Microstructures and Mechanical Properties of Commercially Pure Ti Processed by Rotationally Accelerated Shot Peening

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

4. Conclusions

- (1)

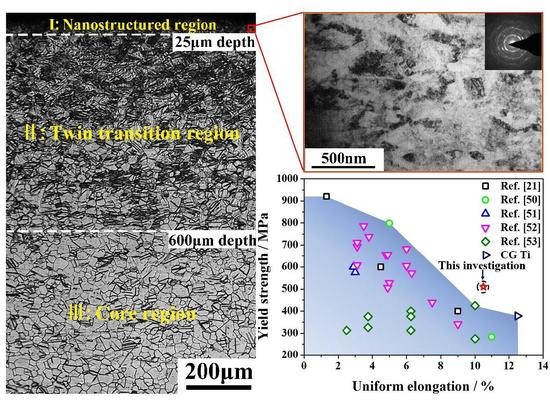

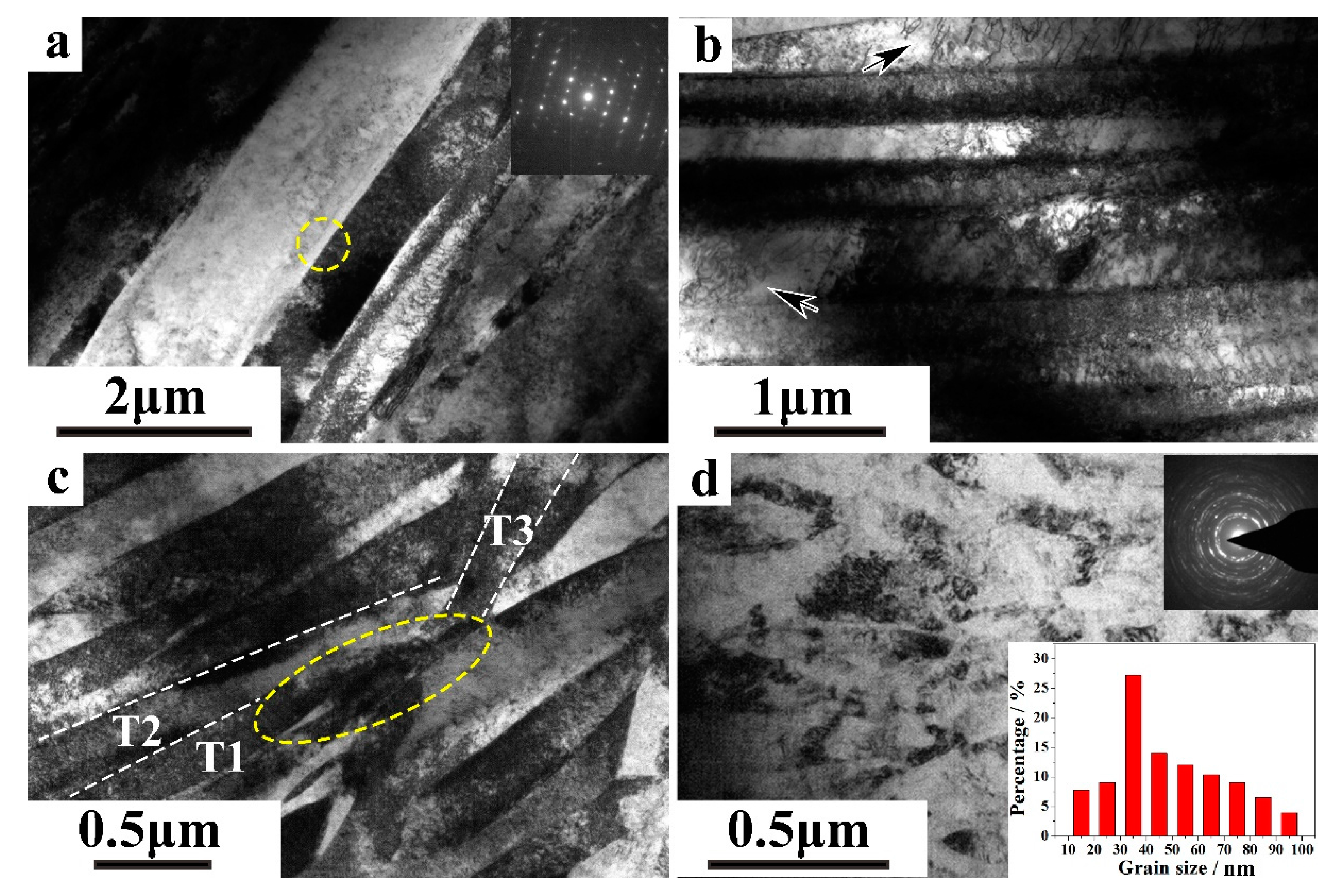

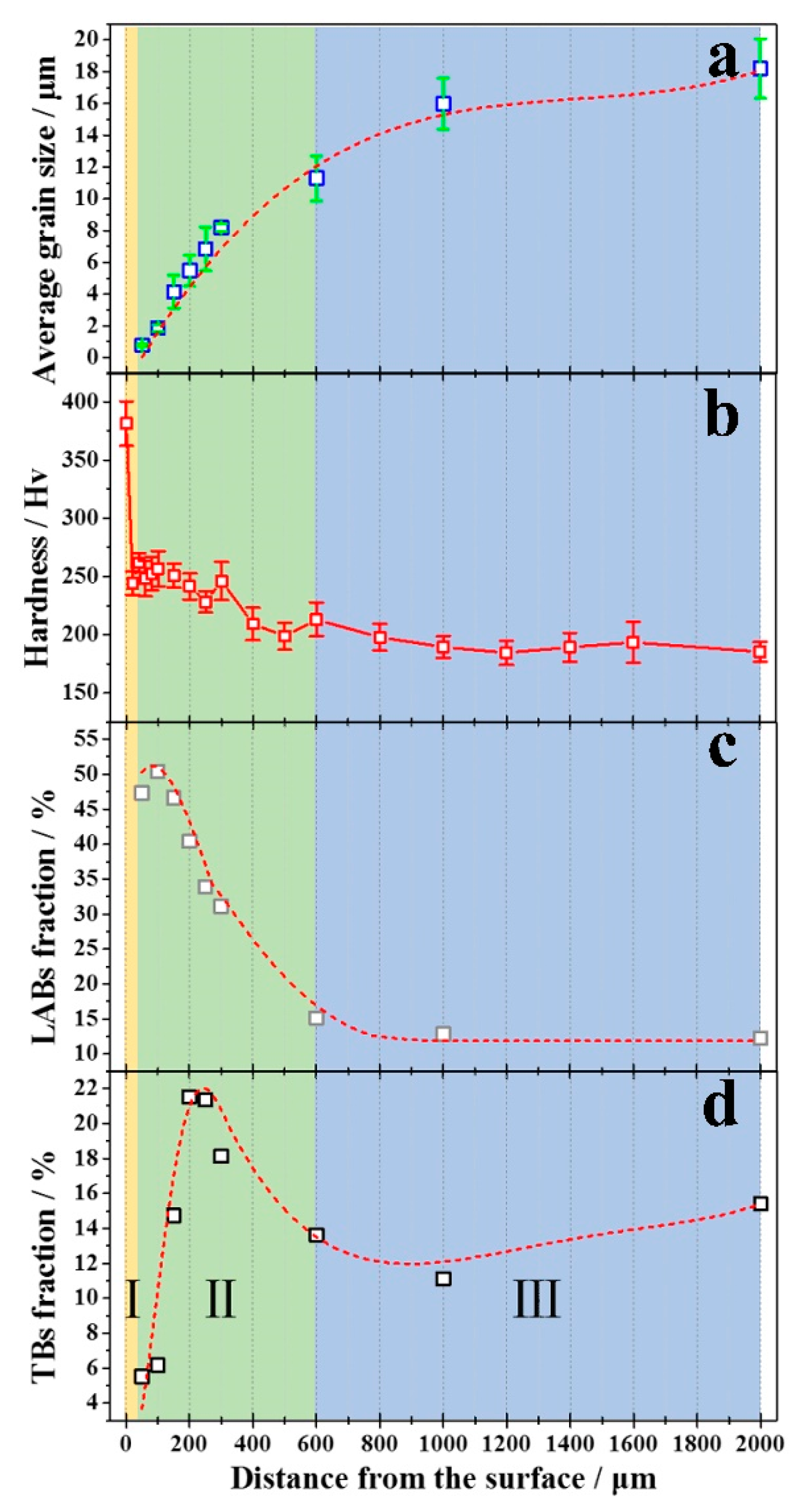

- A gradient structure was introduced to a Ti sample by RASP treatment. The processed sample had a deformed layer of 2000 μm in depth without obvious delamination. The averaged grain size of the RASP-processed Ti decreased from ~18 μm in the center to 50 nm in the surface.

- (2)

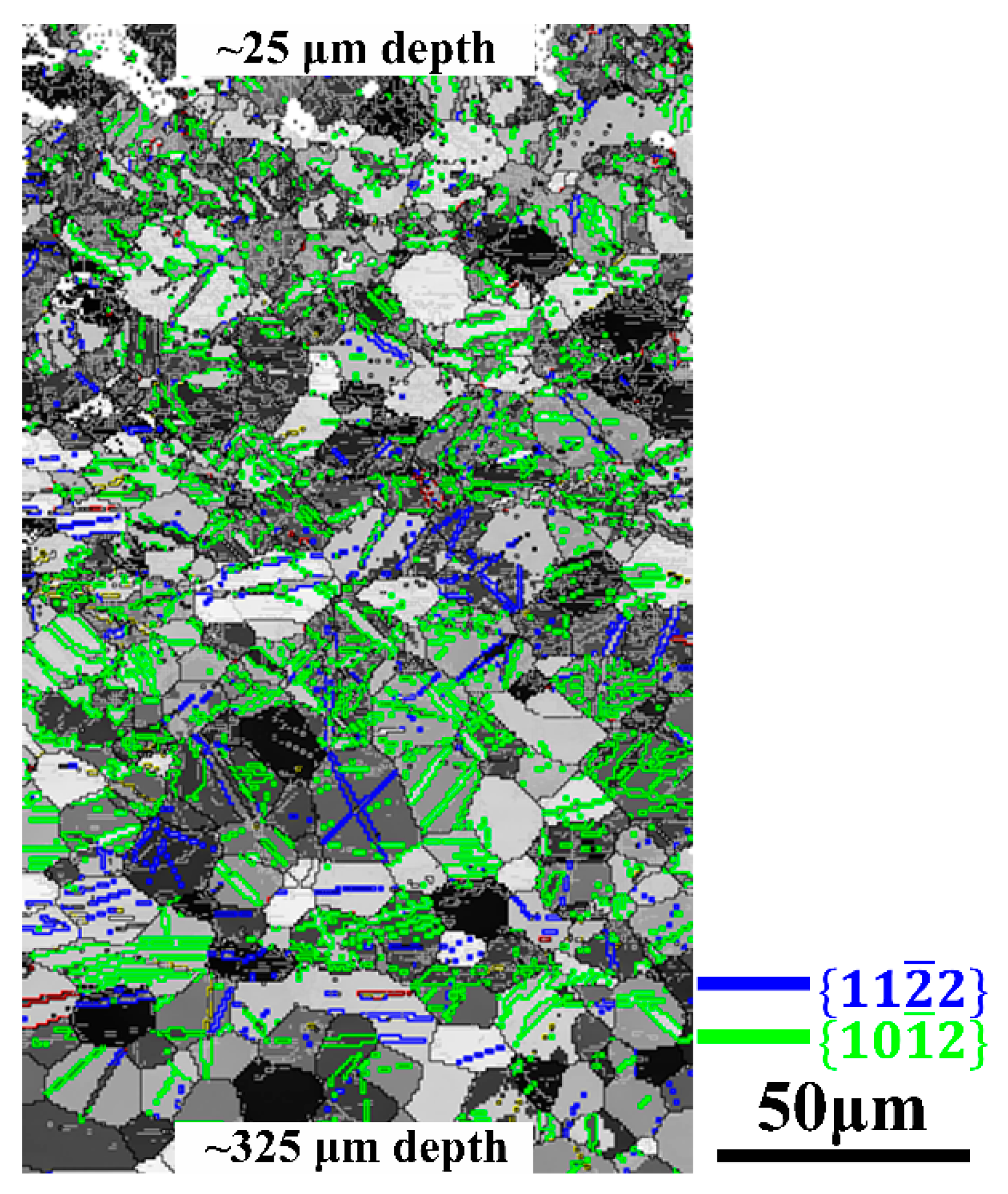

- Different deformation mechanisms were operative during the RASP processing. Deformation twinning was dominant in the core region. The twin volume fraction increased with the decreasing of depth. Meanwhile, dislocation slip occurred inside both twins and parent grains. The LABs fraction increased gradually due to dislocation pile-up and accumulation. Multisystem twinning is activated in the twin transition region. Twin interaction led to further grain refinement, and a smaller grain size resulted in an increase of twinning stress. Hence, twinning is difficult to activate in the nanostructured region with very fine grains, and dislocation activities are dominant in the region.

- (3)

- Hardness gradient was observed in the RASP-processed Ti through the depth. The hardness in the top surface (381 HV) is more than twice that of its CG counterpart (178 HV).

- (4)

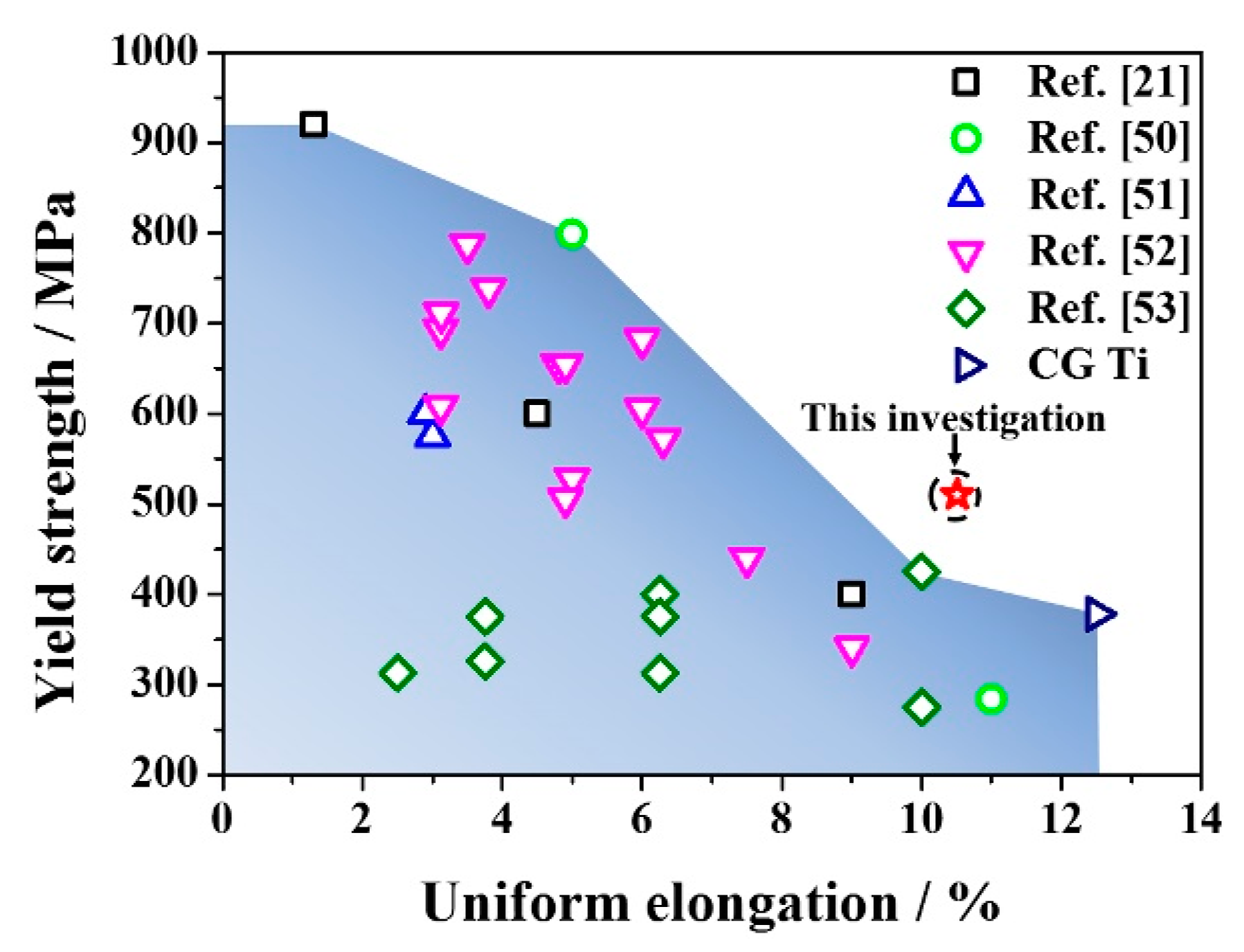

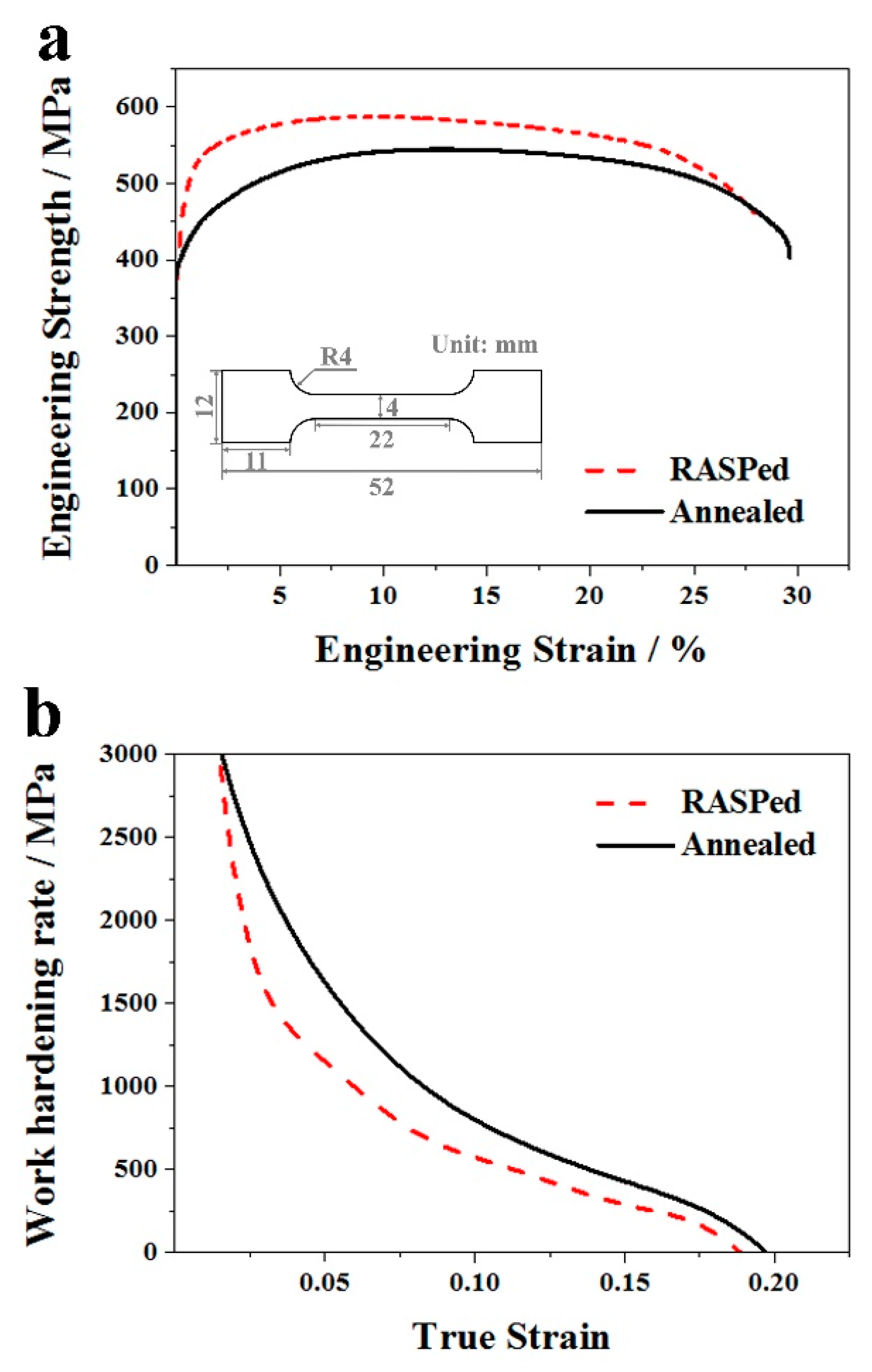

- The RASP-processed Ti showed significant strengthening; the σy and σUTS increase from 378 MPa and 551 MPa to 535 MPa and 593 MPa, respectively. The uniform elongation of the RASP-processed Ti showed a slight decrease from 12.5% to 10.5%. The excellent strength-ductility combination was attributed to the high density of deformation twins, and the back stress strengthening and work hardening.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ehtemam-Haghighi, S.; Liu, Y.J.; Cao, G.H.; Zhang, L.C. Influence of Nb on the β→α″ martensitic phase transformation and properties of the newly designed Ti–Fe–Nb alloys. Mater. Sci. Eng. C 2016, 60, 503–510. [Google Scholar] [CrossRef] [PubMed]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012, 8, 3888–3903. [Google Scholar] [CrossRef] [PubMed]

- Ehteman-Haghighi, S.; Liu, Y.J.; Cao, G.H.; Zhang, L.C. Phase transition, microstructure evolution and mechanical properties of Ti-Nb-Fe alloys induced by Fe addition. Mater. Des. 2016, 97, 279–286. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Cao, G.H.; Zhang, L.C. Nanoindentation study of mechanical properties of Ti based alloys with Fe and Ta additions. J. Alloys Compd. 2017, 692, 892–897. [Google Scholar] [CrossRef]

- Tsuji, N.; Saito, Y.; Utsunomiya, H.; Tanigawa, S. Ultra-fine grained bulk steel produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1999, 40, 795–800. [Google Scholar] [CrossRef]

- Terada, D.; Inoue, S.; Tsuji, N. Microstructure and mechanical properties of commercial purity titanium severely deformed by ARB process. J. Mater. Sci. 2007, 42, 1673–1681. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Alexandrov, I.V.; Lowe, T.C.; Valiev, R.Z. Grain refinement and properties of pure Ti processed by warm ECAP and cold rolling. Mater. Sci. Eng. A 2003, 343, 43–50. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.B.; Figueiredo, R.B.; Chang, L.; Liao, X.Z.; Kawasaki, M.; Zheng, W.L.; Ringer, S.P.; Langdon, T.G.; Zhu, Y.T. Three-dimensional shear-strain patterns induced by high-pressure torsion and their impact on hardness evolution. Acta Mater. 2011, 59, 3903–3914. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.B.; An, X.H.; Liao, X.Z.; Kawasaki, M.; Ringer, S.P.; Langdon, T.G.; Zhu, Y.T. Concurrent microstructural evolution of ferrite and austenite in a duplex stainless steel processed by high-pressure torsion. Acta Mater. 2014, 63, 16–29. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Fundamentals of Superior Properties in Bulk NanoSPD Materials. Mater. Res. Lett. 2016, 4, 1–21. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Liao, X.Z. Nanostructured metals: Retaining ductility. Nat. Mater. 2004, 3, 351–352. [Google Scholar] [CrossRef] [PubMed]

- Lu, K.; Lu, L. Surface Nanocrystallization (SNC) of Metallic Materials-Presentation of the Concept behind a New Approach. J. Mater. Sci. Technol. 1999, 15, 193–197. [Google Scholar]

- Lu, K.; Lu, J. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment. Mater. Sci. Eng. A 2004, 375–377, 38–45. [Google Scholar] [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing Extraordinary Intrinsic Tensile Plasticity in Gradient Nano-Grained Copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef] [PubMed]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.L.; Jiang, P.; Chen, L.; Yuan, F.P.; Zhu, Y.T. Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. USA 2014, 111, 7197–7201. [Google Scholar] [CrossRef] [PubMed]

- Yao, Q.; Sun, J.; Fu, Y.; Tong, W.; Zhang, H. An Evaluation of a Borided Layer Formed on Ti-6Al-4V Alloy by Means of SMAT and Low-Temperature Boriding. Materials 2016, 9, 993. [Google Scholar] [CrossRef] [PubMed]

- Wen, M.; Liu, G.; Gu, J.F.; Guan, W.M.; Lu, J. The tensile properties of titanium processed by surface mechanical attrition treatment. Surf. Coat. Technol. 2008, 202, 728–4733. [Google Scholar] [CrossRef]

- Yang, M.X.; Pan, Y.; Yuan, F.P.; Zhu, Y.T.; Wu, X.L. Back stress strengthening and strain hardening in gradient structure. Mater. Res. Lett. 2016, 4, 145–151. [Google Scholar] [CrossRef]

- Wu, X.L.; Zhu, Y.T. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Lu, K. Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat. Rev. Mater. 2016, 1, 16019. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.S.; Zhang, Q.; Zhao, Y.H.; Zhu, Y.T. Gradient Structured Copper by Rotationally Accelerated Shot Peening. J. Mater. Sci. Technol. 2017, 33, 758–761. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Ng, H.P.; Lapovok, R.; Estrin, Y.; Lowe, T.C.; Anumalasetty, V.N. Effect of bulk microstructure of commercially pure titanium on surface characteristics and fatigue properties after surface modification by sand blasting and acid-etching. J. Mech. Behav. Biomed. Mater. 2016, 57, 55–68. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.S.; Li, L.Z.; Nie, J.F.; Cao, Y.; Zhao, Y.H.; Zhu, Y.T. Microstructural evolution and mechanical properties of a 5052 Al alloy with gradient structures. J. Mater. Res. 2017, 32, 4443–4451. [Google Scholar] [CrossRef]

- Wen, M.; Liu, G.; Gu, J.F.; Guan, W.M.; Lu, J. Dislocation evolution in titanium during surface severe plastic deformation. Appl. Surf. Sci. 2009, 255, 6097–6102. [Google Scholar] [CrossRef]

- Darling, K.A.; Tschopp, M.A.; Roberts, A.J.; Ligda, J.P.; Kecskes, L.J. Enhancing grain refinement in polycrystalline materials using surface mechanical attrition treatment at cryogenic temperatures. Scr. Mater. 2013, 69, 461–464. [Google Scholar] [CrossRef]

- Wu, S.; Fan, K.; Jiang, P.; Chen, S. Grain refinement of pure Ti during plastic deformation. Mater. Sci. Eng. A 2010, 527, 6917–6921. [Google Scholar] [CrossRef]

- Unal, O.; Cahit Karaoglanli, A.; Varol, R.; Kobayashi, A. Microstructure evolution and mechanical behavior of severe shot peened commercially pure titanium. Vacuum 2014, 110, 202–206. [Google Scholar] [CrossRef]

- Yoo, M.H.; Wei, C.T. Slip Modes of Hexagonal-Close-Packed Metals. J. Appl. Phys. 1967, 38, 4317–4322. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. J. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Qin, H.; Jonas, J.J.; Yu, H.; Brodusch, N.; Gauvin, R.; Zhang, X. Initiation and accommodation of primary twins in high-purity titanium. Acta Mater. 2014, 71, 293–305. [Google Scholar] [CrossRef]

- Yoo, M.H. Slip, twinning, and fracture in hexagonal close-packed metals. Metall. Trans. A 1981, 12, 409–418. [Google Scholar] [CrossRef]

- Zhu, K.Y.; Vassel, A.; Brisset, F.; Lu, K.; Lu, J. Nanostructure formation mechanism of α-titanium using SMAT. Acta Mater. 2004, 52, 4101–4110. [Google Scholar] [CrossRef]

- Wang, K.; Tao, N.R.; Liu, G.; Lu, J.; Lu, K. Plastic strain-induced grain refinement at the nanometer scale in copper. Acta Mater. 2006, 54, 5281–5291. [Google Scholar] [CrossRef]

- Yu, Q.; Shan, Z.W.; Li, J.; Huang, X.X.; Xiao, L.; Sun, J.; Ma, E. Strong crystal size effect on deformation twinning. Nature 2010, 463, 335–338. [Google Scholar] [CrossRef] [PubMed]

- Zherebtsov, S.V.; Dyakonov, G.S.; Salishchev, G.A.; Salem, A.A.; Semiatin, S.L. The Influence of Grain Size on Twinning and Microstructure Refinement during Cold Rolling of Commercial-Purity Titanium. Metall. Mater. Trans. A 2016, 47, 5101–5113. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Liao, X.Z.; Wu, X.L.; Narayan, J. Grain size effect on deformation twinning and detwinning. J. Mater. Sci. 2013, 48, 4467–4475. [Google Scholar] [CrossRef]

- Ghaderi, A.; Barnett, M.R. Sensitivity of deformation twinning to grain size in titanium and magnesium. Acta Mater. 2011, 59, 7824–7839. [Google Scholar] [CrossRef]

- Fan, H.D.; Aubry, S.; Arsenlis, A.; El-Awady, J.A. Grain size effects on dislocation and twinning mediated plasticity in magnesium. Scr. Mater. 2016, 112, 50–53. [Google Scholar] [CrossRef]

- Kula, A.; Silva, C.J.; Niewczas, M. Grain size effect on deformation behaviour of Mg–Sc alloys. J. Alloys Compd. 2017, 727, 642–657. [Google Scholar] [CrossRef]

- Yu, H.H.; Li, C.Z.; Xin, Y.C.; Chapuis, A.; Huang, X.X.; Liu, Q. The mechanism for the high dependence of the Hall-Petch slope for twinning/slip on texture in Mg alloys. Acta Mater. 2017, 128, 313–326. [Google Scholar] [CrossRef]

- Gwalani, B.; Soni, V.; Lee, M.; Mantri, S.A.; Ren, Y.; Banerjee, R. Optimizing the coupled effects of Hall-Petch and precipitation strengthening in a Al0.3CoCrFeNi high entropy alloy. Mater. Des. 2017, 121, 254–260. [Google Scholar] [CrossRef]

- You, Z.S.; Li, X.Y.; Gui, L.J.; Lu, Q.H.; Zhu, Y.T.; Gao, H.J.; Lu, L. Plastic anisotropy and associated deformation mechanisms in nanotwinned metals. Acta Mater. 2013, 61, 217–227. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Gao, H.J. Plastic deformation mechanism in nanotwinned metals: An insight from molecular dynamics and mechanistic modeling. Scr. Mater. 2012, 66, 843–848. [Google Scholar] [CrossRef]

- Lu, L.; Shen, Y.F.; Chen, X.H.; Qian, L.H.; Lu, K. Ultrahigh Strength and High Electrical Conductivity in Copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef] [PubMed]

- Fattah-alhosseini, A.; Reza Ansari, A.; Mazaheri, Y.; Karimi, M.; Haghshenas, M. An Investigation of mechanical properties in accumulative roll bonded nano-grained pure titanium. Mater. Sci. Eng. A 2017, 688, 218–224. [Google Scholar] [CrossRef]

- Zhang, Y.; Figueiredo, R.B.; Alhajeri, S.N.; Wang, J.T.; Gao, N.; Langdon, T.G. Structure and mechanical properties of commercial purity titanium processed by ECAP at room temperature. Mater. Sci. Eng. A 2011, 528, 7708–7714. [Google Scholar] [CrossRef]

- Eftekhari, M.; Faraji, G.; Nikbakht, S.; Rashed, R.; Sharifzadeh, R.; Hildyard, R.; Mohammadpour, M. Processing and characterization of nanostructured Grade 2 Ti processed by combination of warm isothermal ECAP and extrusion. Mater. Sci. Eng. A 2017, 703, 551–558. [Google Scholar] [CrossRef]

- Wu, L.J.; Luo, K.Y.; Liu, Y.; Cui, C.Y.; Xue, W.; Lu, J.Z. Effects of laser shock peening on the micro-hardness, tensile properties, and fracture morphologies of CP-Ti alloy at different temperatures. Appl. Surf. Sci. 2017, 431, 122–134. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Cao, Y.; Nie, J.; Zhou, H.; Li, Y. Microstructures and Mechanical Properties of Commercially Pure Ti Processed by Rotationally Accelerated Shot Peening. Materials 2018, 11, 366. https://doi.org/10.3390/ma11030366

Huang Z, Cao Y, Nie J, Zhou H, Li Y. Microstructures and Mechanical Properties of Commercially Pure Ti Processed by Rotationally Accelerated Shot Peening. Materials. 2018; 11(3):366. https://doi.org/10.3390/ma11030366

Chicago/Turabian StyleHuang, Zhaowen, Yang Cao, Jinfeng Nie, Hao Zhou, and Yusheng Li. 2018. "Microstructures and Mechanical Properties of Commercially Pure Ti Processed by Rotationally Accelerated Shot Peening" Materials 11, no. 3: 366. https://doi.org/10.3390/ma11030366

APA StyleHuang, Z., Cao, Y., Nie, J., Zhou, H., & Li, Y. (2018). Microstructures and Mechanical Properties of Commercially Pure Ti Processed by Rotationally Accelerated Shot Peening. Materials, 11(3), 366. https://doi.org/10.3390/ma11030366