Comparison of Analytical Approaches Predicting the Compressive Strength of Fibre Reinforced Polymers

Abstract

1. Introduction

2. Analytical Models for Compressive Strength Prediction of FRP

3. Experimental Methods

3.1. Materials and Sample Preparation

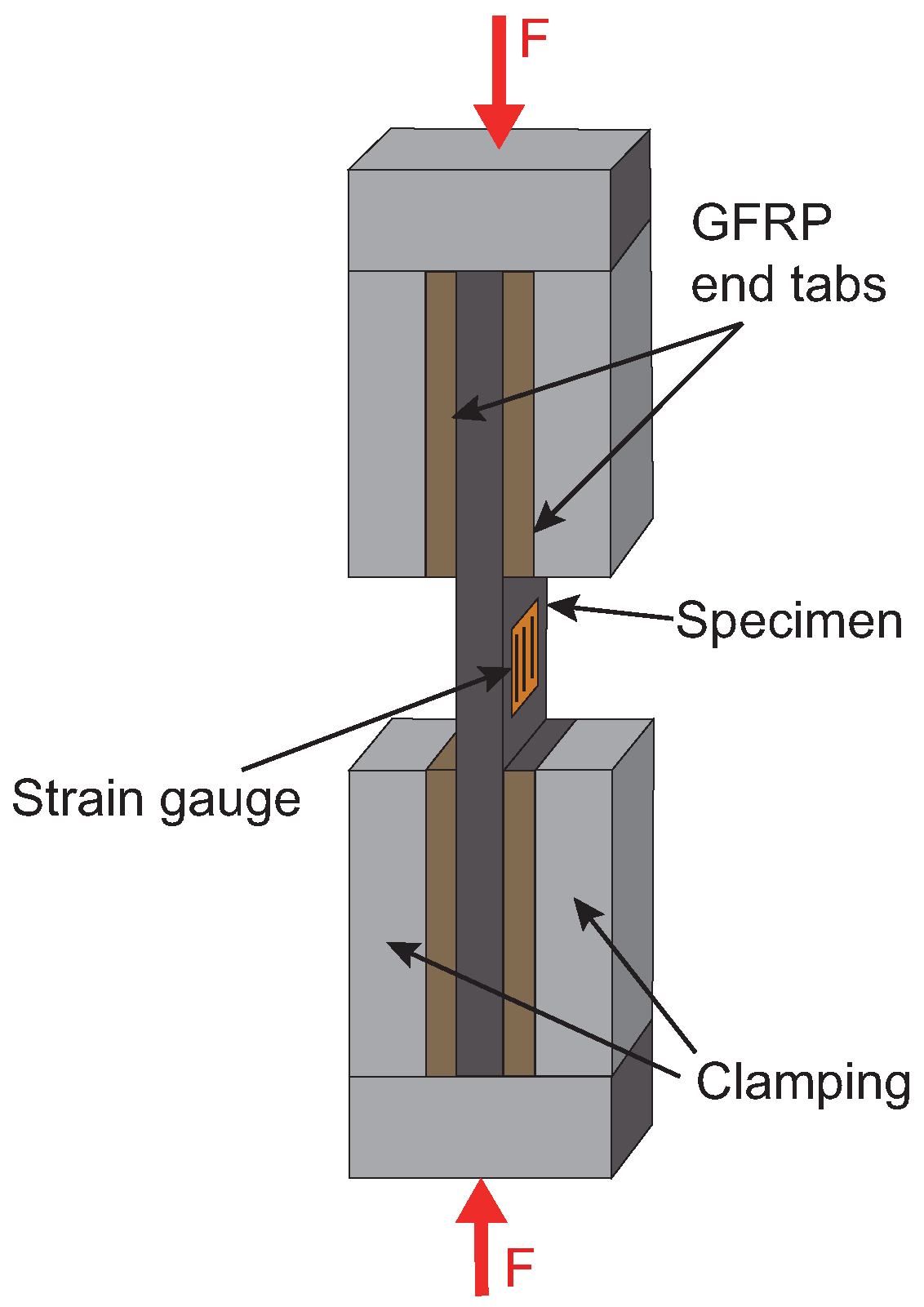

3.2. Quasi-Static Tests

3.3. Measurement of Fibre Misalignment

4. Results and Discussion

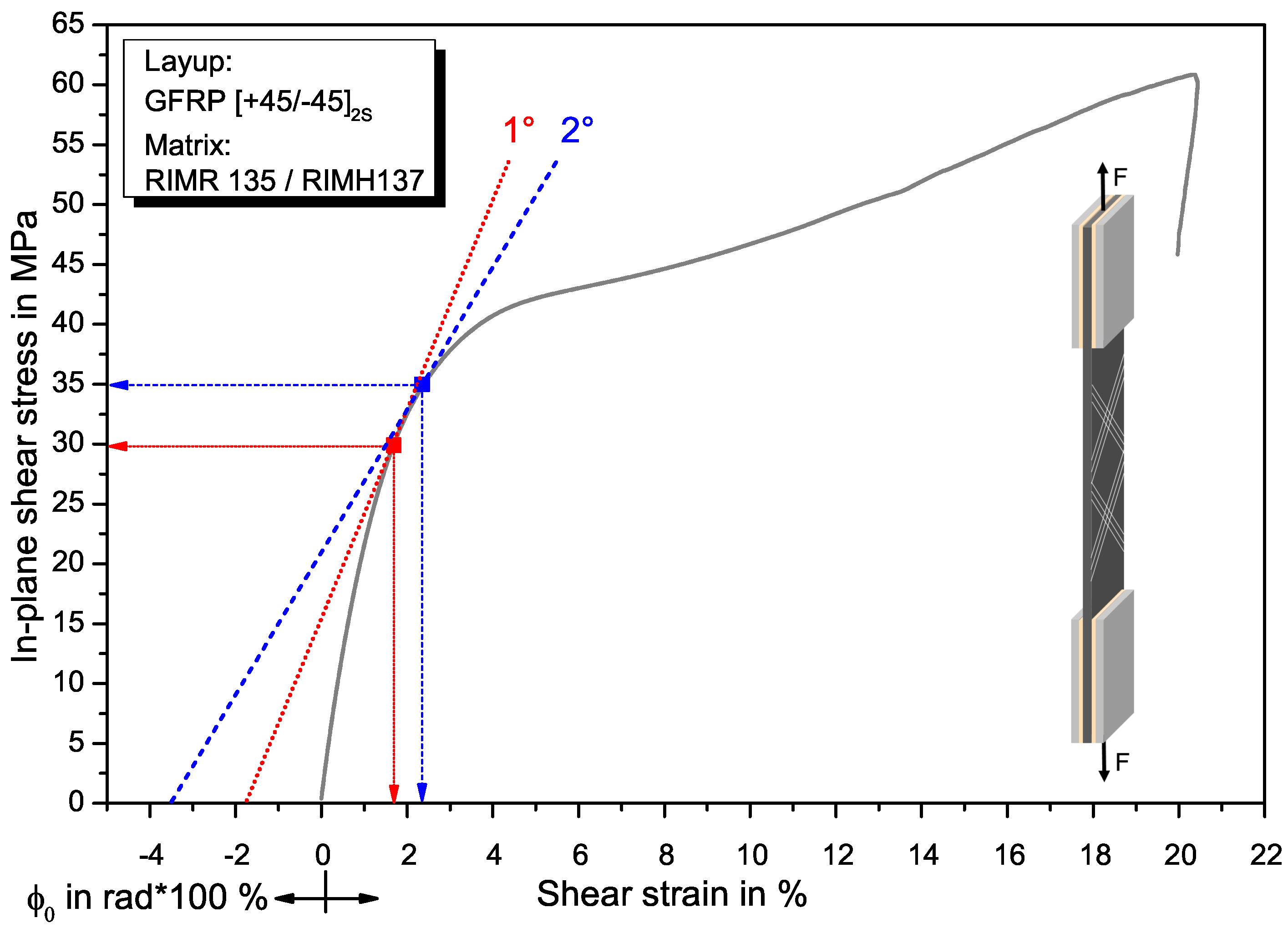

4.1. Tensile Tests with Angle-Ply Laminates

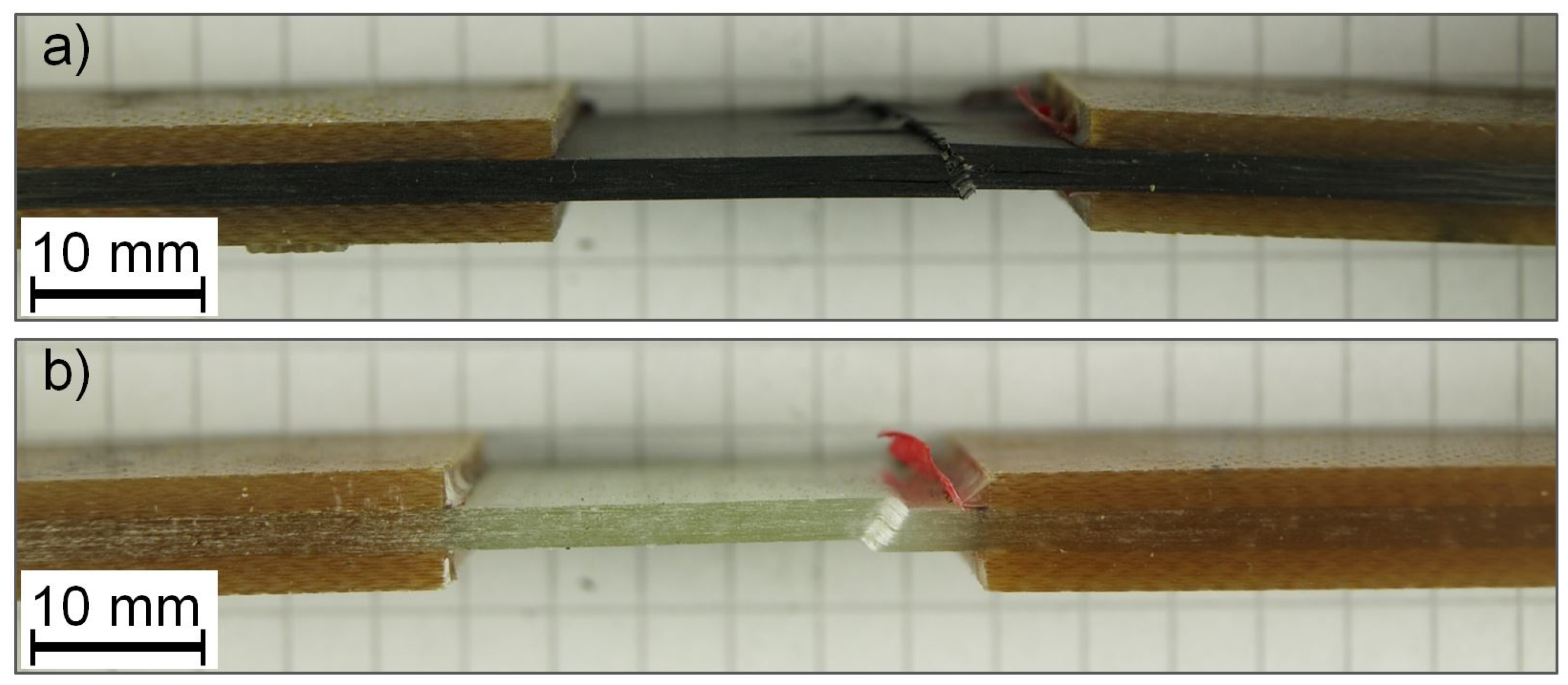

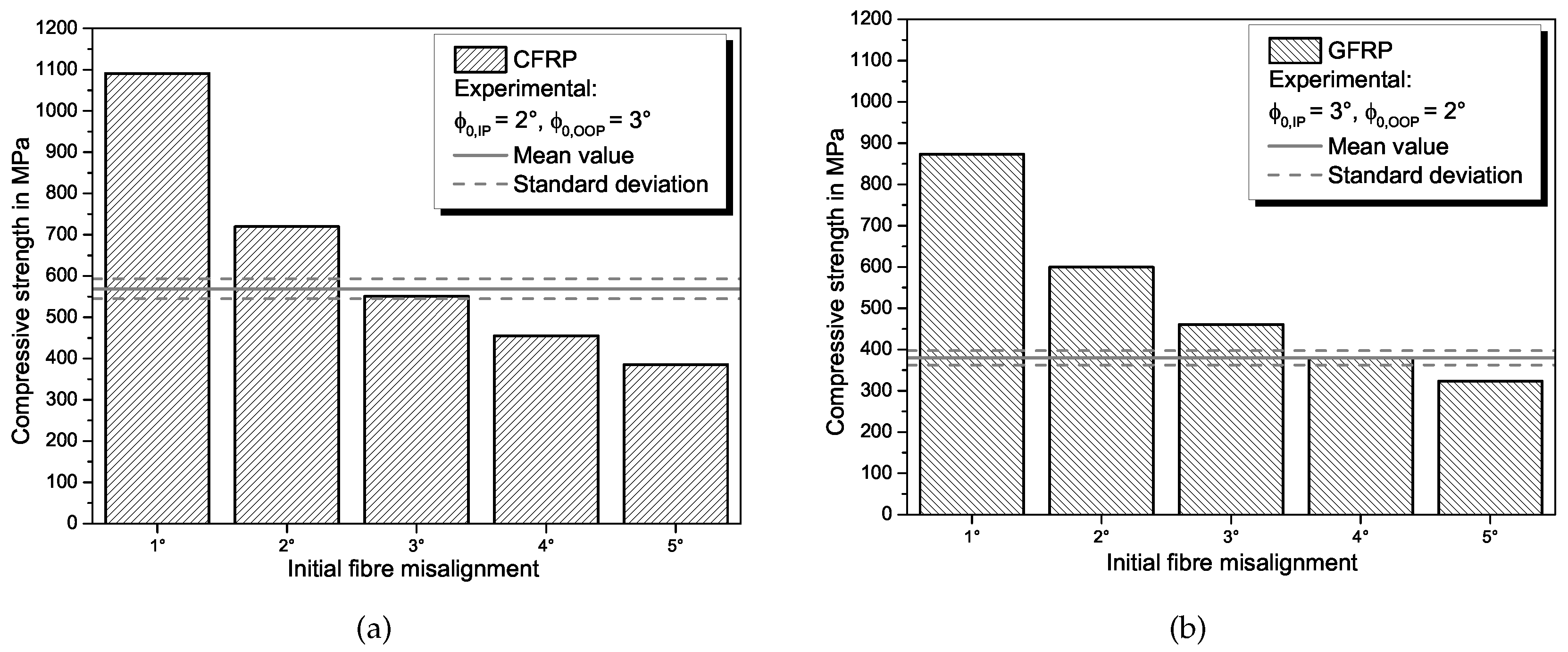

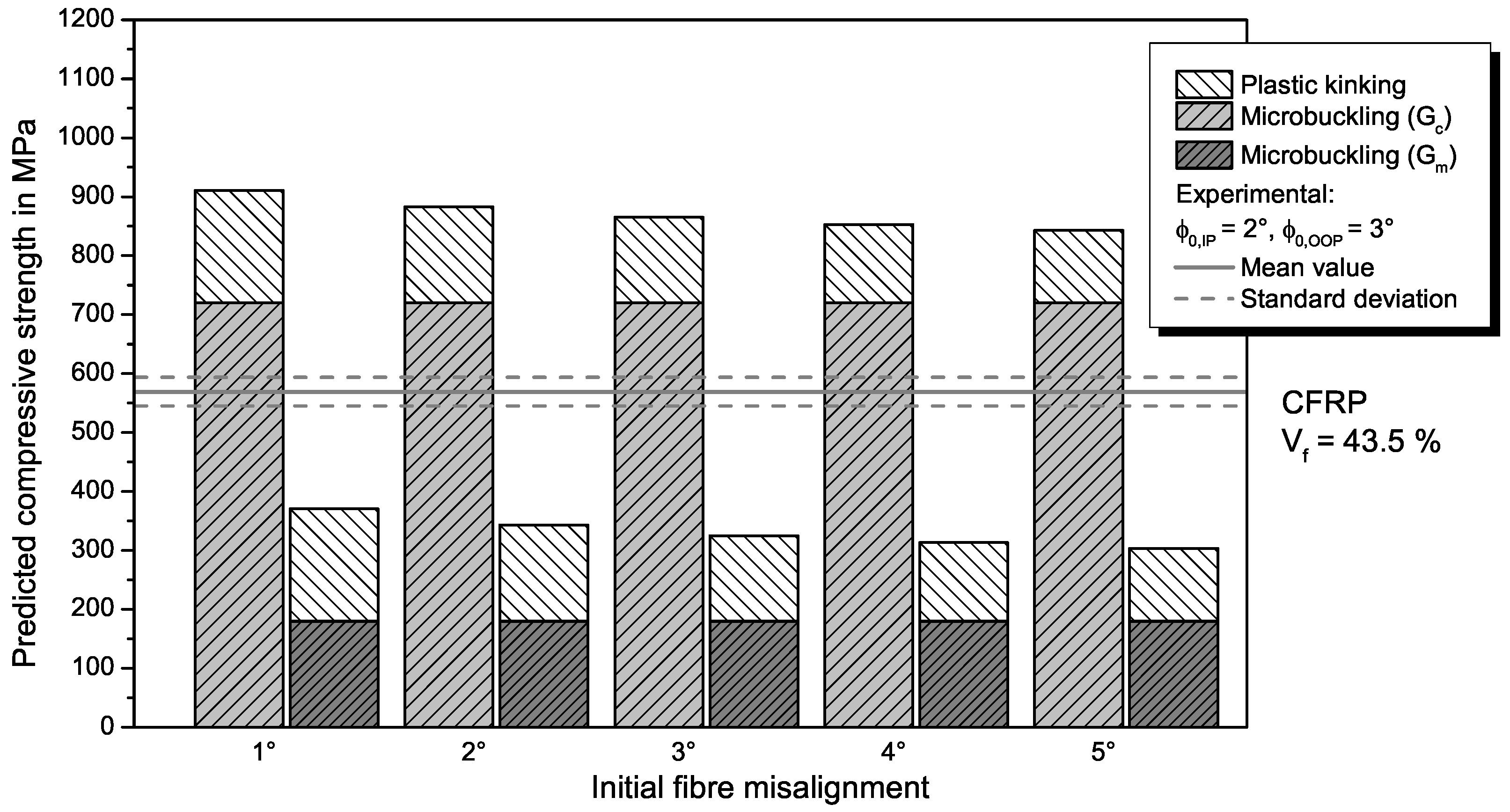

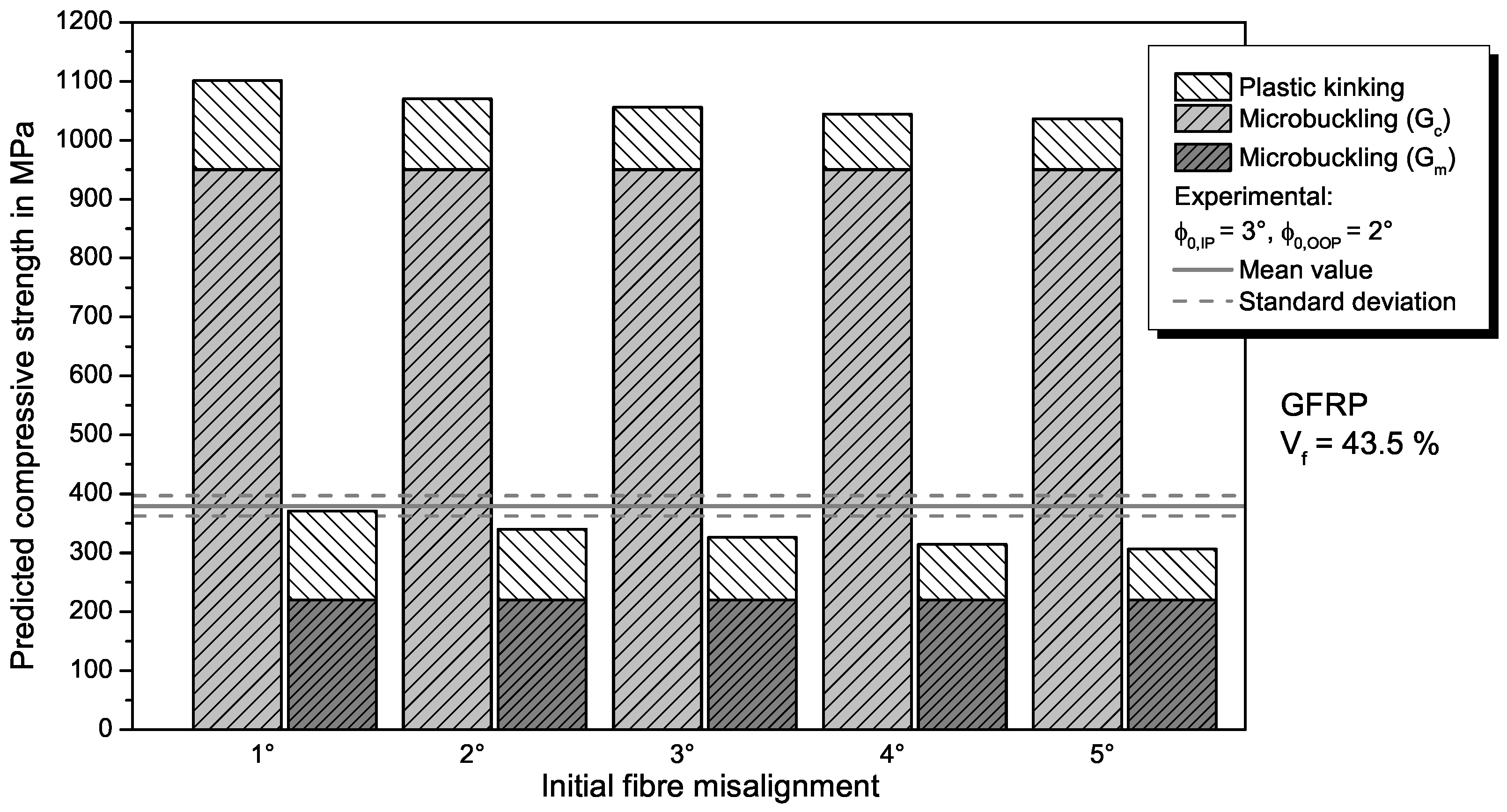

4.2. Compression Tests and Comparison with Analytical Models

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CFRP | Carbon fibre reinforced polymer |

| FRP | Fibre reinforced polymer |

| GFRP | Glass fibre reinforced polymer |

| IP | In-plane |

| OOP | Out-of-plane |

| UD | Unidirectional |

| VARTM | Vacuum assisted resin transfer moulding |

References

- Soutis, C. Measurement of the static compressive strength of carbon-fibre/epoxy laminates. Compos. Sci. Technol. 1991, 42, 373–392. [Google Scholar] [CrossRef]

- Rosen, B.W. Mechanics of composite strengthening: American Society for Metals. In Proceedings of the Seminar on Fiber Composite Materials, Philadelphia, PA, USA, 17–18 October 1964. [Google Scholar]

- Poulsen, J.S.; Moran, P.M.; Shih, C.F.; Byskov, E. Kink band initiation and band broadening in clear wood under compressive loading. Mech. Mater. 1997, 25, 67–77. [Google Scholar] [CrossRef]

- Moran, P.M.; Liu, X.H.; Shih, C.F. Kink band formation and band broadening in fiber composites under compressive loading. Acta Metall. Mater. 1995, 43, 2943–2958. [Google Scholar] [CrossRef]

- Liu, X.H.; Moran, P.M.; Shih, C.F. The mechanics of compressive kinking in unidirectional fiber reinforced ductile matrix composites. Thick Compos. 1996, 27, 553–560. [Google Scholar] [CrossRef]

- Budiansky, B.; Fleck, N.A.; Amazigo, J.C. On kink-band propagation in fiber composites. J. Mech. Phys. Solids 1998, 46, 1637–1653. [Google Scholar] [CrossRef]

- Gutkin, R.; Pinho, S.T.; Robinson, P.; Curtis, P. On the transition from shear-driven fibre compressive failure to fibre kinking in notched CFRP laminates under longitudinal compression. Compos. Sci. Technol. 2010, 70, 1223–1231. [Google Scholar] [CrossRef]

- Gutkin, R.; Pinho, S.T.; Robinson, P.; Curtis, P. Micro-mechanical modelling of shear-driven fibre compressive failure and of fibre kinking for failure envelope generation in CFRP laminates. Compos. Sci. Technol. 2010, 70, 1214–1222. [Google Scholar] [CrossRef]

- Soutis, C.; Turkmen, D. Moisture and Temperature Effects of the Compressive Failure of CFRP Unidirectional Laminates. J. Compos. Mater. 1997, 31, 832–849. [Google Scholar] [CrossRef]

- Prabhakar, P.; Waas, A.M. Micromechanical modeling to determine the compressive strength and failure mode interaction of multidirectional laminates. Compos. Part A Appl. Sci. Manuf. 2013, 50, 11–21. [Google Scholar] [CrossRef]

- Prabhakar, P.; Waas, A.M. Interaction between kinking and splitting in the compressive failure of unidirectional fiber reinforced laminated composites. Compos. Struct. 2013, 98, 85–92. [Google Scholar] [CrossRef]

- Leopold, C.; Schütt, M.; Liebig, W.V.; Philipkowski, T.; Kürten, J.; Schulte, K.; Fiedler, B. Compression Fracture of CFRP Laminates Containing Stress Intensifications. Materials 2017, 10, 39. [Google Scholar] [CrossRef] [PubMed]

- Schultheisz, C.R.; Waas, A.M. Compressive failure of composites, part I: Testing and micromechanical theories. Prog. Aerosp. Sci. 1996, 32, 1–42. [Google Scholar] [CrossRef]

- Waas, A.M.; Schultheisz, C.R. Compressive failure of composites, part II: Experimental studies. Prog. Aerosp. Sci. 1996, 32, 43–78. [Google Scholar] [CrossRef]

- Soutis, C. Compression Failure of Laminated Composites. In Comprehensive Composite Materials II; Beaumont, P.W., Zweben, C.H., Eds.; Elsevier: Oxford, UK, 2018; pp. 221–231. [Google Scholar] [CrossRef]

- Berbinau, P.; Soutis, C.; Guz, I.A. Compressive failure of 0° unidirectional carbon-fibre-reinforced plastic (CFRP) laminates by fibre microbuckling. Compos. Sci. Technol. 1999, 59, 1451–1455. [Google Scholar] [CrossRef]

- Berbinau, P.; Soutis, C.; Goutas, P.; Curtis, P. Effect of off-axis ply orientation on 0°-fibre microbuckling. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1197–1207. [Google Scholar] [CrossRef]

- Argon, A.S. Fracture of Composites. In Reatise of Materials Science and Technology; Academic Press: New York, NY, USA, 1972; Volume 1. [Google Scholar]

- Budiansky, B. Micromechanics. Comput. Struct. 1983, 16, 3–12. [Google Scholar] [CrossRef]

- Budiansky, B.; Fleck, N.A. Compressive failure of fibre composites. J. Mech. Phys. Solids 1993, 41, 183–211. [Google Scholar] [CrossRef]

- Budiansky, B.; Fleck, N.A. Compressive Kinking of Fiber Composites: A Topical Review. Appl. Mech. Rev. 1994, 47, S246–S250. [Google Scholar] [CrossRef]

- Wisnom, M. The effect of fibre misalignment on the compressive strength of unidirectional carbon fibre/epoxy. Composites 1990, 21, 403–407. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Atkinson, J.W. Compressive Failure Due to Shear Instability: Experimental Investigation of Waviness and Correlation with Analysis. J. Reinf. Plast. Compos. 1996, 15, 420–439. [Google Scholar] [CrossRef]

- Shams, S.S.; Elhajjar, R.F. Investigation into the effects of fiber waviness in standard notched composite specimens. CEAS Aeronaut. J. 2015, 6, 541–555. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Jones, M.I.; Hallett, S.R. Compressive failure of laminates containing an embedded wrinkle; experimental and numerical study. Compos. Part A Appl. Sci. Manuf. 2015, 73, 132–142. [Google Scholar] [CrossRef]

- Liebig, W.V.; Leopold, C.; Schulte, K. Photoelastic study of stresses in the vicinity of a unique void in a fibre-reinforced model composite under compression. Compos. Sci. Technol. 2013, 84, 72–77. [Google Scholar] [CrossRef]

- Liebig, W.V.; Viets, C.; Schulte, K.; Fiedler, B. Influence of voids on the compressive failure behaviour of fibre-reinforced composites. Compos. Sci. Technol. 2015, 117, 225–233. [Google Scholar] [CrossRef]

- Liebig, W.V.; Schulte, K.; Fiedler, B. Hierarchical analysis of the degradation of fibre-reinforced polymers under the presence of void imperfections. Philos. Trans. Ser. A Math. Phys. Eng. Sci. 2016, 374, 20150279. [Google Scholar] [CrossRef] [PubMed]

- Bazhenov, S.; Kuperman, A.M.; Zelenskii, E.S.; Berlin, A.A. Compression failure of unidirectional glass-fibre-reinforced plastics. Compos. Sci. Technol. 1992, 45, 201–208. [Google Scholar] [CrossRef]

- Batdorf, S.B.; Ko, R.W.C. Stress-Strain Behavior and Failure of Uniaxial Composites in Combined Compression and Shear-I; Interim Technical Report; School of Engineering and Applied Science, University of California: Oakland, CA, USA, 1985. [Google Scholar]

- Batdorf, S.B.; Ko, R.W.C. Stress-Strain Behavior and Failure of Uniaxial Composites in Combined Compression and Shear-II; Interim Technical Report; School of Engineering and Applied Science, University of California: Oakland, CA, USA, 1985. [Google Scholar]

- Jumahat, A.; Soutis, C.; Jones, F.R.; Hodzic, A. Fracture mechanisms and failure analysis of carbon fibre/toughened epoxy composites subjected to compressive loading. Compos. Struct. 2010, 92, 295–305. [Google Scholar] [CrossRef]

- Jumahat, A.; Soutis, C.; Hodzic, A. A Graphical Method Predicting the Compressive Strength of Toughened Unidirectional Composite Laminates. Appl. Compos. Mater. 2011, 18, 65–83. [Google Scholar] [CrossRef]

- German Institute for Standardisation. Aerospace Series. Carbon Fibre Laminates. Determination of the Fibre, Resin and Void Contents; German Institute for Standardisation: Berlin, Germany, 1998. [Google Scholar]

- ASTM international. Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture; ASTM international: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM international. Test Method for Compressive Properties of Polymer Matrix Composite Materials with Unsupported Gage Section by Shear Loading; ASTM international: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM international. Test Method for In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a 45 Laminate; ASTM international: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Yurgartis, S.W. Measurement of small angle fiber misalignments in continuous fiber composites. Compos. Sci. Technol. 1987, 30, 279–293. [Google Scholar] [CrossRef]

- Steif, P.S. A model for kinking in fiber composites—I. Fiber breakage via micro-buckling. Int. J. Solids Struct. 1990, 26, 549–561. [Google Scholar] [CrossRef]

- Sun, Q.; Guo, H.; Zhou, G.; Meng, Z.; Chen, Z.; Kang, H.; Keten, S.; Su, X. Experimental and computational analysis of failure mechanisms in unidirectional carbon fiber reinforced polymer laminates under longitudinal compression loading. Compos. Struct. 2018, 203, 335–348. [Google Scholar] [CrossRef]

| Rosen [2] | Budiansky [19,20] | Berbinau [16] | Jumahat [32] | |

|---|---|---|---|---|

| Fibre misalignment | X | ✓ | ✓ * | ✓ |

| Fibre radius | X | X | ✓ | ✓ |

| Fibre Young’s modulus | ✓ | X | ✓ | ✓ |

| Matrix shear modulus | ✓ | X | ✓ | ✓ |

| Shear yield stress | X | ✓ | X | ✓ |

| Shear yield strain | X | ✓ | X | ✓ |

| Fibre Type | Layup | Areal Weight in g/m | in % |

|---|---|---|---|

| Carbon fibre | 200 | 43.49 | |

| Carbon fibre | [+45/−45] | 200 | 42.51 |

| Glass fibre | 250 | 43.53 | |

| Glass fibre | [+45/−45] | 250 | 38.86 |

| Material | in MP | in % | |

|---|---|---|---|

| GFRP | 1° | 29.9 | 1.68 |

| GFRP | 2° | 35.0 | 2.35 |

| GFRP | 3° | 36.7 | 2.72 |

| GFRP | 4° | 38.1 | 3.08 |

| GFRP | 5° | 38.9 | 3.31 |

| CFRP | 1° | 36.0 | 1.55 |

| CFRP | 2° | 41.5 | 2.27 |

| CFRP | 3° | 44.6 | 2.87 |

| CFRP | 4° | 46.0 | 3.14 |

| CFRP | 5° | 47.4 | 3.57 |

| Material | Shear Strength | Shear Modulus | Max. Shear Strain | Compressive Strength |

|---|---|---|---|---|

| GFRP | () | () | ()% | () |

| CFRP | () | () | ()% | () |

| Experiment | Rosen [2] | Budiansky [19,20] | Berbinau [16] | Jumahat [32] | |

|---|---|---|---|---|---|

| CFRP in | 1785 | 551 | 720 | 865 | |

| Deviation CFRP in | - | 1216 | * | 151 | 296 |

| Deviation CFRP in % | - | 214 | * | 27 | 52 |

| GFRP in | 1785 | 461 | 950 | 1056 | |

| Deviation GFRP in | - | 1405 | 81 | 570 | 676 |

| Deviation GFRP in % | - | 370 | 21 | 150 | 178 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leopold, C.; Harder, S.; Philipkowski, T.; Liebig, W.V.; Fiedler, B. Comparison of Analytical Approaches Predicting the Compressive Strength of Fibre Reinforced Polymers. Materials 2018, 11, 2517. https://doi.org/10.3390/ma11122517

Leopold C, Harder S, Philipkowski T, Liebig WV, Fiedler B. Comparison of Analytical Approaches Predicting the Compressive Strength of Fibre Reinforced Polymers. Materials. 2018; 11(12):2517. https://doi.org/10.3390/ma11122517

Chicago/Turabian StyleLeopold, Christian, Sergej Harder, Timo Philipkowski, Wilfried V. Liebig, and Bodo Fiedler. 2018. "Comparison of Analytical Approaches Predicting the Compressive Strength of Fibre Reinforced Polymers" Materials 11, no. 12: 2517. https://doi.org/10.3390/ma11122517

APA StyleLeopold, C., Harder, S., Philipkowski, T., Liebig, W. V., & Fiedler, B. (2018). Comparison of Analytical Approaches Predicting the Compressive Strength of Fibre Reinforced Polymers. Materials, 11(12), 2517. https://doi.org/10.3390/ma11122517