Relationship between the Size of the Samples and the Interpretation of the Mercury Intrusion Results of an Artificial Sandstone

Abstract

:1. Introduction

2. Sample Preparation and Derivation of Digital Microstructures

2.1. Materials and Sample Preparation

- -

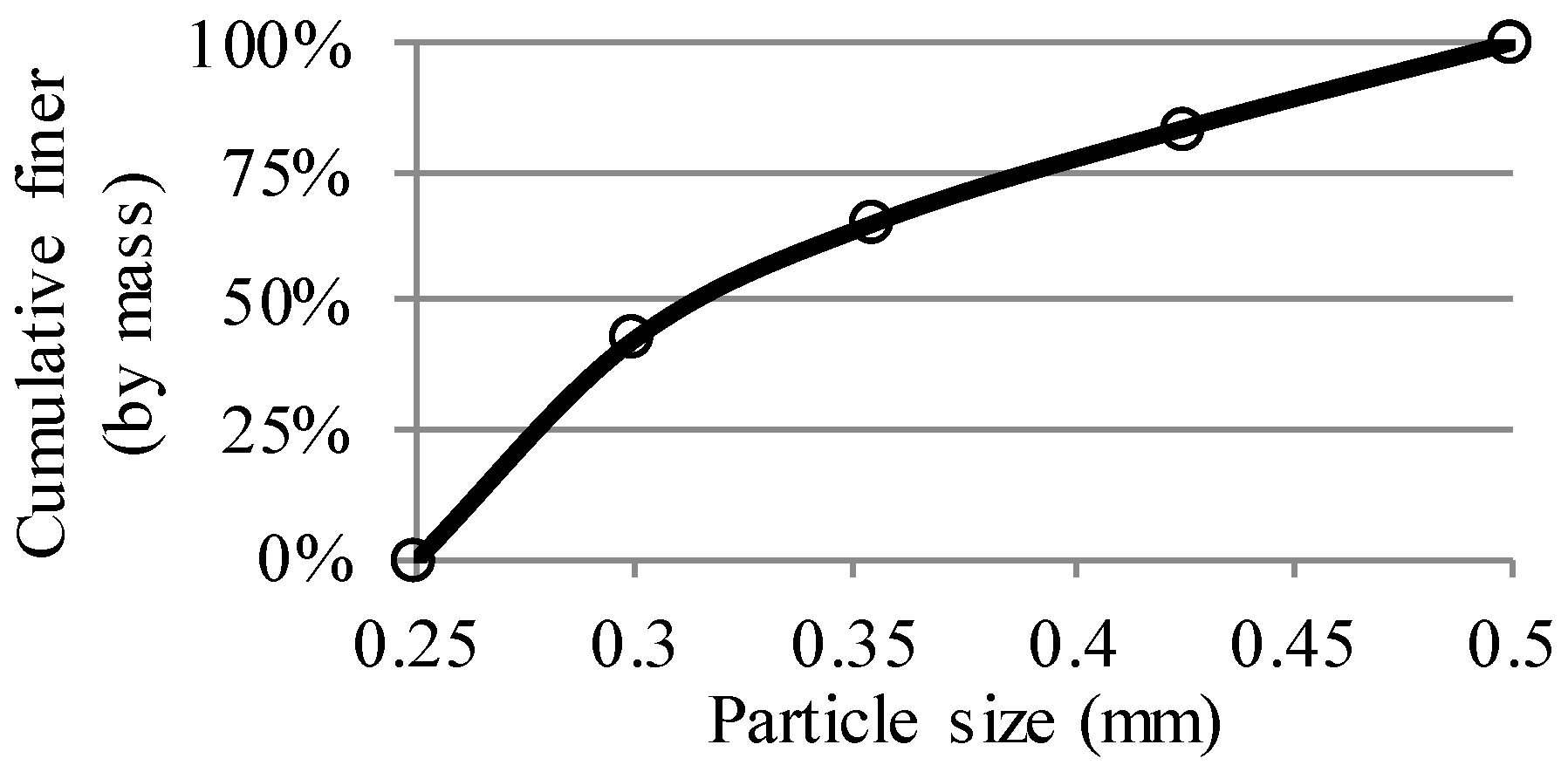

- Quartz sand (particle size: 0.25–0.5 mm): the particle distribution is shown in Figure 1.

- -

- Epoxy resin: the epoxy resin consists of Conpox Harpiks BY 158 and Haerder HY 2996. The mass ratio of hardener to epoxy resin was 0.3. The elastic modulus of the epoxy resin after complete polymerization was 3.8 GPa. The deformation of the epoxy resin under the pressure of mercury in MIP measurements was considered to be minor.

2.2. Derivation of Digital Microstructures of the Sandstone–CT Scan

3. Methods for Determining PSD Curves

3.1. MIP Measurements

3.2. Simulation of Mercury Intrusion

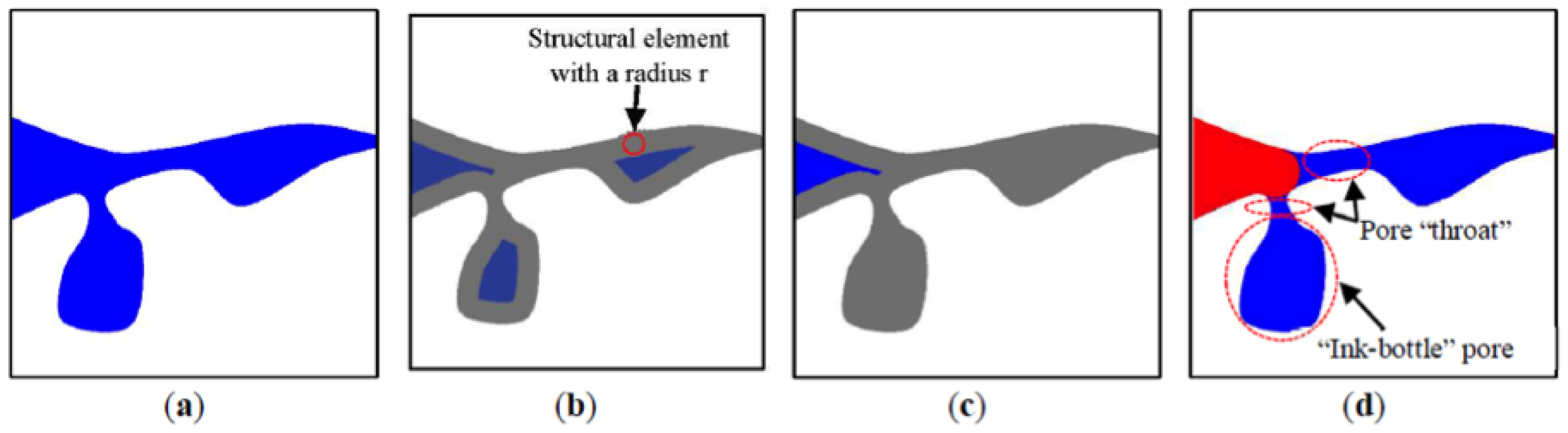

- Connectivity of the eroded pore space from the intruding surfaces is checked. Note that pixels/voxels are considered as connected when sharing an edge/face. Mercury is considered accessible to the pores when the eroded pore space has a continuous connection to the surfaces of the sample. Hence, all pores separated from intruding surfaces are removed from the eroded pore space (Figure 7c and Figure 8c).

4. Results and Discussion

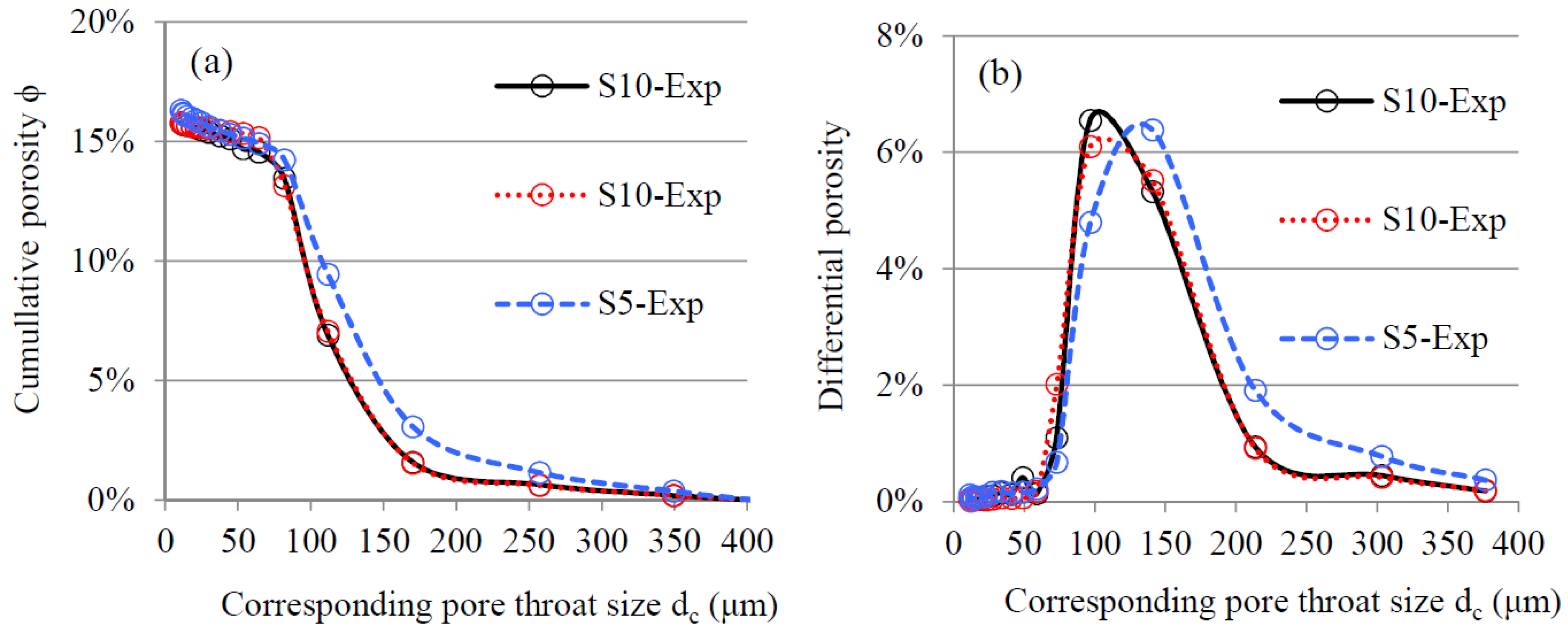

4.1. PSD Curves Determined by MIP Measurements

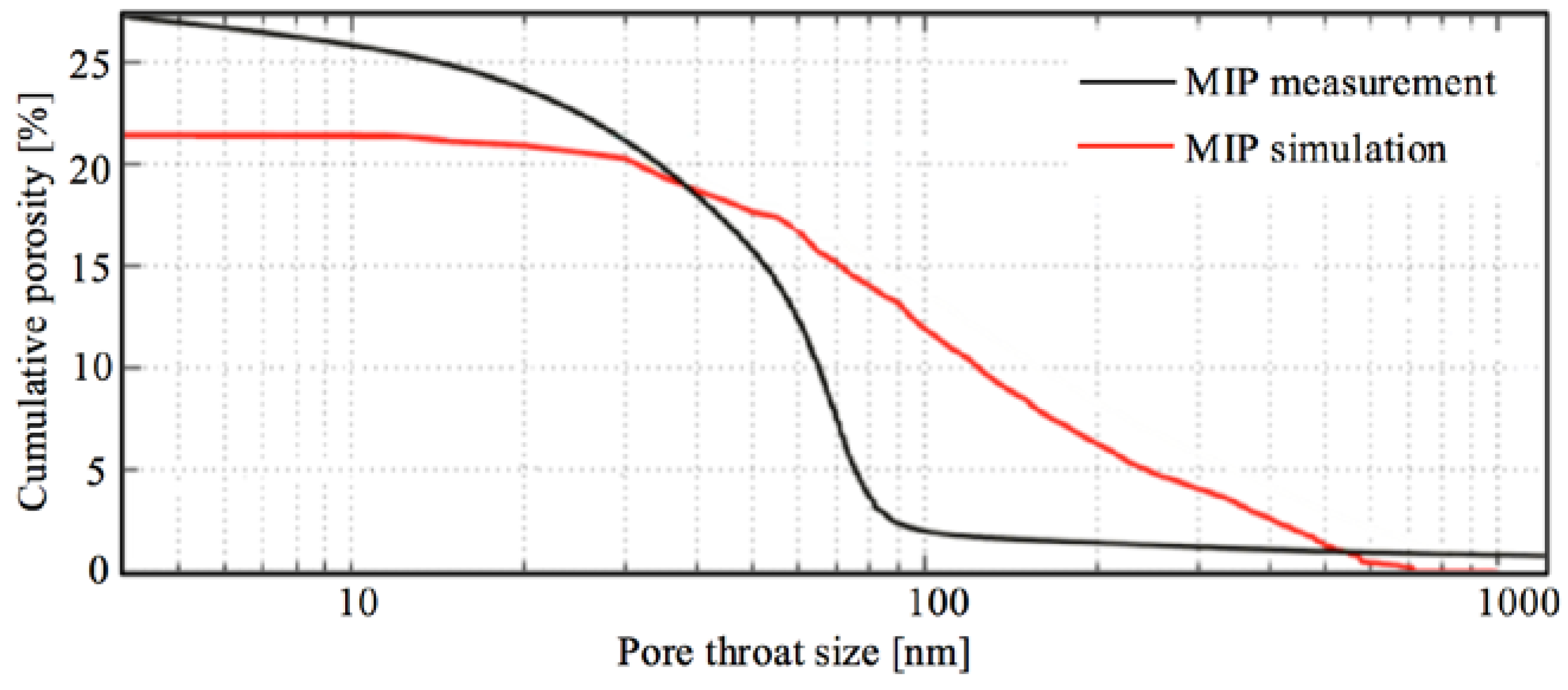

4.2. Simulation of Mercury Intrusion

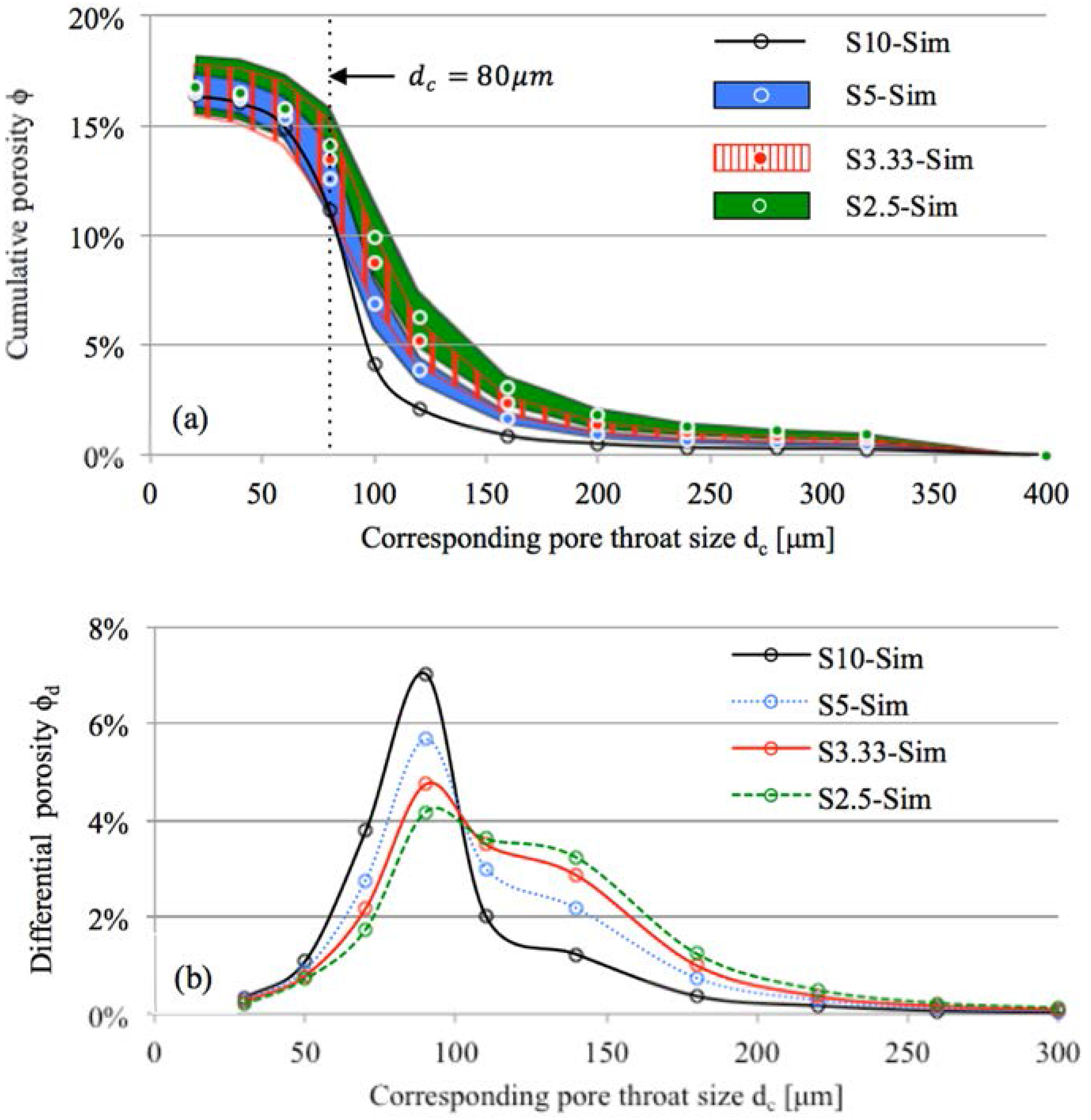

4.2.1. PSD Curves Determined by MIP Simulation

4.2.2. Percolation Analysis of Mercury-Intruded Pores

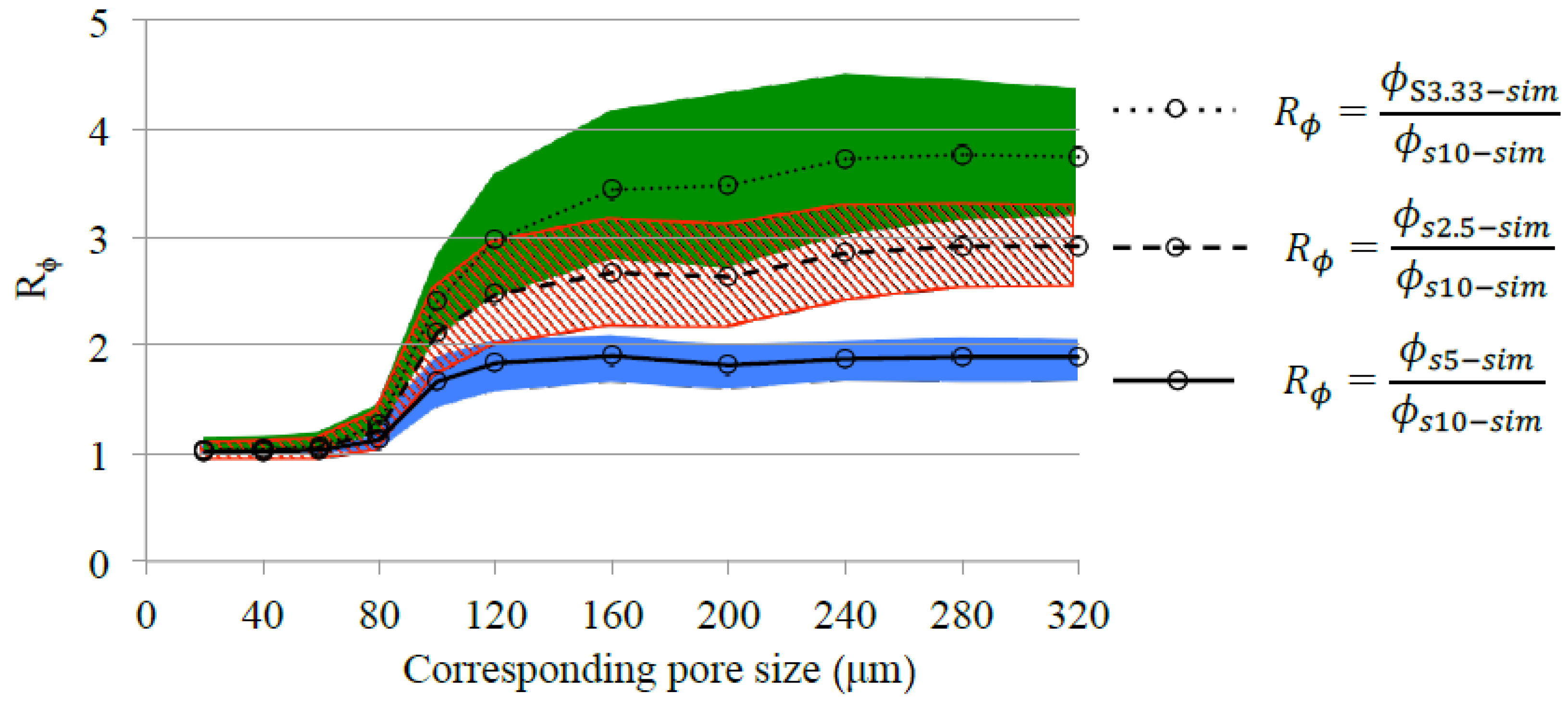

4.2.3. Evaluation of the Effect of Sample Size

- : Mercury first intruded under a low pressure (e.g., corresponding pore throat size ), only vicinities of sample surfaces were filled with mercury. The ratio (i.e., / and /) exhibited a value much greater than 1, indicating a significant effect of sample size on mercury intrusion. In this stage, for a small sample that is the size of the large sample (e.g., S10-Sim), the cumulative porosity of the small sample was scaled up by a factor of approximately (e.g., /, /, and / when ).

- : As the pressure increased (e.g., decreases from 160 to 80 ), mercury continued to penetrate into the samples. The value of decreased with the increasing pressure (or decreasing pore throat size ), but remained far greater than 1. The mercury-filled pores had percolated when the corresponding pore throat size . This led to a smaller value of (approaching 1) for /, /, and /, indicating a minor effect of sample size on mercury intrusion under the pressure corresponding to .

- : After the mercury-filled pores had percolated, the sample size had a negligible effect on mercury intrusion, as indicated by for /, / and /, respectively.

5. Implications

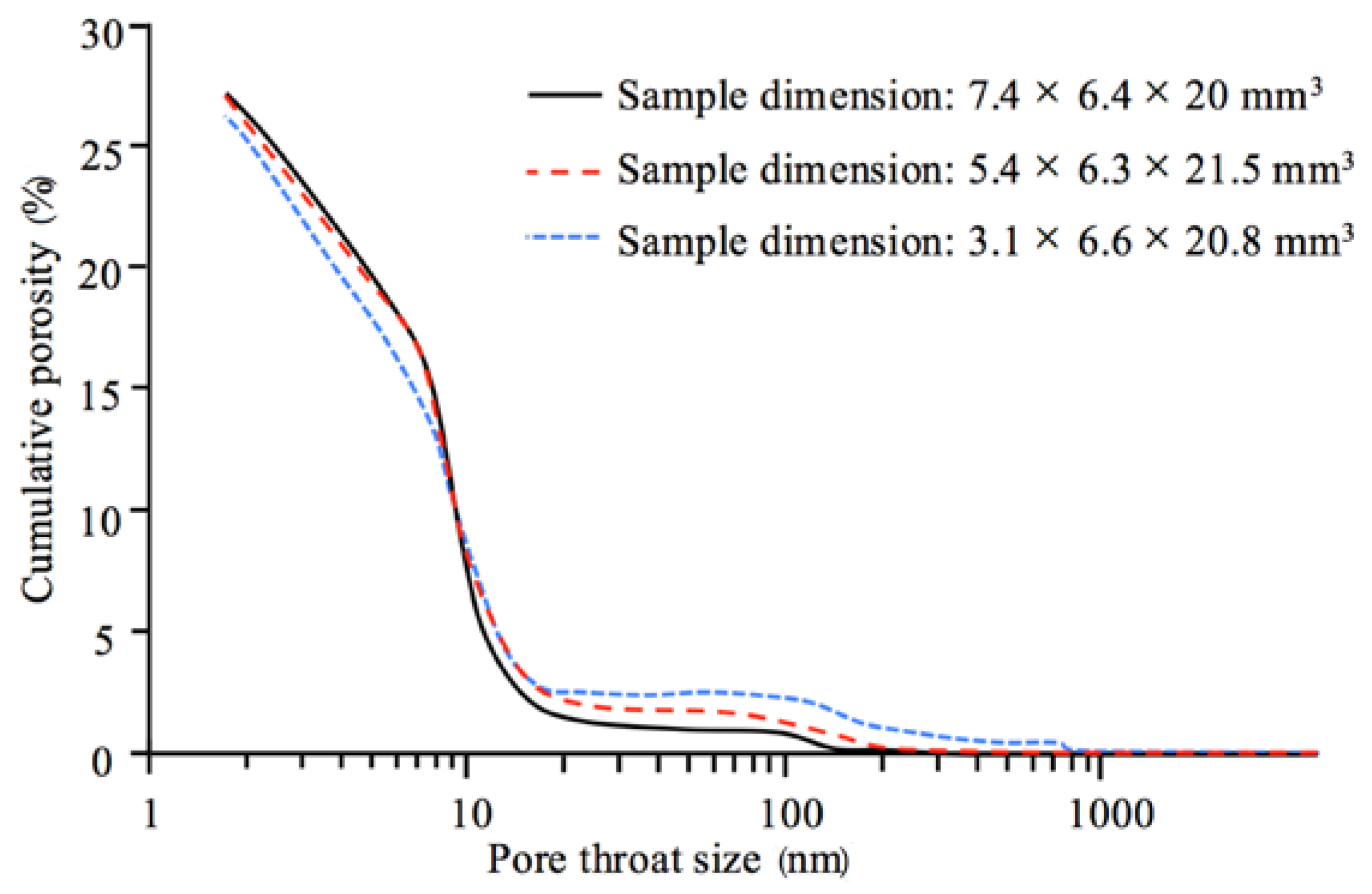

5.1. Implications for the Characterization of Pore Structure of Porous Materials by MIP Measurement

5.2. Implications for the Characterization of the Pore Structure of Porous Materials by MIP Simulation

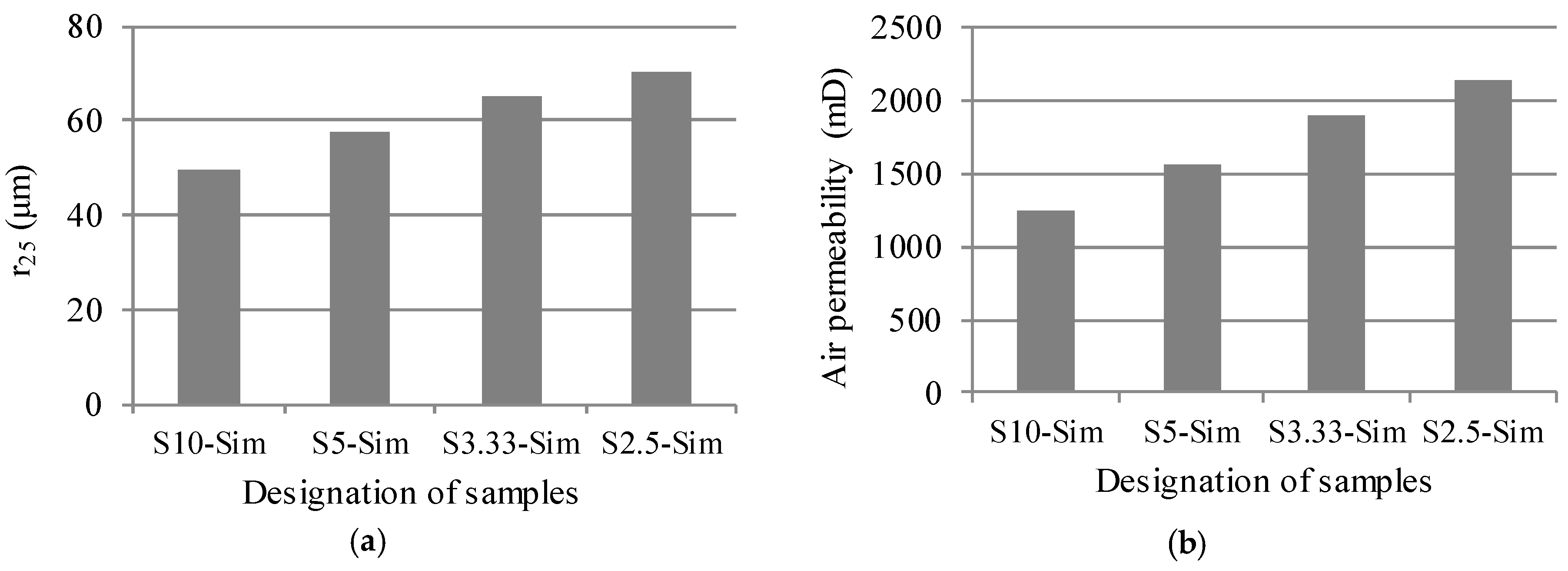

5.3. Implications for the Application of Pore Throat Size in the Estimation of Air Permeability

6. Conclusions

- For a cubic sample with a length 1/n times that of the reference cubic sample, the mercury-intruded porosity of the small sample was scaled up by a factor of approximately under low pressure. The effect of sample size decreased with increasing pressure and became minor after mercury-intruded pores percolated through the samples. It can be concluded that there was no representative elementary volume (REV) in MIP measurements or MIP simulations for the sandstone samples investigated in this study, because a significant effect of sample size always existed before the mercury-intruded pores were percolated in the samples. For a proper comparison of pore structure between the artificial sandstone, the same sample size should be used in MIP measurement and MIP simulation.

- The pore throat radius () corresponding to the 25th percentile of saturation on a cumulative mercury injection plot was used to estimate the air permeability of artificial sandstone, according to the relation proposed in the literature. The calculated air permeability of the smaller sandstone sample had higher air permeability (the calculated air permeability of S2.5-Sim was 1.7 times higher than that of S10-Sim). However, in principle, the air permeability of sandstone samples should be independent of the sample size. This suggests that sample size needs to be considered when pore throat size determined by MIP measurement is used for estimating the air permeability of rocks.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Poon, C.S.; Kou, S.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Aligizaki, K.K. Pore Structure of Cement-Based Materials: Testing, Interpretation and Requirements; CRC Press: London, UK; New York, NY, USA, 2005. [Google Scholar]

- Washburn, E.W. Note on a method of determining the distribution of pore sizes in a porous material. Proc. Natl. Acad. Sci. USA 1921, 7, 115–116. [Google Scholar] [CrossRef] [PubMed]

- Van Brakel, J.; Modrý, S.; Svatá, M. Mercury porosimetry: State of the art. Powder Technol. 1981, 29, 1–12. [Google Scholar] [CrossRef]

- Abell, A.B.; Willis, K.L.; Lange, D.A. Mercury Intrusion Porosimetry and Image Analysis of Cement-Based Materials. J. Colloid Interface Sci. 1999, 211, 39–44. [Google Scholar] [CrossRef] [PubMed]

- Gane, P.A.C.; Ridgway, C.J.; Lehtinen, E.; Valiullin, R.; Furó, I.; Schoelkopf, J.; Paulapuro, H.; Daicic, J. Comparison of NMR Cryoporometry, Mercury Intrusion Porosimetry, and DSC Thermoporosimetry in Characterizing Pore Size Distributions of Compressed Finely Ground Calcium Carbonate Structures. Ind. Eng. Chem. Res. 2004, 43, 7920–7927. [Google Scholar] [CrossRef]

- Romero, E.; Simms, P.H. Microstructure Investigation in Unsaturated Soils: A Review with Special Attention to Contribution of Mercury Intrusion Porosimetry and Environmental Scanning Electron Microscopy. Geotech. Geol. Eng. 2008, 26, 705–727. [Google Scholar] [CrossRef]

- Okolo, G.N.; Everson, R.C.; Neomagus, H.W.J.P.; Roberts, M.J.; Sakurovs, R. Comparing the porosity and surface areas of coal as measured by gas adsorption, mercury intrusion and SAXS techniques. Fuel 2015, 141, 293–304. [Google Scholar] [CrossRef]

- Diamond, S. Mercury porosimetry: An inappropriate method for the measurement of pore size distributions in cement-based materials. Cem. Concr. Res. 2000, 30, 1517–1525. [Google Scholar] [CrossRef]

- Odler, I.; Rößler, M. Investigations on the relationship between porosity, structure and strength of hydrated Portland cement pastes. II. Effect of pore structure and of degree of hydration. Cem. Concr. Res. 1985, 15, 401–410. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Katz, A.; Thompson, A. Quantitative prediction of permeability in porous rock. Phys. Rev. B 1986, 34, 8179. [Google Scholar] [CrossRef]

- Stanley, K.J. Analysis of pore throat size and use of the Waxman-Smits equation to determine OOIP in Spindle Field, Colorado. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 21–24 September 1980; Society of Petroleum Engineers: Richardson, TX, USA, 1980. [Google Scholar]

- Pittman, E.D. Relationship of porosity and permeability to various parameters derived from mercury injection-capillary pressure curves for sandstone (1). AAPG Bull. 1992, 76, 191–198. [Google Scholar]

- Rezaee, M.; Jafari, A.; Kazemzadeh, E. Relationships between permeability, porosity and pore throat size in carbonate rocks using regression analysis and neural networks. J. Geophys. Eng. 2006, 3, 370. [Google Scholar] [CrossRef]

- Shi, D.; Winslow, D.N. Contact angle and damage during mercury intrusion into cement paste. Cem. Concr. Res. 1985, 15, 645–654. [Google Scholar] [CrossRef]

- Hearn, N.; Hooton, R.D. Sample mass and dimension effects on mercury intrusion porosimetry results. Cem. Concr. Res. 1992, 22, 970–980. [Google Scholar] [CrossRef]

- Gallé, C. Effect of drying on cement-based materials pore structure as identified by mercury intrusion porosimetry: A comparative study between oven-, vacuum-, and freeze-drying. Cem. Concr. Res. 2001, 31, 1467–1477. [Google Scholar] [CrossRef]

- Olson, R.A.; Neubauer, C.M.; Jennings, H.M. Damage to the pore structure of hardened Portland cement paste by mercury intrusion. J. Am. Ceram. Soc. 1997, 80, 2454–2458. [Google Scholar] [CrossRef]

- Bager, D.H.; Sellevold, E.J. Mercury porosimetry of hardened cement paste: The influence of particle size. Cem. Concr. Res. 1975, 5, 171–177. [Google Scholar] [CrossRef]

- Larson, R.G.; Morrow, N.R. Effects of sample size on capillary pressures in porous media. Powder Technol. 1981, 30, 123–138. [Google Scholar] [CrossRef]

- Moro, F.; Böhni, H. Ink-Bottle Effect in Mercury Intrusion Porosimetry of Cement-Based Materials. J. Colloid Interface Sci. 2002, 246, 135–149. [Google Scholar] [CrossRef] [PubMed]

- Ma, H. Mercury intrusion porosimetry in concrete technology: Tips in measurement, pore structure parameter acquisition and application. J. Porous Mater. 2014, 21, 207–215. [Google Scholar] [CrossRef]

- Garboczi, E.J.; Bentz, D.P. Digitised simulation of mercury intrusion porosimetry. Ceram. Trans. 1991, 16, 365–380. [Google Scholar]

- Münch, B.; Holzer, L. Contradicting Geometrical Concepts in Pore Size Analysis Attained with Electron Microscopy and Mercury Intrusion. J. Am. Ceram. Soc. 2008, 91, 4059–4067. [Google Scholar] [CrossRef]

- Huy Do, Q.; Bishnoi, S.; Scrivener, K.L. Numerical Simulation of Porosity in Cements. Transp. Porous Med. 2013, 99, 101–117. [Google Scholar] [CrossRef]

- Nelson, P.H. Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG Bull. 2009, 93, 329–340. [Google Scholar] [CrossRef]

- Cnudde, V.; Boone, M.; Dewanckele, J.; Dierick, M.; Van Hoorebeke, L.; Jacobs, P. 3D characterization of sandstone by means of X-ray computed tomography. Geosphere 2011, 7, 54–61. [Google Scholar] [CrossRef]

- Promentilla, M.A.B.; Sugiyama, T.; Hitomi, T.; Takeda, N. Characterizing the 3D pore structure of hardened cement paste with synchrotron microtomography. J. Adv. Concr. Technol. 2008, 6, 273–286. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. The effect of specimen size on compressive strength of coal. Int. J. Rock Mech. Min. Sci. 1968, 5, 325–335. [Google Scholar] [CrossRef]

- Pratt, H.R.; Black, A.D.; Brown, W.S.; Brace, W.F. The effect of speciment size on the mechanical properties of unjointed diorite. Int. J. Rock Mech. Min. Sci. 1972, 9, 513–516. [Google Scholar] [CrossRef]

- Thuro, K.; Plinninger, R.; Zäh, S.; Schütz, S. Scale effects in rock strength properties. Part 1: Unconfined compressive test and Brazilian test. In Proceedings of the ISRM Regional Symposium EUROCK 2001: Rock Mechanics—A Challenge for Society, Espoo, Finland, 3–7 June 2001; pp. 169–174. [Google Scholar]

- Pal, N.R.; Pal, S.K. A review on image segmentation techniques. Pattern Recognit. 1993, 26, 1277–1294. [Google Scholar] [CrossRef]

- Rouquerol, J.; Avnir, D.; Fairbridge, C.; Everett, D.; Haynes, J.; Pernicone, N.; Ramsay, J.; Sing, K.; Unger, K. Recommendations for the characterization of porous solids (Technical Report). Pure Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

- Hazlett, R. Simulation of capillary-dominated displacements in microtomographic images of reservoir rocks. Transp. Porous Med. 1995, 20, 21–35. [Google Scholar] [CrossRef]

- Vogel, H.J.; Tölke, J.; Schulz, V.; Krafczyk, M.; Roth, K. Comparison of a lattice-Boltzmann model, a full-morphology model, and a pore network model for determining capillary pressure–saturation relationships. Vadose Zone J. 2005, 4, 380–388. [Google Scholar] [CrossRef]

- Hilpert, M.; Miller, C.T. Pore-morphology-based simulation of drainage in totally wetting porous media. Adv. Water Resour. 2001, 24, 243–255. [Google Scholar] [CrossRef]

- Hill, R. Elastic properties of reinforced solids: Some theoretical principles. J. Mech. Phys. Solids 1963, 11, 357–372. [Google Scholar] [CrossRef]

- Cook, R.A.; Hover, K.C. Mercury porosimetry of hardened cement pastes. Cem. Concr. Res. 1999, 29, 933–943. [Google Scholar] [CrossRef]

- Heath, J.E.; Dewers, T.A.; McPherson, B.J.O.L.; Nemer, M.B.; Kotula, P.G. Pore-lining phases and capillary breakthrough pressure of mudstone caprocks: Sealing efficiency of geologic CO2 storage sites. Int. J. Greenh. Gas Control 2012, 11, 204–220. [Google Scholar] [CrossRef]

| Designation | Dimension (mm) | Scale Factor | Number of Samples | Description |

|---|---|---|---|---|

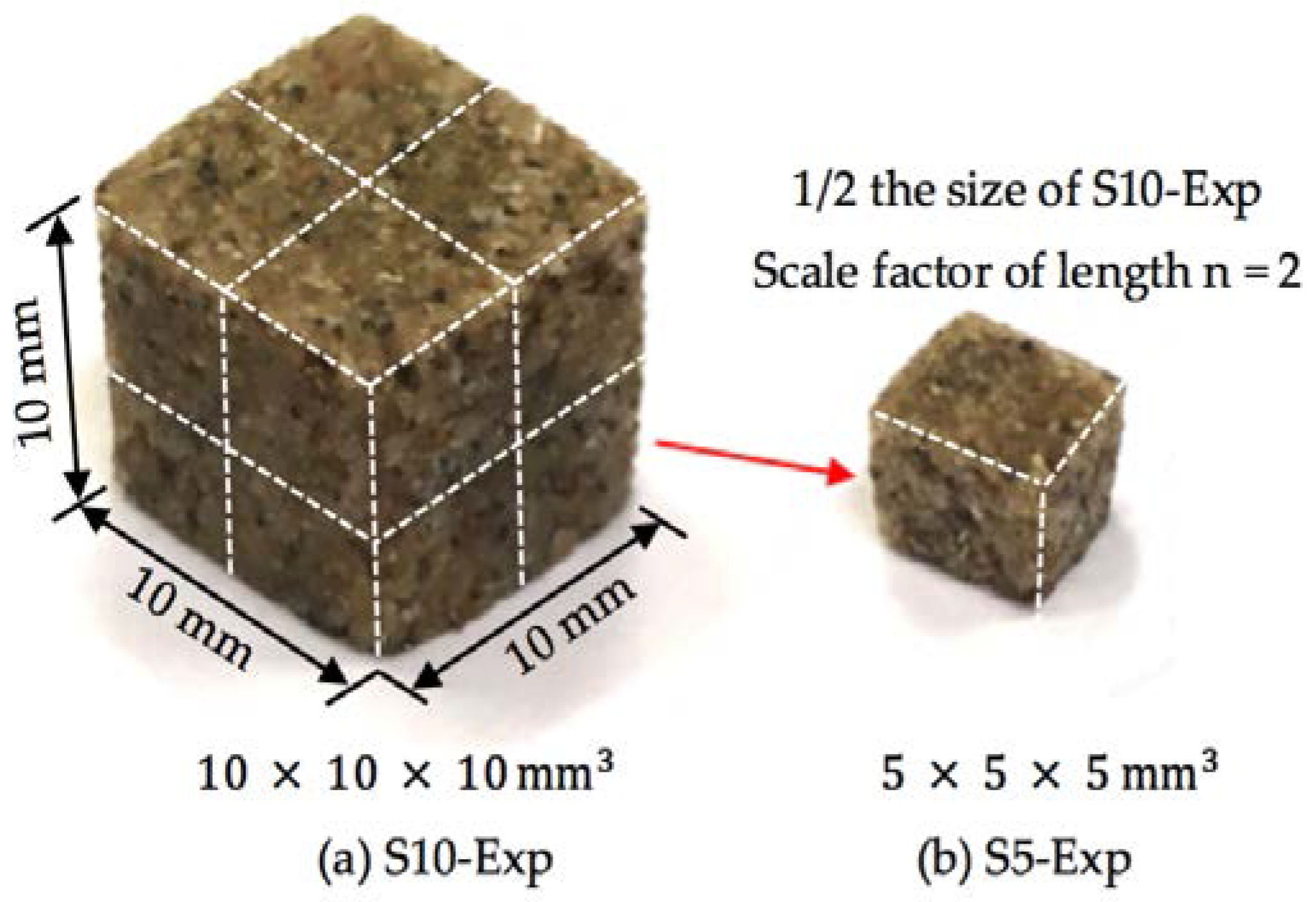

| S10-Exp | 1 | 2 | Samples for MIP test 1 | |

| S5-Exp | 2 | 8 | ||

| C15 | Diameter = 15, height = 15 | - | 1 | Samples for CT scan test 2 |

| S10-Sim | 1 | 1 | Samples for MIP simulation 3 | |

| S5-Sim | 2 | 8 | ||

| S3.33-Sim | 3 | 27 | ||

| S2.5-Sim | 4 | 64 |

| Designation | S10-Sim | S5-Sim | S3.33-Sim | S2.5-Sim |

|---|---|---|---|---|

| Physical Dimension (mm3) | ||||

| Digital resolution | 10 μm/voxel | |||

| Digital dimension (voxel3) | ||||

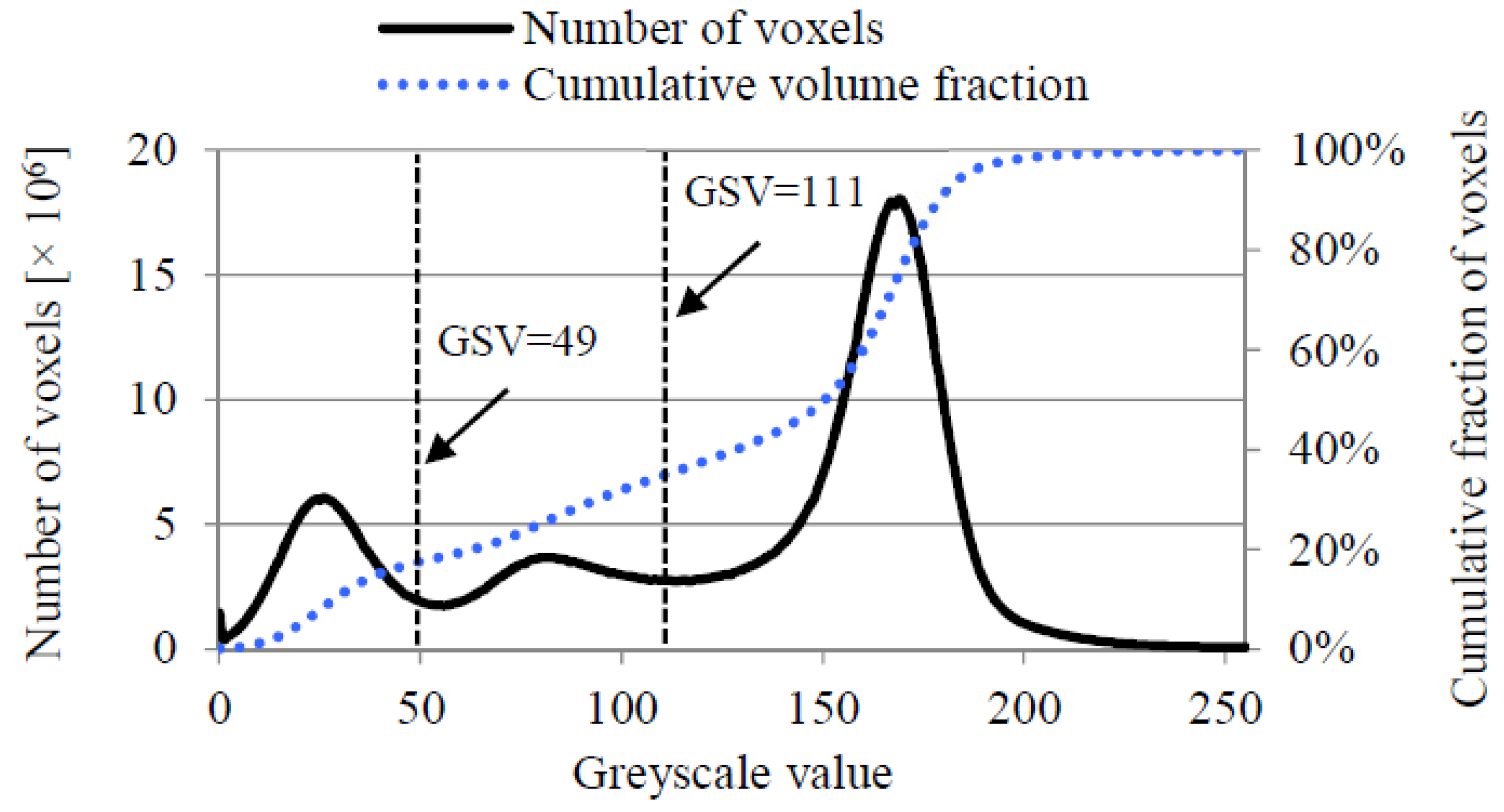

| Segmentation method | Voxels are identified as pores when , epoxy resin when and quartz sand when . | |||

| Number of samples | 1 | 8 | 27 | 64 |

| Average porosity | 17.44% | 17.44% ± 0.66% | 17.44% ± 1.01% | 17.44% ± 1.15% |

| Epoxy resin (V%) | 18.6% | 18.6% ± 0.4% | 18.6% ± 0.63% | 18.6% ± 0.76% |

| Quartz sand (V%) | 64.2% | 64.2% ± 0.3% | 64.2% ± 0.59% | 64.2% ± 0.73% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, H.; Zhang, H.; Zuo, Y.; Gao, P.; Ye, G. Relationship between the Size of the Samples and the Interpretation of the Mercury Intrusion Results of an Artificial Sandstone. Materials 2018, 11, 201. https://doi.org/10.3390/ma11020201

Dong H, Zhang H, Zuo Y, Gao P, Ye G. Relationship between the Size of the Samples and the Interpretation of the Mercury Intrusion Results of an Artificial Sandstone. Materials. 2018; 11(2):201. https://doi.org/10.3390/ma11020201

Chicago/Turabian StyleDong, Hua, Hongzhi Zhang, Yibing Zuo, Peng Gao, and Guang Ye. 2018. "Relationship between the Size of the Samples and the Interpretation of the Mercury Intrusion Results of an Artificial Sandstone" Materials 11, no. 2: 201. https://doi.org/10.3390/ma11020201

APA StyleDong, H., Zhang, H., Zuo, Y., Gao, P., & Ye, G. (2018). Relationship between the Size of the Samples and the Interpretation of the Mercury Intrusion Results of an Artificial Sandstone. Materials, 11(2), 201. https://doi.org/10.3390/ma11020201