Effects of Temperature and Pressure of Hot Isostatic Pressing on the Grain Structure of Powder Metallurgy Superalloy

Abstract

:1. Introduction

2. Materials and Methods

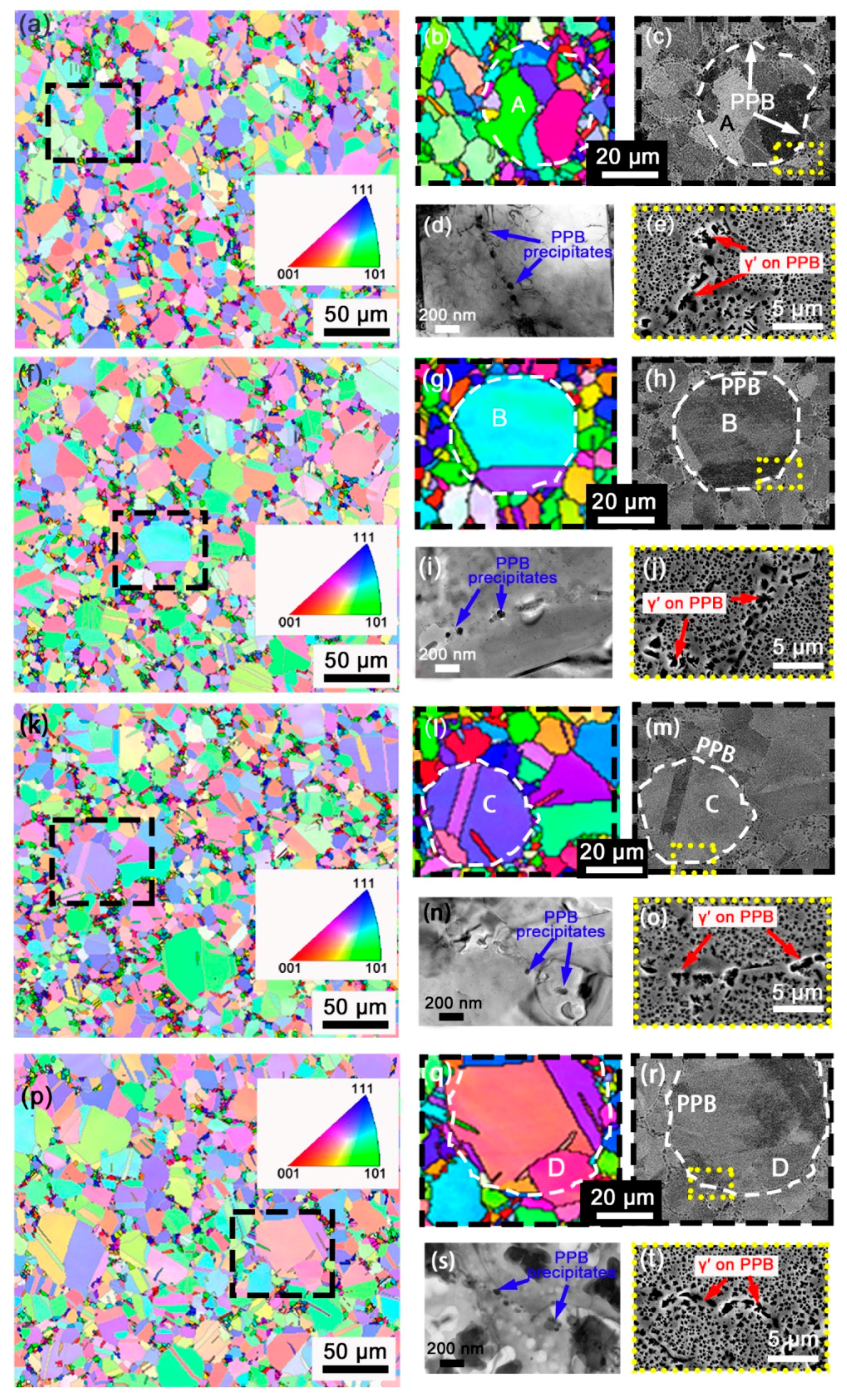

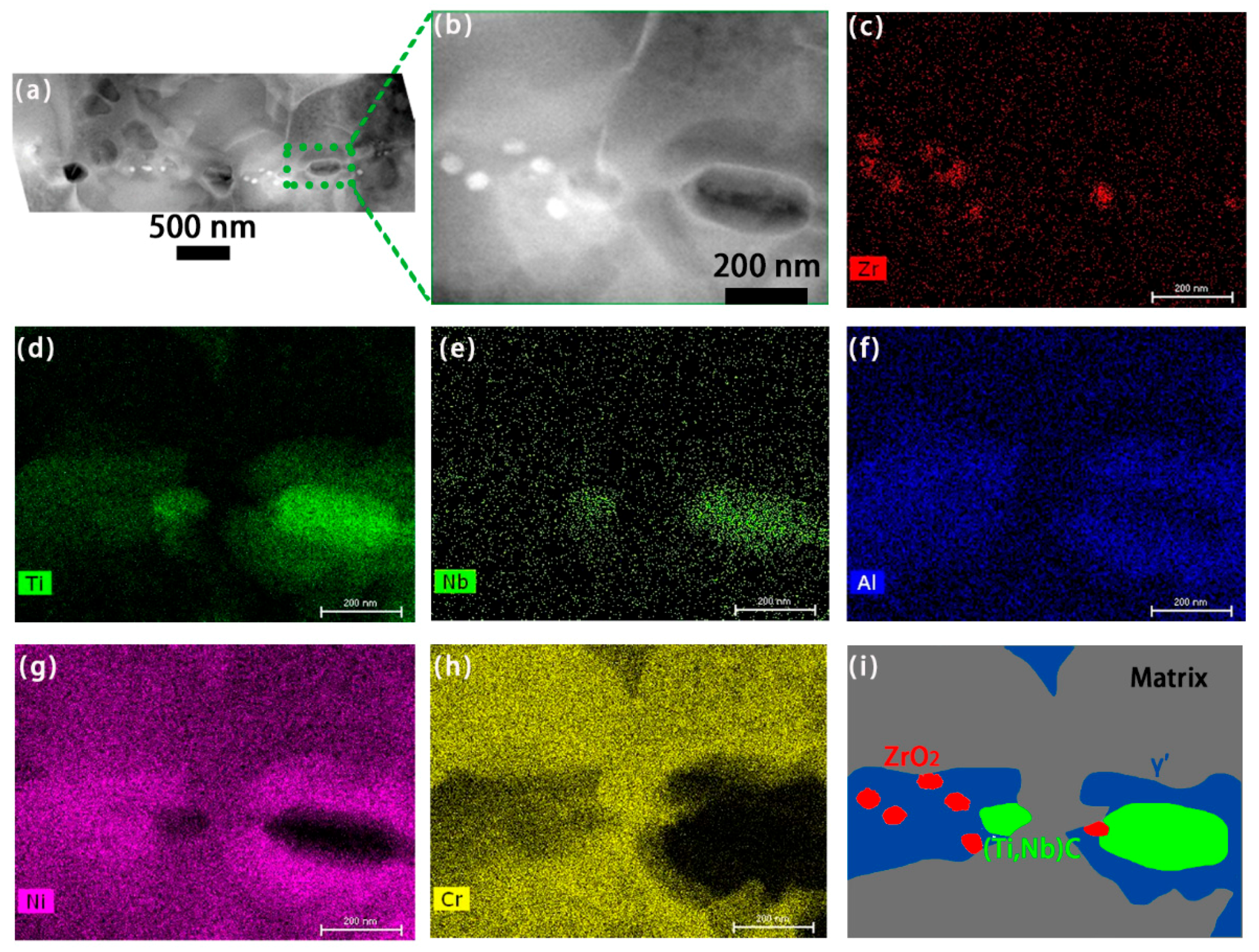

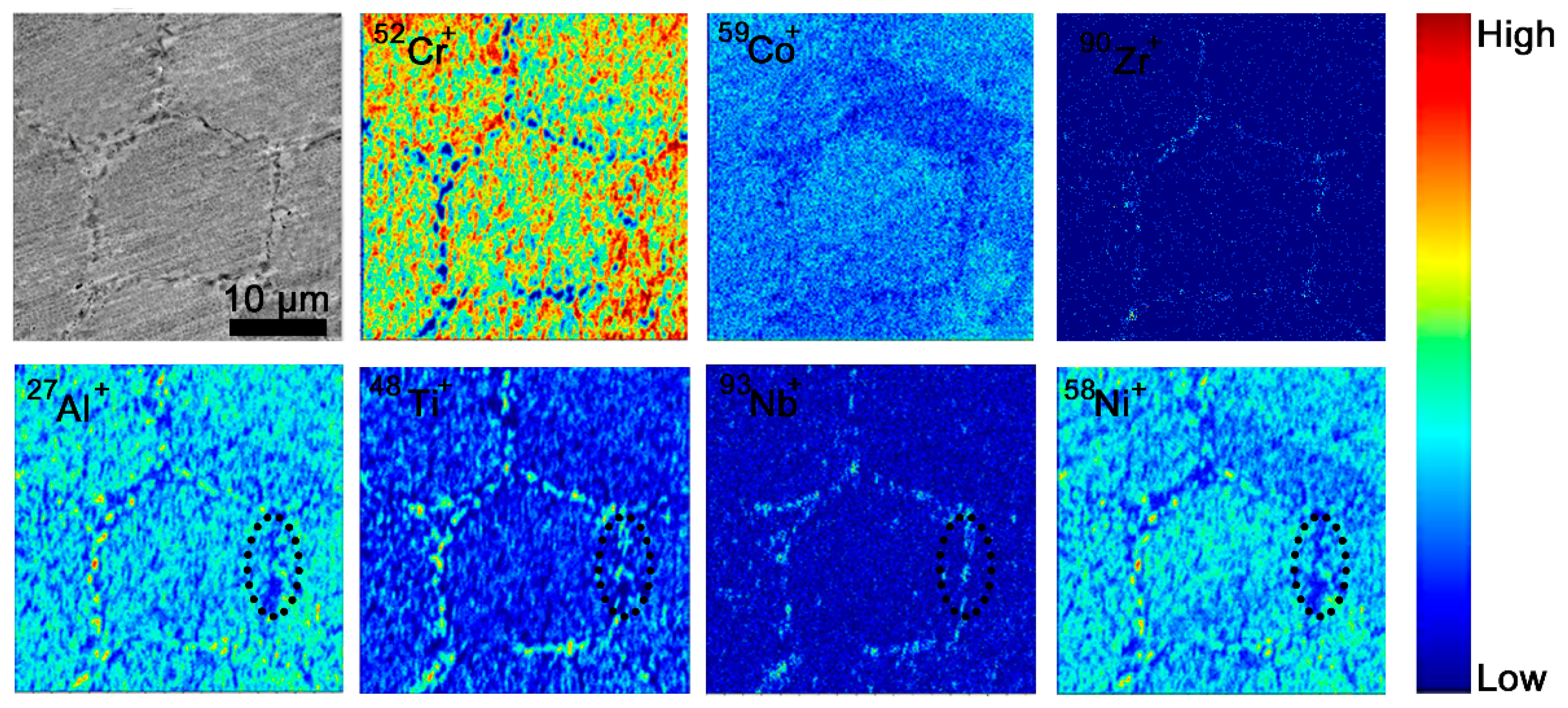

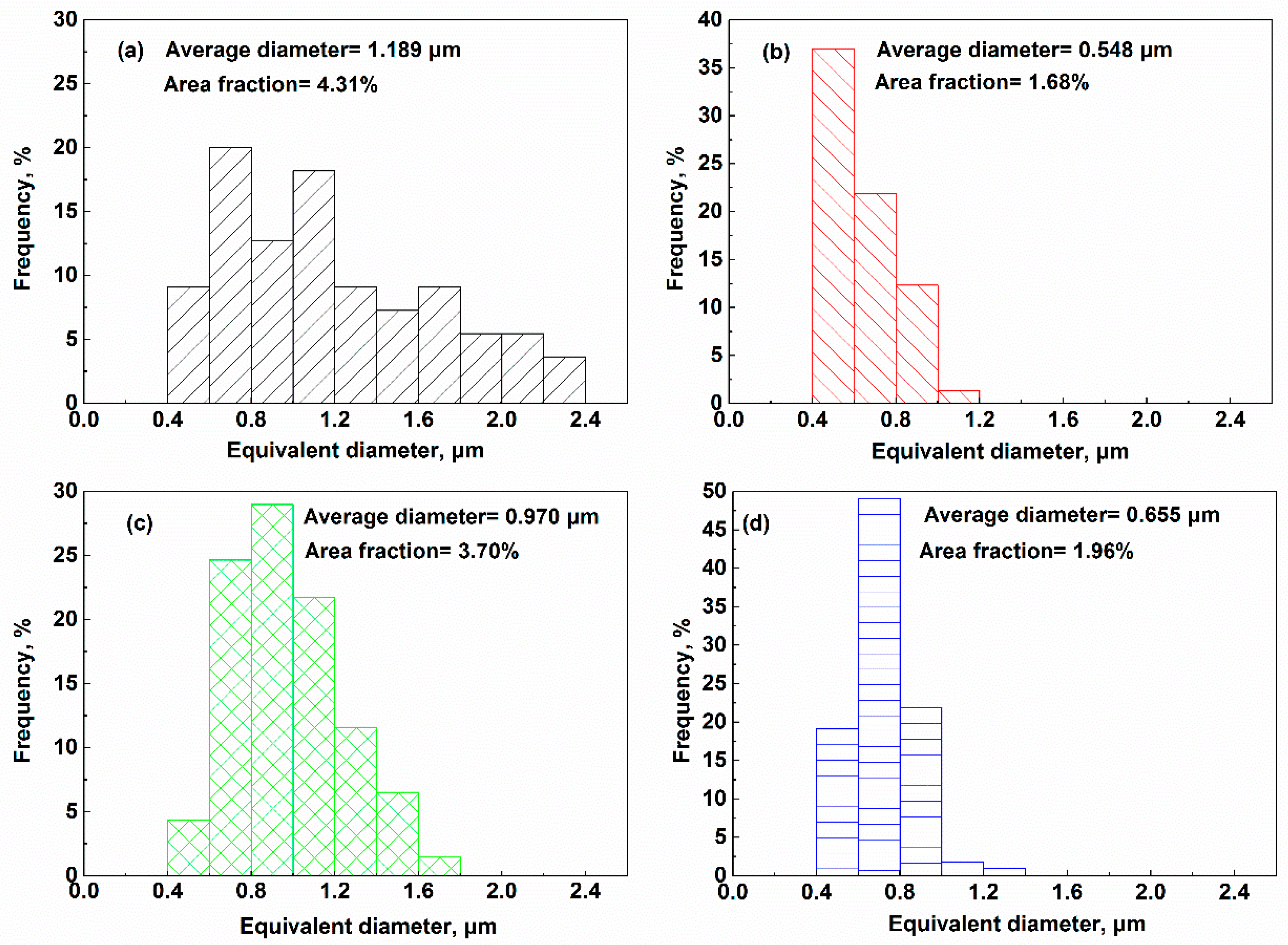

3. Results

4. Discussion

5. Conclusions

- (1)

- The PPB precipitates mainly consisted of large primary γ′, small ZrO2 oxides and MC carbides in the four HIPped FGH96 superalloys.

- (2)

- Comparing with HIPping under near-γ′ solvus 1120 °C, HIPping at 1170 °C accelerates the grain boundary migration and dissolution of γ′ on PPB, which impels the moving grain boundary to bypass the PPB.

- (3)

- As RX is facilitated under higher pressure, HIPping at 150 MPa is preferred to obtain a microstructure with homogeneously refined grains.

- (4)

- In general, reducing the pining effects by dissolution of PPB precipitates through HIPping at high supersolvus temperature may induce excessive grain growth of grains, but increasing the pressure could suppress this tendency.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pollock, T.M.; Tin, S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Osada, T.; Nagashima, N.; Gu, Y.; Yuan, Y.; Yokokawa, T.; Harada, H. Factors contributing to the strength of a polycrystalline nickel–cobalt base superalloy. Scr. Mater. 2011, 64, 892–895. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Zhang, Q.; Chang, Y.; Gu, L.; Luo, Y.; Ge, B. Study of microstructure of nickel-based superalloys at high temperatures. Scr. Mater. 2017, 126, 55–57. [Google Scholar] [CrossRef]

- Gessinger, G.H.; Bomford, M.J. Powder Metallurgy of Superalloys; Butterworths: London, UK, 1974; pp. 51–76. [Google Scholar]

- August, K.; Thompson, V.R.; Moll, J.H. Method for Producing Superalloy Articles by Hot Isostatic Pressing. U.S. Patent No. 3,698,962, 17 October 1972. [Google Scholar]

- Kim, M.T.; Kim, D.S.; Oh, O.Y. Effect of γ′ precipitation during hot isostatic pressing on the mechanical property of a nickel-based superalloy. Mater. Sci. Eng. A 2008, 480, 218–225. [Google Scholar] [CrossRef]

- Qiu, C. Net-Shape Hot Isostatic Pressing of a Nickel-Based Powder Superalloy. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2010. [Google Scholar]

- Qiu, C.L.; Attallah, M.M.; Wu, X.H.; Andrews, P. Influence of hot isostatic pressing temperature on microstructure and tensile properties of a nickel-based superalloy powder. Mater. Sci. Eng. A 2013, 564, 176–185. [Google Scholar] [CrossRef]

- Raisson, G. Evolution of PM nickel base superalloy processes and products. Powder Metall. 2008, 51, 10–13. [Google Scholar] [CrossRef]

- Raisson, G.; Guédou, J.Y.; Guichard, D.; Rongvaux, J.M. Production of Net-Shape Static Parts by Direct HIPing of Nickel Base Superalloy Prealloyed Powders. Adv. Mater. Res. 2011, 278, 277–282. [Google Scholar] [CrossRef]

- Wang, J.W.; Wei, Q.S.; Liu, G.C.; He, Y.K.; Shi, Y.S. Study on Direct Hot Isostatic Pressing Technology for Superalloy Inconel 625. Adv. Mater. Res. 2011, 189–193, 2935–2938. [Google Scholar] [CrossRef]

- Baccino, R.; Moret, F.; Pellerin, F.; Guichard, D.; Raisson, G. High performance and high complexity net shape parts for gas turbines: The ISOPREC® powder metallurgy process. Mater. Des. 2000, 21, 345–350. [Google Scholar] [CrossRef]

- Moll, J.H.; Conway, J.J. Characteristics and Properties of As-HIP P/M Alloy 720. In Proceedings of the Ninth International Symposium on Superalloys, Seven Springs, PA, USA, 17–21 September 2000. [Google Scholar]

- Bai, Q.L.J. Review and Analysis of Powder Prior Boundary (PPB) Formation in Powder Metallurgy Processes for Nickel-based Super Alloys. J. Powder Metall. Min. 2015, 4, 127. [Google Scholar]

- Qiu, C.; Wu, X.; Mei, J.; Andrews, P.; Voice, W. Influence of heat treatment on microstructure and tensile behavior of a hot isostatically pressed nickel-based superalloy. J. Alloys Compd. 2013, 578, 454–464. [Google Scholar] [CrossRef]

- Atkinson, H.V.; Davies, S. Fundamental Aspects of Hot Isostatic Pressing: An Overview. Metall. Mater. Trans. A 2000, 31, 2981–3000. [Google Scholar] [CrossRef]

- Rao, G.A.; Prasad, K.S.; Kumar, M.; Srinivas, M.; Sarma, D.S. Characterisation of hot isostatically pressed nickel base superalloy Inconel* 718. Mater. Sci. Technol. 2003, 19, 313–321. [Google Scholar] [CrossRef]

- Rao, G.A.; Srinivas, M.; Sarma, D.S. Effect of oxygen content of powder on microstructure and mechanical properties of hot isostatically pressed superalloy Inconel 718. Mater. Sci. Eng. A 2006, 435–436, 84–99. [Google Scholar] [CrossRef]

- Ingesten, N.G.; Warren, R.; Winberg, L. The Nature and Origin of Previous Particle Boundary Precipitates in P/M Superalloys. In High Temperature Alloys for Gas Turbines; Springer: Dordrecht, The Netherlands, 1982; pp. 1013–1027. [Google Scholar]

- Ott, E.; Gabb, T.; Helmink, R.; Wusatowska-Sarnek, A. Development of Prior Particle Boundary Free Hot-Isostatic-Pressing Process for Inconel 718 Powder; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 447–458. [Google Scholar]

- Rao, G.A.; Srinivas, M.; Sarma, D.S. Effect of solution treatment temperature on microstructure and mechanical properties of hot isostatically pressed superalloy Inconel* 718. Mater. Sci. Technol. 2004, 20, 1161–1170. [Google Scholar] [CrossRef]

- Chang, L.; Sun, W.; Cui, Y.; Yang, R. Preparation of hot-isostatic-pressed powder metallurgy superalloy Inconel 718 free of prior particle boundaries. Mater. Sci. Eng. A 2017, 682, 341–344. [Google Scholar] [CrossRef]

- Ma, W.B.; Liu, G.Q.; Hu, B.F.; Hu, P.H.; Zhang, Y.W. Study of Metallic Carbide (MC) in a Ni-Co-Cr-Based Powder Metallurgy Superalloy. Metall. Mater. Trans. A 2014, 45, 208–217. [Google Scholar] [CrossRef]

- Crompton, J.S.; Hertzberg, R.W. Analysis of second phase particles in a powder metallurgy HIP nickel-base superalloy. J. Mater. Sci. 1986, 21, 3445–3454. [Google Scholar] [CrossRef]

- Menzies, R.G.; Bricknell, R.H.; Craven, A.J. STEM microanalysis of precipitates and their nuclei in a nickel-base superalloy. Philos. Mag. A 1980, 41, 493–508. [Google Scholar] [CrossRef]

- Kim, Y.-W.; Griffith, W.M.; Froes, F.H. Surface Oxides in P/M Aluminum Alloys. JOM 1985, 37, 27–33. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, H.; He, X.; Qu, X.; Qin, M.; Li, Z.; Zhang, G. Thermal evolution behavior of carbides and γ′ precipitates in FGH96 superalloy powder. Mater. Charact. 2012, 67, 52–64. [Google Scholar] [CrossRef]

- Montheillet, F.; Piot, D.; Matougui, N.; Fares, M.L. A critical assessment of three usual equations for strain hardening and dynamic recovery. Metall. Mater. Trans. A 2014, 45, 4324–4332. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Sietsma, J.; Rivera-Díaz-del-Castillo, P.E.J. Dislocation annihilation in plastic deformation: II. Kocks–Mecking Analysis. Acta Mater. 2012, 60, 2615–2624. [Google Scholar] [CrossRef]

- Peng, H.R.; Gong, M.M.; Chen, Y.Z.; Liu, F. Thermal stability of nanocrystalline materials: Thermodynamics and kinetics. Int. Mater. Rev. 2017, 62, 303–333. [Google Scholar] [CrossRef]

- Vandermeer, R.A.; Jensen, D.J. The migration of high angle grain boundaries during recrystallization. Interface Sci. 1998, 6, 95–104. [Google Scholar] [CrossRef]

- Collins, D.M.; Conduit, B.D.; Stone, H.J.; Hardy, M.C.; Conduit, G.J.; Mitchell, R.J. Grain growth behaviour during near-γ′ solvus thermal exposures in a polycrystalline nickel-base superalloy. Acta Mater. 2013, 61, 3378–3391. [Google Scholar] [CrossRef]

- Hu, H.; Rath, B.B. On the time exponent in isothermal grain growth. Metall. Trans. 1970, 1, 3181–3184. [Google Scholar]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004; pp. 219–224. [Google Scholar]

- Song, K.; Aindow, M. Grain growth and particle pinning in a model Ni-based superalloy. Mater. Sci. Eng. A 2008, 479, 365–372. [Google Scholar] [CrossRef]

| Co | Cr | Mo | W | Al | Ti | Nb | B | Zr | C | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| 13.0 | 16.0 | 4.0 | 4.0 | 2.1 | 3.7 | 0.7 | 0.015 | 0.03 | 0.03 | Bal. |

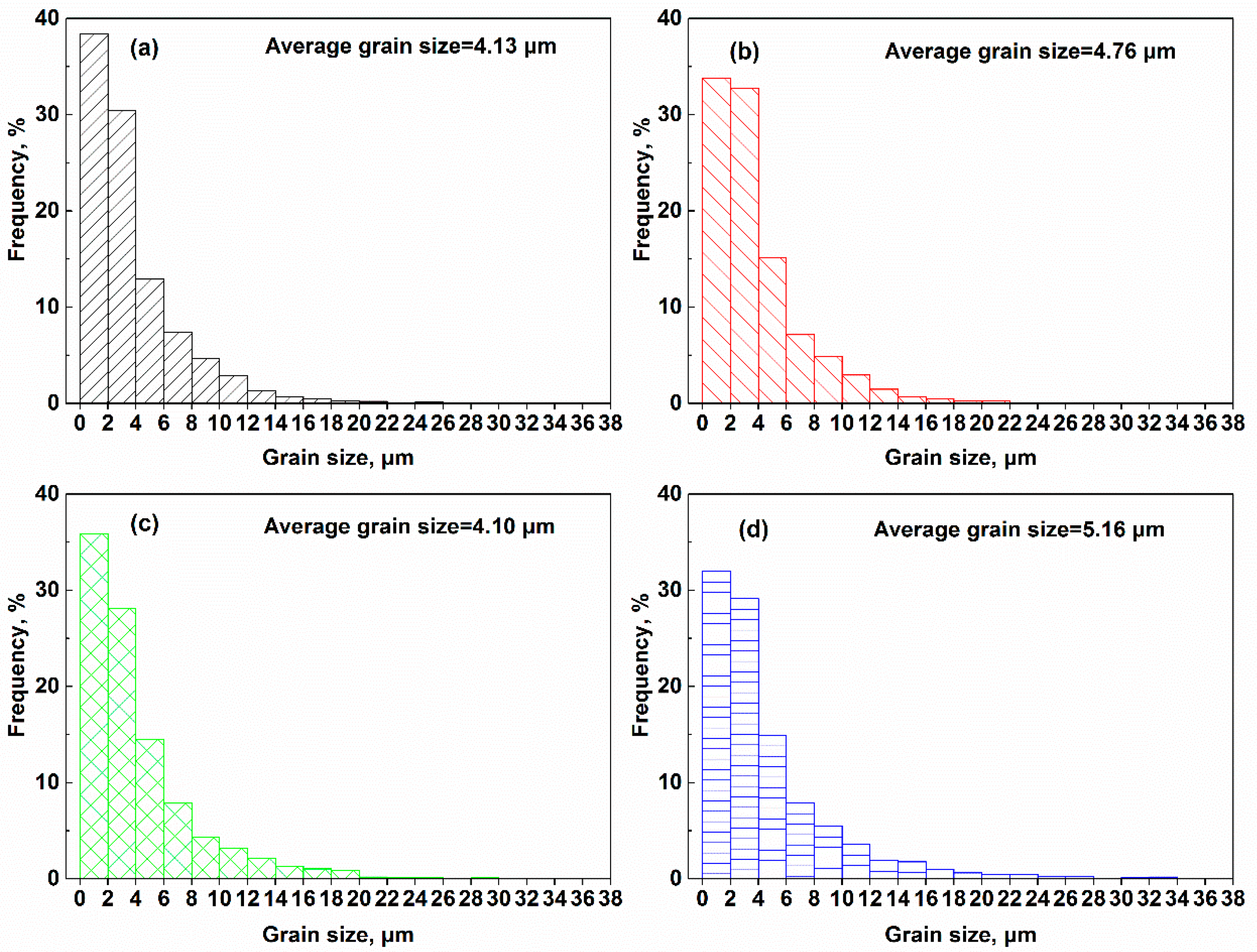

| Samples | Temperature °C | Pressure MPa |

|---|---|---|

| HIP96-1 | 1120 | 150 |

| HIP96-2 | 1170 | 150 |

| HIP96-3 | 1120 | 120 |

| HIP96-4 | 1170 | 120 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, L.; He, G.; Liu, F.; Li, Y.; Jiang, L. Effects of Temperature and Pressure of Hot Isostatic Pressing on the Grain Structure of Powder Metallurgy Superalloy. Materials 2018, 11, 328. https://doi.org/10.3390/ma11020328

Tan L, He G, Liu F, Li Y, Jiang L. Effects of Temperature and Pressure of Hot Isostatic Pressing on the Grain Structure of Powder Metallurgy Superalloy. Materials. 2018; 11(2):328. https://doi.org/10.3390/ma11020328

Chicago/Turabian StyleTan, Liming, Guoai He, Feng Liu, Yunping Li, and Liang Jiang. 2018. "Effects of Temperature and Pressure of Hot Isostatic Pressing on the Grain Structure of Powder Metallurgy Superalloy" Materials 11, no. 2: 328. https://doi.org/10.3390/ma11020328

APA StyleTan, L., He, G., Liu, F., Li, Y., & Jiang, L. (2018). Effects of Temperature and Pressure of Hot Isostatic Pressing on the Grain Structure of Powder Metallurgy Superalloy. Materials, 11(2), 328. https://doi.org/10.3390/ma11020328