Fabrication of Titanium-Niobium-Zirconium-Tantalium Alloy (TNZT) Bioimplant Components with Controllable Porosity by Spark Plasma Sintering

Abstract

1. Introduction

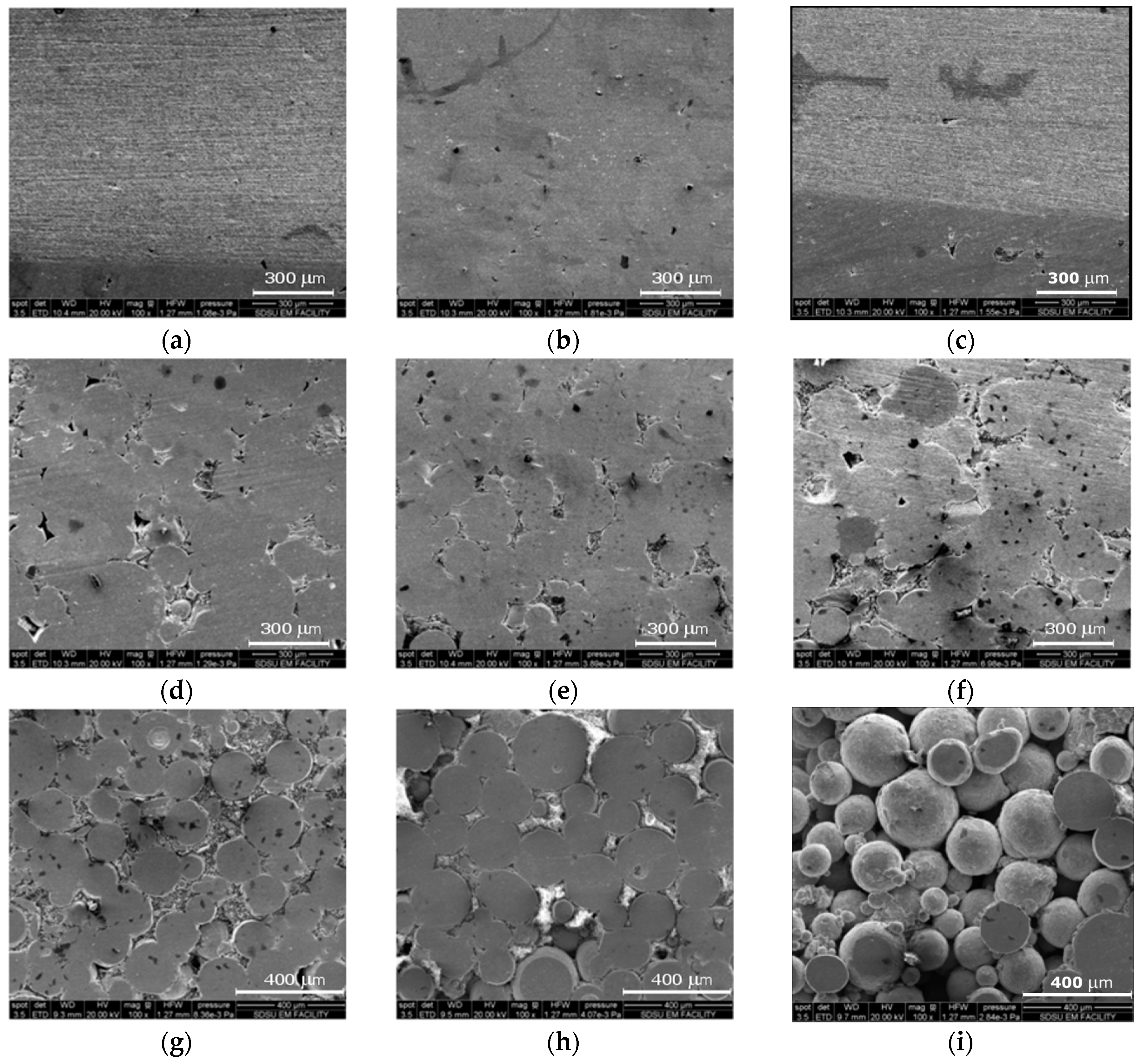

2. Experimental

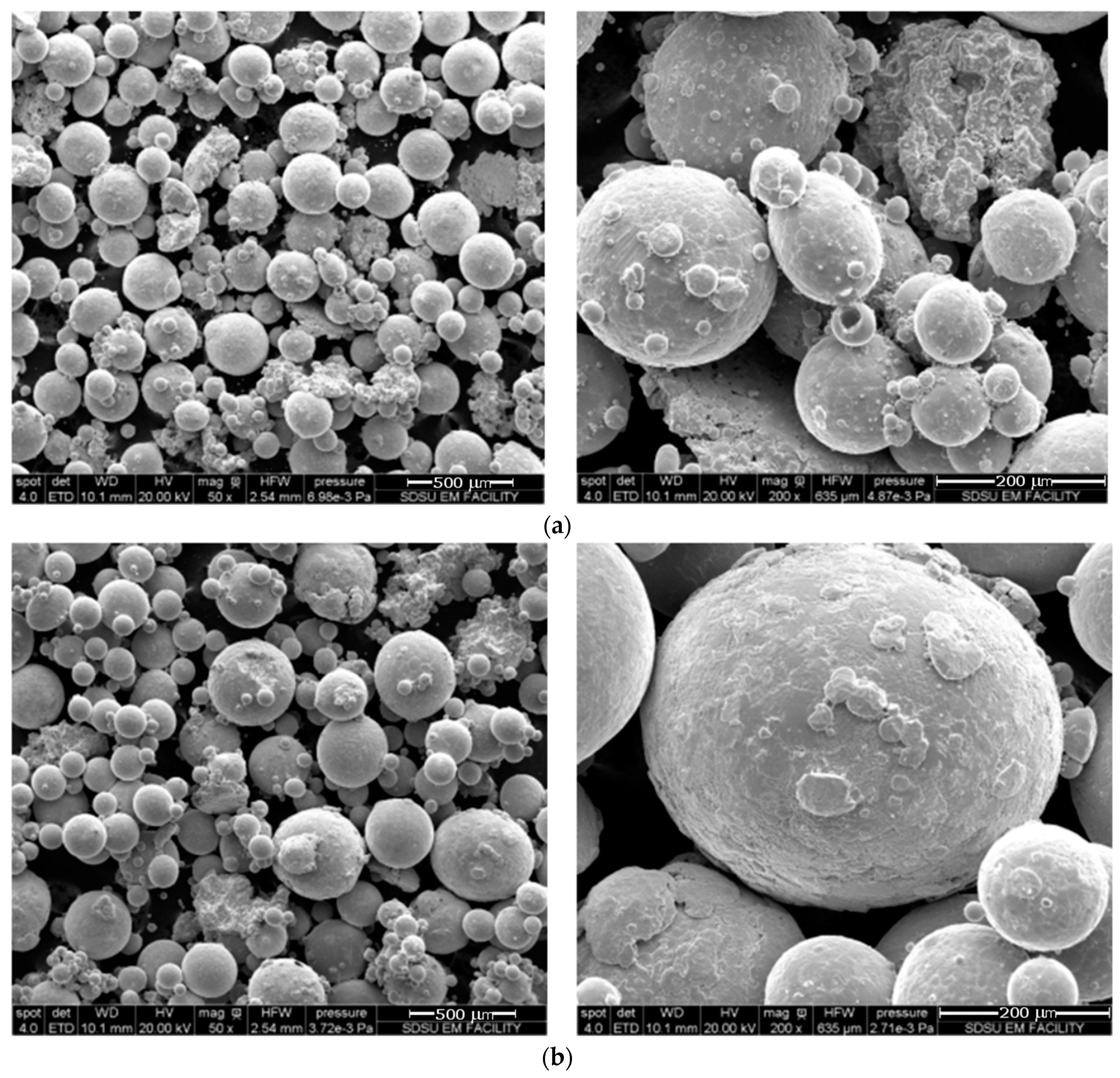

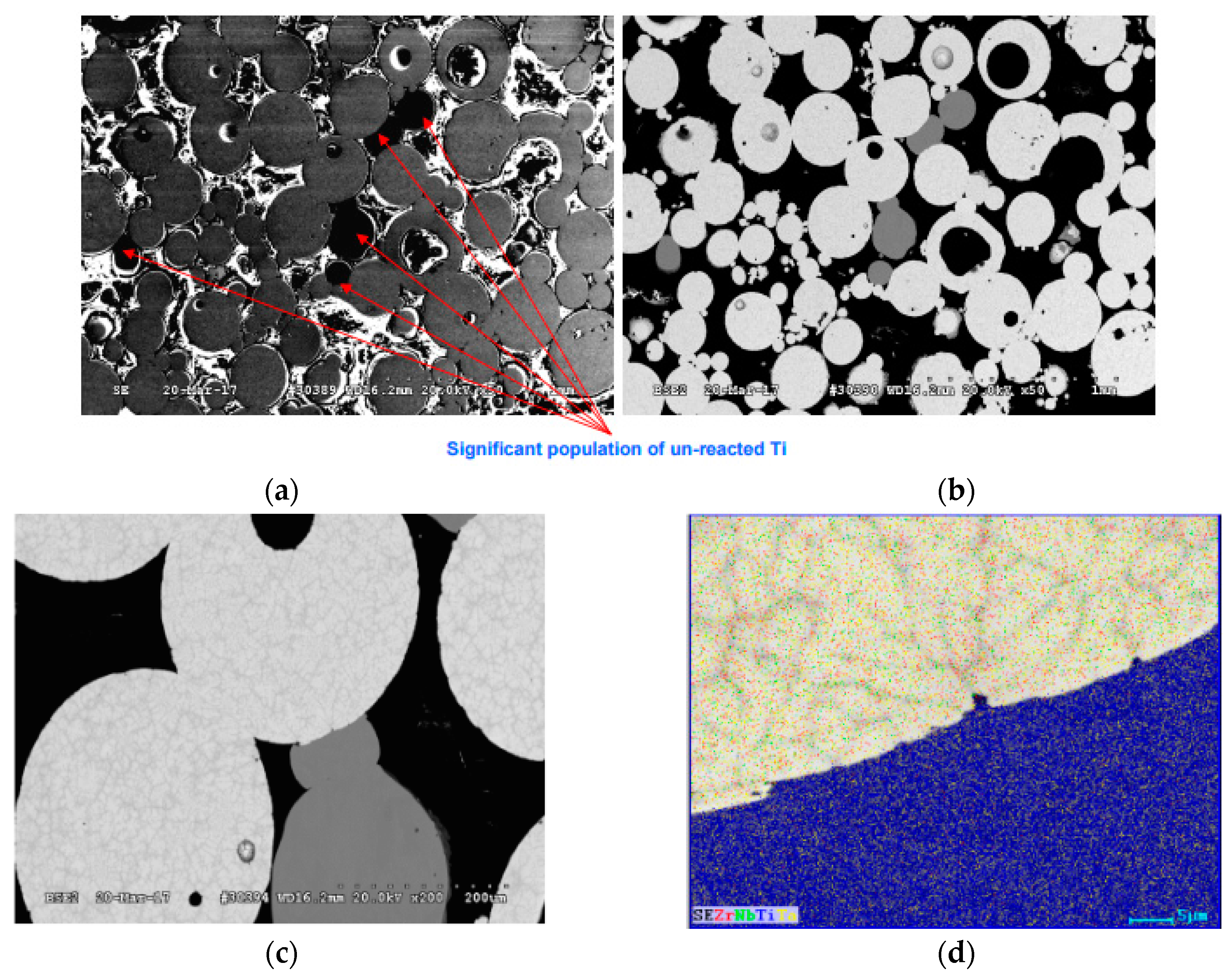

2.1. Powder Characterization

2.2. SPS Process

2.3. Microstructure and Mechanical Prorpietes Characterization

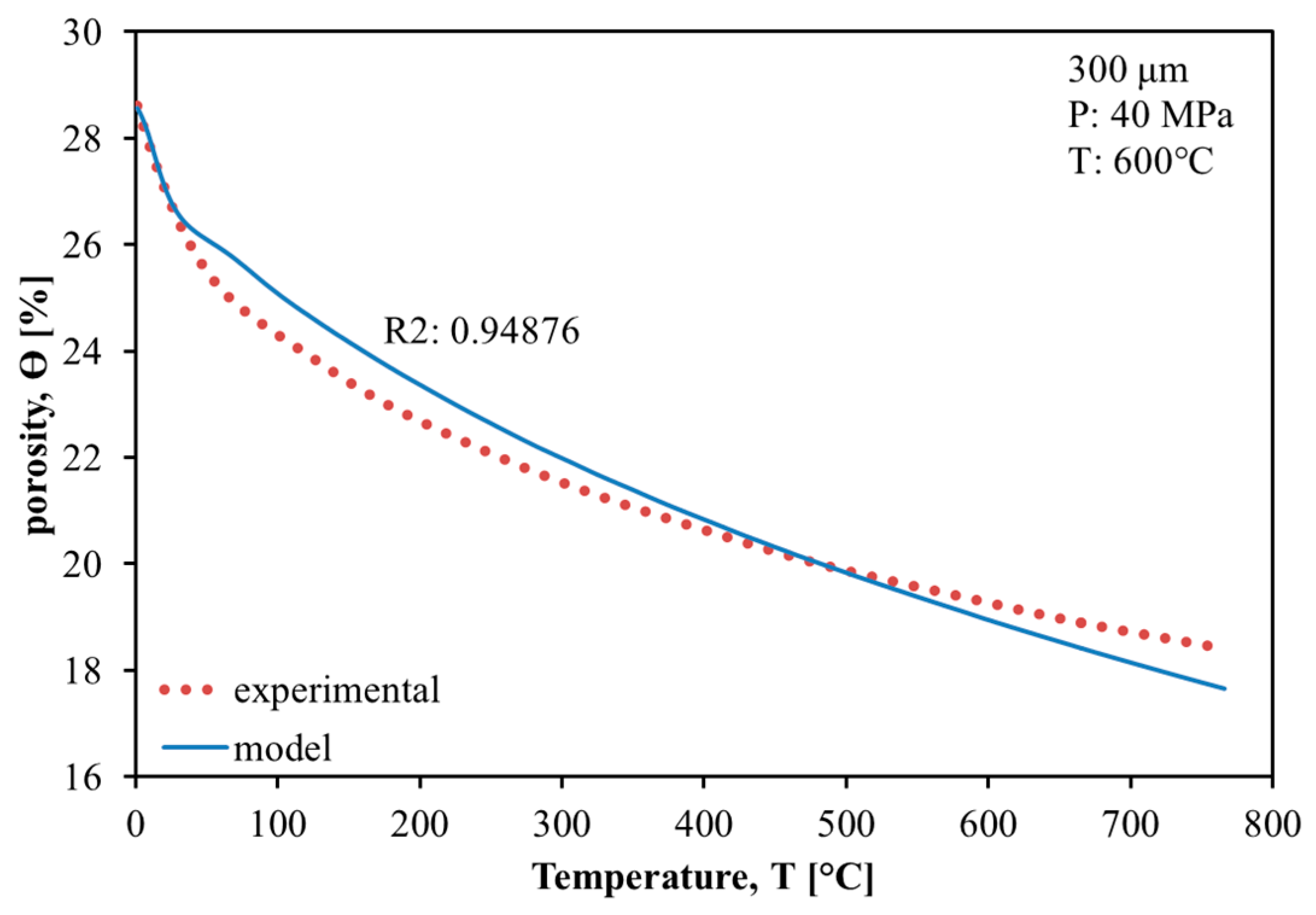

2.4. Densification Model

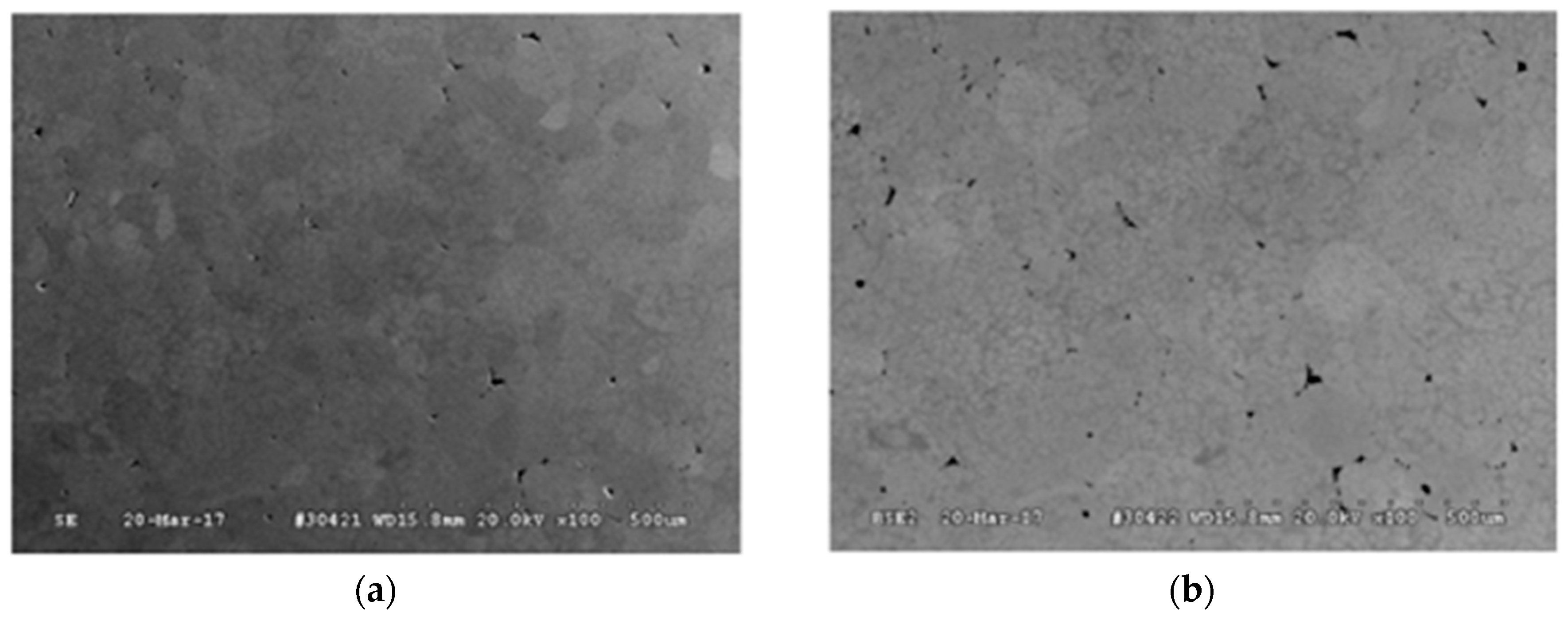

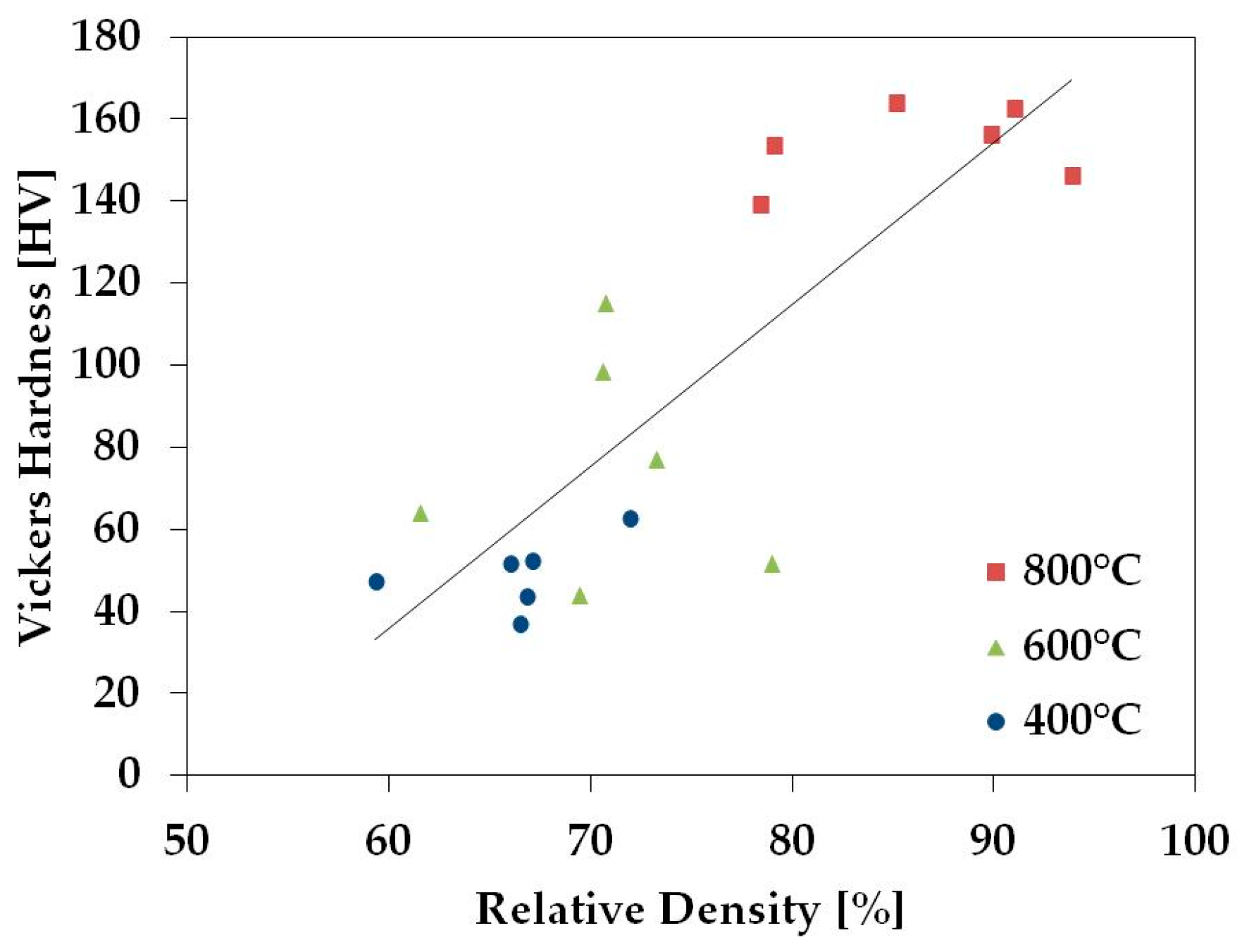

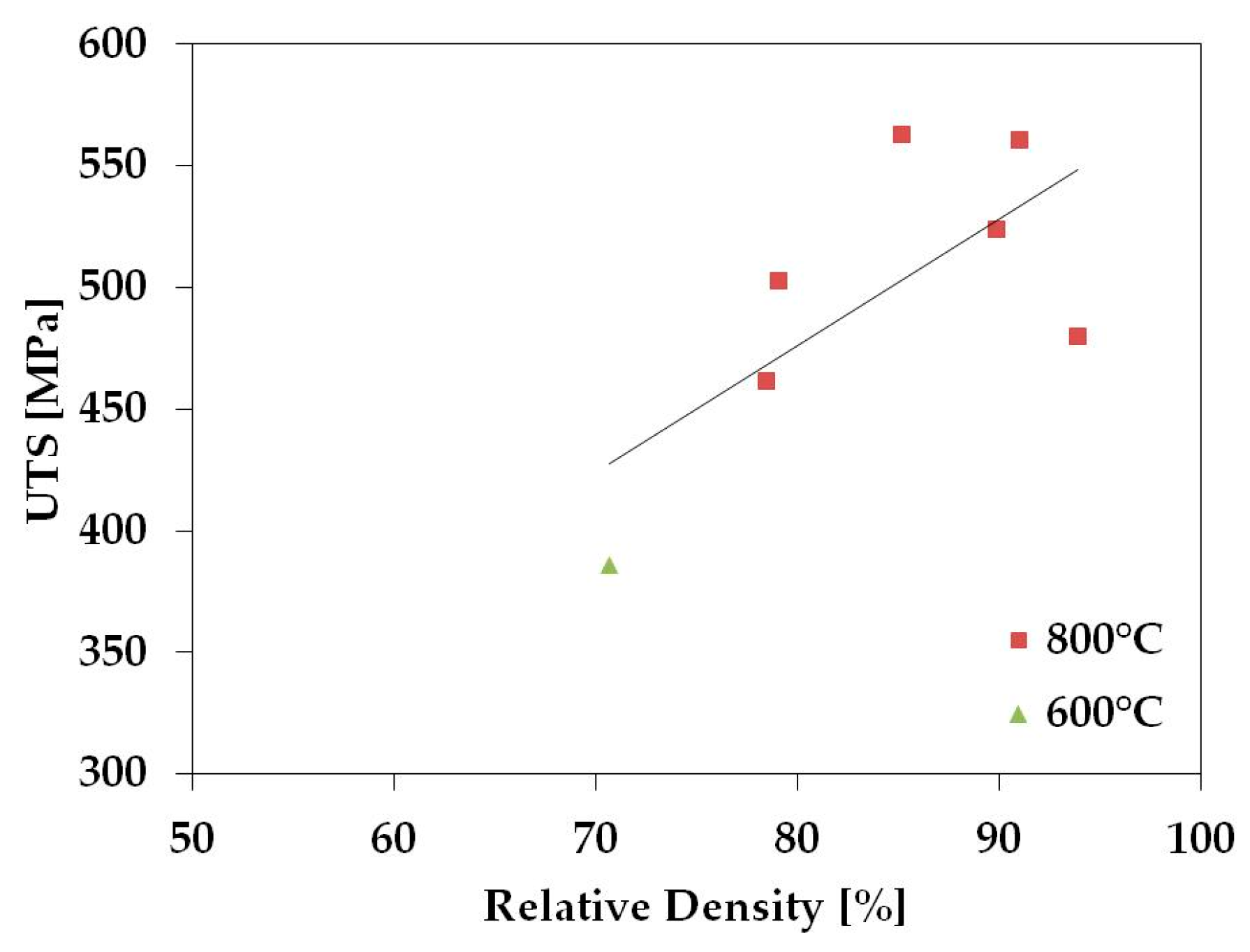

3. Results

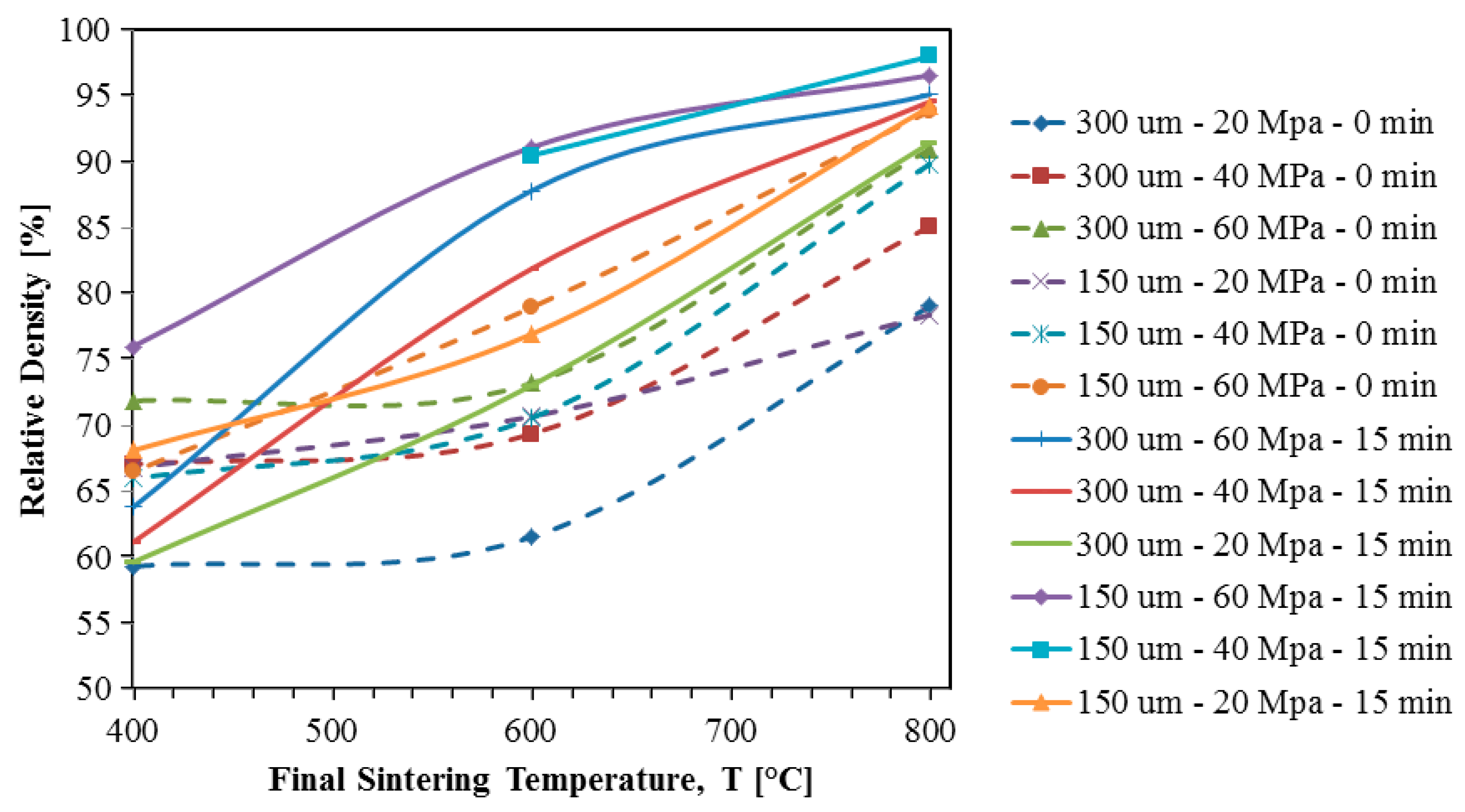

- ❖

- Increasing the sintering temperature should increase the final sample density [29];

- ❖

- Increasing the sintering pressure should increase the final sample density [29];

- ❖

- Increasing the holding time should increase the final sample density [32];

- ❖

- Decreasing the initial particle size should increase the final sample density [33];

- ❖

- Using designed particle distributions can be employed to tune the compaction density [31].

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Spriggs, R.M. Expression for Effect of Porosity on Elastic Modulus of Polycrystalline Refractory Materials, Particularly Aluminum Oxide. J. Am. Ceram. Soc. 1961, 44, 628–629. [Google Scholar] [CrossRef]

- Kawai, C.; Yamakawa, A. Effect of Porosity and Microstructure on the Strength of Si3N4: Designed Microstructure for High Strength, High Thermal Shock Resistance, and Facile Machining. J. Am. Ceram. Soc. 1997, 80, 2705–2708. [Google Scholar] [CrossRef]

- Coble, R.L.; Kingery, W.D. Effect of Porosity on Physical Properties of Sintered Alumina. J. Am. Ceram. Soc. 1956, 39, 377–385. [Google Scholar] [CrossRef]

- Knudsen, F.P. Dependence of Mechanical Strength of Brittle Polycrystalline Specimens on Porosity and Grain Size. J. Am. Ceram. Soc. 1959, 42, 376–387. [Google Scholar] [CrossRef]

- Robertson, D.M.; St Pierre, L.; Chahal, R. Preliminary observations of bone ingrowth into porous materials. J. Biomed. Mater. Res. A 1976, 10, 335–344. [Google Scholar] [CrossRef] [PubMed]

- Head, W.C.; Bauk, D.J.; Emerson, R.H., Jr. Titanium as the material of choice for cementless femoral components in total hip arthroplasty. Clin. Orthop. Relat. Res. 1995, 311, 85–90. [Google Scholar]

- Bandyopadhyay, A.; Espana, F.; Balla, V.K.; Bose, S.; Ohgami, Y.; Davies, N.M. Influence of porosity on mechanical properties and in vivo response of Ti-6Al-4V implants. Acta Biomater. 2010, 6, 1640–1648. [Google Scholar] [CrossRef] [PubMed]

- Cameron, H.U.; Macnab, I.; Pilliar, R.M. A porous metal system for joint replacement surgery. Int. J. Artif. Organs 1978, 1, 104–109. [Google Scholar] [PubMed]

- Evin, M.P.; Getter, L.; Adrian, J.; Cutright, D. Healing of periodontal defects with ceramic implants. J. Clin. Periodontol. 1974, 1, 197–205. [Google Scholar] [CrossRef]

- Grandjean-Laquerriere, A.; Laquerriere, P.; Guenounou, M.; Laurent-Maquin, D.; Phillips, T.M. Importance of the surface area ratio on cytokines production by human monocytes in vitro induced by various hydroxyapatite particles. Biomaterials 2005, 26, 2361–2369. [Google Scholar] [CrossRef] [PubMed]

- Laquerriere, P.; Grandjean-Laquerriere, A.; Jallot, E.; Balossier, G.; Frayssinet, P.; Guenounou, M. Importance of hydroxyapatite particles characteristics on cytokines production by human monocytes in vitro. Biomaterials 2003, 24, 2739–2747. [Google Scholar] [CrossRef]

- Yablon, I.G. The Effect of Methylmethacrylate on Fracture Healing. Clin. Orthop. Relat. Res. 1975, 114, 358–363. [Google Scholar] [CrossRef]

- Revell, P.A.; Braden, M.; Freeman, M.A.R. Review of the biological response to a novel bone cement containing poly(ethyl methacrylate) and n-butyl methacrylate. Biomaterials 1998, 19, 1579–1586. [Google Scholar] [CrossRef]

- El-Warrak, A.O.; Olmstead, M.; Schneider, R.; Meinel, L.; Bettschart-Wolfisberger, R.; Akens, M.K.; Auer, J.; Von Rechenberg, B. An experimental animal model of aseptic loosening of hip prostheses in sheep to study early biochemical changes at the interface membrane. BMC Musculoskelet. Disord. 2004, 5, 1–13. [Google Scholar] [CrossRef] [PubMed]

- El-Warrak, A.O.; Olmstead, M.L.; von Rechenberg, B.; Auer, J.A. A Review of Aseptic Loosening in Total Hip Arthroplasty. Vet. Comp. Orthop. Traumatol. 2002, 14, 115–124. [Google Scholar]

- Taniguchi, N.; Fujibayashi, S.; Takemoto, M.; Sasaki, K.; Otsuki, B.; Nakamura, T.; Matsushita, T.; Kokubo, T.; Matsuda, S. Effect of pore size on bone ingrowth into porous titanium implants fabricated by additive manufacturing: An in vivo experiment. Mater. Sci. Eng. C 2016, 59, 690–701. [Google Scholar] [CrossRef] [PubMed]

- Nag, S.; Banerjee, R.; Fraser, H.L. Microstructural evolution and strengthening mechanisms in Ti–Nb–Zr–Ta, Ti–Mo–Zr–Fe and Ti–15Mo biocompatible alloys. Mater. Sci. Eng. C 2005, 25, 357–362. [Google Scholar] [CrossRef]

- Özcan, M.; Hämmerle, C. Titanium as a Reconstruction and Implant Material in Dentistry: Advantages and Pitfalls. Materials 2012, 5, 1528–1545. [Google Scholar] [CrossRef]

- Niinomi, M. Recent metallic materials for biomedical applications. Metall. Mater. Trans. A 2002, 33, 477–486. [Google Scholar] [CrossRef]

- Hendrickson, M.; Mantri, S.A.; Ren, Y.; Alam, T.; Soni, V.; Gwalani, B.; Styles, M.; Choudhuri, D.; Banerjee, R. The evolution of microstructure and microhardness in a biomedical Ti-35Nb-7Zr-5Ta alloy. J. Mater. Sci. 2017, 52, 3062–3073. [Google Scholar] [CrossRef]

- Kuroda, D.; Niinomi, M.; Morinaga, M.; Kato, Y.; Yashiro, T. Design and mechanical properties of new β type titanium alloys for implant materials. Mater. Sci. Eng. A 1998, 243, 244–249. [Google Scholar] [CrossRef]

- Niinomi, M.; Kuroda, D.; Fukunaga, K.; Morinaga, M.; Kato, Y.; Yashiro, T.; Suzuki, A. Corrosion wear fracture of new β type biomedical titanium alloys. Mater. Sci. Eng. A 1999, 263, 193–199. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

- Taddei, E.B.; Henriques, V.A.R.; Silva, C.R.M.; Cairo, C.A.A. Production of new titanium alloy for orthopedic implants. Mater. Sci. Eng. C 2004, 24, 683–687. [Google Scholar] [CrossRef]

- Hutmacher, D.W. Scaffolds in tissue engineering bone and cartilage. Biomaterials 2000, 21, 2529–2543. [Google Scholar] [CrossRef]

- Ryan, G.; Pandit, A.; Apatsidis, D.P. Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials 2006, 27, 2651–2670. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.H.; Yang, C.; Wang, F.; Zhao, H.D.; Qu, S.G.; Li, X.Q.; Zhang, W.W.; Li, Y.Y. Biomedical TiNbZrTaSi alloys designed by d-electron alloy design theory. Mater. Des. 2015, 85, 7–13. [Google Scholar] [CrossRef]

- Bordia, R.K.; Kang, S.-J.L.; Olevsky, E.A. Current understanding and future research directions at the onset of the next century of sintering science and technology. J. Am. Ceram. Soc. 2017, 100, 2314–2352. [Google Scholar] [CrossRef]

- Wei, X.; Maximenko, A.L.; Back, C.; Izhvanov, O.; Olevsky, E.A. Effects of loading modes on densification efficiency of spark plasma sintering: Sample study of zirconium carbide consolidation. Philos. Mag. Lett. 2017, 97, 265–272. [Google Scholar] [CrossRef]

- Bellosi, A.; Monteverde, F.; Sciti, D. Fast Densification of Ultra-high-temperature ceramics by spark plasma sintering. Int. J. Appl. Ceram. Technol. 2006, 3, 32–40. [Google Scholar] [CrossRef]

- Petersen, A.S.; Cheung, A.M.; Neilson, H.J.; Poon, S.J.; Shiflet, G.J.; Lewandowski, J.J. Processing and properties of Ni-based bulk metallic glass via spark plasma sintering of pulverized amorphous ribbons. Mater. Res. Soc. Adv. 2017, 1–6. [Google Scholar] [CrossRef]

- Ghasali, E.; Fazili, A.; Alizadeh, M.; Shirvanimoghaddam, K.; Ebadzadeh, T. Evaluation of Microstructure and Mechanical Properties of Al-TiC Metal Matrix Composite Prepared by Conventional, Microwave and Spark Plasma Sintering Methods. Materials 2017, 10, 1255. [Google Scholar] [CrossRef] [PubMed]

- Olevsky, E.A. Theory of sintering: From discrete to continuum. Mater. Sci. Eng. R Rep. 1998, 23, 41–100. [Google Scholar] [CrossRef]

- Lee, G.; McKittrick, J.; Ivanov, E.; Olevsky, E.A. Densification mechanism and mechanical properties of tungsten powder consolidated by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2016, 61, 22–29. [Google Scholar] [CrossRef]

- Ashby, M.F. HIP 6.0 Background Reading; University Of Cambridge: Cambridge, UK, 1990. [Google Scholar]

- Kun, W.; Zhengyi, F.; Weimin, W.; Yucheng, W.; Jinyong, Z.; Qingjie, Z. Study on fabrication and mechanism in of porous metals by spark plasma sintering. J. Mater. Sci. 2007, 42, 302–306. [Google Scholar] [CrossRef]

- Coble, R.L. Effects of Particle-Size Distribution in Initial-Stage Sintering. J. Am. Ceram. Soc. 1973, 56, 461–466. [Google Scholar] [CrossRef]

- Revankar, G.; Saxena, A.; Voorhees, H.; Ritchie, R.; Shapiro, E.; Walsh, R.; Robinson, R.; Shoberg, R.S.; Waterhouse, R.; Roos, E.; et al. Harness Testing. Mechanical Testing and Evaluation, 1st ed.; ASM International Press: Materials Park, OH, USA, 2000; Volume 8, pp. 282–287. [Google Scholar]

- Nakai, M.; Niinomi, M.; Akahori, T.; Tsutsumi, H.; Ogawa, M. Effect of Oxygen Content on Microstructure and Mechanical Properties of Biomedical Ti-29Nb-13Ta-4.6Zr Alloy under Solutionized and Aged Conditions. Mater. Trans. 2009, 50, 2716–2720. [Google Scholar] [CrossRef]

- Kopova, I.; Stráský, J.; Harcuba, P.; Landa, M.; Janeček, M.; Bačákova, L. Newly developed Ti–Nb–Zr–Ta–Si–Fe biomedical beta titanium alloys with increased strength and enhanced biocompatibility. Mater. Sci. Eng. C 2016, 60, 230–238. [Google Scholar] [CrossRef] [PubMed]

- Paneto, F.J.; Pereira, J.L.; Lima, J.O.; Jesus, E.J.; Silva, L.A.; Lima, E.S.; Cabral, R.F.; Santos, C. Effect of porosity on hardness of Al2O3–Y3Al5O12 ceramic composite. Int. J. Refract. Met. Hard Mater. 2015, 48, 365–368. [Google Scholar] [CrossRef]

- Wei, X.; Back, C.; Izhvanov, O.; Haines, C.D.; Olevsky, E.A. Zirconium carbide produced by spark plasma sintering and hot pressing: Densification kinetics, grain growth, and thermal properties. Materials 2016, 9, 577. [Google Scholar] [CrossRef] [PubMed]

- Manière, C.; Olevsky, E.A. Porosity Dependence of Powder Compaction Constitutive Parameters: Determination Based on Spark Plasma Sintering Tests. Scr. Mater. 2017, 141, 62–66. [Google Scholar] [CrossRef]

- Lee, G.; Olevsky, E.A.; Manière, C.; Maximenko, A.; Izhvanov, O.; Back, C.; McKittrick, J. Effect of electric current on densification behavior of conductive ceramic powders consolidated by spark plasma sintering. Acta Mater. 2018, 144, 524–533. [Google Scholar] [CrossRef]

| d (μm) | P (Mpa) | T (°C) | Q (kJ/mol) | m | R2 | Error |

|---|---|---|---|---|---|---|

| 300 | 20 | 400 | 153.91 | 0.23 | 0.741 | 0.052 |

| 600 | 154.00 | 0.23 | 0.989 | 0.001 | ||

| 800 | 131.37 | 0.23 | 0.987 | 0.007 | ||

| 40 | 400 | - | 0.23 | - | - | |

| 600 | 153.00 | 0.23 | 0.948 | 0.005 | ||

| 800 | - | 0.23 | - | -- | ||

| 60 | 400 | - | 0.23 | - | - | |

| 600 | 148.55 | 0.23 | 0.997 | 0.001 | ||

| 800 | - | 0.23 | - | - | ||

| 150 | 20 | 400 | - | 0.23 | - | - |

| 600 | - | 0.23 | - | - | ||

| 800 | 145.59 | 0.23 | 0.995 | 0.001 | ||

| 40 | 400 | - | 0.23 | - | - | |

| 600 | 141.65 | 0.23 | 0.997 | 0.001 | ||

| 800 | 149.15 | 0.23 | 0.949 | 0.001 | ||

| 60 | 400 | 153.89 | 0.23 | 0.824 | 0.0004 | |

| 600 | 146.23 | 0.23 | 0.996 | 0.001 | ||

| 800 | 144.87 | 0.23 | 2.699 | 0.006 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rechtin, J.; Torresani, E.; Ivanov, E.; Olevsky, E. Fabrication of Titanium-Niobium-Zirconium-Tantalium Alloy (TNZT) Bioimplant Components with Controllable Porosity by Spark Plasma Sintering. Materials 2018, 11, 181. https://doi.org/10.3390/ma11020181

Rechtin J, Torresani E, Ivanov E, Olevsky E. Fabrication of Titanium-Niobium-Zirconium-Tantalium Alloy (TNZT) Bioimplant Components with Controllable Porosity by Spark Plasma Sintering. Materials. 2018; 11(2):181. https://doi.org/10.3390/ma11020181

Chicago/Turabian StyleRechtin, Jack, Elisa Torresani, Eugene Ivanov, and Eugene Olevsky. 2018. "Fabrication of Titanium-Niobium-Zirconium-Tantalium Alloy (TNZT) Bioimplant Components with Controllable Porosity by Spark Plasma Sintering" Materials 11, no. 2: 181. https://doi.org/10.3390/ma11020181

APA StyleRechtin, J., Torresani, E., Ivanov, E., & Olevsky, E. (2018). Fabrication of Titanium-Niobium-Zirconium-Tantalium Alloy (TNZT) Bioimplant Components with Controllable Porosity by Spark Plasma Sintering. Materials, 11(2), 181. https://doi.org/10.3390/ma11020181