Tribological Behavior of the 316L Stainless Steel with Heterogeneous Lamella Structure

Abstract

:1. Introduction

2. Experimental

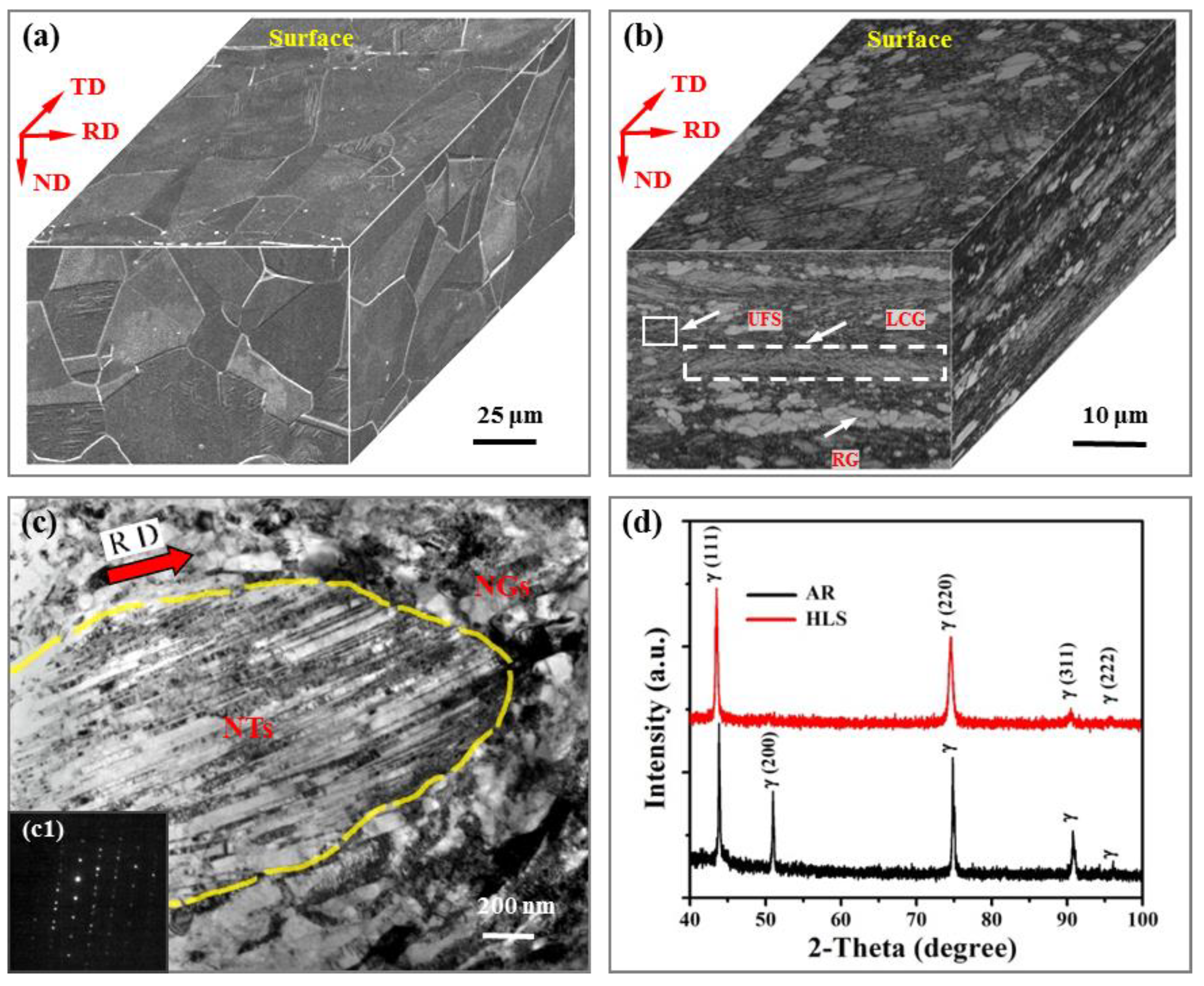

2.1. Material Preparation and Characteristics

2.2. Ball-on-Disc Tribotests

2.3. Detailed Analysis Methods

3. Results

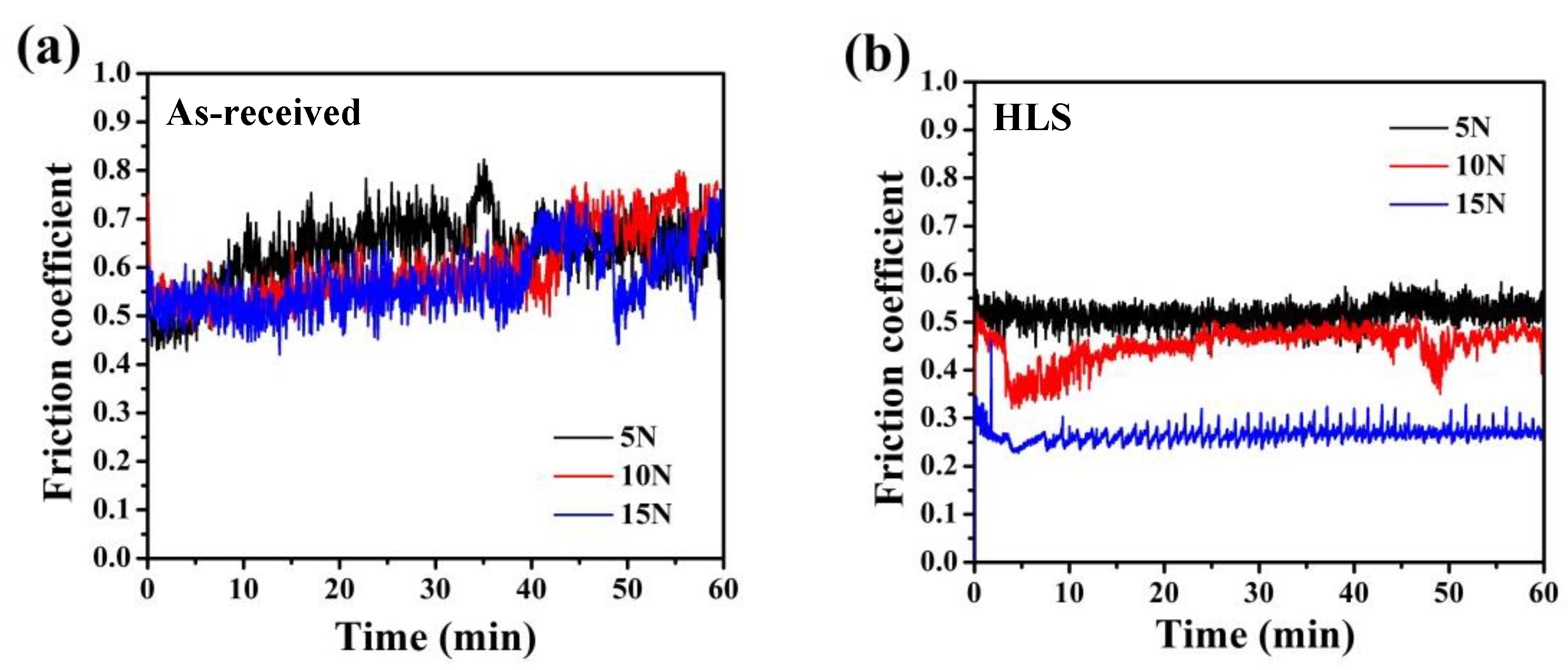

3.1. Friction Behavior

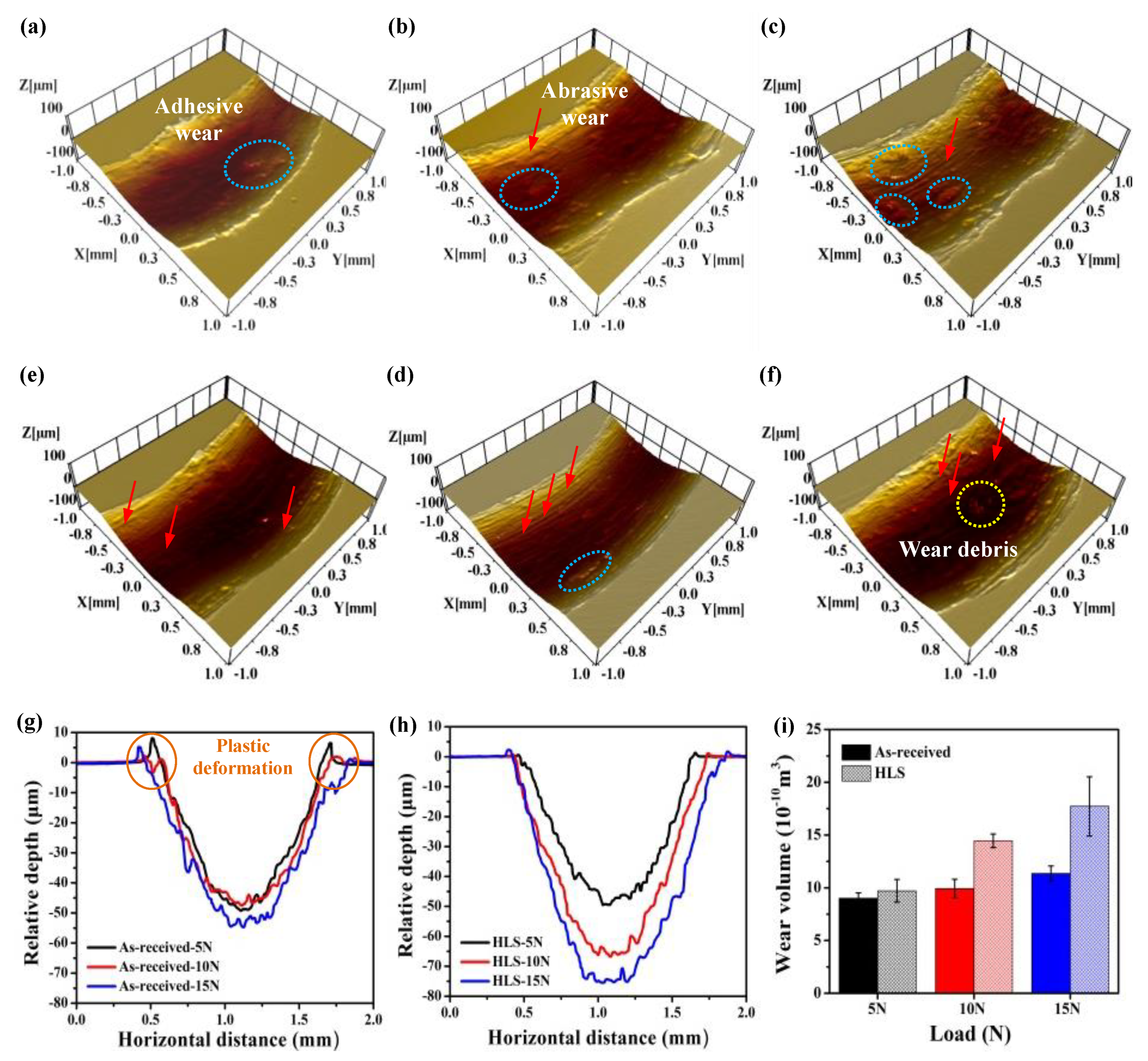

3.2. Wear Performance

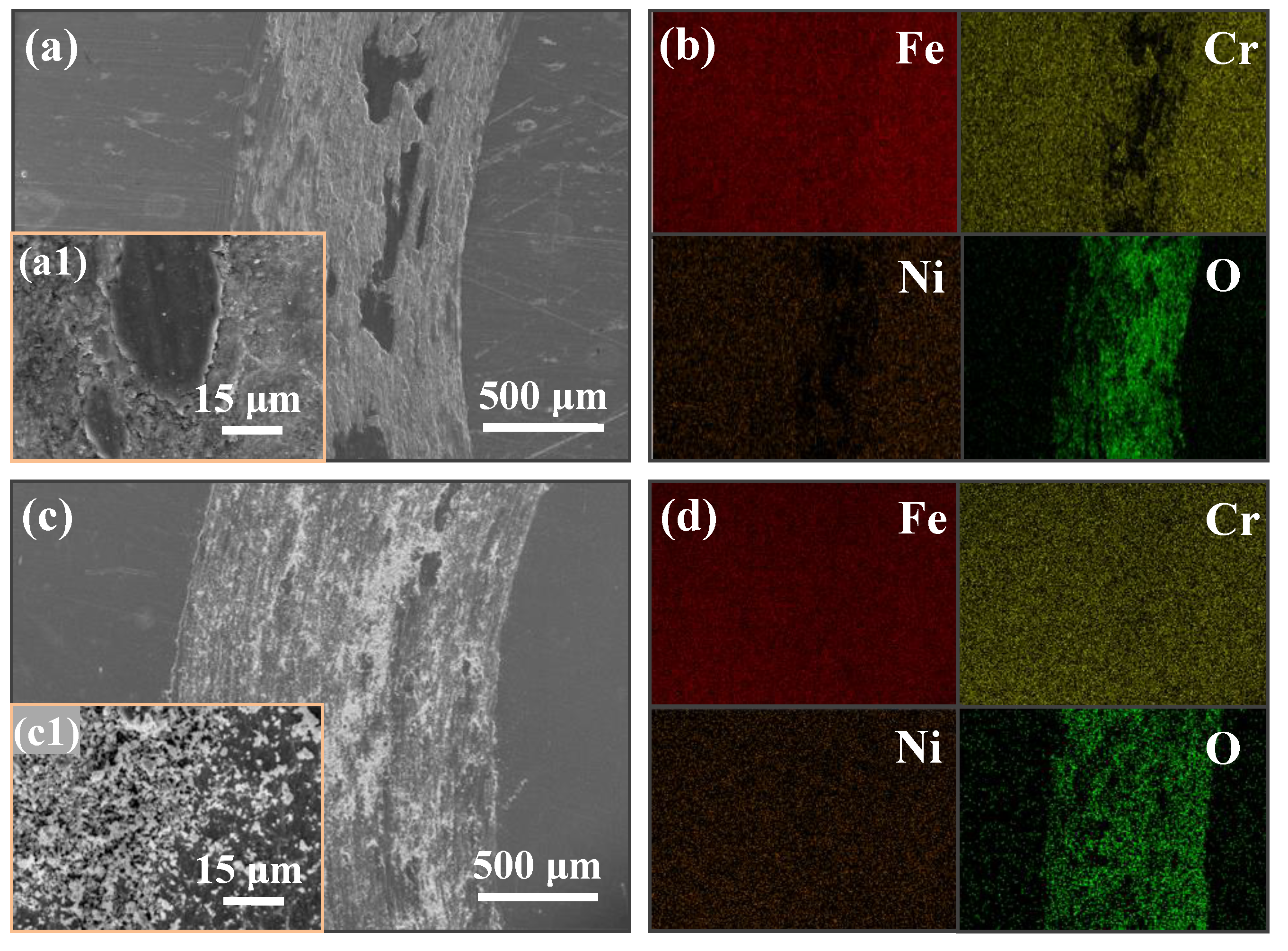

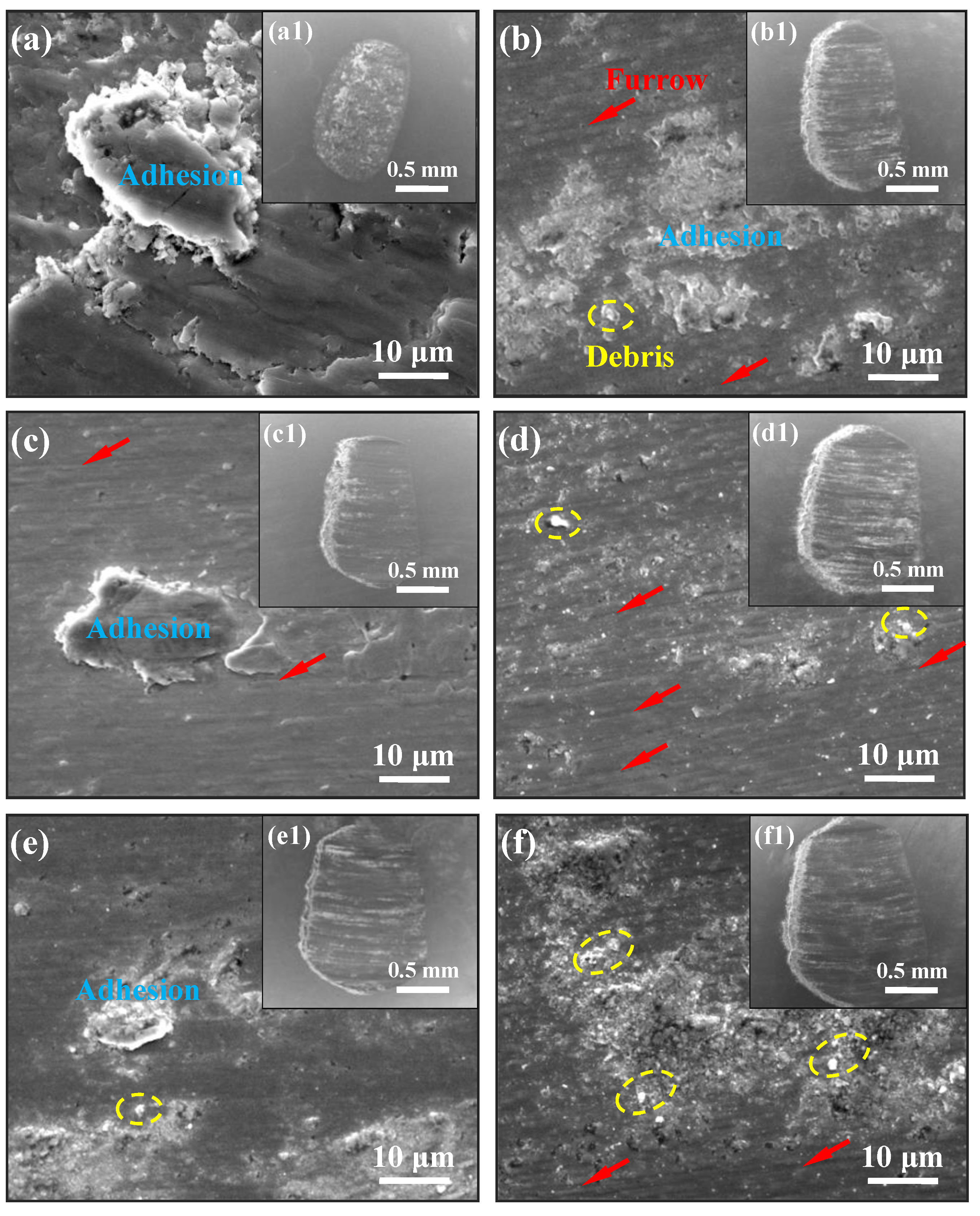

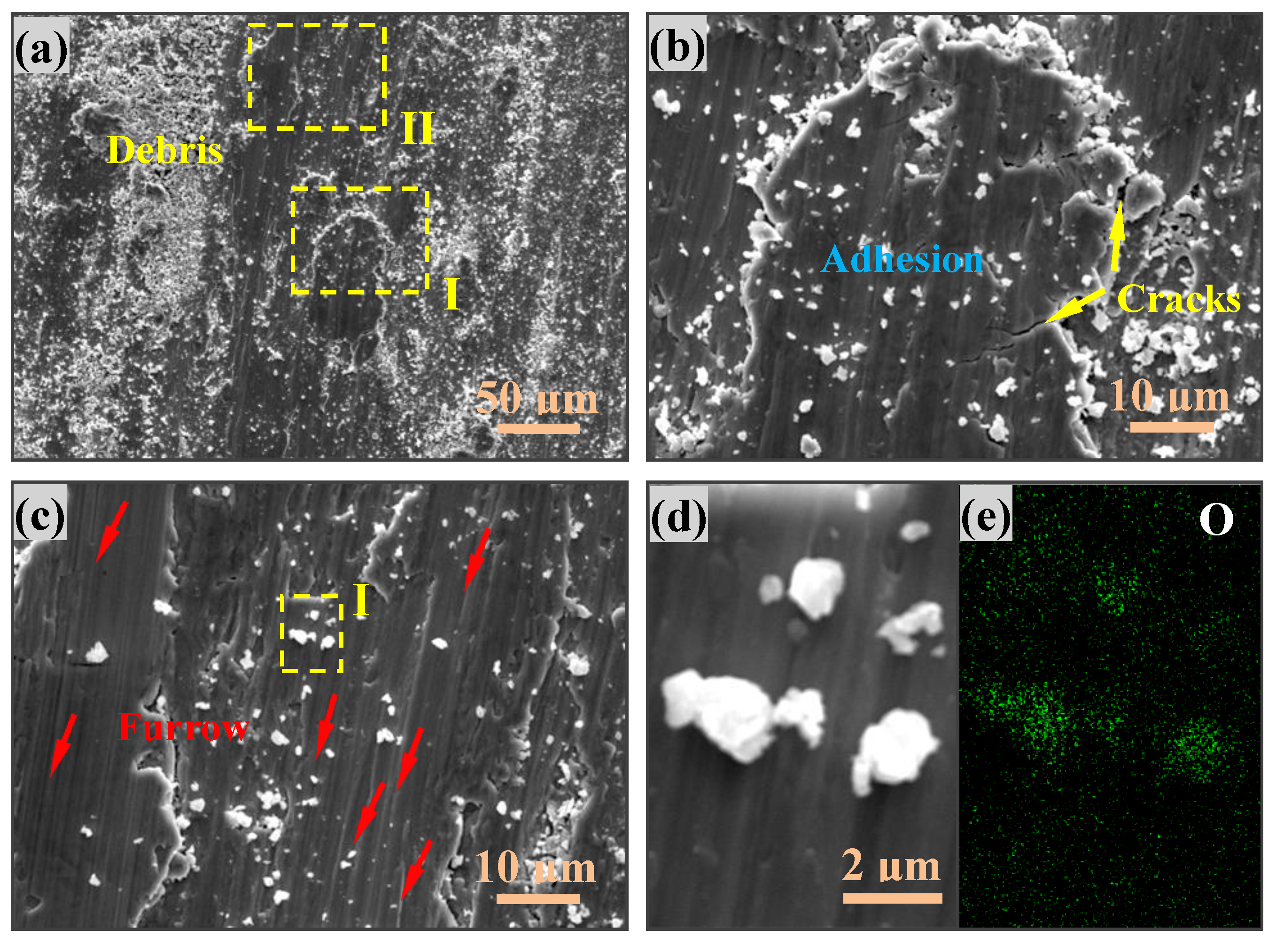

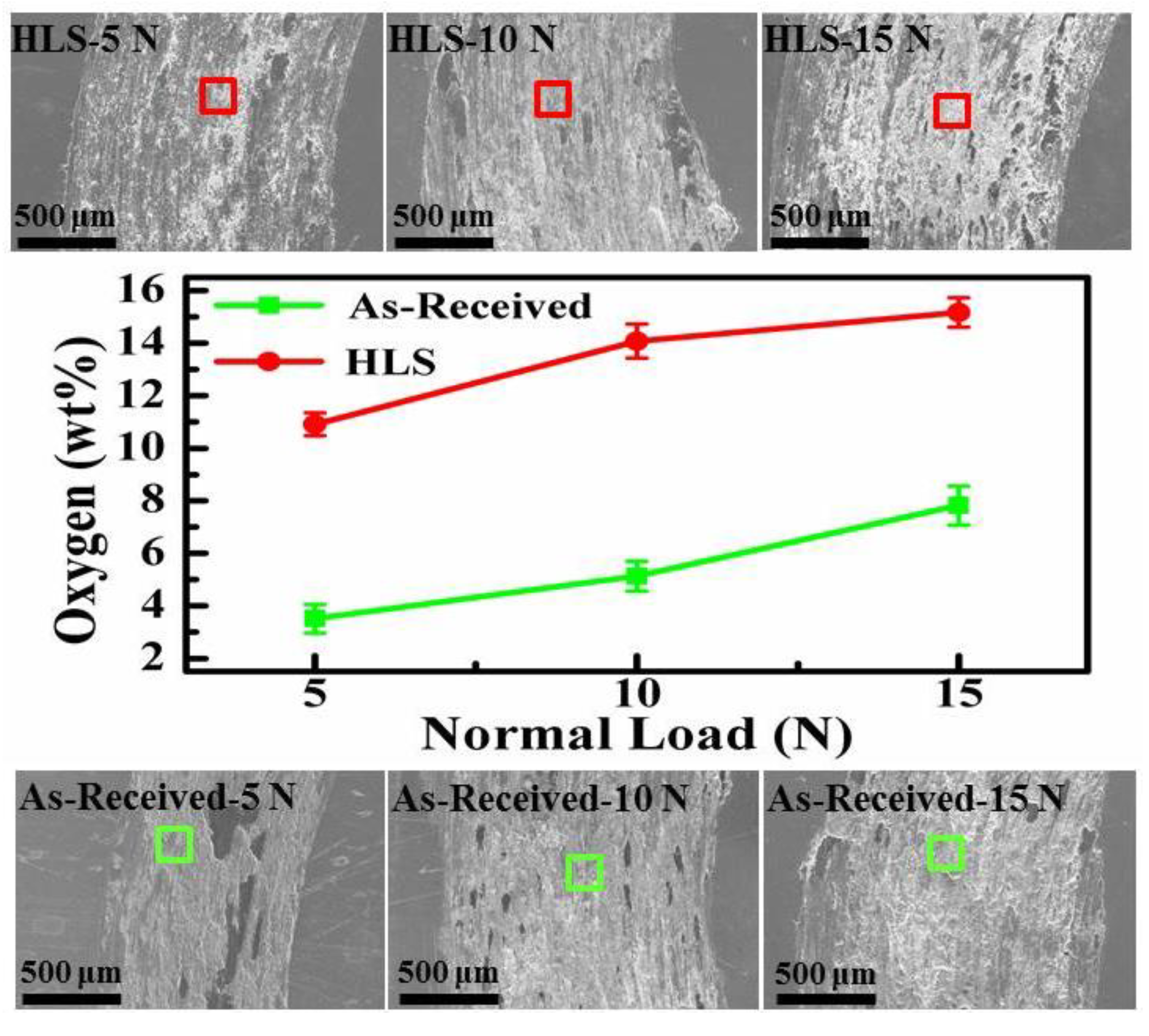

3.3. SEM and EDS Mapping Measurements on Worn Surfaces

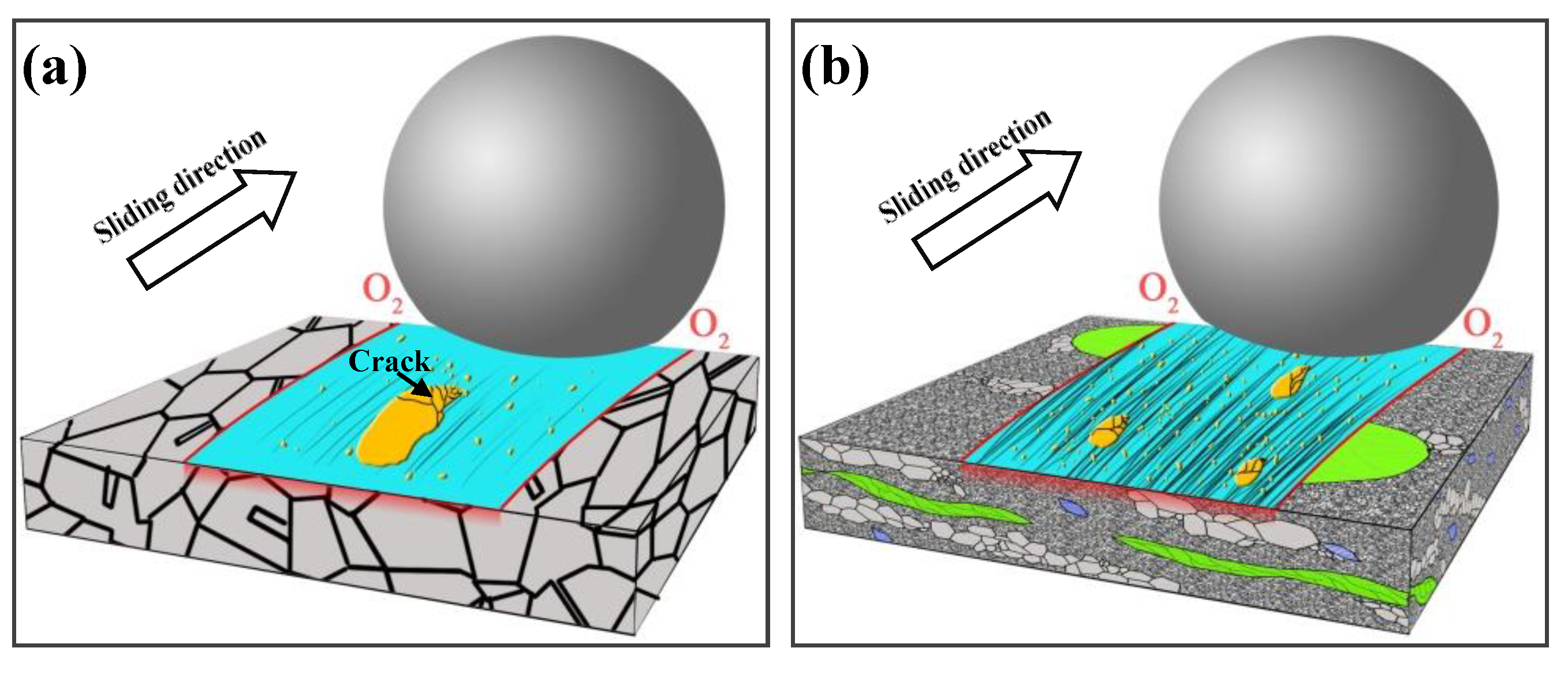

4. Discussion

5. Conclusions

- A 316L stainless steel with the heterogeneous lamella structure was successfully prepared through 85% cold rolling and subsequent annealing treatment in air (750 °C, 10 min).

- The friction coefficient of the heterogeneous lamella structure 316L stainless steel is lower than that of as-received samples with coarse-grained state, which is ascribed to the frictional reduction effect of the oxidative particles generated at the sliding interfaces.

- The formation of heterogeneous lamella structure is more easily subjected to severe tribo-oxidative and abrasive wear process, which results in the increase of wear rates. Additionally, with increasing normal loads, the enhancement of the oxidation process markedly increases, accompanied with the thermal effect of sliding interfaces, and more oxide particles are formed, and the oxidation wear becomes more severe, accompanied by more wear loss.

Author Contributions

Funding

Conflicts of Interest

References

- Yan, F.K.; Liu, G.Z.; Tao, N.R.; Lu, K. Strength and ductility of 316L austenitic stainless steel strengthened by nano-scale twin bundles. Acta Mater. 2012, 60, 1059–1071. [Google Scholar] [CrossRef]

- Sharifitabar, M.; Halvaee, A.; Khorshahian, S. Microstructure and mechanical properties of resistance upset butt welded 304 austenitic stainless steel joints. Mater. Des. 2011, 32, 3854–3864. [Google Scholar] [CrossRef]

- Gnilitskyi, I.; Rotundo, F.; Martini, C.; Pavlov, I.; Ilday, S.; Vovk, E.; Orazi, L. Nano patterning of AISI 316l stainless steel with nonlinear laser lithography: Sliding under dry and oil-lubricated conditions. Tribol. Int. 2016, 99, 67–76. [Google Scholar] [CrossRef]

- Chi, H.; Jiang, L.; Chen, G.; Kang, P.; Lin, X.; Wu, G. Dry sliding friction and wear behavior of (TiB2+h-BN)/2024Al composites. Mater. Des. 2015, 87, 960–968. [Google Scholar] [CrossRef]

- Jiang, J.Y.; Li, X.Y. The microstructure evolution in early running-in stage and its effect on the friction behavior in 304 stainless steel. Tribology 2018, 38, 37–43. [Google Scholar]

- Cao, H.M.; Zhou, X.; Li, X.Y.; Lu, K. Friction mechanism in the running-in stage of copper: From plastic deformation to delamination and oxidation. Tribol. Int. 2017, 115, 3–7. [Google Scholar] [CrossRef]

- Tuckart, W.; Iurman, L.; Forlerer, E. Influence of microstructure on tribologically mixed layers. Wear 2011, 271, 792–801. [Google Scholar] [CrossRef]

- So, H.; Yu, D.S.; Chuang, C.Y. Formation and wear mechanism of tribo-oxides and the regime of oxidational wear of steel. Wear 2002, 253, 1004–1015. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N. Study of cracking mechanisms in multi-layered composite nano-structured coatings. Wear 2017, 378, 43–57. [Google Scholar] [CrossRef]

- Fellah, M.; Labaïz, M.; Assala, O.; Iost, A.; Dekhil, L. Tribological behaviour of AISI 316l stainless steel for biomedical applications. Tribol. Mater. Surf. Interfaces 2004, 7, 135–149. [Google Scholar] [CrossRef]

- Jourani, A.; Bouvier, S. Friction and wear mechanisms of 316L stainless steel in dry sliding contact: Effect of abrasive particle size. Tribol. Trans. 2015, 58, 131–139. [Google Scholar] [CrossRef]

- Barrau, O.; Boher, C.; Gras, R.; Rezai-Aria, F. Analysis of the friction and wear behaviour of hot work tool steel for forging. Wear 2003, 255, 1444–1454. [Google Scholar] [CrossRef]

- Mishra, A.; Maity, J. Wear behavior of an ultra-high-strength eutectoid steel. J. Mater. Eng. Perform. 2018, 27, 398–410. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Kelly, G.; Rolfe, B.F.; Pereira, M.P. The effect of sliding speed on the wear of steel–tool steel pairs. Tribol. Int. 2016, 97, 218–227. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Kelly, G.; Rolfe, B.F.; Pereira, M.P. The effect of temperature on sliding wear of steel-tool steel pairs. Wear 2012, 282, 22–30. [Google Scholar] [CrossRef]

- Viafara, C.C.; Castro, M.I.; Velez, J.M.; Toro, A. Unlubricated sliding wear of pearlitic and bainitic steels. Wear 2005, 259, 405–411. [Google Scholar] [CrossRef]

- Gård, A.; Hallbäck, N.; Krakhmalev, P.; Bergström, J. Temperature effects on adhesive wear in dry sliding contacts. Wear 2010, 268, 968–975. [Google Scholar]

- Sullivan, J.L.; Quinn, T.F.J.; Rowson, D.M. Developments in the oxidational theory of mild wear. Tribol. Int. 1980, 13, 153–158. [Google Scholar] [CrossRef]

- Quinn, T.F.J. Oxidational wear modelling Part III, the effects of speed and elevated temperatures. Wear 1998, 216, 262–275. [Google Scholar] [CrossRef]

- Cui, X.H.; Wang, S.Q.; Wang, F.; Chen, K.M. Research on oxidative wear mechanism of the cast steels. Wear 2008, 265, 468–476. [Google Scholar] [CrossRef]

- Hogmark, S.; Vingsbo, O. Adhesive mechanisms in the wear of some tool steels. Wear 1976, 38, 341–359. [Google Scholar] [CrossRef]

- Hurricks, P.L. Some metallurgical factors controlling the adhesive and abrasive wear resistance of steels. A review. Wear 1973, 26, 285–304. [Google Scholar] [CrossRef]

- Yao, S.H.; Su, Y.L.; Lai, Y.C. Antibacterial and tribological performance of carbonitride coatings doped with W, Ti, Zr, or Cr deposited on AISI 316L stainless steel. Materials 2017, 10, 1189. [Google Scholar] [CrossRef] [PubMed]

- Lin, N.; Liu, Q.; Zou, J.; Guo, J.; Li, D.; Yuan, S.; Tang, B. Surface texturing-plasma nitriding duplex treatment for improving tribological performance of aisi 316 stainless steel. Materials 2016, 9, 875. [Google Scholar] [CrossRef] [PubMed]

- Vereschaka, A.; Aksenenko, A.; Sitnikov, N.; Migranov, M.; Shevchenko, S.; Sotova, C.; Andreev, N. Effect of adhesion and tribological properties of modified composite nanostructured multi-layer nitride coatings on WC-Co tools life. Tribol. Int. 2018, 128, 313–327. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 2004, 24, 981–988. [Google Scholar] [CrossRef]

- Archard, J.F. The temperature of rubbing surfaces. Wear 1959, 2, 438–455. [Google Scholar] [CrossRef]

- Archard, J.F.; Hirst, W. The wear of metals under unlubricated conditions. Proc. R. Soc. Lond. 1956, 236, 397–410. [Google Scholar] [CrossRef]

- Chen, X.; Han, Z.; Lu, K. Wear mechanism transition dominated by subsurface recrystallization structure in Cu–Al alloys. Wear 2014, 320, 41–50. [Google Scholar] [CrossRef]

- Wang, Y.; Yue, W.; She, D.; Fu, Z.; Huang, H.; Liu, J. Effects of surface nanocrystallization on tribological properties of 316l stainless steel under MoDTC/ZDDP lubrications. Tribol. Int. 2014, 79, 42–51. [Google Scholar] [CrossRef]

- Shaikh, Q.A.; Coleman, D.S.; Bates, J.; Nurthen, P.D.; Brewin, P.R. Wear and microstructural studies of alloy sintered steels. Met. Sci. Technol. 2014, 7, 728–738. [Google Scholar]

- Lim, S.C.; Isaacs, D.C.; McClean, R.H.; Brunton, J.H. The unlubricated wear of sintered steels. Tribol. Int. 1987, 20, 144–149. [Google Scholar] [CrossRef]

- Shen, M.X.; Zheng, J.P.; Meng, X.K.; Li, X.; Peng, X.D. Influence of Al2O3 particles on the friction and wear behaviors of nitrile rubber against 316l stainless steel. J. Zhejiang Univ. Sci. A 2015, 16, 151–160. [Google Scholar] [CrossRef]

- Qin, W.; Li, J.; Liu, Y.; Yue, W.; Wang, C.; Mao, Q.; Li, Y. Effect of rolling strain on the mechanical and tribological properties of 316L stainless steel. J. Tribol. 2018, in press. [Google Scholar] [CrossRef]

- Wu, X.; Yang, M.; Yuan, F.; Wu, G.; Wei, Y.; Huang, X.; Zhu, Y. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl. Acad. Sci. USA 2015, 112, 14501. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Cao, Y.; Gao, B.; Li, Y.; Zhu, Y. Superior strength and ductility of 316L stainless steel with heterogeneous lamella structure. J. Mater. Sci. 2018, 53, 10442–10456. [Google Scholar] [CrossRef]

- Wang, S.; Li, J.; Cao, Y.; Gao, B.; Mao, Q.; Li, Y. Thermal stability and tensile property of 316L stainless steel with heterogeneous lamella structure. Vacuum 2018, 152, 261–264. [Google Scholar] [CrossRef]

- Li, J.; Gao, B.; Huang, Z.; Zhou, H.; Mao, Q.; Li, Y. Design for strength-ductility synergy of 316L stainless steel with heterogeneous lamella structure through medium cold rolling and annealing. Vacuum 2018, 157, 128–135. [Google Scholar] [CrossRef]

- Qin, W.; Yue, W.; Wang, C. Controllable wear behaviors of silicon nitride sliding against sintered polycrystalline diamond via altering humidity. J. Am. Ceram. Soc. 2018, 101, 2506–2515. [Google Scholar] [CrossRef]

- Li, J.; Yue, W.; Qin, W.; Mao, Q.; Gao, B.; Li, Y. Effect of quenching processes on microstructures and tribological behaviors of polycrystalline diamond compact (PCD/WC-Co) in annealing treatment. Diam. Relat. Mater. 2017, 79, 79–87. [Google Scholar] [CrossRef]

- Wang, S.Q.; Wei, M.X.; Wang, F.; Cui, X.H.; Dong, C. Transition of mild wear to severe wear in oxidative wear of H21 steel. Tribol. Lett. 2008, 32, 67–72. [Google Scholar] [CrossRef]

| Material | Chemical Compositions (wt %) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cr | Ni | Mo | C | Si | Mn | P | S | Fe | |

| 316L | 16.47 | 10.10 | 1.97 | 0.03 | 0.53 | 1.42 | 0.03 | 0.005 | Bal. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, W.; Kang, J.; Li, J.; Yue, W.; Liu, Y.; She, D.; Mao, Q.; Li, Y. Tribological Behavior of the 316L Stainless Steel with Heterogeneous Lamella Structure. Materials 2018, 11, 1839. https://doi.org/10.3390/ma11101839

Qin W, Kang J, Li J, Yue W, Liu Y, She D, Mao Q, Li Y. Tribological Behavior of the 316L Stainless Steel with Heterogeneous Lamella Structure. Materials. 2018; 11(10):1839. https://doi.org/10.3390/ma11101839

Chicago/Turabian StyleQin, Wenbo, Jiajie Kang, Jiansheng Li, Wen Yue, Yaoyao Liu, Dingshun She, Qingzhong Mao, and Yusheng Li. 2018. "Tribological Behavior of the 316L Stainless Steel with Heterogeneous Lamella Structure" Materials 11, no. 10: 1839. https://doi.org/10.3390/ma11101839

APA StyleQin, W., Kang, J., Li, J., Yue, W., Liu, Y., She, D., Mao, Q., & Li, Y. (2018). Tribological Behavior of the 316L Stainless Steel with Heterogeneous Lamella Structure. Materials, 11(10), 1839. https://doi.org/10.3390/ma11101839