P-Texture Effect on the Fatigue Crack Propagation Resistance in an Al-Cu-Mg Alloy Bearing a Small Amount of Silver

Abstract

1. Introduction

2. Materials and Methods

3. Results

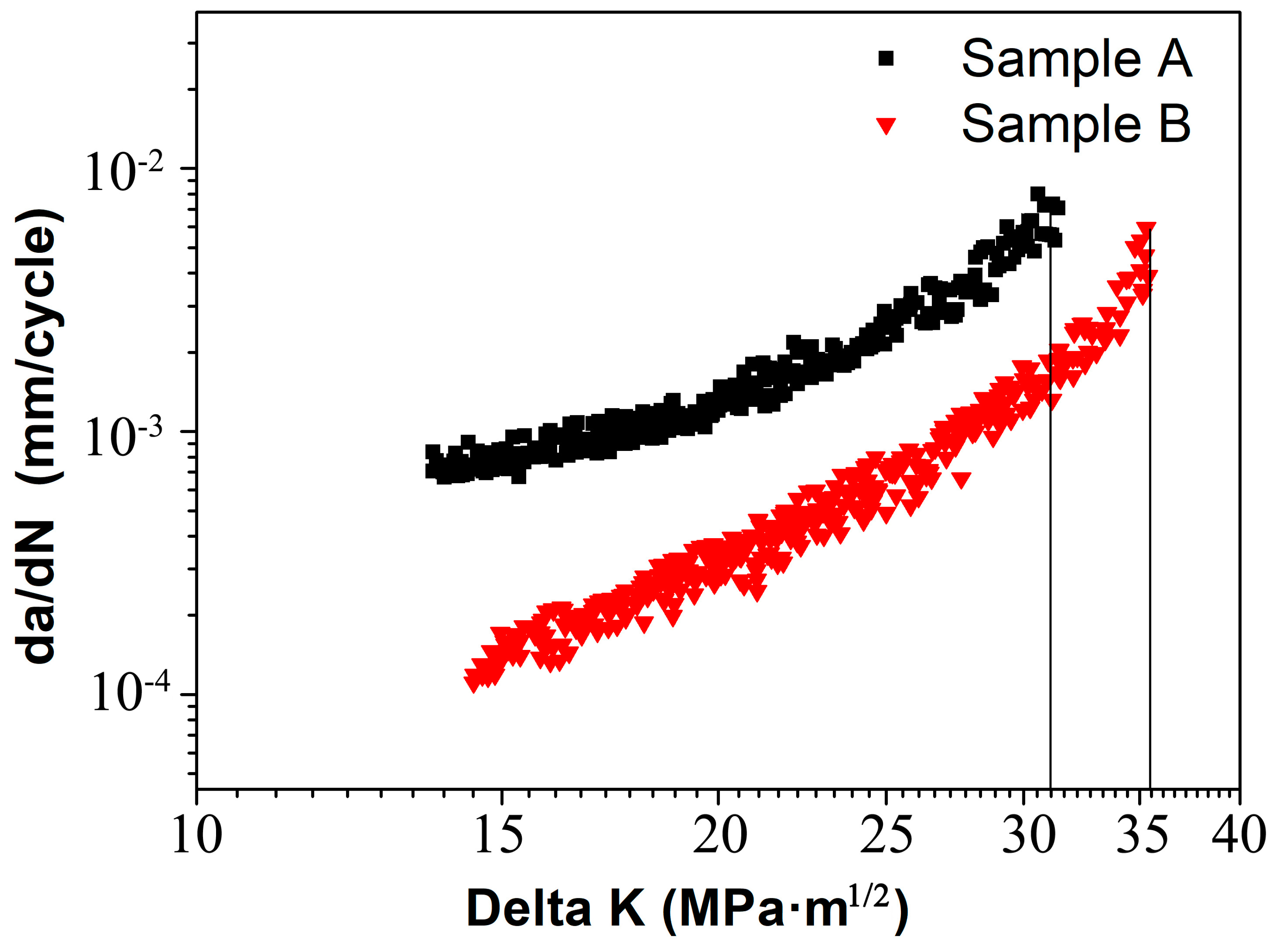

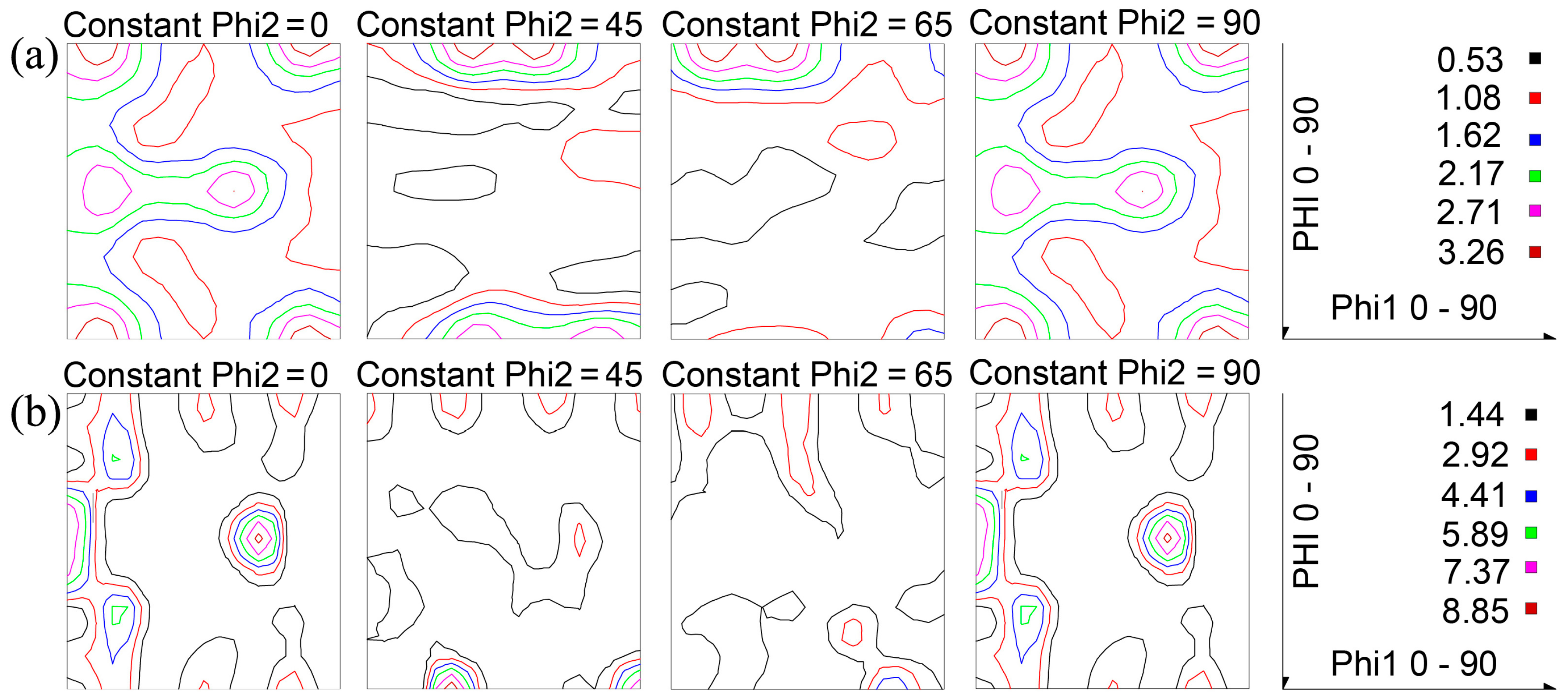

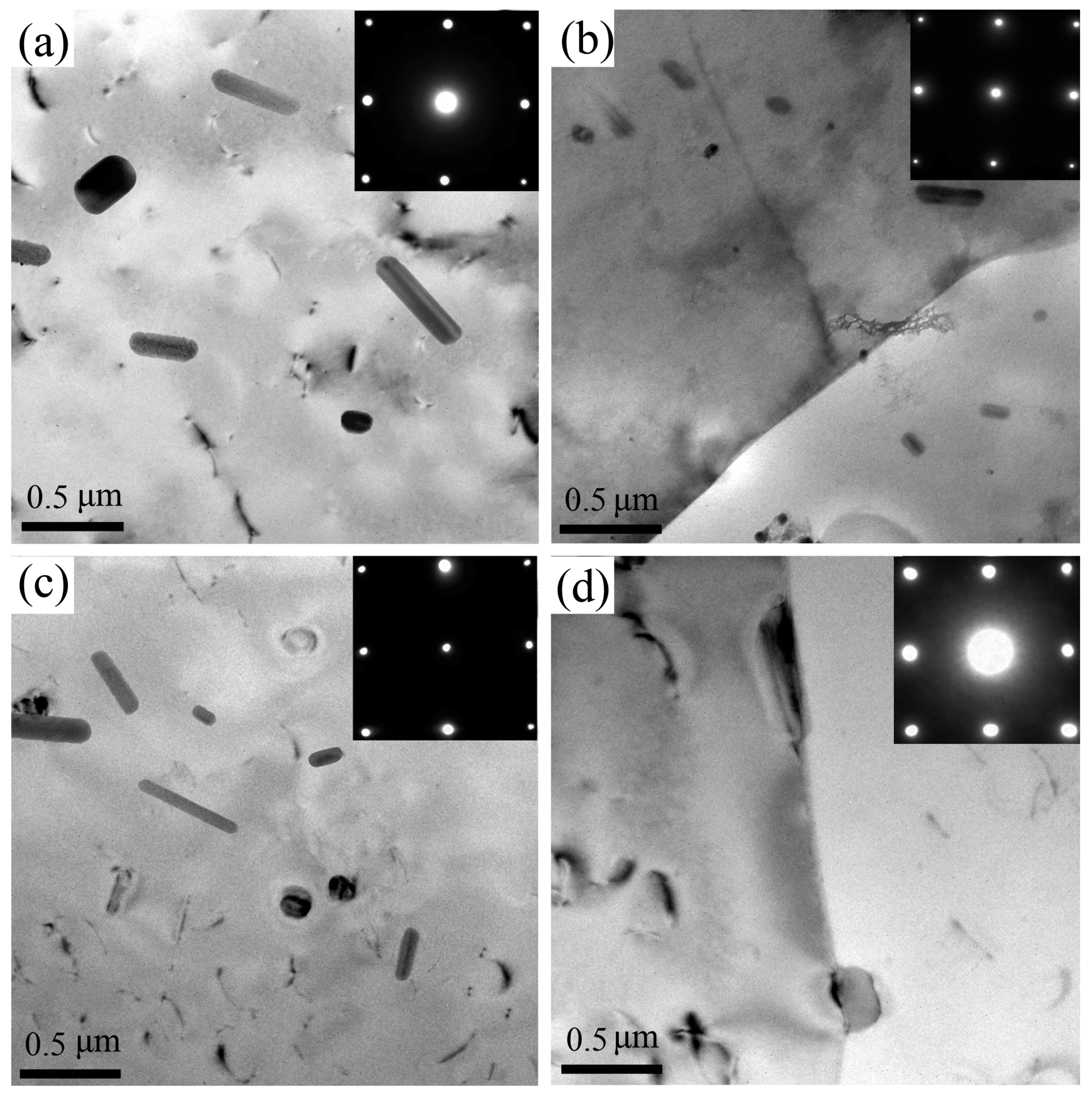

3.1. Mechanical Properties and Textures

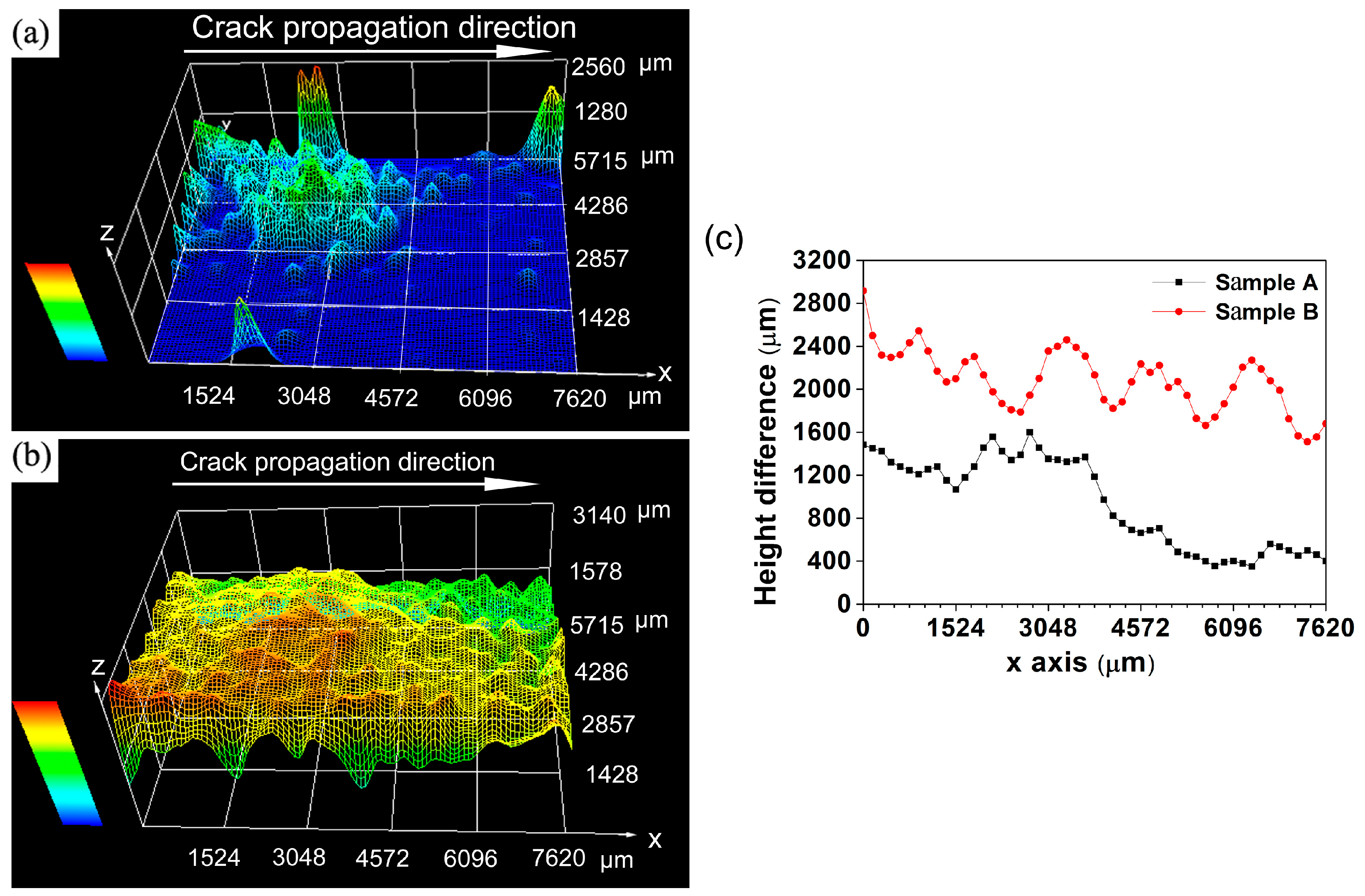

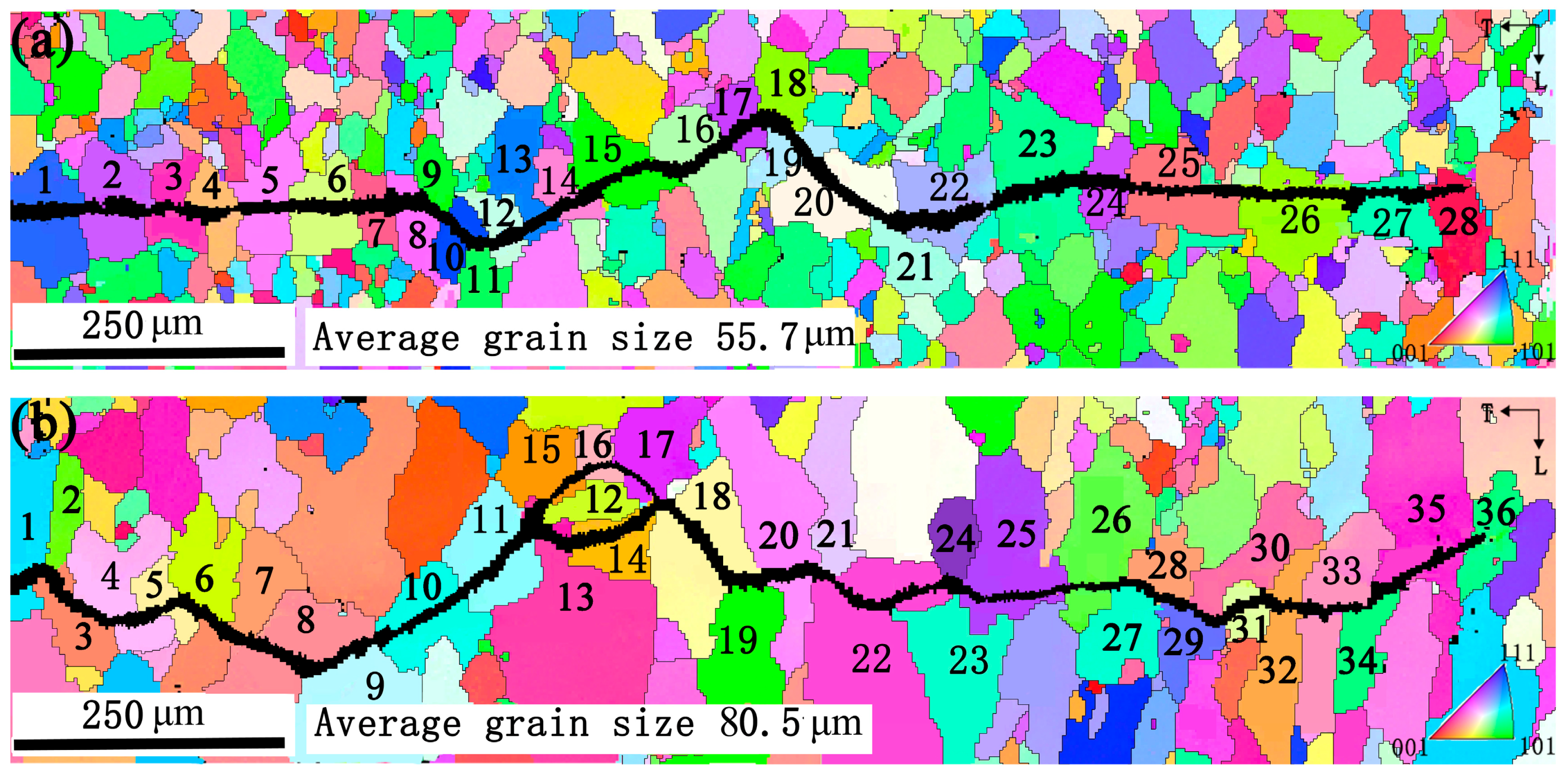

3.2. Fatigue Crack Propagation Morphology

4. Discussion

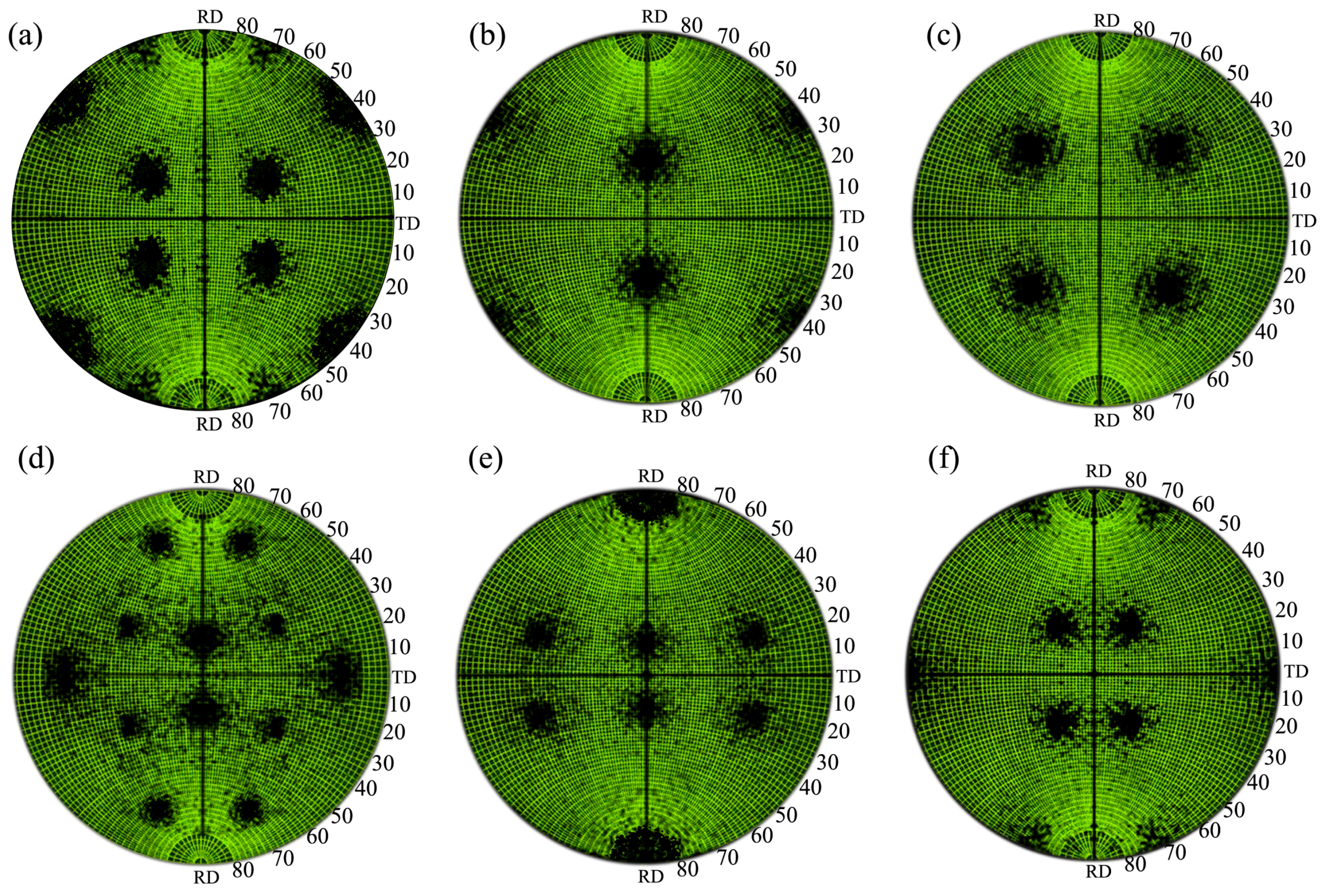

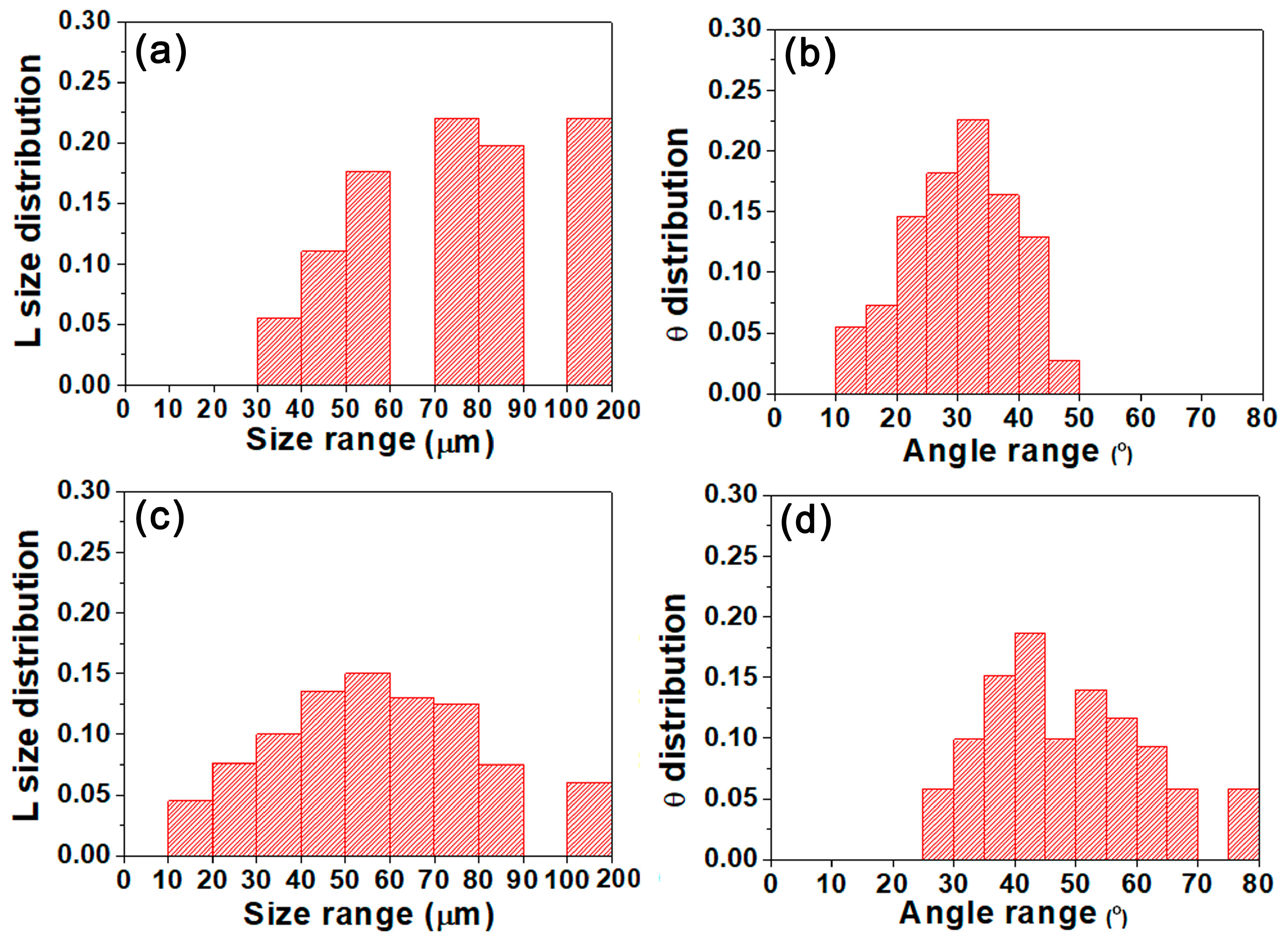

4.1. Effect of Grain Orientation on FCP

4.2. Effect of Texture on Crack Closure Behavior

5. Conclusions

- (1)

- High intensity P-texture sheet has lower , lower FCP rate and higher damage tolerance than random texture sheet.

- (2)

- High intensity P-texture induces significant fatigue crack deflection and severe RICC effect up to 0.74, which are responsible for the large FCP resistance of Al-Cu-Mg-Ag alloy.

- (3)

- P-grains possess large twist angle of 105–170° and tilt angle of 5–60° with neighboring grains, which is similar to Goss-grains. However, the grain boundaries of other grains such as Copper-, R-, Cube- and Brass-grains are distinct different from that of P- or Goss-grains. This is the fundamental reason that P-grains give rise to great fatigue crack deflection as Goss-grains.

- (4)

- Similar to Goss-grains, the most {111} slipping planes of P-grains are distributed in the range of 30–50° deviating from transverse direction (TD) of the sheet, which is close to the direction of maximum shear stress. This is beneficial to promote the reciprocating slip of dislocation near fatigue crack tip, reduce stress concentration and fatigue damage accumulation rate and improve damage tolerance of Al-Cu-Mg-Ag alloy.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bray, G.H.; Glazov, M.; Rioja, R.J.; Li, D.; Gangloff, R.P. Effect of artificial aging on the fatigue crack propagation resistance of 2000 series aluminum alloys. Int. J. Fatigue 2001, 23, 265–276. [Google Scholar] [CrossRef]

- Liu, Y.B.; Liu, Z.Y.; Li, Y.T.; Xia, Q.K.; Zhou, J. Enhanced fatigue crack propagation resistance of an Al-Cu-Mg alloy by artificial aging. Mater. Sci. Eng. A 2008, 492, 333–336. [Google Scholar]

- Bai, S.; Liu, Z.Y.; Zhou, X.W.; Gu, Y.X.; Yu, D.E. Strain-induced dissolution of Cu-Mg co-clusters and dynamic recrystallization near a fatigue crack tip of an underaged Al-Cu-Mg alloy during cyclic loading at ambient temperature. Scr. Mater. 2011, 64, 1133–1136. [Google Scholar] [CrossRef]

- Chen, D.L.; Chaturvedi, M.C.; Goel, N.; Richards, N.L. Fatigue crack growth behavior of X2095 Al-Li alloy. Int. J. Fatigue 1999, 21, 1079–1086. [Google Scholar] [CrossRef]

- Blankenship, C.P., Jr.; Starke, E.A., Jr. The fatigue crack growth behavior of the Al-Cu-Li alloy weldalite 049. Fatigue Fract. Eng. Mater. Struct. 1990, 14, 103–114. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Fatigue behaviour of light alloys with ultrafine grain structure produced by severe plastic deformation: An overview. Int. J. Fatigue 2010, 32, 898–907. [Google Scholar] [CrossRef]

- Yin, D.Y.; Liu, H.Q.; Chen, Y.Q.; Yi, D.Q.; Wang, B.; Wang, B.; Shen, F.H.; Fu, S.; Tang, C.; Pan, S.P. Effect of grain size on fatigue-crack growth in 2524 aluminium alloy. Int. J. Fatigue 2016, 84, 9–16. [Google Scholar] [CrossRef]

- Hockauf, K.; Wagner, M.F.X.; Halle, T.; Niendorf, T.; Hockauf, M.; Lampke, T. Influence of precipitates on low-cycle fatigue and crack growth behavior in an ultrafine-grained aluminum alloy. Acta Mater. 2014, 80, 250–263. [Google Scholar] [CrossRef]

- Ahadi, A.; Sun, Q.P. Grain size dependence of fracture toughness and crack-growth resistance of superelastic NiTi. Scr. Mater. 2016, 113, 171–175. [Google Scholar] [CrossRef]

- Gourgues, A.F. Electron back scatter diffraction and cracking. Mater. Sci. Technol. 2002, 18, 119–133. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1. [Google Scholar] [CrossRef]

- Li, L.L.; Zhang, Z.J.; Zhang, P.; Zhang, Z.F. Higher fatigue cracking resistance of twin boundaries than grain boundaries in Cu bicrystals. Scr. Mater. 2011, 65, 505–508. [Google Scholar] [CrossRef]

- Watanabe, C.; Monzen, R.; Tazaki, K. Effects of Al3Sc particle size and precipitate-free zones on fatigue behavior and dislocation structure of an aged Al-Mg-Sc alloy. Int. J. Fatigue 2008, 30, 635–641. [Google Scholar] [CrossRef]

- Zhai, T.; Wilkinson, A.J.; Martin, J.W. A crystallographic mechanism for fatigue crack propagation through grain boundaries. Acta Mater. 2000, 48, 4917–4927. [Google Scholar] [CrossRef]

- Zhai, T.; Jiang, X.P.; Li, J.X.; Garratt, M.D.; Bray, G.H. The grain boundary geometry for optimum resistance to growth of short fatigue cracks in high strength Al-alloys. Int. J. Fatigue 2005, 27, 1202–1209. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Li, F.D.; Xia, P.; Bai, S.; Gu, Y.X.; Yu, D.E.; Zeng, S.M. Mechanisms for Goss-grains induced crack deflection and enhanced fatigue crack propagation resistance in fatigue stage II of an AA2524 alloy. Mater. Sci. Eng. A 2015, 625, 271–277. [Google Scholar] [CrossRef]

- Li, F.D.; Liu, Z.Y.; Wu, W.T.; Xia, P.; Ying, P.Y.; Zhao, Q.; Li, J.L.; Bai, S.; Ye, C.W. On the role of texture in governing fatigue crack propagation behavior of 2524 aluminum alloy. Mater. Sci. Eng. A 2016, 669, 367–378. [Google Scholar] [CrossRef]

- Jung, J.Y.; Yoon, J.I.; Lee, D.N.; Kim, H.S. Numerical analysis on the formation of P-orientation near coarse precipitates in FCC crystals during recrystallization. Acta Mater. 2017, 131, 363–372. [Google Scholar] [CrossRef]

- Huang, K.; Zhang, K.; Marthinsen, K.; Logé, R.E. Controlling grain structure and texture in Al-Mn from the competition between precipitation and recrystallization. Acta Mater. 2017, 141, 360–373. [Google Scholar]

- Huang, K.; Li, Y.J.; Marthinsen, K. Effect of heterogeneously distributed preexisting dispersoids on the recrystallization behavior of a cold-rolled Al-Mn-Fe-Si alloy. Mater. Charact. 2015, 102, 92–97. [Google Scholar] [CrossRef]

- Schulthess, T.C.; Turchi, P.E.A.; Gonis, A.; Nieh, T.G. Systematic study of stacking fault energies of random Al-based alloys. Acta Mater. 1998, 46, 2215–2221. [Google Scholar] [CrossRef]

- Duckham, A.; Knutsen, R.D.; Engler, O. Influence of deformation variables on the formation of copper-type shear bands in Al-1Mg. Acta Mater. 2001, 49, 2739–2749. [Google Scholar] [CrossRef]

- Jia, N.; Eisenlohr, P.; Roters, F.; Raabe, D.; Zhao, X. Orientation dependence of shear banding in face-centered-cubic single crystals. Acta Mater. 2012, 60, 3415–3434. [Google Scholar] [CrossRef]

- Sidor, J.J.; Petrov, R.H.; Kestens, L.A.I. Modeling the crystallographic texture changes in aluminum alloys during recrystallization. Acta Mater. 2011, 59, 5735–5748. [Google Scholar] [CrossRef]

- Srivatsan, T.S.; Kolar, D.; Magnusen, P. The cyclic fatigue and final fracture behavior of aluminum alloy 2524. Mater. Des. 2002, 23, 129–139. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Yi, D.Q.; Yi, J.; Wang, B.; Xu, D.Z.; Li, S.C. Twinning and orientation relationships of T-phase precipitates in an Al matrix. J. Mater. Sci. 2013, 48, 3225–3231. [Google Scholar] [CrossRef]

- Malekjani, S.; Hodgson, P.D.; Cizek, P.; Sabirov, I.; Hilditch, T.B. Cyclic deformation response of UFG 2024 Al alloy. Int. J. Fatigue 2011, 33, 700–717. [Google Scholar] [CrossRef]

- Wu, W.T.; Liu, Z.Y.; Hu, Y.C.; Li, F.D.; Bai, S.; Xia, P.; Wang, A.; Ye, C.W. Goss texture intensity effect on fatigue crack propagation resistance in an Al-Cu-Mg alloy. J. Alloys Compd. 2018, 730, 318–326. [Google Scholar] [CrossRef]

- Parry, M.R.; Syngellakis, S.; Sinclair, I. Numerical modelling of combined roughness and plasticity induced crack closure effects in fatigue. Mater. Sci. Eng. A 2000, 291, 224–234. [Google Scholar] [CrossRef]

- Llorca, J. Roughness-induced fatigue crack closure: a numerical study. Fatigue Fract. Eng. Mater. Struct. 1992, 15, 655–669. [Google Scholar] [CrossRef]

- Kamp, N.; Parry, M.R.; Singh, K.D.; Sinclair, I. Analytical and finite element modelling of roughness induced crack closure. Acta Mater. 2004, 52, 343–353. [Google Scholar] [CrossRef]

- Dugdale, D.S. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Carter, R.D.; Lee, E.W.; Starke, E.A.; Beevers, C.J. The effect of microstructure and environment on fatigue crack closure of 7475 aluminum alloy. Metall. Trans. A 1984, 15, 555–563. [Google Scholar] [CrossRef]

| Procedures | Experimental Parameters |

|---|---|

| I | Hot rolling at 450–460 °C + annealing at 320 °C/4 h + 490 °C/20 min + water quenching + natural aging (sample A) |

| II | Hot rolling at 450–460 °C + annealing at 420 °C/4 h + 490 °C/20 min + water quenching + natural aging (sample B) |

| Samples | Yield Strength (σ0.2) (MPa) | Tensile Strength (σb) (MPa) | σ0.2/σb | Elongation (%) |

|---|---|---|---|---|

| A | 302 | 474 | 0.64 | 19.7 |

| B | 290 | 462 | 0.62 | 22.4 |

| Grain | Measured Indices | Simplified Indices | Measured Texture |

|---|---|---|---|

| 1 | (6 8 9)[21 9 −22] | Close to (111)[221] | Close to Brass |

| 2 | (6 −7 −13)[9 4 2] | Close to (112)(210) | Close to Copper |

| 3 | (5 4 19)[9 22 −7] | Close to (100)(321) | Close to CubeND |

| 4 | (1 4 −13)[−2 7 2] | Close to (013)[311] | Close to Q |

| 5 | (11 −9 25)[−6 1 3] | Close to (112)[210] | Close to Copper |

| 6 | (0 4 9)[−26 −9 4] | Close to (013)[631] | Close to Q |

| 7 | (3 5 22)[−1 27 -6] | Close to (100)[100] | Close to Cube |

| 8 | (7 4 8)[−4 11 −2] | Close to (122)[412] | Close to R |

| 9 | (19 −1 21)[−6 −9 5] | Close to (011)[112] | Close to P |

| 10 | (13 12 15)[12 −13 0] | Close to (111)[110] | Close to L |

| 11 | (2 15 22)[−29 −2 4] | Close to (011)[100] | Close to Goss |

| 12 | (4 13 23)[14 −6 1] | Close to (124)[210] | Close to R |

| 13 | (16 12 17)[3 −4 0] | Close to (111)[110] | Close to L |

| 14 | (8 5 20)[15 −20 −1] | Close to (124)[110] | Close to R |

| 15 | (24 1 33)[29 −3 −21] | Close to (011)[110] | Close to L |

| 16 | (2 8 13)[−17 14 6] | Close to (011)[122] | Close to P |

| 17 | (11 12 20)[−20 20 −1] | Close to (112)[110] | Close to Copper |

| 18 | (3 11 19)[16 −13 5] | Close to (012)[122] | Close to P |

| 19 | (13 6 20)[14 −27 −1] | Close to (123)[210] | Random |

| 20 | (4 9 17)[2 1 −1] | Close to (124)[211] | Close to R |

| 21 | (5 0 8)[−16 9 10] | Close to (011)[122] | Close to P |

| 22 | (5 9 13)[21 10 −15] | Close to (123)[634] | Close to S |

| 23 | (1 6 7)[5 12 −11] | Close to (011)[221] | Close to P |

| 24 | (12 11 22)[−22 −2 13] | Close to (112)[210] | Close to Copper |

| 25 | (2 5 −23)[−10 27 5] | Close to (001)[310] | Close to CubeND |

| 26 | (4 0 7 )[−21 1 12] | Close to (012)[012] | Random |

| 27 | (5 17 20)[−11 −5 7] | Close to (134)[211] | Close to R |

| 28 | (2 −2 25)[−1 −1 0] | Close to (001)(110) | Close to H |

| Grain | Measured Indices | Simplified Indices | Measured Texture |

|---|---|---|---|

| 1 | (9 4 9)[1 9 −5] | Close to (122)[210] | Random |

| 2 | (5 0 8)[8 −28 −5] | Close to (011)[100] | Close to Goss |

| 3 | (1 6 27)[3 13 −3] | Close to (001)[100] | Close to Cube |

| 4 | (7 4 16)[−12 17 1] | Close to (001)[110] | Close to H |

| 5 | (2 7 15)[7 −2 0] | Close to (012)[100] | Close to CubeRD |

| 6 | (0 1 2)[−16 14 −7] | Close to (011)[122] | Close to P |

| 7 | (2 7 −27)[−24 3 1] | Close to (001)[100] | Close to Cube |

| 8 | (2 1 7)[−4 −27 5] | Close to (001)[100] | Close to Cube |

| 9 | (8 3 −12)[3 20 7] | Close to (011)[100] | Close to Goss |

| 10 | (6 17 20)[23 −14 9] | Close to (011)[211] | Close to Brass |

| 11 | (16 7 22)[−5 2 3] | Close to (011)[211] | Close to Brass |

| 12 | (11 1 23)[15 19 −8] | Close to (012)[221] | Close to P |

| 13 | ( 3 1 14)[−9 −1 2] | Close to (001)[10 0] | Close to Cube |

| 14 | (−4 0 13)[ 26 1 8] | Close to (001)[310] | Close to CubeND |

| 15 | (3 7 17)[−17 17 −4] | Close to (001)[110] | Close to H |

| 16 | (3 11 23)[4 1 −1] | Close to (012)[100] | Close to CubeRD |

| 17 | (1 1 2)[−4 6 −1] | Close to (112)[110] | Close to Copper |

| 18 | (7 10 −22)[−4 5 1] | Close to (012)[110] | Close to H |

| 19 | (0 3 4)[26 12 −9] | Close to (011)[100] | Close to Goss |

| 20 | (4 −2 7)[1 −12 −4] | Close to (123)[100] | Close to CubeRD |

| 21 | (1 4 6)[−18 21−11] | Close to (011)[122] | Close to P |

| 22 | (9 11 36)[ 13 −27 5] | Close to (001)[100] | Close to Cube |

| 23 | (3 12 17)[−10 11 −6] | Close to (011)[122] | Close to P |

| 24 | (7 6 11)[4 -23 10] | Close to (112)[012] | Close to Copper |

| 25 | (13 9 19)[5 −3 −2] | Close to (112)[111] | Close to Copper |

| 26 | (1 12 18)[6 10 −7] | Close to (011)[211] | Close to Brass |

| 27 | (1 3 3)[−21 19 −12] | Close to (133)[535] | Close to S |

| 28 | (2 12 19)[5 −4 2] | Close to (012)[122] | Close to P |

| 29 | (4 3 5)[−17 −9 19] | Close to (111)[122] | Close to P |

| 30 | (−5 3 18)[ 21 11 4] | Close to (126)(210) | Close to R |

| 31 | (12 3 22)[6 −2 −3] | Close to (012)(211) | Close to Brass |

| 32 | (3 1 11)[23 −3 −6] | Close to (013)[100] | Close to CubeRD |

| 33 | (4 2 11)[6 −1 −2] | Close to (013)[100] | Close to CubeRD |

| 34 | (5 1 6)[9 −21 4] | Close to (011)[100] | Close to Goss |

| 35 | (3 3 11)[51 4 −15] | Close to (001)[100] | Close to Cube |

| 36 | (14 3 17)[11 −23 −5] | Close to (011)[210] | Close to Goss |

| Samples | KImax (MPa·m1/2) | σ0.2 (MPa) | L (μm) | λrp (μm) | θ (°) | Kcl/KImax |

|---|---|---|---|---|---|---|

| A | 25.32 | 302 | 76 | 36 | 30 | 0.25 |

| B | 23.04 | 290 | 52 | 33 | 47 | 0.73 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Liu, Z.; Zhao, Q.; Bai, S.; Liu, F. P-Texture Effect on the Fatigue Crack Propagation Resistance in an Al-Cu-Mg Alloy Bearing a Small Amount of Silver. Materials 2018, 11, 2481. https://doi.org/10.3390/ma11122481

Hu Y, Liu Z, Zhao Q, Bai S, Liu F. P-Texture Effect on the Fatigue Crack Propagation Resistance in an Al-Cu-Mg Alloy Bearing a Small Amount of Silver. Materials. 2018; 11(12):2481. https://doi.org/10.3390/ma11122481

Chicago/Turabian StyleHu, Yangcheng, Zhiyi Liu, Qi Zhao, Song Bai, and Fei Liu. 2018. "P-Texture Effect on the Fatigue Crack Propagation Resistance in an Al-Cu-Mg Alloy Bearing a Small Amount of Silver" Materials 11, no. 12: 2481. https://doi.org/10.3390/ma11122481

APA StyleHu, Y., Liu, Z., Zhao, Q., Bai, S., & Liu, F. (2018). P-Texture Effect on the Fatigue Crack Propagation Resistance in an Al-Cu-Mg Alloy Bearing a Small Amount of Silver. Materials, 11(12), 2481. https://doi.org/10.3390/ma11122481