Improvement of Laser Transmission Welding of Glass with Titanium Alloy by Laser Surface Treatment

Abstract

1. Introduction

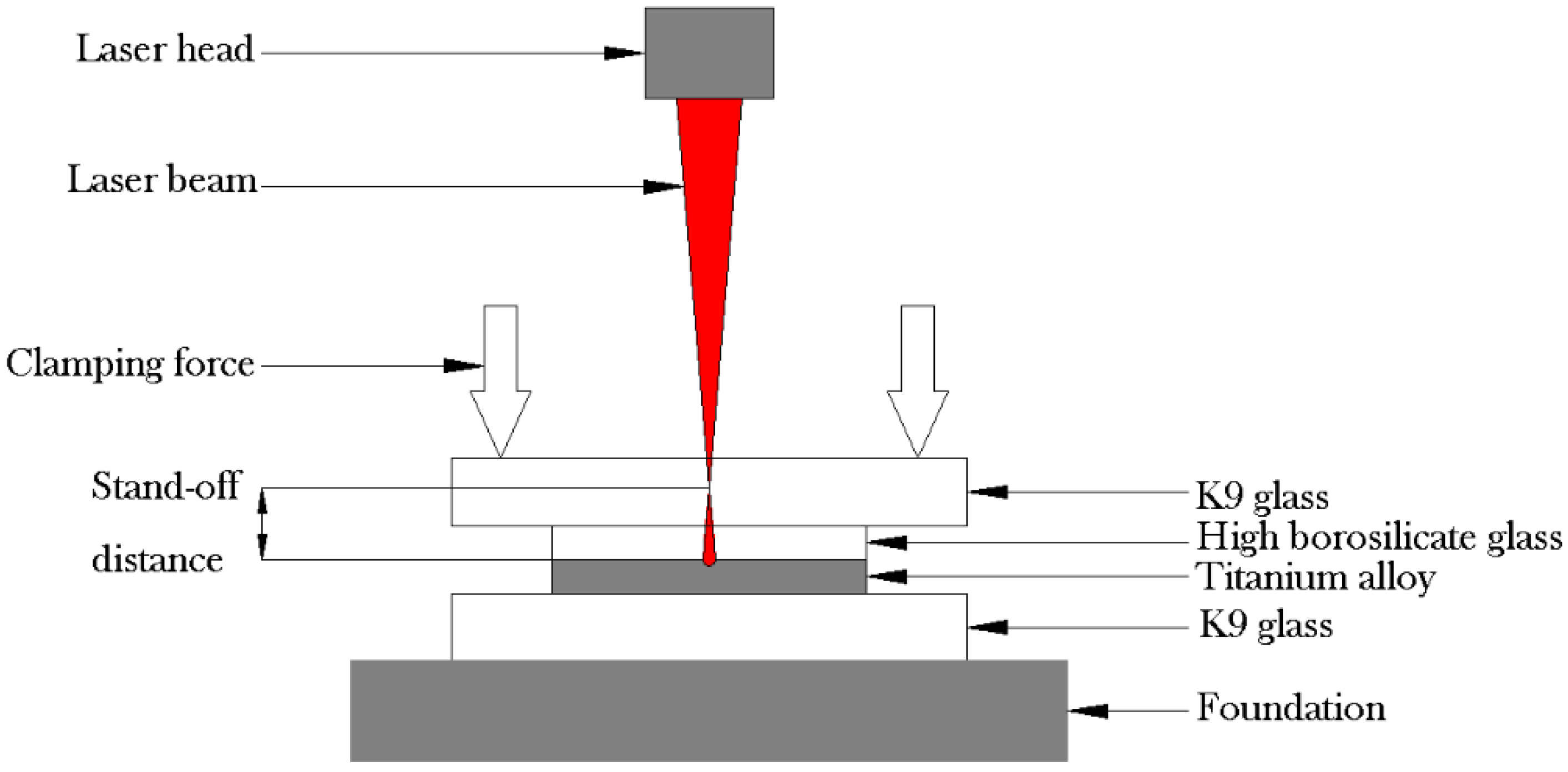

2. Materials and Methods

3. Results and Discussion

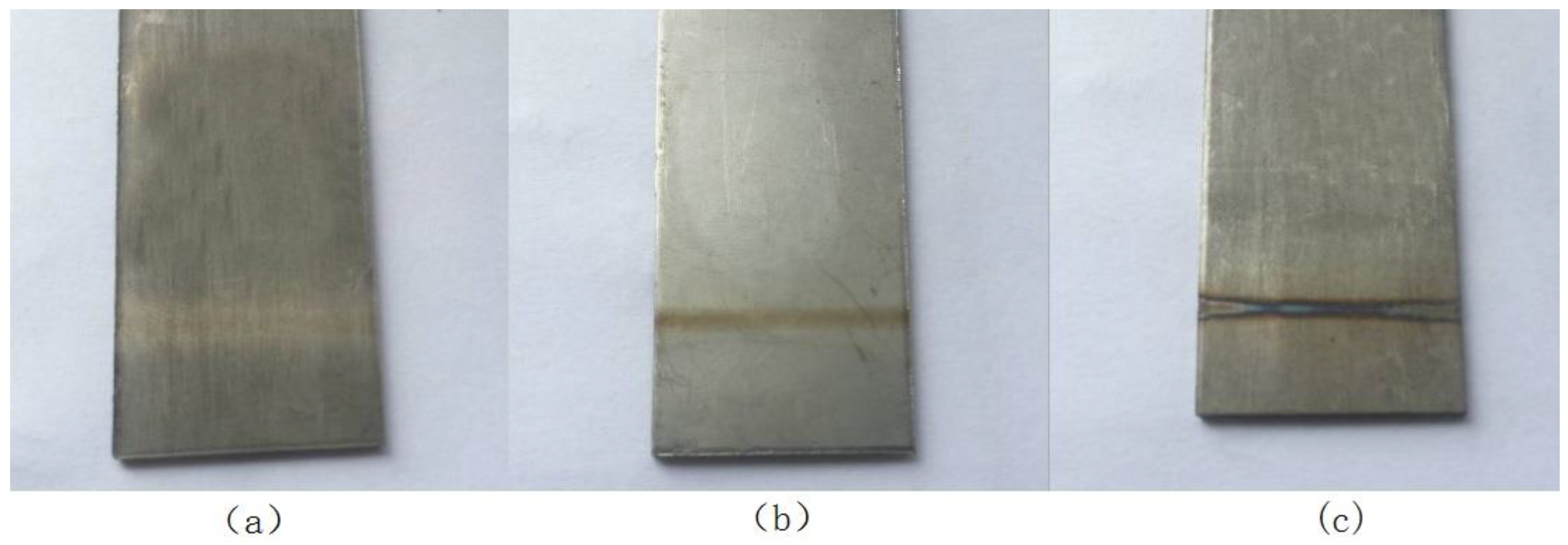

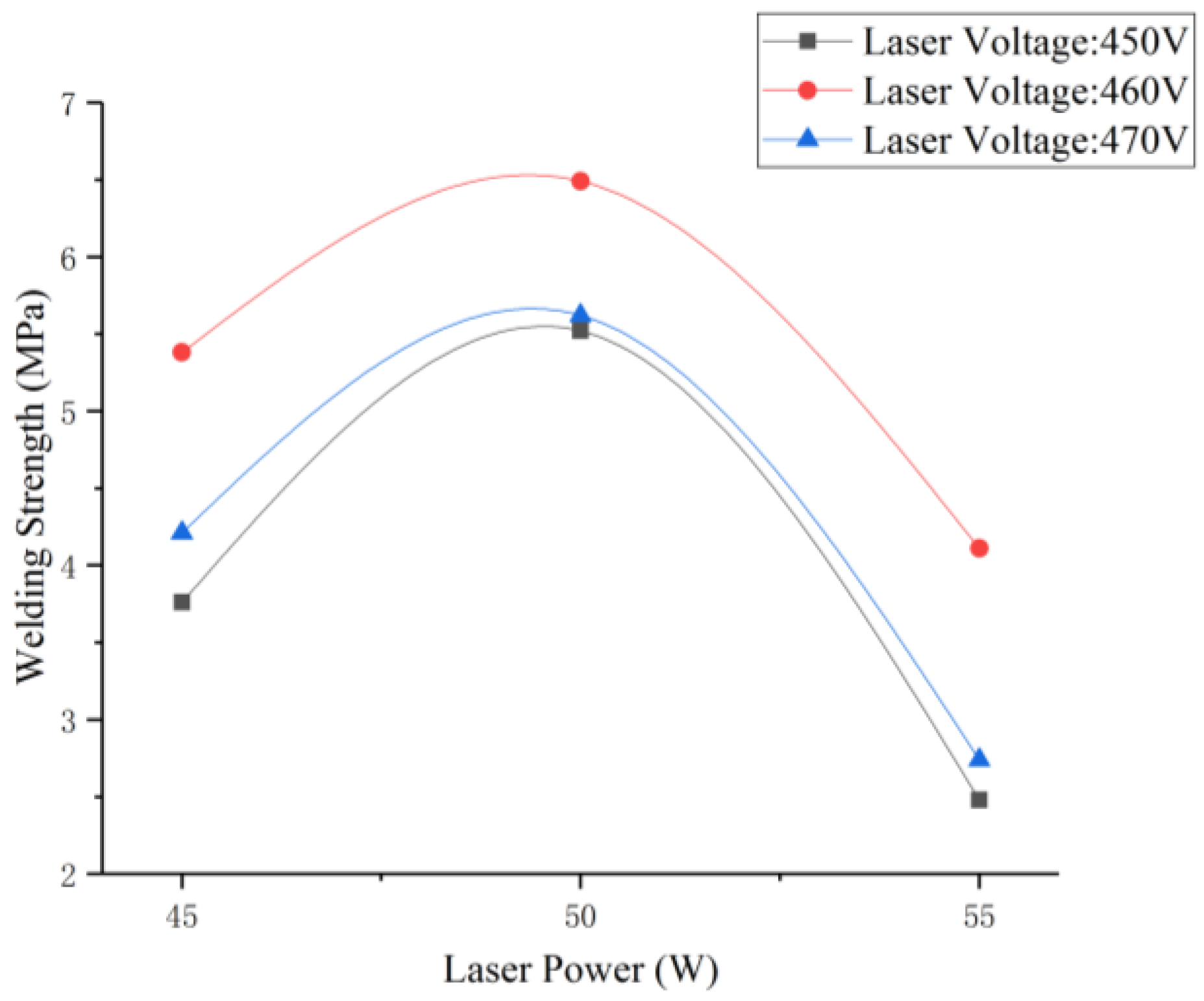

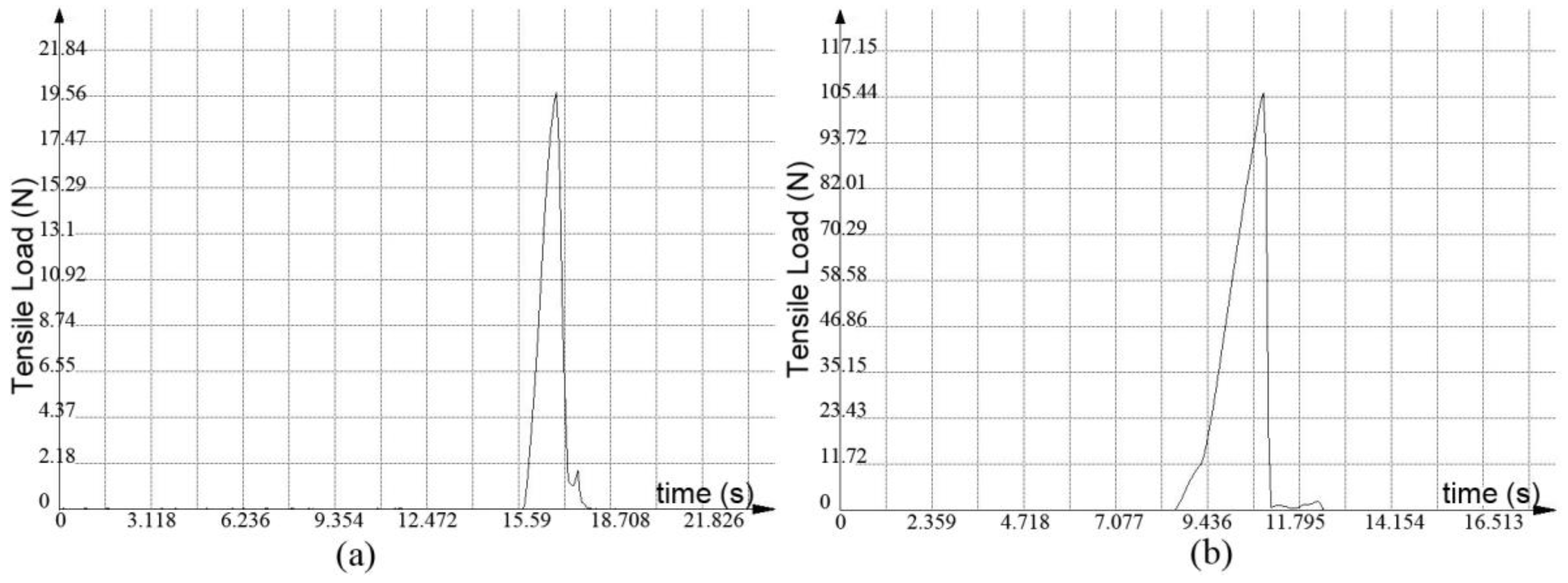

3.1. Effect of Laser Surface Treatment on Welding Strength

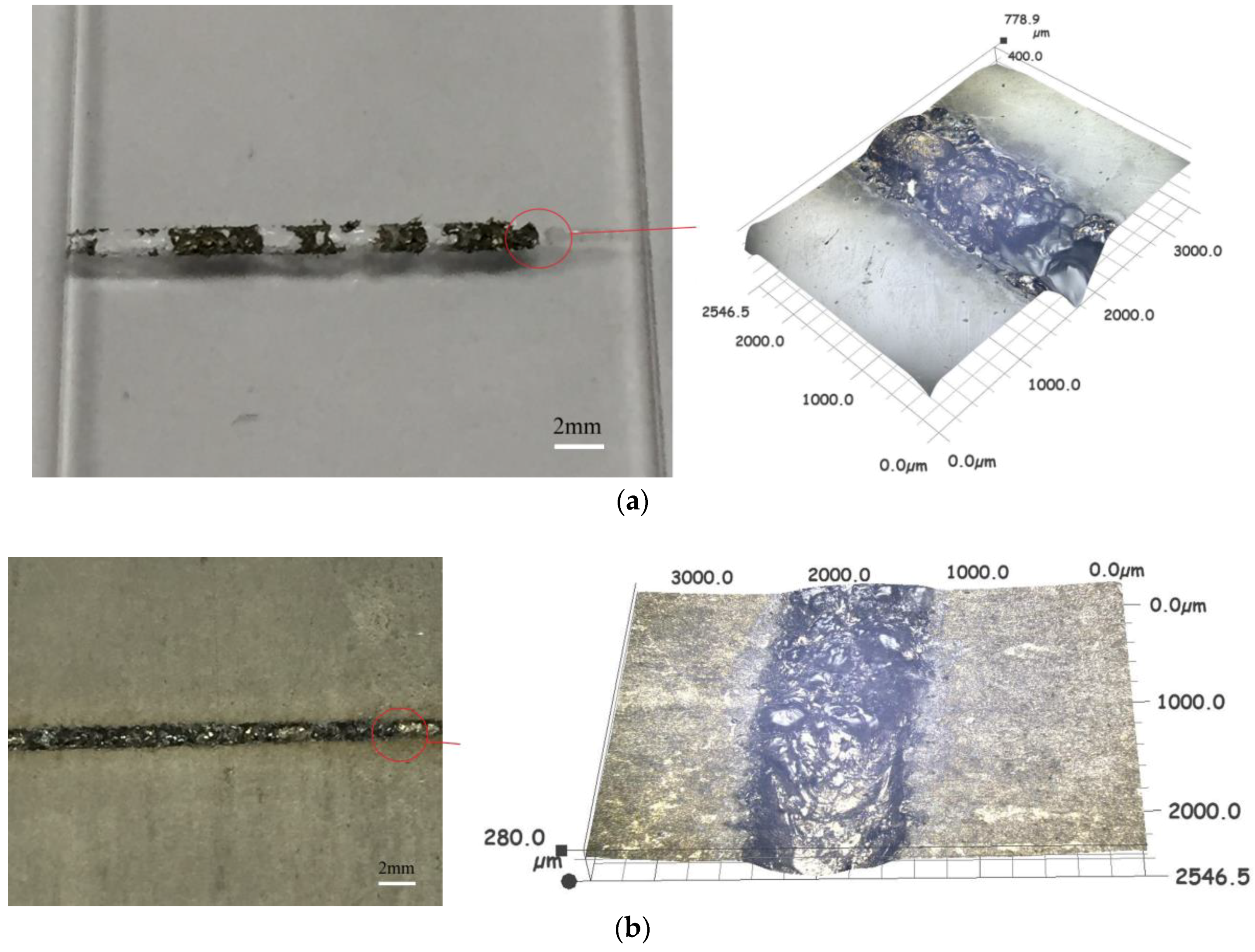

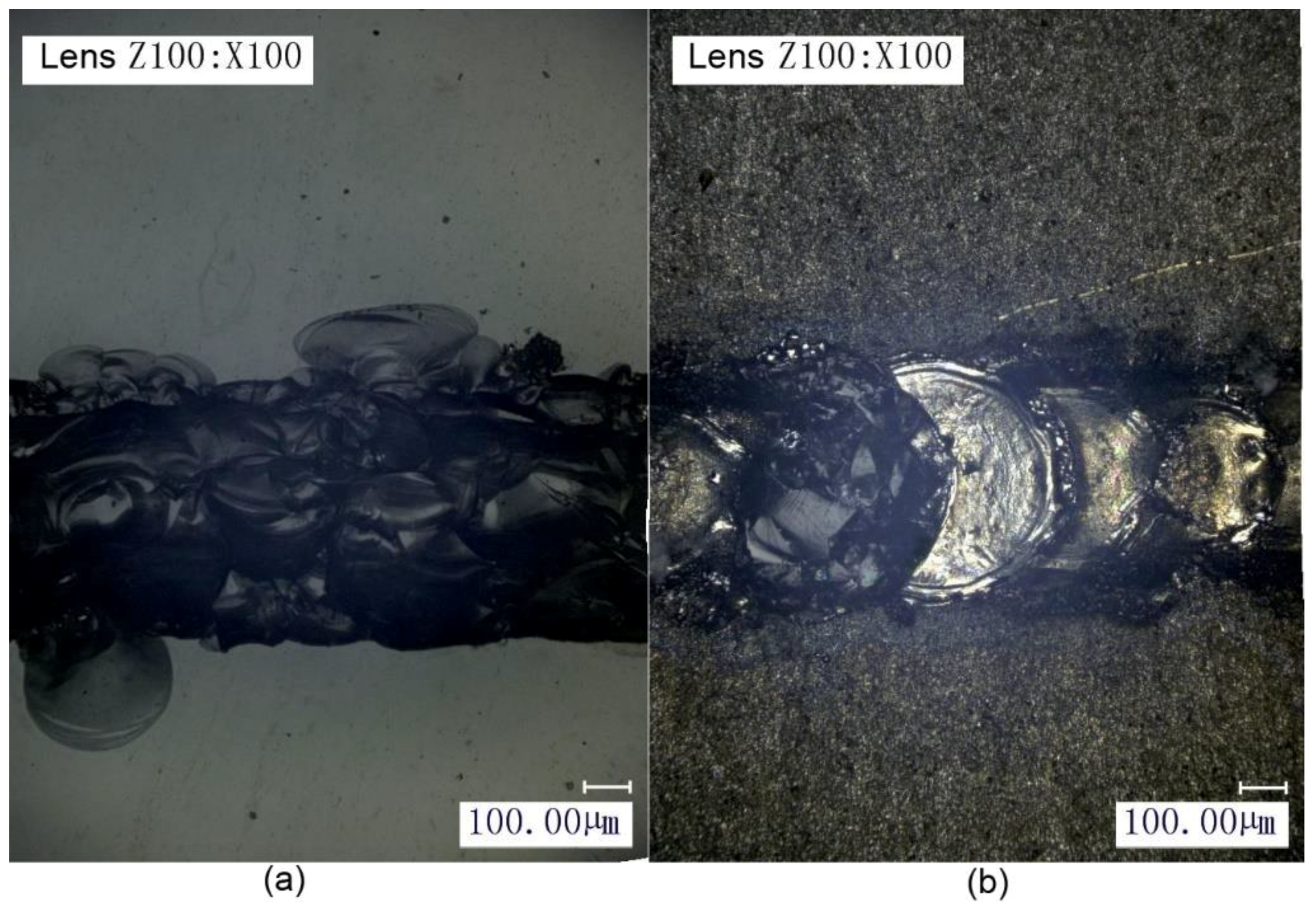

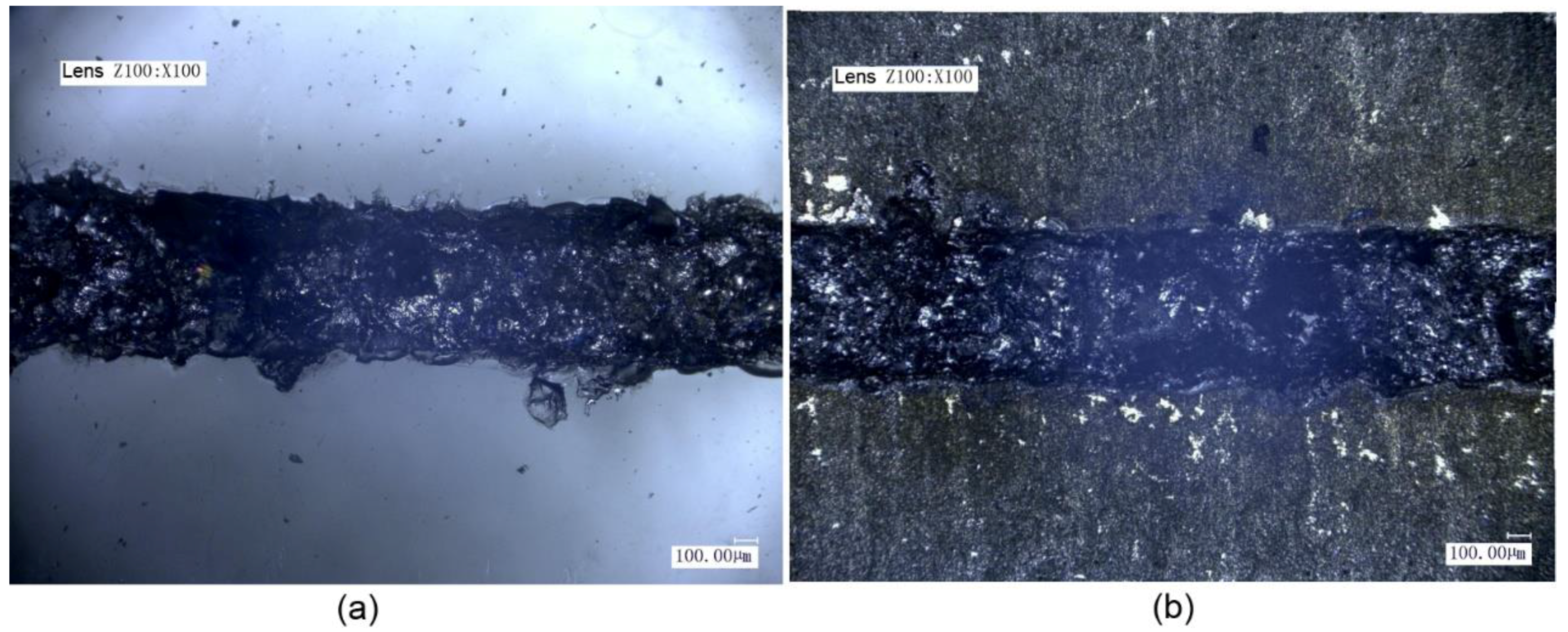

3.2. Micromorphology of Welding Seam and Tensile Failure Analysis

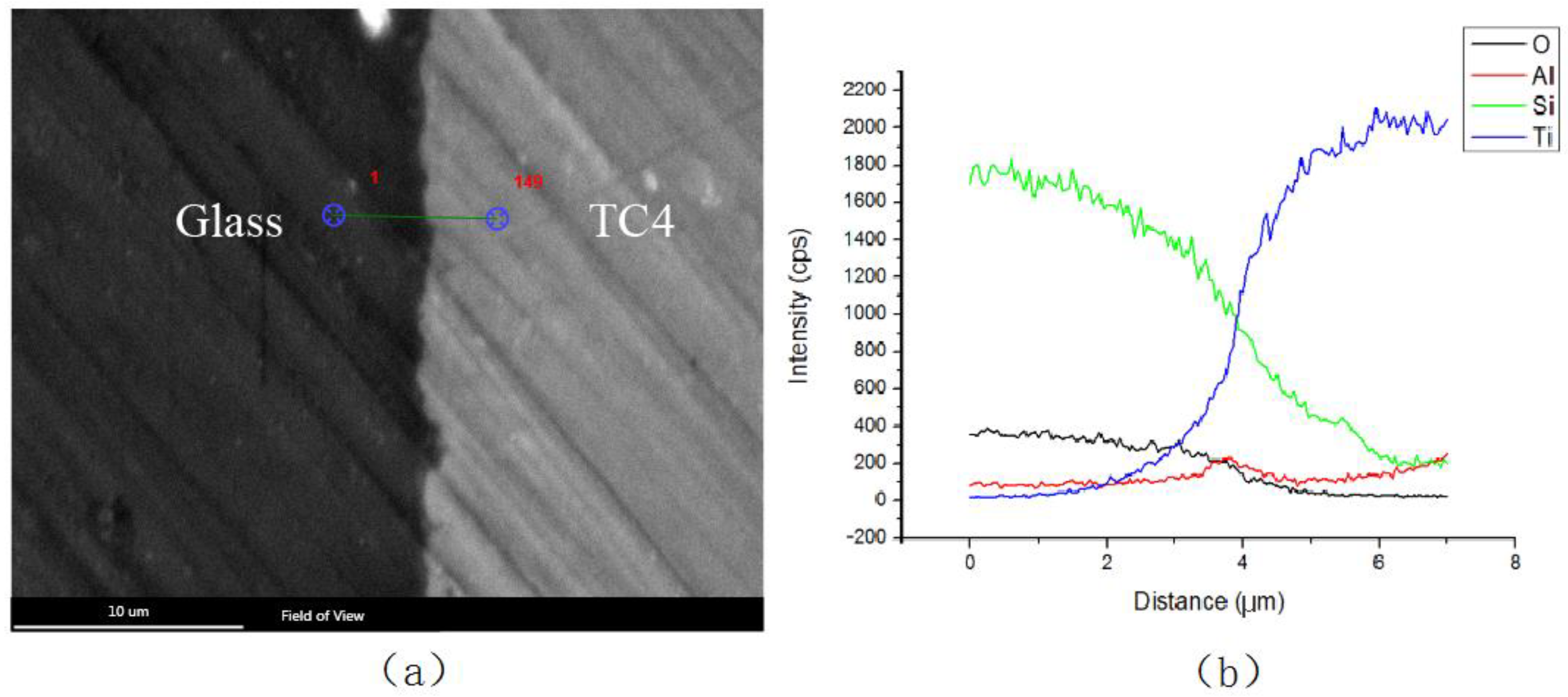

3.3. Diffusion of Elements at the Joint Interface

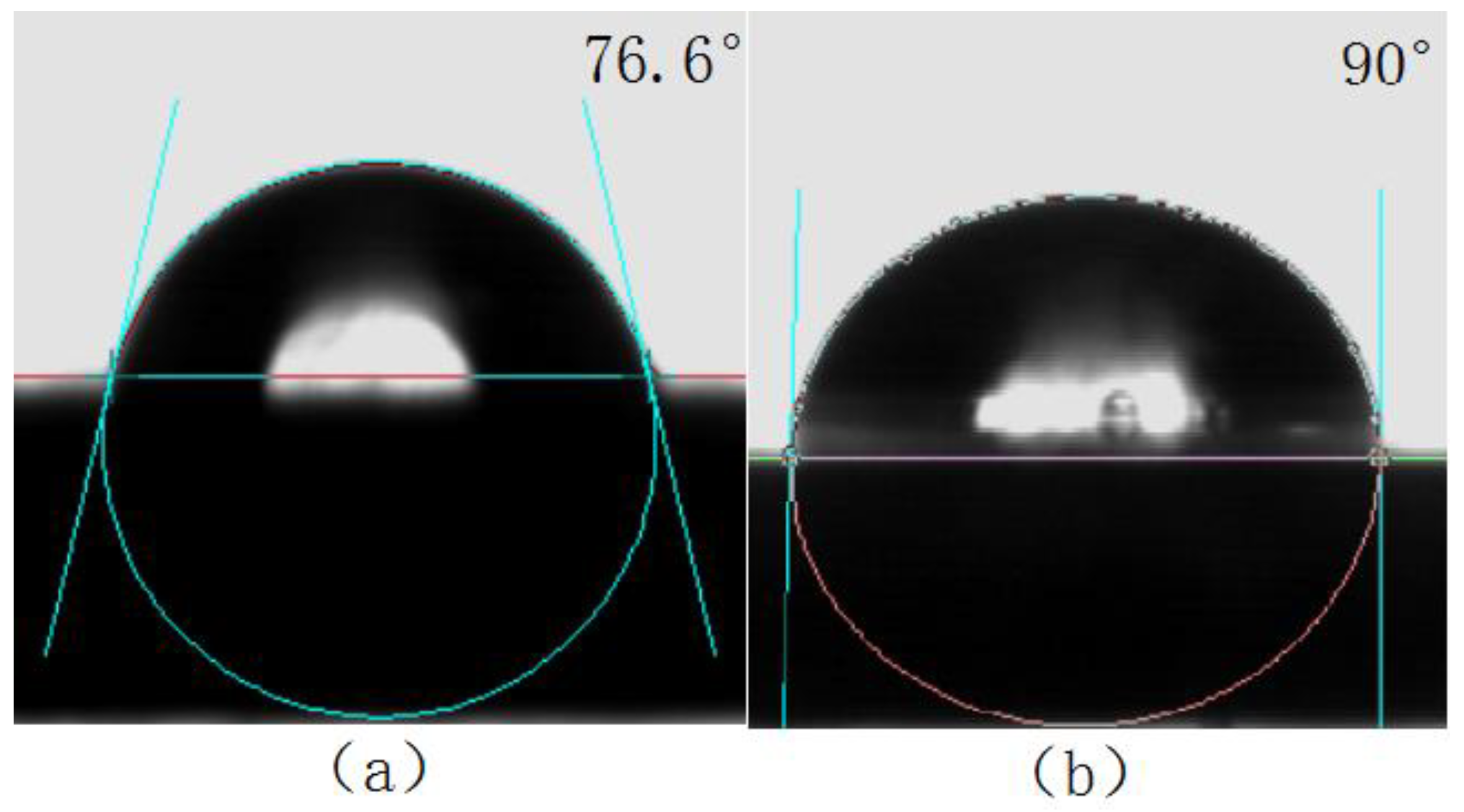

3.4. Contact Angle and Surface Energy

4. Conclusions

- (1)

- A large number of black adherents were observed at the weld between the laser-surface-treated titanium alloy and the high borosilicate glass. A small-size interlock effect may be formed, resulting in a strong joining effect;

- (2)

- The welding strength was the higher when the laser voltage for transmission welding was 460 V, and the tensile-fracture failure mode was mainly ductile fracture. When the voltage for transmission welding was high, the titanium alloy was ablated due to excessive energy input, and the glass was cracked, thus reducing the welding strength;

- (3)

- It was found that there was elemental diffusion at the weld interface between the titanium alloy and the glass, which is an important reason for the formation of high-strength welded joints;

- (4)

- The measurement of the surface contact angles of the titanium alloy shows that the laser surface treatment of the titanium alloy increased the surface energy and promoted the compatibility between the titanium alloy and the glass, thus improving the welding strength of the two materials.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lei, D.; Wang, Z. The calculation and analysis of glass-to-metal sealing stress in solar absorber tube. Renew. Energy 2010, 35, 405–411. [Google Scholar] [CrossRef]

- Leichtfried, G.; Thurner, G. Molybdenum alloys for glass-to-metal seals. Int. J. Refract. Met. Hard Mater. 1998, 16, 13–22. [Google Scholar] [CrossRef]

- Lei, D.; Wang, Z. Experimental study of glass to metal seals for parabolic trough receivers. Renew. Energy 2012, 48, 85–91. [Google Scholar] [CrossRef]

- Butkus, S.; Paipulas, D. Improvement of Cut Quality in Rapid-Cutting of Glass Method via Femtosecond Laser Filamentation. J. Laser Micro Nanoeng. 2015, 10, 59–63. [Google Scholar] [CrossRef]

- Athanasiou, C.E.; Hongler, M.O. Unraveling Brittle-Fracture Statistics from Intermittent Patterns Formed During Femtosecond Laser Exposure. Phys. Rev. Appl. 2017, 8. [Google Scholar] [CrossRef]

- Carter, R.M.; Troughton, M. Towards industrial ultrafast laser microwelding: SiO2 and BK7 to aluminum alloy. Appl. Opt. 2017, 56, 4873–4881. [Google Scholar] [CrossRef] [PubMed]

- Volpe, A.; Di Niso, F. Welding of PMMA by a femtosecond fiber laser. Opt. Express 2015, 23, 4114–4124. [Google Scholar] [CrossRef] [PubMed]

- Richter, S.; Doering, S. Bonding of glass with femtosecond laser pulses at high repetition rates. Appl. Phys. A 2011, 103, 257–261. [Google Scholar] [CrossRef]

- Itoh, K.; Tamaki, T. Ultrafast laser microwelding for transparent and heterogeneous materials. In Proceedings of the Commercial and Biomedical Applications of Ultrafast Lasers VIII, San Jose, CA, USA, 20–23 January 2008; Volume 6881. [Google Scholar]

- Utsumi, A.; Ooie, T. Direct Bonding of Glass and Metal Using Short Pulsed Laser. J. Laser Micro Nanoeng. 2007, 2, 133–136. [Google Scholar] [CrossRef]

- Quintino, L.; Liu, L. Bonding NiTi to glass with femtosecond laser pulses. Mater. Lett. 2013, 98, 142–145. [Google Scholar] [CrossRef]

- Flury, M.; Pedri, C. Laser Induced Reverse Transfer with metal and hybrid material prepared with sol-gel process used on glass substrate. Appl. Surf. Sci. 2013, 278, 142–145. [Google Scholar] [CrossRef]

- Ciuca, O.P.; Carter, R.M. Characterisation of weld zone reactions in dissimilar glass-to-aluminium pulsed picosecond laser welds. Mater. Charact. 2016, 120, 53–62. [Google Scholar] [CrossRef]

- Carter, R.M.; Chen, J. Picosecond laser welding of similar and dissimilar materials. Appl. Opt. 2014, 53, 4233–4238. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.K.; Hong, S.Z. Characterization of local laser bonding quartz to anodic aluminum oxide in light emission device. Opt. Quantum Electron. 2017, 49. [Google Scholar] [CrossRef]

- Caccia, M.; Rodriguez, A. Diamond Surface Modification to Enhance Interfacial Thermal Conductivity in Al/Diamond Composites. JOM 2014, 66. [Google Scholar] [CrossRef]

- Molina, J.-M.; Rodríguez-Guerrero, A.; Louis, E.; Rodríguez-Reinoso, F.; Narciso, J. Porosity Effect on Thermal Properties of Al-12 wt % Si/Graphite Composites. Materials 2017, 10, 177. [Google Scholar] [CrossRef] [PubMed]

- Chern, T.-S.; Tsai, H.-L. Wetting and sealing of interface between 7056 Glass and Kovar alloy. Mater. Chem. Phys. 2007, 104, 472–478. [Google Scholar] [CrossRef]

- Zhang, M.; Yao, Y.L. Effects of Laser Radiation on the Wetting and Diffusion Characteristics of Kovar Alloy on Borosilicate Glass. J. Manuf. Sci. Eng. 2018, 140. [Google Scholar] [CrossRef]

- Li, P.; Li, J. Experimental Study on the Laser Transmission Joining of Polystyrene and Titanium. Materials 2018, 11, 1513. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Li, P. Laser transmission joint between PET and titanium for biomedical application. J. Mater. Process. Technol. 2010, 210, 1767–1771. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Schrader, M.E.; Loeb, G.I. Modern Approaches to Wettability: Theory and Applications; Springer: New York, NY, USA, 1992. [Google Scholar]

- Baldan, A. Adhesively-bonded joints and repairs in metallic alloys, polymers and composite materials: Adhesives, adhesion theories and surface pretreatment. J. Mater. Sci. 2004, 39, 1–49. [Google Scholar] [CrossRef]

- Liu, F.C.; Liao, J. Joining of metal to plastic using friction lap welding. Mater. Des. 2014, 54, 236–244. [Google Scholar] [CrossRef]

- Ochoa-Putman, C.; Vaidya, U.K. Mechanisms of interfacial adhesion in metal-polymer composites—Effect of chemical treatment. Compos. Part A Appl. Sci. Manuf. 2011, 42, 906–915. [Google Scholar] [CrossRef]

- Liu, H.; Chen, G. Performance and mechanism of laser transmission joining between glass fiber-reinforced PA66 and PC. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

| Property | Titanium Alloy | High Borosilicate Glass |

|---|---|---|

| Density (g/cm3) | 4.5 | 2.23 |

| Specific heat J/(kg K) | 520 | 98 |

| Thermal conductivity (W/mK) | 7.95 | 1.2 |

| Melting temperature, Tm (°C) | 1660 | 1680 |

| Ultimate tensile stress (MPa) | 895 | 40–100 |

| Chemical Composition | Mass Percentag |

|---|---|

| Ti | Bal |

| Fe | ≤ 0.3% |

| C | ≤ 0.1% |

| N | ≤ 0.05% |

| O | ≤ 0.015% |

| H | ≤ 0.2% |

| V | 5.5~6.8% |

| Al | 3.5~4.5% |

| Chemical Composition | Mass Percentag |

|---|---|

| SiO2 | 80.4% |

| B2O3 | 12.7% |

| Al2O3 | 2.4% |

| Na2O & K2O | 4.2% |

| Others | 0.3% |

| Parameter | Limits | ||

|---|---|---|---|

| Laser power for surface treatment (W) | 40 | 50 | 60 |

| Laser scanning speed (mm/s) | 5 | 5 | 5 |

| Number of scans (n) | 8 | 8 | 8 |

| Spot diameter (mm) | 2 | 2 | 2 |

| Parameter | Limits | |||

|---|---|---|---|---|

| Laser voltage for transmission welding (W) | 450 | 460 | 470 | 480 |

| Laser welding speed (mm/s) | 3 | 3 | 3 | 3 |

| Laser frequency (Hz) | 10 | 10 | 10 | 10 |

| Laser pulse width (ms) | 2.5 | 2.5 | 2.5 | 2.5 |

| Stand-off distance (mm) | 0 | 0 | 0 | 0 |

| Material Type | γ (mN/m) | γD (mN/m) | γP (mN/m) |

|---|---|---|---|

| Titanium alloy | 19.31 | 16.45 | 2.86 |

| Laser-treated | 23.60 | 22.01 | 1.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Xu, X.; Tan, W.; Liu, H.; Wang, X. Improvement of Laser Transmission Welding of Glass with Titanium Alloy by Laser Surface Treatment. Materials 2018, 11, 2060. https://doi.org/10.3390/ma11102060

Li P, Xu X, Tan W, Liu H, Wang X. Improvement of Laser Transmission Welding of Glass with Titanium Alloy by Laser Surface Treatment. Materials. 2018; 11(10):2060. https://doi.org/10.3390/ma11102060

Chicago/Turabian StyleLi, Pin, Xingwen Xu, Wensheng Tan, Huixia Liu, and Xiao Wang. 2018. "Improvement of Laser Transmission Welding of Glass with Titanium Alloy by Laser Surface Treatment" Materials 11, no. 10: 2060. https://doi.org/10.3390/ma11102060

APA StyleLi, P., Xu, X., Tan, W., Liu, H., & Wang, X. (2018). Improvement of Laser Transmission Welding of Glass with Titanium Alloy by Laser Surface Treatment. Materials, 11(10), 2060. https://doi.org/10.3390/ma11102060