The Out-of-Plane Compression Behavior of Cross-Ply AS4/PEEK Thermoplastic Composite Laminates at High Strain Rates

Abstract

1. Introduction

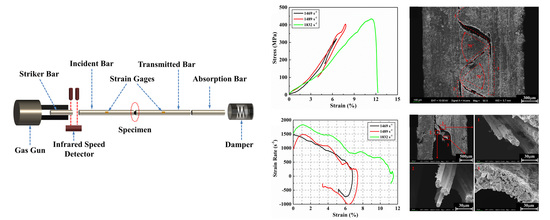

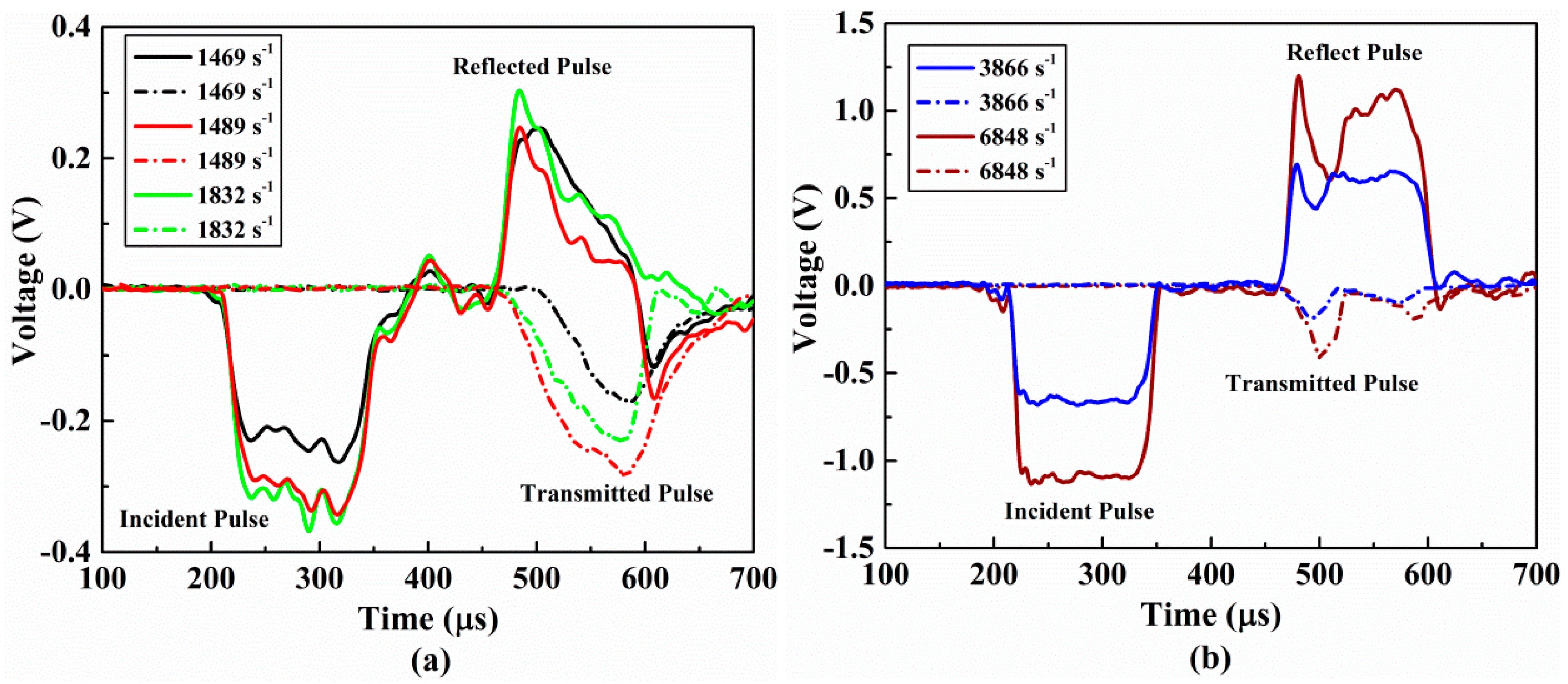

2. Materials and Methods

2.1. Material and Specimens

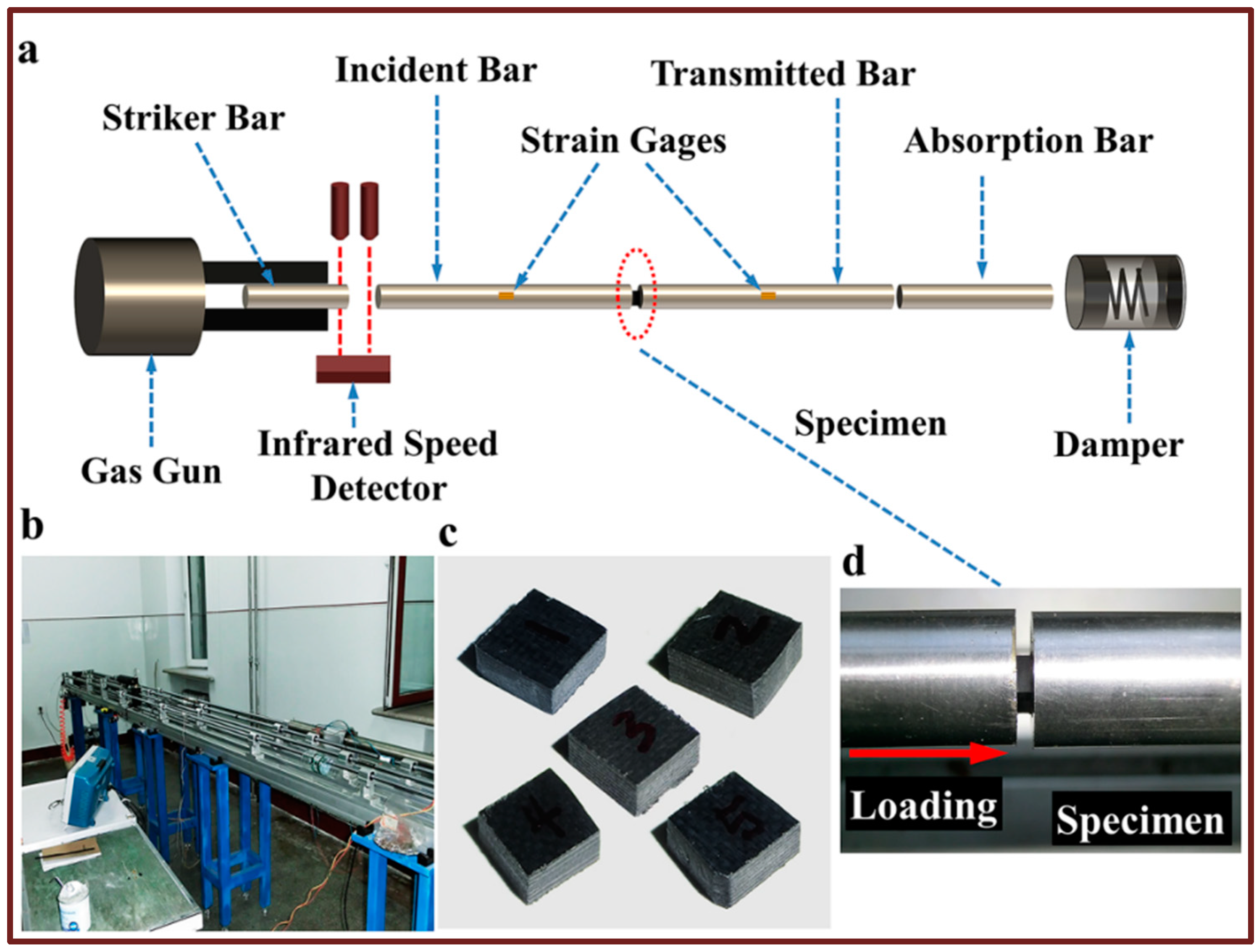

2.2. Theory and Experimental Scheme

3. Results and Discussion

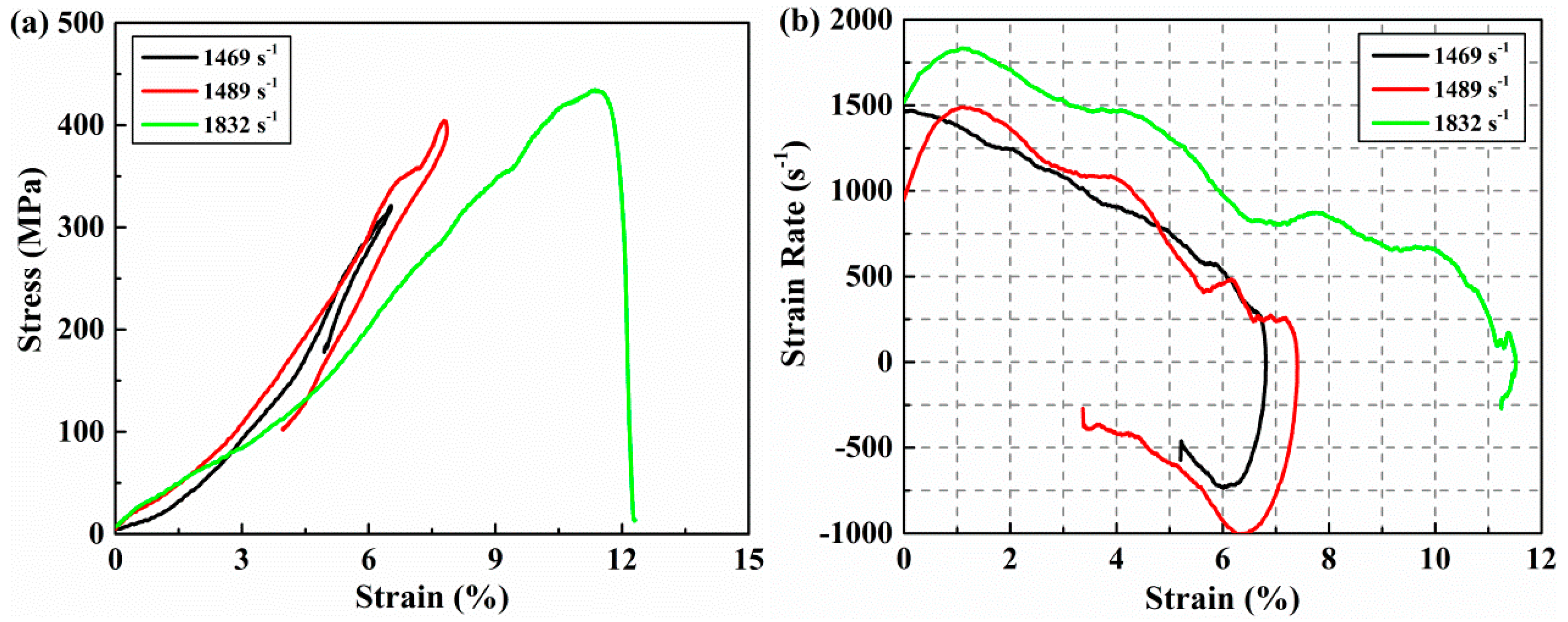

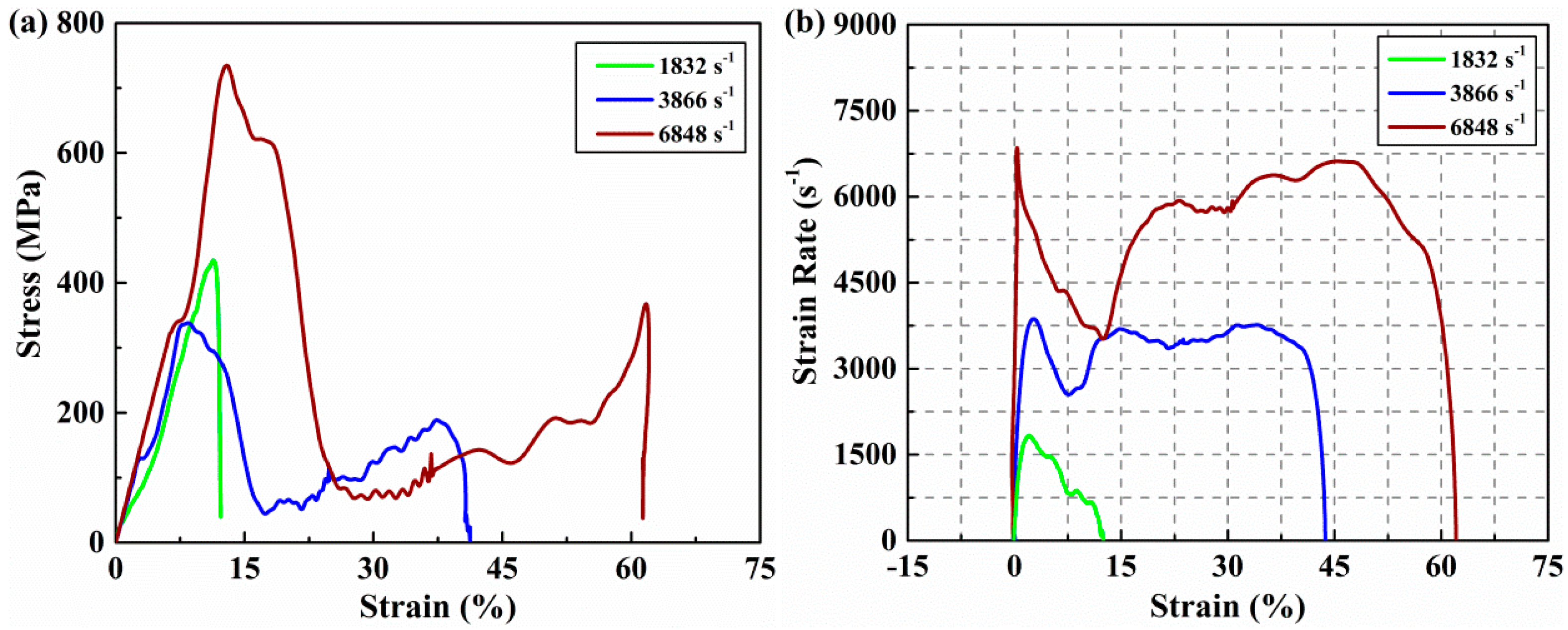

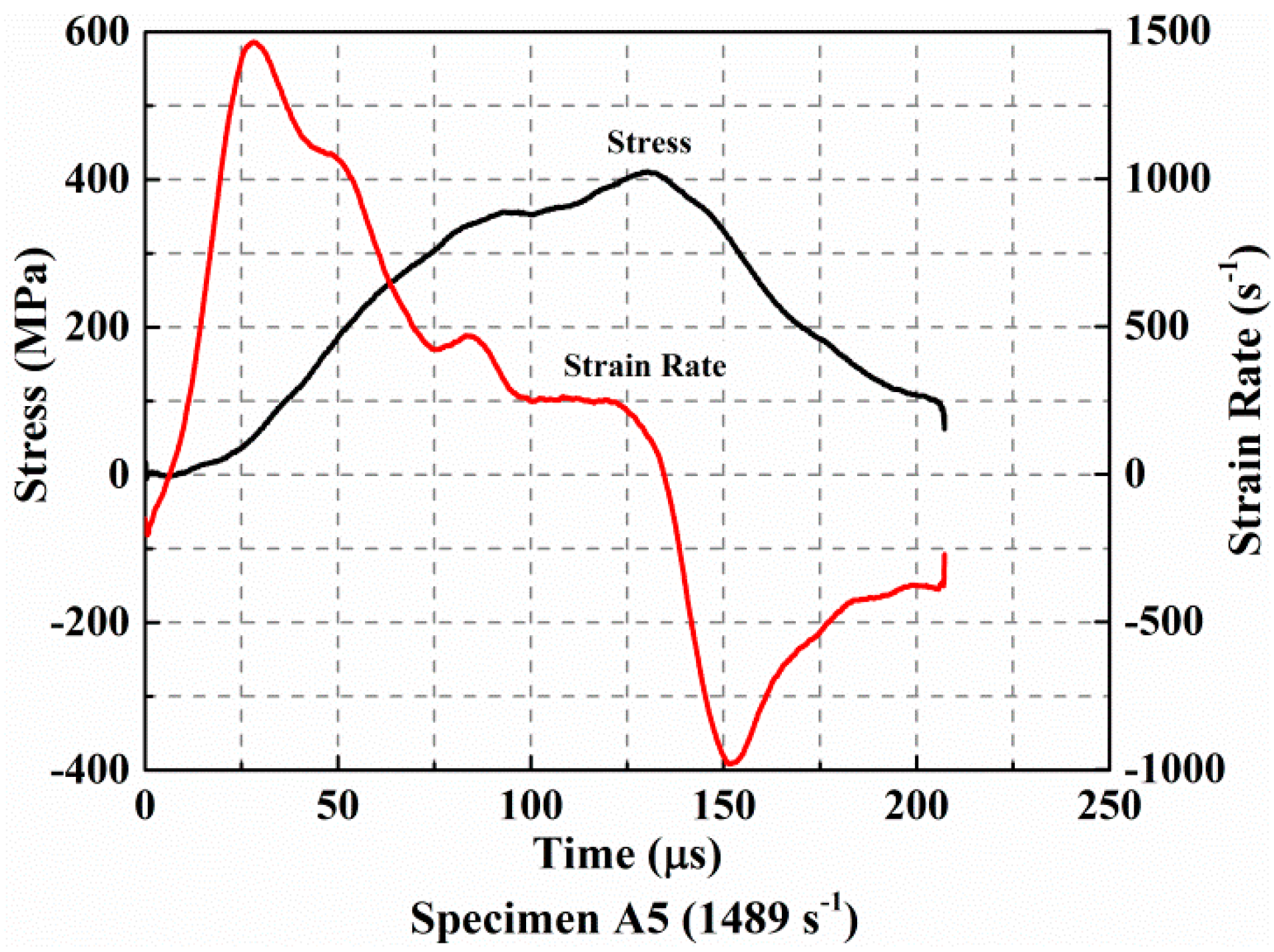

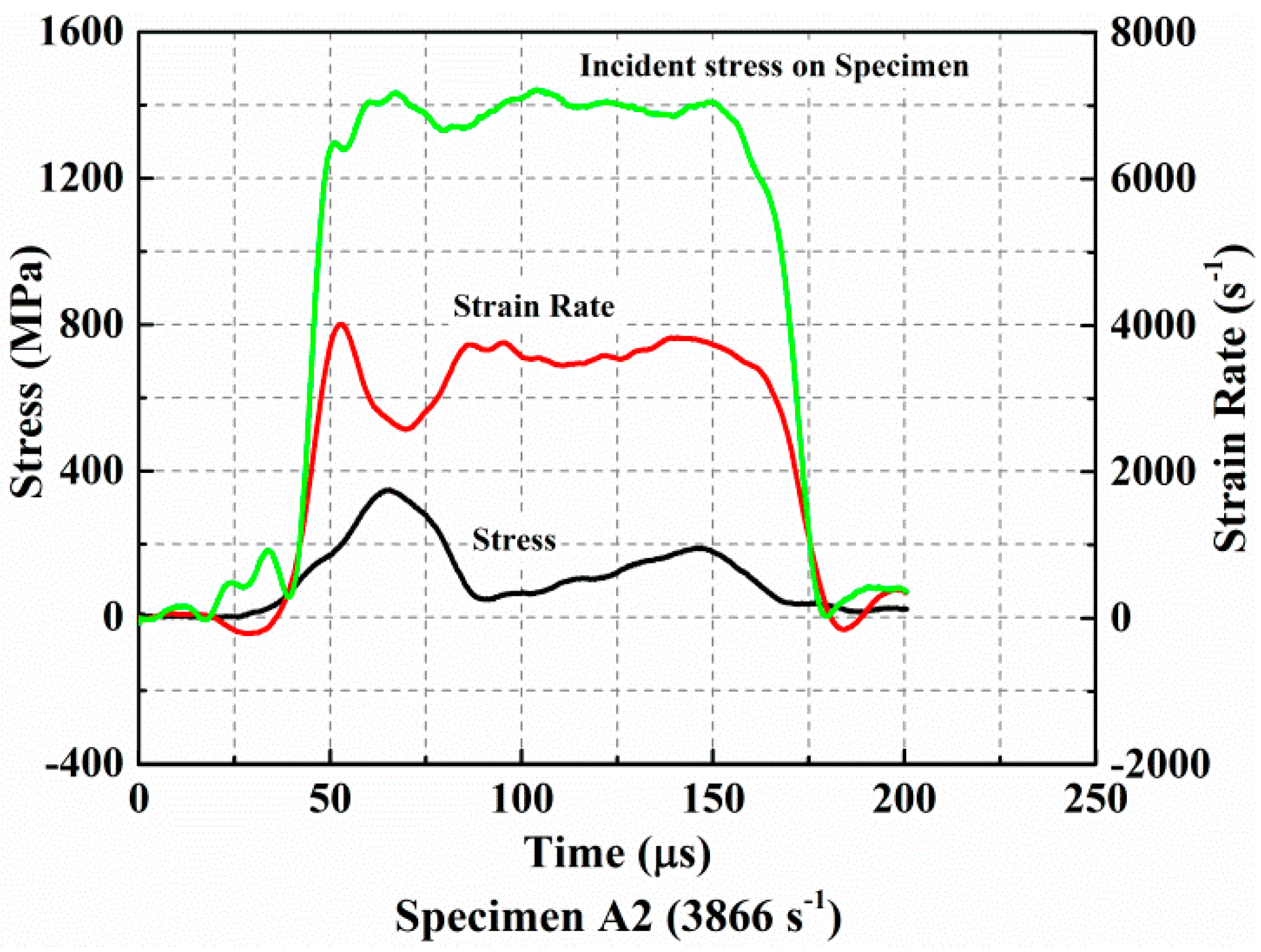

3.1. The Strain Rate Dependence of an Out-of-Plane Compression Response

3.2. Damage Kinetics

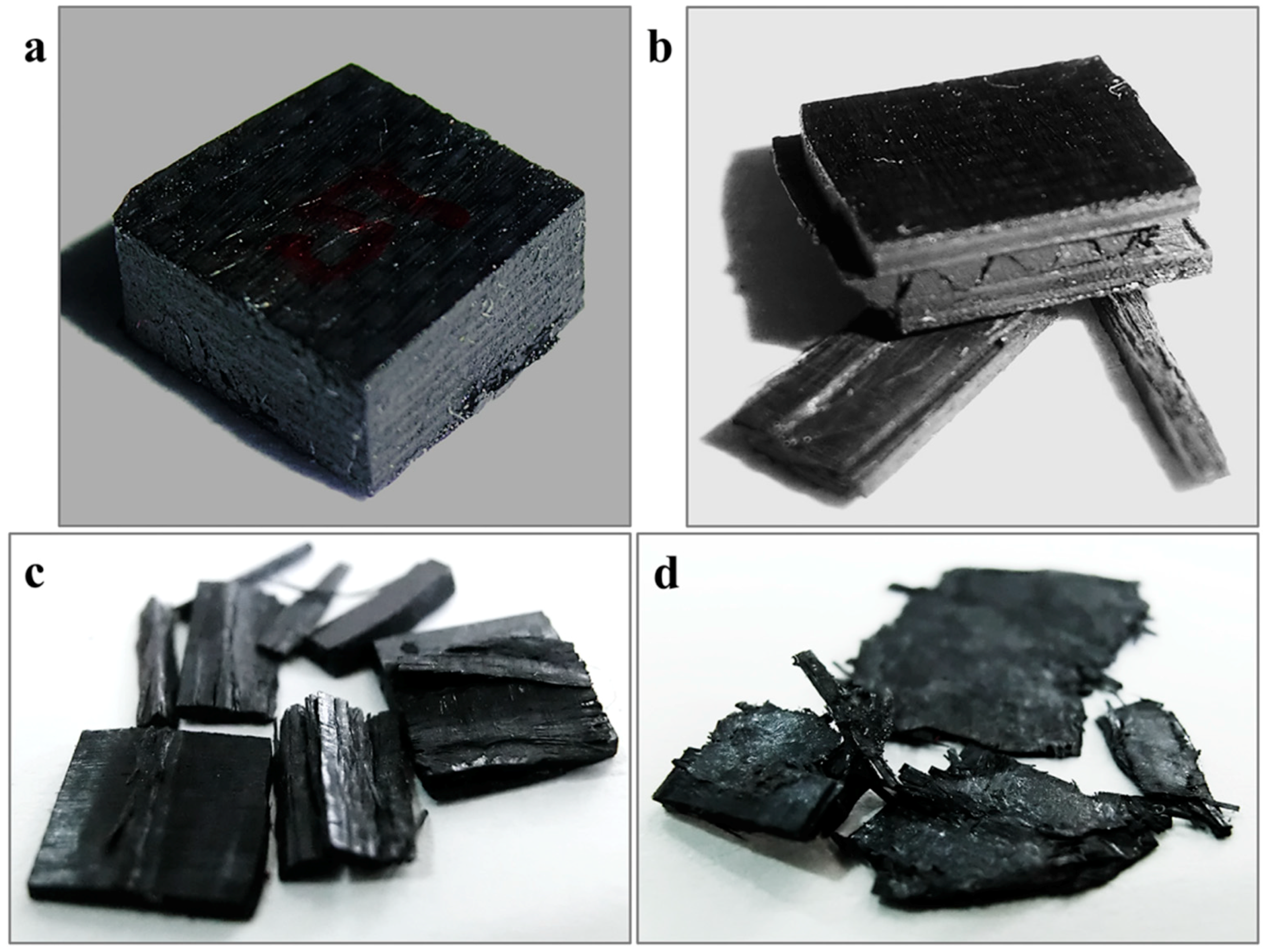

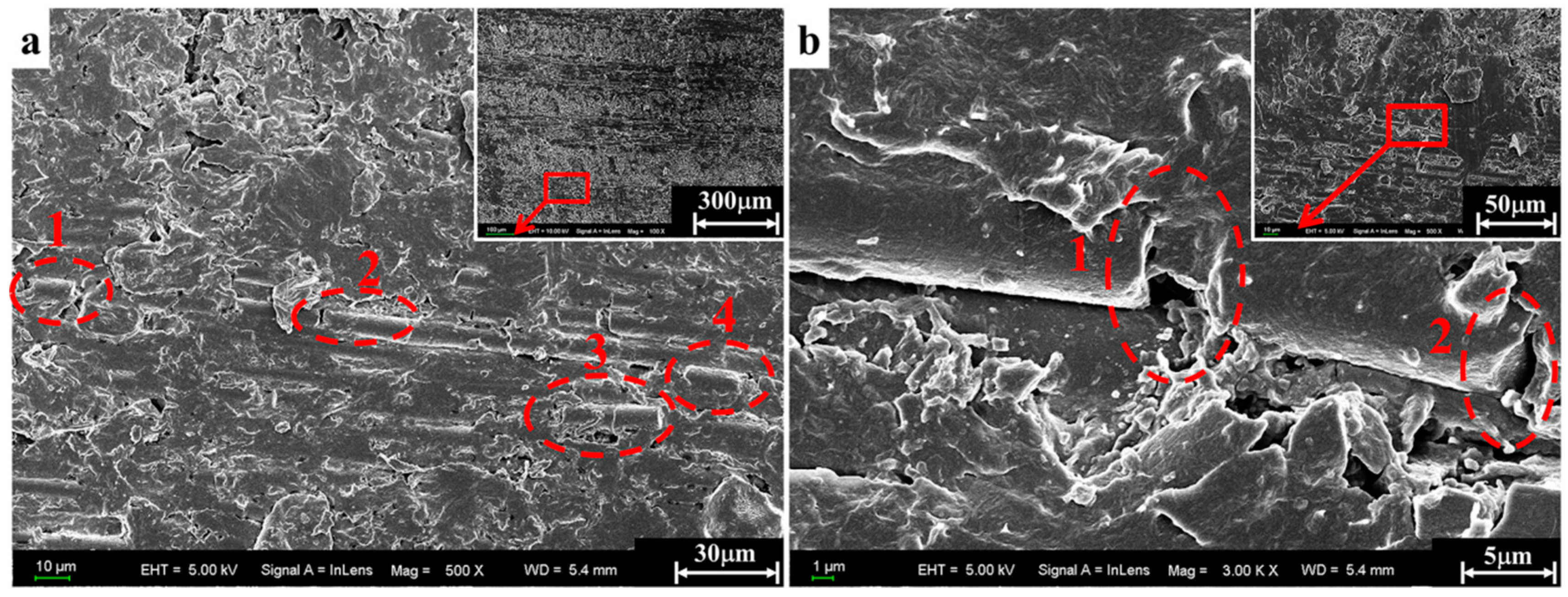

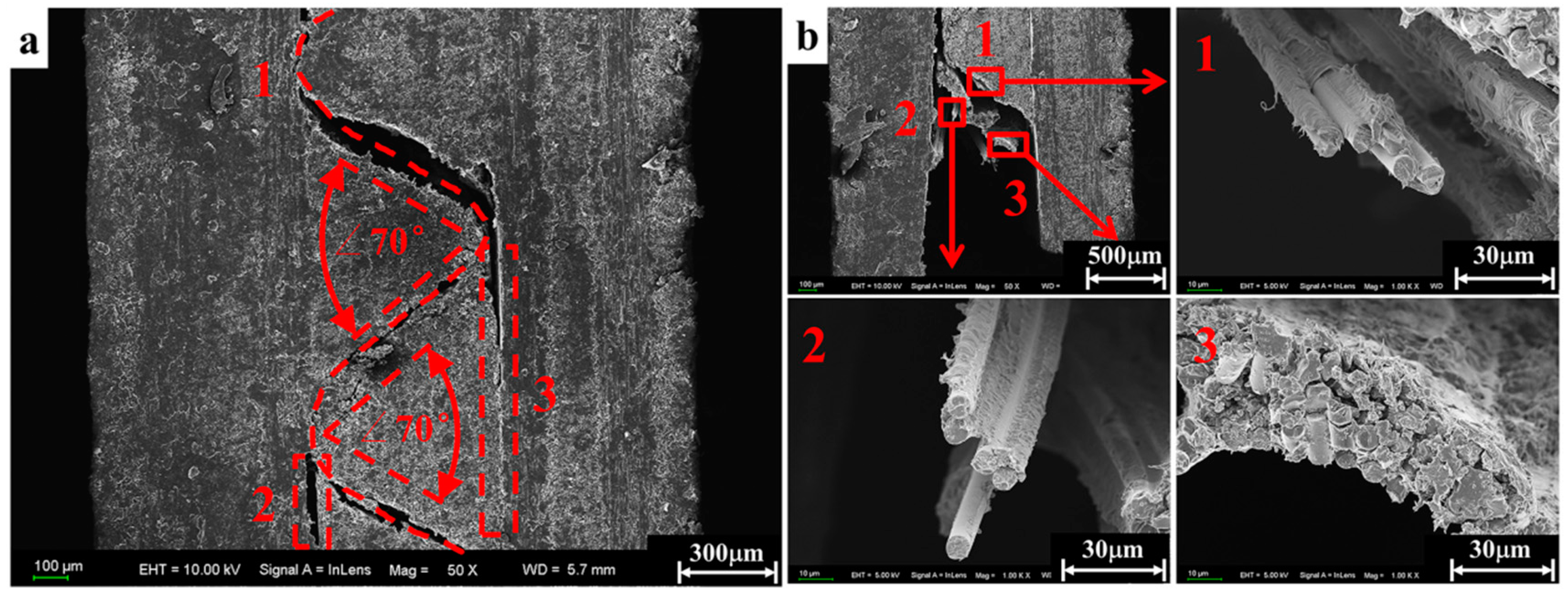

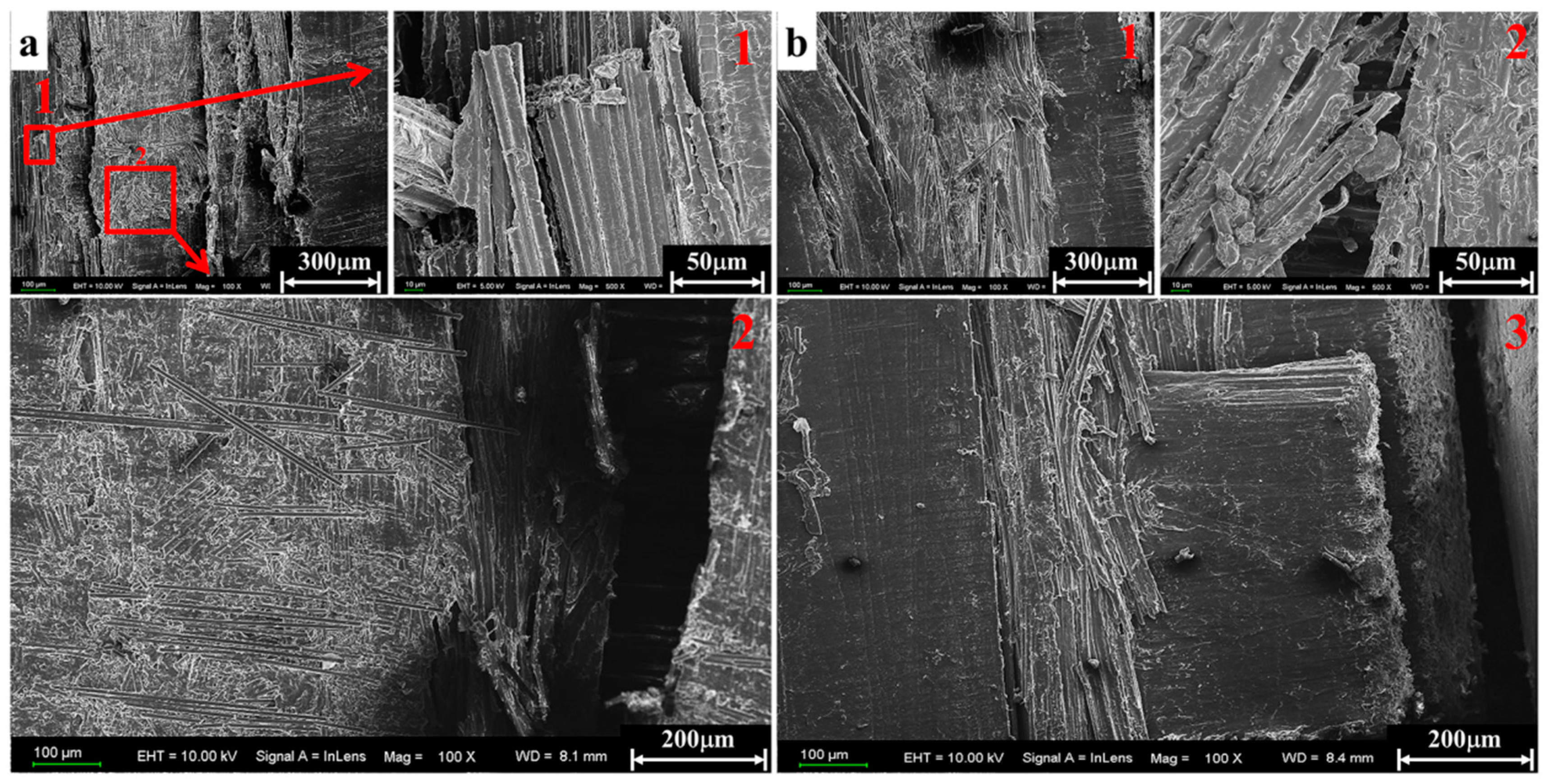

3.3. Failure Mode and Damage Mechanism

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Yoshida, T.; Uenoya, T.; Miyamoto, H. Impact damage characterization in cross-plied carbon fiber/thermoplastic composites using thermoelastic stress analysis. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 1 May 2012. [Google Scholar]

- Bishop, S.M. The mechanical performance and impact behavior of carbon-fibre reinforced PEEK. Compos. Struct. 1985, 3, 295–318. [Google Scholar] [CrossRef]

- Dorey, G.; Bishop, S.M.; Curtis, P.T. On the impact performance of carbon fibre laminates with epoxy and PEEK matrices. Compos. Sci. Technol. 1985, 23, 221–237. [Google Scholar] [CrossRef]

- Ishikawa, T.; Sugimoto, S.; Matsushima, M.; Hayashi, Y. Some experimental findings in compression-after-impact (CAI) tests of CF/PEEK (APC-2) and conventional CF/epoxy flat plates. Compos. Sci. Technol. 1995, 55, 349–363. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, L.; Hong, H.; Zhang, J. A strain-rate-dependent damage model for evaluating the low velocity impact induced damage of composite laminates. Compos. Struct. 2018, 201, 995–1003. [Google Scholar] [CrossRef]

- Thierry, V.; Brown, L.; Chronopoulos, D. Multi-scale wave propagation modelling for two-dimensional periodic textile composites. Compos. Part B Eng. 2018, 150, 144–156. [Google Scholar] [CrossRef]

- Johnson, A.F.; Pickett, A.K.; Rozycki, P. Computational methods for predicting impact damage in composite structures. Compos. Sci. Technol. 2001, 61, 2183–2192. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Silani, M.; Weinberg, K. Fracture studies of Ultra-High Performance Concrete using dynamic Brazilian tests. Theor. Appl. Fract. Mech. 2018, 93, 302–310. [Google Scholar] [CrossRef]

- Weinberg, K.; Khosravani, M.R. On the tensile resistance of UHPC at impact. Eur. Phys. J. Spec. Top. 2018, 227, 167–177. [Google Scholar] [CrossRef]

- Field, J.E.; Walley, S.M.; Proud, W.G.; Goldrein, H.T.; Siviour, C.R. Review of experimental techniques for high rate deformation and shock studies. Int. J. Impact Eng. 2004, 30, 725–775. [Google Scholar] [CrossRef]

- Ninan, L.; Tsai, J.; Sun, C. Use of split Hopkinson pressure bar for testing off-axis composites. Int. J. Impact Eng. 2001, 25, 291–313. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Zhi, Z.; Guo, Y.; Ouyang, N. The compressive and tensile behavior of a 0/90 C fiber woven composite at high strain rates. Carbon 2013, 61, 97–104. [Google Scholar] [CrossRef]

- Tsai, J.; Sun, C.T. Constitutive model for high strain rate response of polymeric composites. Compos. Sci. Technol. 2002, 62, 1289–1297. [Google Scholar] [CrossRef]

- Kumar, P.; Garg, A.; Agarwal, B.D. Dynamic compressive behavior of unidirectional GFRP for various fibre orientations. Mater. Lett. 1986, 4, 111–116. [Google Scholar] [CrossRef]

- Hosur, M.V.; Alexander, J.; Vaidya, U.K.; Jeelani, S.; Mayer, A. Studies on the off-axis high strain rate compression loading of satin weave carbon/epoxy composites. Compos. Struct. 2004, 63, 75–85. [Google Scholar] [CrossRef]

- Li, D.S.; Chen, H.R.; Ge, D.Y.; Jiang, N.; Jiang, L. Split Hopkinson pressure bar testing of 3D multi-axial warp knitted carbon/epoxy composites. Compos. Part B Eng. 2015, 79, 692–705. [Google Scholar] [CrossRef]

- Yuan, Q.; Li, Y.; Li, H.; Li, S.; Guo, L. Quasi-static and dynamic compressive fracture behavior of carbon/carbon composites. Carbon 2008, 46, 699–703. [Google Scholar]

- Tarfaoui, M.; Choukri, S.; Neme, A. Effect of fibre orientation on mechanical properties of the laminated polymer composites subjected to out-of-plane high strain rate compressive loadings. Compos. Sci. Technol. 2008, 68, 477–485. [Google Scholar] [CrossRef]

- Arbaoui, J.; Tarfaoui, M.; Alaoui, A.E.M. Mechanical behavior and damage kinetics of woven E-glass/vinylester laminate composites under high strain rate dynamic compressive loading: Experimental and numerical investigation. Int. J. Impact Eng. 2016, 87, 44–54. [Google Scholar] [CrossRef]

- Kapoor, R.; Pangeni, L.; Bandaru, A.K.; Ahmad, S.; Bhatnagar, N. High strain rate compression response of woven Kevlar reinforced polypropylene composites. Compos. Part B 2016, 89, 374–382. [Google Scholar] [CrossRef]

- Weeks, C.A.; Sun, C.T. Modeling non-linear rate-dependent behavior in fiber-reinforced composites. Compos. Sci. Technol. 1998, 58, 603–611. [Google Scholar] [CrossRef]

- Kawai, M.; Masuko, Y.; Kawase, Y.; Negishi, R. Micromechanical analysis of the off-axis rate-dependent inelastic behavior of unidirectional AS4/PEEK at high temperature. Int. J. Mech. Sci. 2001, 43, 2069–2090. [Google Scholar] [CrossRef]

- Totry, E.; González, C.; Llorca, J. Prediction of the failure locus of C/PEEK composites under transverse compression and longitudinal shear through computational micromechanics. Compos. Sci. Technol. 2008, 68, 3128–3136. [Google Scholar] [CrossRef]

- Hsu, S.Y.; Vogler, T.J.; Kyriakides, S. Inelastic behavior of an AS4/PEEK composite under combined transverse compression and shear. Part II: Modeling. Int. J. Plast. 1999, 15, 807–836. [Google Scholar]

- Vogler, T.J.; Kyriakides, S. Inelastic behavior of an AS4/PEEK composite under combined transverse compression and shear. Part I: Experiments. Int. J. Plast. 1999, 15, 783–806. [Google Scholar]

- Dong, L.; Harding, J. A single-lap shear specimen for determining the effect of strain rate on the interlaminar shear strength of carbon fibre-reinforced laminates. Composites 1994, 25, 129–138. [Google Scholar] [CrossRef]

- Khosravani, M.R. Composite Materials Manufacturing Processes. Appl. Mech. Mater. 2012, 110, 1361–1367. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Weinberg, K. A review on split Hopkinson bar experiments on the dynamic characterisation of concrete. Constr. Build. Mater. 2018, 190, 1264–1283. [Google Scholar] [CrossRef]

- Kolsky, H. An investigation of the mechanical properties of materials at very high rates of loading. Proc. Phys. Soc. Sec. B 1949, 62, 676. [Google Scholar] [CrossRef]

- Davies, R. A critical study of the Hopkinson pressure bar. Phil. Trans. R. Soc. Lond. A 1948, 240, 375–457. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, B.; Forrestal, M. A split Hopkinson bar technique for low-impedance materials. Exp. Mech. 1999, 39, 81–85. [Google Scholar] [CrossRef]

- Yang, L.M.; Shim, V.P.W. An analysis of stress uniformity in split Hopkinson bar test specimens. Int. J. Impact Eng. 2005, 31, 129–150. [Google Scholar] [CrossRef]

- Wang, T.-T.; Shang, B. Three-wave mutual-checking method for data processing of SHPB experiments of concrete. J. Mech. 2014, 30, N5–N10. [Google Scholar] [CrossRef]

- Francis, D.K.; Whittington, W.R.; Lawrimore, W.B.; Allison, P.G.; Turnage, S.A.; Bhattacharyya, J.J. Split Hopkinson Pressure Bar Graphical Analysis Tool. Exp. Mech. 2017, 57, 179–183. [Google Scholar] [CrossRef]

| Specimens | Thickness (mm) | Surface (mm2) | Stacking Sequence | Strain Rates (/s) |

|---|---|---|---|---|

| A1 | 2.02 | 4.96 × 4.98 | (0°/90°)4s | 6848 |

| A2 | 2.00 | 5.06 × 5.02 | (0°/90°)4s | 3866 |

| A3 | 1.98 | 4.98 × 5.04 | (0°/90°)4s | 1469 |

| A4 | 1.98 | 5.04 × 5.02 | (0°/90°)4s | 1832 |

| A5 | 2.02 | 5.88 × 5.90 | (0°/90°)4s | 1489 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, H.; Yin, W.; Cai, C.; Wang, B.; Liu, A.; Yang, Z.; Li, Y.; He, X. The Out-of-Plane Compression Behavior of Cross-Ply AS4/PEEK Thermoplastic Composite Laminates at High Strain Rates. Materials 2018, 11, 2312. https://doi.org/10.3390/ma11112312

Zou H, Yin W, Cai C, Wang B, Liu A, Yang Z, Li Y, He X. The Out-of-Plane Compression Behavior of Cross-Ply AS4/PEEK Thermoplastic Composite Laminates at High Strain Rates. Materials. 2018; 11(11):2312. https://doi.org/10.3390/ma11112312

Chicago/Turabian StyleZou, Huiran, Weilong Yin, Chaocan Cai, Bing Wang, Ankang Liu, Zhen Yang, Yibin Li, and Xiaodong He. 2018. "The Out-of-Plane Compression Behavior of Cross-Ply AS4/PEEK Thermoplastic Composite Laminates at High Strain Rates" Materials 11, no. 11: 2312. https://doi.org/10.3390/ma11112312

APA StyleZou, H., Yin, W., Cai, C., Wang, B., Liu, A., Yang, Z., Li, Y., & He, X. (2018). The Out-of-Plane Compression Behavior of Cross-Ply AS4/PEEK Thermoplastic Composite Laminates at High Strain Rates. Materials, 11(11), 2312. https://doi.org/10.3390/ma11112312