Surface Roughness of Composite Panels as a Quality Control Tool

Abstract

:1. Introduction

2. Materials and Methods

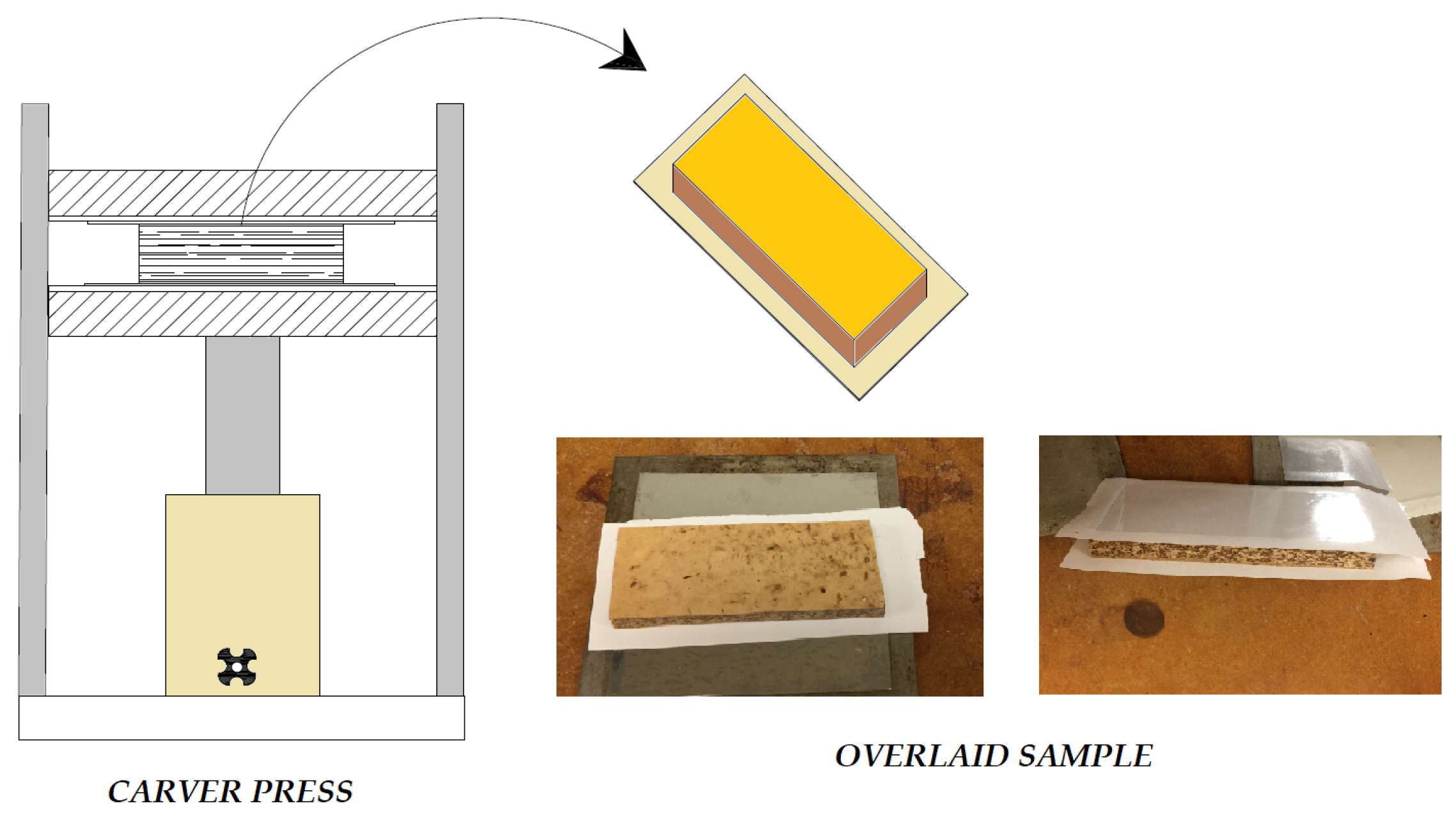

2.1. Panel Manufacture

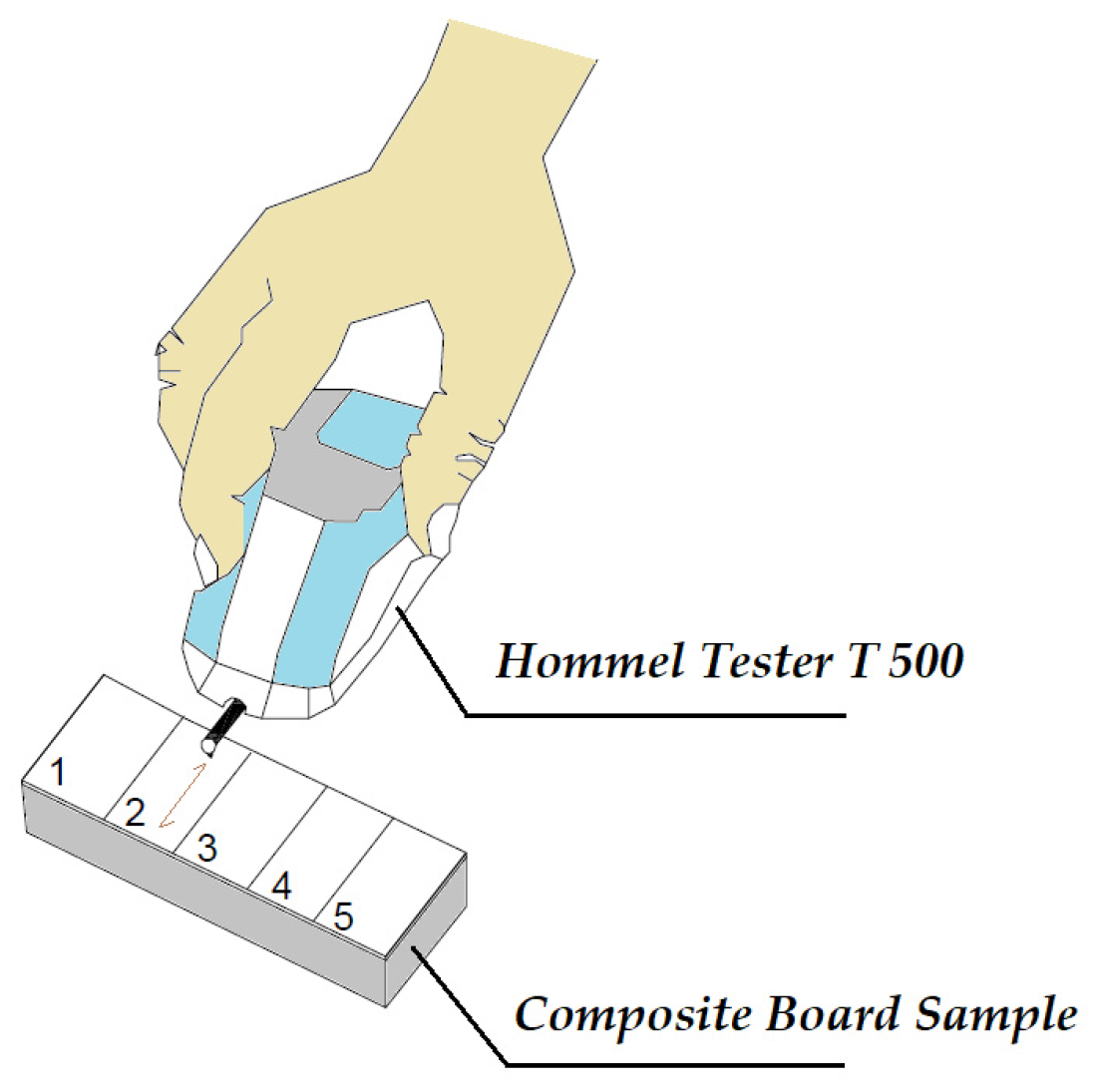

2.2. Roughness Test of Samples

2.3. Hardness Test of Samples

2.4. Overlaying of Samples and Relative Humidity Exposure

2.5. Analysis of Data

3. Results and Discussion

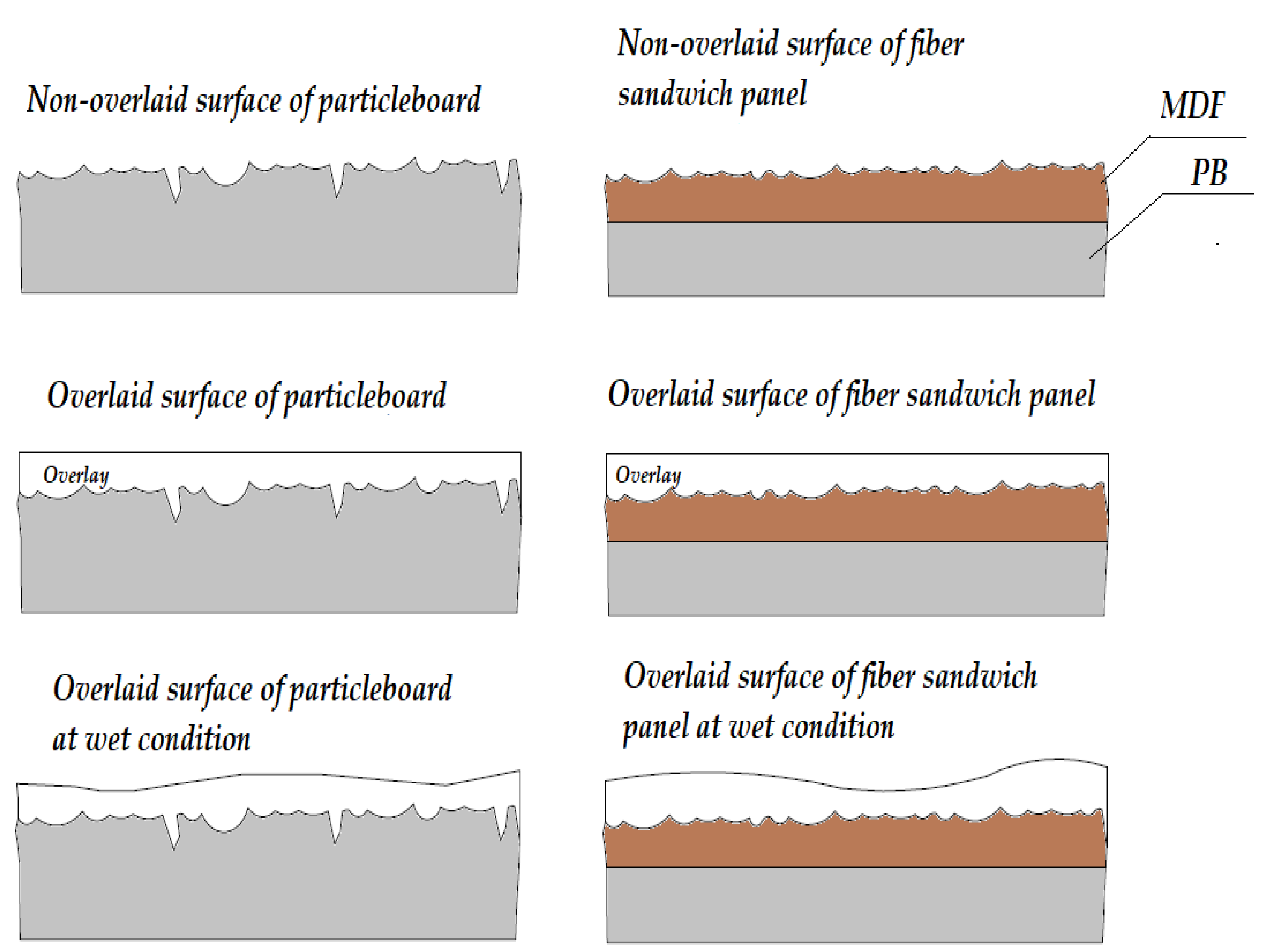

3.1. Effect of the Relative Humidity Level on Roughness Values of Fiber-Sandwich Panels

3.2. Evaluation of Surface Roughness Values at Fiber-Sandwich Panels

3.3. Surface Roughness Values of Particleboard Panels

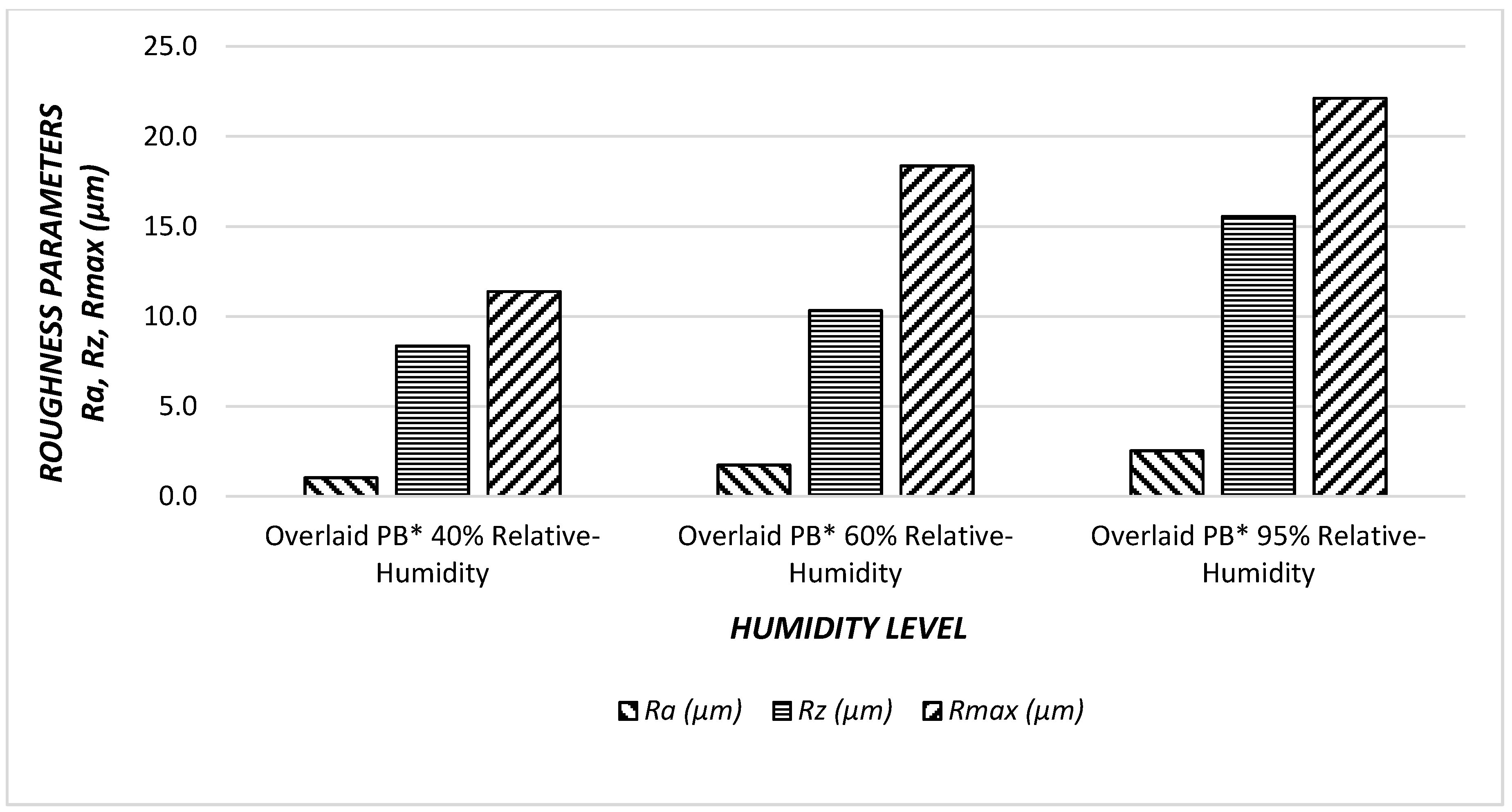

3.4. Results of Janka Hardness Values

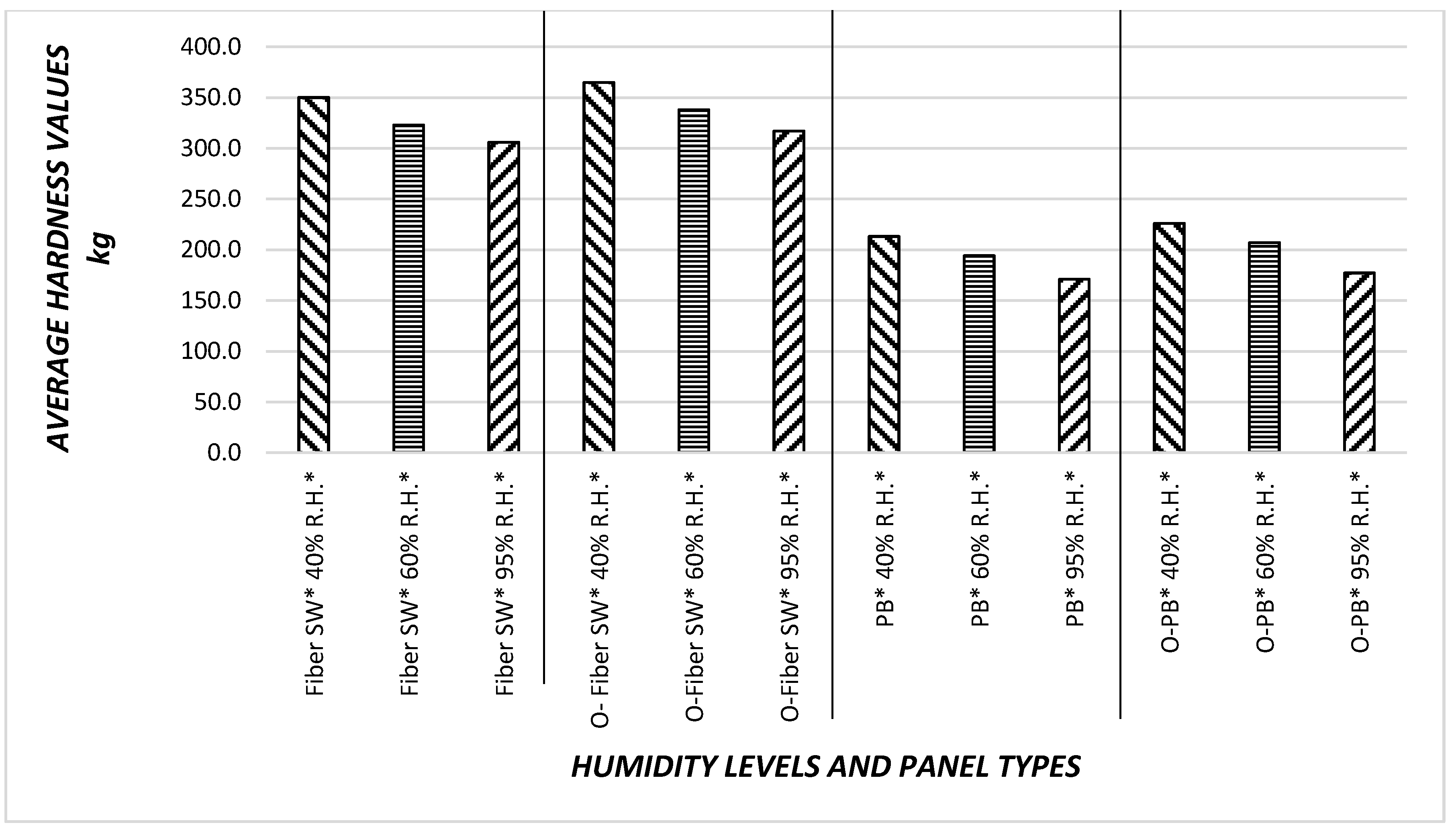

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Kalaycioglu, H.; Hiziroglu, S. Evaluation of surface characteristics of laminated flooring. Build. Environ. 2006, 41, 756–762. [Google Scholar] [CrossRef]

- Tanritanir, E.; Akbulut, T. Plywood industry and general situation of plywood trade. Laminart 1999, 9, 122–132. [Google Scholar]

- Hiziroglu, S. Surface roughness analysis of wood composites a stylus method. For. Prod. J. 1996, 46, 67–72. [Google Scholar]

- Hiziroglu, S.; Jarusombuti, S.; Fuengvivat, V. Surface characteristics of wood composites manufactured in Thailand. J. Build. Environ. 2004, 39, 1359–1364. [Google Scholar] [CrossRef]

- Kutnar, A.; Sernek, M. Densification of wood. Zbornik Gozdarstva Lesarstva 2007, 82, 53–62. [Google Scholar]

- Stumbo, D.A. Surface texture measuring methods. For. Prod. J. 1963, 12, 299–303. [Google Scholar]

- Hiziroglu, S.; Kosonkorn, P. Evaluation of surface roughness of Thai medium density fiberboard (MDF). Build. Environ. 2006, 41, 527–533. [Google Scholar] [CrossRef]

- Lemaster, R.L.; Beal, F.C. The use of dual sensors to measure surface roughness of wood based composites. In Proceedings of the 9th International Symposium on Non-Destructive Testing of Wood, Madison, WI, USA, 22–24 September 1993; Forest Products Society: Madison, WI, USA, 1993. [Google Scholar]

- Peters, C.; Cumming, J.D. Measuring wood surface smoothness, a review. For. Prod. J. 1970, 20, 40–43. [Google Scholar]

- Peters, C.; Mergen, A. Measuring wood surface smoothness: A proposed method. For. Prod. J. 1971, 21, 28–30. [Google Scholar]

- Drew, W.E. Surface texture measurement errors stylus type instruments. J. Qual. 1992, 10, 41–44. [Google Scholar]

- Kilic, M.; Hiziroglu, S.; Burdurlu, E. Effect of machining on surface roughness of wood. Build. Environ. 2006, 41, 1074–1078. [Google Scholar] [CrossRef]

- Burdurlu, E.; Usta, I.; Ulupinar, M.; Aksu, B.; Eraslan, T.C. The effect of the number of blades and the grain size of abrasives in planing and sanding on the surface roughness of European black pine and Lombardy poplar. Turk. J. Agric. For. 2005, 29, 315–322. [Google Scholar]

- İmirzi, H.Ö.; Ülker, O.; Burdurlu, E. Effect of densification temperature and some surfacing techniques on the surface roughness of densified Scots pine (Pinus sylvestris L.). BioResources 2013, 9, 191–209. [Google Scholar] [CrossRef]

- Shida, S.; Hiziroglu, S. Evaluation of shear strength of Japanese wood species as a function of surface roughness. For. Prod. J. 2010, 60, 400–404. [Google Scholar] [CrossRef]

- Kminiak, R.; Gaff, M. Roughness of surface created by transversal sawing of spruce, beech, and oak wood. BioResources 2015, 10, 2873–2887. [Google Scholar] [CrossRef]

- Istek, A.; Aydemir, D.; Aksu, S. The effect of décor paper and resin type on the physical, mechanical, and surface quality properties of particleboards coated with impregnated décor papers. BioResources 2010, 5, 1074–1083. [Google Scholar]

- Ulker, O.; Hiziroglu, S. Some properties of densified eastern redcedar as function of heat and pressure. Materials 2017, 10, 1275. [Google Scholar] [CrossRef] [PubMed]

| Panel Types | Statistical Value | Surface Roughness | ||

|---|---|---|---|---|

| Ra (μm) | Rz (μm) | Rmax (μm) | ||

| Non-Overlaid Fiber-Sw * 40% Relative-Humidity | Mean | 4.41 | 36.20 | 38.19 |

| Standard Err. | 0.77 | 10.83 | 6.59 | |

| Non-Overlaid Fiber-Sw * 60% Relative-Humidity | Mean | 5.57 | 37.35 | 46.29 |

| Standard Err. | 1.16 | 8.46 | 10.80 | |

| Non-Overlaid Fiber-Sw * 95% Relative-Humidity | Mean | 8.10 | 50.12 | 62.88 |

| Standard Err. | 1.92 | 9.46 | 12.49 | |

| Overlaid Fiber-Sw * 40% Relative-Humidity | Mean | 0.48 | 4.19 | 5.90 |

| Standard Err. | 0.13 | 2.49 | 4.05 | |

| Overlaid Fiber-Sw * 60% Relative-Humidity | Mean | 0.62 | 3.97 | 6.90 |

| Standard Err. | 0.19 | 2.45 | 5.04 | |

| Overlaid Fiber-Sw * 95% Relative-Humidity | Mean | 1.67 | 7.44 | 9.82 |

| Standart Err. | 0.71 | 3.40 | 4.08 | |

| Panel Types | Statistical Value | Surface Roughness | ||

|---|---|---|---|---|

| Ra (μm) | Rz (μm) | Rmax (μm) | ||

| Non-Overlaid PB * 40% Relative-Humidity | Mean | 6.95 | 54.84 | 64.31 |

| Standard Err. | 1.13 | 10.14 | 9.75 | |

| Non-Overlaid PB * 60% Relative-Humidity | Mean | 8.24 | 59.37 | 75.34 |

| Standard Err. | 1.20 | 8.50 | 9.83 | |

| Non-Overlaid PB * 95% Relative-Humidity | Mean | 10.99 | 56.50 | 83.71 |

| Standard Err. | 1.80 | 15.66 | 8.70 | |

| Overlaid PB * 40% Relative-Humidity | Mean | 1.04 | 8.36 | 11.38 |

| Standard Err. | 0.34 | 4.76 | 4.73 | |

| Overlaid PB * 60% Relative-Humidity | Mean | 1.74 | 10.32 | 18.37 |

| Standard Err. | 0.80 | 5.00 | 8.63 | |

| Overlaid PB * 95% Relative-Humidity | Mean | 2.53 | 15.56 | 22.12 |

| Standart Err. | 0.72 | 10.19 | 12.22 | |

| Applied Tests | Mean Square | F Value | Level of Significance (p ≤ 0.05) |

|---|---|---|---|

| Intercept | 5717.19 | 5067.70 | 0.000 |

| Panel Types | 3027.47 | 894.51 | 0.000 |

| Relative Humidity Levels | 353.75 | 156.78 | 0.000 |

| Panel Types x Relative Humidity Level | 85.88 | 12.68 | 0.000 |

| Parameters | Groups | HG. * A | HG. * B | HG. * C | HG. * D |

|---|---|---|---|---|---|

| Materials | Overlaid Fiber-Sw * | 0.92 | - | - | - |

| Overlaid Particleboard | - | 1.77 | - | - | |

| Non-Overlaid Fiber-Sw * | - | - | 6.02 | - | |

| Non-Overlaid PB * | - | - | - | 8.73 | |

| Relative Humidity Levels | 40% Relative Humidity | 3.22 | - | - | - |

| 60% Relative Humidity | - | 4.04 | - | - | |

| 95% Relative Humidity | - | - | 5.82 | - |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ulker, O. Surface Roughness of Composite Panels as a Quality Control Tool. Materials 2018, 11, 407. https://doi.org/10.3390/ma11030407

Ulker O. Surface Roughness of Composite Panels as a Quality Control Tool. Materials. 2018; 11(3):407. https://doi.org/10.3390/ma11030407

Chicago/Turabian StyleUlker, Onur. 2018. "Surface Roughness of Composite Panels as a Quality Control Tool" Materials 11, no. 3: 407. https://doi.org/10.3390/ma11030407

APA StyleUlker, O. (2018). Surface Roughness of Composite Panels as a Quality Control Tool. Materials, 11(3), 407. https://doi.org/10.3390/ma11030407