Strain-Compensated InGaAsP Superlattices for Defect Reduction of InP Grown on Exact-Oriented (001) Patterned Si Substrates by Metal Organic Chemical Vapor Deposition

Abstract

:1. Introduction

2. Materials Growth

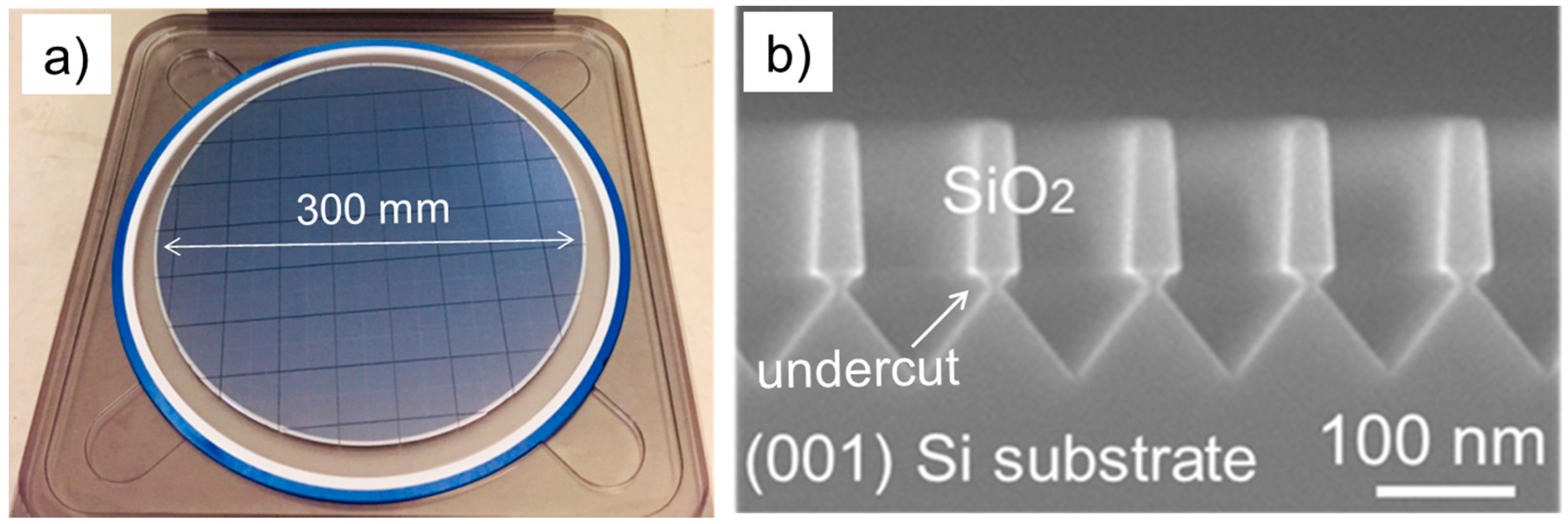

2.1. GaAs on Si

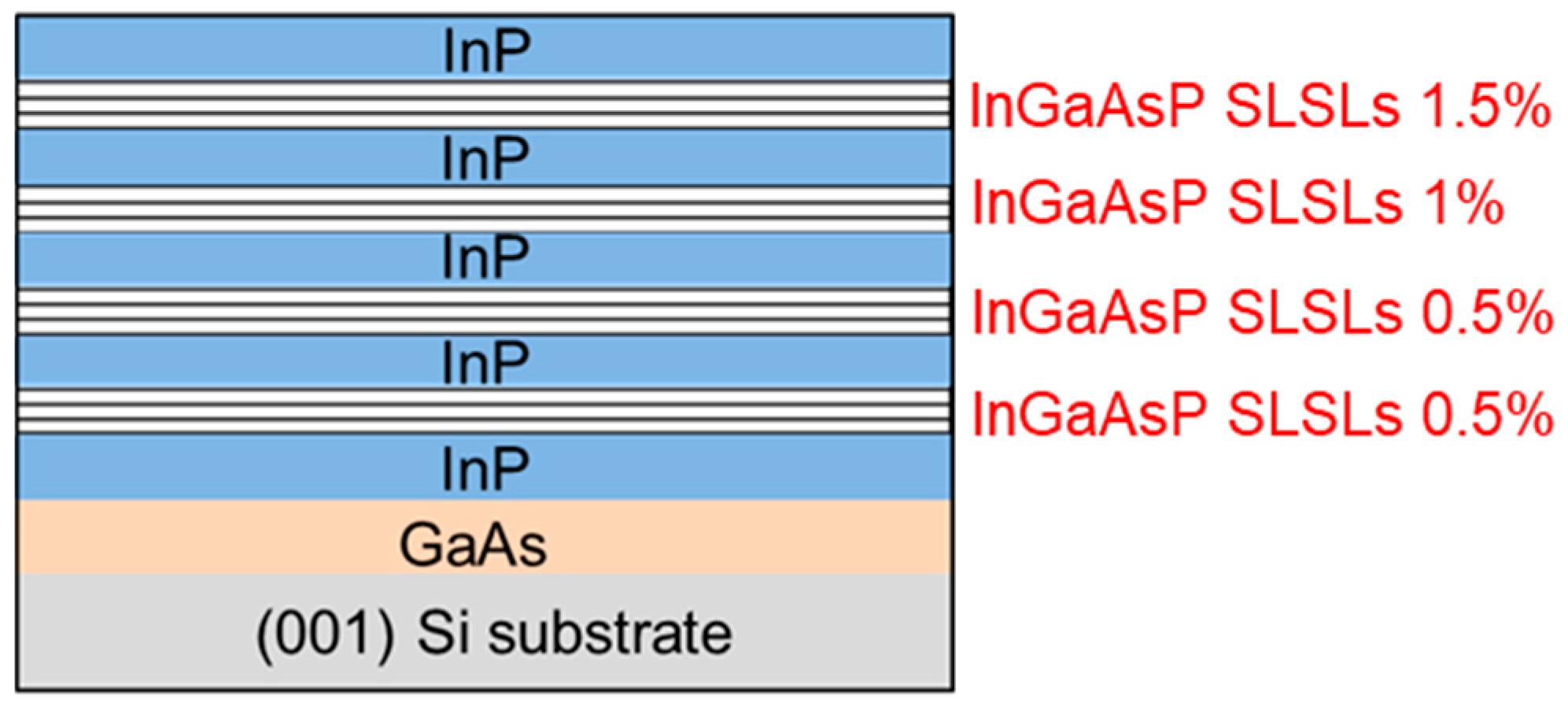

2.2. InP and Strain Compensated InGaAsP Superlattice on Si

3. Materials Characterization

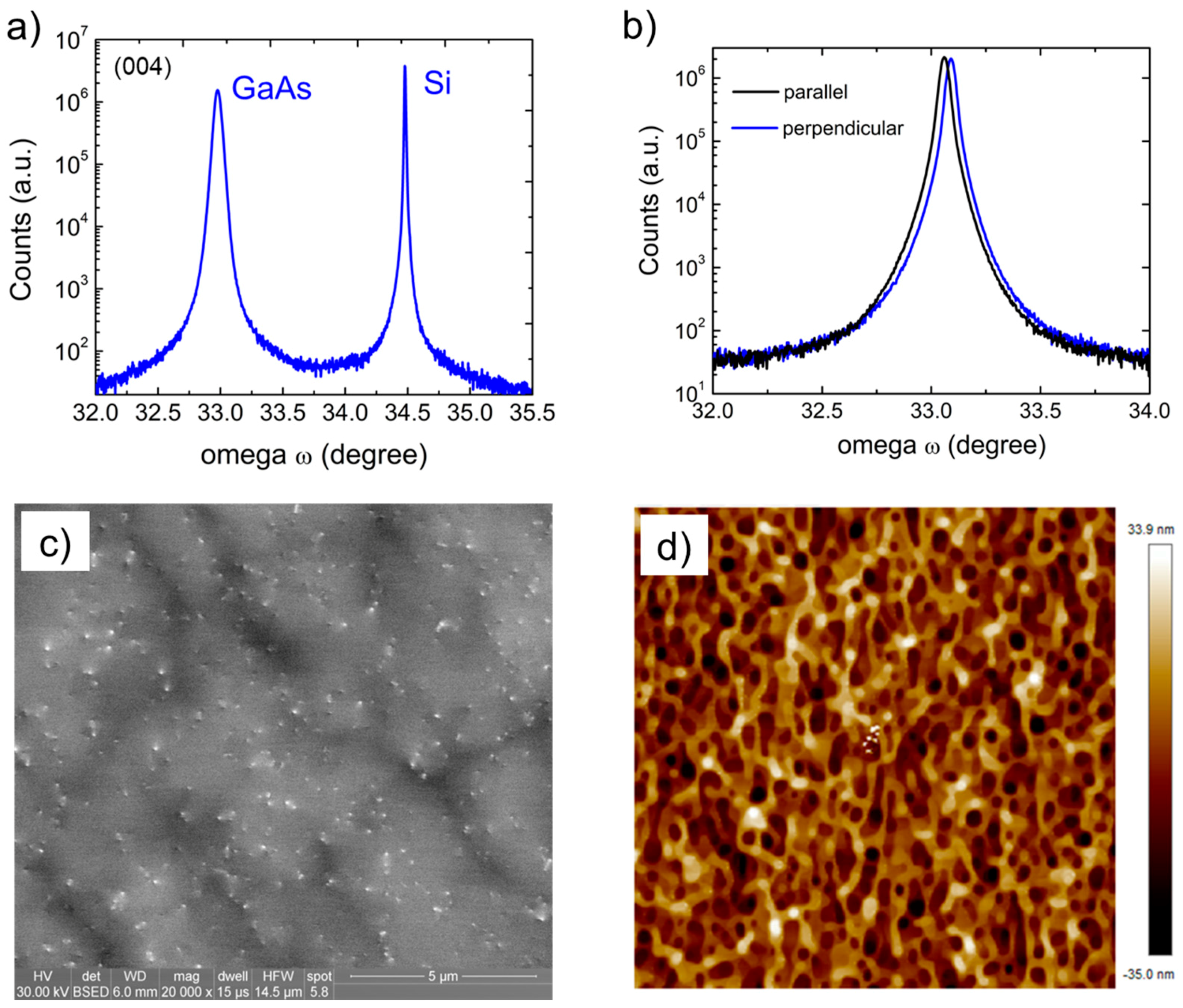

3.1. GaAs on Si

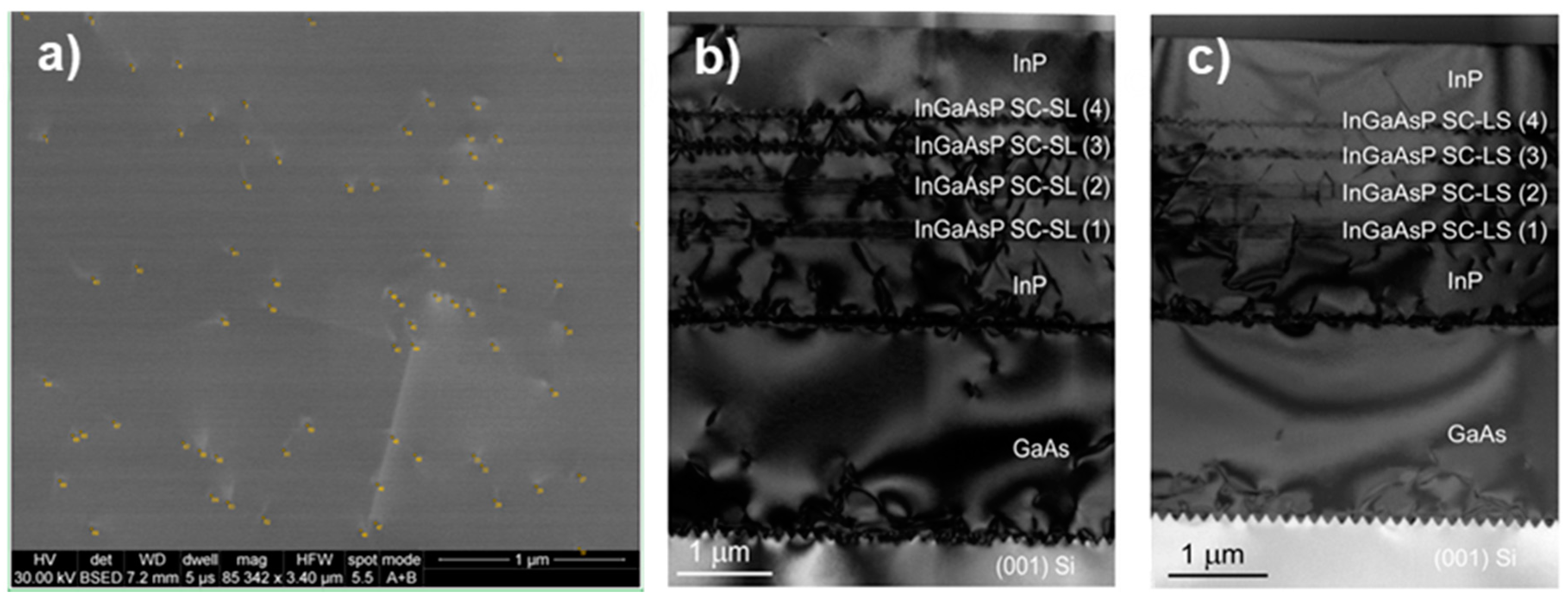

3.2. InP-on-GaAs-on-Si

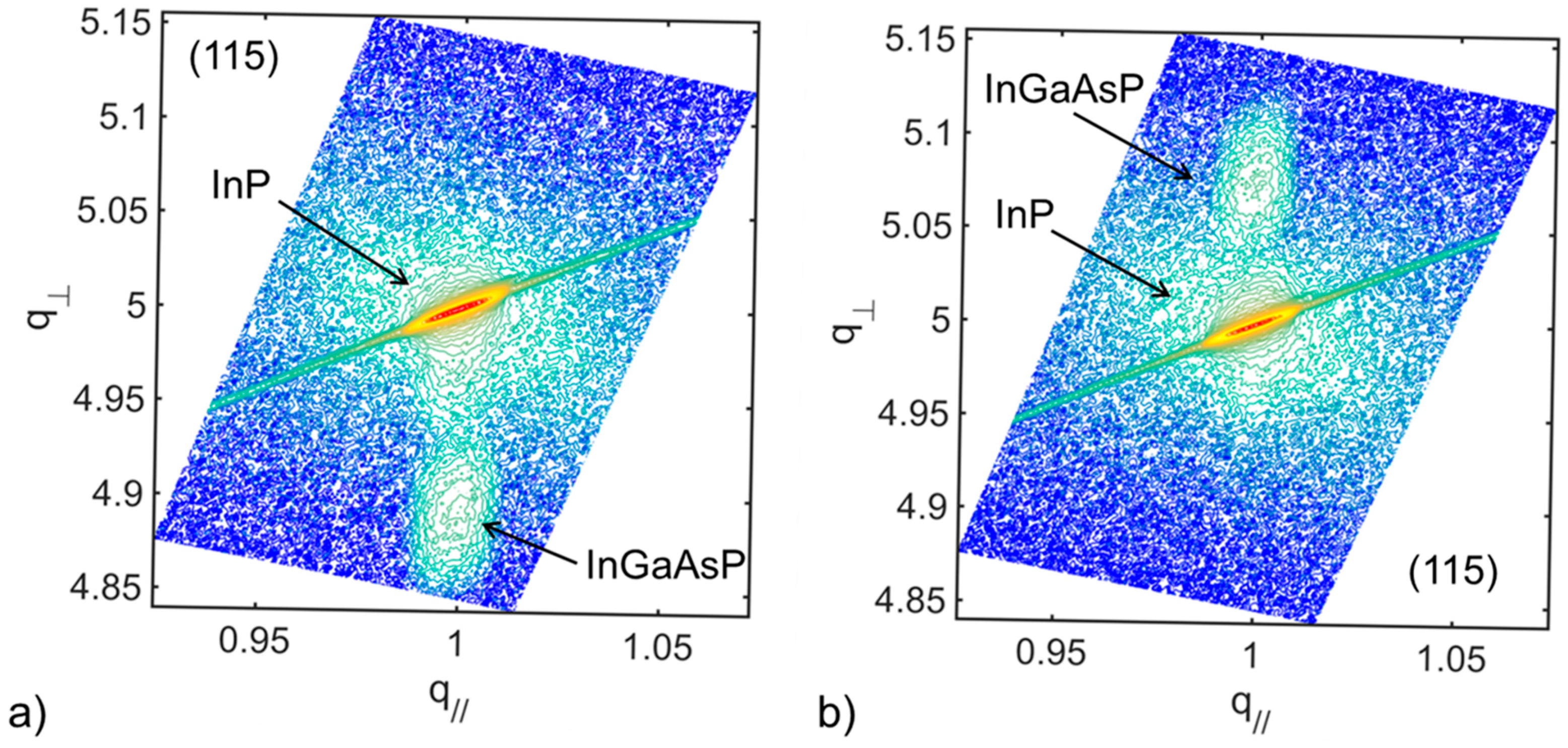

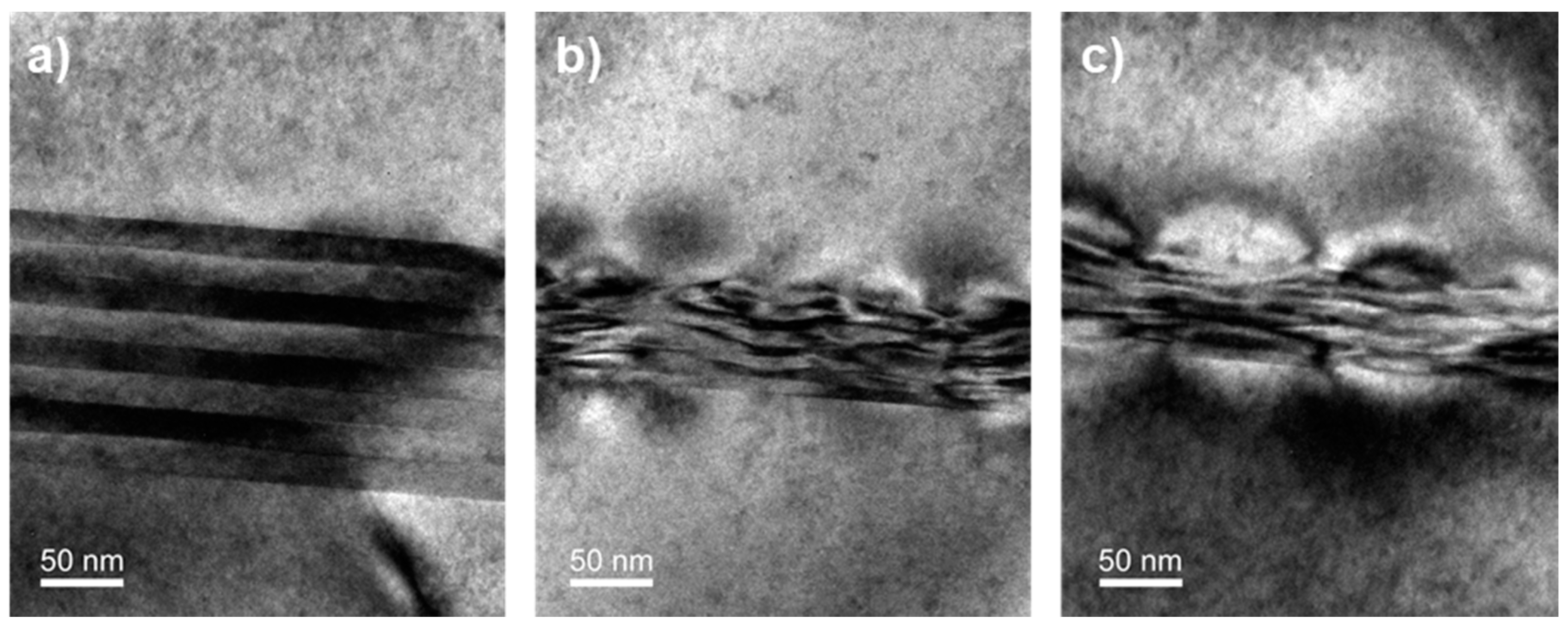

3.3. InGaAsP Strain Compensated Superlattice

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Song, B.; Megalini, L.; Dwivedi, S.; Ristic, S.; Klamkin, J. High-thermal-performance 3D hybrid silicon lasers. IEEE Photonics Technol. Lett. 2017, 29, 1143–1146. [Google Scholar] [CrossRef]

- Liang, D.; Bowers, J.E. Recent progress in lasers on silicon. Nat. Photonics 2011, 4, 511–517. [Google Scholar] [CrossRef]

- Stringfellow, G.B. Organometallic Vapor-Phase Epitaxy, Second Edition: Theory and Practice, 2nd ed.; Academic Press: Cambridge, MA, USA, 1998. [Google Scholar]

- Kohen, D.; Sang, X.; Riko, N.; Made, I.; Heidelberger, C.; Hong Lee, K.; Eng, K.; Lee, K.; Fitzgerald, E.A. Preventing phase separation in MOCVD-grown InAlAs compositionally graded buffer on silicon substrate using InGaAs interlayers. J. Cryst. Growth 2017, 478, 64–70. [Google Scholar] [CrossRef]

- Choi, D.; Harris, J.S.; Kim, E.; McIntyre, P.C.; Cagnon, J.; Stemmer, S. High-quality III–V semiconductor MBE growth on Ge/Si virtual substrates for metal-oxide-semiconductor device fabrication. J. Cryst. Growth 2009, 311, 1962–1971. [Google Scholar] [CrossRef]

- Sugo, M.; Yamaguchi, M. Buffer layer effects on residual stress in InP on Si substrates. Appl. Phys. Lett. 1989, 54, 1754. [Google Scholar] [CrossRef]

- Schulze, C.S.; Huang, X.; Prohl, C.; Füllert, V.; Rybank, S.; Maddox, S.J.; March, S.D.; Bank, S.R.; Lee, M.L.; Lenz, A. Atomic structure and stoichiometry of In(Ga)As/GaAs quantum dots grown on an exact-oriented GaP/Si(001) substrate. Appl. Phys. Lett. 2016, 108, 143101. [Google Scholar] [CrossRef]

- Grundmann, M.; Krost, A.; Bimberg, D. Antiphase-domain-free InP on Si(001): Optimization of MOCVD process. J. Cryst. Growth 1991, 115, 150–153. [Google Scholar] [CrossRef]

- Ababou, Y.; Desjardins, P.; Chennouf, A.; Leonelli, R.; Hetherington, D.; Yelon, A.; L’Esperance, G.; Masut, R.A. Structural and optical characterization of InP grown on Si(111) by metalorganic vapor phase epitaxy using thermal cycle growth. J. Appl. Phys. 1996, 80, 4997–5005. [Google Scholar] [CrossRef]

- Fitzgerald, E.A.; Chand, N. Epitaxial necking in GaAs grown on pre-pattemed Si substrates. J. Electron. Mater. 1991, 20, 839–853. [Google Scholar] [CrossRef]

- Guo, W.; Date, L.; Pena, V.; Bao, X.; Merckling, C.; Waldron, N.; Collaert, N.; Caymax, M.; Sanchez, E.; Vancoille, E.; et al. Anisotropic relaxation behavior of InGaAs/GaAs selectively grown in narrow trenches on (001) Si substrates. Appl. Phys. Lett. 2014, 105, 062101. [Google Scholar] [CrossRef]

- Megalini, L.; Cabinian, B.C.; Zhao, H.; Oakley, D.C.; Bowers, J.E.; Klamkin, J. Large-area direct hetero-epitaxial growth of 1550-nm ingaasp multi-quantum-well structures on patterned exact-oriented (001) silicon substrates by metal organic chemical vapor deposition. J. Electron. Mater. 2017, 47, 982–987. [Google Scholar] [CrossRef]

- Merckling, C.; Waldron, N.; Jiang, S.; Guo, W.; Richard, O.; Douhard, B.; Moussa, A.; Vanhaeren, D.; Bender, H.; Collaert, N.; et al. Heteroepitaxy of InP on Si (001) by selective-area metal organic vapor-phase epitaxy in sub-50 nm width trenches: The role of the nucleation layer and the recess engineering. J. Appl. Phys. 2013, 114, 033708. [Google Scholar] [CrossRef]

- Li, J.Z.; Bai, J.; Park, J.S.; Adekore, B.; Fox, K.; Carroll, M.; Lochtefeld, A.; Shellenbarger, Z. Defect reduction of GaAs epitaxy on Si (001) using selective aspect ratio trapping. Appl. Phys. Lett. 2007, 91, 021114. [Google Scholar] [CrossRef]

- Liu, W.K.; Lubyshev, D.; Fastenau, J.M.; Wu, Y.; Bulsara, T.; Fitzgerald, E.A.; Urteaga, M.; Ha, W.; Bergman, J.; Brar, B.; et al. Monolithic integration of InP-based transistors on Si substrates using MBE. J. Cryst. Growth 2009, 311, 1979–1983. [Google Scholar] [CrossRef]

- Osbourn, G.C. Strained-layer superlattices: A brief review. IEEE J. Sel. Top. Quantum Electron. 1986, 22, 1677–1681. [Google Scholar] [CrossRef]

- Matthews, J.W.; Blakeslee, A.E.; Mader, S. Use of misfit strain to remove dislocations from epitaxial thin films. Thin Solid Films 1976, 33, 253–266. [Google Scholar] [CrossRef]

- Takano, Y.; Hisaka, M.; Fujii, N.; Suzuki, K.; Kuwahara, K.; Fuke, S. Reduction of threading dislocations by InGaAs interlayer in GaAs layers grown on Si substrates. Appl. Phys. Lett. 1998, 73, 2917–2919. [Google Scholar] [CrossRef]

- MacPherson, G.; Goodhew, P.J. A refined scheme for the reduction of threading dislocation densities in InxGaAs1−xAs/GaAs epitaxial layers. J. Appl. Phys. 1996, 80, 6706–6710. [Google Scholar] [CrossRef]

- Fritz, I.J.; Gourley, P.L.; Dawson, R.L.; Schirber, J.E. Electrical and optical studies of dislocation filtering in InGaAs/GaAs strained-layer superlattices. Appl. Phys. Lett. 1988, 53, 1098–1100. [Google Scholar] [CrossRef]

- Tang, M.; Chen, S.; Wu, J.; Jiang, Q.; Kennedy, K.; Jurczak, P.; Liao, M.; Beanland, R.; Seeds, A.; Liu, H. Optimizations of defect filter layers for 1.3-μm InAs/GaAs quantum-dot lasers monolithically grown on Si substrates. IEEE J. Sel. Top. Quantum Electron. 2016, 22, 1900207. [Google Scholar] [CrossRef]

- George, I.; Becagli, F.; Liu, H.Y.; Wu, J.; Tang, M.; Beanland, R. Dislocation filters in GaAs on Si. Semicond. Sci. Technol. 2015, 30, 114004. [Google Scholar] [CrossRef]

- Nakamura, S.; Senoh, M.; Nagahama, S.; Iwasa, N.; Yamada, T.; Matsushita, T.; Kiyoku, H.; Sugimoto, Y.; Kozaki, T.; Umemoto, H.; et al. InGaN/GaN/AlGaN-based laser diodes with modulation-doped strained-layer superlattices grown on an epitaxially laterally overgrown GaN substrate. Appl. Phys. Lett. 1998, 72, 211–213. [Google Scholar] [CrossRef]

- Kladko, V.; Kuchuk, A.; Lytvyn, P.; Yefanov, O.; Safriuk, N.; Belyaev, A.; Mazur, Y.I.; DeCuir, E.A.; Ware, M.E.; Salamo, G.J. Substrate effects on the strain relaxation in GaN/AlN short-period superlattices. Nanoscale Res. Lett. 2012, 7, 289. [Google Scholar] [CrossRef] [PubMed]

- Ni, Y.; He, Z.; Yang, F.; Zhou, D.; Yao, Y.; Zhou, G.; Shen, Z.; Zhong, J.; Zhen, Y.; Wu, Z. Effect of AlN/GaN superlattice buffer on the strain state in GaN-on-Si(111) system. Jpn. J. Appl. Phys. 2014, 54, 015505. [Google Scholar] [CrossRef]

- Lin, P.J.; Huang, S.Y.; Wang, W.K.; Chen, C.L.; Chung, B.C.; Wu, D.S. Controlling the stress of growing GaN on 150-mm Si (111) in an AlN/GaN strained layer superlattice. Appl. Surf. Sci. 2016, 362, 434–440. [Google Scholar] [CrossRef]

- Samonji, K.; Yonezu, H.; Takagi, Y.; Iwaki, K.; Ohshima, N.; Shin, J.K.; Pak, K. Reduction of threading dislocation density in InP-on-Si heteroepitaxy with strained short-period superlattices. Appl. Phys. Lett. 1996, 69, 100–102. [Google Scholar] [CrossRef]

- Fireman, M.N.; Bonef, B.; Young, E.C.; Nookala, N.; Belkin, M.A.; Speck, J.S. Strain compensated superlattices on m-plane gallium nitride by ammonia molecular beam epitaxy. J. Appl. Phys. 2017, 122, 075105. [Google Scholar] [CrossRef]

- Paladugu, M.; Merckling, C.; Loo, R.; Richard, O.; Bender, H.; Dekoster, J.; Vandervorst, W.; Caymax, M.; Heyns, M. Site Selective Integration of III–V materials on Si for nanoscale logic and photonic devices. Cryst. Growth Des. 2012, 12, 4696–4702. [Google Scholar] [CrossRef]

- Megalini, L.; Bonef, B.; Cabinian, B.C.; Zhao, H.; Taylor, A.; Speck, J.S.; Bowers, J.E.; Klamkin, J. 1550-nm InGaAsP multi-quantum-well structures selectively grown on V-groove-patterned SOI substrates. Appl. Phys. Lett. 2017, 111, 032105. [Google Scholar] [CrossRef]

- Li, Q.; Ng, K.W.; Lau, K.M. Growing antiphase-domain-free GaAs thin films out of highly ordered planar nanowire arrays on exact (001) silicon. Appl. Phys. Lett. 2015, 106, 072105. [Google Scholar] [CrossRef]

- Orzali, T.; Vert, A.; O’Brien, B.; Herman, J.L.; Vivekanand, S.; Hill, R.J.W.; Karim, Z.; Papa Rao, S.S. GaAs on Si epitaxy by aspect ratio trapping: Analysis and reduction of defects propagating along the trench direction. J. Appl. Phys. 2015, 118, 105307. [Google Scholar] [CrossRef]

- Megalini, L.; Cabinian, B.C.; Zhao, H.; Oakley, D.; Bowers, J.E.; Klamkin, J. Toward fully monolithic 1550-nm lasers on silicon by direct hetero-epitaxy growth on patterned substrates. In Proceedings of the CLEO: Applications and Technology, San Jose, CA, USA, 14–19 May 2017. [Google Scholar] [CrossRef]

- Megalini, L.; Cabinian, B.C.; Bonef, B.; Zhao, H.; Mates, T.; Speck, J.S.; Bowers, J.E.; Klamkin, J. 1550-nm InGaAsP multi-quantum-well structures in InP nano-ridges by selective MOCVD growth on SOI substrates. In Proceedings of the Integrated Photonics Research, Silicon and Nanophotonics, New Orleans, LA, USA, 24–27 July 2017. [Google Scholar] [CrossRef]

- Merckling, C.; Waldron, N.; Jiang, S.; Weiming, G.; Barla, K.; Heynsa, M.; Collaert, N.; Thean, A.; Vandervors, W. Selective-area metal organic Vapor-Phase Epitaxy of III-V on Si: What about defect density? ECS Trans. 2014, 64, 513–521. [Google Scholar] [CrossRef]

- Coldren, L.A.; Corzine, S.W.; Mašanović, M. Gain and current relations. In Diode Lasers and Photonic Integrated Circuits, 2nd ed.; Chang, K., Ed.; Wiley: New York, NY, USA, 2012; pp. 157–246. [Google Scholar]

- Thiis, P.J.A.; Tiemeijer, L.F.; Binsma, J.J.M.; Van Dongen, T. Progress in long-wavelength strained-layer InGaAs(P) quantum-well semiconductor lasers and amplifiers. IEEE J. Quantum Electron. 1994, 30, 477–499. [Google Scholar] [CrossRef]

- Cunningham, J.E.; Goossen, K.W.; Williams, M.; Jan, W.Y. Pseudomorphic InGaAs-GaAsP quantum well modulators on GaAs. Appl. Phys. Lett. 1992, 60, 727–729. [Google Scholar] [CrossRef]

- Miller, B.I.; Koren, U.; Young, M.G.; Chien, M.D. Strain-compensated strained layer superlattices for 1.5 μm wavelength laser. Appl. Phys. Lett. 1991, 58, 1952–1954. [Google Scholar] [CrossRef]

- Chiu, T.H.; Cunningham, J.E.; Woodward, T.K.; Sizer, T., II. Growth of strain-balanced InAsP-InGaP superlattice for 1.06 μm optical modulator. Appl. Phys. Lett. 1993, 62, 340–342. [Google Scholar] [CrossRef]

- Ayers, J.E. Heteroepitaxy of Semiconductors: Theory, Growth, and Characterization; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Yan, C.H.; Tu, C.W. Synthesis of highly strained InyGa1−yP/InxGa1−xAs/InyGa1−yP quantum well structures with strain compensation. J. Cryst. Growth 1996, 164, 276–280. [Google Scholar] [CrossRef]

| Superlattice | Composition | Strain (%) | PL (nm) | hc (Å) |

|---|---|---|---|---|

| 1st–c | In69.7Ga30.3As50P50 | +0.5 | 1164.3 | 244.6 |

| 1st–t | In69.7Ga30.3As80.9P19.1 | −0.5 | 1569.7 | 242.1 |

| 2nd–c | In69.7Ga30.3As50P50 | +0.5 | 1164.3 | 244.6 |

| 2nd–t | In69.7Ga30.3As80.9P19.1 | −0.5 | 1569.7 | 242.1 |

| 3rd–c | In94.1Ga5.9As44.2P55.8 | +1.0 | 1302.8 | 86.2 |

| 3rd–t | In63.2Ga36.8As49P51 | −1.0 | 1105.9 | 94.7 |

| 4th–c | In52Ga48As58P42 | +1.5 | 1104.1 | 64.2 |

| 4th–t | In90Ga10As68.7P31.3 | −1.5 | 1649.2 | 60.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Megalini, L.; Šuran Brunelli, S.T.; Charles, W.O.; Taylor, A.; Isaac, B.; Bowers, J.E.; Klamkin, J. Strain-Compensated InGaAsP Superlattices for Defect Reduction of InP Grown on Exact-Oriented (001) Patterned Si Substrates by Metal Organic Chemical Vapor Deposition. Materials 2018, 11, 337. https://doi.org/10.3390/ma11030337

Megalini L, Šuran Brunelli ST, Charles WO, Taylor A, Isaac B, Bowers JE, Klamkin J. Strain-Compensated InGaAsP Superlattices for Defect Reduction of InP Grown on Exact-Oriented (001) Patterned Si Substrates by Metal Organic Chemical Vapor Deposition. Materials. 2018; 11(3):337. https://doi.org/10.3390/ma11030337

Chicago/Turabian StyleMegalini, Ludovico, Simone Tommaso Šuran Brunelli, William O. Charles, Aidan Taylor, Brandon Isaac, John E. Bowers, and Jonathan Klamkin. 2018. "Strain-Compensated InGaAsP Superlattices for Defect Reduction of InP Grown on Exact-Oriented (001) Patterned Si Substrates by Metal Organic Chemical Vapor Deposition" Materials 11, no. 3: 337. https://doi.org/10.3390/ma11030337

APA StyleMegalini, L., Šuran Brunelli, S. T., Charles, W. O., Taylor, A., Isaac, B., Bowers, J. E., & Klamkin, J. (2018). Strain-Compensated InGaAsP Superlattices for Defect Reduction of InP Grown on Exact-Oriented (001) Patterned Si Substrates by Metal Organic Chemical Vapor Deposition. Materials, 11(3), 337. https://doi.org/10.3390/ma11030337