Highly Conductive and Transparent AZO Films Fabricated by PLD as Source/Drain Electrodes for TFTs

Abstract

:1. Introduction

2. Experimental

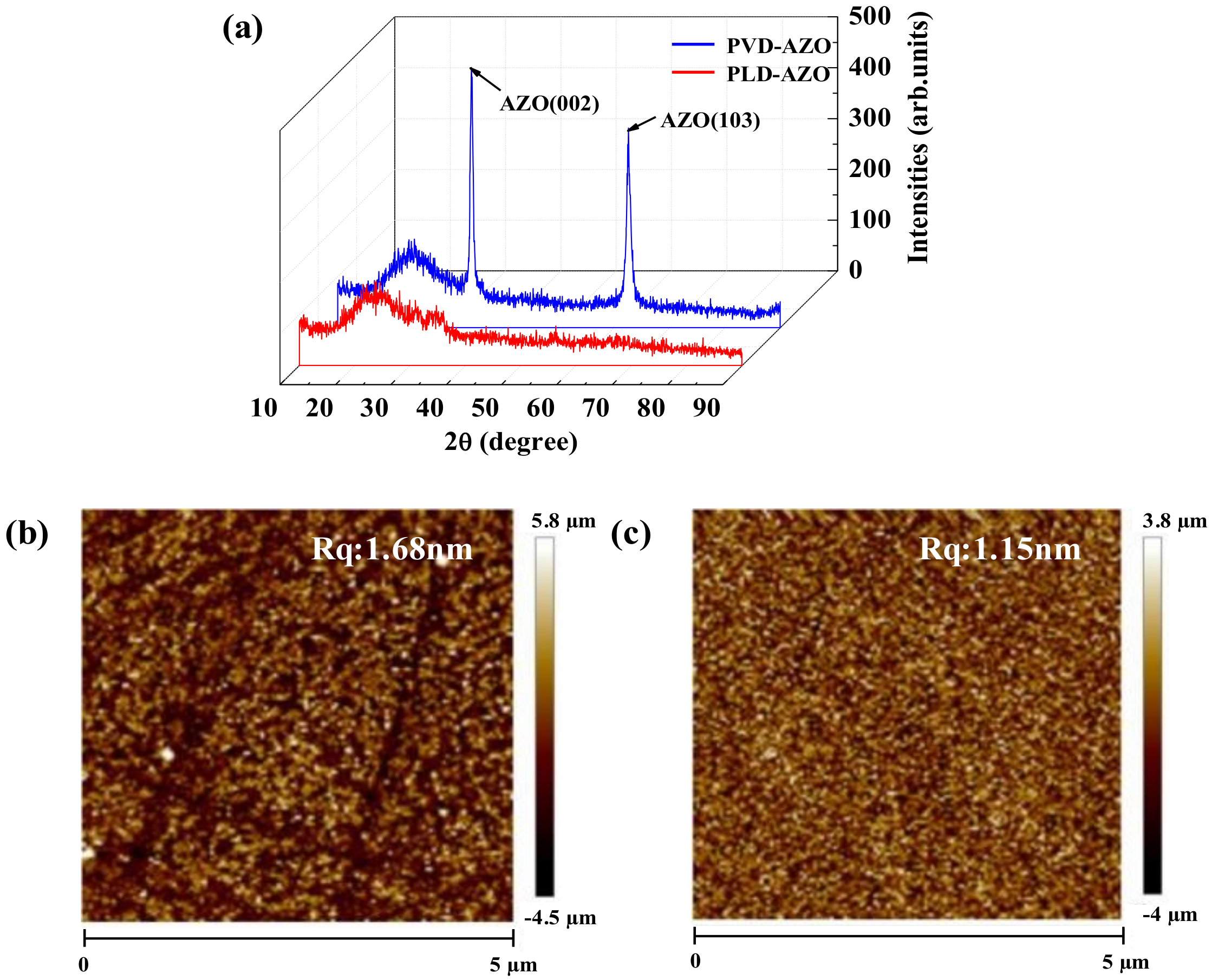

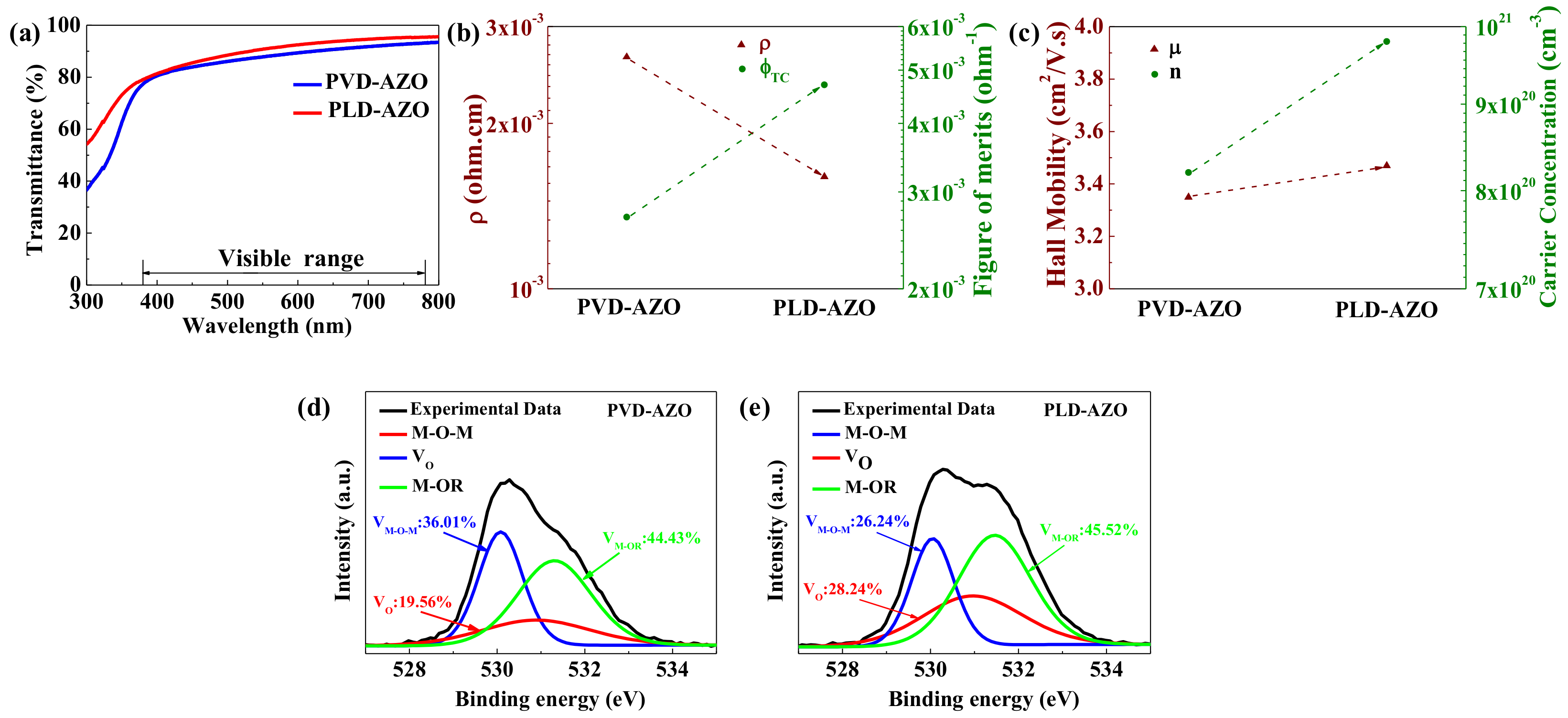

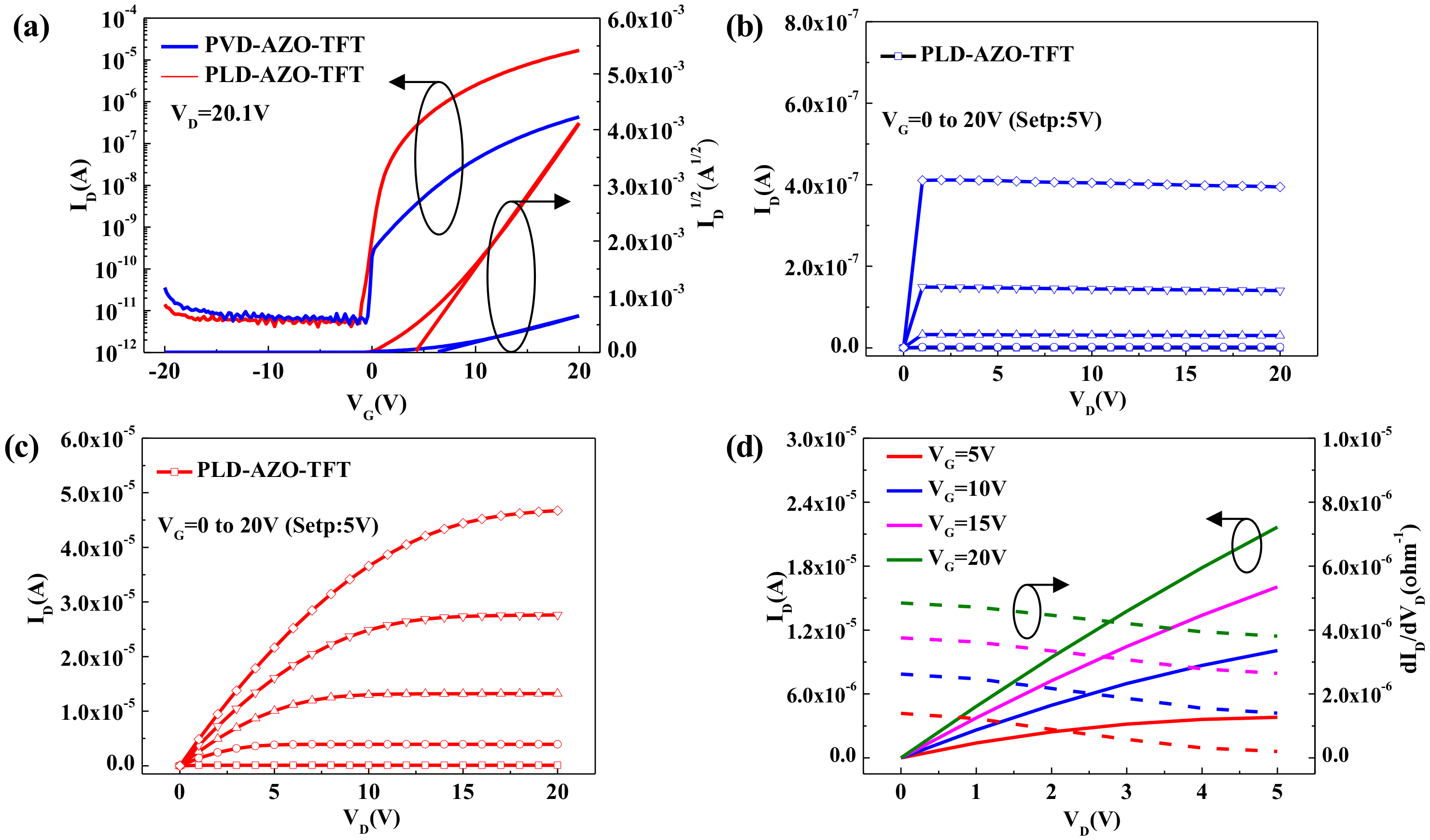

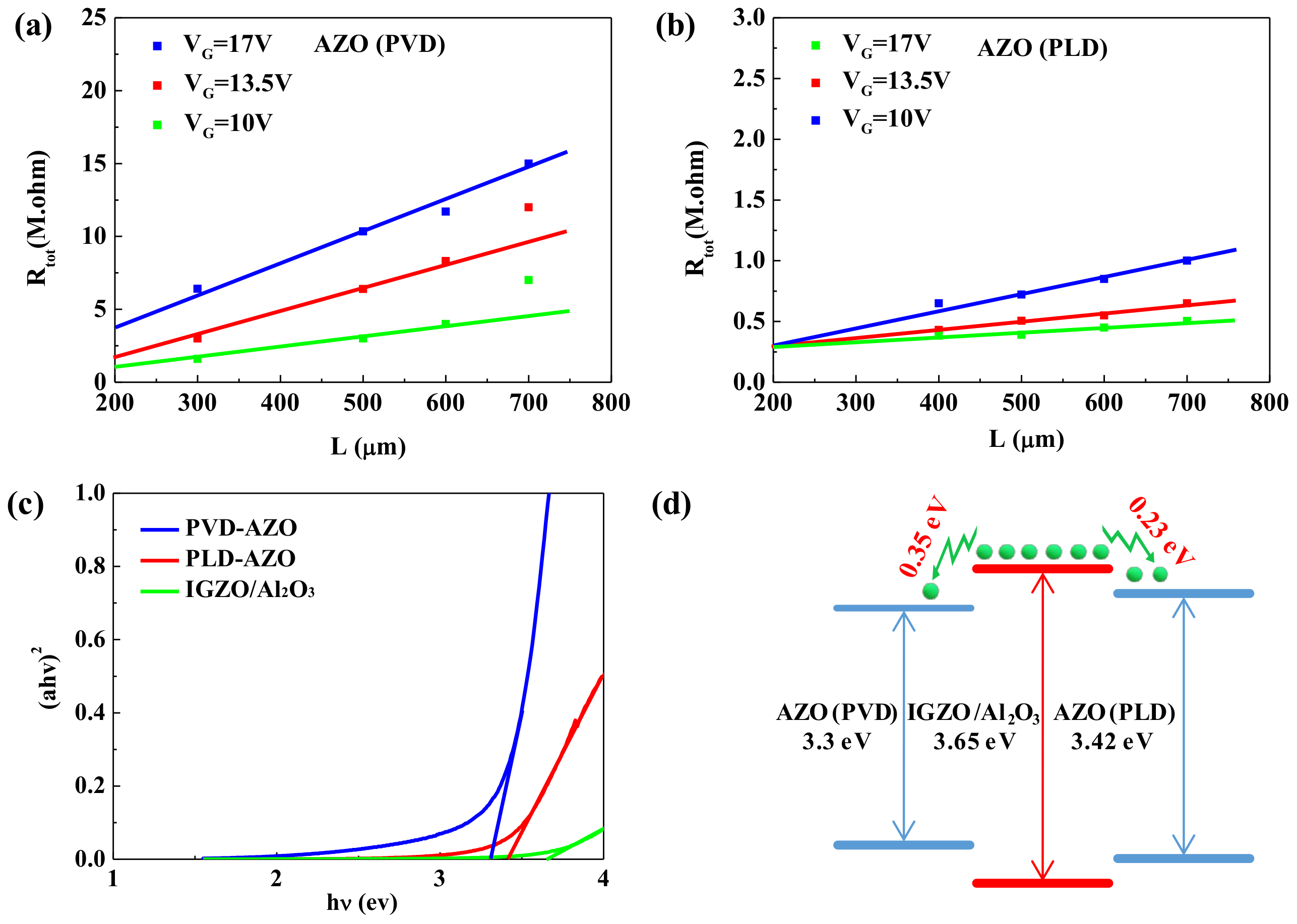

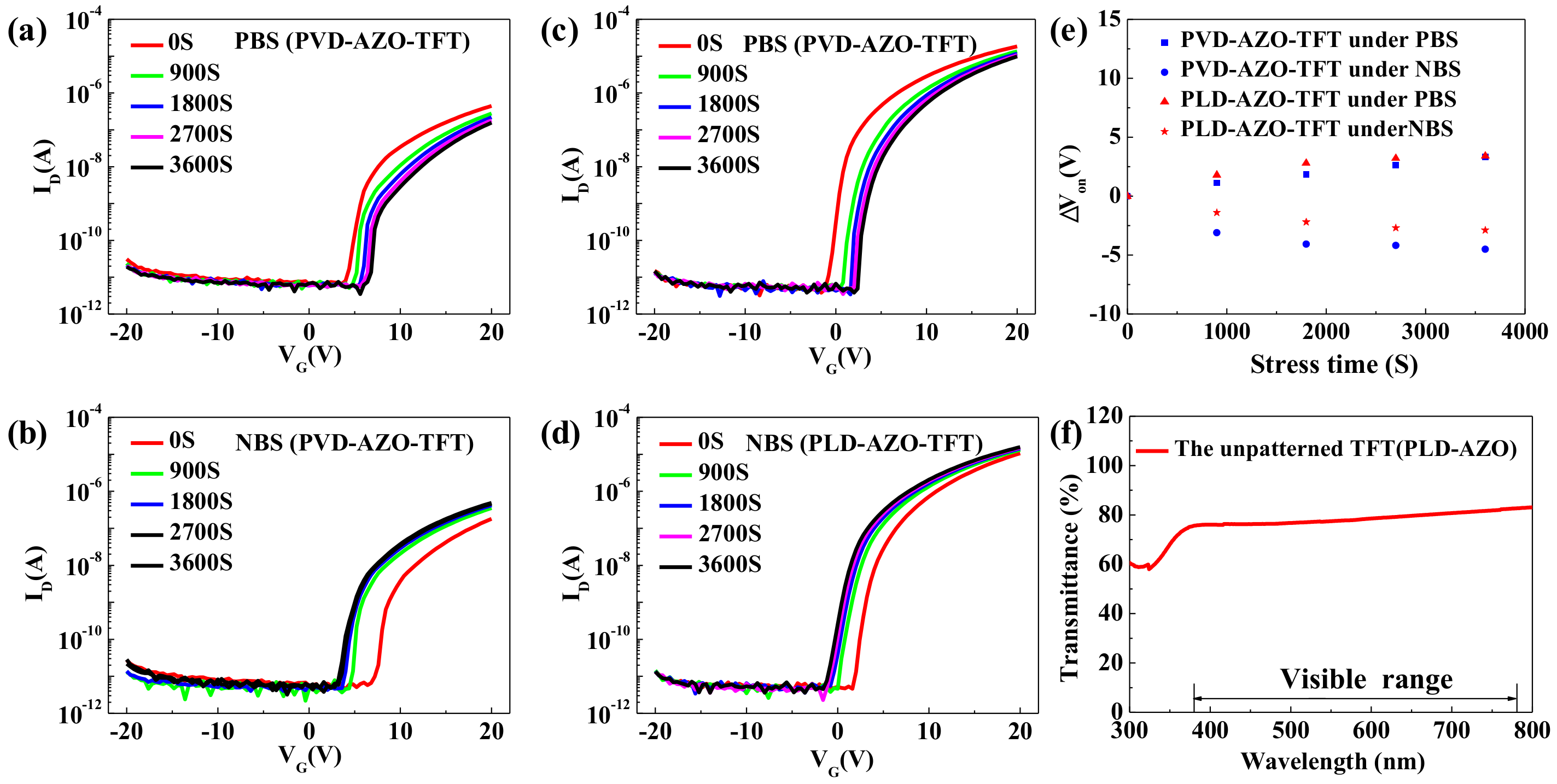

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hoffman, R.L.; Norris, B.J.; Wager, J.F. Zno-based transparent thin-film transistors. Appl. Phys. Lett. 2003, 82, 733–735. [Google Scholar] [CrossRef]

- Fortunato, E.; Barquinha, P.; Pimentel, A.; Gonçalves, A.; Marques, A.; Pereira, L.; Martins, R. Recent advances in ZnO transparent thin film transistors. Thin Solid Films 2005, 487, 205–211. [Google Scholar] [CrossRef]

- Chiang, H.Q.; Wager, J.F.; Hoffman, R.L. High mobility transparent thin-film transistors with amorphous zinc tin oxide channel layer. Appl. Phys. Lett. 2005, 86, 1624–1621. [Google Scholar] [CrossRef]

- Dehuff, N.L.; Kettenring, E.S.; Hong, D.; Chiang, H.Q.; Wager, J.F.; Hoffman, R.L.; Park, C.H.; Keszler, D.A. Transparent thin-film transistors with zinc indium oxide channel layer. J. Appl. Phys. 2005, 97, 064505. [Google Scholar] [CrossRef]

- Kenji, N.; Hiromichi, O.; Akihiro, T.; Toshio, K.; Masahiro, H.; Hideo, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef]

- Su, S.H.; Wu, C.M.; Tsai, H.L.; Yokoyama, M. Transparent organic thin film transistors using an oxide/metal/oxide trilayer as low-resistance transparent source/drain electrodes. Jpn. J. Appl. Phys. 2013, 52, 04CK09. [Google Scholar] [CrossRef]

- Park, S.H.K.; Hwang, C.S.; Ryu, M.; Yang, S.; Byun, C.; Shin, J.; Lee, J.I.; Lee, K.; Min, S.O.; Im, S. Transparent and photo-stable zno thin-film transistors to drive an active matrix organic-light-emitting-diode display panel. Adv. Mater. 2010, 21, 678–682. [Google Scholar] [CrossRef]

- Fang, G.; Li, D.; Yao, B.L. Fabrication and vacuum annealing of transparent conductive azo thin films prepared by dc magnetron sputtering. Vacuum 2002, 68, 363–372. [Google Scholar] [CrossRef]

- Chipman, A. A commodity no more. Nature 2007, 449, 131. [Google Scholar] [CrossRef]

- Maghanga, C.M.; Niklasson, G.A.; Granqvist, C.G. Optical properties of sputter deposited transparent and conducting Tio2: Nb films. Thin Solid Films 2009, 518, 1254–1258. [Google Scholar] [CrossRef]

- Chen, T.L.; Furubayashi, Y.; Hirose, Y.; Hitosugi, T.; Shimada, T.; Hasegawa, T. Anatase phase stability and doping concentration dependent refractivity in codoped transparent conducting Tio2 films. J. Phys. D Appl. Phys. 2007, 40, 5961. [Google Scholar] [CrossRef]

- Minami, T. Present status of transparent conducting oxide thin-film development for indium-tin-oxide (ITO) substitutes. Thin Solid Films 2008, 516, 5822–5828. [Google Scholar] [CrossRef]

- Murdoch, G.B.; Hinds, S.; Sargent, E.H.; Tsang, S.W.; Mordoukhovski, L.; Lu, Z.H. Aluminum doped zinc oxide for organic photovoltaics. Appl. Phys. Lett. 2009, 94, 138. [Google Scholar] [CrossRef]

- Miyata, T.; Ohtani, Y.; Kuboi, T.; Minami, T. Stability of nano-thick transparent conducting oxide films for use in a moist environment. Thin Solid Films 2008, 516, 1354–1358. [Google Scholar] [CrossRef]

- Ruske, F.; Roczen, M.; Lee, K.; Wimmer, M.; Gall, S.; Hupkes, J.; Hrunski, D.; Rech, B. Improved electrical transport in al-doped zinc oxide by thermal treatment. J. Appl. Phys. 2010, 107, 242–1790. [Google Scholar] [CrossRef]

- Greiner, D.; Papathanasiou, N.; Pflug, A.; Ruske, F.; Klenk, R. Influence of damp heat on the optical and electrical properties of al-doped zinc oxide. Thin Solid Films 2009, 517, 2291–2294. [Google Scholar] [CrossRef]

- Lin, W.; Ma, R.; Xue, J.; Kang, B. Rf magnetron sputtered zno: Al thin films on glass substrates: A study of damp heat stability on their optical and electrical properties. Sol. Energy Mater. Sol. Cells 2007, 91, 1902–1905. [Google Scholar] [CrossRef]

- Sankir, N.D.; Aydin, E.; Ugur, E.; Sankir, M. Non-toxic and environmentally friendly route for preparation of copper indium sulfide based thin film solar cells. J. Alloys Compd. 2015, 640, 468–474. [Google Scholar] [CrossRef]

- Jin, M. Optical and electronic properties of transparent conducting ZnO and ZnO: Al films prepared by evaporating method. Thin Solid Films 1999, 357, 98–101. [Google Scholar] [CrossRef]

- Jin, B.J.; Woo, H.S.; Im, S.; Bae, S.H.; Lee, S.Y. Relationship between photoluminescence and electrical properties of zno thin films grown by pulsed laser deposition. Appl. Surf. Sci. 2001, 169, 521–524. [Google Scholar] [CrossRef]

- Park, D.C.; Fujita, S.; Fujita, S. Growth of polycrystalline GaN on silicon (001) substrates by RF plasma chemical vapor deposition with ZnO buffer layer. Phys. Status Solidi 1999, 176, 579–582. [Google Scholar] [CrossRef]

- Yao, R.; Zheng, Z.; Fang, Z.; Zhang, H.; Zhang, X.; Ning, H.; Wang, L.; Peng, J.; Xie, W.; Lu, X. High-performance flexible oxide TFTs: Optimization of a-IGZO film by modulating voltage waveform of pulse DC magnetron sputtering without post treatments. J. Mater. Chem. C 2018, 6, 2522–2532. [Google Scholar] [CrossRef]

- Marom, H.; Ritterband, M.; Eizenberg, M. The contribution of grain boundary scattering versus surface scattering to the resistivity of thin polycrystalline films. Thin Solid Films 2006, 510, 62–67. [Google Scholar] [CrossRef]

- Lee, S.; Bang, S.; Park, J.; Park, S.; Jeong, W.; Jeon, H. The effect of oxygen remote plasma treatment on zno tfts fabricated by atomic layer deposition. Phys. Status Solidi 2010, 207, 1845–1849. [Google Scholar] [CrossRef]

- Kumomi, H.; Kanicki, J.; Abe, K.; Fung, T.C. Electrical instability of RF sputter amorphous In-Ga-Zn-O thin-film transistors. J. Disp. Technol. 2009, 5, 452–461. [Google Scholar] [CrossRef]

- Schroder, D.K. Semiconductor Material and Device Characterization; Wiley: Hoboken, NJ, USA, 1998; pp. 107–108. [Google Scholar]

- Kim, W.S.; Moon, Y.K.; Kim, K.T.; Lee, J.H.; Ahn, B.D.; Park, J.W. An investigation of contact resistance between metal electrodes and amorphous gallium–indium–zinc oxide (a-GIZO) thin-film transistors. Thin Solid Films 2010, 518, 6357–6360. [Google Scholar] [CrossRef]

- Tauc, J.; Grigorovici, R.; Vancu, A. Optical properties and electronic structure of amorphous germanium. Phys. Status Solidi (b) 1966, 15, 627–637. [Google Scholar] [CrossRef]

- Shin, J.H.; Shin, S.H.; Park, J.I.; Kim, H.H. Properties of dc magnetron sputtered indium tin oxide films on polymeric substrates at room temperature. J. Appl. Phys. 2001, 89, 5199–5203. [Google Scholar] [CrossRef]

| Films | Resistivity (Ω cm) | Hall Mobility (cm2/V·s) | n (cm−3) | Transmittance | ФTC (Ω−1) | Eg (eV) |

|---|---|---|---|---|---|---|

| PVD-AZO | 2.64 × 10−3 | 3.35 | 8.2 × 1020 | 88% | 2.7 × 10−3 | 3.3 |

| PLD-AZO | 1.6 × 10−3 | 3.47 | 9.8 × 1020 | 90.43% | 4.7 × 10−3 | 3.42 |

| Devices | µsat (cm2/V·s) | Ion/Ioff | SS (V/dec) | RSD(MΩ) | Vth (V) | Output Current (μA) |

|---|---|---|---|---|---|---|

| PVD-AZO-TFT | 0.34 | 9.06 × 104 | 1.104 | 1, 1.7, 3.8 | 6.36 | 0.4 |

| PLD-AZO-TFT | 8.59 | 4.13 × 106 | 0.435 | 0.3 | 4.17 | 46.1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Li, X.; Fang, Z.; Yao, R.; Zhang, X.; Deng, Y.; Lu, X.; Tao, H.; Ning, H.; Peng, J. Highly Conductive and Transparent AZO Films Fabricated by PLD as Source/Drain Electrodes for TFTs. Materials 2018, 11, 2480. https://doi.org/10.3390/ma11122480

Zhang H, Li X, Fang Z, Yao R, Zhang X, Deng Y, Lu X, Tao H, Ning H, Peng J. Highly Conductive and Transparent AZO Films Fabricated by PLD as Source/Drain Electrodes for TFTs. Materials. 2018; 11(12):2480. https://doi.org/10.3390/ma11122480

Chicago/Turabian StyleZhang, Hongke, Xiaoqing Li, Zhiqiang Fang, Rihui Yao, Xiaochen Zhang, Yuxi Deng, Xubing Lu, Hong Tao, Honglong Ning, and Junbiao Peng. 2018. "Highly Conductive and Transparent AZO Films Fabricated by PLD as Source/Drain Electrodes for TFTs" Materials 11, no. 12: 2480. https://doi.org/10.3390/ma11122480

APA StyleZhang, H., Li, X., Fang, Z., Yao, R., Zhang, X., Deng, Y., Lu, X., Tao, H., Ning, H., & Peng, J. (2018). Highly Conductive and Transparent AZO Films Fabricated by PLD as Source/Drain Electrodes for TFTs. Materials, 11(12), 2480. https://doi.org/10.3390/ma11122480