Effect of Silica Fume as a Component of Alternative Binder on the Selected Technically Important Characteristics of Bio-Aggregate-Based Composites

Abstract

1. Introduction

2. Materials and Methods

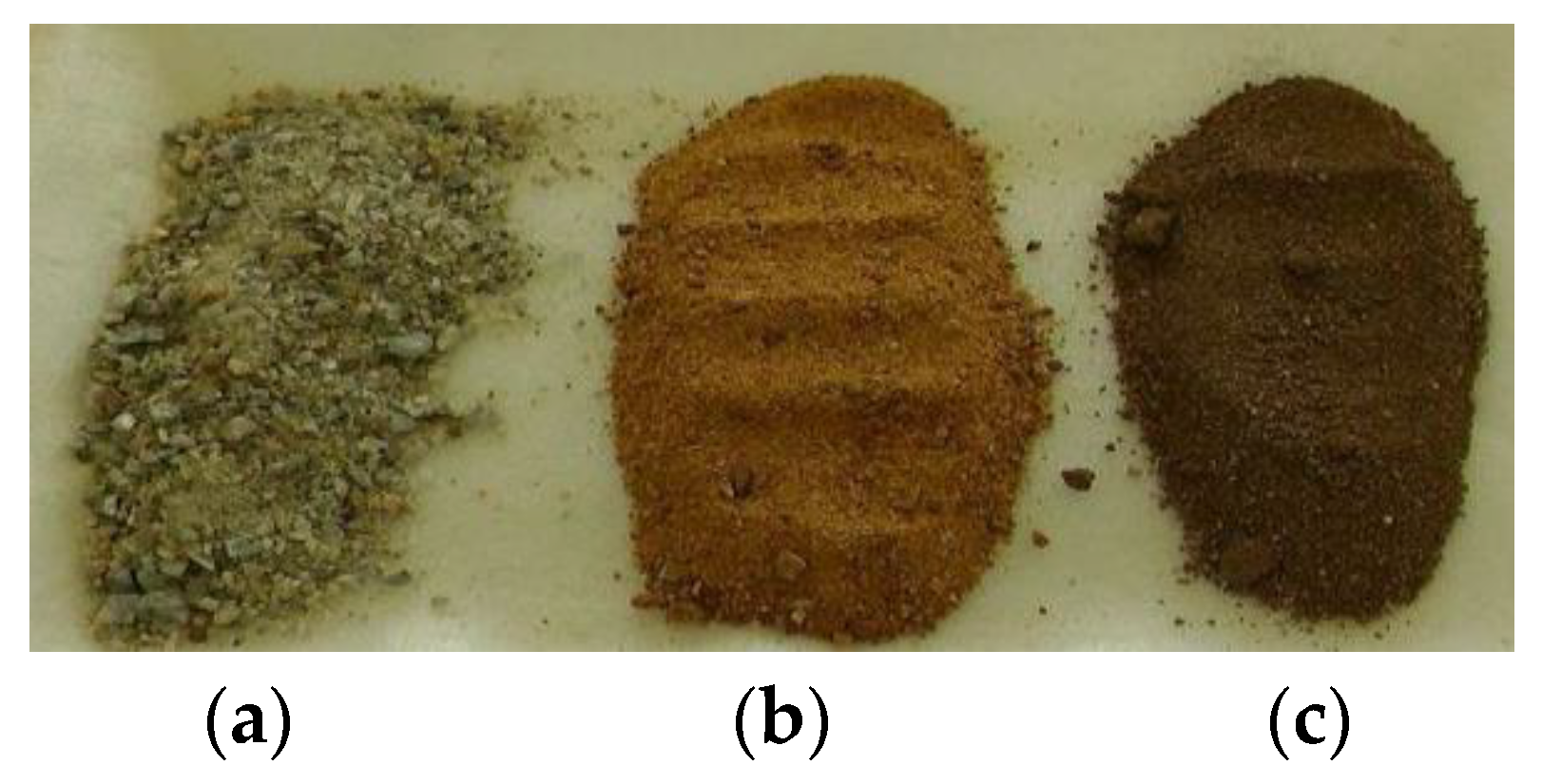

2.1. Material

2.2. Preparation of Hemp Hurd Composites

2.3. Testing Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Novel sustainable hemp based for application in the building industry: Physical, thermal, and mechanical characterization. Energy Build. 2014, 77, 219–226. [Google Scholar] [CrossRef]

- Balčiūnas, G.; Vėjelis, S.; Vaitkus, S.; Kairytė, A. Physical properties and structure of composite made by using hemp hurds and different binding materials. Procedia Eng. 2013, 57, 159–166. [Google Scholar] [CrossRef]

- Wang, H.; Lau, A.K.T. Hemp and hemp based composites. In Green Composites from Natural Resources, 1st ed.; Thakur, V.K., Ed.; Taylor & Francis (CRC Press): Boca Raton, FL, USA, 2013; pp. 63–94. ISBN 978-1-4665-7069-6. [Google Scholar]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Allin, S. Building with Hemp, 2nd ed.; Seed Press: Kenmare, Ireland, 2012. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F. Eco-efficient construction and building materials research under the EU Framework Programme Horizon 2020. Constr. Build. Mater. 2014, 51, 151–162. [Google Scholar] [CrossRef]

- Amziane, S.; Collet, F. (Eds.) Bio-Aggregates Based Building Materials: State-Of-The-Art Report of the RILEM; Technical Committee 236-BBM; Springer Nature: Dortdrecht, The Netherland, 2017; ISBN 978-94-024-1031-0. [Google Scholar]

- Holmer, S., Jr.; Fiorelli, J.; Santos, S.F. (Eds.) Sustainable and Nonconventional Construction Materials Using Inorganic Bonded Fiber Composites, 1st ed.; Woodhead Publishing: Duxford, UK, 2017; ISBN 978-0-08-102002-9. [Google Scholar]

- Taylor, M.; Tam, C.; Gielen, D. Energy Efficiency and CO2 Emissions from the Global Cement Industry. IEA-WBCSD Workshop, Proceedings of the “Energy Efficiency and CO2 Emission Reduction Potential and Policies in the Cement Industry: Towards a Plan of Action, Paris, France, 4–5 September 2006. Available online: http://s3.amazonaws.com/zanran_storage/www.iea.org/ContentPages/10979134.pdf (accessed on 1 November 2018).

- Moya, J.A.; Pardo, N.; Mercier, A. Energy Efficiency and CO2 Emissions: Prospective Scenarios for the Cement Industry; EUR 24592 EN; Joint Research Centre, Institute for Energy, Office for Official Publications of the European Communities: Luxembourg, 2010; ISSN 1018-5593; ISBN 978-92-79-17644-9. [Google Scholar] [CrossRef]

- Karade, S.R. Cement-bonded composites from lignocellulosic wastes. Constr. Build. Mater. 2010, 24, 1323–1330. [Google Scholar] [CrossRef]

- Mármol, G.; Savastano, H., Jr. Study of the degradation of non-conventional MgO-SiO2 cement reinforced with lignocellulosic fibers. Cem. Concr. Compos. 2017, 80, 258–267. [Google Scholar] [CrossRef]

- Mármol, G.; Santos, S.F.; Savastano, H., Jr.; Borrachero, M.V.; Monzo, J.; Paya, J. Mechanical and physical performance of low alkalinity cementitious composites reinforced with recycled cellulosic fibres pulp from cement kraft bags. Ind. Crops Prod. 2013, 49, 422–427. [Google Scholar] [CrossRef]

- Dharani, K.; Dhanaseker, N. Experimental study on partial replacement of cement by marble powder & quarry dust. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 5, 1766–1770. [Google Scholar] [CrossRef]

- Rominiyi, O.L.; Adaramola, B.A.; Ikumapayi, O.M.; Oginni, O.T.; Akinola, S.A. Potential utilization of sawdust in energy, manufacturing and agricultural industry: Waste to wealth. World J. Eng. Technol. 2017, 5, 526–539. [Google Scholar] [CrossRef]

- Safiuddin, M.; Jumaat, M.Z.; Salam, M.A.; Islam, M.S.; Hashim, R. Utilization of solid wastes in construction materials. Int. J. Phys. Sci. 2010, 5, 1952–1963. [Google Scholar]

- Faleschini, F.; Zanini, M.A.; Brunelli, K.; Pellegrino, C. Valorization of co-combustion fly ash in concrete production. Mater. Des. 2015, 85, 687–694. [Google Scholar] [CrossRef]

- Junakova, N.; Junak, J. Sustainable use of reservoir sediment through partial application in building material. Sustainability 2017, 9, 852. [Google Scholar] [CrossRef]

- Carsana, M.; Frassoni, M.; Bertolini, L. Comparison of ground waste glass with other supplementary cementitious materials. Cem. Concr. Comp. 2014, 45, 39–45. [Google Scholar] [CrossRef]

- Viramgama, P.D.; Vanyia, S.R.; Parikh, K.B. Effect of ceramic waste powder in self-compacting concrete properties: A critical review. IOSR J. Mech. Civ. Eng. 2016, 13, 8–13. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Shasavandi, A.; Jalali, S. Eco-efficient concrete using industrial wastes: A review. Mater. Sci. Forum 2013, 730–732, 581–585. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Kidalova, L. Lightweight composites based on cellulosic material. Int. J. Mod. Manuf. Technol. 2013, 5, 75–82. [Google Scholar]

- Stevulova, N.; Kidalova, L.; Cigasova, J.; Junak, J.; Sicakova, A.; Terpakova, E. Lightweight Composites Containing Hemp Hurds. Procedia Eng. 2013, 65, 69–74. [Google Scholar] [CrossRef]

- Kidalova, L.; Terpakova, E.; Stevulova, N. MgO cement as suitable conventional binder’s replacement in hemp concrete. Pollack Period. 2011, 6, 107–112. [Google Scholar] [CrossRef]

- Amziane, S.; Sonebi, M. Overview on bio-based building material made with plant aggregate. RILEM Tech. Lett. 2016, 1, 31–38. [Google Scholar] [CrossRef]

- Cigasova, J.; Stevulova, N.; Junak, J. Properties monitoring of fibrous composites based on hemp hurds with different mean particle size. Pollack Period. 2013, 8, 41–46. [Google Scholar] [CrossRef]

- Brzyski, P.; Barnat-Hunek, D.; Suchorab, Z.; Łagód, G. Composite materials based on hemp and flax for low-energy buildings. Materials 2017, 10, 510. [Google Scholar] [CrossRef] [PubMed]

- Niyigena, C.; Amziane, S.; Chateauneuf, A. Multicriteria analysis demonstrating the impact of shiv on the properties of hemp concrete. Constr. Build. Mater. 2018, 160, 211–222. [Google Scholar] [CrossRef]

- Escadeillas, G.; Magniont, C.; Amziane, S.; Nozahic, V. Binders. In Bio-Aggregate-Based Building Materials; Amziane, S., Arnaud, L., Challamel, N., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; pp. 75–116. [Google Scholar] [CrossRef]

- Dalmay, P.; Smith, A.; Chotard, T.; Sahay-Turner, P.; Gloaguen, V.; Krausz, P. Properties of cellulosic fibre reinforced plaster: Influence of hemp or flax fibers on the properties of set gypsum. J. Mater. Sci. 2010, 45, 793. [Google Scholar] [CrossRef]

- Sedan, D.; Pagnoux, C.; Chotard, T.; Smith, A.; Lejolly, D.; Gloaguen, V.; Krausz, P. Effect of calcium rich and alkaline solutions on the chemical behavior of hemp fibres. J. Mater. Sci. 2007, 42, 9336–9342. [Google Scholar] [CrossRef]

- Colinart, T.; Glouannec, P.; Chauvelon, P. Influence of the setting process and the formulation on the drying of hemp concrete. Constr. Build. Mater. 2012, 30, 372–380. [Google Scholar] [CrossRef]

- Kidalová, L.; Števulová, N.; Terpáková, E.; Sičáková, A. Utilization of alternative materials in lightweight composites. J. Clean. Prod. 2012, 34, 116–119. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Schwarzova, I.; Sicakova, A.; Junak, J. Sustainable bio-aggregate-based composites containing hemp hurds and alternative binder. Buildings 2018, 8, 25. [Google Scholar] [CrossRef]

- Stevulova, N.; Schwarzova, I. Testing hemp hurds composites with alternative binder. J. Civ. Eng. Environ. Archit. 2017, 34, 61–66. [Google Scholar] [CrossRef]

- Schwarzova, I. Lightweight Composites Based on Hemp Hurds. Ph.D. Thesis, Technical University of Kosice, Kosice, Slovakia, 2017. [Google Scholar]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties characterization of chemically modified hemp hurds. Materials 2014, 7, 8131–8150. [Google Scholar] [CrossRef] [PubMed]

- Kidalova, L. Determination of selected characteristics in hemp concrete. In Young Scientist, Proceedings of the 3rd Ph.D. Student Conference of Civil Engineering and Architecture, Herľany, Slovakia, 5–7 April 2011; Technical University of Kosice: Kosice, Slovakia, 2011; pp. 1–6. ISBN 978-80-553-0639-1. [Google Scholar]

- Bydzovsky, J. Utilization of rapidly renewable raw materials in building materials. In Proceedings of the 12th International Scientific Conference “Material Engineering”, Brno, Czech Republic, 12–14 May 2009; CERM: Brno, Czech Republic, 2009; pp. 43–46, ISBN 978-80-7204-629-4. [Google Scholar]

- STN EN 12390-3. Testing Hardened Concrete. Part 3: Compressive Strength of Test Specimens; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2010. [Google Scholar]

- STN EN 12390-7. Testing Hardened Concrete. Part 7: Density of Hardened Concrete; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2011. [Google Scholar]

- STN EN 12087/A1. Thermal Insulating Products for Building Applications. Determination of Long Term Water Absorption by Immersion; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2013. [Google Scholar]

- Cigasova, J.; Stevulova, N.; Junak, J. Influence of binder nature on properties of lightweight composites based on hemp hurds. Int. J. Mod. Manuf. Technol. 2013, 5, 27–31. [Google Scholar]

- Li, Z.; Zhang, T.; Hu, J.; Tang, Y.; Niu, Y.; Wie, J.; Yu, Q. Characterization of reaction products and reaction process of MgO–SiO2–H2O system at room temperature. Constr. Build. Mater. 2014, 61, 252–259. [Google Scholar] [CrossRef]

- Stevulova, N.; Schwarzova, I.; Estokova, A.; Holub, M. MgO-based cement as an inorganic binder for hemp hurds composites. Cheminé Technologija 2016, 67, 24–29. [Google Scholar] [CrossRef]

- Grubb, J.A.; Limaye, H.S.; Kakade, A.M. Testing pH of concrete. Concr. Int. 2007, 29, 78–83. [Google Scholar]

| Oxide | Content (%) | |

|---|---|---|

| MgO–C | MgO–L | |

| MgO | 84.0 | 69.1 |

| CaO | 5.5 | 5.2 |

| Fe2O3 | 7.5 | 6.0 |

| SiO2 | 1.0 | 0.6 |

| Al2O3 | 0.2 | 0.08 |

| Loss on ignition (%) | 1.7 | 18.5 |

| Specific surface area (m2·g−1) | 47.0 | 88.1 |

| Binder Sample | Components Variation in Binder (%) | ||||

|---|---|---|---|---|---|

| MgO–C | MgO–L | RS | SF | A | |

| B0 | 33.3 | 33.3 | 33.3 | ||

| B1 | 50 | 50 | |||

| B2 | 33.3 | 33.3 | 33.3 | ||

| B3 | 50 | 50 | |||

| B4 | 33.3 | 33.3 | 33.3 | ||

| B5 | 50 | 50 | |||

| B6 | 33.3 | 33.3 | 33.3 | ||

| B7 | 50 | 50 | |||

| Binder Sample | Density (kg/m3) | Thermal Conductivity Coefficient (W/m·K) | Shor-Term Water Absorption (%) | Compressive Strength (MPa) |

|---|---|---|---|---|

| B0 | 890 ± 4 | 0.195 ± 0.015 | 22.4 ± 1.05 | 1.55 ± 0.06 |

| B1 | 910 ± 3 | 0.205 ± 0.014 | 19.8 ± 1.24 | 2.84 ± 0.16 |

| B2 | 810 ± 3 | 0.180 ± 0.011 | 19.9 ± 0.97 | 2.40 ± 0.11 |

| B3 | 790 ± 8 | 0.180 ± 0.011 | 16.1 ± 0.83 | 3.32 ± 0.21 |

| B4 | 770 ± 7 | 0.170 ± 0.009 | 20.2 ± 1.06 | 1.75 ± 0.10 |

| B5 | 920 ± 6 | 0.190 ± 0.018 | 15.1 ± 1.12 | 2.94 ± 0.19 |

| B6 | 805 ± 5 | 0.175 ± 0.015 | 20.3 ± 1.02 | 2.76 ± 0.15 |

| B7 | 760 ± 4 | 0.175 ± 0.011 | 15.3 ± 0.74 | 3.51 ± 0.17 |

| Hardening Time (Days) | Short-Term Water Absorption (%) | Compressive Strength (MPa) |

|---|---|---|

| 28 | 15.3 ± 0.74 | 3.51 ± 0.17 |

| 60 | 11.1 ± 0.53 | 4.59 ± 0.28 |

| 90 | 8.9 ± 0.41 | 8.12 ± 0.62 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stevulova, N.; Junak, J.; Vaclavik, V. Effect of Silica Fume as a Component of Alternative Binder on the Selected Technically Important Characteristics of Bio-Aggregate-Based Composites. Materials 2018, 11, 2153. https://doi.org/10.3390/ma11112153

Stevulova N, Junak J, Vaclavik V. Effect of Silica Fume as a Component of Alternative Binder on the Selected Technically Important Characteristics of Bio-Aggregate-Based Composites. Materials. 2018; 11(11):2153. https://doi.org/10.3390/ma11112153

Chicago/Turabian StyleStevulova, Nadezda, Jozef Junak, and Vojtech Vaclavik. 2018. "Effect of Silica Fume as a Component of Alternative Binder on the Selected Technically Important Characteristics of Bio-Aggregate-Based Composites" Materials 11, no. 11: 2153. https://doi.org/10.3390/ma11112153

APA StyleStevulova, N., Junak, J., & Vaclavik, V. (2018). Effect of Silica Fume as a Component of Alternative Binder on the Selected Technically Important Characteristics of Bio-Aggregate-Based Composites. Materials, 11(11), 2153. https://doi.org/10.3390/ma11112153