High Temperature Deformation Behavior of In-Situ Synthesized Titanium-Based Composite Reinforced with Ultra-Fine TiB Whiskers

Abstract

:1. Introduction

2. Materials and Methods

3. Results

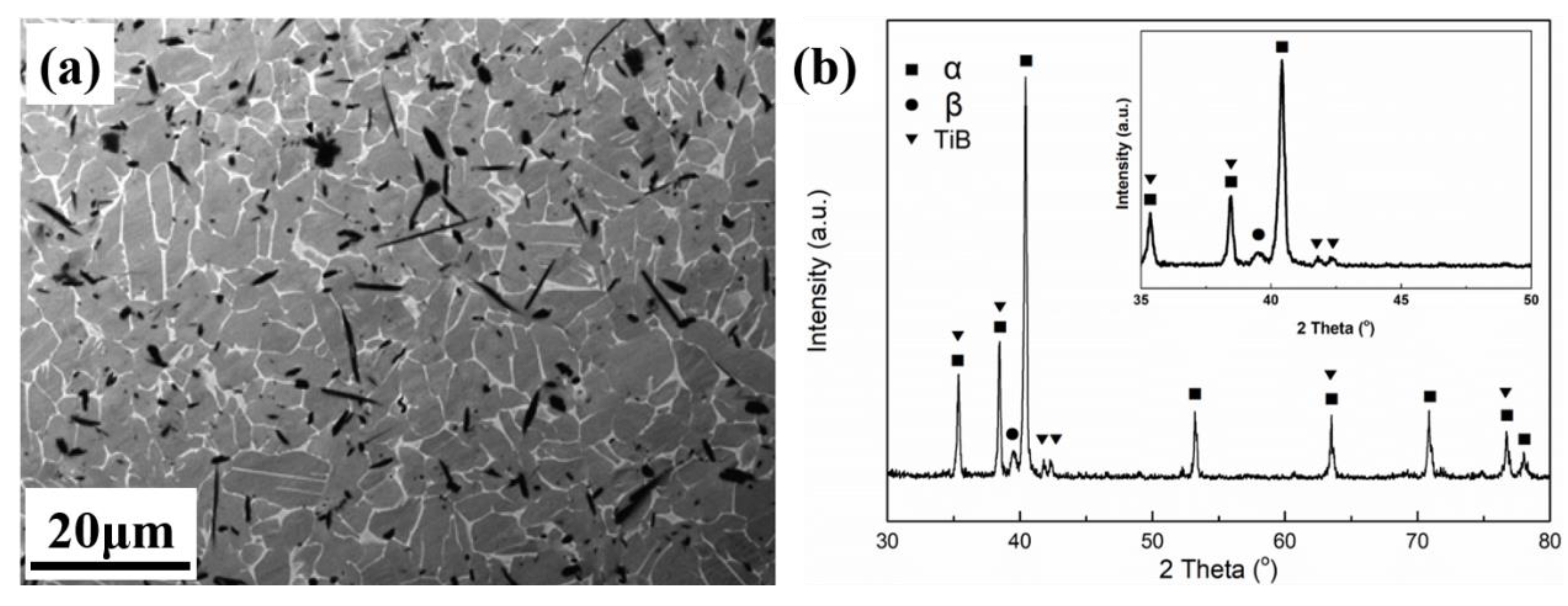

3.1. Initial Microstructure of the UF-TiB/Ti-6Al-4V Composite

3.2. Hot Deformation of the UF-TiB/Ti-6Al-4V Composite

3.3. Processing Map of the UF-TiB/Ti-6Al-4V Composite

3.4. Deformed Microstructures

4. Discussion

4.1. Damage Mechanism of the UF-TiB/Ti-6Al-4V Composite

4.2. Improved Deformability of the UF-TiB/Ti-6Al-4V Composite

5. Conclusions

- A UF-TiB/Ti-6Al-4V composite is prepared by the spark plasma sintering method. The grain size of the matrix is approximately 5–12 μm, the length of the TiB whiskers is approximately 5–20 μm, and the diameter is 0.1–2 μm.

- The stable deformation of the UF-TiB/Ti-6Al-4V composite occurs at the conditions of 900–1200 °C/0.001–0.01 s−1. The optimum hot working condition is 900 °C/0.001 s−1, with the deformation mechanism of dynamic recrystallization (DRX).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Elanchezhian, C.; Ramnath, B.V.; Ramakrishnan, G.; Raghavendra, K.N.S.; Muralidharan, M. Review on metal matrix composites for marine applications. Mater. Today Proc. 2018, 5, 1211–1218. [Google Scholar] [CrossRef]

- Tjong, S.C.; Mai, Y.W. Processing-structure-property aspects of particulate-and whisker-reinforced titanium matrix composites. Compos. Sci. Technol. 2008, 68, 583–601. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, W.; Li, Z.; Cui, G.; Chen, W. Room-temperature and high-temperature tensile mechanical properties of TA15 titanium alloy and TiB whisker-reinforced TA15 matrix composites fabricated by vacuum hot-pressing sintering. Materials 2017, 10, 424. [Google Scholar] [CrossRef] [PubMed]

- Jiao, Y.; Huang, L.; Geng, L. Progress on discontinuously reinforced titanium matrix composites. J. Alloys Compd. 2018, 767, 1196–1215. [Google Scholar] [CrossRef]

- Zhang, E.; Gang, Z.; Zeng, S. Oxidation behavior of in situ TiB short fibre reinforced Ti-6Al-1.2B alloy in air. J. Mater. Sci. 2002, 37, 4063–4071. [Google Scholar] [CrossRef]

- Huang, L.; Wang, L.; Qian, M.; Zhou, J. High tensile-strength and ductile titanium matrix composites strengthened by TiB nanowires. Scr. Mater. 2017, 141, 133–137. [Google Scholar] [CrossRef]

- Liu, B.; Li, Y.P.; Matsumoto, H.; Liu, Y.B.; Liu, Y.; Tang, H.P.; Chiba, A. Thermomechanical response of particulate-reinforced powder metallurgy titanium matrix composites—A study using processing map. Mater. Sci. Eng. A 2010, 527, 4733–4741. [Google Scholar] [CrossRef]

- Guo, X.; Wang, L.; Wang, M.; Qin, J.; Zhang, D.; Lu, W. Effects of degree of deformation on the microstructure, mechanical properties and texture of hybrid-reinforced titanium matrix composites. Acta Mater. 2012, 60, 2656–2667. [Google Scholar] [CrossRef]

- Cortazar, M.G.D.; Peñalba, F.; Silveira, E.; Gómez-Mitxelena, X.; Carsí, M.; Ruano, O.A. Modelling the optimum hot workability of TiB reinforced Ti-6Al-4V alloy by stability maps. Int. J. Mater. Form. 2017, 10, 379–387. [Google Scholar] [CrossRef]

- Bhat, R.B.; Tamirisakandala, S.; Miracle, D.B.; Ravi, V.A. Thermomechanical response of a powder metallurgy Ti-6Al-4V alloy modified with 2.9 pct boron. Metall. Mater. Trans. A 2005, 36, 845–857. [Google Scholar] [CrossRef]

- Huang, L.J.; Zhang, Y.Z.; Geng, L.; Wang, B.; Ren, W. Hot compression characteristics of TiBw/Ti6Al4V composites with novel network microstructure using processing maps. Mater. Sci. Eng. A 2013, 580, 242–249. [Google Scholar] [CrossRef]

- Sun, X.; Han, Y.; Cao, S.; Qiu, P.; Lu, W. Rapid in-situ reaction synthesis of novel TiC and carbon nanotubes reinforced titanium matrix composites. J. Mater. Sci. Technol. 2013, 10, 1165–1171. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, L.; Jiang, W.; Shi, L.; Chen, L. Fabrication microstructure and mechanical properties of TiC/Ti2AlC/TiAl3 in situ composite. J. Mater. Sci. Technol. 2011, 27, 239–244. [Google Scholar] [CrossRef]

- Feng, H.; Zhou, Y.; Jia, D.; Meng, Q. Rapid synthesis of Ti alloy with B addition by spark plasma sintering. Mater. Sci. Eng. A 2005, 390, 344–349. [Google Scholar] [CrossRef]

- Angerer, P.; Yu, L.G.; Khor, K.A.; Korb, G.; Zalite, I. Spark-plasma-sintering (SPS) of nanostructured titanium carbonitride powders. J. Eur. Ceram. Soc. 2005, 25, 1919–1927. [Google Scholar] [CrossRef]

- Cao, Y.K.; Zeng, F.; Lu, J.; Liu, B.; Liu, Y.; Li, Y. In situ synthesis of TiB/Ti6Al4V composites reinforced with nano TiB through SPS. Mater. Trans. 2015, 56, 259–263. [Google Scholar] [CrossRef]

- Li, Y.P.; Onodera, E.; Matsumoto, H.; Chiba, A. Correcting the stress-strain curve in hot compression process to high strain level. Metall. Mater. Trans. A 2009, 40, 982–990. [Google Scholar] [CrossRef]

- Fan, Z.; Guo, Z.X.; Cantor, B. The kinetics and mechanism of interfacial reaction in sigma fibre-reinforced Ti MMCs. Compos. Part. A 1997, 28, 131–140. [Google Scholar] [CrossRef]

- Liu, B.; Li, Y.P.; Matsumoto, H.; Liu, Y.B.; Liu, Y.; Chiba, A. Thermomechanical characterization of P/M Ti-Fe-Mo-Y alloy with a fine lamellar microstructure. Mater. Sci. Eng. A 2011, 528, 2345–2352. [Google Scholar] [CrossRef]

- Jonas, J.J.; Sellars, C.M.; Tegart, W.J.M. Strength and structure under hot-working conditions. Metall. Rev. 1969, 14, 1–24. [Google Scholar] [CrossRef]

- Wanjara, P.; Jahazi, M.; Monajati, H.; Yue, S.; Immarigeon, J.P. Hot working behavior of near-α alloy IMI834. Mater. Sci. Eng. A 2005, 396, 50–60. [Google Scholar] [CrossRef]

- Braga, H.C.; Barbosa, R.; Breme, J. Hot strength of Ti and Ti6Al4V deformed in axial compression. Scr. Metal. Mater. 1993, 28, 979–983. [Google Scholar] [CrossRef]

- Briottet, L.; Jonas, J.J.; Montheillet, F. A mechanical interpretation of the activation energy of high temperature deformation in two phase materials. Acta Mater. 1996, 44, 1665–1672. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Frazier, W.G.; Prasad, Y.V.R.K. Hot working of commercial Ti–6Al–4V with an equiaxed α-β microstructure: Materials modeling considerations. Mater. Sci. Eng. A 2000, 284, 184–194. [Google Scholar] [CrossRef]

- Sneddon, I.N.; Jahsman, W.E.; Hill, R. Progress in Solid Mechanics; John Wiley: New York, NY, USA, 1965; pp. 191–193. [Google Scholar]

- Sen, I.; Kottada, R.S.; Ramamurty, U. High temperature deformation processing maps for boron modified Ti–6Al–4V alloys. Mater. Sci. Eng. A 2010, 527, 6157–6165. [Google Scholar] [CrossRef]

- Meyers, M.A.; Nesterenko, V.F.; Lasalvia, J.C.; Xue, Q. Shear localization in dynamic deformation of materials: Microstructural evolution and self-organization. Mater. Sci. Eng. A 2001, 317, 204–225. [Google Scholar] [CrossRef]

- Kolachev, B.A.; Egorova, Y.B.; Belova1, S.B. Relation between the temperature of the α + β to β transformation of commercial titanium alloys and their chemical composition. Met. Sci. Heat. Treat. 2008, 50, 7–8. [Google Scholar] [CrossRef]

- Tamirisakandala, S.; Bhat, R.B.; Miracle, D.B.; Boddapati, S.; Bordia, R.; Vanover, R.; Vasudevan, V.K. Effect of boron on the beta transus of Ti-6Al-4V alloy. Scr. Mater. 2005, 53, 217–222. [Google Scholar] [CrossRef]

- Cherukuri, B. Microstructural Stability and Thermomechanical Processing of Boron Modified Beta Titanium Alloys. Ph.D. Thesis, Wright State University, Dayton, OH, USA, 2004. [Google Scholar]

- Koeller, R.C.; Raj, R. Diffusional relaxation of stress concentration at second phase particles. Acta Metall. 1978, 26, 1551–1558. [Google Scholar] [CrossRef]

| Powders | Mass Percentage wt. % | Average Particle Size (μm) | Oxygen Content (wt. %) | Preparation a |

|---|---|---|---|---|

| Ti-6Al-4V | 89.7 | 11 ± 3.29 | 0.32 ± 0.025 | GA |

| Ti | 4.1 | 39 ± 2.16 | 0.25 ± 0.022 | HDDH |

| TiB2 | 6.2 | 3.8 ± 0.59 | 0.39 ± 0.017 | RO |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, R.; Liu, B.; Liu, Y.; Cao, Y.; Guo, W.; Nie, Y.; Liu, S. High Temperature Deformation Behavior of In-Situ Synthesized Titanium-Based Composite Reinforced with Ultra-Fine TiB Whiskers. Materials 2018, 11, 1863. https://doi.org/10.3390/ma11101863

Xu R, Liu B, Liu Y, Cao Y, Guo W, Nie Y, Liu S. High Temperature Deformation Behavior of In-Situ Synthesized Titanium-Based Composite Reinforced with Ultra-Fine TiB Whiskers. Materials. 2018; 11(10):1863. https://doi.org/10.3390/ma11101863

Chicago/Turabian StyleXu, Rongjun, Bin Liu, Yong Liu, Yuankui Cao, Wenmin Guo, Yan Nie, and Shifeng Liu. 2018. "High Temperature Deformation Behavior of In-Situ Synthesized Titanium-Based Composite Reinforced with Ultra-Fine TiB Whiskers" Materials 11, no. 10: 1863. https://doi.org/10.3390/ma11101863

APA StyleXu, R., Liu, B., Liu, Y., Cao, Y., Guo, W., Nie, Y., & Liu, S. (2018). High Temperature Deformation Behavior of In-Situ Synthesized Titanium-Based Composite Reinforced with Ultra-Fine TiB Whiskers. Materials, 11(10), 1863. https://doi.org/10.3390/ma11101863