3.2. Orthogonal Analysis

To reduce the fitting time and evaluate the computation results, an effective design method is needed [

23]. Several different factors and levels need to be considered when optimizing the parameters during the clinching joint. The purpose of the optimization of parameters during the clinched joint is to get the damage parameters of the Rousselier damage model. Orthogonal design is a kind of design method that is mainly used to study multiple factors and multiple levels. This design method is uniformly dispersed, neat, and comparable, making each design highly representative. The selection of the representative points from the comprehensive design can fully reflect the impact of different levels of each factor on the design result that takes less time. Oudjene and Ben-Ayed [

24] used the Taguchi’s experiment design method that is used to investigate the effects of geometry tools on the clinch joint resistance as well as on its shape. Chen [

25] designed a plan to optimize the shape of the rivet to reduce the protrusion height and increase the strength of clinched joint. Wen [

26] presented a response surface optimization of the clinching tools.

During the clinched process, the clinched joints with fracture zone in the groove of the clinched joint are obtained. The previous research mainly discussed how to get some qualified samples to avoid the failure samples. In the discussion, some ideas are discussed. A lot of experiments show that the surface stage will affect the quality of the clinched joint; thus, in our research, the grease is used to avoid the damage that comes from the surface stage. The friction between tools and sheets slightly influences the intensity of the punch force and the distribution of deformation between the upper and lower sheets. This tendency is even greater with respect to metal hardening.

Since the fracture just happened, in the groove of the clinched joint during the clinched process, it must be ensured that there will be no cracks in the neck of the clinched joint. In the paper by Xu [

8], the clinched joint is divided into four parts, including no deformation zone, tensile deformation zone, shear deformation, and bending deformation zone. Zhao [

9] presented that the shear damage will happen in the neck of the clinching joint. Therefore, the assumption is that the shear deformation region check the shear damage parameter

and the tensile deformation region and validate the initial void volume fraction

has been made. In other words, the shear damage parameter

and the initial void volume fraction

affect the quality of the clinched joint. The purpose functions are

,

, and

. The function

expresses the void volume fraction when crack happens in the neck of the clinched joint, whereas

expresses the void volume fraction when crack happens in the groove of the clinched joint. The function

expresses the deformed force from the experimental results when the bottom thickness of the clinched joint is 0.56 mm.

Several factors and levels have been investigated. In order to facilitate research, it need to construct a suitable orthogonal table [

23]. In

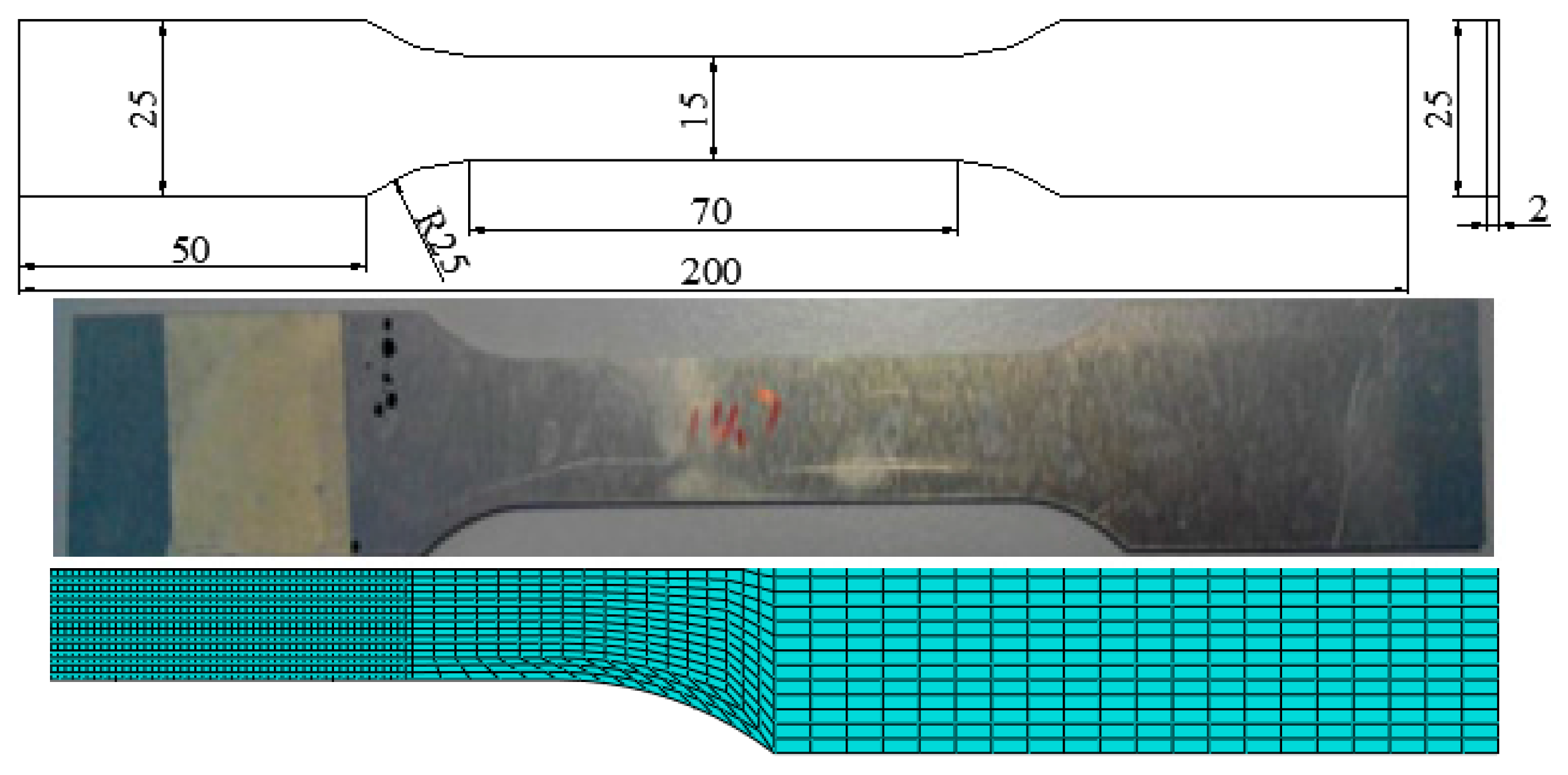

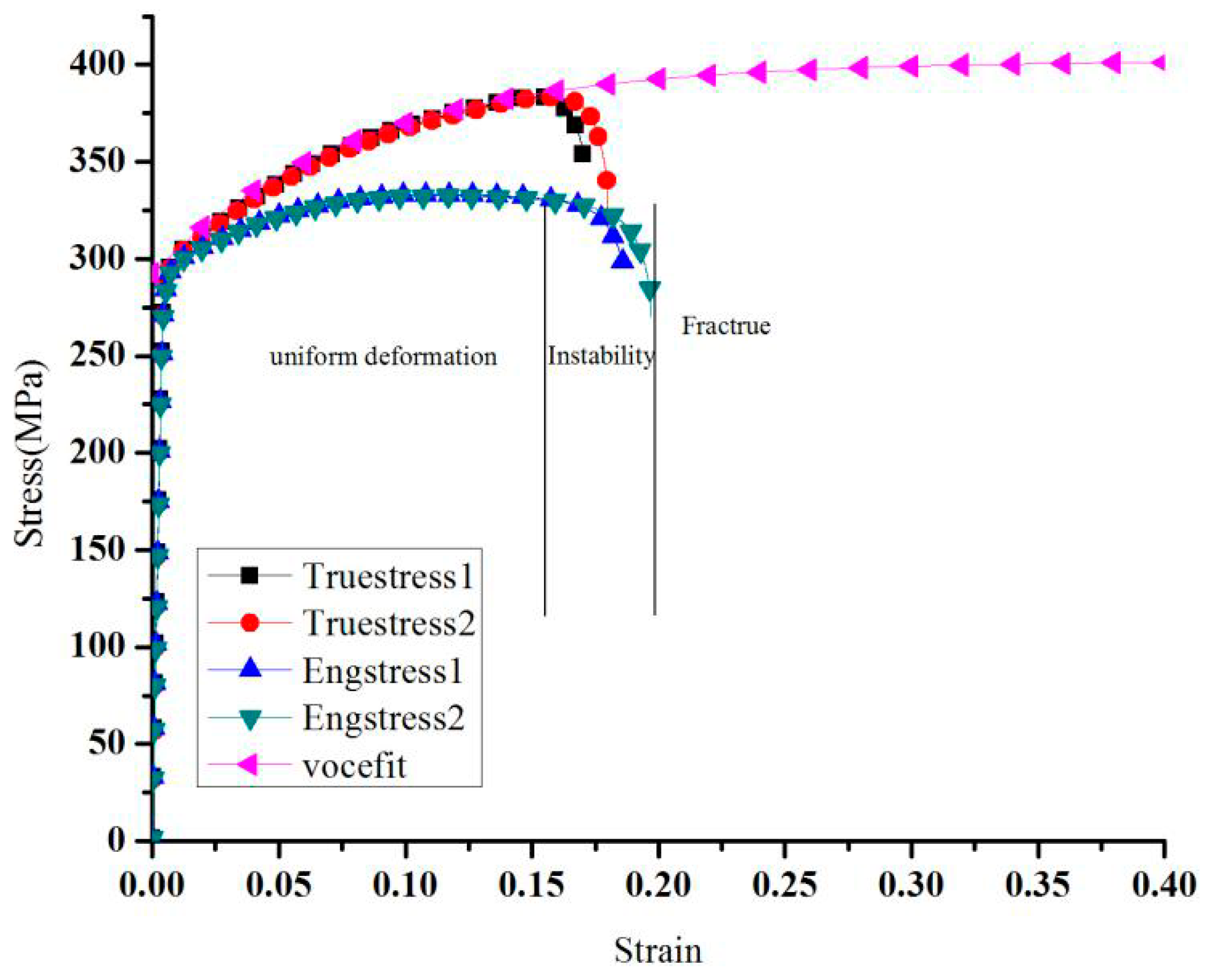

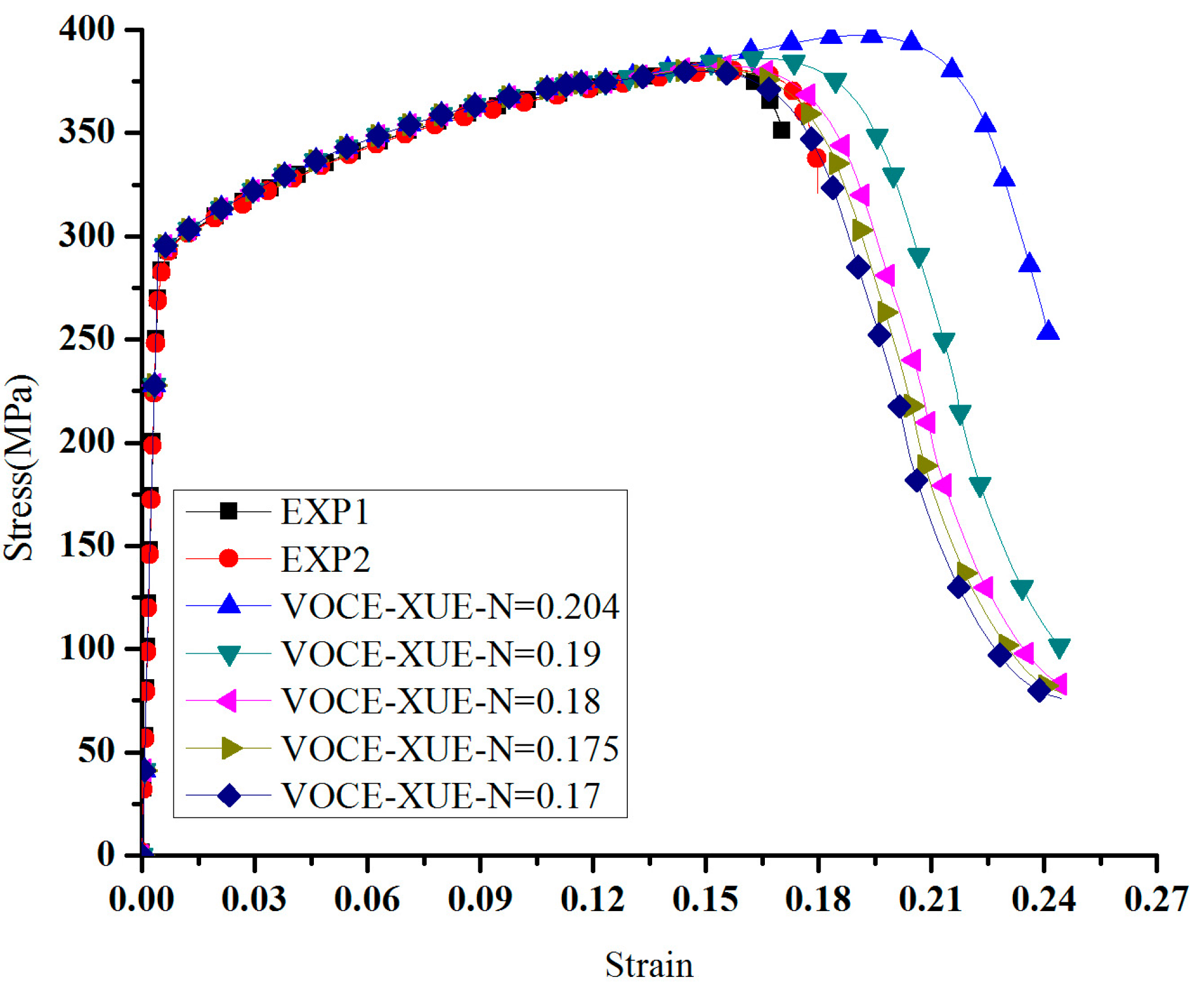

Section 2, it introduces the function of the void volume fraction and discusses the relationship between the shear damage parameter and the initial void volume fraction. It has explained that the shear damage parameter and the initial void volume fraction, they are independent parameters. In this paper, the relationship between shear damage parameter and the initial void volume fraction is ignored. The suitable level range will reduce the number of optimization design. Therefore, before the orthogonal analysis, it is necessary to predict the shear damage parameter and the initial void volume fraction, that is, use the specimen shown in

Figure 1 to determine a rough range. Finally, six five-level factors are contained in the orthogonal array used for the optimization of parameters during the clinched process as presented in

Table 2 (L25(5

6)). These factors are more helpful in getting the suitable damage parameters during the clinching process. Commonly, lubricant is used between punch and upper sheet, so

is equal to 0. The critical void volume fraction is equal to 0.2 [

27]. In fact, four parameters,

,

,

, and

need be calibrated by this method.

and

are regarded as fixed constants. Then a group of 25 different parameter combinations should be simulated to find the optimal the damage parameters and the state parameters according to the orthogonal array as shown in

Table 3A–F represent the friction coefficient between punch and the upper sheet

, the friction coefficient between the upper sheet and the under sheet

, the friction coefficient between the die and the under sheet

, the shear damage parameter

, the initial void volume fraction

, the critical void volume fraction

, respectively.

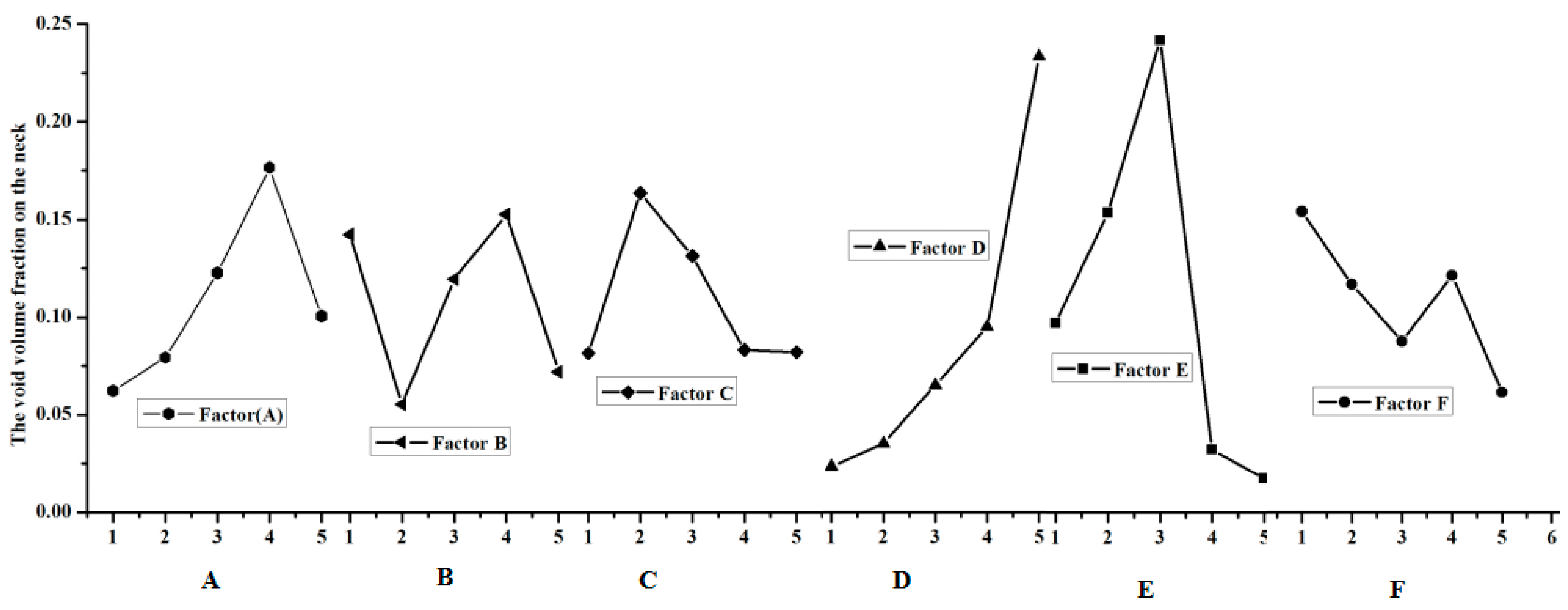

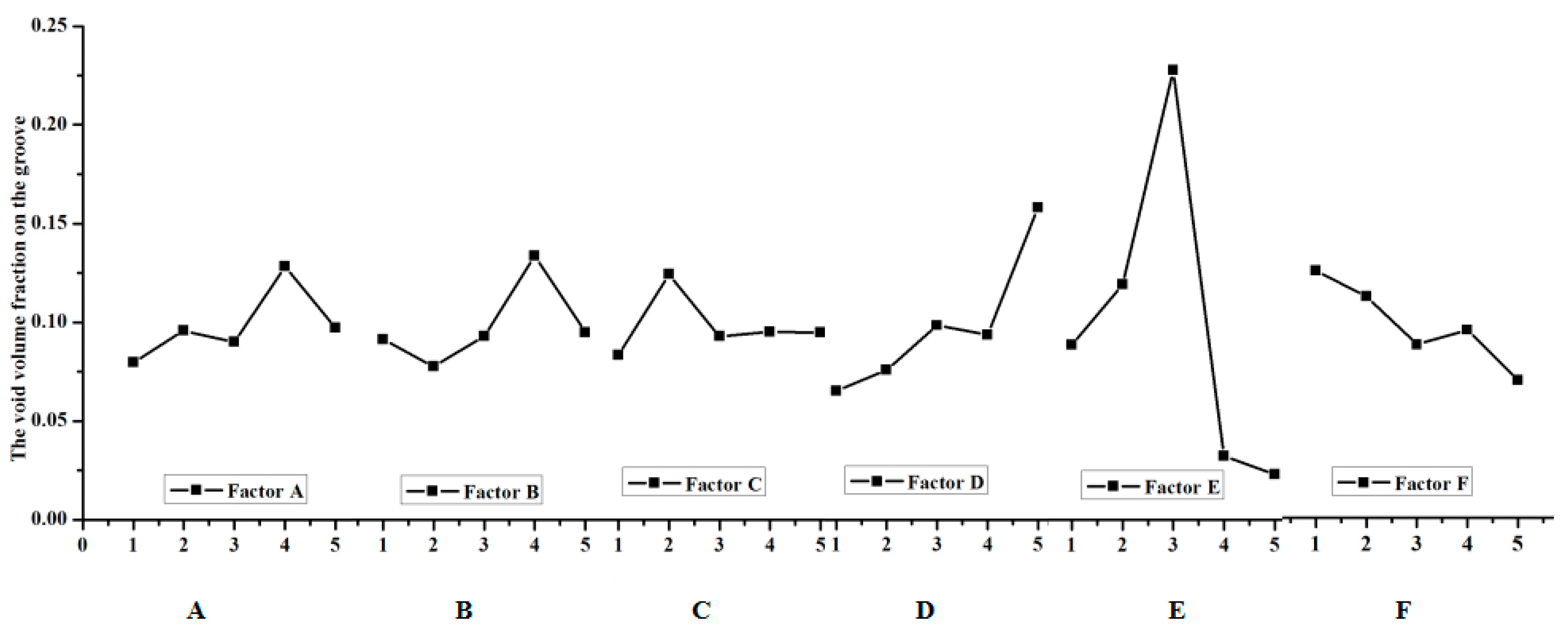

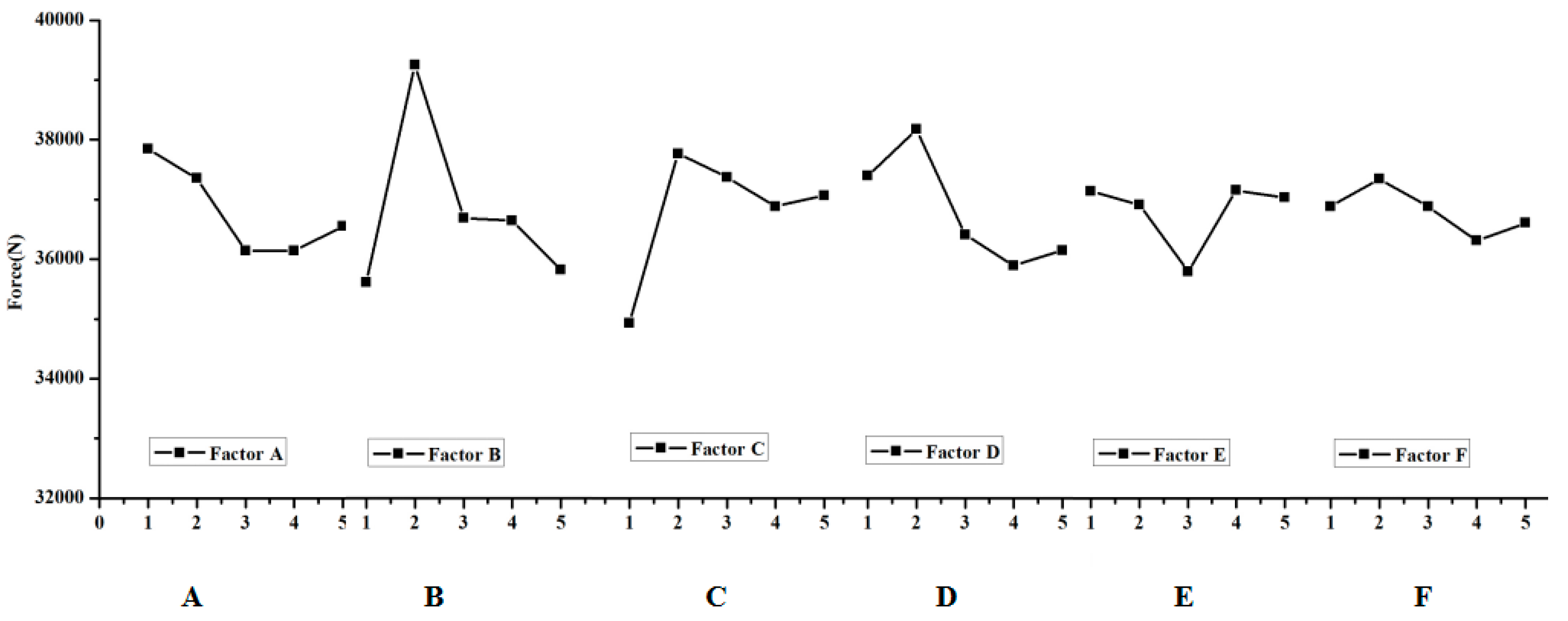

The extent of the effect in the void volume fraction during the clinching process should be investigate; in other words, a method should be developed on how to get the crack that happens in the groove of the clinched joint. The range analysis was made according to the results of the numerical simulation. The data of the range analysis are shown in

Table 4,

Table 5 and

Table 6. The effect curves of the parameters are shown in

Figure 5,

Figure 6 and

Figure 7.

The most important factor that affects the fracture location in the neck of the clinching joint is shown in

Table 4. K

a expresses the sum of test indicators (a expresses level (1, 2, 3, 4, 5)), i expresses level (1, 2, 3, 4, 5), j expresses factor (A, B, C, D, E, F), k

ij is equal to K

ij divided by 5, rank is equal to the maximum (k

ij) minus the minimum (k

ij).

Table 4 shows thatextreme difference analysis for the void volume fraction on the neck of the clinched joint. Factor D has an influence on the void volume fraction

on the neck of the clinched joint. D expresses the shear damage parameter

. The previous research shows that the shear stress leads to the failure on the neck of the clinched joint. Thus, the orthogonal analysis method can describe the trend.

Table 4 shows that the shear damage parameter

has a great influence on the void volume on the neck of the clinched joint; simultaneously, the initial void volume fraction

also influences the void volume fraction

on the neck of the clinched joint. The shear damage parameter

is the one of the most important factors on the neck of the clinched joint. Except on the shear damage parameter

and the initial void volume fraction

, the shear damage parameter

also has an impact on other factors.

Table 5 shows that the initial void volume

has a signification influence on the void volume fraction

on the groove of the clinched joint.

Table 6 shows that the coefficient friction

between the two sheets is one of the most important factors on the force

. The extent in which the factors affect the deform force

is shown in

Figure 6, and the effect curves of the factors are also shown in

Figure 6. The final optimized results cannot be obtained through extreme difference analysis because the orthogonal analysis’ maximum or minimum value is not a subject value. The orthogonal analysis was used to get the influence trend of the void volume fraction on the different deformation regions (neck and grove regions). The initial void volume fraction

and the shear damage parameter

also obviously affect the void volume fraction

on the neck of the clinched joint (

Figure 5 and

Table 4). During the simulation process, the initial void volume fraction

and the shear damage parameter

must be controlled to ensure that there will be an absence of cracks in the neck of the clinched joint. Apparently, the initial void volume fraction

affected the void volume fraction

distribution in the groove of the clinched joint as shown in

Figure 6 and

Table 5. Simultaneously, the factor that influences the deform force is known.

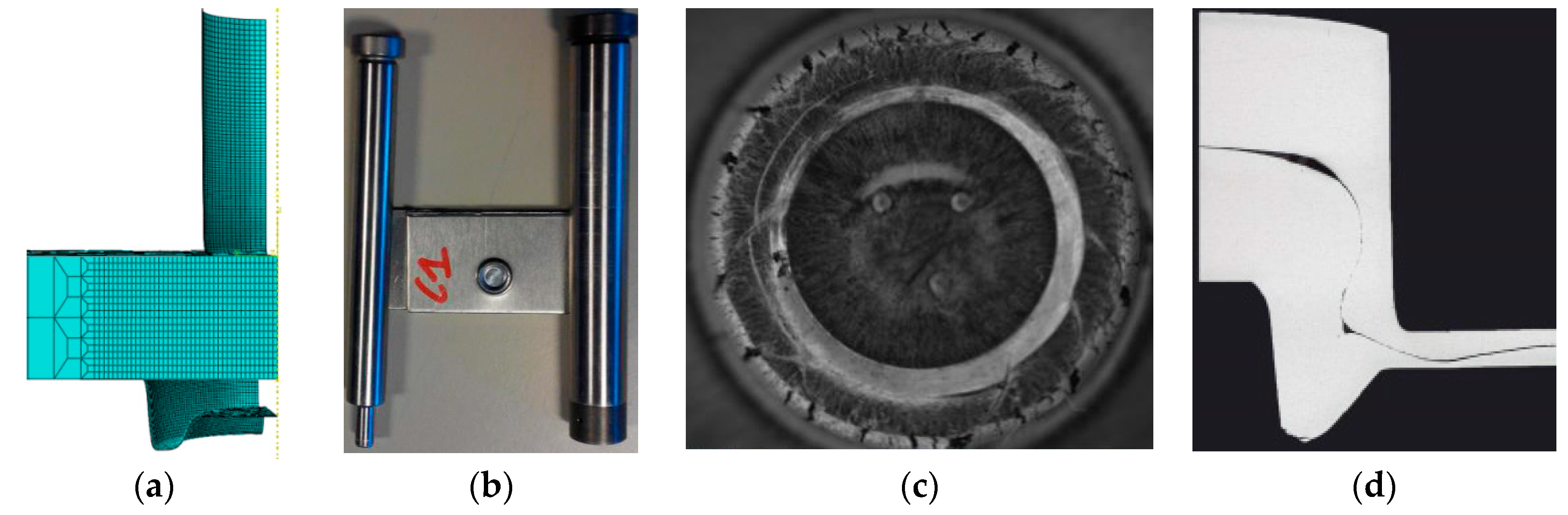

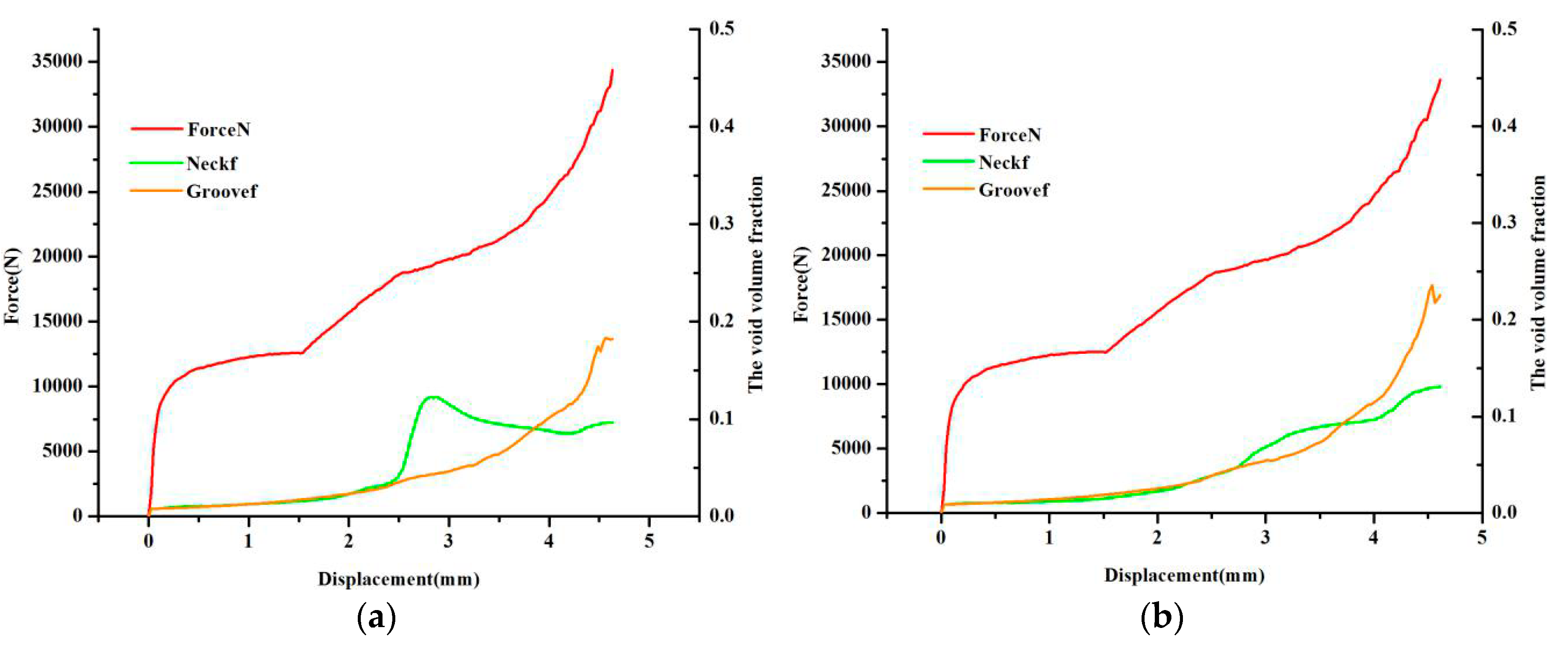

Unlike other studies, in this paper, the orthogonal analysis method was used, but the subject function cannot be considered as the final result. The maximum or minimum value can evaluate the influence trend, but it cannot be considered as the final result. The aim of the paper is to discuss the calibration of the damage parameters for AA6082-T6 sheet with a thickness of 2 mm by the clinching process according to the fracture location. After 25 simulation results, it is easy to find that the simulation of No.10 is close to the experimental result. However, as shown in

Figure 8a, no fracture happens in the neck and the groove of the clinched joint. Apparently, the void volume fraction

in the groove of the clinched joint is close to 0.2, whereas the void volume fraction

in the neck of the clinched joint is almost close to 0.1. The subject stage is the fracture in the groove of the clinched joint; thus, according to the above analysis, an investigation must be conducted if the initial void volume fraction meets the fracture location. The second optimized result was shown in

Table 7.

Compared with the two group parameters as shown in

Figure 8, the fracture obviously happens in the groove of the clinched joint, but in the neck of the clinched joint, as shown in

Figure 8b, there was no crack that was observed anywhere because the void volume fraction

is smaller than the critical void volume fraction

when the initial void volume fraction

is 0.009. Evolution of the damage at the neck of the clinched joint, shear damage parameter

, and the initial void volume fraction

lead to the damage. In the groove of the clinched joint, the initial void volume fraction

leads to the fracture. If the shear damage parameter

was not discussed, the shear stress in the neck of the clinched joint will be neglected. That means an important factor can be ignored, and then there is a greater difference between the simulation results and the experiment results. It was observed that the void volume fraction of tracked nodes normally ranged from 0.001 to 0.01. The shear damage parameter

normally ranged from 0.5 to 1.

The simulation result for the damage parameter of the initial void volume fraction

distribution on the clinched joint is shown in

Figure 9. The maximum value of SDV16 (the void volume fraction) is shown in the groove of the clinched joint. Compared with the experimental results, the fracture that happens in the groove of the clinched joint is obviously noted. Thus, this model is known to describe the failure location; in other words, these damage parameters can accurately describe the performance of the AA6082 sheet with a thickness of 2 mm during the clinched process.

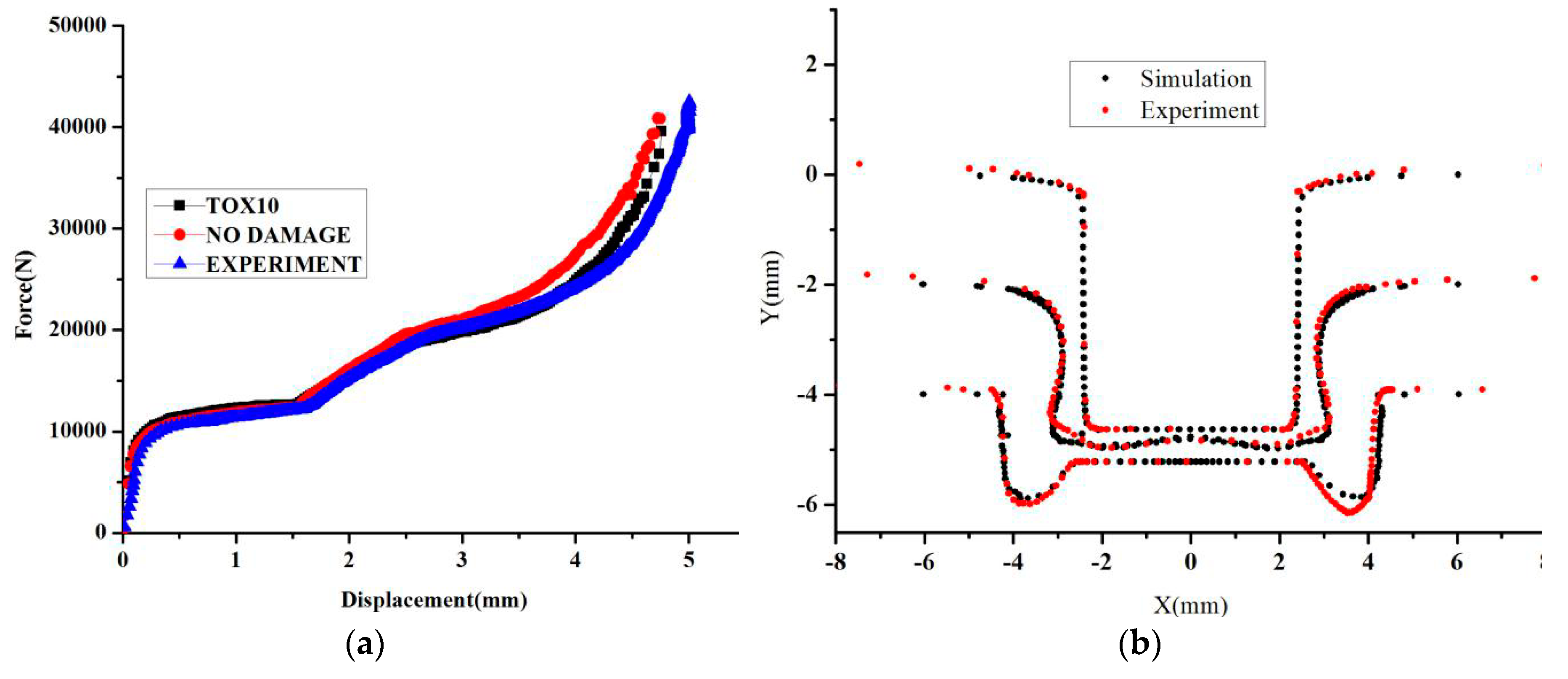

Figure 10 shows that the displacement-force curve and the shape of the clinched joint is shown in

Figure 10. The comparison experiment results and simulation results, including undamaged model and Rousselier damage model, are shown in

Figure 10a. The undamaged model was used to describe the clinching process, and a larger difference between the simulation results and the experiment results is noted. When the Rousselier damage model was used to describe the clinching process, a good consistency was shown in

Figure 10a. Therefore, this model is suitable for describing the clinching process and explaining the performance of the AA6082-T6 sheet with 2 mm thickness. In

Figure 10b, the shape from simulation is known to be in accordance with the shape from the experiment. In summary, this model can describe the clinching process, including the force-displacement curve, the crack location, and the clinched joint shape. Thus, the orthogonal analysis method is also shown to obtain the suitable damage parameters, and the damage parameters can be obtained by the clinching process.