Temperature-Dependent Domain Dynamics and Electrical Properties of Nd-doped Bi4Ti2.99Mn0.01O12 Thin Films in Fatigue Process

Abstract

1. Introduction

2. Experimental

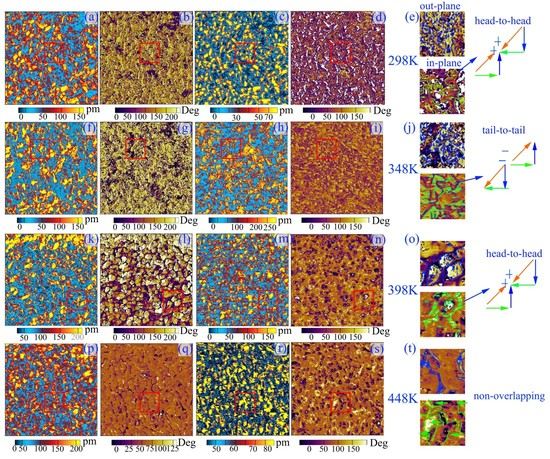

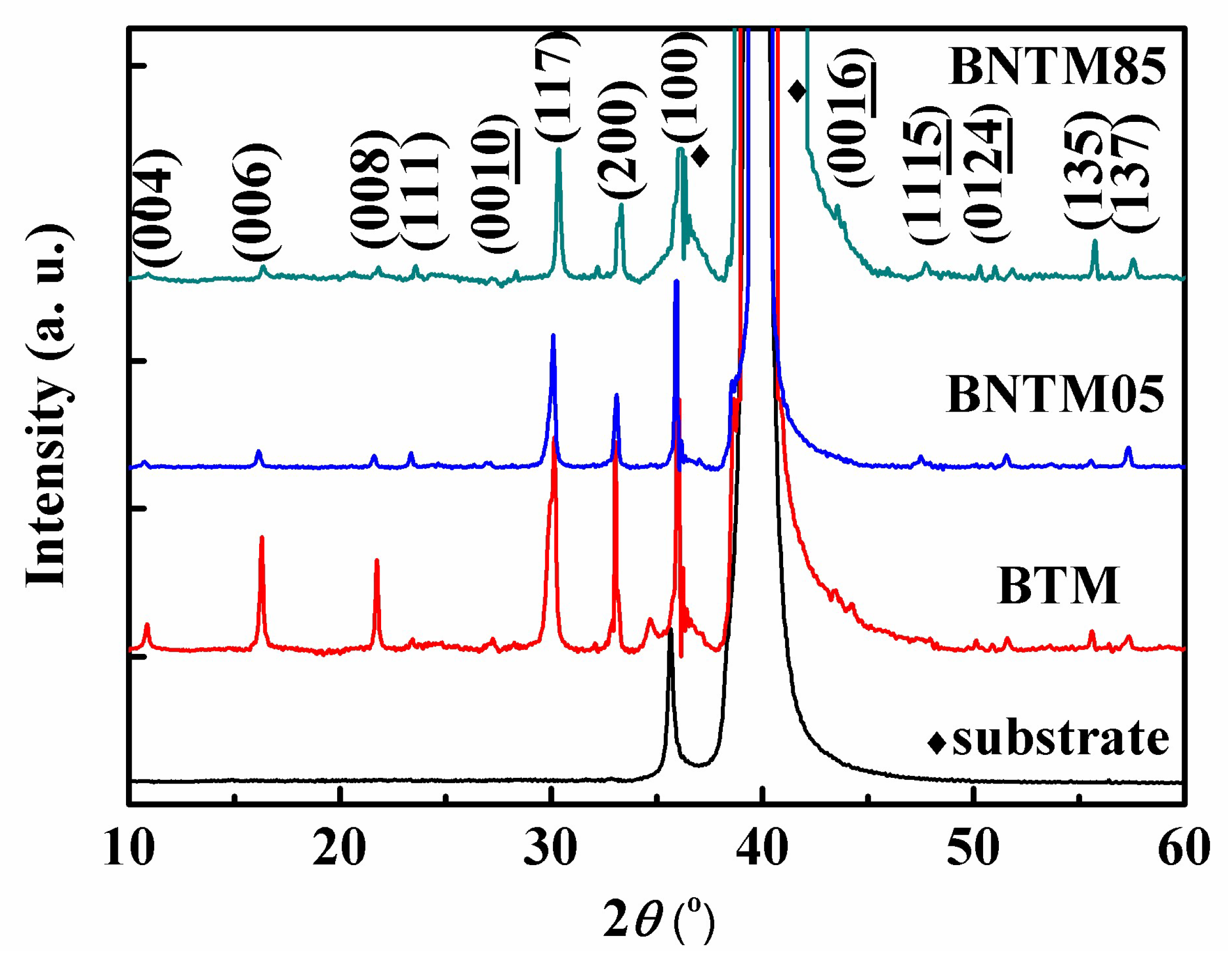

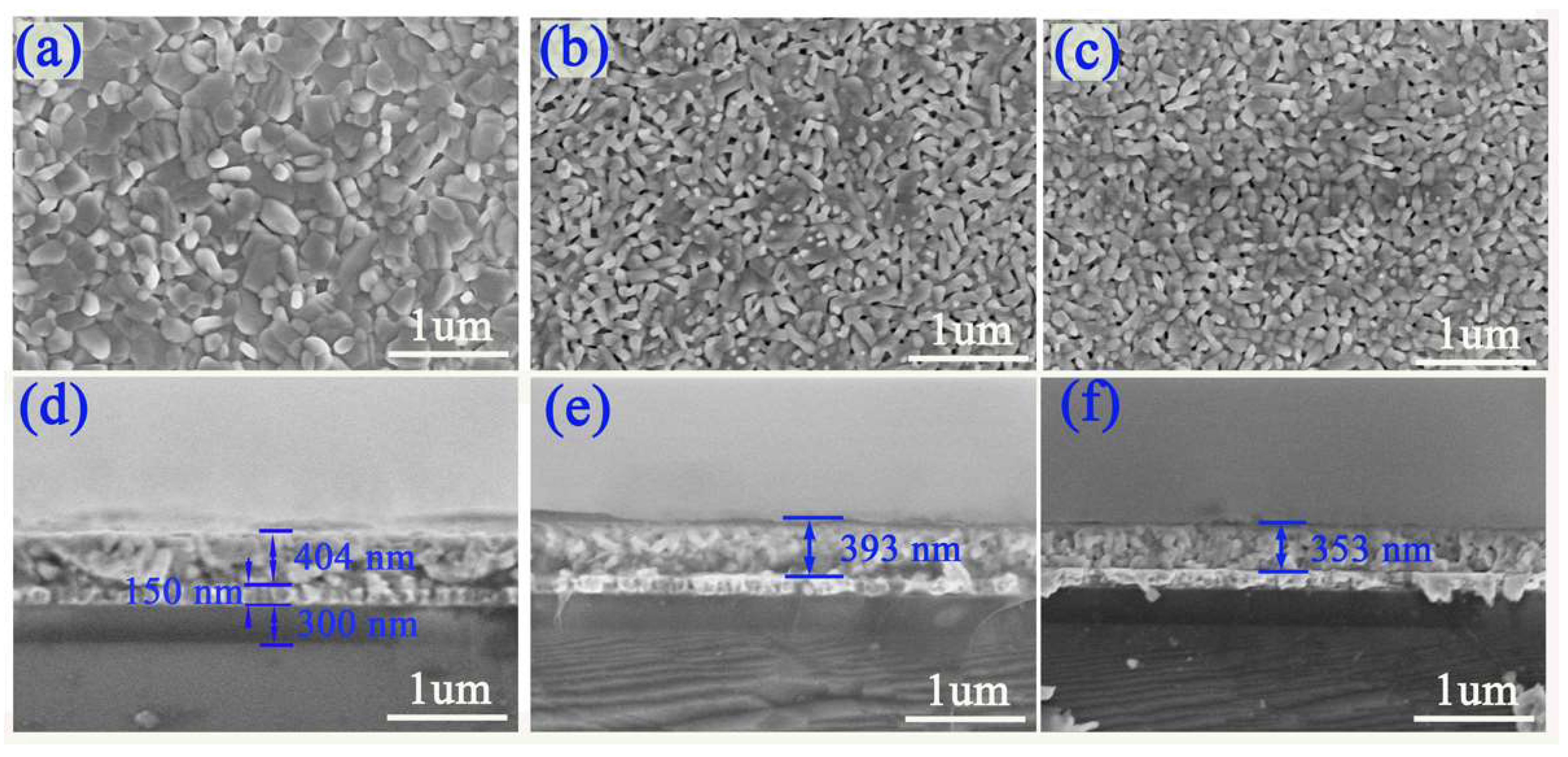

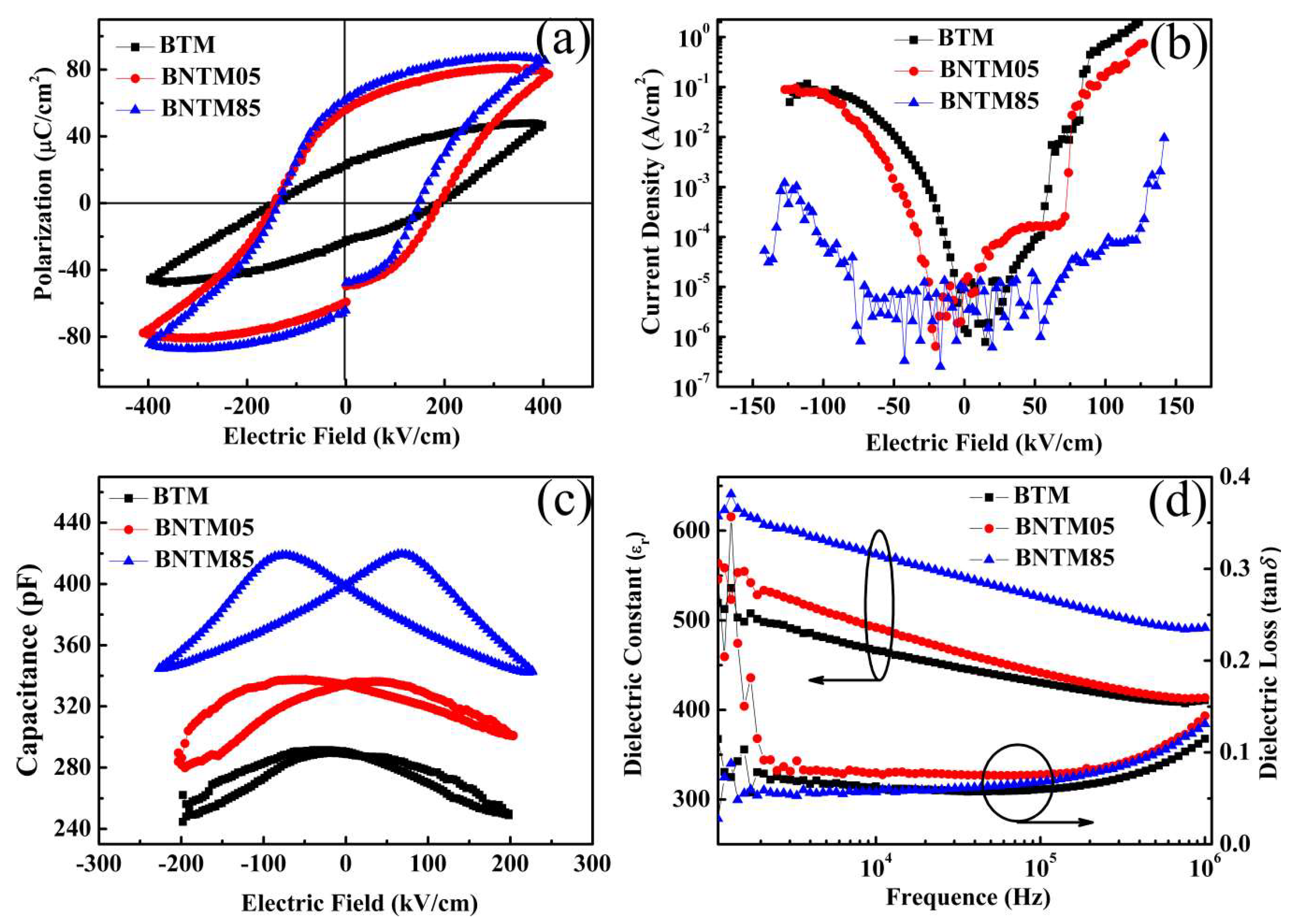

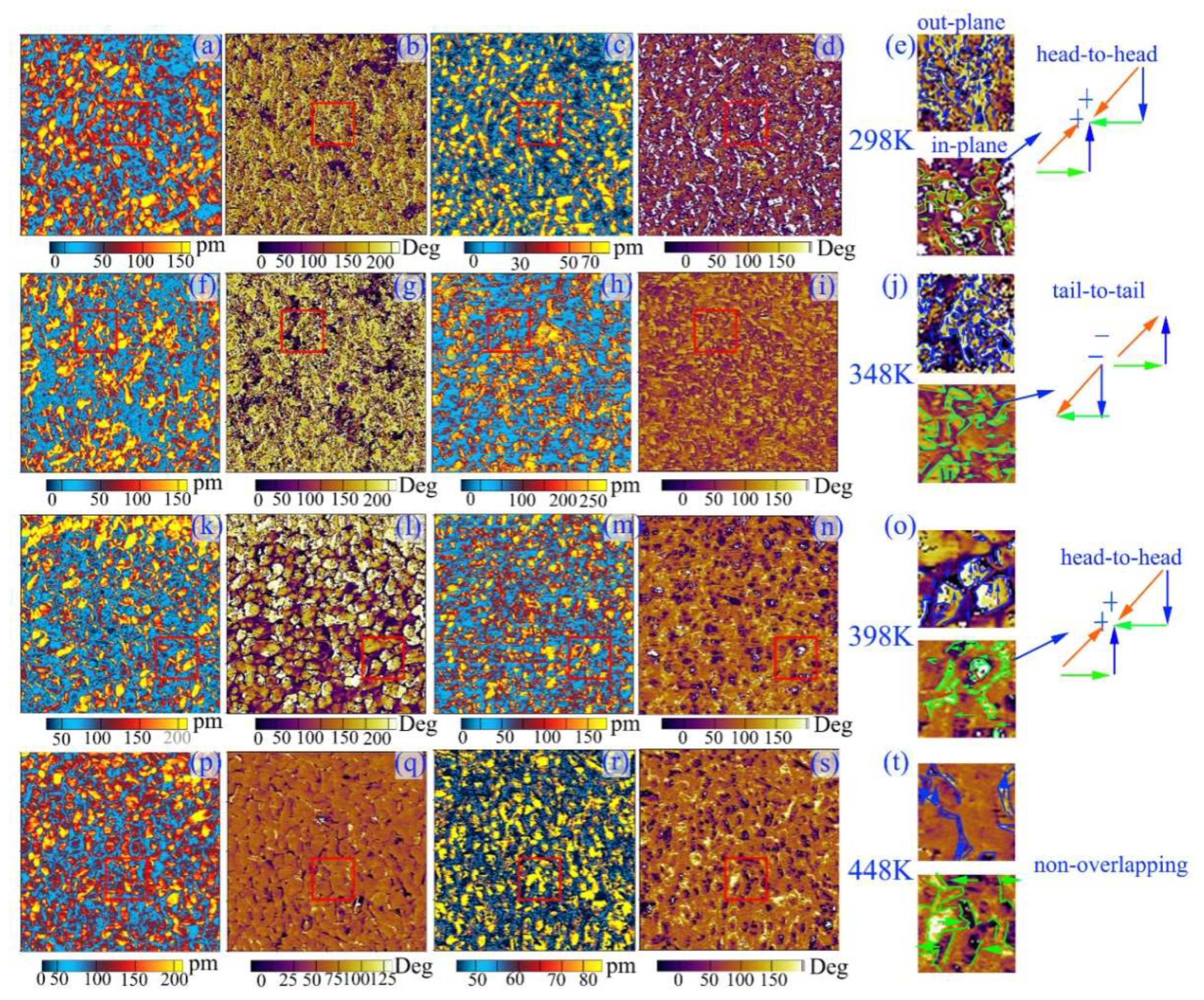

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lee, H.N.; Hesse, D.; Zakharov, N.; Gosele, U. Ferroelectric Bi3.25La0.75Ti3O12 films of uniform a-axis orientation on silicon substrates. Science 2002, 296, 2006–2009. [Google Scholar] [CrossRef] [PubMed]

- Chon, U.; Jang, H.M.; Kim, M.G.; Chang, C.H. Layered perovskites with giant spontaneous polarizations for nonvolatile memories. Phys. Rev. Lett. 2002, 89, 087601. [Google Scholar] [CrossRef] [PubMed]

- Xie, D.; Luo, Y.; Han, X.; Ren, T.; Liu, L. Characterization of Pt/Bi3.15Nd0.85Ti3O12/HfO2/Si structure using a hafnium oxide as buffer layer for ferroelectric-gate field effect transistors. J. Appl. Phys. 2009, 106, 114117. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, C.; Wang, J.; Luo, B.; Duan, M.; Jin, K. Enhancing micro-electromechanical and tuning optical properties in Nd-doped BIT thin film. Mod. Phys. Lett. B 2016, 30, 1650145. [Google Scholar] [CrossRef]

- Zhong, X.; Wang, J.; Liao, M.; Tan, C.; Shu, H.; Zhou, Y. Effect of Mn doping on the microstructures and dielectric properties of Bi3.15Nd0.85Ti3O12 thin films. Thin Solid Films 2008, 516, 8240–8243. [Google Scholar] [CrossRef]

- Pei, L.; Li, M.; Liu, J.; Yu, B.; Wang, J.; Guo, D.; Zhao, X. Preparation and electrical properties of Nd and Mn co-doped Bi4Ti3O12 thin films. J. Sol-Gel Sci. Technol. 2010, 53, 193–198. [Google Scholar] [CrossRef]

- Wen, Z.; Lv, Y.; Wu, D.; Li, A. Polarization fatigue of Pr and Mn co-substituted BiFeO3 thin films. Appl. Phys. Lett. 2011, 99, 012903. [Google Scholar] [CrossRef]

- Yuan, G.; Liu, J.; Wang, Y.; Wu, D.; Zhang, S.; Shao, Q.; Liu, Z. Temperature-dependent fatigue behaviors of ferroelectric ABO3-type and layered perovskite oxide thin films. Appl. Phys. Lett. 2004, 84, 3352–3354. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, F.; Hu, G.; Zong, Z.; Tang, M. Thickness-dependent ferroelectric behavior of predominantly (117)-oriented Bi3.15Nd0.85Ti3O12 thin-film capacitors. Appl. Phys. Lett. 2015, 106, 172903. [Google Scholar] [CrossRef]

- Zhao, C.; Wu, D.; Li, A.; Xia, Y. Fatigue characteristics of Nd-substituted Bi4Ti3O12 ferroelectric thin films at elevated temperatures. J. Phys. D Appl. Phys. 2008, 41, 122003. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, X.; Chen, Z.; Wang, J.; Zhou, Y. Temperature dependence of polarization switching properties of Bi3.15Nd0.85Ti3O12 ferroelectric thin film. J. Appl. Phys. 2011, 110, 014102. [Google Scholar] [CrossRef]

- Yang, F.; Guo, Y.; Li, L.; Tang, M. Anisotropic polarization fatigue in Bi3.15Nd0.85Ti3O12 thin films. J. Phys. D Appl. Phys. 2016, 49, 195305. [Google Scholar] [CrossRef]

- Ke, Q.; Kumar, A.; Lou, X.; Feng, Y.; Zeng, K.; Cai, Y.; Wang, J. Microstructural evolution of charged defects in the fatigue process of polycrystalline BiFeO3 thin films. Acta Mater. 2015, 82, 190–197. [Google Scholar] [CrossRef]

- Zhang, W.; Tang, M.; Xiong, Y.; Yan, S.; Cheng, C.; Li, G.; Xiao, Y.; Li, Z. Polarization switching and fatigue characteristics of highly (117)-oriented Bi3.15Nd0.85Ti2.99Mn0.01O12 ferroelectric thin films at both low and elevated temperatures. RSC Adv. 2017, 7, 20929–20935. [Google Scholar] [CrossRef]

- Zhang, W.; Tang, M.; Xiong, Y.; Wang, K.; Wang, Z.; Xiao, Y.; Yan, S.; Li, Z.; He, J. Influence of the annealing temperature of the Bi4Ti3O12 seeding layer on the structural and electrical properties of Bi3.15Nd0.85Ti2.99Mn0.01O12 thin films. RSC Adv. 2016, 6, 88668–88673. [Google Scholar] [CrossRef]

- Zhang, W.; Tang, M.; Xiong, Y.; Wang, Z.; Xiao, Y.; Yan, S.; Li, Z.; He, J. Improvement of nucleation and electrical properties of Bi3.15Nd0.85Ti2.99Mn0.01O12 thin films with an upper Bi4Ti3O12 buffer layer. J. Sol-Gel Sci. Technol. 2016, 80, 853–859. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhong, X.; Liao, H.; Wang, F.; Wang, J.; Zhou, Y. Composition depth profiles of Bi3.15Nd0.85Ti3O12 thin films studied by X-ray photoelectron spectroscopy. Appl. Surf. Sci. 2011, 257, 7461–7465. [Google Scholar] [CrossRef]

- Sun, W.; Wang, J.; Hu, G.; Yan, J. Orientation control of a seeding layer and its effect on structure, ferro-and piezoelectric properties of sol-gel derived Bi3.15Nd0.85Ti3O12 thin films. J. Mater. Sci. Mater. Electron. 2013, 24, 2853–2857. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, K.; Zhu, C.; Liu, J. Polarization fatigue of ferroelectric Pb(Zr0.1Ti0.9)O3 thin films: Temperature dependence. J. Appl. Phys. 2006, 99, 044109. [Google Scholar] [CrossRef]

- Guo, D.; Wang, C.; Shen, Q.; Zhang, L.; Li, M.; Liu, J. Effect of measuring factors on ferroelectric properties of Bi3.15Nd0.85Ti3O12 thin films prepared by sol-gel method for non-volatile memory. Appl. Phys. A 2009, 97, 877. [Google Scholar] [CrossRef]

- Zhong, N.; Xiang, P.; Zhang, Y.; Wu, X.; Tang, X.; Yang, P.; Duan, C.; Chu, J. Polarization fluctuation behavior of lanthanum substituted Bi4Ti3O12 thin films. J. Appl. Phys. 2015, 118, 104102. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, Z.; Zhang, C.; Yuan, G.L. Temperature-dependent ferroelectric and dielectric properties of Bi3.25La0.75Ti3O12 thin films. Appl. Surf. Sci. 2010, 256, 2468–2473. [Google Scholar] [CrossRef]

- Li, K.; Dong, X.; Rémiens, D.; Li, T.; Chen, Y.; Wang, G. Effect of polarization switching cycles on the dielectric response and Rayleigh constant in Pb0.4Sr0.6TiO3 thin films. J. Appl. Phys. 2014, 115, 064102. [Google Scholar] [CrossRef]

- Ke, Q.; Lou, X.; Yang, H.; Kumar, A.; Zeng, Y.; Wang, J. Negative capacitance induced by redistribution of oxygen vacancies in the fatigued BiFeO3-based thin film. Appl. Phys. Lett. 2012, 101, 022904. [Google Scholar] [CrossRef]

- Shur, V.Y.; Akhmatkhanov, A.R.; Baturin, I.S. Fatigue effect in ferroelectric crystals: Growth of the frozen domains. J. Appl. Phys. 2012, 111, 124111. [Google Scholar] [CrossRef]

- Pintilie, L.; Hrib, L.; Pasuk, I.; Ghica, C.; Iuga, A.; Pintilie, I. General equivalent circuit derived from capacitance and impedance measurements performed on epitaxial ferroelectric thin films. J. Appl. Phys. 2014, 116, 044108. [Google Scholar] [CrossRef]

- Park, J.H.; Bae, J.S.; Choi, B.C.; Jeong, J.H. Impedance spectroscopy of Bi3.25La0.75Ti3O12 ceramics above and below ferroelectric transition temperatures. J. Phys. D Appl. Phys. 2007, 40, 579. [Google Scholar] [CrossRef]

- Zou, X.; You, L.; Chen, W.; Ding, H.; Wu, D.; Wu, T.; Chen, L.; Wang, J. Mechanism of polarization fatigue in BiFeO3. ACS Nano 2012, 6, 8997–9004. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Cai, J.; Li, M.; Nan, C.; He, J. Grain boundary behavior in varistor-capacitor TiO2-rich CaCu3Ti4O12 ceramics. J. Appl. Phys. 2008, 103, 074111. [Google Scholar] [CrossRef]

- Wen, B.; Zhang, Y.; Liu, X.; Ma, L.; Wang, X. Temperature-dependent ferroelectric hysteresis properties of modified lead zirconate titanate ceramics. J. Mater. Sci. 2012, 47, 4299–4304. [Google Scholar] [CrossRef]

- Kitanaka, Y.; Noguchi, Y.; Miyayama, M. Oxygen-vacancy-induced 90°-domain clamping in ferroelectric Bi4Ti3O12 single crystals. Phys. Rev. B 2010, 81, 094114. [Google Scholar] [CrossRef]

- Guo, H.; Liu, X.; Rödel, J.; Tan, X. Nanofragmentation of ferroelectric domains during polarization fatigue. Adv. Funct. Mater. 2015, 25, 270–277. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Mao, Y.; Yan, S.; Xiao, Y.; Tang, M.; Li, G.; Peng, Q.; Li, Z. Temperature-Dependent Domain Dynamics and Electrical Properties of Nd-doped Bi4Ti2.99Mn0.01O12 Thin Films in Fatigue Process. Materials 2018, 11, 2418. https://doi.org/10.3390/ma11122418

Zhang W, Mao Y, Yan S, Xiao Y, Tang M, Li G, Peng Q, Li Z. Temperature-Dependent Domain Dynamics and Electrical Properties of Nd-doped Bi4Ti2.99Mn0.01O12 Thin Films in Fatigue Process. Materials. 2018; 11(12):2418. https://doi.org/10.3390/ma11122418

Chicago/Turabian StyleZhang, Wanli, Yanhu Mao, Shaoan Yan, Yongguang Xiao, Minghua Tang, Gang Li, Qiangxiang Peng, and Zheng Li. 2018. "Temperature-Dependent Domain Dynamics and Electrical Properties of Nd-doped Bi4Ti2.99Mn0.01O12 Thin Films in Fatigue Process" Materials 11, no. 12: 2418. https://doi.org/10.3390/ma11122418

APA StyleZhang, W., Mao, Y., Yan, S., Xiao, Y., Tang, M., Li, G., Peng, Q., & Li, Z. (2018). Temperature-Dependent Domain Dynamics and Electrical Properties of Nd-doped Bi4Ti2.99Mn0.01O12 Thin Films in Fatigue Process. Materials, 11(12), 2418. https://doi.org/10.3390/ma11122418