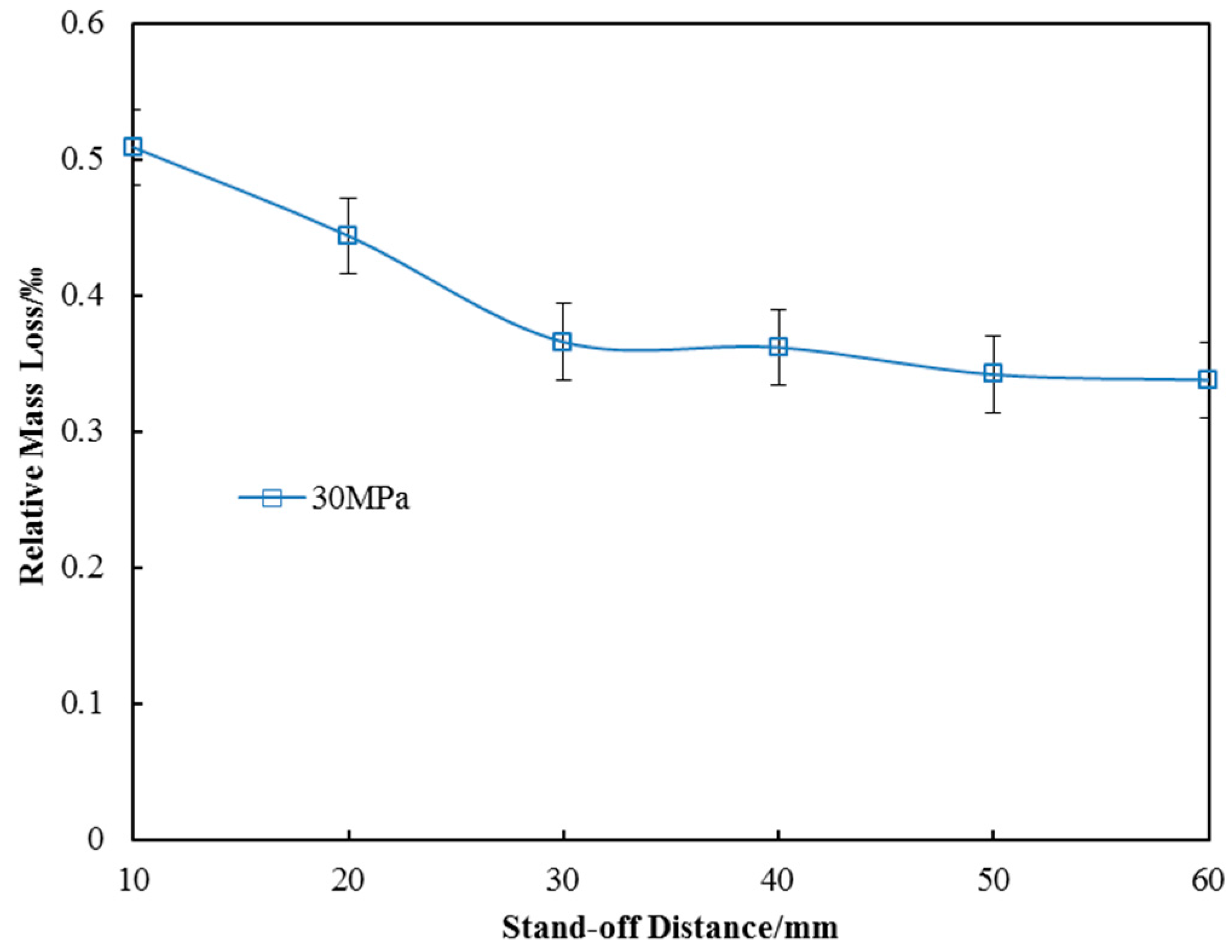

4.1. Mass Loss

Mass loss is an important indicator to ensure the feasibility of surface peening. If the parts weight decreases significantly in the surface treatment process, it will not only affect the physical properties of the material itself, but also adversely affect metal parts assembly and operation.

As is well-known, the higher the pressure, the greater the impact force of the waterjet beam. In order to verify the maximum mass loss under all operating pressures, the pressure of 30 MPa was selected for this test.

Figure 4 shows the relative mass loss of the specimens in the process of SOPWP. It is clearly shown that the mass loss decreases as the stand-off distance increases. Moreover, the slope of the mass loss curve is decreases with the increase in stand-off distance, indicating that the impact capacity of the waterjet beam is weakened. When the operating pressure is 30 MPa and the stand-off distance is 10 mm, the relative mass loss reaches its maximum value of 0.5‰. This is an acceptable value in the surface peening process.

There are two main reasons for the specimen mass loss in the process of SOPWP. Firstly, water hammer effect was generated due to the unique characteristics of SOPW itself. To be more specific, according to the theory of water hammer effect, the fluctuations in the instantaneous flow produce a huge instantaneous pressure which is 1.5–2.5 times that of a continuous waterjet. When high- speed water droplets impact on the aluminum alloy surface, most of the surface crystals bear the impact of the water droplets, and then generate plastic deformation. A small amount of metal crystals are eroded and forced to leave the specimens surface. Secondly, as all the experiments were conducted in a submerged environment, high-speed gradient was generated on the boundary between the high-velocity fluid and the surrounding stationary fluid. The regions where the local pressure was below the local vapor pressure appeared in turn, to stimulate the growth of cavitation nuclei. The cavitation bubbles grew further by evolving in the jets until they were close to the surface. In the process of bubble breakup, the high local pressure and micro jets impacted on the peening surface. As a result, the metal crystals were removed and the mass was slightly smaller than the untreated one.

4.2. Surface Topography

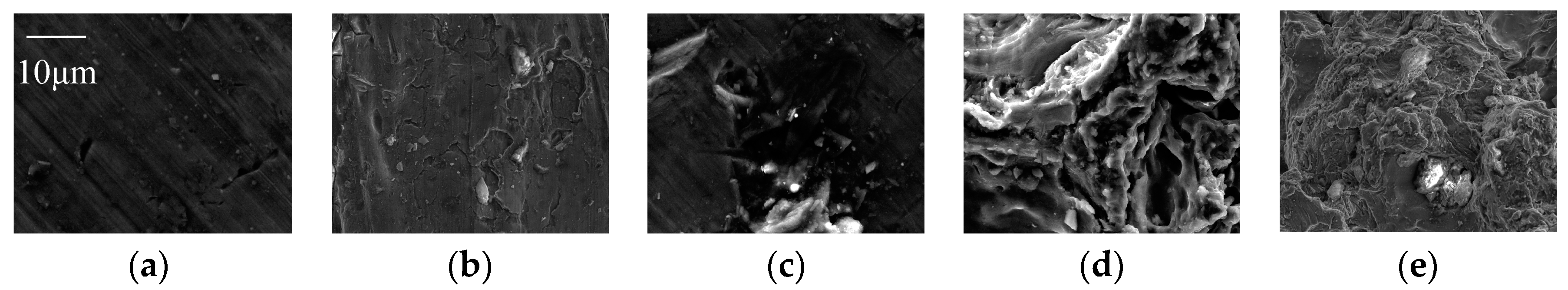

SEM was performed to analyze the microstructure of the specimens. These test results can help us to observe the peened surface micro topography directly, and then analyze the principles of the SOPWP.

Figure 5 and

Figure 6 are the surface topography of the processed aluminum alloy specimens.

Figure 5 shows the surface topography which was treated by SOPW using the operating pressures of 15, 20, 25 and 30 MPa at the scale of 100 μm, as well as an untreated one.

Figure 6 shows an untreated surface and the peened specimen’s surface treated by SOPW using the same pressures at the scale of 10 μm.

As is seen from

Figure 5a, the topography of the specimen surface is relatively smooth, which indicates that the original surface roughness is low enough to perform the tests. However,

Figure 5b–e show different surface topographies. For example, in

Figure 5b, there exist a few concave points on the surface. The concave points are dense but not too deep, indicating that the waterjet beam is capable of generating impact force on the metal surface. However, because the pressure is 15 MPa, the water droplets do not have enough energy to cause serious deformation. More details were showed in

Figure 6b. There are a few small particles attached on the specimen surface which are generated by the waterjet impaction. The diameters are about 2–5 μm. The concave points are also found at the scale of 10 μm and the depths are no more than 1 μm. Generally speaking, with an increase in operating pressures, surface topography becomes rougher according to the next images. Finally, in

Figure 5e when the operating pressure is 30 MPa, the specimen surface experiences a severe plastic deformation. As we can see, the peened surface has deep pits and a number of folds. Lots of small particles have appeared and gathered in the pits inside. On a smaller scale,

Figure 6e gives a more detailed and clear visual illustration of the pits and folds. The diameters of these pits vary from each other. Among the figures,

Figure 5d,e show similar characteristics of surface topography. This illustrates that the SOPW peening ability is almost the same when the operating pressures are 25 and 30 MPa. This kind of phenomenon also affects the surface roughness, hardness and residual stress in this experiment. The specific reasons are analyzed in the following section. Although the micro pits have adverse effects on material surface quality, a comprehensive analysis needs to be conducted to determine the optimal parameters.

When SOPW hits the specimen surface, there are two factors that affect the surface topography. On one hand, high-speed water droplets have a strong ability to compress and erode. Due to the characteristics of SOPW, the droplets hit the surface with a certain frequency with high pressure. The surface metal crystals do not have enough compressive stress. Thus, severe plastic deformation occurs on the specimen surface. As a result, the surface becomes rugged. The specimen surface crystals are compressed, fractured and deformed. On the other hand, as mentioned above, the generation of cavitation also plays an active role during the process of peening. The high temperature and pressure generated by the collapse of the bubbles can also affect the surface topography. The tiny particles may be caused by micro waterjets during cavitation. As a result, the SOPW has the ability to strengthen the material surface by generating the plastic deformation and thus, we know that with the increase in the waterjet pressure, the specimen surface gets rougher.

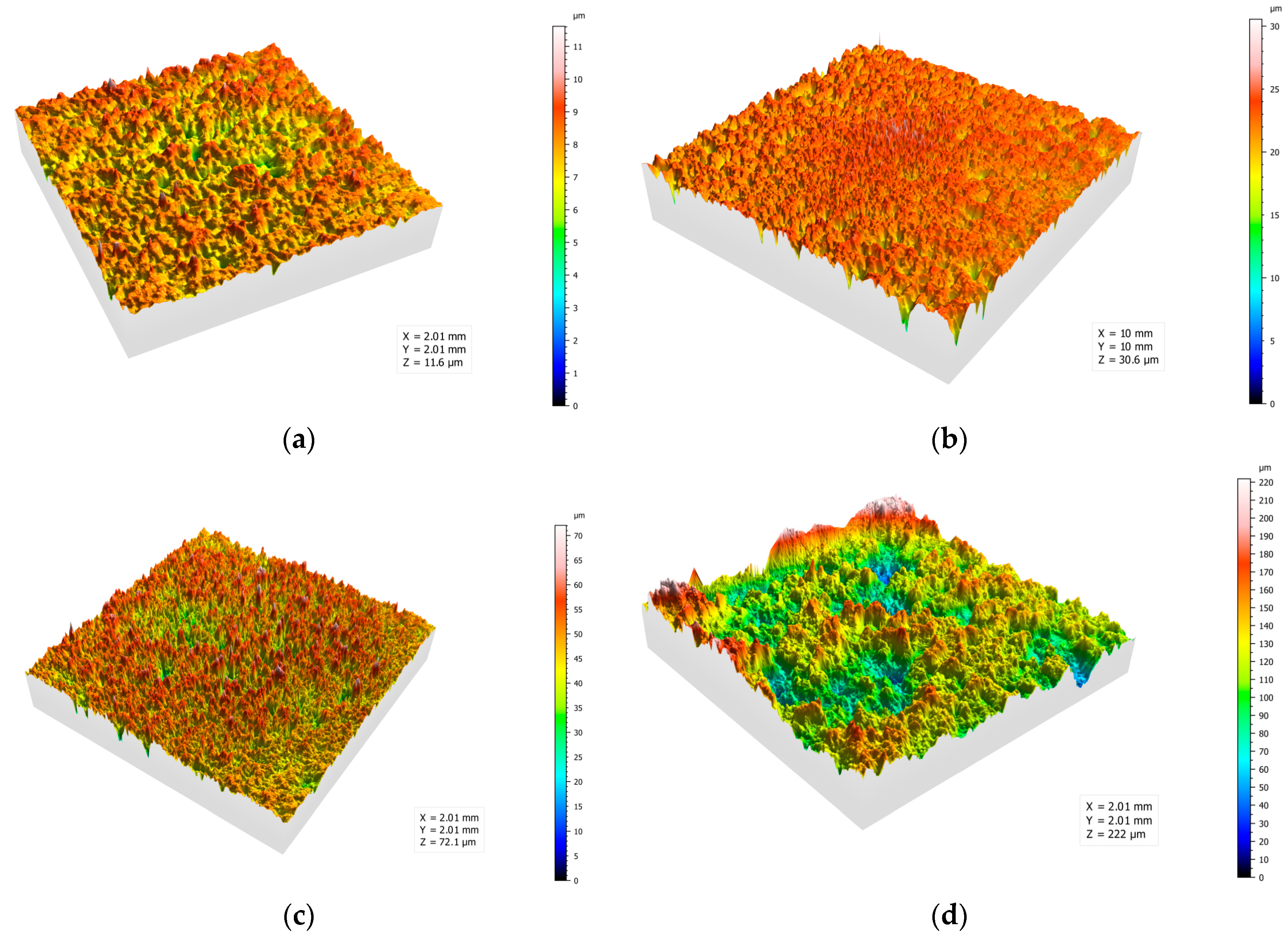

4.3. Surface Roughness

In order to further explore the relationship between surface roughness and SOPW parameters, the surface roughness measurements were conducted with an optical profiler. The 3D view, surface profiles and roughness distribution curve were shown to analyze the influence of SOPW on surface roughness.

Figure 7a–d show the 3D view of the surface topography from the optical profiler at 15, 20, 25 and 30 MPa. The stand-off distance is optimal at the parameter of 20 mm. As a whole, the specimen surfaces are rough with concave points and compressional folds. The height of the concave points ranges from 8 to 160 μm. The surface roughness increases with the increase in operating pressure, and the depth and height of the concave points become greater from an intuitive point of view. Especially in

Figure 7d, the concave points are overly impacted to form larger pits. We can infer from these images that concave points are formed by the impacting of SOPW, and the droplets cause metal crystals to compress, bend and deform. These crystals behaviors transform the mechanical property of the specimen surface.

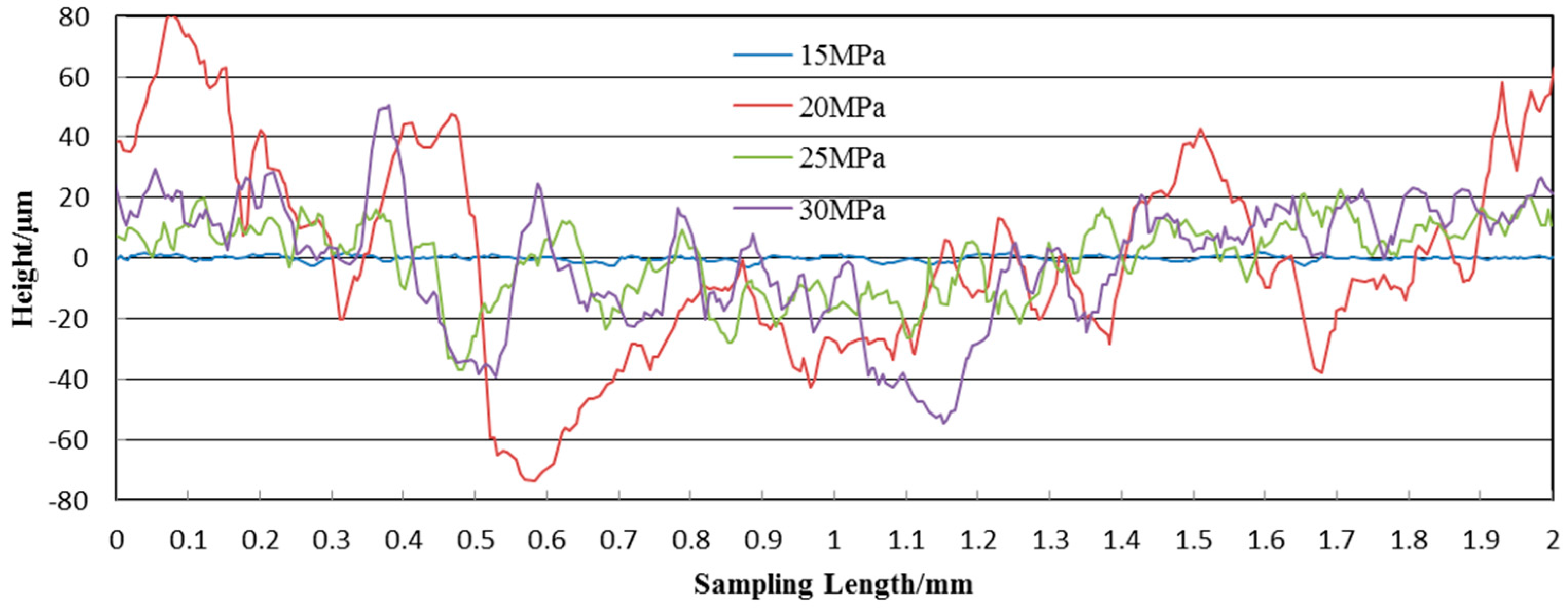

Figure 8 shows the profile lines of the peened specimen surfaces at four pressures. As we can see, the peak and valley values of the curves increase with the increasing pressure. For instance, the peak values are 15 and 80 μm when the pressures are 15 and 30 MPa, respectively. Besides, the trend of the profile lines is almost the same in

Figure 8 at 20, 25 and 30 MPa. There is only a mild increase in the surface roughness of the specimen. In contrast, the profile line under the pressure of 15 MPa exhibits significant changes in the curve patterns. It has more ups and downs than the others. This can be explained by the energy density and intensity in the water droplets. When the pressure is 15 MPa, each drop does not have the ability to destroy the surface alone. Although a large number of water droplets hit the surface continuously, they can only produce shallow indentations. However, as the pressure increases, water droplets have the energy to erode the surface. Each drop has a slight compression effect on the surface. After a long period of accumulation, the surface of the specimen has large potholes. This is just a qualitative analysis, quantitative analysis will be carried out next.

The arithmetical mean deviation of the profile (R

a) and maximum height of the profile (R

z) against stand-off distance under the four operating pressures are plotted in

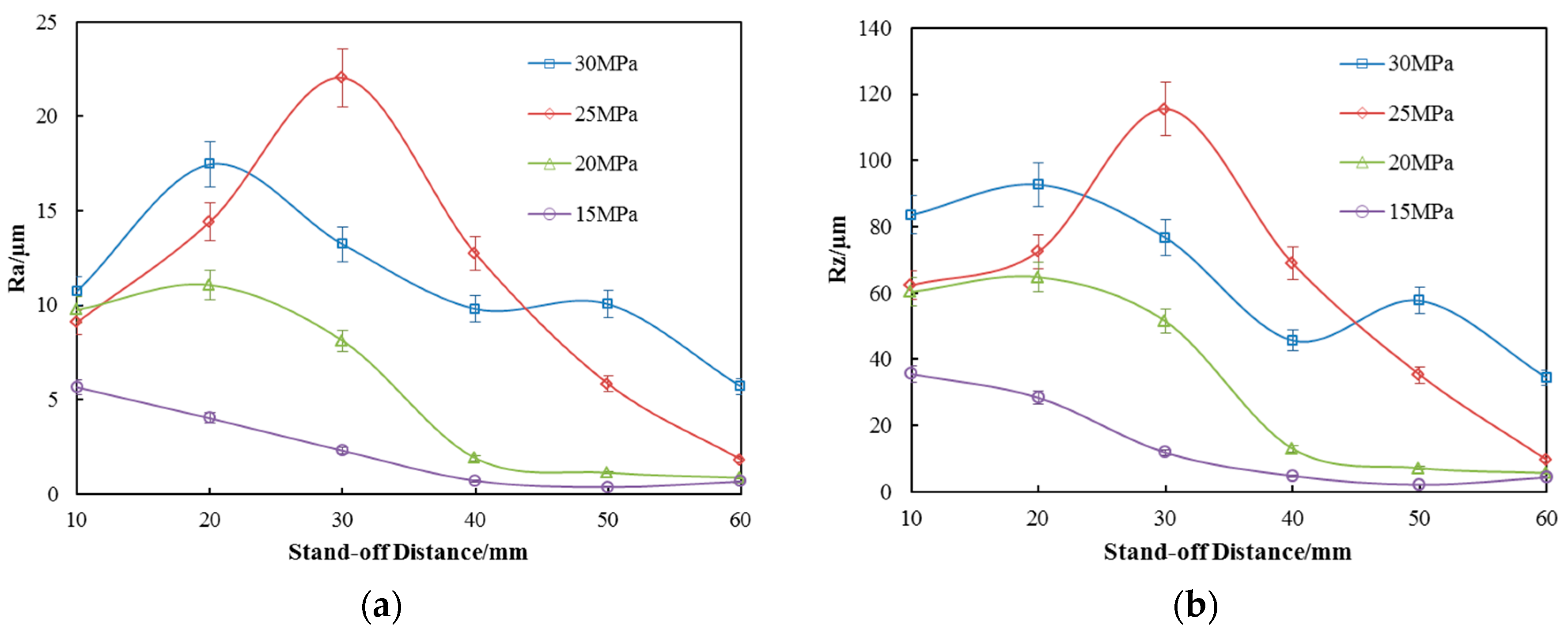

Figure 9a,b, respectively. The R

a of the untreated specimen surface is 0.5 μm which can be used as a baseline for comparison.

It is obvious that the SOPWP can make the surface rougher than the untreated surface at almost all the test stand-off distances; meaning, the peening capabilities of SOPWs are strong. This is in agreement with the previous findings on surface topography, which indicates the reliability of this experiment to a certain degree. Moreover, by taking the mass loss (shown in

Figure 4) into consideration, it can be determined that the mass loss caused by the peening process can be disregarded in the following discussion.

Figure 9a shows the arithmetical mean deviation of the profile (R

a) against stand-off distance under the four operating pressures. R

a is arithmetic mean value of the absolute value of the contour height. It is clearly observed in

Figure 9a that, the R

a increases with the increase in operating pressure. The SOPWP has a specific stand-off distance where the R

a reaches a maximum. The R

a first goes up and then drops with the increase in stand-off distance, which is independent of the operating pressure. However, the specific stand-off distance for each pressure is a little different. The existence of a specific stand-off distance depends on two facts. First, the organ-pipe nozzle produces different waterjet oscillation effects under different operating pressures. Secondly, the cavitation bubbles generated around the periphery of the jet need a certain time to grow to the appropriate size, until they collapse and yield micro jets or pressure strong enough to strengthen the surface. In more specific terms, when stand-off distance is 10 mm and the operating pressure is 30 MPa, the R

a is about 10.8 ± 0.54 μm. Then, the R

a increases with the stand-off distance increasing until the stand-off distance reaches 20 mm. The R

a reaches a maximum value of 17 ± 0.85 μm. Then, the R

a in all operating pressures decreases with the increase in stand-off distance except for an operating pressure of 25 MPa. When the pressure reaches 25 MPa and the stand-off distance is 30 mm, the surface average roughness (R

a) reaches its maximum value, 22 ± 1.1 μm which is much larger than the one at 30 MPa. Lastly, the R

a of all the pressures goes down when stand-off distance is greater than 30 mm.

Figure 9b shows the maximum height of the profile (R

z). It is obvious that the tendency of R

z against stand-off distance under the four operating pressures is similar to R

a. There is just a numerical difference. The R

z first goes up and then drops down with the increase in stand-off distance, which is independent of the operating pressures. At the stand-off distance of 20 mm, the R

z reaches a maximum of 95 ± 4.75 μm with a pressure of 30 MPa, and the R

z reaches a maximum value of 120 ± 6 μm when the operating pressure is 25 MPa. Lastly, the R

z of all the pressures goes down when the stand-off distance is greater than 30 mm. It can be inferred that the maximum height of the profile shares the same characteristics as the arithmetical mean deviation of the profile.

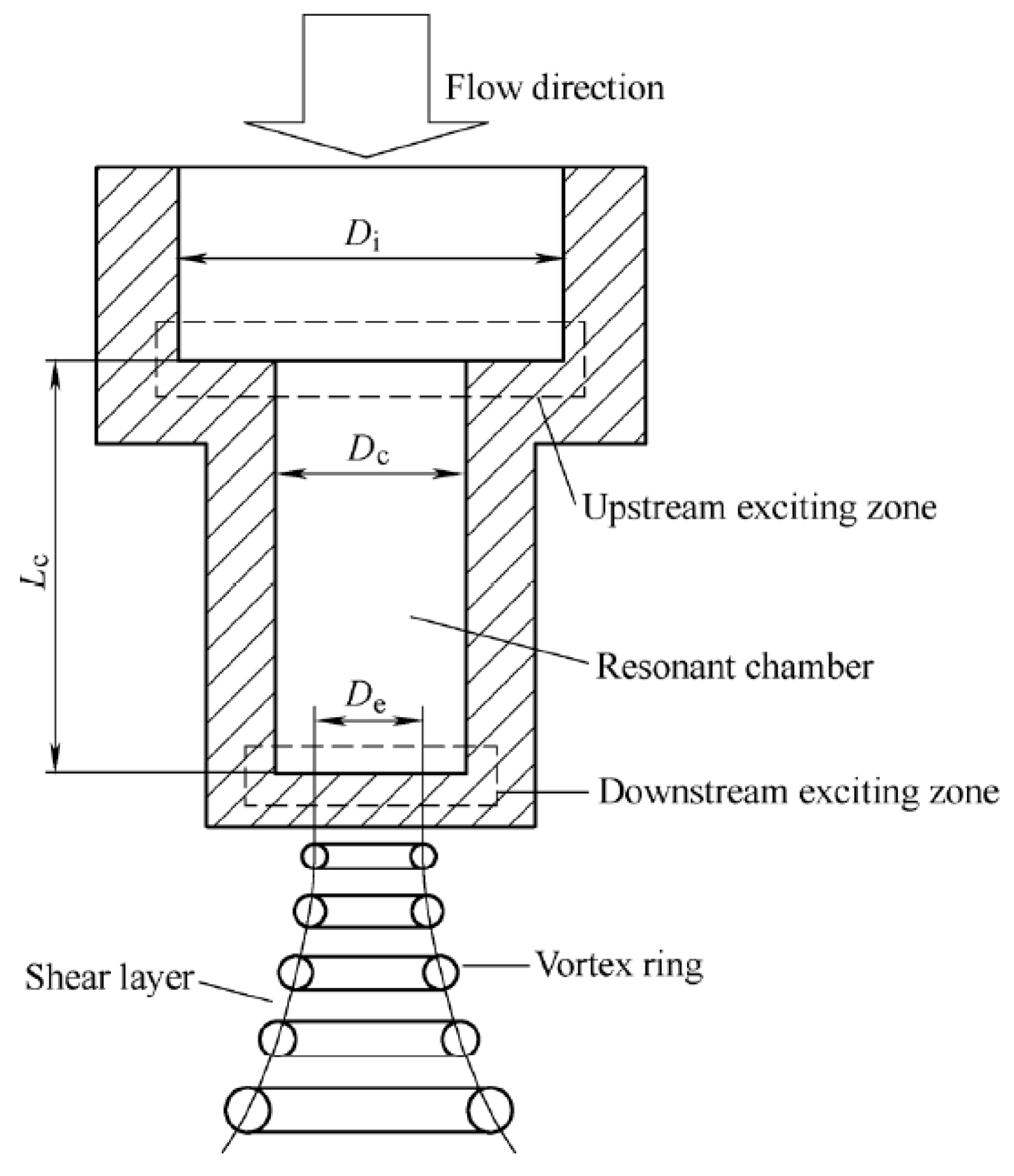

As for the trend of surface roughness described above, it was interesting to find that the roughness at 25 MPa is different with respect to the others. At the stand-off distance of 30 mm and 40 mm, the roughness of the 25 MPa is greater than the others, especially at 30 MPa. Combined with the above description of the surface topography, there are several ways to explain this phenomenon. First of all, the impact effect of SOPW is related to operating pressures. It is not a simple linear relationship. There exists an optimal pressure that can make the oscillation effect most obvious. The oscillation intensity can have a significant effect on surface topography and surface hardness. Secondly, according to the generation mechanism of SOPW, the exact frequency for peak resonance is dependent on the end impedances, which in turn depend on the upstream contraction ratio (Di/Dc) and the downstream contraction ratio (Dc/De), respectively. In other words, the specific geometric parameters and operating pressure determine the SOPW behaviors. In our experiment, when operating pressure is 25 MPa, the nozzle has the best impinging performance when compared to other pressures. So, the surface hardness at a pressure of 25 MPa is higher than that at a pressure of 30 MPa.

In general, the results clearly show that the SOPWP has an obvious effect on the surface roughness at different operating pressures. Surface roughness is an important evaluation indicator in the manufacturing process related to mechanical coordination, resistance to corrosion and abrasive resistance. It is one of the most significant indicators that determine the part’s qualities. As we carried out the SOPWP to strengthen the surface, roughness is something that had to be suppressed. The experiments results show that the roughness has improved somewhat. However, compared to shot peening and abrasive waterjet peening where roughness is more than 30 μm, the SOPWP surface roughness is much less and smoother. It is also helpful in the following processing procedure.

4.4. Surface Hardness Distribution

As severe plastic deformation is generated in the process of SOPWP, the surfaces roughness is increased to a certain degree which is negative to the surface property [

28]. However, the surface metal crystals are squeezed due to the plastic deformation, resulting in the formation of a hardened layer. In order to determine the surface hardness variation, Vickers hardness tests were conducted with different operating pressures and stand-off distances.

The surface hardness distribution is plotted against stand-off distance under four operating pressures in

Figure 10. As we can see from the graph, the surface hardness of peened specimens is actually greater than that of untreated specimens. In addition, the Vickers hardness is increasing with the increase in operating pressure. For example, when the stand-off distance is 10 mm, the Vickers hardness of the surfaces are 215.45 ± 6.46, 186.6 ± 5.6, 154.8 ± 4.64 and 133.25 ± 4 HV at the operating pressures of 30, 25, 20 and 15 MPa, respectively. The average of treated-surface hardness is 1.5 times greater than the untreated surface. This is equivalent to the shot peening and better than conventional waterjet peening. Besides, the surface hardness decreases with the increase in the stand-off distance which is independent of operating pressure. The downward trend is basically linear. This indicates that the instantaneous pressure of SOPW goes down with the increase in stand-off distance. According to the theory of waterjets, the geometry of the jet is divided into the initial region, the transition region, and the basic region. The velocity of the core region in the initial region is the same as the velocity of the nozzle outlet which is greater than other regions. The length of the initial region is decreased with the decreasing pressure. As a result, when operating pressure is 30 MPa, the hardness is almost the same as during the stand-off distances from 10 to 20 mm, which is in the core region of the initial region. When the stand-off distance is outside the core region, the jet velocity and the pressure decreases with the increase in stand-off distance.

Surface hardness is a measuring method for solid matter surface resistant to various kinds of permanent shape change when a compressive force is applied. It relates to wear resistance, pressure resistance and stability of material surface. Generally speaking, surface hardness is an important indicator of the normal use of metal materials. SOPWP improves the surface hardness of the material by the cold-processing method. Due to the characteristics of SOPW, the instantaneous pressure is much larger than that of the continuous waterjet. The droplets with more kinetic energy impact on the material surface directly, causing severe plastic deformation. As a result, the hard layer is deformed. In the process of peening, the metal crystals are compressed by water droplets. The original arrangement of metal crystals is damaged and the crystals are forced to move away from the original location. Crystal dislocation and folds are thus generated. This dislocation and the folds are used to protect the internal metal from friction and extrusion. Besides, the hardened layer is beneficial to prevent the crack initiation from the metal surface. So, the SOPWP achieves the same goal with a smaller pressure than conventional waterjet peening.

4.5. Surface Residual Stress Distribution

In the process of manufacturing, the stress induced by cutting or local temperature will remain on the surface. Generally speaking, these stresses are almost residual tensile stress which largely contributes cracks [

29,

30]. In other words, the fatigue life of metal materials will be greatly improved if the residual tensile stress becomes smaller or translates into residual compressive stress. Therefore, the SOPWP process aims at generating residual compressive stress on the surface. The untreated surface residual stress is about −36.2 MPa as it was produced by the rolling method.

Figure 11 shows the residual stress distribution of the peened surface against stand-off distance at four operating pressures. As we can see from the graph, residual compressive stresses were indeed produced as the stresses are negative along the vertical coordinates. As the stress of untreated surface is −36.2 ± 1.81 MPa, the maximum of the stress value by SOPWP is −122.35 ± 6.12 MPa indicating that the SOPWP is able to increase the residual compressive stress. Furthermore, the residual compressive stress is slightly decreased when the stand-off distance increases. This is because the surge pressure goes down when the nozzle gets far away from the specimens. The residual compressive stresses are increased with the increase in the operating pressure, in general. However, when the operating pressure is 30 MPa and the stand-off distance is 10 mm, the value of the residual stress is smaller. By observing the surface topography, it is found that the surface which peened at 30 MPa and 10 mm was slightly eroded and the most superficial metal was gone in the process of peening. It can be inferred from this phenomenon, that at the beginning of the peening process, the hardened layer was generated and the residual compressive stress was accumulated by the water droplet impact. With the extension of the SOPWP time, the power is so great that the surface is not strong enough to resist impacting. As a result, the hardened layer generated by water droplets impacting was eroded off. The residual compressive stress does not have enough time to accumulate under such circumstance.

The residual compressive stresses are obviously improved by SOPWP according to the results above. It can be argued that the deformation energy is stored in the material by the SOPWP application. A material having compressive residual stress helps to prevent brittle fracture because the initial crack can be formed under compressive (negative tensile) stress. To cause brittle fracture by crack propagation of the initial crack, the external tensile stress must overcome the compressive residual stress before the crack tips experience sufficient tensile stress to propagate. So, it can be confirmed that the larger the residual compressive stress, the longer the fatigue life. Under the experimental conditions, the highest residual compressive stress occurs at an operating pressure of 30 MPa and stand-off distance of 20 mm. Under such parameters, Ra and Rz of the specimen surface are 17 and 86.2 μm, and the hardness of the specimen surface is 212 HV. Taking the roughness and hardness, as well as the residual stress of the specimen surface into consideration, the optimal parameters can be determined as 30 MPa and 20 mm. With the obtained experimental parameters, the physical properties of the peened materials can be applied in industrial practice.