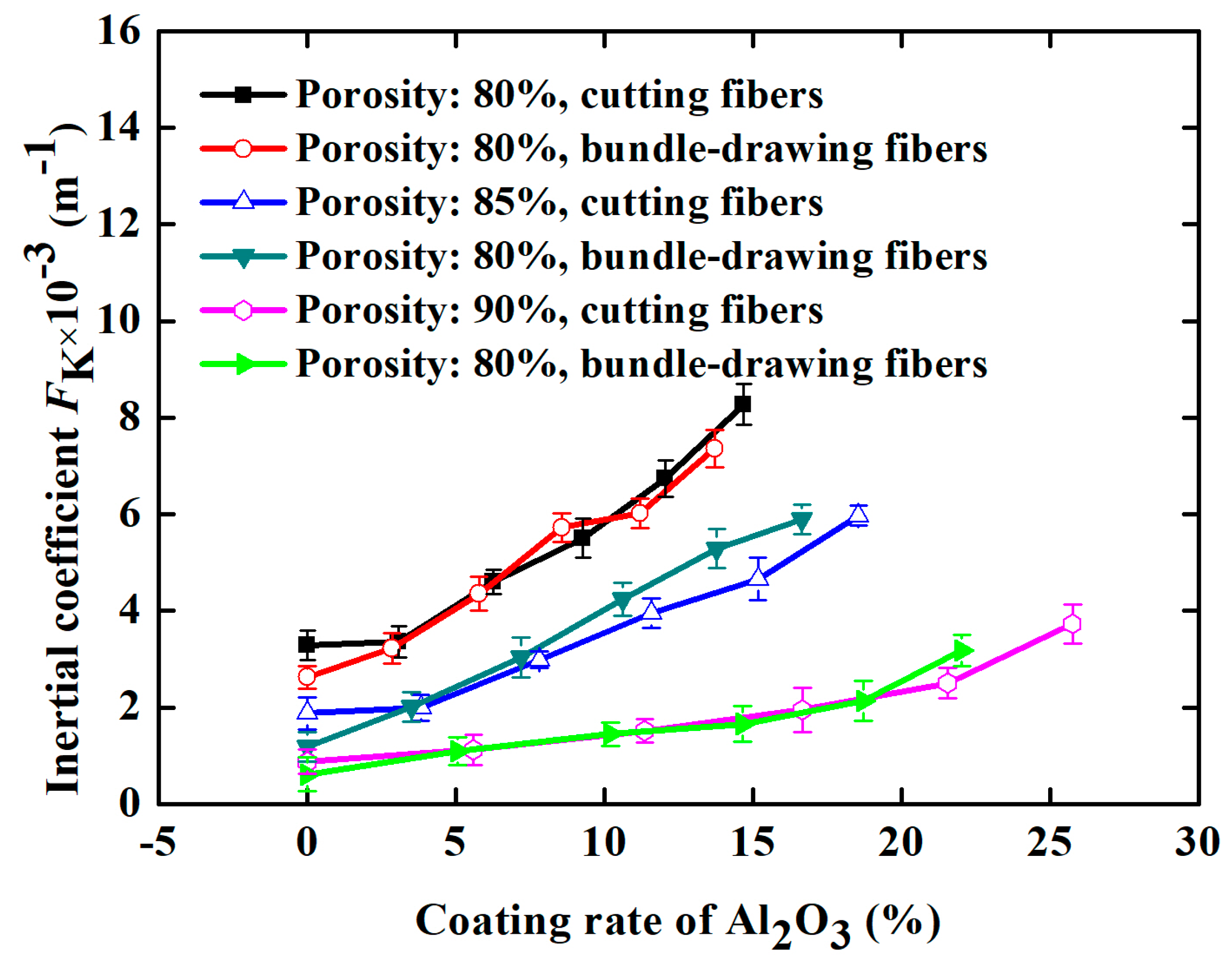

4.1. Comparison with Smooth SBDSSFFC/Al2O3

4.2. Comparison with Previous Work

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| K | permeability (m2) |

| FK | inertial coefficient (m−1) |

| M | mass of sample (kg) |

| Δp | pressure drop (Pa) |

| D | sample diameter (m) |

| d | channel diameter (m) |

| H | thickness of sample (m) |

| N | channel number |

| u | air velocity (m/s) |

| Ck | correction coefficient of permeability |

| CF | correction coefficient of inertial coefficient |

| Greek symbol | |

| ε | porosity, dimensionless |

| ρ | density of air (kg/m3) |

| ρ′ | density of 1Cr18Ni9Ti (kg/m3) |

| μ | dynamic viscosity of air (Pa s) |

| α | open ratio, dimensionless, dimensionless |

| β | coating rate of sample, dimensionless |

| φ | weight loss rate of sample, dimensionless |

References

- Roso, M.; Boaretti, C.; Pelizzo, M.G.; Lauria, A.; Modesti, M.; Lorenzetti, A. Nanostructured photocatalysts based on different oxidized graphenes for VOCs removal. Ind. Eng. Chem. Res. 2017, 56, 9980–9992. [Google Scholar] [CrossRef]

- Kamal, M.S.; Razzak, S.A.; Hossain, M.M. Catalytic oxidation of volatile organic compounds (VOCs)—A review. Atmos. Environ. 2016, 140, 117–134. [Google Scholar] [CrossRef]

- Li, L.; Jing, F.; Yan, J.; Jing, J.; Chu, W. Highly effective self-propagating synthesis of CeO2-doped MnO2 catalysts for toluene catalytic combustion. Catal. Today 2017. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, Z.; Shangguan, W. Low-temperature catalysis for VOCs removal in technology and application: A state-of-the-art review. Catal. Today 2015, 264, 270–278. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, L.; Zhang, H. Catalytic combustion of volatile organic compounds over Co/ZSM-5 coated on stainless steel fibers. Chem. Eng. J. 2014, 255, 195–204. [Google Scholar] [CrossRef]

- Iwaniszyn, M.; Piątek, M.; Gancarczyk, A.; Jodłowski, P.J.; Łojewska, J.; Kołodziej, A. Flow resistance and heat transfer in short channels of metallic monoliths: Experiments versus CFD. Int. J. Heat Mass Transf. 2017, 109, 778–785. [Google Scholar] [CrossRef]

- Lup, A.N.K.; Abnisa, F.; Wan, M.A.W.D.; Aroua, M.K. A review on reactivity and stability of heterogeneous metal catalysts for deoxygenation of bio-oil model compounds. J. Ind. Eng. Chem. 2017, 56, 1–34. [Google Scholar] [CrossRef]

- Beek, R.V.; Ommen, J.G.V.; Lefferts, L. Immobilization of carbon nanofibers (CNFs) on a stainless steel filter as a catalyst support layer. Catal. Today 2018, 301, 134–140. [Google Scholar] [CrossRef]

- Huang, Y.; Ho, S.S.; Lu, Y.; Niu, R.; Xu, L.; Cao, J.; Lee, S. Removal of indoor volatile organic compounds via photocatalytic oxidation: A Short Review and Prospect. Molecules 2016, 21, 56. [Google Scholar] [CrossRef] [PubMed]

- Reichelt, E.; Heddrich, M.P.; Jahn, M.; Michaelis, A. Fiber based structured materials for catalytic applications. Appl. Catal. A Gen. 2014, 476, 78–90. [Google Scholar] [CrossRef]

- Jo, S.; Jin, J.; Kwon, S. The preparation of a metal foam support of Pt/Al2O3 for combustion of hydrogen. Catal. Today 2010, 155, 45–50. [Google Scholar] [CrossRef]

- Hernández-Garrido, J.C.; Gaona, D.; Gómez, D.M.; Gatica, J.M.; Vidal, H.; Sanz, O.; Rebled, J.M.; Peiró, F.; Calvino, J.J. Comparative study of the catalytic performance and final surface structure of CO3O4/La-CeO2 washcoated ceramic and metallic honeycomb monoliths. Catal. Today 2015, 253, 190–198. [Google Scholar] [CrossRef]

- Gómez, D.M.; Gatica, J.M.; Hernández-Garrido, J.C.; Cifredo, G.A.; Montes, M.; Sanz, O.; Rebled, J.M.; Vidal, H. A novel CoOx/La-modified-CeO2 formulation for powdered and washcoated onto cordierite honeycomb catalysts with application in VOCs oxidation. Appl. Catal. B Environ. 2014, 144, 425–434. [Google Scholar] [CrossRef]

- Jodłowski, P.J.; Kryca, J.; Rogulska, A.; Gil, B.; Iwaniszyn, M.; Łojewska, J.; Kołodziej, A. Advantages of a wire gauze structured reactor with a zeolite (Cu-USY) catalyst for NH3-SCR of NOx. Chem. Eng. J. 2013, 214, 319–326. [Google Scholar] [CrossRef]

- Kim, K.J.; Ahn, H.G. A study on utilization of stainless steel wire cloth as a catalyst support. J. Ind. Eng. Chem. 2012, 18, 668–673. [Google Scholar] [CrossRef][Green Version]

- Korkmaz, K. The effect of Micro-arc Oxidation treatment on the microstructure and properties of open cell Ti6Al4V alloy foams. Surf. Coat. Technol. 2015, 272, 72–78. [Google Scholar] [CrossRef]

- Giani, L.; Cristiani, C.; Groppi, G.; Tronconi, E. Washcoating method for Pd/γ-Al2O3 deposition on metallic foams. Appl. Catal. B Environ. 2006, 62, 121–131. [Google Scholar] [CrossRef]

- Yang, S.; Pan, X.; Han, Z.; Zhao, D.; Liu, B.; Zheng, D.; Yan, Z. Kinetics of nitric oxide absorption from simulated flue gas by a wet UV/chlorine advanced oxidation process. Energy Fuels 2017, 31, 7263–7271. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Wang, T.; Lin, J.W.; Romero, C.E.; Pan, W.P. Oxidation of elemental mercury with non-thermal plasma coupled with a wet process. Fuel 2017, 197, 320–325. [Google Scholar] [CrossRef]

- Mori, T.; Egawa, T.; Miyoshi, M. Growth of rough-surface p-GaN layers on InGaN/GaN multiple-quantum-well structures by metalorganic chemical vapor deposition and their application to GaN-based solar cells. Mater. Res. Express 2017, 4, 085904. [Google Scholar] [CrossRef]

- Tahmasebpoor, R.; Babaluo, A.A.; Shahrouzi, J.R.; Tahmasebpoor, M.; Shahrezaei, M. Theoretical and experimental studies on the anodic oxidation process for synthesis of self-ordering TiO2 nanotubes: Effect of TiO2 nanotube lengths on photocatalytic activity. J. Environ. Chem. Eng. 2017, 5, 1227–1237. [Google Scholar] [CrossRef]

- Hadzima, B.; Nový, F.; Trško, L.; Pastorek, F.; Jambor, M.; Fintová, S. Shot peening as a pre-treatment to anodic oxidation coating process of AW 6082 aluminum for fatigue life improvement. Int. J. Adv. Manuf. Technol. 2017, 93, 3315–3323. [Google Scholar] [CrossRef]

- Dai, H.; Fang, H.; Zhao, J.; Sun, J.; Yu, X.; Yu, K. Layer roughness reduction and light harvest from Ag nanowires on a silicon surface through wet etching embedding. Appl. Phys. Lett. 2017, 111, 021601. [Google Scholar] [CrossRef]

- Wan, Z.P.; Tang, Y.; Liu, Y.J.; Liu, W.Y. High efficient production of slim long metal fibers using bifurcating chip cutting. J. Mater. Process. Technol. 2007, 189, 273–278. [Google Scholar] [CrossRef]

- Tang, Y.; Zhou, W.; Xiang, J.; Liu, W.; Pan, M. An Innovative fabrication process of porous metal fiber sintered felts with three-dimensional reticulated structure. Adv. Manuf. Process. 2010, 25, 565–571. [Google Scholar] [CrossRef]

- Yu, H.; Chen, H.; Pan, M.; Tang, Y.; Zeng, K.; Feng, P.; Wang, H. Effect of the metal foam materials on the performance of methanol steam micro-reformer for fuel cells. Appl. Catal. A Gen. 2007, 327, 106–113. [Google Scholar] [CrossRef]

- Zhang, R.; Hou, X.; Ye, C.; Wang, B. Enhanced mechanical and thermal properties of anisotropic fibrous porous mullite–zirconia composites produced using sol-gel impregnation. J. Alloys Compd. 2017, 699, 511–516. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, J.; Weng, D.; Wu, X. A method to form well-adhered γ-Al2O3 layers on FeCrAl metallic supports. Surf. Coat. Technol. 2003, 167, 97–105. [Google Scholar] [CrossRef]

- Avila, P.; Montes, M.; Miró, E.E. Monolithic reactors for environmental applications: A review on preparation technologies. Chem. Eng. J. 2005, 109, 11–36. [Google Scholar] [CrossRef]

- Mancin, S.; Zilio, C.; Cavallini, A.; Rossetto, L. Pressure drop during air flow in aluminum foams. Int. J. Heat Mass Transf. 2010, 53, 3121–3130. [Google Scholar] [CrossRef]

- Liu, J.; Li, P.; Sun, Z.; Lu, Z.; Du, Z.; Liang, H.; Lu, D. A new method for analysis of dual pore size distributions in shale using nitrogen adsorption measurements. Fuel 2017, 210, 446–454. [Google Scholar] [CrossRef]

- Kumar, P.; Topin, F. Investigation of fluid flow properties in open cell foams: Darcy and weak inertia regimes. Chem. Eng. Sci. 2014, 116, 793–805. [Google Scholar] [CrossRef]

- Dietrich, B. Pressure drop correlation for ceramic and metal sponges. Chem. Eng. Sci. 2012, 74, 192–199. [Google Scholar] [CrossRef]

| ε | Current Experimental Data | Topin et al. [32] | Dietrich [33] | |||||

|---|---|---|---|---|---|---|---|---|

| α | β | K × 108 m2 | Fk × 10−3 m−1 | K × 108 m2 | Fk × 10−3 m−1 | K × 108 m2 | Fk × 10−3 m−1 | |

| 0.80 | 4% | 2.5% | 1.5 | 3.3 | 1.1 | 1.318 | 1.1 | 0.618 |

| 0.85 | 4% | 0% | 3.0 | 2.0 | 2.91 | 0.742 | 2.91 | 0.348 |

| 0.90 | 12.25% | 10% | 8.2 | 0.76 | 4.9 | 0.523 | 4.9 | 0.24 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Wan, Z.; Zou, S. Fabrication and Characteristics of Sintered Cutting Stainless Steel Fiber Felt with Internal Channels and an Al2O3 Coating. Materials 2018, 11, 455. https://doi.org/10.3390/ma11030455

Huang S, Wan Z, Zou S. Fabrication and Characteristics of Sintered Cutting Stainless Steel Fiber Felt with Internal Channels and an Al2O3 Coating. Materials. 2018; 11(3):455. https://doi.org/10.3390/ma11030455

Chicago/Turabian StyleHuang, Shufeng, Zhenping Wan, and Shuiping Zou. 2018. "Fabrication and Characteristics of Sintered Cutting Stainless Steel Fiber Felt with Internal Channels and an Al2O3 Coating" Materials 11, no. 3: 455. https://doi.org/10.3390/ma11030455

APA StyleHuang, S., Wan, Z., & Zou, S. (2018). Fabrication and Characteristics of Sintered Cutting Stainless Steel Fiber Felt with Internal Channels and an Al2O3 Coating. Materials, 11(3), 455. https://doi.org/10.3390/ma11030455