The Determining Role of Nb Interlayer on Interfacial Microstructure and Mechanical Properties of Ti/Steel Clad Plate by Vacuum Rolling Cladding

Abstract

:1. Introduction

2. Experimental

2.1. Preparation of Raw Materials

2.2. Vacuum Electron Beam Welding Process

2.3. Hot Roll Bonding

2.4. Evaluation of Interfacial Structure and Mechanical Properties

3. Results and Discussion

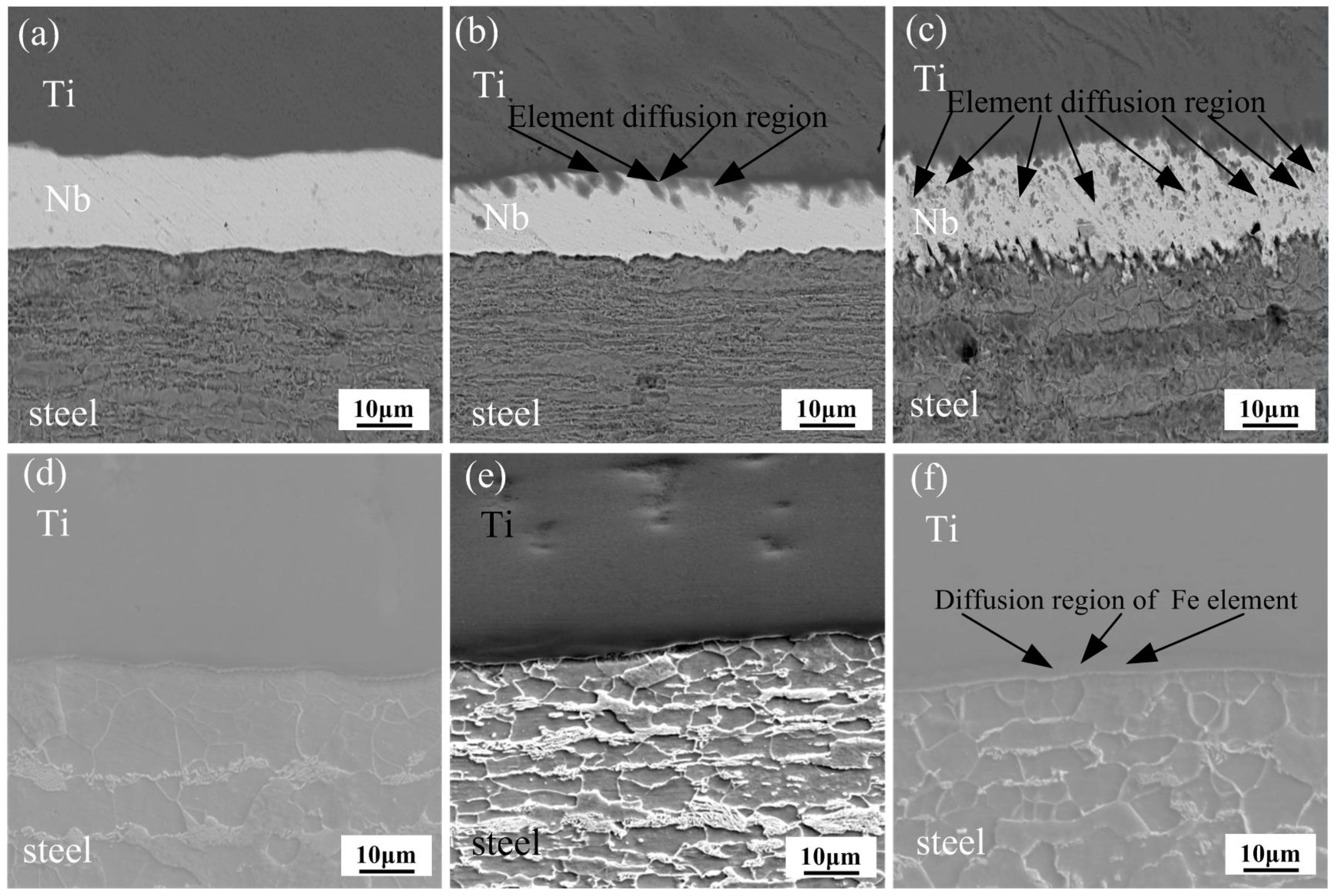

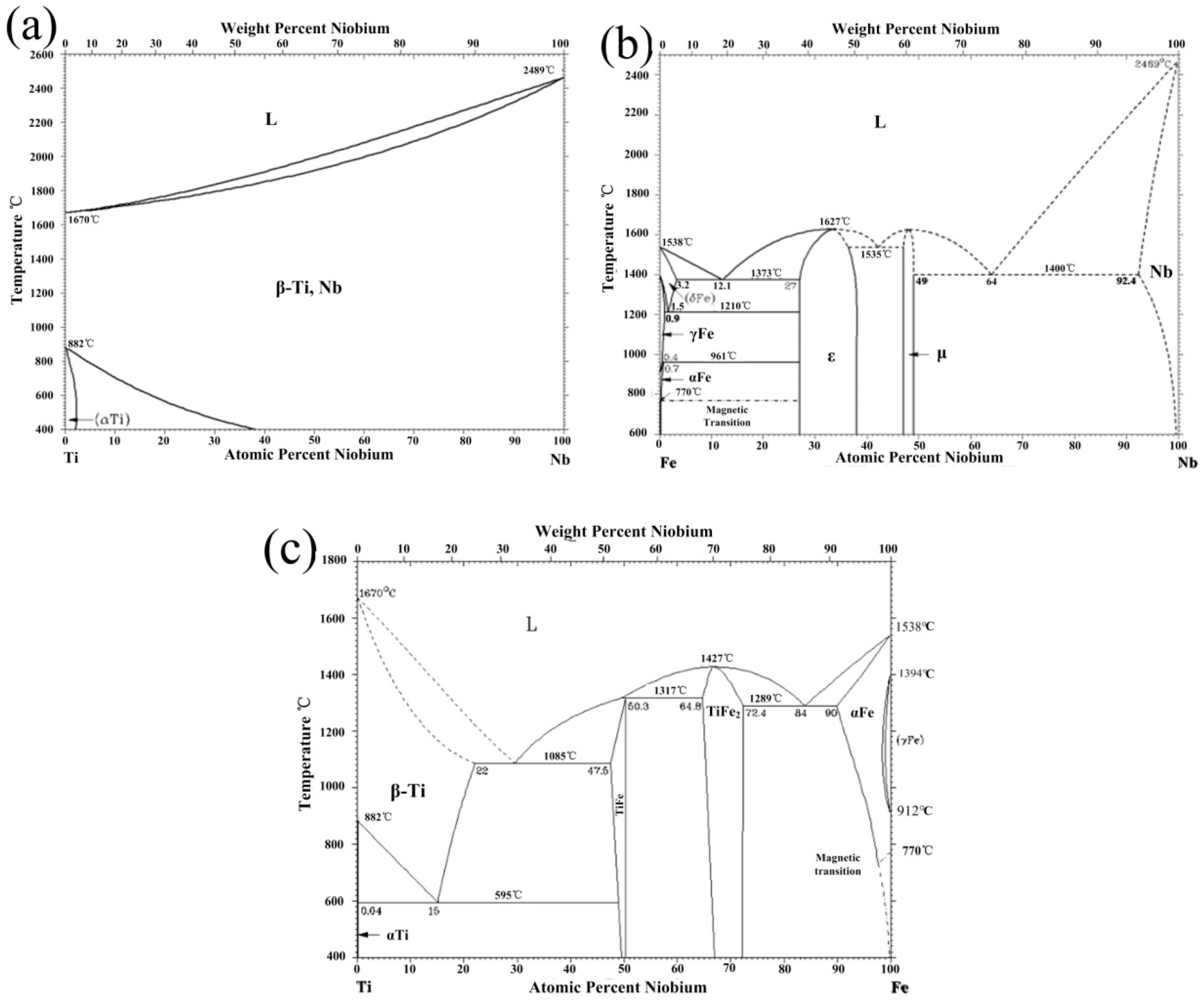

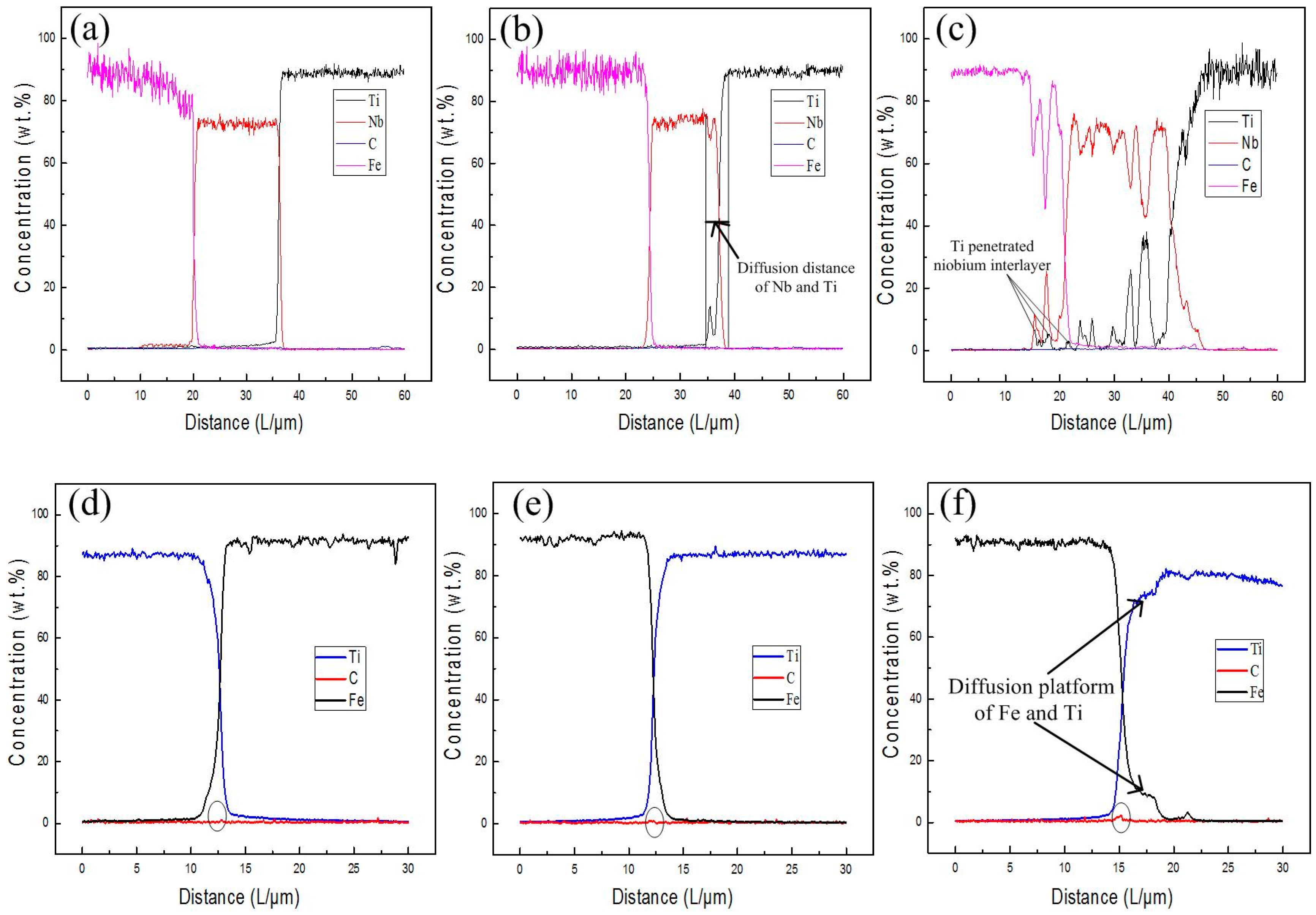

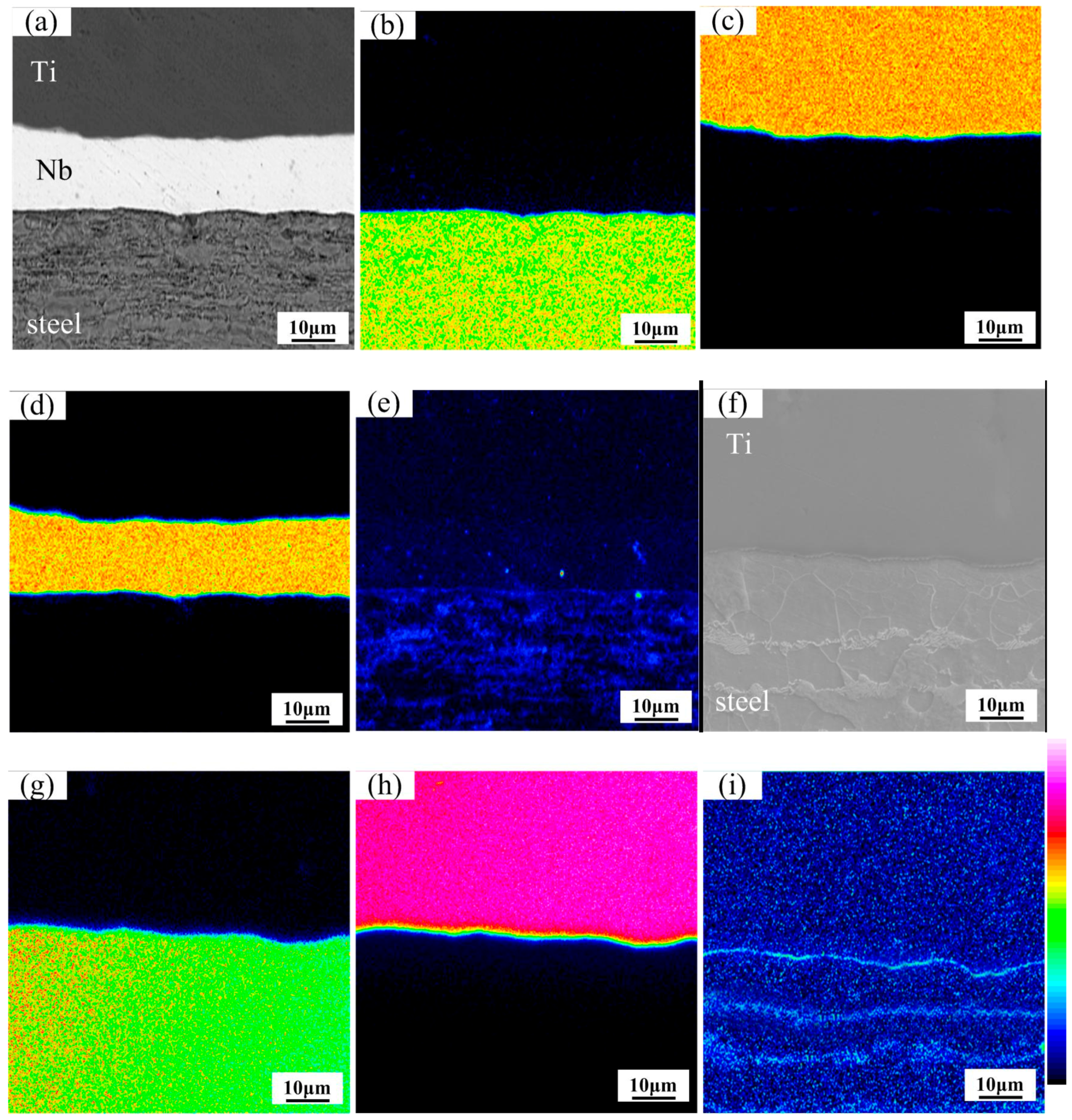

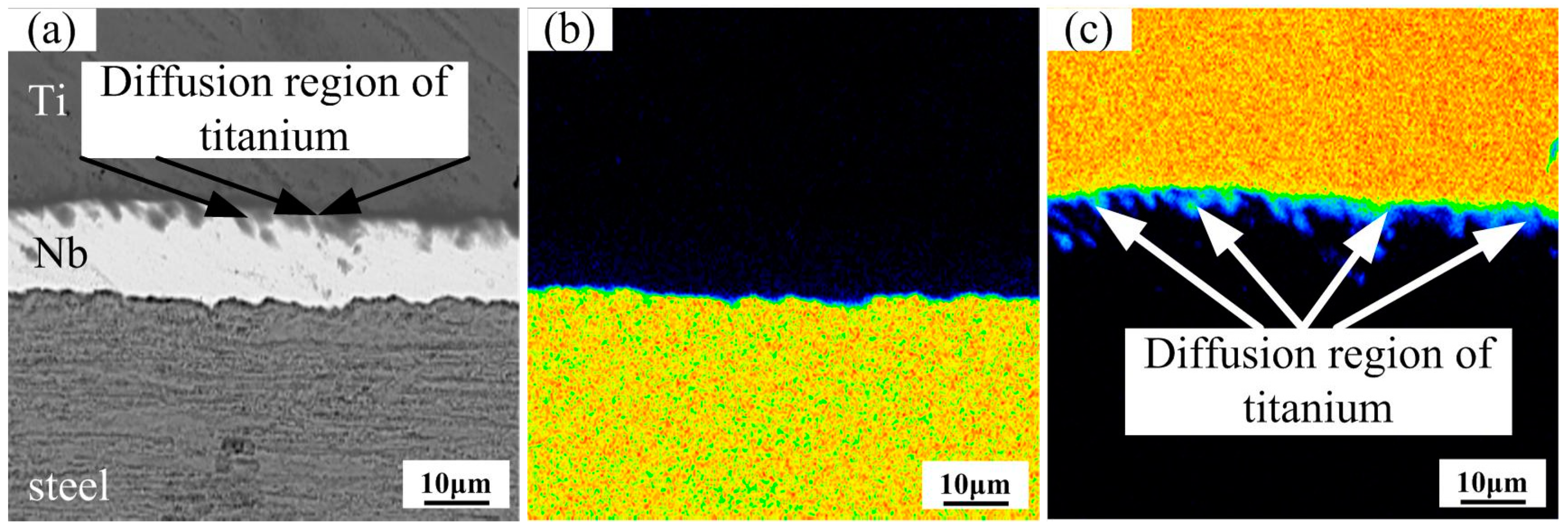

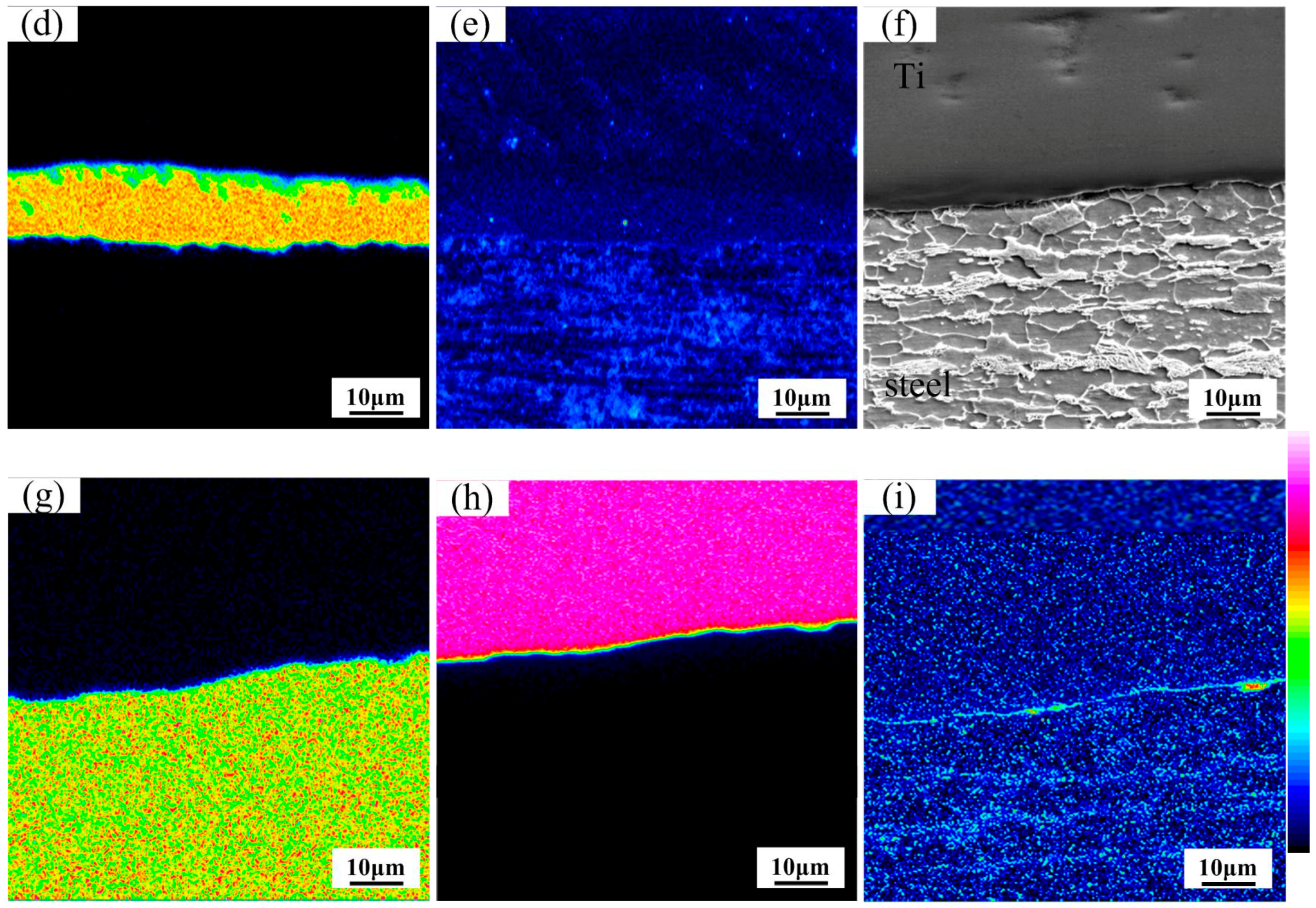

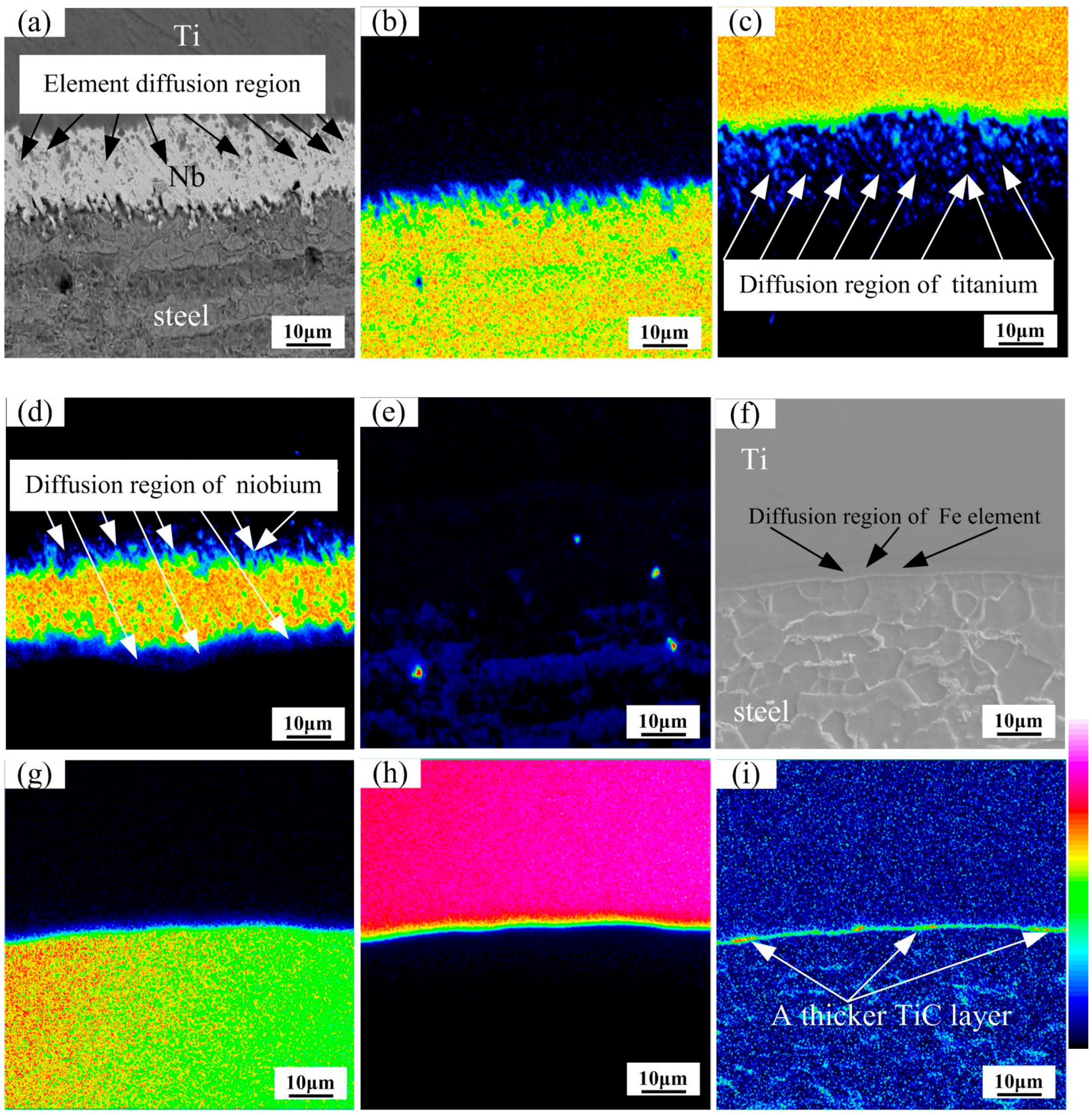

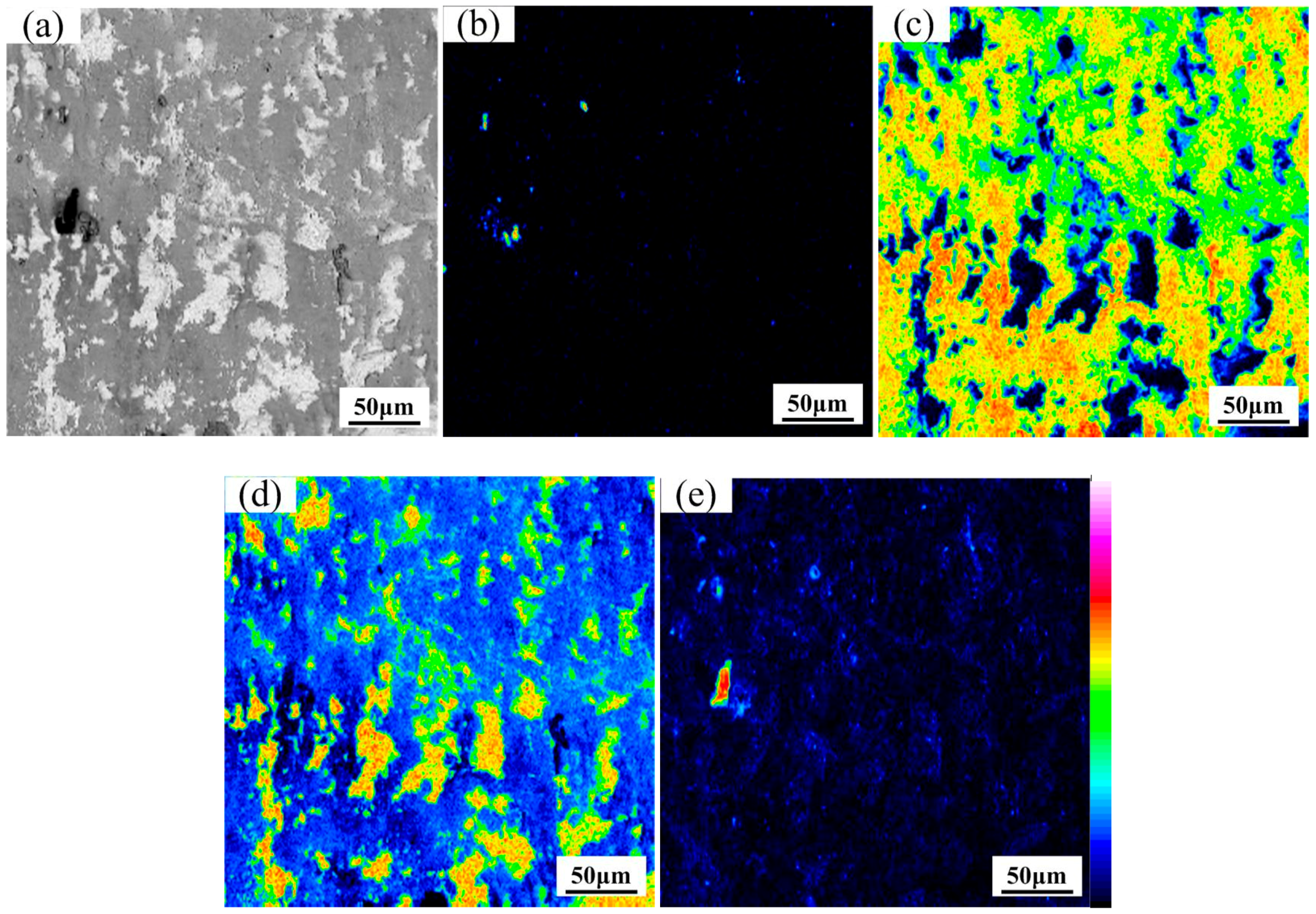

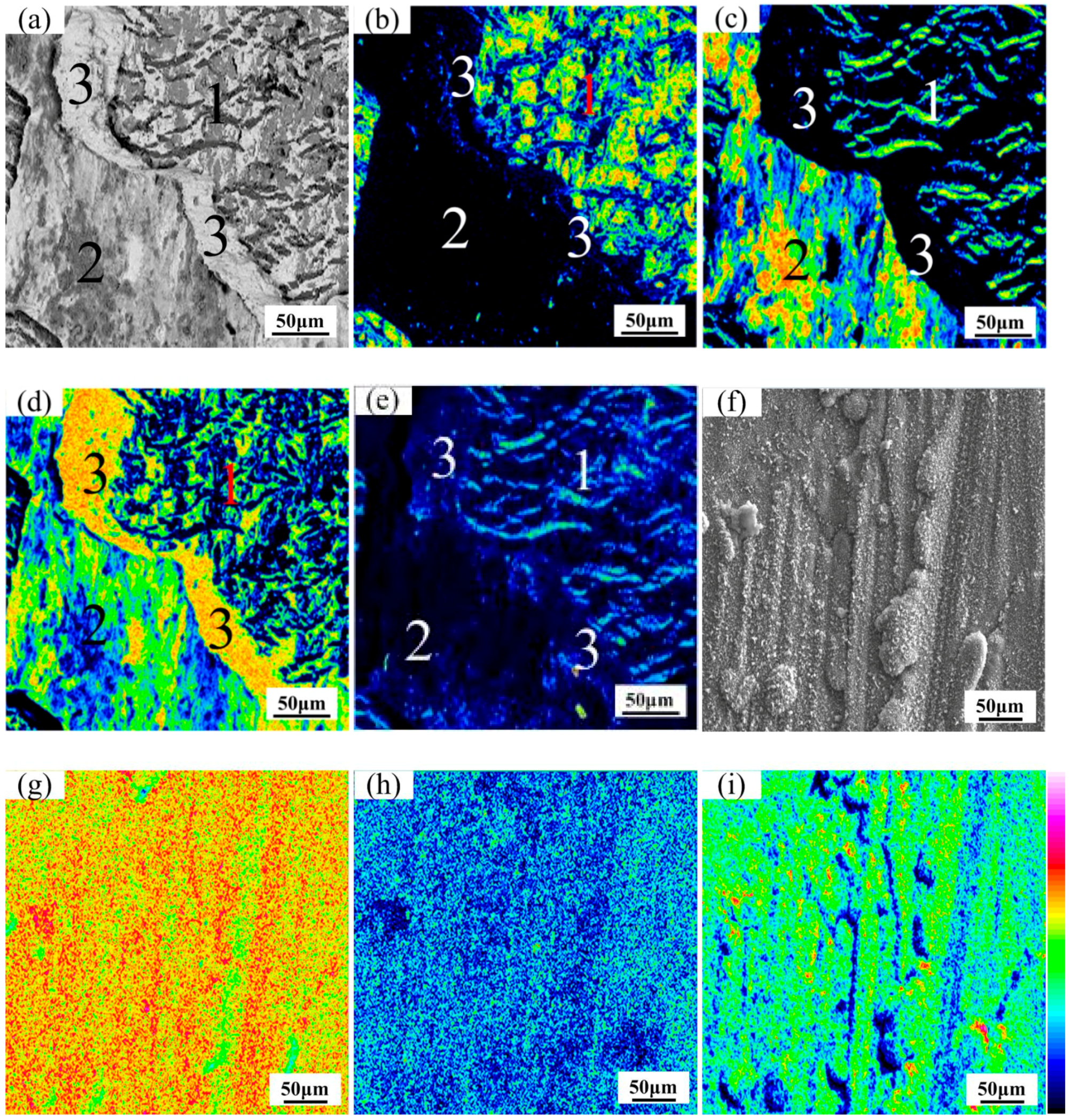

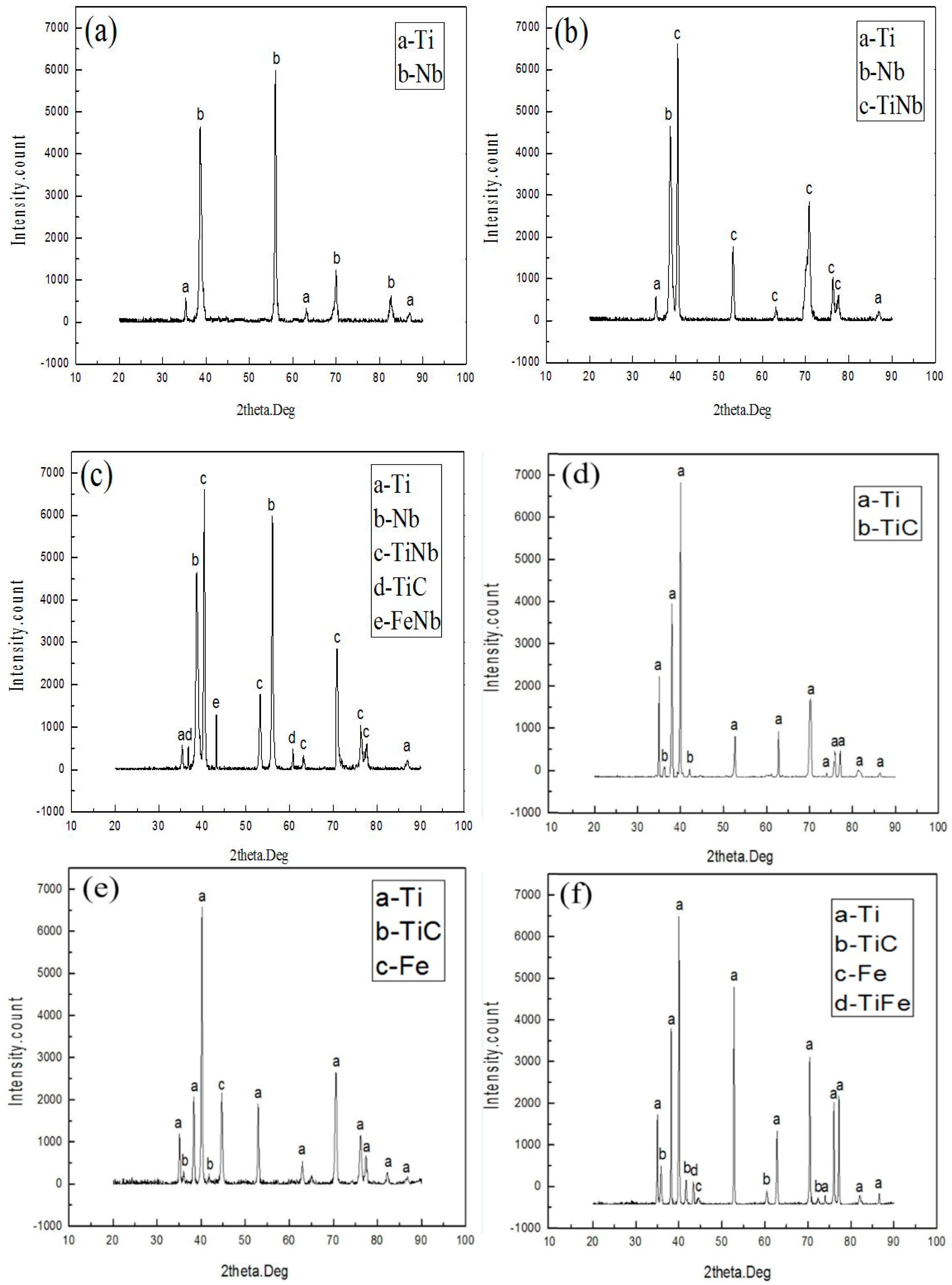

3.1. Microstructural Characterization of Bonded Interfaces

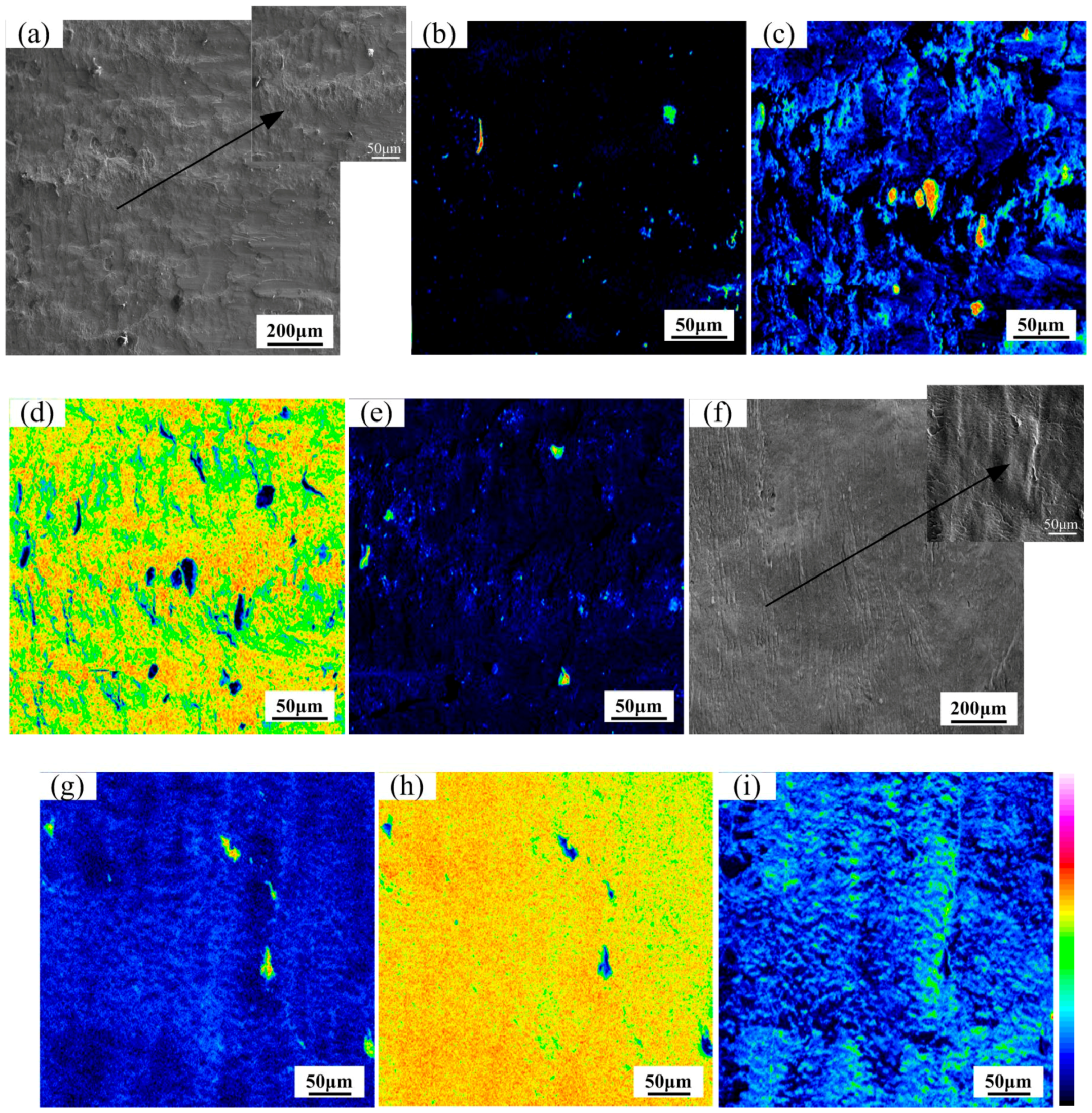

3.2. Fractural Surface of the Bonded Interface

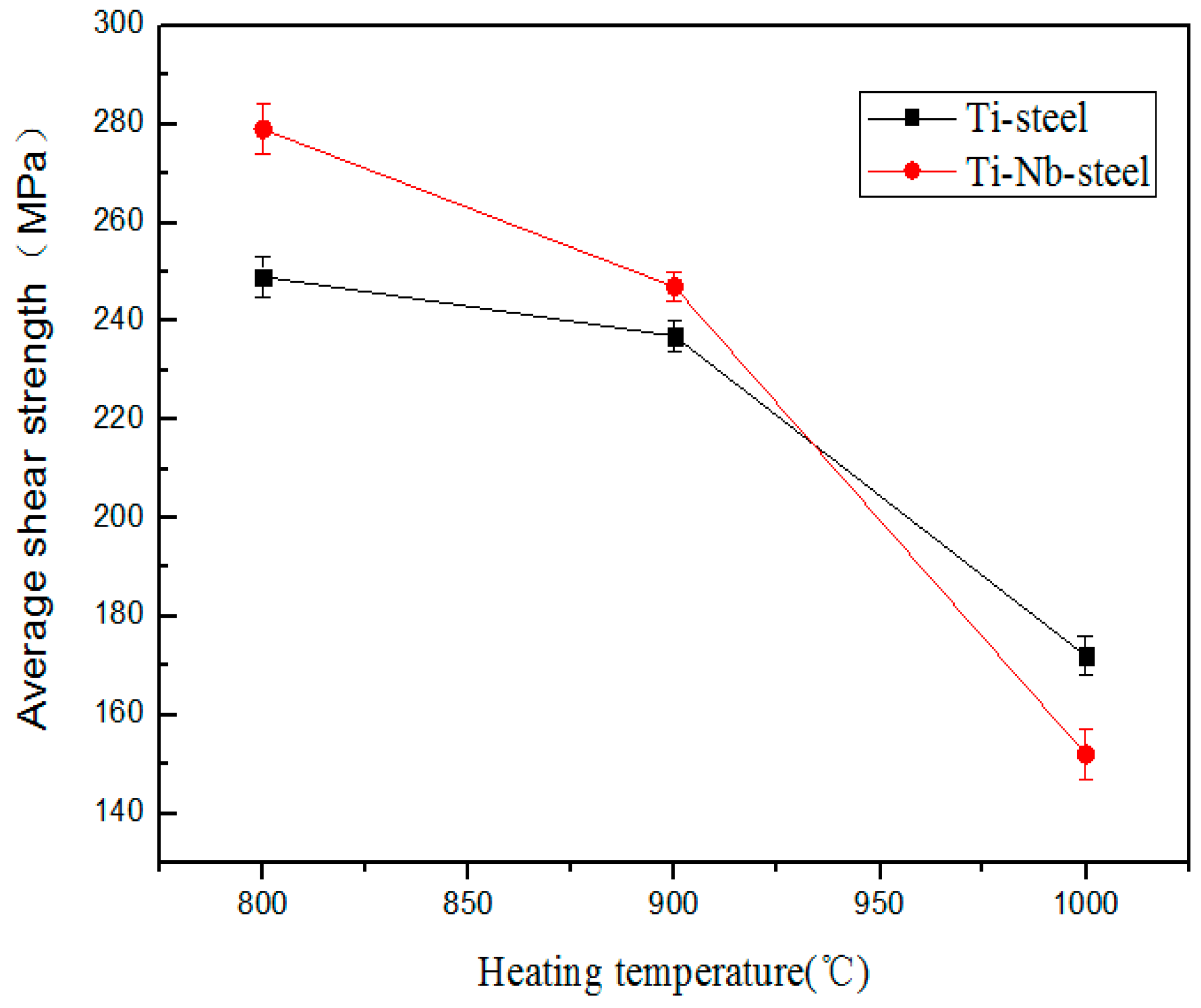

3.3. Shear Property of the Clad Interface

4. Conclusions

- The inter-diffusion between Ti, C and Fe was effectively restrained by the Nb interlayer at heating temperature of 800 °C, and the Nb-Ti solid solution, TiC and Nb-Fe intermetallic compounds were not detected on the fractural surface. An average shear strength of 279 MPa was achieved.

- At heating temperature of 900 °C, the inter-diffusion of Ti, C and Fe was remarkably restrained by the Nb interlayer, whereas Nb-Ti solid solution was formed at the Ti/Nb interface, which reduced the shear properties in the clad plate.

- At heating temperature of 1000 °C, TiC and Nb-Fe compounds were formed at the Nb/steel interface, and the Nb-Ti solid solution was formed at the Ti/Nb interface. The mechanical properties of clad plates were seriously affected by those compounds. Minimum average shear strength of 152 MPa was gained.

- The average shear strength of 249 and 172 MPa was obtained at Ti/steel interface at 800 and 1000 °C, respectively. The shear strength of the Ti/steel interface was higher than that of the Ti/Nb/steel interface at 1000 °C. Shear strength of Ti/steel clad plate can be modified by using VRC with Nb interlayer at 800 and 900 °C.

Author Contributions

Funding

Acknowledgment

Conflict of interest

References

- Jiang, H.T.; Yan, X.Q.; Liu, J.X.; Duan, X.G.; Zeng, S.W. Influence of asymmetric rolling parameters on the microstructure and mechanical properties of titanium explosive clad plate. Rare. Metal. Mat. Eng. 2014, 43, 2631–2636. [Google Scholar]

- Ramirez, J.E. Characterization of CSC-GMAW titanium-rich weld overlays. Welding J. 2014, 93, 338–350. [Google Scholar]

- Xiao, H.; Qi, Z.; Yu, C.; Xu, C. Preparation and properties for Ti-Al clad plates generated by differential temperature rolling. J. Mater. Process. Tech. 2017, 249, 285–290. [Google Scholar] [CrossRef]

- Zhu, Z.; He, Y.; Zhang, X.; Liu, H.; Li, X. Effect of interface oxides on shear properties of hot-rolled stainless steel clad plate. Mater. Sci. Eng. A 2016, 669, 344–349. [Google Scholar] [CrossRef]

- Ha, J.S.; Hong, S.I. Deformation and fracture of Ti-439 stainless steel clad composite at intermediate temperatures. Mater. Sci. Eng. A 2016, 651, 805–809. [Google Scholar] [CrossRef]

- Yun, J.G.; Yan, Y.; Long, F.W.; Li, X.W. characterizations of temperature-dependent tensile deformation and fracture features of commercially pure titanium. Mater. Trans. 2013, 54, 1709–1714. [Google Scholar] [CrossRef]

- Su, H.; Luo, X.; Chai, F.; Shen, J.; Sun, X.; Lu, F. Manufacturing technology and application trends of titanium clad steel plates. J. Iron. Steel. Res. Int. 2015, 22, 977–982. [Google Scholar] [CrossRef]

- Orhan, N.; Khan, T.I.; Eroğlu, M. Diffusion bonding of a microduplex stainless steel to Ti-6Al-4V. Scripta Mater. 2001, 45, 441–446. [Google Scholar] [CrossRef]

- Zhao, D.S.; Yan, J.C.; Wang, Y.; Yang, S.Q. Relative slipping of interface of titanium alloy to stainless steel during vacuum hot roll bonding. Mater. Sci. Eng. A 2009, 499, 282–286. [Google Scholar] [CrossRef]

- Prasanthi, T.N.; Sudha, R.C.; Saroja, S. Explosive cladding and post-weld heat treatment of mild steel and titanium. Mater. Design 2016, 93, 180–193. [Google Scholar] [CrossRef]

- Mousavi, S.A.A.; Sartangi, P.F. Effect of post-weld heat treatment on the interface microstructure of explosively welded titanium-stainless steel composite. Mater. Sci. Eng. A 2008, 494, 329–336. [Google Scholar] [CrossRef]

- Gloc, M.; Wachowski, M.; Plocinski, T.; Kurzydlowski, K.J. Microstructural and microanalysis investigations of bond titanium grade1/low alloy steel st52-3N obtained by explosive welding. J. Alloy. Compd. 2016, 671, 446–451. [Google Scholar] [CrossRef]

- Bae, D.S.; Chae, Y.R.; Lee, S.P.; Lee, J.K.; Park, S.S.; Lee, Y.S.; Lee, S.M. Effect of post heat treatment on bonding interfaces in Ti-mild steel-Ti clad materials. Procedia Eng. 2011, 10, 996–1001. [Google Scholar] [CrossRef]

- Ghosh, M.; Bhanumurthy, K.; Kale, G.B.; Krishnan, J.; Chatterjee, S. Diffusion bonding of titanium to 304 stainless steel. J. Nucl. Mater. 2003, 322, 235–241. [Google Scholar] [CrossRef]

- Xie, G.; Luo, Z.; Wang, G.; Li, L.; Wang, G. Interface characteristic and properties of stainless steel-HSLA steel clad plate by vacuum rolling cladding. Mater. Trans. 2011, 52, 1709–1712. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, G.; Xie, G.; Wang, L.; Zhao, K. Interfacial microstructure and properties of a vacuum hot roll-bonded titanium-stainless steel clad plate with a niobium interlayer. Acta Metall. Sin. 2013, 26, 754–760. [Google Scholar] [CrossRef]

- Wang, G.L.; Luo, Z.A.; Xie, G.M.; Zhao, K. Experiment research on impact of total rolling reduction ratio on the properties of vacuum rolling-bonding ultra-thick steel plate. Adv. Mater. Res. 2011, 299–300, 962–965. [Google Scholar] [CrossRef]

- Yang, D.H.; Luo, Z.A.; Xie, G.M.; Misra, R.D.K. Effect of vacuum level on microstructure and mechanical properties of titanium-steel vacuum roll clad plates. J. Iron. Steel Res. Int. 2018, 25, 72–80. [Google Scholar] [CrossRef]

- Kundu, S.; Chatterjee, S. Evolution of Interface Microstructure and mechanical properties of titanium-304 stainless steel diffusion bonded joint using Nb interlayer. ISIJ Int. 2010, 50, 1460–1465. [Google Scholar] [CrossRef]

- Eroglu, M.; Khan, T.I.; Orhan, N. Diffusion bonding between Ti-6Al-4V alloy and microduplex stainless steel with copper interlayer. Mater. Sci. Technol. 2002, 18, 68–72. [Google Scholar] [CrossRef]

- Kundu, S.; Chatterjee, S. Effects of temperature on interface microstructure and strength properties of titanium-niobium stainless steel diffusion bonded. Mater. Sci. Technol. 2013, 27, 1177–1182. [Google Scholar] [CrossRef]

- Yu, C.; Xiao, H.; Yu, H.; Qi, Z.C.; Xu, C. Mechanical properties and interfacial structure of hot-roll bonding TA2-Q235B plate using DT4 interlayer. Mater. Sci. Eng. A 2017, 695, 120–125. [Google Scholar] [CrossRef]

- ASTM B898-11. Standard Specification for Reactive and Refractory Metal Clad Plate; ASTM International: West Conshohocken, PA, USA, 1 September 2011. [Google Scholar]

- Jiang, H.; Yan, X.; Liu, J.; Duan, X. Effect of heat treatment on microstructure and mechanical property of Ti-steel explosive-rolling clad plate. T. Nonferr. Metal. Soc. 2014, 24, 697–704. [Google Scholar] [CrossRef]

- Nishio, K.; Kato, M.; Yamaguchi, T.; Tokunaga, T.; Matsumoto, A. Lap welding of titanium and mild steel sheets by seam welding. Welding Int. 2004, 18, 771–776. [Google Scholar] [CrossRef]

- Elrefaey, A.; Tillmann, W. Interface characteristics and mechanical properties of the vacuum-brazed joint of titanium-steel having a silver-based brazing alloy. Metall. Mater. Trans. A 2007, 38, 2956–2962. [Google Scholar] [CrossRef]

- Kundu, S.; Ghosh, M.; Laik, A.; Bhanumurthy, K.; Kale, G.B.; Chatterjee, S. Diffusion bonding of commercially pure titanium to 304 stainless steel using copper interlayer. Mater. Sci. Eng. A 2005, 407, 154–160. [Google Scholar] [CrossRef]

- Momono, T.; Enjo, T.; Ikeuchi, K. Effects of carbon content on the diffusion bonding of iron and steel to titanium. ISIJ Int. 1990, 30, 978–984. [Google Scholar] [CrossRef]

- Xia, C.Q.; Jin, Z.P. On the evolution of microstructure and diffusion paths in the titanium-steel explosion weld interface during heat treatment. J. Less Common Met. 1990, 158, 315–322. [Google Scholar] [CrossRef]

- Laik, A.; Shirzadi, A.A.; Sharma, G.; Tewari, R.; Jayakumar, T.; Dey, G.K. Microstructure and interfacial reactions during vacuum brazing of stainless steel to titanium using Ag-28pct Cu alloy. Metall. Mater. Trans. A 2015, 46, 771–782. [Google Scholar] [CrossRef]

| Material | Ti | C | N | H | O | Fe | Mn | P | S | Si | Al | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TA2 | Bal | 0.01 | 0.02 | 0.002 | 0.14 | 0.07 | - | - | - | - | - | - |

| steel | - | 0.2 | - | - | - | Bal | 1.2 | 0.025 | 0.015 | 0.55 | 0.02 | 0.05 |

| Pass | Pre-Rolling Thickness (mm) | Post-Rolling Thickness (mm) | Reduction (mm) | Reduction Ratio (%) | Temperature (°C) | Temperature (°C) | Temperature (°C) |

|---|---|---|---|---|---|---|---|

| 1 | 60 | 45 | 15 | 25.00 | 800 | 900 | 1000 |

| 2 | 45 | 32 | 13 | 28.89 | 792 | 891 | 992 |

| 3 | 32 | 23 | 9 | 28.13 | 783 | 884 | 985 |

| 4 | 23 | 18 | 5 | 21.74 | 774 | 873 | 971 |

| 5 | 18 | 14 | 4 | 22.22 | 767 | 868 | 964 |

| 6 | 14 | 11 | 3 | 21.43 | 758 | 855 | 950 |

| 7 | 11 | 9 | 2 | 18.18 | 750 | 848 | 941 |

| Heating Temperature | Shear Strength, MPa | Average Shear Strength, MPa | |||||

|---|---|---|---|---|---|---|---|

| 800 °C | 285 | 292 | 278 | 281 | 263 | 272 | 279 |

| 900 °C | 127 | 234 | 251 | 245 | 257 | 270 | 247 |

| 1000 °C | 151 | 174 | 147 | 145 | 168 | 125 | 152 |

| Heating Temperature | Shear Strength, MPa | Average Shear Strength, MPa | |||||

|---|---|---|---|---|---|---|---|

| 800 °C | 257 | 260 | 249 | 250 | 230 | 245 | 249 |

| 900 °C | 216 | 225 | 246 | 230 | 242 | 265 | 237 |

| 1000 °C | 169 | 196 | 169 | 163 | 191 | 142 | 172 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, G.-m.; Yang, D.-h.; Luo, Z.-a.; Li, M.; Wang, M.-k.; Misra, R.D.K. The Determining Role of Nb Interlayer on Interfacial Microstructure and Mechanical Properties of Ti/Steel Clad Plate by Vacuum Rolling Cladding. Materials 2018, 11, 1983. https://doi.org/10.3390/ma11101983

Xie G-m, Yang D-h, Luo Z-a, Li M, Wang M-k, Misra RDK. The Determining Role of Nb Interlayer on Interfacial Microstructure and Mechanical Properties of Ti/Steel Clad Plate by Vacuum Rolling Cladding. Materials. 2018; 11(10):1983. https://doi.org/10.3390/ma11101983

Chicago/Turabian StyleXie, Guang-ming, De-han Yang, Zong-an Luo, Ming Li, Ming-kun Wang, and R. D. K. Misra. 2018. "The Determining Role of Nb Interlayer on Interfacial Microstructure and Mechanical Properties of Ti/Steel Clad Plate by Vacuum Rolling Cladding" Materials 11, no. 10: 1983. https://doi.org/10.3390/ma11101983

APA StyleXie, G.-m., Yang, D.-h., Luo, Z.-a., Li, M., Wang, M.-k., & Misra, R. D. K. (2018). The Determining Role of Nb Interlayer on Interfacial Microstructure and Mechanical Properties of Ti/Steel Clad Plate by Vacuum Rolling Cladding. Materials, 11(10), 1983. https://doi.org/10.3390/ma11101983