Effect of Silica Fume as a Component of Alternative Binder on the Selected Technically Important Characteristics of Bio-Aggregate-Based Composites

Abstract

:1. Introduction

2. Materials and Methods

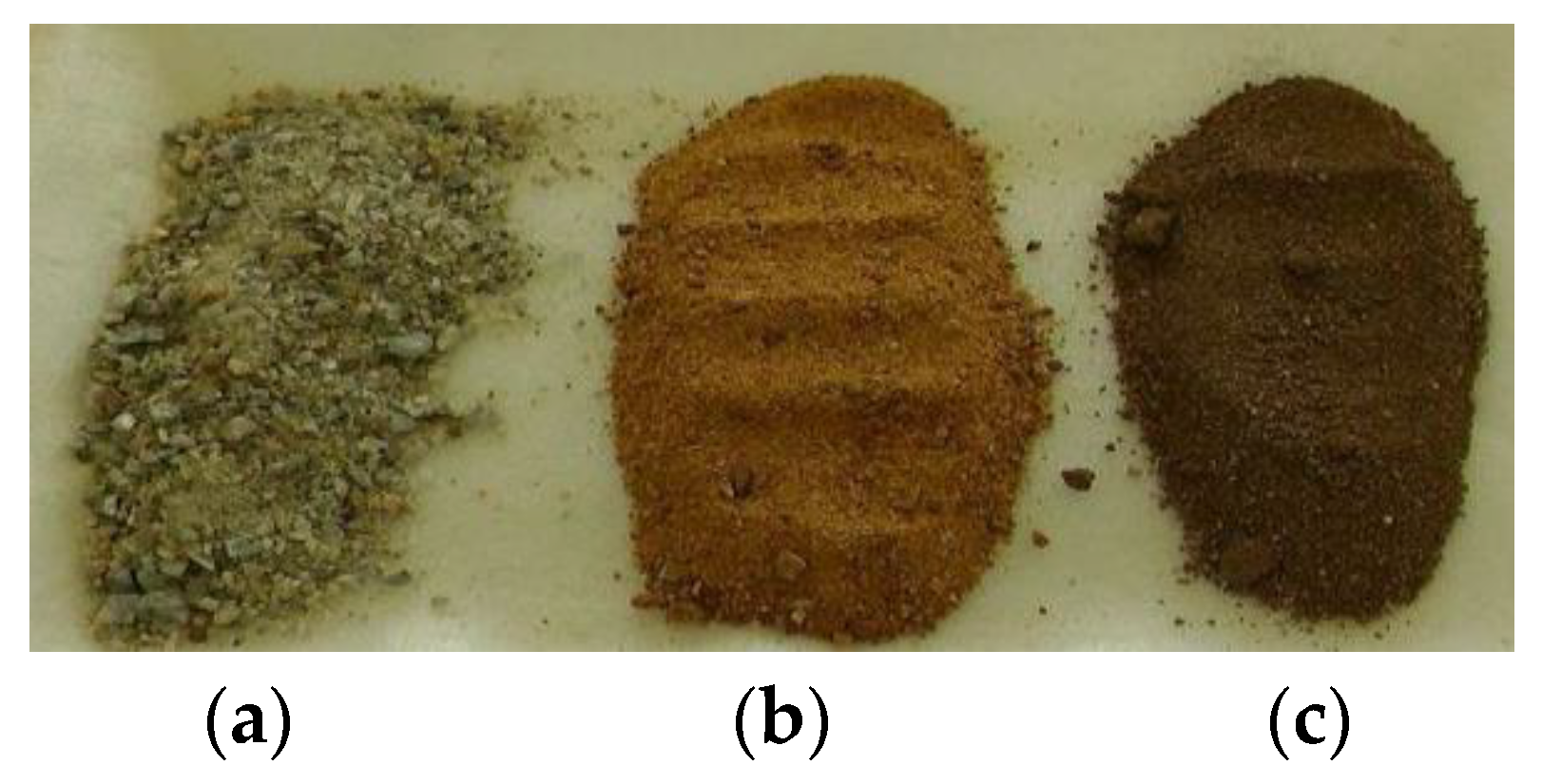

2.1. Material

2.2. Preparation of Hemp Hurd Composites

2.3. Testing Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Novel sustainable hemp based for application in the building industry: Physical, thermal, and mechanical characterization. Energy Build. 2014, 77, 219–226. [Google Scholar] [CrossRef]

- Balčiūnas, G.; Vėjelis, S.; Vaitkus, S.; Kairytė, A. Physical properties and structure of composite made by using hemp hurds and different binding materials. Procedia Eng. 2013, 57, 159–166. [Google Scholar] [CrossRef]

- Wang, H.; Lau, A.K.T. Hemp and hemp based composites. In Green Composites from Natural Resources, 1st ed.; Thakur, V.K., Ed.; Taylor & Francis (CRC Press): Boca Raton, FL, USA, 2013; pp. 63–94. ISBN 978-1-4665-7069-6. [Google Scholar]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Allin, S. Building with Hemp, 2nd ed.; Seed Press: Kenmare, Ireland, 2012. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F. Eco-efficient construction and building materials research under the EU Framework Programme Horizon 2020. Constr. Build. Mater. 2014, 51, 151–162. [Google Scholar] [CrossRef] [Green Version]

- Amziane, S.; Collet, F. (Eds.) Bio-Aggregates Based Building Materials: State-Of-The-Art Report of the RILEM; Technical Committee 236-BBM; Springer Nature: Dortdrecht, The Netherland, 2017; ISBN 978-94-024-1031-0. [Google Scholar]

- Holmer, S., Jr.; Fiorelli, J.; Santos, S.F. (Eds.) Sustainable and Nonconventional Construction Materials Using Inorganic Bonded Fiber Composites, 1st ed.; Woodhead Publishing: Duxford, UK, 2017; ISBN 978-0-08-102002-9. [Google Scholar]

- Taylor, M.; Tam, C.; Gielen, D. Energy Efficiency and CO2 Emissions from the Global Cement Industry. IEA-WBCSD Workshop, Proceedings of the “Energy Efficiency and CO2 Emission Reduction Potential and Policies in the Cement Industry: Towards a Plan of Action, Paris, France, 4–5 September 2006. Available online: http://s3.amazonaws.com/zanran_storage/www.iea.org/ContentPages/10979134.pdf (accessed on 1 November 2018).

- Moya, J.A.; Pardo, N.; Mercier, A. Energy Efficiency and CO2 Emissions: Prospective Scenarios for the Cement Industry; EUR 24592 EN; Joint Research Centre, Institute for Energy, Office for Official Publications of the European Communities: Luxembourg, 2010; ISSN 1018-5593; ISBN 978-92-79-17644-9. [Google Scholar] [CrossRef]

- Karade, S.R. Cement-bonded composites from lignocellulosic wastes. Constr. Build. Mater. 2010, 24, 1323–1330. [Google Scholar] [CrossRef]

- Mármol, G.; Savastano, H., Jr. Study of the degradation of non-conventional MgO-SiO2 cement reinforced with lignocellulosic fibers. Cem. Concr. Compos. 2017, 80, 258–267. [Google Scholar] [CrossRef]

- Mármol, G.; Santos, S.F.; Savastano, H., Jr.; Borrachero, M.V.; Monzo, J.; Paya, J. Mechanical and physical performance of low alkalinity cementitious composites reinforced with recycled cellulosic fibres pulp from cement kraft bags. Ind. Crops Prod. 2013, 49, 422–427. [Google Scholar] [CrossRef]

- Dharani, K.; Dhanaseker, N. Experimental study on partial replacement of cement by marble powder & quarry dust. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 5, 1766–1770. [Google Scholar] [CrossRef]

- Rominiyi, O.L.; Adaramola, B.A.; Ikumapayi, O.M.; Oginni, O.T.; Akinola, S.A. Potential utilization of sawdust in energy, manufacturing and agricultural industry: Waste to wealth. World J. Eng. Technol. 2017, 5, 526–539. [Google Scholar] [CrossRef]

- Safiuddin, M.; Jumaat, M.Z.; Salam, M.A.; Islam, M.S.; Hashim, R. Utilization of solid wastes in construction materials. Int. J. Phys. Sci. 2010, 5, 1952–1963. [Google Scholar]

- Faleschini, F.; Zanini, M.A.; Brunelli, K.; Pellegrino, C. Valorization of co-combustion fly ash in concrete production. Mater. Des. 2015, 85, 687–694. [Google Scholar] [CrossRef]

- Junakova, N.; Junak, J. Sustainable use of reservoir sediment through partial application in building material. Sustainability 2017, 9, 852. [Google Scholar] [CrossRef]

- Carsana, M.; Frassoni, M.; Bertolini, L. Comparison of ground waste glass with other supplementary cementitious materials. Cem. Concr. Comp. 2014, 45, 39–45. [Google Scholar] [CrossRef]

- Viramgama, P.D.; Vanyia, S.R.; Parikh, K.B. Effect of ceramic waste powder in self-compacting concrete properties: A critical review. IOSR J. Mech. Civ. Eng. 2016, 13, 8–13. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Shasavandi, A.; Jalali, S. Eco-efficient concrete using industrial wastes: A review. Mater. Sci. Forum 2013, 730–732, 581–585. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Kidalova, L. Lightweight composites based on cellulosic material. Int. J. Mod. Manuf. Technol. 2013, 5, 75–82. [Google Scholar]

- Stevulova, N.; Kidalova, L.; Cigasova, J.; Junak, J.; Sicakova, A.; Terpakova, E. Lightweight Composites Containing Hemp Hurds. Procedia Eng. 2013, 65, 69–74. [Google Scholar] [CrossRef]

- Kidalova, L.; Terpakova, E.; Stevulova, N. MgO cement as suitable conventional binder’s replacement in hemp concrete. Pollack Period. 2011, 6, 107–112. [Google Scholar] [CrossRef]

- Amziane, S.; Sonebi, M. Overview on bio-based building material made with plant aggregate. RILEM Tech. Lett. 2016, 1, 31–38. [Google Scholar] [CrossRef]

- Cigasova, J.; Stevulova, N.; Junak, J. Properties monitoring of fibrous composites based on hemp hurds with different mean particle size. Pollack Period. 2013, 8, 41–46. [Google Scholar] [CrossRef]

- Brzyski, P.; Barnat-Hunek, D.; Suchorab, Z.; Łagód, G. Composite materials based on hemp and flax for low-energy buildings. Materials 2017, 10, 510. [Google Scholar] [CrossRef] [PubMed]

- Niyigena, C.; Amziane, S.; Chateauneuf, A. Multicriteria analysis demonstrating the impact of shiv on the properties of hemp concrete. Constr. Build. Mater. 2018, 160, 211–222. [Google Scholar] [CrossRef]

- Escadeillas, G.; Magniont, C.; Amziane, S.; Nozahic, V. Binders. In Bio-Aggregate-Based Building Materials; Amziane, S., Arnaud, L., Challamel, N., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; pp. 75–116. [Google Scholar] [CrossRef]

- Dalmay, P.; Smith, A.; Chotard, T.; Sahay-Turner, P.; Gloaguen, V.; Krausz, P. Properties of cellulosic fibre reinforced plaster: Influence of hemp or flax fibers on the properties of set gypsum. J. Mater. Sci. 2010, 45, 793. [Google Scholar] [CrossRef]

- Sedan, D.; Pagnoux, C.; Chotard, T.; Smith, A.; Lejolly, D.; Gloaguen, V.; Krausz, P. Effect of calcium rich and alkaline solutions on the chemical behavior of hemp fibres. J. Mater. Sci. 2007, 42, 9336–9342. [Google Scholar] [CrossRef]

- Colinart, T.; Glouannec, P.; Chauvelon, P. Influence of the setting process and the formulation on the drying of hemp concrete. Constr. Build. Mater. 2012, 30, 372–380. [Google Scholar] [CrossRef]

- Kidalová, L.; Števulová, N.; Terpáková, E.; Sičáková, A. Utilization of alternative materials in lightweight composites. J. Clean. Prod. 2012, 34, 116–119. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Schwarzova, I.; Sicakova, A.; Junak, J. Sustainable bio-aggregate-based composites containing hemp hurds and alternative binder. Buildings 2018, 8, 25. [Google Scholar] [CrossRef]

- Stevulova, N.; Schwarzova, I. Testing hemp hurds composites with alternative binder. J. Civ. Eng. Environ. Archit. 2017, 34, 61–66. [Google Scholar] [CrossRef]

- Schwarzova, I. Lightweight Composites Based on Hemp Hurds. Ph.D. Thesis, Technical University of Kosice, Kosice, Slovakia, 2017. [Google Scholar]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties characterization of chemically modified hemp hurds. Materials 2014, 7, 8131–8150. [Google Scholar] [CrossRef] [PubMed]

- Kidalova, L. Determination of selected characteristics in hemp concrete. In Young Scientist, Proceedings of the 3rd Ph.D. Student Conference of Civil Engineering and Architecture, Herľany, Slovakia, 5–7 April 2011; Technical University of Kosice: Kosice, Slovakia, 2011; pp. 1–6. ISBN 978-80-553-0639-1. [Google Scholar]

- Bydzovsky, J. Utilization of rapidly renewable raw materials in building materials. In Proceedings of the 12th International Scientific Conference “Material Engineering”, Brno, Czech Republic, 12–14 May 2009; CERM: Brno, Czech Republic, 2009; pp. 43–46, ISBN 978-80-7204-629-4. [Google Scholar]

- STN EN 12390-3. Testing Hardened Concrete. Part 3: Compressive Strength of Test Specimens; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2010. [Google Scholar]

- STN EN 12390-7. Testing Hardened Concrete. Part 7: Density of Hardened Concrete; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2011. [Google Scholar]

- STN EN 12087/A1. Thermal Insulating Products for Building Applications. Determination of Long Term Water Absorption by Immersion; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2013. [Google Scholar]

- Cigasova, J.; Stevulova, N.; Junak, J. Influence of binder nature on properties of lightweight composites based on hemp hurds. Int. J. Mod. Manuf. Technol. 2013, 5, 27–31. [Google Scholar]

- Li, Z.; Zhang, T.; Hu, J.; Tang, Y.; Niu, Y.; Wie, J.; Yu, Q. Characterization of reaction products and reaction process of MgO–SiO2–H2O system at room temperature. Constr. Build. Mater. 2014, 61, 252–259. [Google Scholar] [CrossRef]

- Stevulova, N.; Schwarzova, I.; Estokova, A.; Holub, M. MgO-based cement as an inorganic binder for hemp hurds composites. Cheminé Technologija 2016, 67, 24–29. [Google Scholar] [CrossRef]

- Grubb, J.A.; Limaye, H.S.; Kakade, A.M. Testing pH of concrete. Concr. Int. 2007, 29, 78–83. [Google Scholar]

| Oxide | Content (%) | |

|---|---|---|

| MgO–C | MgO–L | |

| MgO | 84.0 | 69.1 |

| CaO | 5.5 | 5.2 |

| Fe2O3 | 7.5 | 6.0 |

| SiO2 | 1.0 | 0.6 |

| Al2O3 | 0.2 | 0.08 |

| Loss on ignition (%) | 1.7 | 18.5 |

| Specific surface area (m2·g−1) | 47.0 | 88.1 |

| Binder Sample | Components Variation in Binder (%) | ||||

|---|---|---|---|---|---|

| MgO–C | MgO–L | RS | SF | A | |

| B0 | 33.3 | 33.3 | 33.3 | ||

| B1 | 50 | 50 | |||

| B2 | 33.3 | 33.3 | 33.3 | ||

| B3 | 50 | 50 | |||

| B4 | 33.3 | 33.3 | 33.3 | ||

| B5 | 50 | 50 | |||

| B6 | 33.3 | 33.3 | 33.3 | ||

| B7 | 50 | 50 | |||

| Binder Sample | Density (kg/m3) | Thermal Conductivity Coefficient (W/m·K) | Shor-Term Water Absorption (%) | Compressive Strength (MPa) |

|---|---|---|---|---|

| B0 | 890 ± 4 | 0.195 ± 0.015 | 22.4 ± 1.05 | 1.55 ± 0.06 |

| B1 | 910 ± 3 | 0.205 ± 0.014 | 19.8 ± 1.24 | 2.84 ± 0.16 |

| B2 | 810 ± 3 | 0.180 ± 0.011 | 19.9 ± 0.97 | 2.40 ± 0.11 |

| B3 | 790 ± 8 | 0.180 ± 0.011 | 16.1 ± 0.83 | 3.32 ± 0.21 |

| B4 | 770 ± 7 | 0.170 ± 0.009 | 20.2 ± 1.06 | 1.75 ± 0.10 |

| B5 | 920 ± 6 | 0.190 ± 0.018 | 15.1 ± 1.12 | 2.94 ± 0.19 |

| B6 | 805 ± 5 | 0.175 ± 0.015 | 20.3 ± 1.02 | 2.76 ± 0.15 |

| B7 | 760 ± 4 | 0.175 ± 0.011 | 15.3 ± 0.74 | 3.51 ± 0.17 |

| Hardening Time (Days) | Short-Term Water Absorption (%) | Compressive Strength (MPa) |

|---|---|---|

| 28 | 15.3 ± 0.74 | 3.51 ± 0.17 |

| 60 | 11.1 ± 0.53 | 4.59 ± 0.28 |

| 90 | 8.9 ± 0.41 | 8.12 ± 0.62 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stevulova, N.; Junak, J.; Vaclavik, V. Effect of Silica Fume as a Component of Alternative Binder on the Selected Technically Important Characteristics of Bio-Aggregate-Based Composites. Materials 2018, 11, 2153. https://doi.org/10.3390/ma11112153

Stevulova N, Junak J, Vaclavik V. Effect of Silica Fume as a Component of Alternative Binder on the Selected Technically Important Characteristics of Bio-Aggregate-Based Composites. Materials. 2018; 11(11):2153. https://doi.org/10.3390/ma11112153

Chicago/Turabian StyleStevulova, Nadezda, Jozef Junak, and Vojtech Vaclavik. 2018. "Effect of Silica Fume as a Component of Alternative Binder on the Selected Technically Important Characteristics of Bio-Aggregate-Based Composites" Materials 11, no. 11: 2153. https://doi.org/10.3390/ma11112153

APA StyleStevulova, N., Junak, J., & Vaclavik, V. (2018). Effect of Silica Fume as a Component of Alternative Binder on the Selected Technically Important Characteristics of Bio-Aggregate-Based Composites. Materials, 11(11), 2153. https://doi.org/10.3390/ma11112153