Influence of Dielectric Barrier Discharge Treatment on Surface Structure of Polyoxymethylene Fiber and Interfacial Interaction with Cement

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

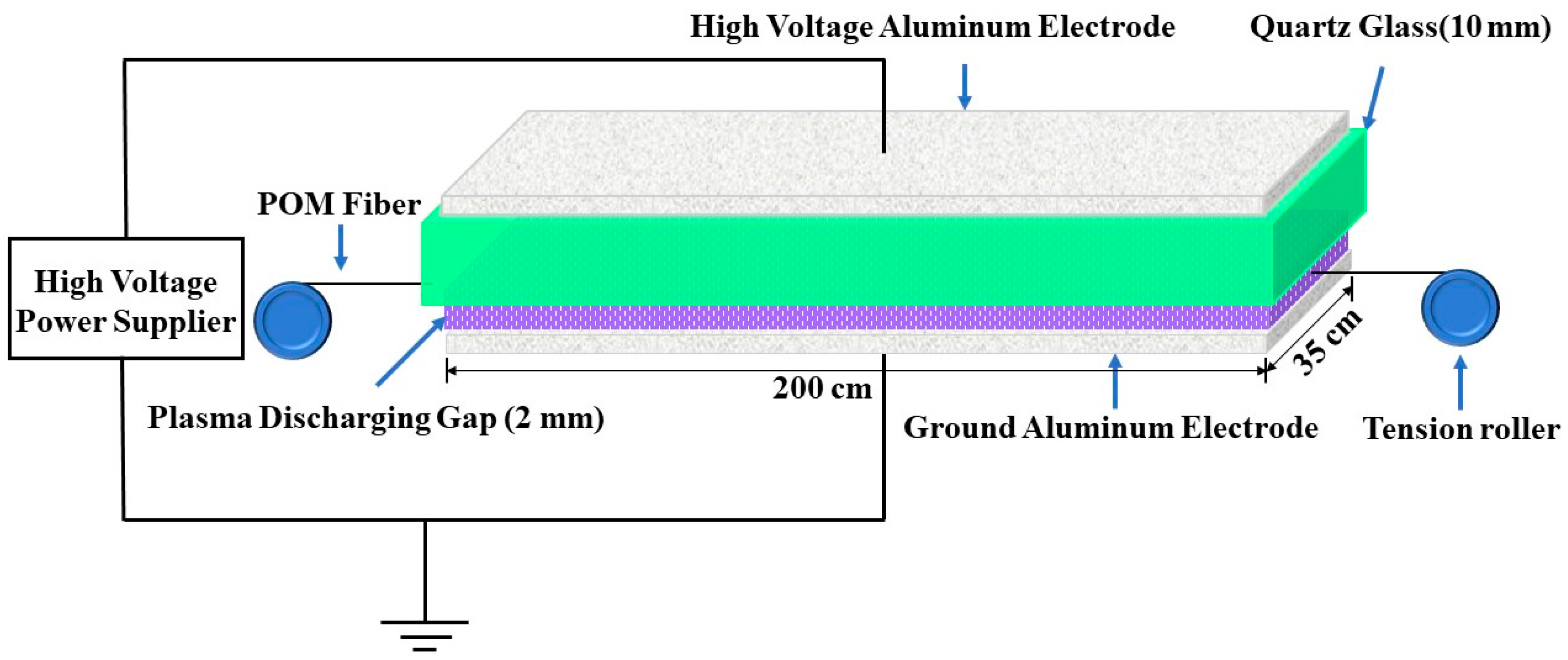

2.2. Plasma Treatment and Methods

3. Results and Discussion

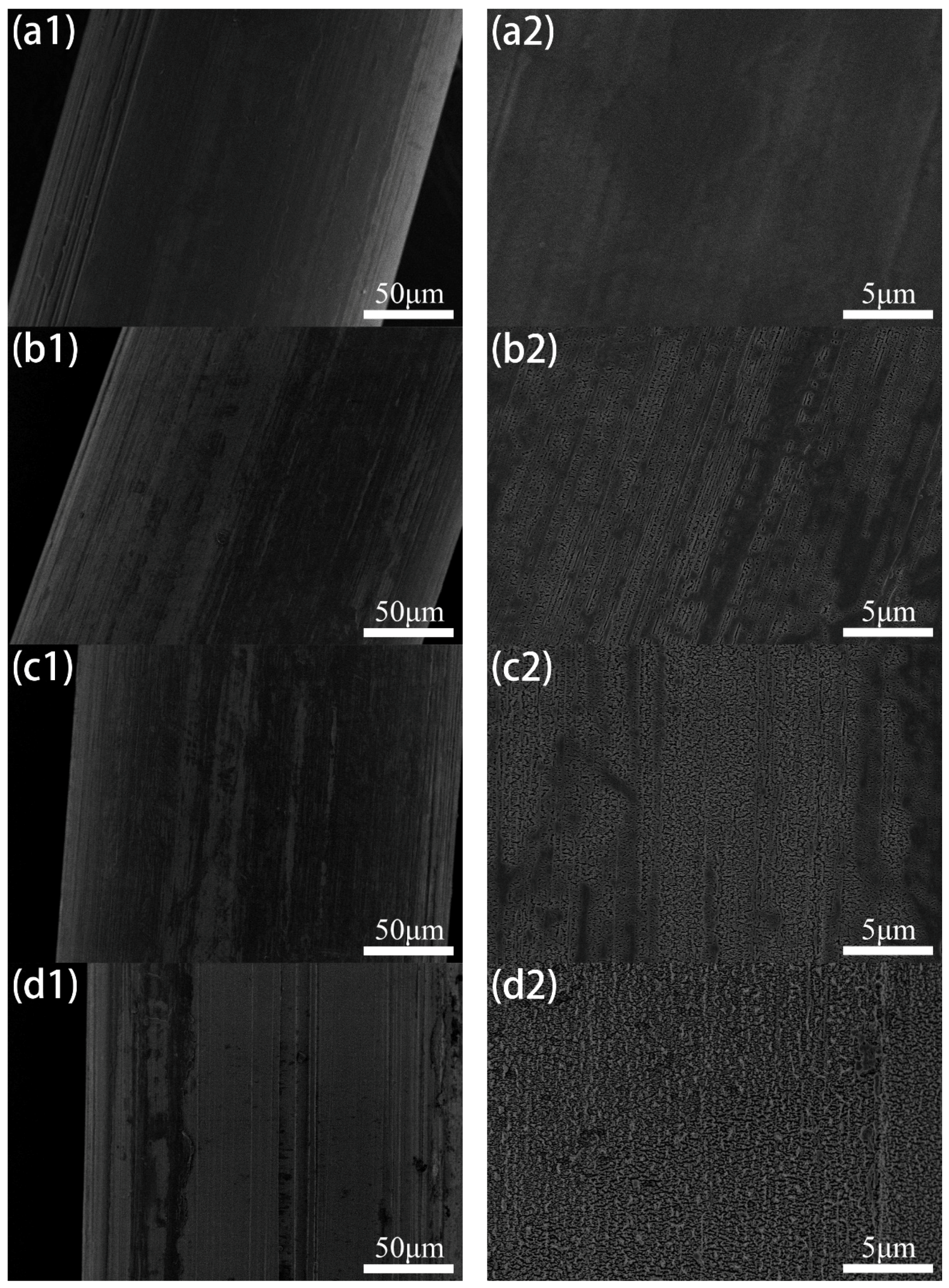

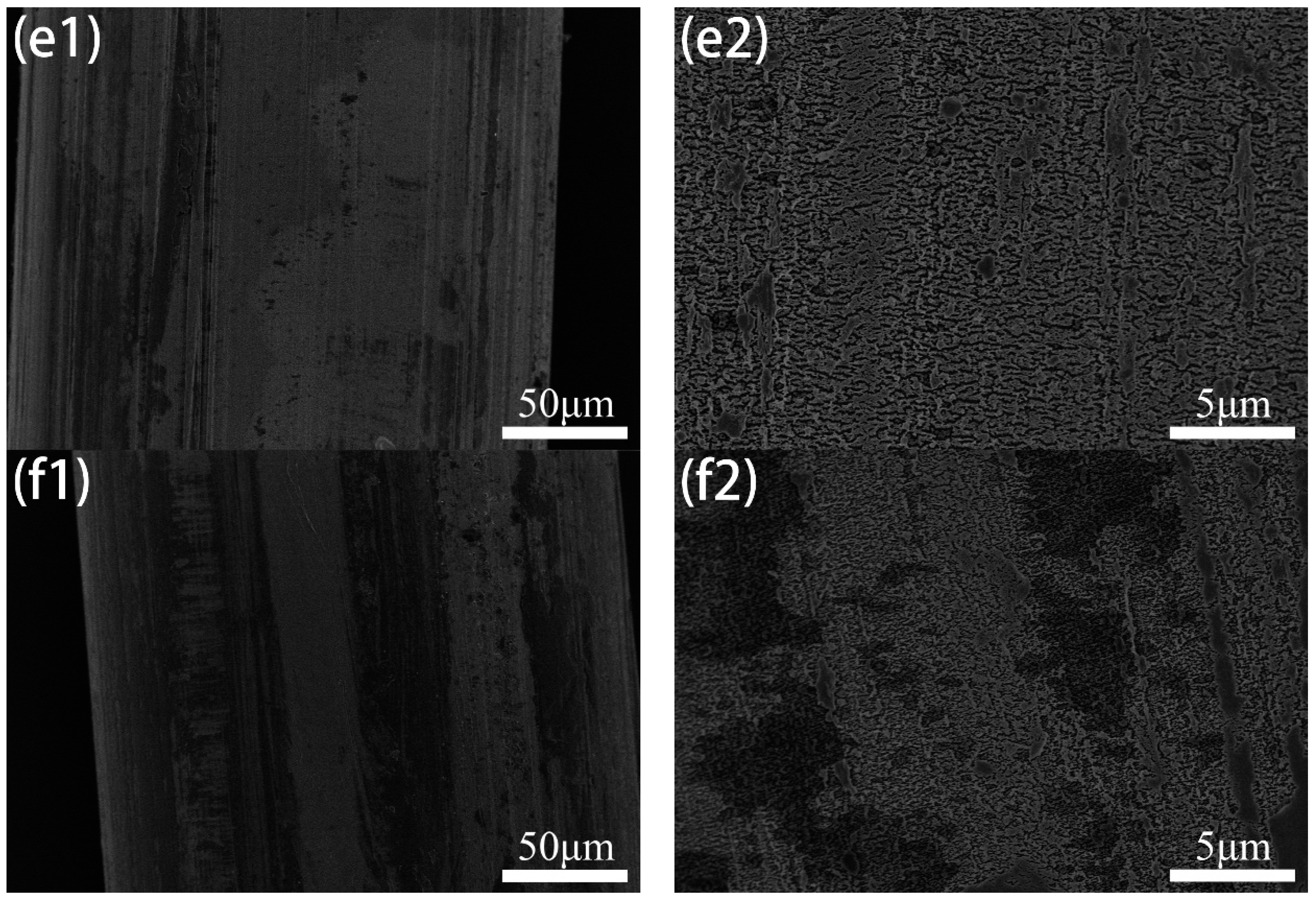

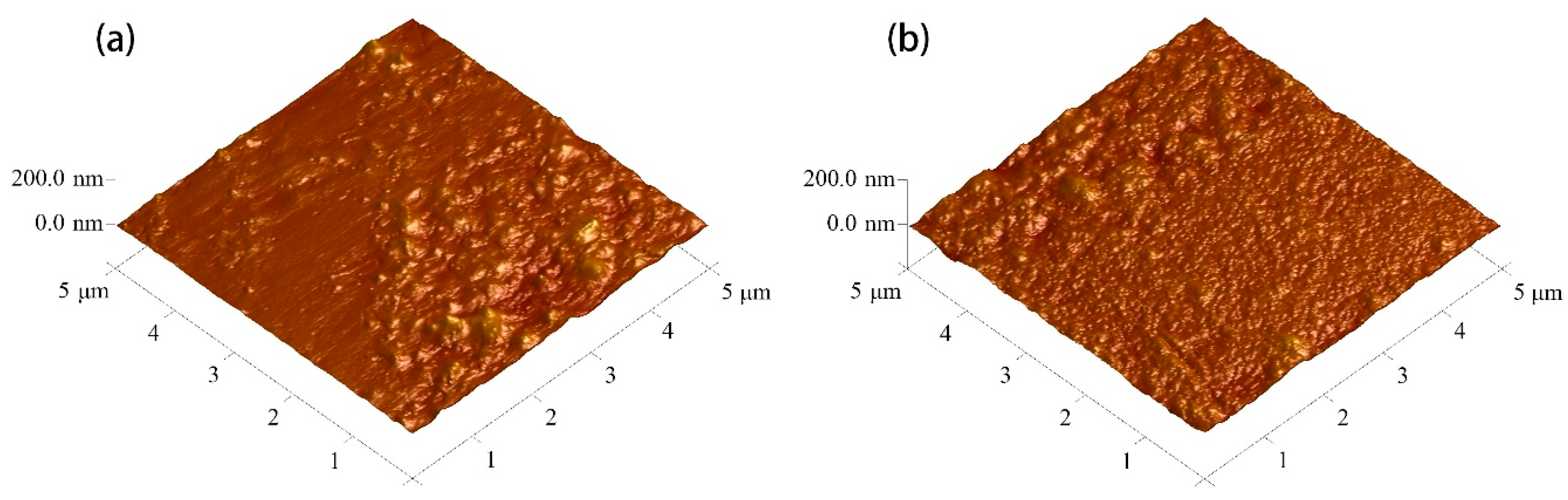

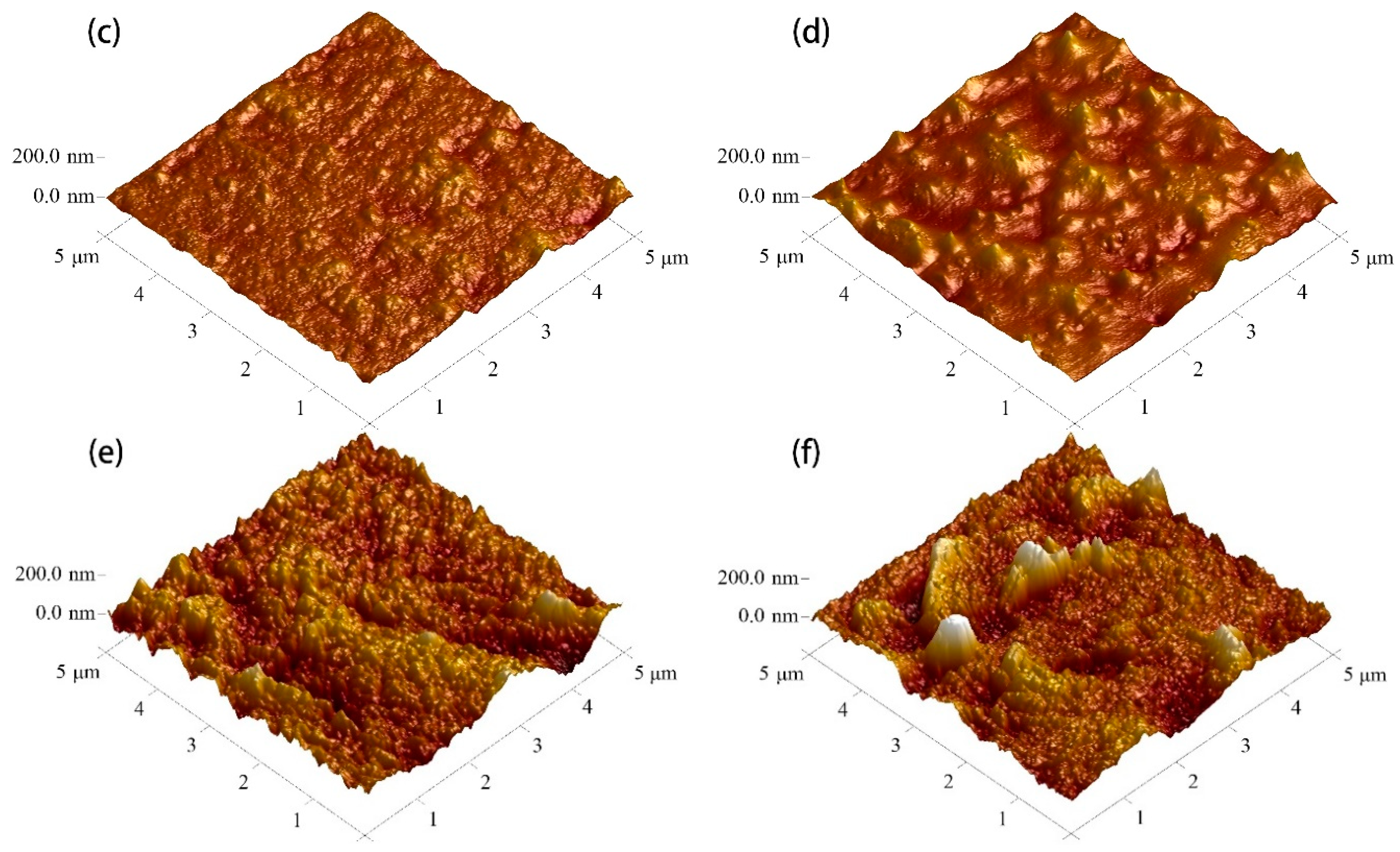

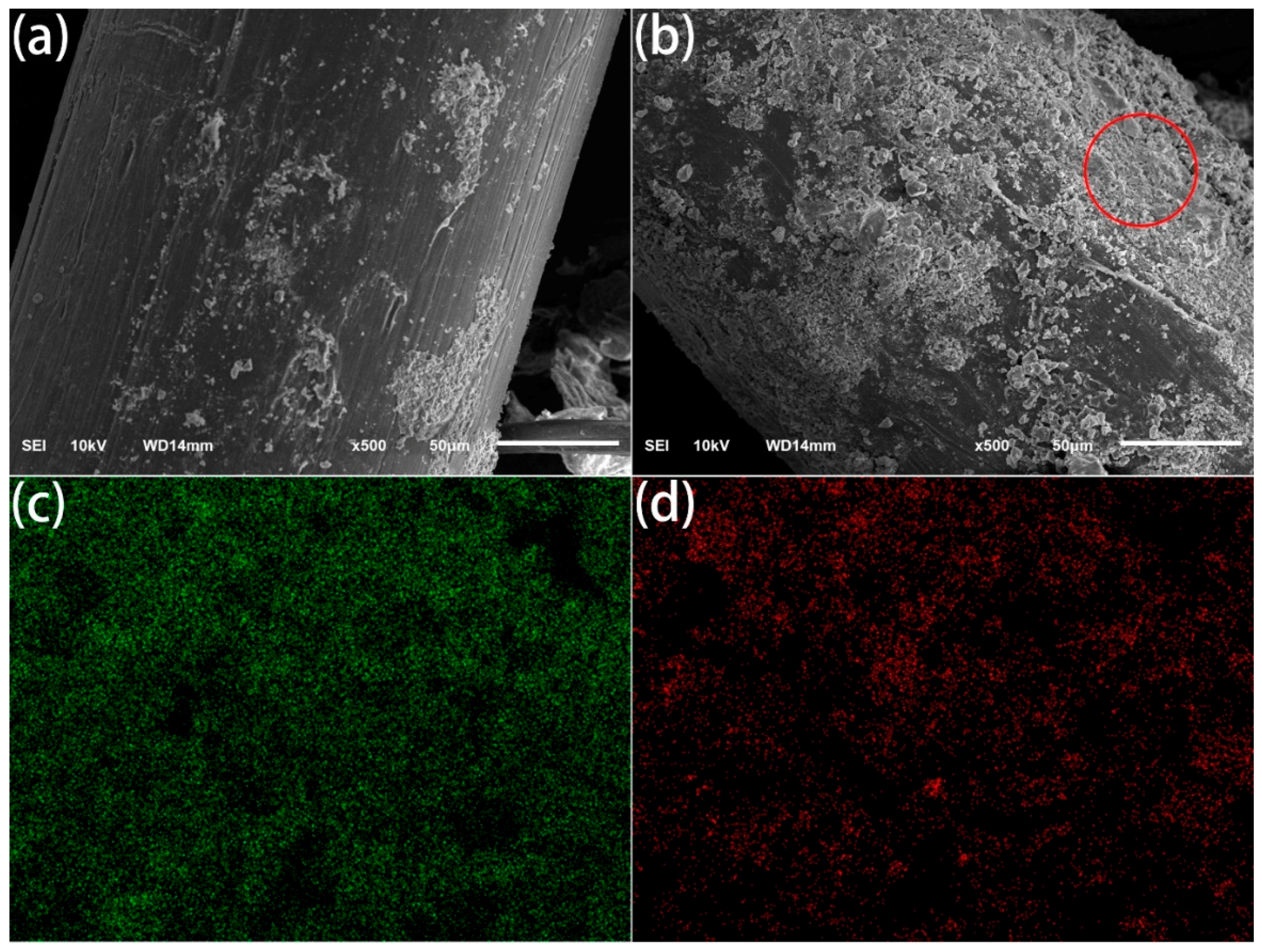

3.1. Surface Morphology Analysis

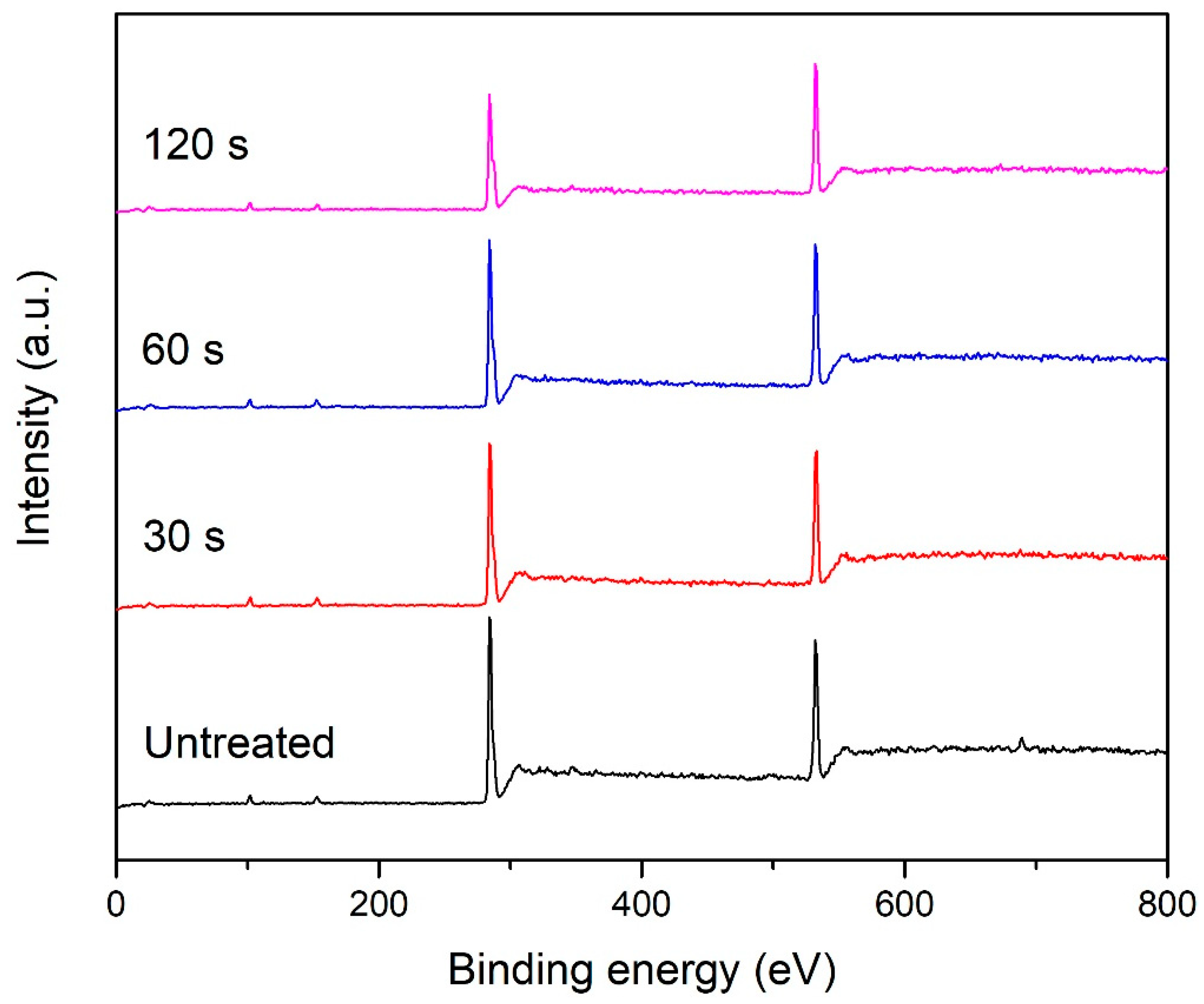

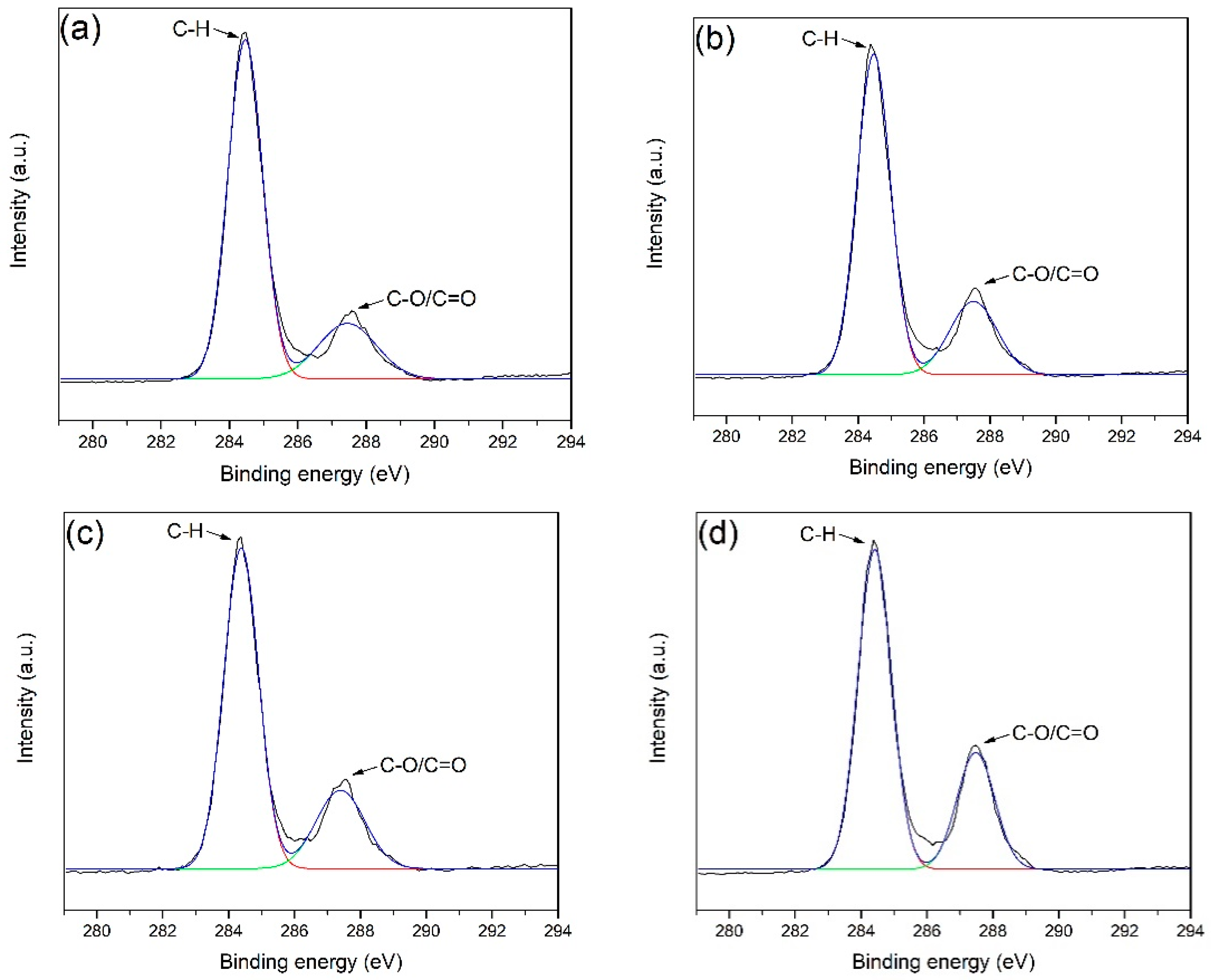

3.2. Chemical Analysis of Surface

3.3. Hydrophilic Analysis of Surface

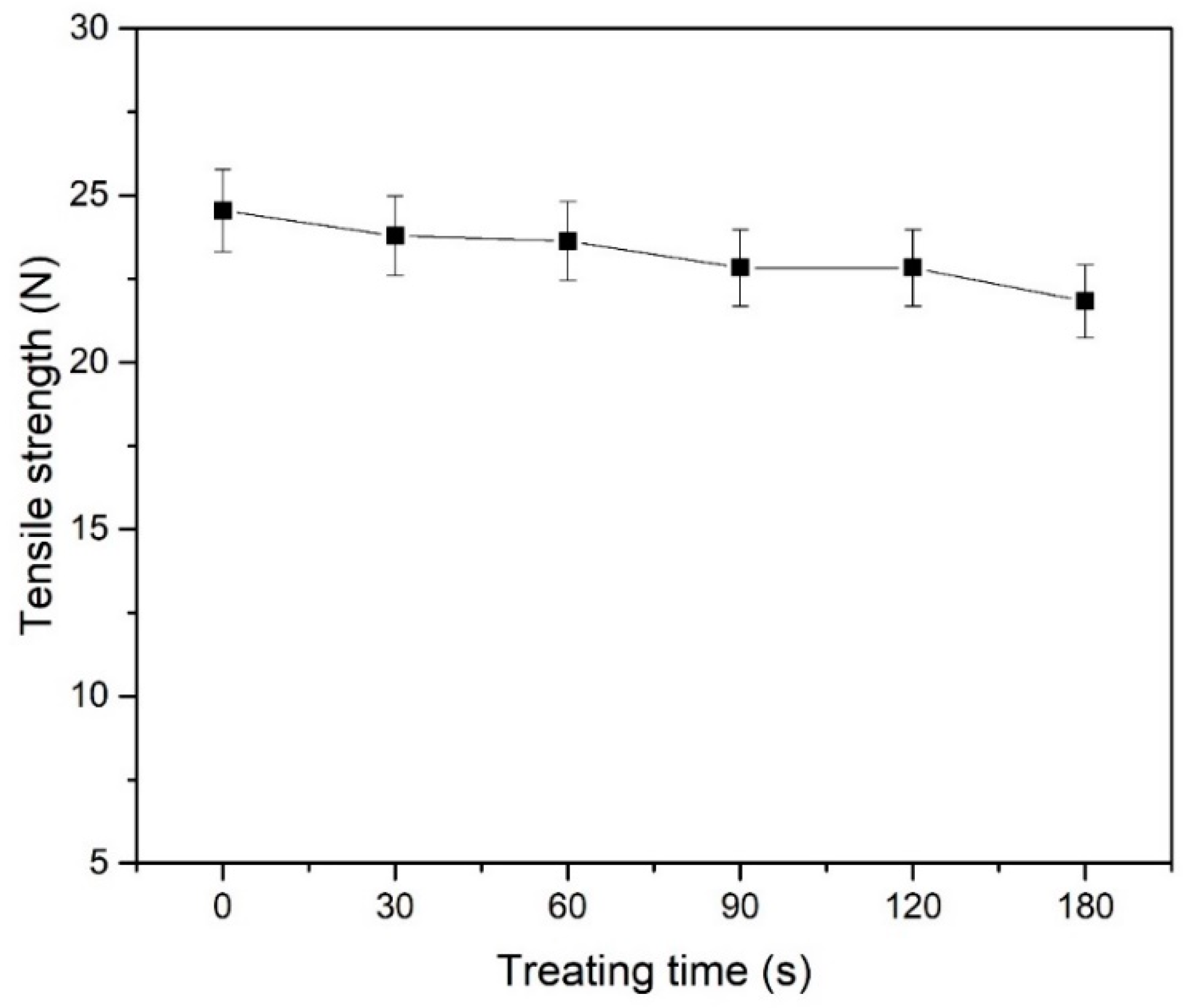

3.4. Tensile Properties of Fiber

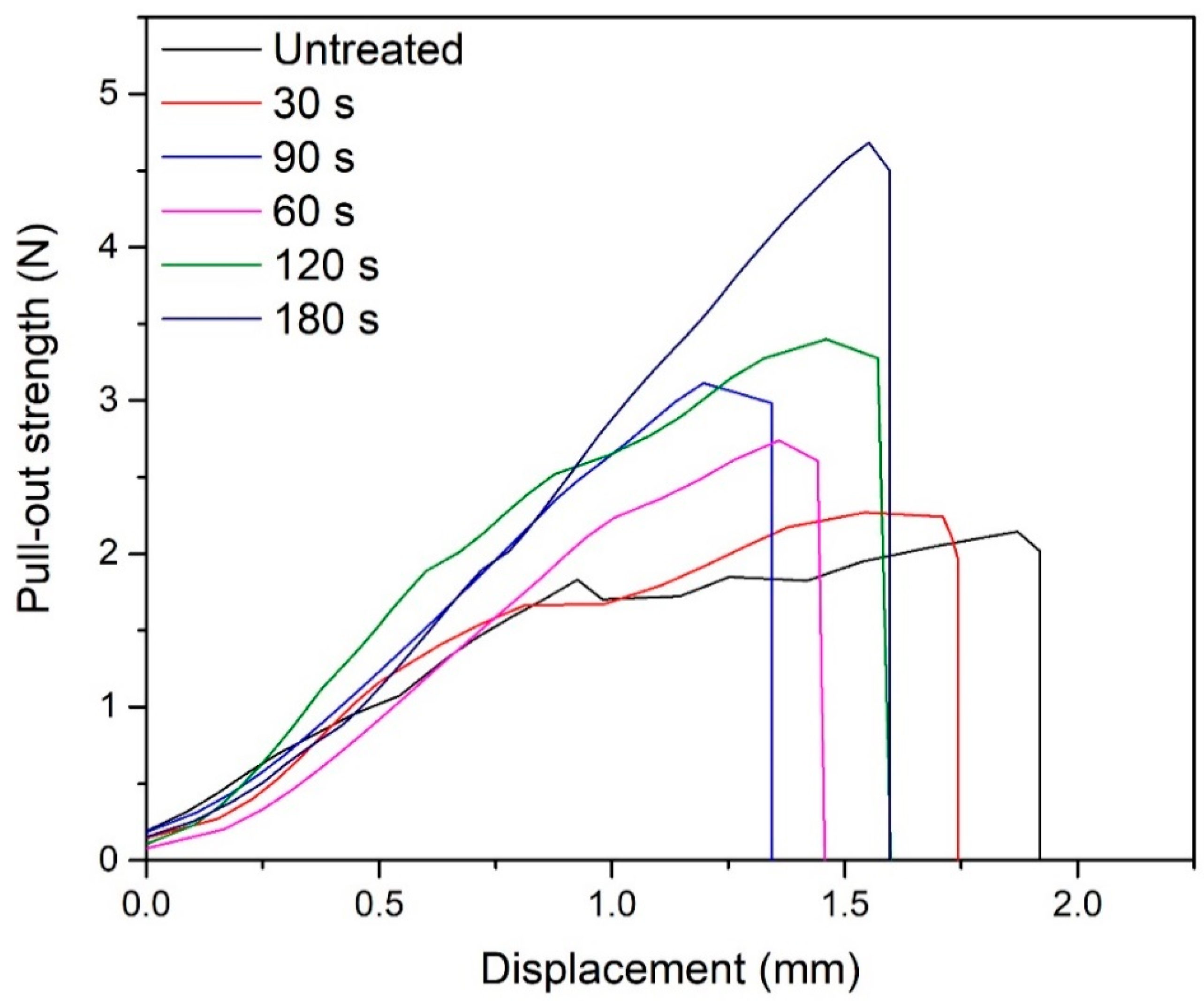

3.5. Pull-Out Bonding Strength Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xu, W.; Ge, M.; He, P. Nonisothermal crystallization kinetics of polyoxymethylene/montmorillonite nanocomposite. J. Appl. Polym. Sci. 2001, 82, 2281–2289. [Google Scholar] [CrossRef]

- Kummara, S.; Tashiro, K. Isotope effect on the structural evolution process in the isothermal crystallization phenomenon of polyoxymethylene. Polymer 2016, 90, 76–88. [Google Scholar] [CrossRef]

- Heinlein, G.S.; Timpe, S.J. Development of elastic and plastic properties of polyoxymethylene during bending fatigue. J. Appl. Polym. Sci. 2014, 131, 9225–9234. [Google Scholar] [CrossRef]

- Petrica, M.; Duscher, B.; Koch, T.; Archodoulaki, V.M. Impact of surface roughness and contact pressure on wear behaviour of PEEK, POM, and PE-UHMW. Int. J. Surf. Sci. Eng. 2017, 11, 65–84. [Google Scholar] [CrossRef]

- Samyn, P.; Baets, P.D.; Schoukens, G.; Quintelier, J. Wear transitions and stability of polyoxymethylene homopolymer in highly loaded applications compared to small-scale testing. Tribol. Int. 2007, 40, 819–833. [Google Scholar] [CrossRef]

- Karahaliou, P.K.; Kerasidou, A.P.; Georga, S.N.; Psarras, G.C.; Krontiras, C.A.; Karger-Kocsis, J. Dielectric relaxations in polyoxymethylene and in related nanocomposites: Identification and molecular dynamics. Polymer 2014, 55, 6819–6826. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, W.; Wang, X.; Wu, D. Preparation, mechanical properties and microstructure of polyoxymethylene fiber through melt spinning and hot drawing by using injection-molding grade resins. Fibers Polym. 2016, 17, 1464–1474. [Google Scholar] [CrossRef]

- Samon, J.M.; Schultz, J.M.; Hsiao, B.S.; Khot, S.; Johnson, H.R. Structure development during the melt spinning of poly(oxymethylene) fiber. Polymer 2001, 42, 1547–1559. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A Review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, Y.; Wang, X.; Wu, D. Fabrication, mechanical performance and tribological behaviors of polyacetal-fiber-reinforced metakaolin-based geopolymeric composites. Ceram. Int. 2016, 42, 6329–6341. [Google Scholar] [CrossRef]

- Ren, Y.; Ding, Z.; Wang, C.; Zang, C.; Zhang, Y.; Xu, L. Influence of DBD plasma pretreatment on the deposition of chitosan onto UHMWPE fiber surfaces for improvement of adhesion and dyeing properties. Appl. Surf. Sci. 2016, 396, 1571–1579. [Google Scholar] [CrossRef]

- Zhang, C.; Fang, K. Surface modification of polyester fabrics for inkjet printing with atmospheric-pressure air/Ar plasma. Surf. Coat. Technol. 2009, 203, 2058–2063. [Google Scholar] [CrossRef]

- Wang, C.; Du, M.; Lv, J.; Zhou, Q.; Ren, Y.; Liu, G.; Gao, D.; Jin, L. Surface modification of aramid fiber by plasma induced vapor phase graft polymerization of acrylic acid. I. Influence of plasma conditions. Appl. Surf. Sci. 2015, 349, 333–342. [Google Scholar] [CrossRef]

- Vasilieva, T.; Chuhchin, D.; Lopatin, S.; Varlamov, V.; Sigarev, A.; Vasiliev, M. Chitin and Cellulose Processing in Low-Temperature Electron Beam Plasma. Molecules 2017, 22, 1908. [Google Scholar] [CrossRef] [PubMed]

- Yáñez-Pacios, A.J.; Martín-Martínez, J.M. Comparative Adhesion, Ageing Resistance, and Surface Properties of Wood Plastic Composite Treated with Low Pressure Plasma and Atmospheric Pressure Plasma Jet. Polymers 2018, 10, 643. [Google Scholar] [CrossRef]

- Cools, P.; Asadian, M.; Nicolaus, W.; Declercq, H.; Morent, R.; De Geyter, N. Surface Treatment of PEOT/PBT (55/45) with a Dielectric Barrier Discharge in Air, Helium, Argon and Nitrogen at Medium Pressure. Materials 2018, 11, 391. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhao, M.; Wang, L.; Qu, L.; Men, Y. Surface modification of polyester fabrics by atmospheric-pressure air/He plasma for color strength and adhesion enhancement. Appl. Surf. Sci. 2016, 400, 304–311. [Google Scholar] [CrossRef]

- Qiu, J.; Xin, N.; Yang, E. Fatigue-induced in-situ strength deterioration of micro-polyvinyl alcohol (PVA) fiber in cement matrix. Cement Concrete Comp. 2017, 82, 128–136. [Google Scholar] [CrossRef]

- Teixeira, R.S.; Tonoli, G.H.D.; Santos, S.F.; Rayon, E.; Amigo, V.; Savastano, H.; Rocco Lahr, F.A. Nanoindentation study of the interfacial zone between cellulose fiber and cement matrix in extruded composites. Cement Concrete Comp. 2018, 85, 1–8. [Google Scholar] [CrossRef]

- Chakraborty, S.; Kundu, S.P.; Roy, A.; Adhikari, B.; Majumder, S.B. Effect of jute as fiber reinforcement controlling the hydration characteristics of cement matrix. Ind. Eng. Chem. Res. 2013, 52, 1252–1260. [Google Scholar] [CrossRef]

- Zhang, Z.; Scherer, G.W.; Bauer, A. Morphology of cementitious material during early hydration. Cement Concrete Res. 2018, 107, 85–100. [Google Scholar] [CrossRef]

- Katz, A.; Li, V.C. Bond properties of micro-fibers in cementitious matrix. Mat. Res. Soc. Symp. Proc. 1995, 370, 529–537. [Google Scholar] [CrossRef]

- Katz, A.; Li, V.C. A special technique for determining the bond strength of microfibres in cement matrix by pullout test. J. Mater. Sci. Lett. 1996, 15, 1821–1823. [Google Scholar] [CrossRef]

- Zia, A.W.; Wang, Y.; Lee, S. Effect of physical and chemical plasma etching on surface wettability of carbon fiber-reinforced polymer composites for bone plate applications. Adv. Polym. Technol. 2015, 34, 21480. [Google Scholar] [CrossRef]

- Ren, Y.; Xu, L.; Wang, C.; Wang, X.; Ding, Z.; Chen, Y. Effect of dielectric barrier discharge treatment on surface nanostructure and wettability of polylactic acid (PLA) nonwoven fabrics. Appl. Surf. Sci. 2017, 426, 612–621. [Google Scholar] [CrossRef]

- Pappas, D.; Bujanda, A.; Demaree, J.D.; Hirvonen, J.K.; Kosik, W.; Jensen, R.; McKnight, S. Surface modification of polyamide fibers and films using atmospheric plasmas. Surf. Coat. Technol. 2006, 201, 4384–4388. [Google Scholar] [CrossRef]

- Leroux, F.; Perwuelz, A.; Campagne, C.; Behary, N. Atmospheric air-plasma treatments of polyester textile structures. J. Adhes. Sci. Technol. 2006, 20, 939–957. [Google Scholar] [CrossRef]

- Xi, M.; Li, Y.; Shang, S.; Li, D.; Yin, Y.; Dai, X. Surface modification of aramid fiber by air DBD plasma at atmospheric pressure with continuous on-line processing. Surf. Coat. Technol. 2008, 202, 6029–6033. [Google Scholar] [CrossRef]

- Lee, E.S.; Lee, C.H.; Chun, Y.S.; Han, C.J.; Lim, D.S. Effect of hydrogen plasma-mediated surface modification of carbon fibers on the mechanical properties of carbon-fiber-reinforced polyetherimide composites. Compos. Part B Eng. 2017, 116, 451–458. [Google Scholar] [CrossRef]

- Pielichowska, K.; Szczygielska, A.; Spasówka, E. Preparation and characterization of polyoxymethylene-copolymer/hydroxyapatite nanocomposites for long-term bone implants. Polym. Adv. Technol. 2012, 23, 1141–1150. [Google Scholar] [CrossRef]

- Hu, P.; Shang, T.; Jiang, M.; Chen, M. Investigation of the thermal decomposition properties of polyoxymethylene. J. Wuhan Univ. Technol. 2007, 22, 171–173. [Google Scholar] [CrossRef]

- Grimblot, J.; Mutel, B.; Moineau, V.; Colson, T.; Dessaux, O.; Goudmand, P. Comparative study by XPS of nitrogen and oxygen implantation in different carbonaceous polymers using flowing nitrogen plasma. Surf. Interface Anal. 2000, 30, 415–419. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, Y.; Tan, W.; Wang, X. Enhancement of the laser transmission weldability between polyethylene and polyoxymethylene by plasma surface treatment. Materials 2018, 11, 29. [Google Scholar] [CrossRef] [PubMed]

- Correia, D.M.; Ribeiro, C.; Sencadas, V.; Botelho, G.; Carabineiro, S.A.C.; Ribelles, J.L.G.; Lanceros-Méndez, S. Influence of oxygen plasma treatment parameters on poly(vinylidene fluoride) electrospun fiber mats wettability. Prog. Org. Coat. 2015, 85, 151–158. [Google Scholar] [CrossRef]

- Jin, X.; Wang, W.; Xiao, C.; Lin, T.; Bian, L.; Hauser, P. Improvement of coating durability, interfacial adhesion and compressive strength of UHMWPE fiber/epoxy composites through plasma pre-treatment and polypyrrole coating. Compos. Sci. Technol. 2016, 128, 169–175. [Google Scholar] [CrossRef]

| Condition | Rms Roughness (nm) | Ra Roughness (nm) | |

|---|---|---|---|

| Untreated | 7.38 | 5.72 | |

| Plasma treatment for | 30 s | 7.40 | 5.47 |

| 60 s | 13.10 | 9.31 | |

| 90 s | 15.30 | 10.10 | |

| 120 s | 12.50 | 9.97 | |

| 180 s | 14.20 | 10.40 | |

| Condition | Chemical Composition (%) | Atomic Ratio (%) | |||

|---|---|---|---|---|---|

| C1s | O1s | N1s | O/C | N/C | |

| Untreated | 78.72 | 20.13 | 1.15 | 0.26 | 0.01 |

| 30 s Plasma treatment | 77.10 | 21.85 | 1.05 | 0.28 | 0.01 |

| 60 s Plasma treatment | 76.39 | 22.71 | 0.90 | 0.30 | 0.01 |

| 120 s Plasma treatment | 72.70 | 26.38 | 0.93 | 0.36 | 0.01 |

| Condition | Relative Area Corresponding to Different Chemical Bonds (%) | |

|---|---|---|

| C–H | C–O/C=O | |

| Untreated | 78.51 | 21.49 |

| 30 s Treated | 75.46 | 24.54 |

| 60 s Treated | 74.50 | 25.50 |

| 120 s Treated | 70.99 | 29.01 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Xu, X.; Wei, F.; Zou, X.; Zhang, Y. Influence of Dielectric Barrier Discharge Treatment on Surface Structure of Polyoxymethylene Fiber and Interfacial Interaction with Cement. Materials 2018, 11, 1873. https://doi.org/10.3390/ma11101873

Zhang W, Xu X, Wei F, Zou X, Zhang Y. Influence of Dielectric Barrier Discharge Treatment on Surface Structure of Polyoxymethylene Fiber and Interfacial Interaction with Cement. Materials. 2018; 11(10):1873. https://doi.org/10.3390/ma11101873

Chicago/Turabian StyleZhang, Wei, Xiao Xu, Fayun Wei, Xueshu Zou, and Yu Zhang. 2018. "Influence of Dielectric Barrier Discharge Treatment on Surface Structure of Polyoxymethylene Fiber and Interfacial Interaction with Cement" Materials 11, no. 10: 1873. https://doi.org/10.3390/ma11101873

APA StyleZhang, W., Xu, X., Wei, F., Zou, X., & Zhang, Y. (2018). Influence of Dielectric Barrier Discharge Treatment on Surface Structure of Polyoxymethylene Fiber and Interfacial Interaction with Cement. Materials, 11(10), 1873. https://doi.org/10.3390/ma11101873