Cerium Addition Improved the Dry Sliding Wear Resistance of Surface Welding AZ91 Alloy

Abstract

:1. Introduction

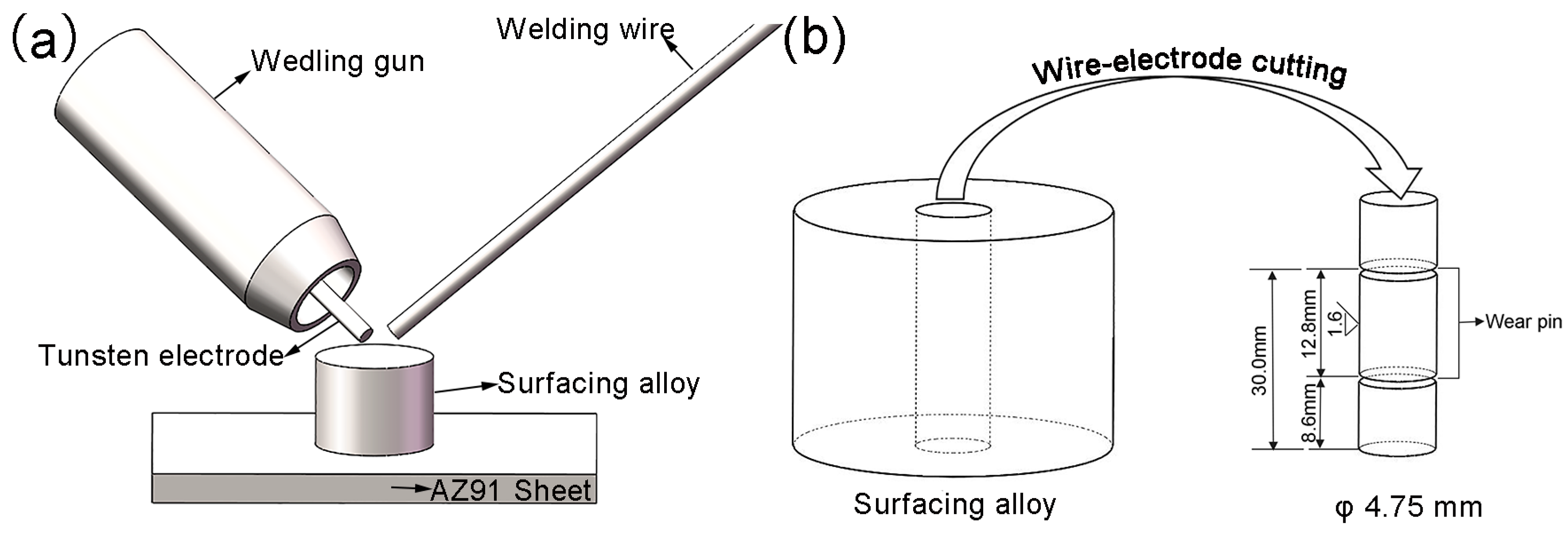

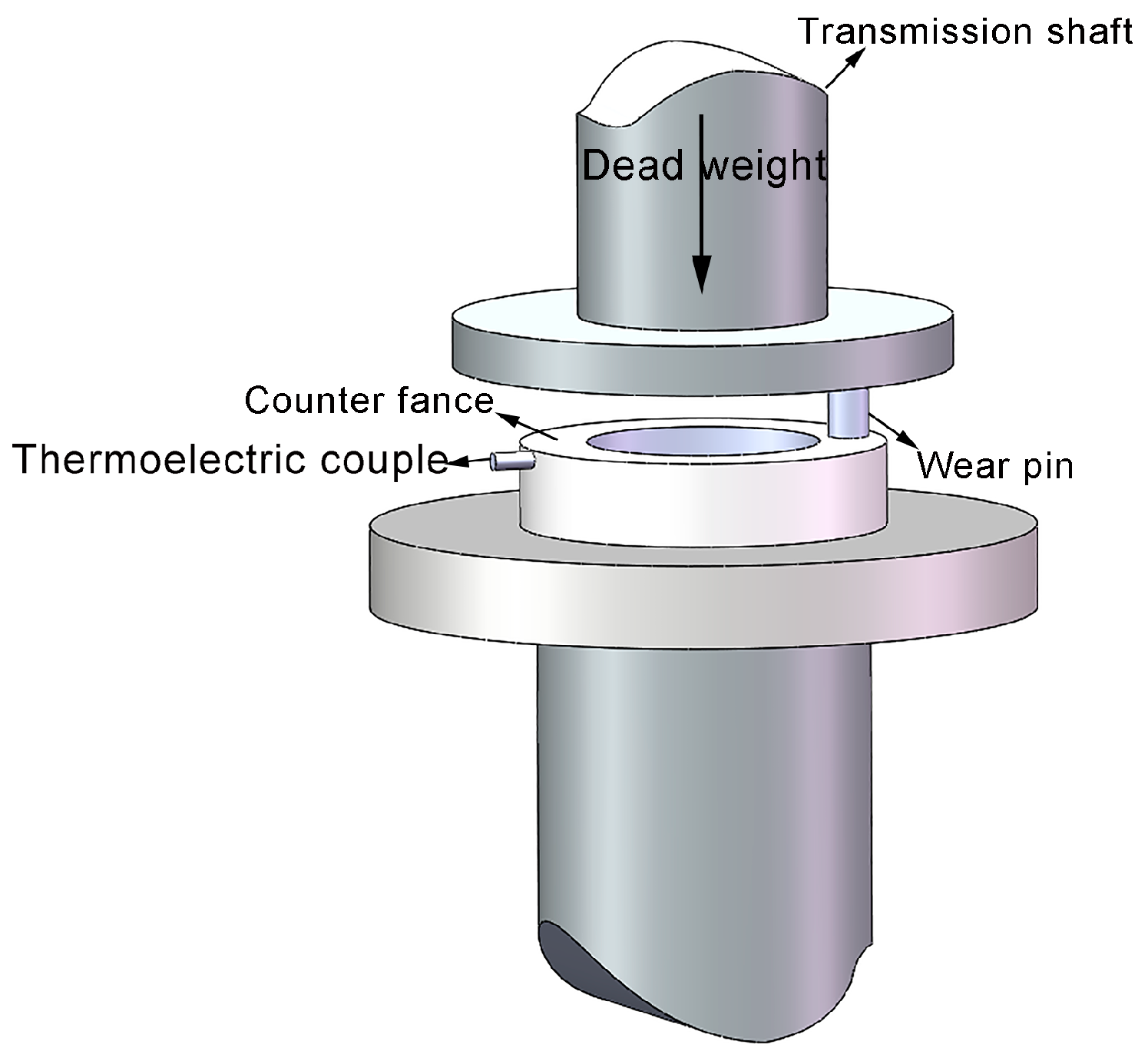

2. Experimental Procedure

3. Results and Discussion

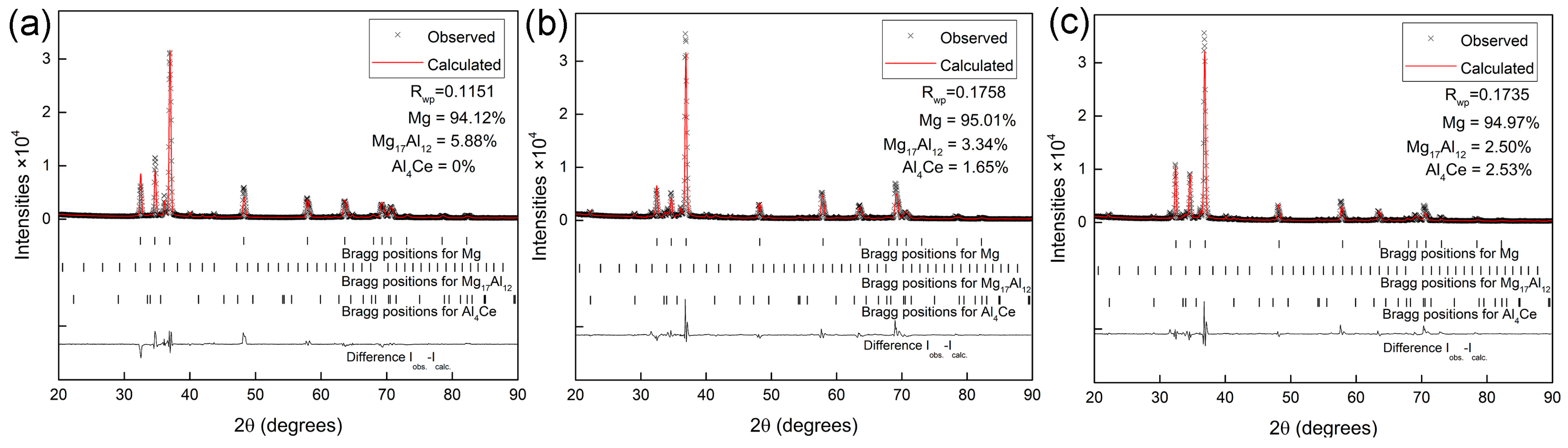

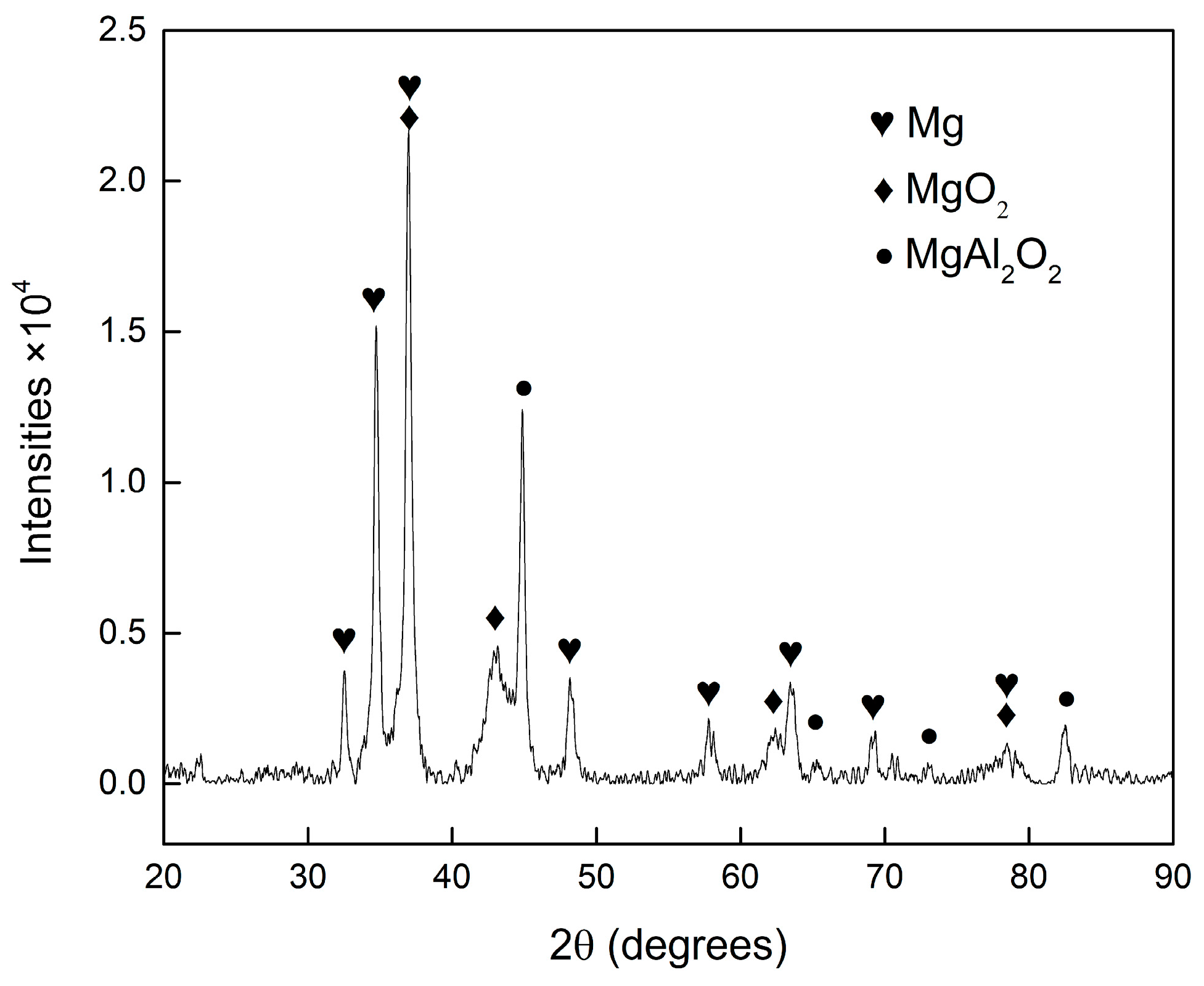

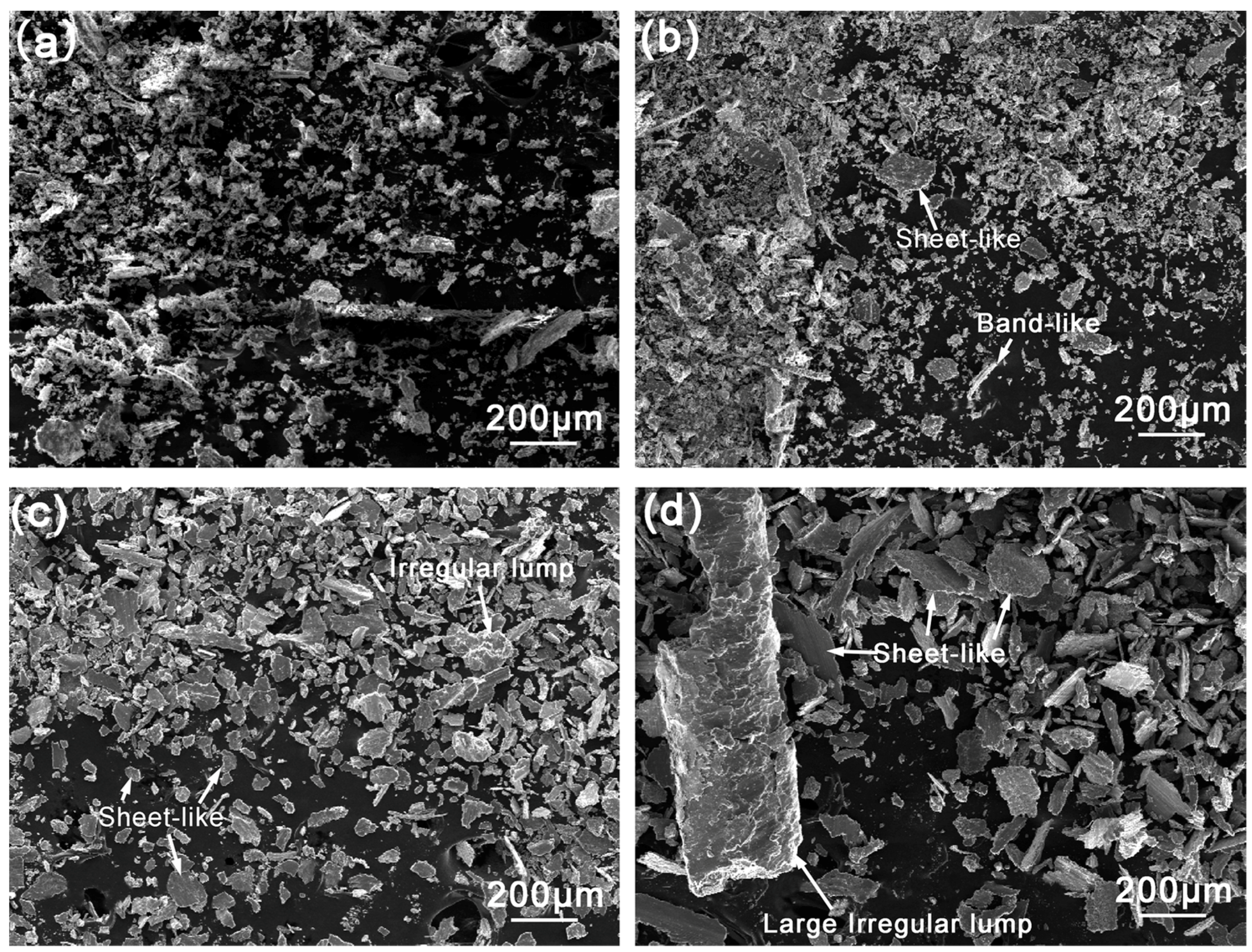

3.1. Composition and Microstructure

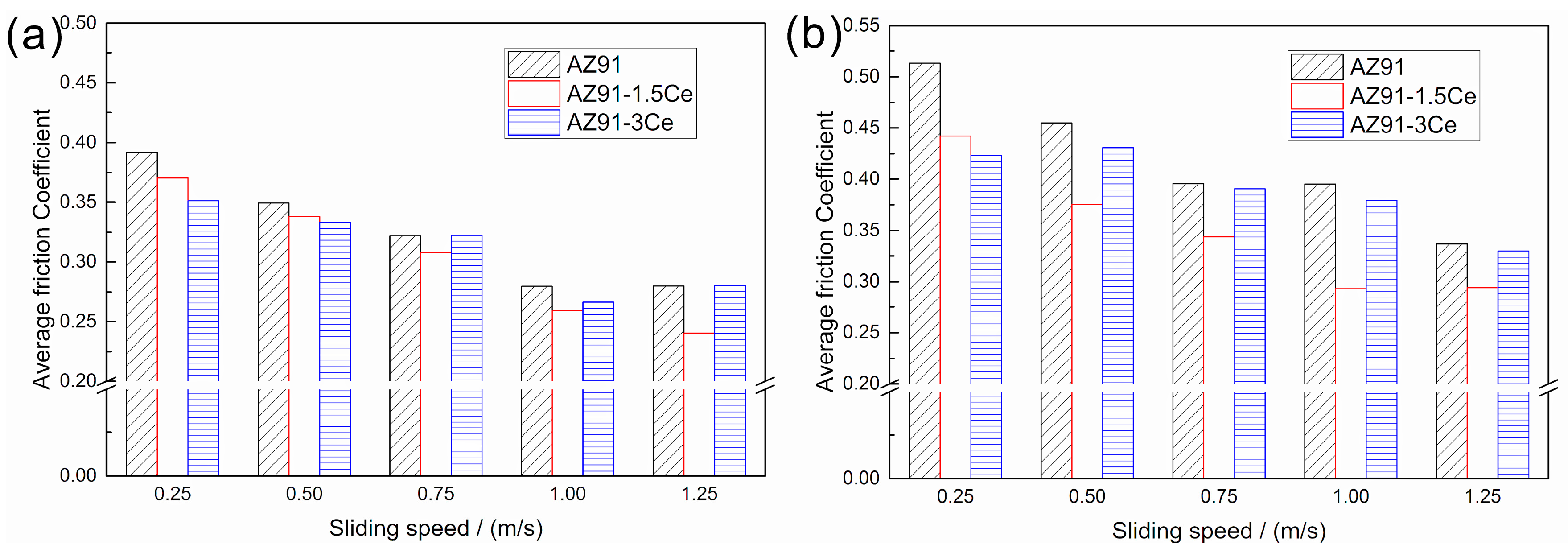

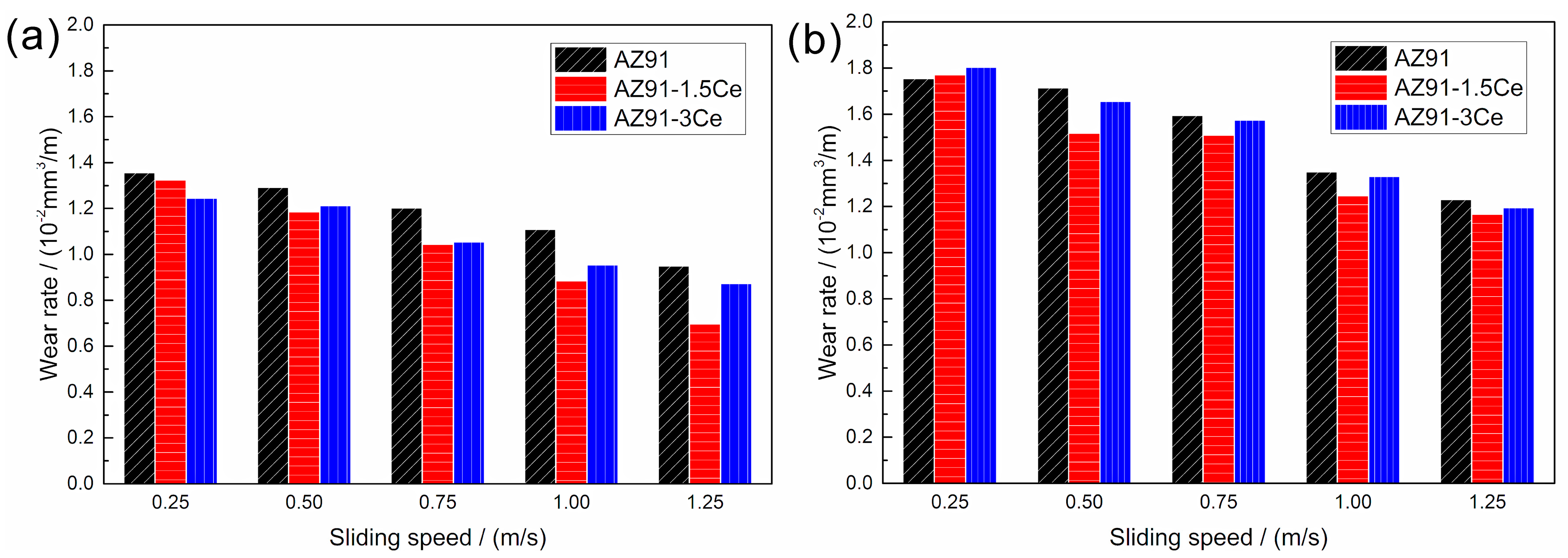

3.2. Friction and Wear Performance

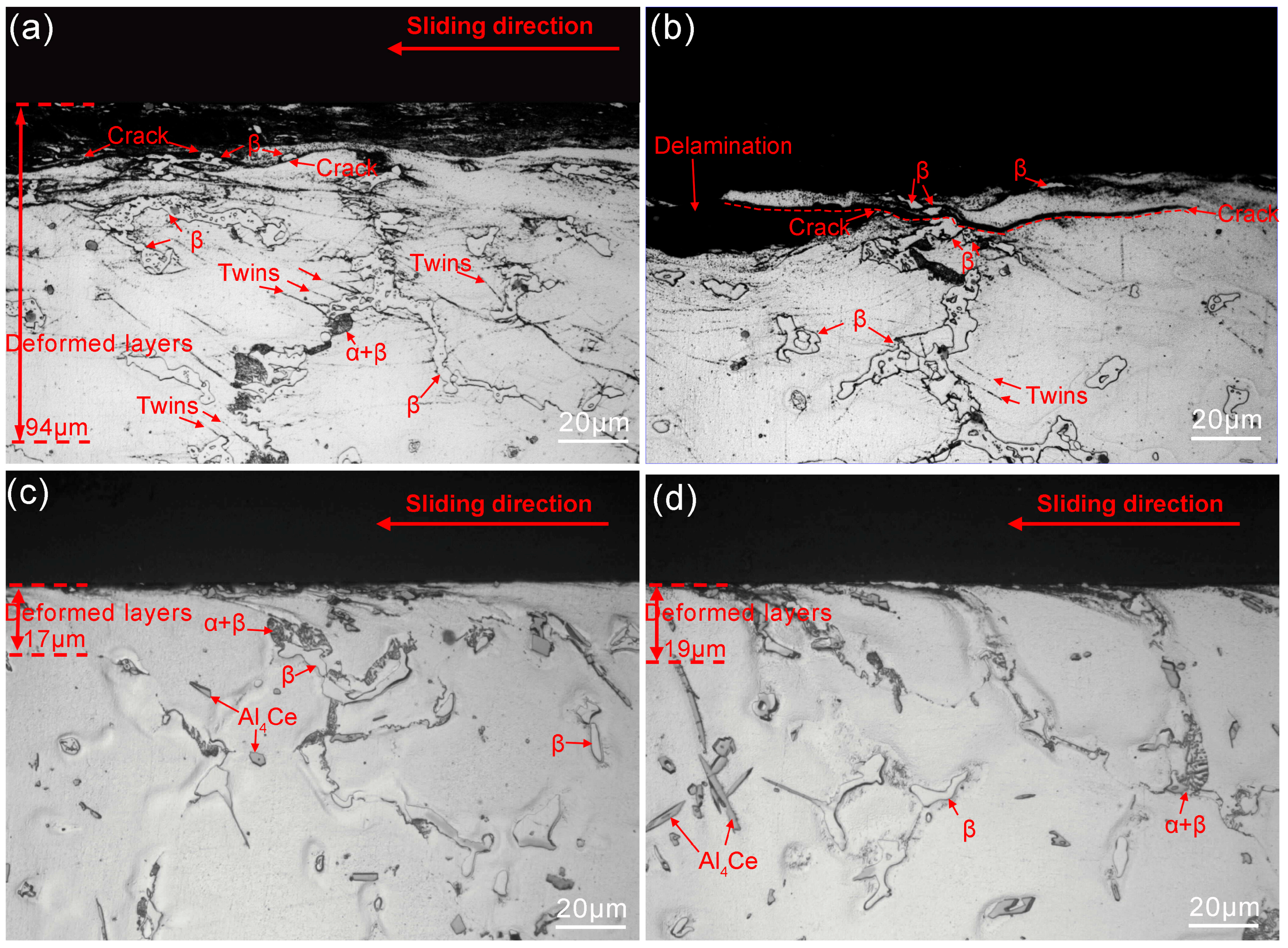

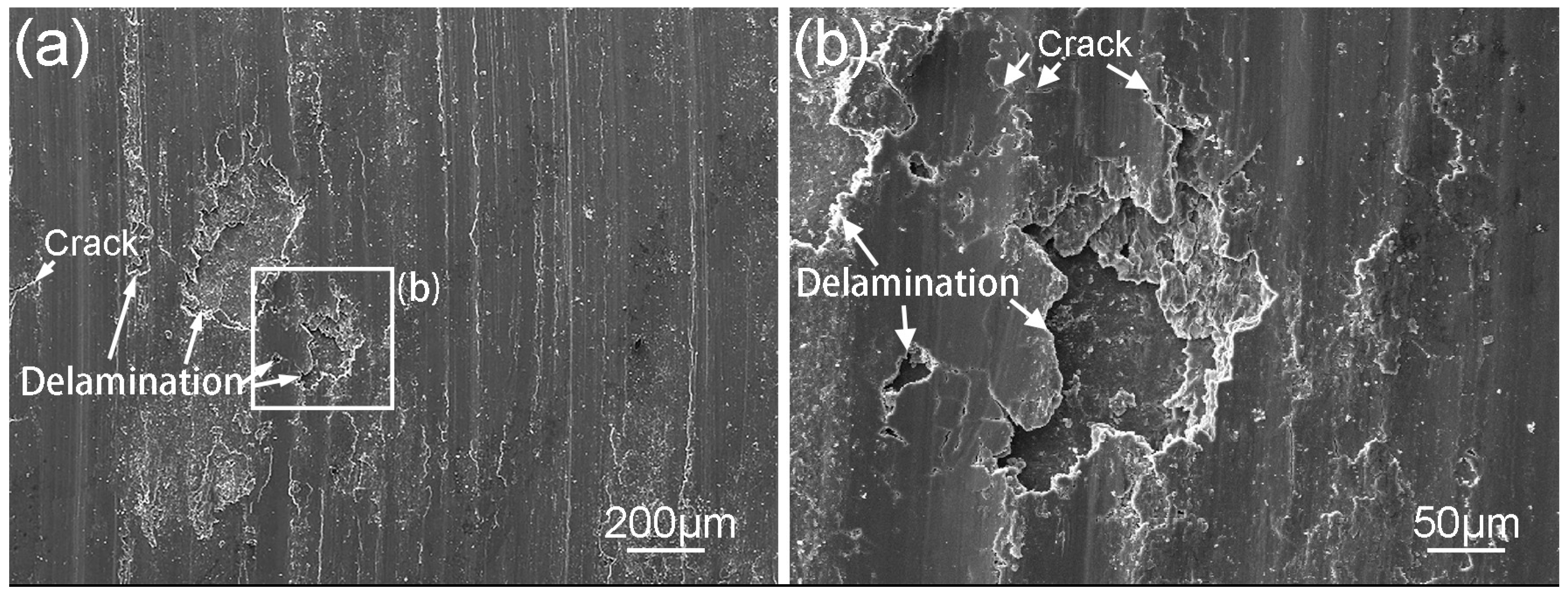

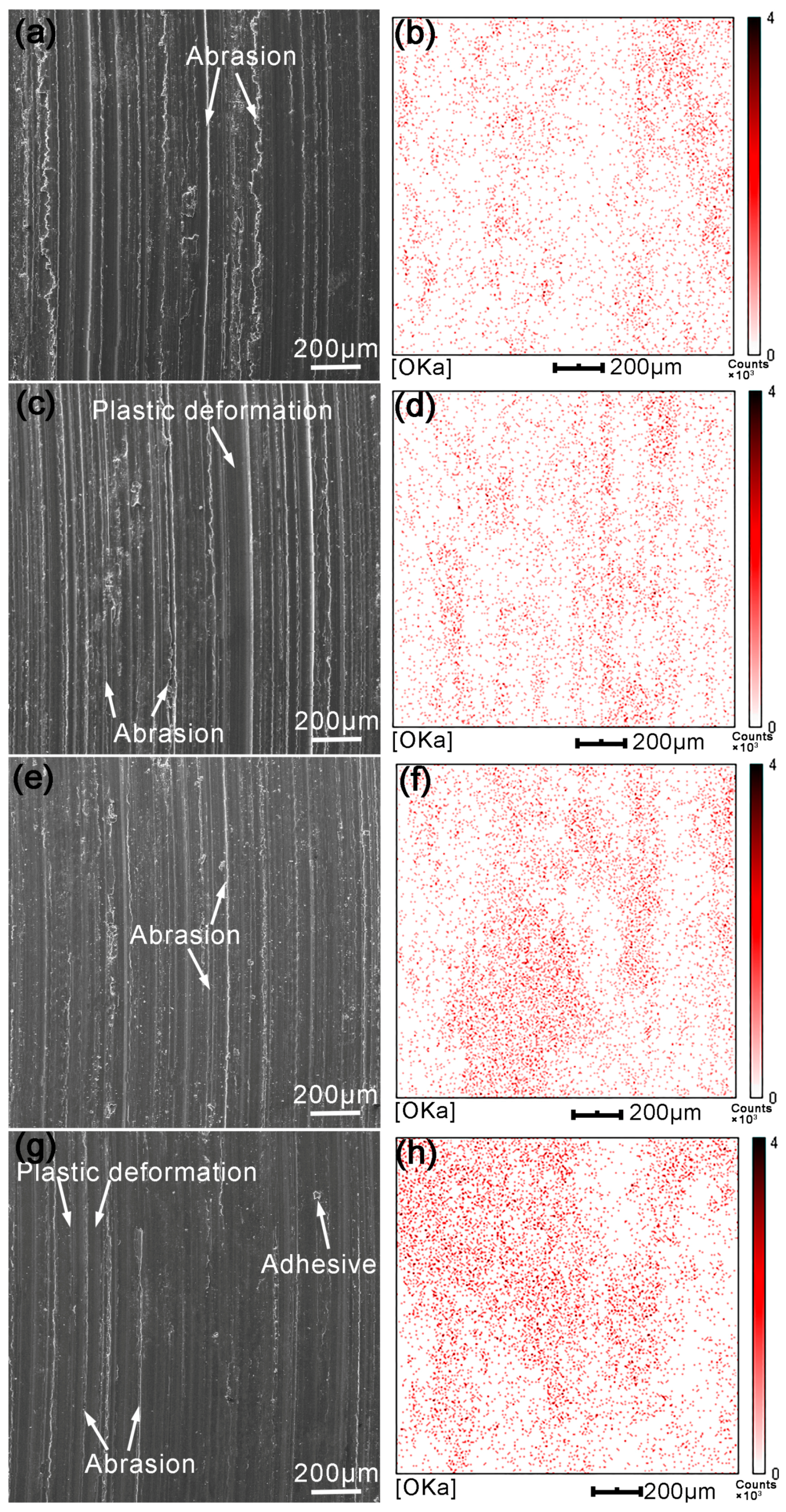

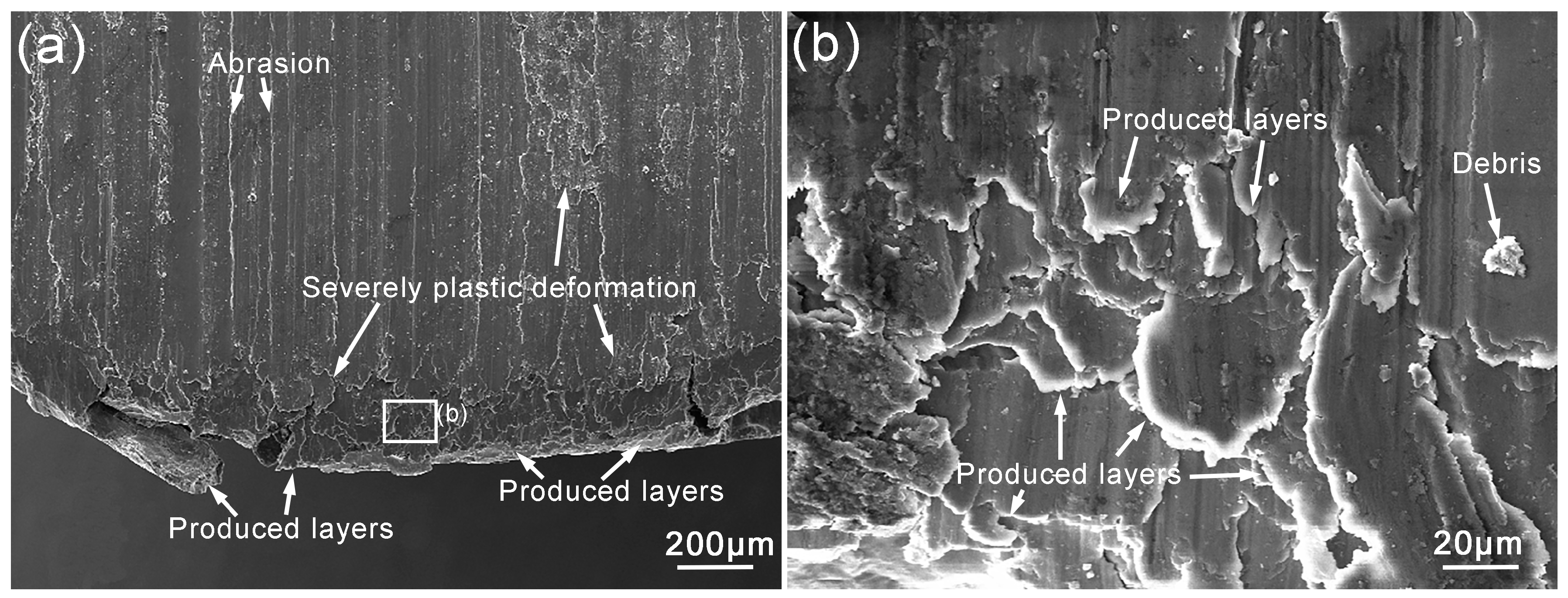

3.3. Wear Mechanism

4. Conclusions

- (1)

- Within the parameter range of our experiment, with the decrease in load and increase in sliding speed, both the friction coefficient and wear rate of three surface welding magnesium alloys with different compositions decreased. When the load was fixed, in the sliding speed range of 0.5–1.25 m/s, the surface welding AZ91 magnesium alloy with 1.5% Ce had the lowest friction coefficient and wear rate.

- (2)

- Within the parameter range of our experiment, four wear mechanisms were observed for the surface welding AZ91 alloy containing 1.5% Ce. Among them, abrasive wear, oxidative wear, and severe plastic deformation were the primary wear mechanisms; delamination wear was the secondary wear mechanism.

- (3)

- The friction and wear of surface welding AZ91 magnesium alloys were mainly related to their microstructures. The addition of rare-earth element Ce to the surface welding AZ91 magnesium alloy facilitated the formation of Al4Ce phase with a higher thermal stability, thus hindering the sliding and migration of grain boundaries and reducing the degree of plastic deformation of subsurface metal during friction. The addition of Ce element also decreased the size and amount of irregularly shaped bulky β-Mg17Al12 phase in the surface welding alloy, thus reducing its adverse effects on the friction and wear of the alloy and improving the wear resistance of magnesium alloys.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pan, H.; Ren, Y.; Fu, H.; Zhao, H.; Wang, L.; Meng, X.; Qin, G. Recent developments in rare-earth free wrought magnesium alloys having high strength: A review. J. Alloys Compd. 2016, 663, 321–331. [Google Scholar] [CrossRef]

- Friedrich, H.; Schumann, S. Research for a “new age of magnesium” in the automotive industry. J. Mater. Process. Technol. 2001, 117, 276–281. [Google Scholar] [CrossRef]

- Song, B.; Wang, C.; Guo, N.; Pan, H.; Xin, R. Improving tensile and compressive properties of an extruded AZ91 rod by the combined use of torsion deformation and aging treatment. Materials 2017, 10, 280. [Google Scholar] [CrossRef] [PubMed]

- Pripanapong, P.; Kariya, S.; Luangvaranunt, T.; Umeda, J.; Tsutsumi, S.; Takahashi, M.; Kondoh, K. Corrosion behavior and strength of dissimilar bonding material between Ti and Mg alloys fabricated by spark plasma sintering. Materials 2016, 9, 665. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Li, C.; Shen, C.D.; Liu, J. Microstructure and micro mechanical property of part formed by gmaw surfacing rapid prototyping. Key Eng. Mater. 2009, 419–420, 853–856. [Google Scholar] [CrossRef]

- Zhu, S.; Wang, Q.W.; Yin, F.L.; Liang, Y.Y.; Chen, L. Influence of alternative magnetic field frequency on microstructure and properties of surfacing welding layer of aluminum alloy. Mater. Sci. Forum 2011, 697–698, 351–355. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Jing, T.; Zhang, L.; Zhang, Y.; Yao, S. Research on material structure integration design of missile magnesium alloy components. J. Proj. Rocket. Missiles Guid. 2013, 33, 46–48. [Google Scholar]

- Champagne, V.K. The repair of magnesium rotorcraft components by cold spray. J. Fail. Anal. Prev. 2008, 8, 164–175. [Google Scholar] [CrossRef]

- Jones, T.L.; Burkins, M.S.; Gooch, W.A. An analysis of magnesium alloy AZ31B-H24 for ballistic applications. In Magnesium Technology; Pekguleryuz, M., Neelameggham, N., Beals, R., Nyberg, E., Eds.; Minerals, Metals & Materials Society: Warrendale, PA, USA; New Orleans, LA, USA, 2008; pp. 81–84. [Google Scholar]

- Yan, H.; Wang, Z. Effect of heat treatment on wear properties of extruded AZ91 alloy treated with yttrium. J. Rare Earths 2016, 34, 308–314. [Google Scholar] [CrossRef]

- Liu, Y.; Jin, B.; Shao, S.; Li, D.; Zeng, X.; Xu, C. Dry sliding wear behavior of Mg-Zn-Gd alloy before and after cryogenic treatment. Tribol. Trans. 2014, 57, 275–282. [Google Scholar] [CrossRef]

- Somekawa, H.; Maeda, S.; Hirayama, T.; Matsuoka, T.; Inoue, T.; Mukai, T. Microstructural evolution during dry wear test in magnesium and Mg–Y alloy. Mater. Sci. Eng. A 2013, 561, 371–377. [Google Scholar] [CrossRef]

- Asl, K.M.; Masoudi, A.; Khomamizadeh, F. The effect of different rare earth elements content on microstructure, mechanical and wear behavior of Mg–Al–Zn alloy. Mater. Sci. Eng. A 2010, 527, 2027–2035. [Google Scholar] [CrossRef]

- Liu, L.; Yuan, F.; Zhao, M.; Gao, C.; Feng, P.; Yang, Y.; Yang, S.; Shuai, C. Rare earth element yttrium modified Mg–Al–Zn alloy: Microstructure, degradation properties and hardness. Materials 2017, 10, 477. [Google Scholar] [CrossRef] [PubMed]

- Rietveld, H.M. A profile refinement method for nuclear and magnetic structures. J. Appl. Crystallogr. 1969, 2, 65–71. [Google Scholar] [CrossRef]

- Toby, B.H. EXPGUI, a graphical user interface for GSAS. J. Appl. Crystallogr. 2001, 34, 210–213. [Google Scholar] [CrossRef]

- Chye, L.T.; Zamzuri, M.Z.M.; Norbahiyah, S.; Ismail, K.A.; Derman, M.N.B.; Illias, S. Effect of heat treatment on microstructure and corrosion behavior of AZ91D magnesium alloy. Adv. Mater. Res. 2013, 685, 102–106. [Google Scholar] [CrossRef]

- Luong, D.D.; Shunmugasamy, V.C.; Cox, J.; Gupta, N.; Rohatgi, P.K. Heat treatment of AZ91D Mg–Al–Zn alloy: Microstructural evolution and dynamic response. JOM 2013, 66, 312–321. [Google Scholar] [CrossRef]

- Tkacz, J.; Minda, J.; Fintova, S.; Wasserbauer, J. Comparison of electrochemical methods for the evaluation of cast AZ91 magnesium alloy. Materials 2016, 9, 925. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Wang, Q.; Wu, Y.; Ye, B. Friction and wear behavior of Mg–11Y–5Gd–2Zn–0.5Zr (wt %) alloy with oil lubricant. Rare Met. 2013, 32, 453–458. [Google Scholar] [CrossRef]

- Zafari, A.; Ghasemi, H.M.; Mahmudi, R. Tribological behavior of AZ91D magnesium alloy at elevated temperatures. Wear 2012, 292–293, 33–40. [Google Scholar] [CrossRef]

- Ramezani, M.; Ripin, Z.M. A friction model for dry contacts during metal-forming processes. Int. J. Adv. Manuf. Technol. 2010, 51, 93–102. [Google Scholar] [CrossRef]

- Hu, M.; Wang, Q.; Li, C.; Ding, W. Dry sliding wear behavior of cast Mg–11Y–5Gd–2Zn magnesium alloy. Trans. Nonferrous Met. Soc. China 2012, 22, 1918–1923. [Google Scholar] [CrossRef]

- Aung, N.N.; Zhou, W.; Lim, L.E.N. Wear behaviour of AZ91D alloy at low sliding speeds. Wear 2008, 265, 780–786. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Feng, A.H.; Ma, Z.Y. Enhanced mechanical properties of Mg–Al–Zn cast alloy via friction stir processing. Scr. Mater. 2007, 56, 397–400. [Google Scholar] [CrossRef]

- Lit, Y.Z.; Wang, Q.D.; Ding, W.J.; Zeng, X.Q.; Zhu, Y.P. Fracture behavior of AZ91 magnesium alloy. Mater. Lett. 2000, 44, 265–268. [Google Scholar] [CrossRef]

- Chen, Q.; Li, K.; Liu, Y.; Zhao, Z.; Tao, K.; Zhu, Q. Effects of heat treatment on the wear behavior of surfacing AZ91 magnesium alloy. J. Mater. Res. 2017, 32, 2161–2168. [Google Scholar] [CrossRef]

- Min, X.G.; Du, W.W.; Xue, F.; Sun, Y.S. Analysis of EET on Ca increasing the melting point of Mg17Al12 phase. Chin. Sci. Bull. 2002, 47, 1082–1086. [Google Scholar] [CrossRef]

- Yang, X.; Hou, H.; Zhao, Y.; Yang, L.; Han, P. First-principles study of structural stabilities and elastic properties of Mg17Al12, Al2Y and Al2Ca phases. Rare Met. Mater. Eng. 2014, 43, 875–880. [Google Scholar]

- Zhou, D.; Peng, P.; Zhuang, H.; Hu, Y.; Liu, J. First-principle study on structural stability of Ca alloying Mg17Al12 phase. Chin. J. Nonferrous Met. 2005, 15, 546–551. [Google Scholar]

| Sample | Al | Zn | Mn | Ce | Fe | Si | Ni | Cu | Mg |

|---|---|---|---|---|---|---|---|---|---|

| AZ91 | 8.64 | 0.90 | 0.28 | — | 0.0051 | 0.0140 | 0.0057 | ≤0.0020 | Bal. |

| AZ91 + 1.5Ce | 8.83 | 0.89 | 0.22 | 1.40 | 0.0055 | 0.0125 | 0.0065 | ≤0.0020 | Bal. |

| AZ91 + 3Ce | 8.66 | 0.82 | 0.30 | 3.05 | 0.0050 | 0.0135 | 0.0085 | ≤0.0020 | Bal. |

| Basic metal | 8.95 | 0.71 | 0.33 | — | 0.0169 | 0.0107 | 0.0051 | ≤0.0020 | Bal. |

| Alloy | Macrohardness HV |

|---|---|

| Surfacing AZ91 alloy | 69.0 ± 2.1 |

| Surfacing AZ91 alloy with 1.5%Ce | 63.7 ± 1.7 |

| Surfacing AZ91 alloy with 3%Ce | 59.1 ± 1.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Q.; Zhao, Z.; Zhu, Q.; Wang, G.; Tao, K. Cerium Addition Improved the Dry Sliding Wear Resistance of Surface Welding AZ91 Alloy. Materials 2018, 11, 250. https://doi.org/10.3390/ma11020250

Chen Q, Zhao Z, Zhu Q, Wang G, Tao K. Cerium Addition Improved the Dry Sliding Wear Resistance of Surface Welding AZ91 Alloy. Materials. 2018; 11(2):250. https://doi.org/10.3390/ma11020250

Chicago/Turabian StyleChen, Qingqiang, Zhihao Zhao, Qingfeng Zhu, Gaosong Wang, and Kai Tao. 2018. "Cerium Addition Improved the Dry Sliding Wear Resistance of Surface Welding AZ91 Alloy" Materials 11, no. 2: 250. https://doi.org/10.3390/ma11020250

APA StyleChen, Q., Zhao, Z., Zhu, Q., Wang, G., & Tao, K. (2018). Cerium Addition Improved the Dry Sliding Wear Resistance of Surface Welding AZ91 Alloy. Materials, 11(2), 250. https://doi.org/10.3390/ma11020250