Residual Tensile Strength and Bond Properties of GFRP Bars after Exposure to Elevated Temperatures

Abstract

:1. Introduction

1.1. Background

1.2. Basic Mechanical Properties of GFRP

1.3. Bond of GFRP with Concrete

1.4. GFRP-Reinforced Concrete Members

1.5. Research Significance

2. Materials and Methods

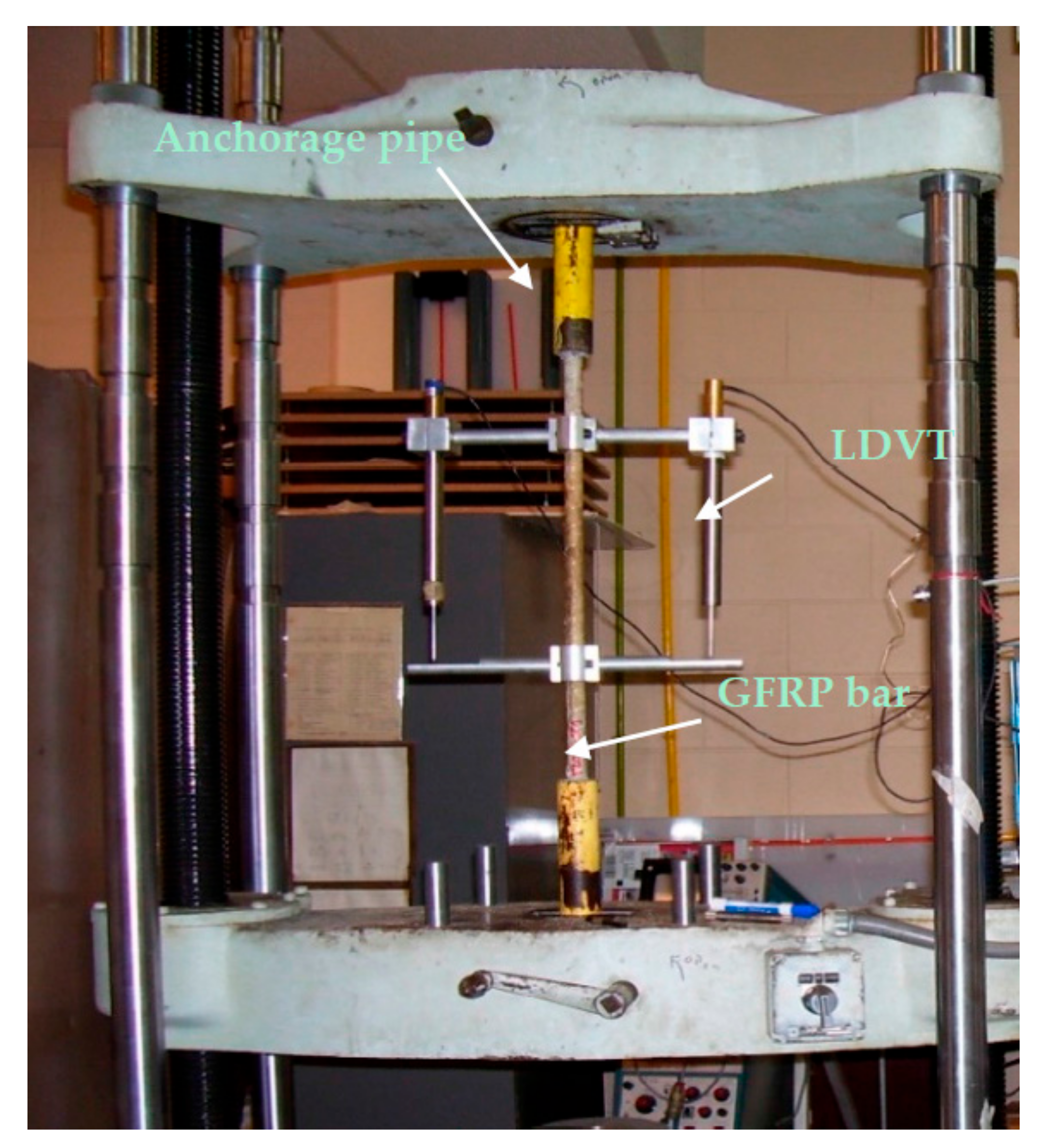

2.1. Tensile Strength Tests

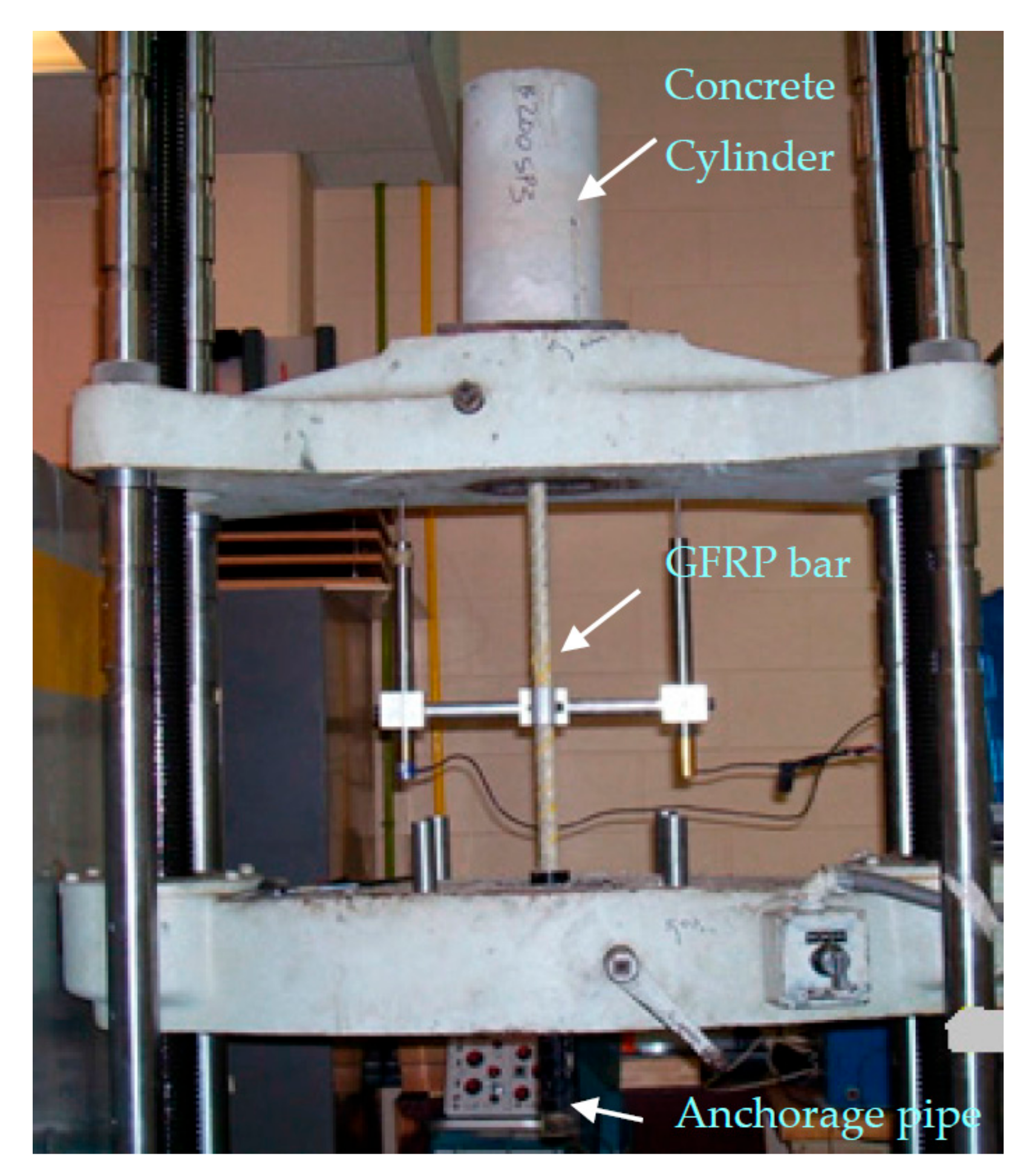

2.2. Bond Pull-out Tests

3. Results

3.1. Tensile Test Results

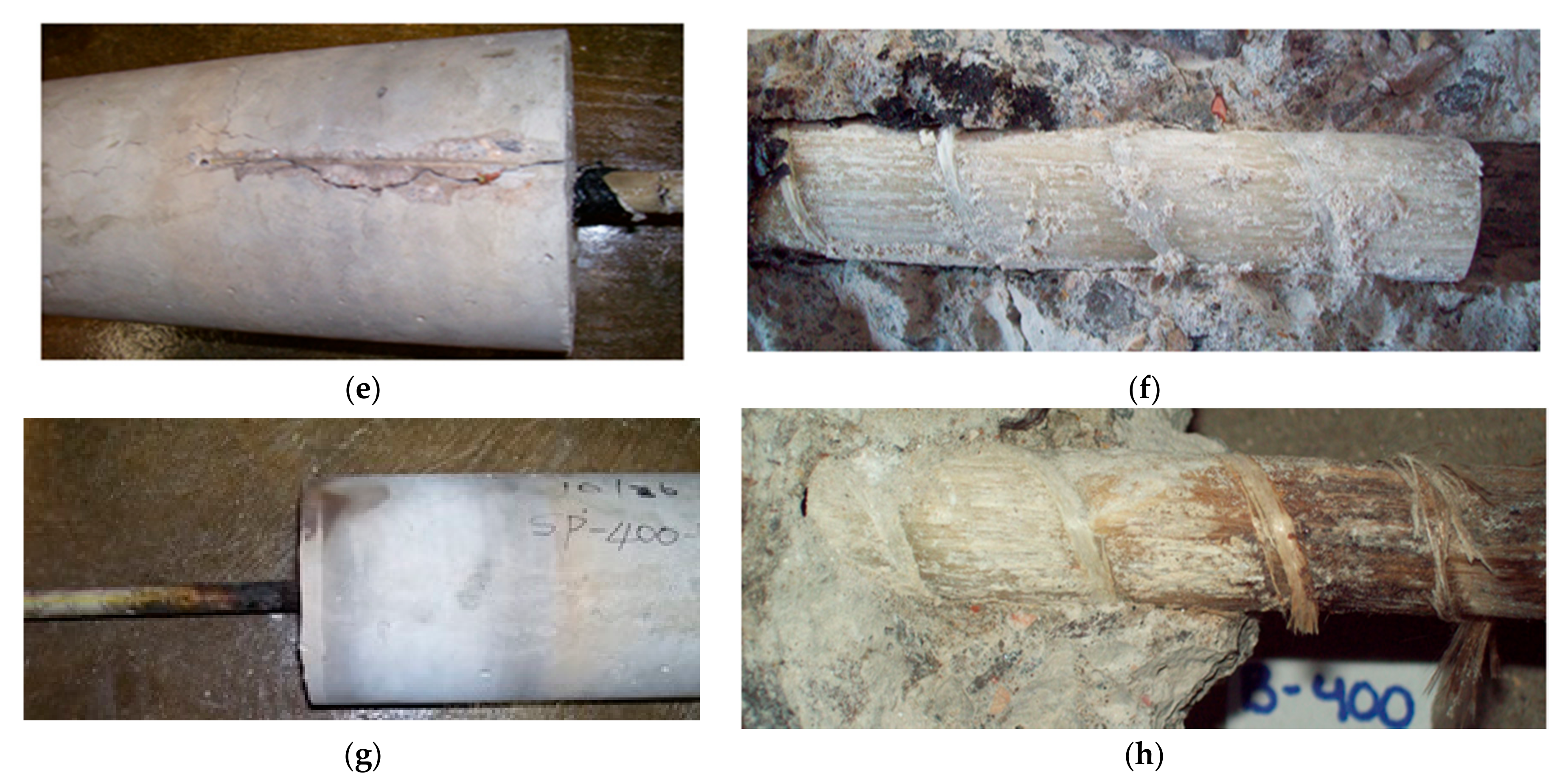

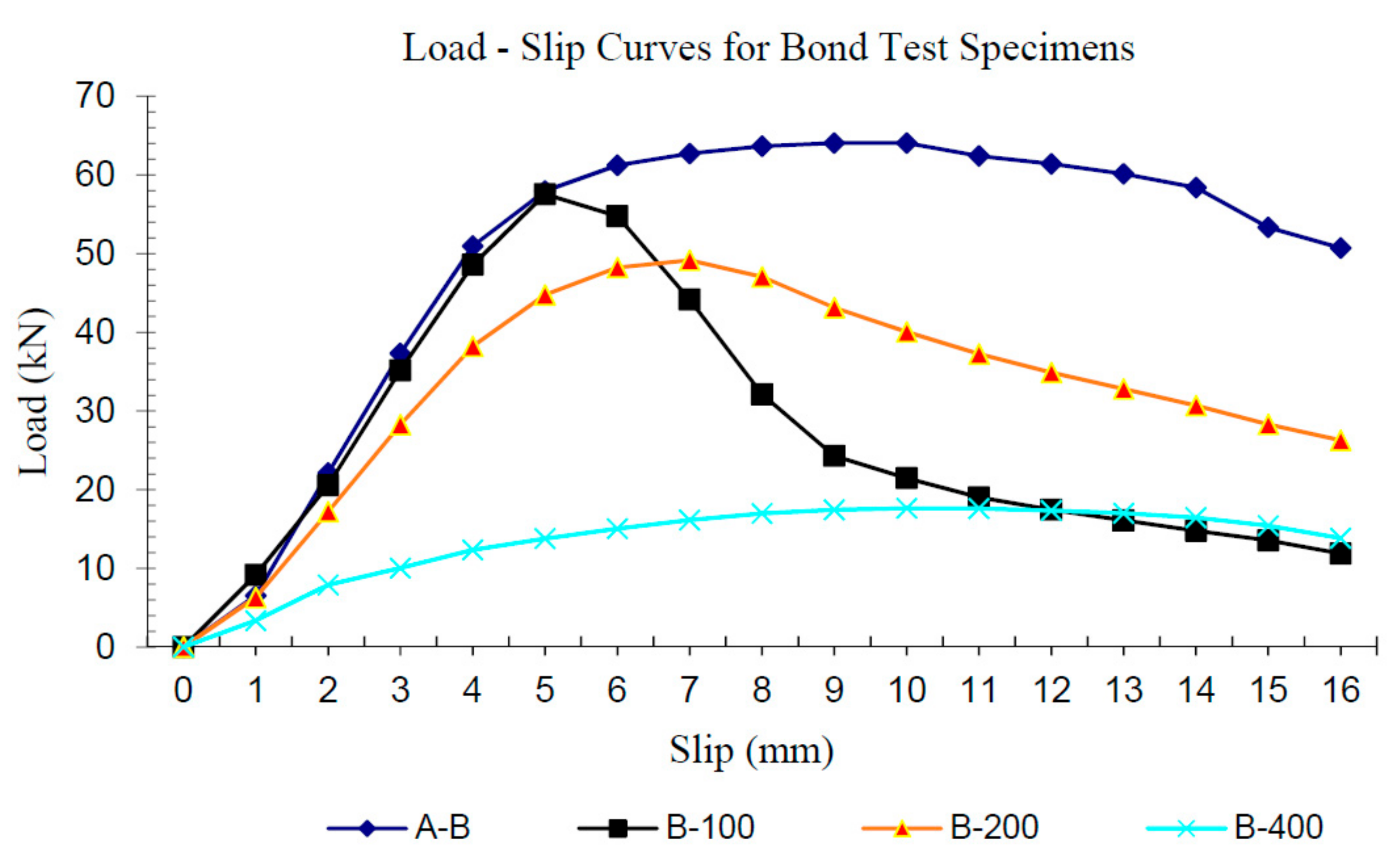

3.2. Bond Test Results

4. Discussion

4.1. Discussion of Tensile Test Results

4.2. Discussion of Bond Test Results

5. Conclusions

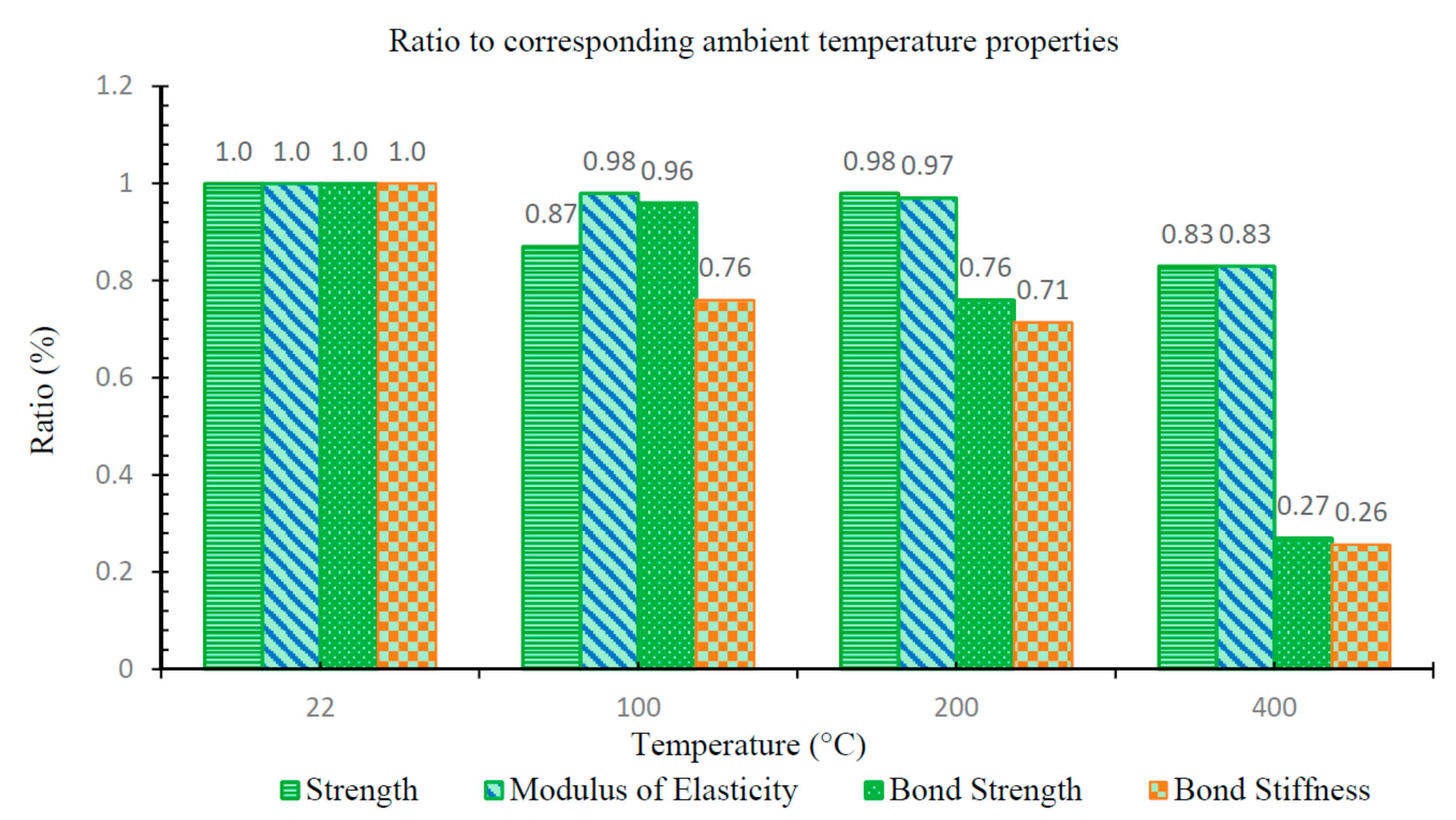

- The residual tensile strength and modulus of vinyl ester GFRP bars generally decreases as the exposure temperature increases. However, the residual strength of the bar that was exposed to 200 °C was larger than the bar exposed 100 °C, which is attributed to the post-cure phenomenon.

- Vinyl ester GFRP bars retain a significant percentage of their tensile strength and elastic modulus after they have cooled from elevated temperatures of up to 400 °C. For example, after exposure to a temperature of 400 °C, the average residual strength of the bar (upon cooling) was 83% of its ambient temperature strength. This contrasts with the percentage of retained properties during exposure to elevated temperature. According to Wang et al. [8], GFRP bars retain about 35% of their ambient temperature strength while subjected to a temperature of 400 °C.

- Generally, the residual pull-out bond strength of the GFRP bars decreased as the exposure temperature increased. There was no significant change in bond stiffness with exposure temperatures of less than 100 °C. The mechanisms of bond transfer also change for different levels of temperature exposure. There is a drastic reduction in bond strength and bond stiffness as prior exposure temperatures reach 400 °C. This is believed to be a major factor affecting post-fire strength assessments of GFRP-reinforced concrete beams, and must be carefully considered in such assessments.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Katz, A.; Berman, N.; Bank, L.C. Effect of high temperature on bond strength of FRP rebars. J. Compos. Constr. 1999, 3, 73–81. [Google Scholar] [CrossRef]

- American Concrete Institute (ACI). Report on Fiber-Reinforced Polymer Reinforcement for Concrete Structures; ACI 440R-07; ACI: Farmington Hills, MI, USA, 2007. [Google Scholar]

- American Concrete Institute (ACI). Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars; ACI 440.1R-15; ACI: Farmington Hills, MI, USA, 2015. [Google Scholar]

- Canadian Standards Association. Design and Construction of Building Structures with Fibre-Reinforced Polymers; CSA S806-12 (R2017); Canadian Standards Association: Mississauga, ON, Canada, 2017. [Google Scholar]

- Italian National Research Council. Guide for the Design and Construction of Concrete Structures Reinforced with Fiber-Reinforced Polymer Bars; CNR-DT 203; Italian National Research Council: Roma, Italy, 2006. [Google Scholar]

- Malvar, L.J. Tensile and bond properties of GFRP reinforcing bars. Mater. J. 1995, 92, 276–285. [Google Scholar]

- Okelo, R.; Yuan, R.L. Bond strength of fiber reinforced polymer rebars in normal strength concrete. J. Compos. Constr. 2005, 9, 203–213. [Google Scholar] [CrossRef]

- Wang, Y.C.; Wong, P.M.H.; Kodur, V.K.R. Mechanical properties of fiber reinforced polymer reinforcing bars at elevated temperatures. In Proceedings of the SFPE/ASCE Specialty Conference: Designing Structures for Fire, Baltimore, MD, USA, 30 September–1 October 2003; pp. 183–192. [Google Scholar]

- Nanni, A.; Faza, S. Design and Construction of Concrete Reinforced with FRP Bars: An Emerging Technology. Concr. Int. 2002, 24, 53–58. [Google Scholar]

- Bank, L.C.; Gentry, T.R.; Thompson, B.P.; Russell, J.S. A model specification for FRP composites for civil engineering structures. Constr. Build. Mater. 2003, 17, 405–437. [Google Scholar] [CrossRef]

- Daniel, I.M.; Ishai, O.; Daniel, I.M.; Daniel, I. Engineering Mechanics of Composite Materials; Oxford University Press: New York, NY, USA, 1994; Volume 3, p. 256. [Google Scholar]

- Glass Fiber Reinforced Polymer (GFRP) Rebar Aslan 100. Hughes Brothers: St. Seward, NE, USA, 2001; Available online: www.aslanfrp.com/Aslan100/Aslan_100_GFRP_Rebar_Brochure.pdf (accessed on 11 January 2018).

- Da Costa Pires, J.M. Mechanical Behaviour at Elevated Temperatures of GFRP Pultruded Composite Profiles. Master’s Thesis, Technico Lisboa, Lisboa, Portugal, 2012. [Google Scholar]

- Robert, M.; Benmokrane, B. Behavior of GFRP reinforcing bars subjected to extreme temperatures. J. Compos. Constr. 2010, 14, 353–360. [Google Scholar] [CrossRef]

- Kashwani, G.A.; Al-Tamimi, A.K. Evaluation of FRP bars performance under high temperature. Phys. Procedia 2014, 55, 296–300. [Google Scholar] [CrossRef]

- Lees, J.M.; Burgoyne, C.J. Transfer bond stresses generated between FRP tendons and concrete. Mag. Concr. Res. 1999, 51, 229–239. [Google Scholar] [CrossRef]

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Behavior and modeling of bond of FRP rebars to concrete. J. Compos. Constr. 1997, 1, 40–51. [Google Scholar] [CrossRef]

- Achillides, Z.; Pilakoutas, K. Bond behavior of fiber reinforced polymer bars under direct pull-out conditions. J. Compos. Constr. 2004, 8, 173–181. [Google Scholar] [CrossRef]

- Katz, A. Bond to concrete of FRP rebars and tendons. In Proceedings of the International Workshop on Composites in Construction, Capri, Italy, 20–21 July 2001; pp. 121–129. [Google Scholar]

- Lublóy, É.; Balázs, G.L.; Borosnyói, A.; Nehme, B.S.G. Bond of CFRP wires under elevated temperature. In Proceedings of the International Symposium on Bond Behaviour of FRP in Structures 2005, Hong Kong, China, 7–9 December 2005; pp. 163–168. [Google Scholar]

- Galati, N.; Nanni, A.; Dharani, L.R.; Focacci, F.; Aiello, M.A. Thermal effects on bond between FRP rebars and concrete. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1223–1230. [Google Scholar] [CrossRef]

- Bai, Y.; Keller, T.; Vallee, T. Modeling of thermo-physical properties and thermal responses for FRP composites in fire. In Proceedings of the Asia-Pacific Conference on FRP in Structures, Hong Kong, China, 12–14 December 2007; pp. 645–650. [Google Scholar]

- Bellakehal, H.; Zaidi, A.; Masmoudi, R.; Bouhicha, M. Behavior of FRP bars-reinforced concrete slabs under temperature and sustained load effects. Polymers 2014, 6, 873–889. [Google Scholar] [CrossRef]

- Masmoudi, A.; Masmoudi, R.; Ouezdou, M.B. Thermal effects on GFRP rebars: Experimental study and analytical analysis. Mater. Struct. 2010, 43, 775–788. [Google Scholar] [CrossRef]

- Wang, X.L.; Zha, X.X. Experimental research on mechanical behavior of GFRP bars under high temperature. Appl. Mech. Mater. 2011, 71, 3591–3594. [Google Scholar] [CrossRef]

- Wang, Y.C.; Wong, P.M.H.; Kodur, V. An experimental study of the mechanical properties of fibre reinforced polymer (FRP) and steel reinforcing bars at elevated temperatures. Compos. Struct. 2007, 80, 131–140. [Google Scholar] [CrossRef]

- Wang, K.; Young, B.; Smith, S.T. Mechanical properties of pultruded carbon fibre-reinforced polymer (CFRP) plates at elevated temperatures. Eng. Struct. 2011, 33, 2154–2161. [Google Scholar] [CrossRef]

- Rafi, M.; Nadjai, A.; Ali, F.; O’Hare, P. Evaluation of thermal resistance of FRP reinforced concrete beams in fire. J. Struct. Fire Eng. 2011, 2, 91–107. [Google Scholar] [CrossRef]

- Nadjai, A.; Talamona, D.; Ali, F. Fire performance of concrete beams reinforced with FRP bars. Proceeding of the International Symposium on Bond Behaviour of FRP in Structures, Hong Kong, China, 7–9 December 2005; pp. 401–410. [Google Scholar]

- Abbasi, A.; Hogg, P.J. Fire testing of concrete beams with fiber reinforced plastic rebar. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1142–1150. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Tensile Properties of Fiber Reinforced Polymer Matrix Composite Bars; ASTM D7205/D7205M; Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar] [CrossRef]

- Castro, P.F.; Carino, N.J. Tensile and nondestructive testing of FRP bars. J. Compos. Constr. 1998, 2, 17–27. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Bond Strength of Fiber Reinforced Polymer Matrix Composite Bars to Concrete by Pull-Out Testing; ASTM D7913/D7913M; Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Gibson, A.G. Fire Properties of Polymer Composite Materials; Springer: Berlin, Germany, 2007; Volume 143. [Google Scholar]

- Karbhari, V.M.; Chin, J.; Hunston, D.; Benmokrane, B.; Juska, T.; Morgan, R.; Lesko, J.J.; Sorathia, U.; Reynaud, D. Durability gap analysis for fiber-reinforced polymer composites in civil infrastructure. J. Compos. Constr. 2003, 7, 238–247. [Google Scholar] [CrossRef]

- Ellis, D.S. Evaluation of Post-Fire Strength of Concrete Flexural Members Reinforced with Glass Fiber Reinforced Polymer (GFRP) Bars. Ph.D. Thesis, University of Wisconsin-Milwaukee, Milwaukee, WI, USA, 2009. [Google Scholar]

| Specimen | No. of Tests | Test Type 1 | Description |

|---|---|---|---|

| T-A | 3 | TS | Test at ambient temperature. No heat exposure. |

| T-100 | 3 | TS | Test at ambient temperature after exposure to temperature of 100 °C at constant load. |

| T-200 | 3 | TS | Test at ambient temperature after exposure to temperature of 200 °C at constant load. |

| T-400 | 3 | TS | Test at ambient temperature after exposure to temperature of 400 °C at constant load. |

| B-A | 3 | PO | Test at ambient temperature. No heat exposure. |

| B-100 | 3 | PO | Test at ambient temperature after exposure to temperature of 100 °C. |

| B-200 | 3 | PO | Test at ambient temperature after exposure to temperature of 200 °C. |

| B-400 | 3 | PO | Test at ambient temperature after exposure to temperature of 400 °C. |

| Specimen | Temperature Exposure, °C | Mean Failure Load, kN | COV (%) of Strength | Mean Residual Tensile Strength, MPa | Mean Residual Modulus of Elasticity, MPa | COV (%) of Modulus of Elasticity | Ratio of Residual Strength to Ambient Temperature Strength | Ratio of Residual Modulus to Ambient Temperature Modulus |

|---|---|---|---|---|---|---|---|---|

| T-A | 22 | 191.7 | 4.1 | 648.9 | 39603 | 3.9 | 1 | 1 |

| T-100 | 100 | 167.3 | 1.3 | 566.1 | 38969 | 2.2 | 0.87 | 0.98 |

| T-200 | 200 | 187.3 | 4.2 | 633.8 | 38388 | 5.2 | 0.98 | 0.97 |

| T-400 | 400 | 158.3 | 1.4 | 535.7 | 32839 | 3.1 | 0.83 | 0.83 |

| Specimen Name | Temperature at Embedded Portion of Bar, °C | Mean Failure Load, KN | COV (%) of Failure Load | Mean Residual Bond Strength, MPa | Ratio of Residual Bond Strength to Ambient Temperature Bond Strength |

|---|---|---|---|---|---|

| B-A | 22 | 64.2 | 7.9 | 11.3 | 1.00 |

| B-100 | 100 | 61.9 | 13.3 | 10.9 | 0.96 |

| B-200 | 200 | 48.6 | 4.6 | 8.5 | 0.76 |

| B-400 | 400 | 17.6 | 64.7 | 3.1 | 0.27 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ellis, D.S.; Tabatabai, H.; Nabizadeh, A. Residual Tensile Strength and Bond Properties of GFRP Bars after Exposure to Elevated Temperatures. Materials 2018, 11, 346. https://doi.org/10.3390/ma11030346

Ellis DS, Tabatabai H, Nabizadeh A. Residual Tensile Strength and Bond Properties of GFRP Bars after Exposure to Elevated Temperatures. Materials. 2018; 11(3):346. https://doi.org/10.3390/ma11030346

Chicago/Turabian StyleEllis, Devon S., Habib Tabatabai, and Azam Nabizadeh. 2018. "Residual Tensile Strength and Bond Properties of GFRP Bars after Exposure to Elevated Temperatures" Materials 11, no. 3: 346. https://doi.org/10.3390/ma11030346

APA StyleEllis, D. S., Tabatabai, H., & Nabizadeh, A. (2018). Residual Tensile Strength and Bond Properties of GFRP Bars after Exposure to Elevated Temperatures. Materials, 11(3), 346. https://doi.org/10.3390/ma11030346