3.1. Phase Transformation Probed by XRD

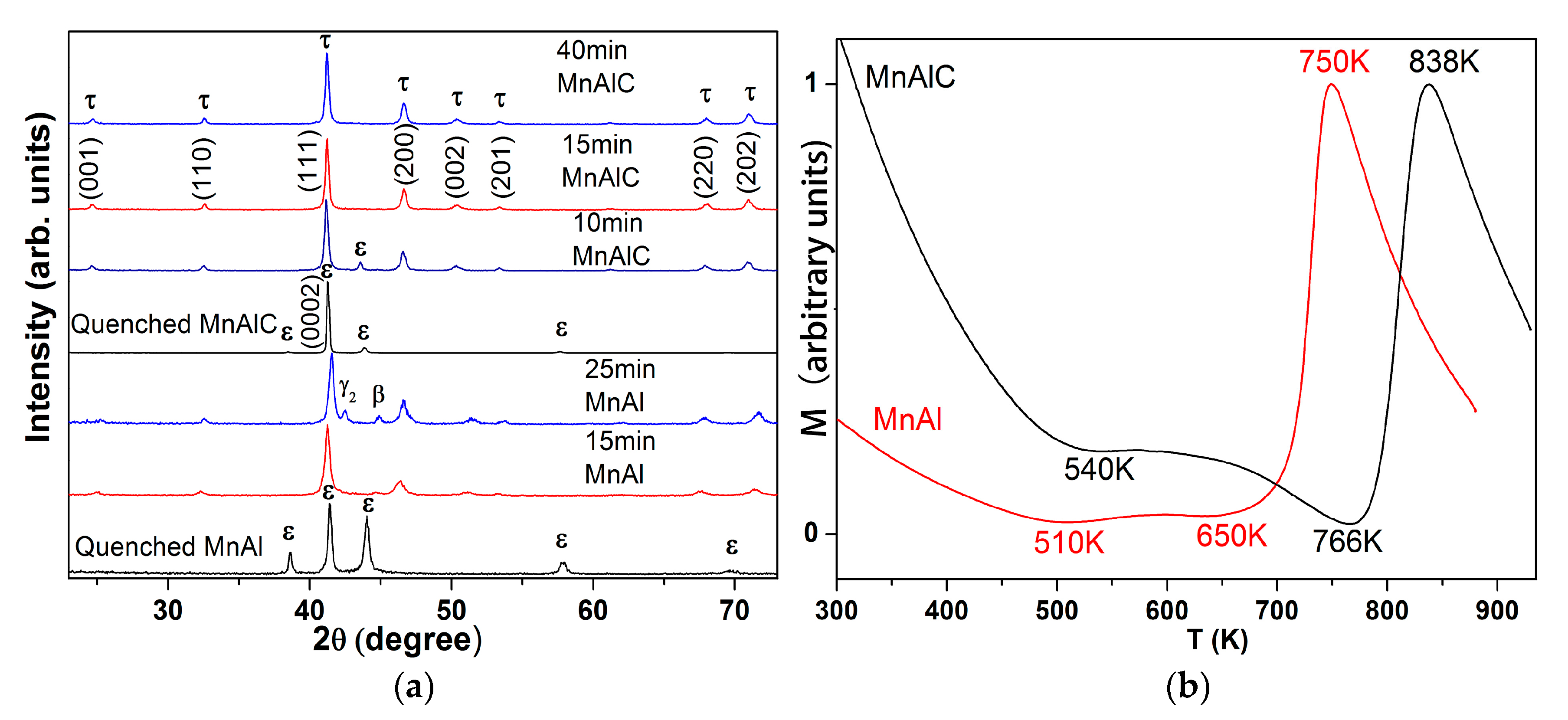

The XRD patterns of both MnAl and MnAlC alloys after 1423 K-homogenization followed by water quenching could be indexed with a single ε-phase, as shown in

Figure 1a. Both ε-MnAl and ε-MnAlC, when heated at 773 K, transformed into pure τ-phase in 15 min. Trace amounts of γ

2 and β phases precipitate from τ-MnAl after heating for 25 min, indicating decomposition of τ-MnAl under prolonged heating time at 773 K, owing to the lower decomposition temperature of τ-MnAl as determined by magnetic measurements below. However, no decomposition was found in the τ-MnAlC after heating for 40 min, indicating a structural stabilization effect of carbon in the lattices. Both ε- and τ-phases exist in MnAlC heated for 10 min, indicating incomplete PT in this stage. The time windows for the precipitation of different phases during the ε→τ PT at 773 K are important for guiding the following

in situ TEM heating and observations. The stress level and grain size of the ε- and τ-phase, both of which are metastable, might have effect on the position and broadening of the XRD peaks. The (111) peak of the τ-MnAl obtained by 25-min annealing shifts slightly to a higher degree in comparison with that of the τ-MnAl obtained by 15-min annealing, indicating smaller lattice parameters of τ-MnAl after prolonged annealing. The reduced lattice parameters of the τ-MnAl obtained by 25-min annealing were ascribed to its partial decomposition during prolonged annealing that can, to some extent, release the lattice stresses. In comparison with τ-MnAlC, the τ-MnAl exhibits broadened diffraction peaks, as shown in

Figure 1a, indicating smaller grain size of τ-MnAl than that of τ-MnAlC.

It is interesting that the ε-MnAlC shows a much stronger diffraction peak of (0002) planes and very weak diffraction of the other planes. For comparison, the X-ray diffraction intensities of different planes in ε-MnAl do not vary much. According to the Scherrer equation, the intensity of X-ray diffraction is largely dependent on the crystalline dimensions or size in the samples. Therefore, the strong diffraction peak of the (0002) plane in ε-MnAlC might indicate a larger dimension of the ε-phase along the c-axis than that along directions perpendicular to the c-axis. The comparable diffraction intensities of different peaks in ε-MnAl indicate comparable dimensions of the ε-phase in different directions. It seems that the carbon atoms in ε-MnAl(C) lattices hinder the growth of ε-phase along the basal plane and thus the dimension of atomic long-range ordering along the basal plane is reduced.

3.2. Phase Transformation Probed by M-T Curves

Figure 1b plots the temperature dependence of magnetization of the ε-MnAl and ε-MnAlC measured with increasing temperature (20 K/min) under an applied field of 2 Tesla. The magnetization of paramagnetic ε-MnAl/ε-MnAlC decreases with increasing temperature from 300 K due to thermal agitation. However, the downward tendency of M reversed at temperatures above 510 K and 540 K for MnAl and MnAlC, respectively, indicating transformation of paramagnetic ε/ε’ to ferromagnetic τ-phase. The magnetizations of MnAl and MnAlC do not vary too much at 510–650 K and 540–766 K, respectively, indicating the occurrence of additional magnetization in compensation of the thermal driven magnetization loss in this temperature range. The PT during this stage was slow and was ascribed to the displacive PT, which is a low temperature diffusionless process involving co-operative shear movements of atoms on (001) ε’ along [010] ε’ that produces the final tetragonal lattice of τ-phase.

A sharp magnetization increase was observed at temperatures above 650 K and 766 K for MnAl and MnAlC, respectively, indicating occurrence of high-rate PT in the samples. The PT during this stage was fast and was ascribed to the massive growth of τ-phase from paramagnetic ε/ε’-phase. It should be noted that the τ-phase is paramagnetic in this temperature range for the Curie temperature Tc of our τ-MnAl and τ-MnAlC is measured to be ~630 K and ~550 K, respectively. This sharp magnetization increase for τ-phase in high temperature paramagnetic state could be explained by Curie–Weiss law. The M of most substances, no matter ferromagnetic or paramagnetic, normally decreases with increasing temperature in the presence of a certain external field due to thermal agitation. However, for substances with thermal driven phase transformation, the fraction change of different phases may result in abnormal temperature dependence of magnetization. For ferromagnetic τ-phase at temperatures above Tc, the paramagnetic behavior follows the Curie–Weiss law, M = CH/(T − θ), where the term θ describes the exchange interaction that is present albeit overcome by thermal motion. The sign of θ is positive for ferromagnetic τ-phase and is negative for antiferromagnetic/papramagnetic ε-ε’-phase, respectively. As a result, the paramagnetic τ-phase shows much larger magnetization than ε-phase.

At temperatures above 750 K (838 K), the magnetization of MnAl (MnAlC) decreases quickly with increasing temperature, indicating decomposition of the ferromagnetic τ-phase or possibly a completion of the PT. This result shows the reason for the decomposition of τ-MnAl and no decomposition of τ-MnAlC at 773 K as observed in the above XRD patterns. The annealing temperature of 773 K is higher (lower) than the decomposition temperature of τ-MnAl (τ-MnAlC). As a result, τ-MnAl decomposed while τ-MnAlC did not decompose after prolonged heating time.

It is known that the addition of a small amount of carbon (within the solubility limits) could stabilize the τ-phase of MnAl as evidenced that τ-MnAl tends to decompose into γ

2 and β-phase while τ-MnAlC does not decompose in the same heat treatment conditions. The mechanisms for such a stabilizing effect can be found in

Figure 1b, which shows that the minimal temperature (766 K) for activation of massive growth of τ-MnAlC is higher than the decomposing temperature (750 K) of τ-MnAl. As a result, it is not strange to observe the decomposition of τ-MnAl if we want to obtain τ-MnAlC by the same heating process. In fact, carbon not only increases the decomposition temperature of τ-phase, but also increases the activation temperatures for both displacive and massive transformations of ε-phase, as shown in

Figure 1b. This result is in agreement with the results in reference [

4]. It seems that carbon increased the energy barriers of the PT and phase decomposition.

3.3. Short-Range Displacive Mode Probed by In situ TEM

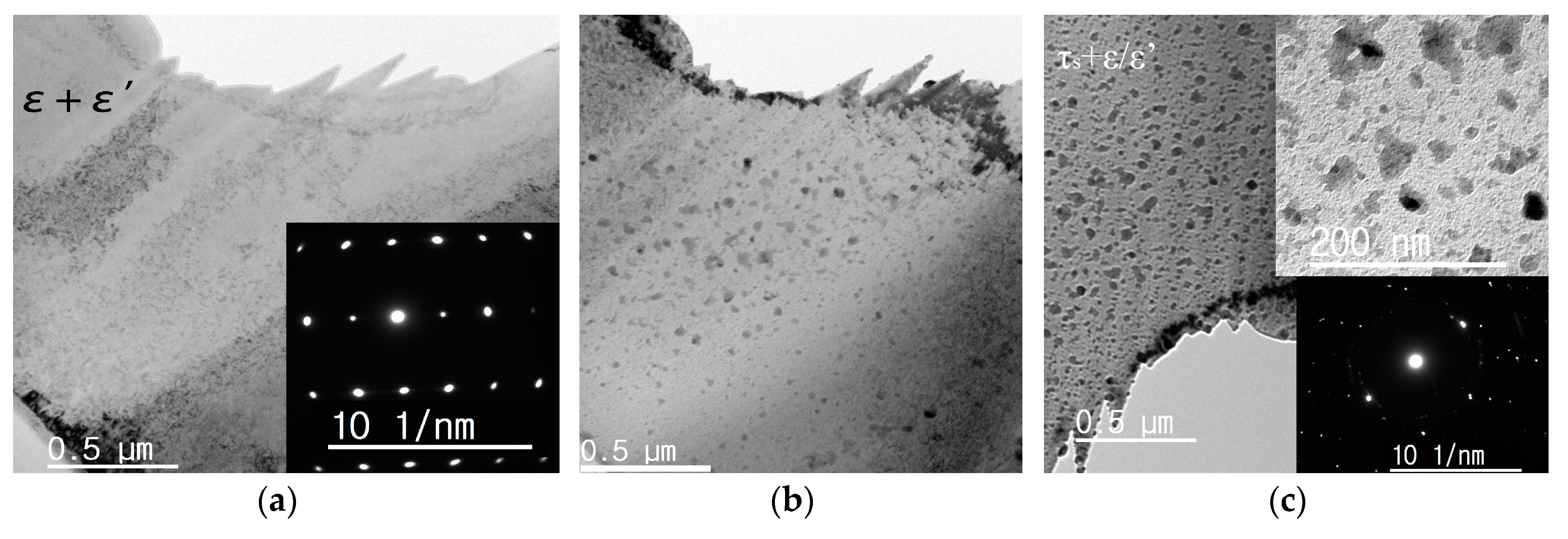

The

in situ heating TEM bright field images of the ε-MnAlC within the initial 10 min are shown in

Figure 2. The parent ε-MnAlC shows a continuous bright contrast before heating, as seen in

Figure 2a. It had been proved that the water-quenched materials, which from X-ray analysis were expected to be pure hexagonal ε-phase, already contain numerous small nuclei of the ordered orthorhombic ε’-phase that are 4–10 nm in size, which grows to 30–40 nm upon heating to 723 K [

17].

The ε→ε’ process is one of ordering in the close-packed

c-plane of the six-fold symmetry hcp structure. The reduction in symmetry to twofold caused by the ordering results in the orthorhombic unit cell of the ε’-phase. Therefore, there are three symmetry-equivalent variants for ε’ in one original ε crystal. The orientation relationships between the ε-phase and the three variants of ε’ precipitates are as follows: [

19]

The ε/ε’ phase, when heated for several minutes, starts to precipitate small τ-grains, as shown in

Figure 2b.

Figure 2c shows that the small τ-grains embedded in the ε/ε’ matrix grows slowly to a maximum size of about 40 nm with increasing heating time. It is interesting that these evenly distributed τ-grains could not grow further when its size reached ~40 nm, which is the size of a ε’ grain as observed previously [

17]. The distribution of isolated island-like τ-grains embedded in ε-matrix is quite different from the massive transformation characteristics, but could be well explained by the displacive mode.

Although there are three variants of ε’, only one type of partial dislocation can shear one of the three possible ε’-phase variants that may be produced in a given ε-grain into the L1

0 structure with the required correct ordering of atoms. If several partial dislocations glide on every other close-packed plane of the parent phase in which there are two or three variants of ε’, the resulting structure will not be L1

0. Hence, in a given ε-phase grain, one ‘correct’ variant and two obstacle variants of the ε’-phase exist [

19]. The two obstacle ε’ variants neighboring to the correct one have largely restrained the maximal size of τ-grain formed by displacive mode. The τ-phase grows through the motion of the partial dislocations along the close-packed plane. When a dislocation encounters the obstacle variants of ε

2’ and ε

3’, its motion is obstructed. The ε

2’ and ε

3’ variants have to reorder to become τ-phase. However, motion of a partial dislocation group with a Burgers vector that transforms ε

1’ into the correct L1

0 order would not lead to the formation of the L1

0 structure from ε

2’ and ε

3’, but to a higher energy structure which was not observed. The strain originating from the transformation of ε

1’ to τ and obstacle effect of ε

2’ and ε

3’ would hinder the subsequent growth of τ-grains. There are also some larger τ-islands that were actually composed of two or three connected smaller τ-grains, owing to the presence of neighboring ε’ variants of the same type. The inset of

Figure 2c shows that the region for τ-phase with dark contrast accounts roughly one-third of the total area in view. This further proved that only one of the three variants was transformed into τ-phase by displacive mode. More evidence for this one-third phenomenon could be found in the following magnetic measurements. The small τ-gains are also difficult to propagate to the neighboring ε’ grains through the boundaries via shear mode due to incoherent interfaces and increasing shear strains.

In fact, it is difficult to observe the transformation sequence of these three ε’ variants by postmortem TEM because we could not distinguish the τ-phase formed by different variants. Our

in situ TEM observations provide the time resolution for these transformations. Besides many small τ-grains formed in the parent ε-grains through shear mode (marked as τ

s), a much larger τ-grain with size up to 180 nm nucleated at grain boundary has also been observed with increasing observation time. The τ-phase grown at grain boundaries has been proved to be crucial for the massive mode of PT [

19,

20].

3.4. Long-Range Massive Mode Probed by In situ TEM

The massive transformation is generally defined as a compositionally invariant nucleation and growth process involving a change in crystal structure and/or degree of long-range order. The growth of the massive τ-phase in MnAl is accomplished with the migration of incoherent heterophase interfaces by essentially random atomic attachment across the growth interface and is associated with the genesis of characteristic defect such as stacking faults, microtwins, and antiphase boundaries in the τ-phase product [

19]. Since the shear mode itself could not transform all the ε-phase into τ-phase, a diffusion controlled reordering process must occur for all the three ε’ variants to transform into τ finally, but it is not clear when it takes place. Two possible mechanisms for (ε

2’ and ε

3’)→τ were proposed in the previous work [

16]. It might occur in the bulk as a consequence of coarsening of ε

1’. A second possibility is that the reordering occurs near the core of the transformation dislocations where diffusion is enhanced. Our work shows that the ε

2’ and ε

3’ transformed into τ mainly through thermally activated massive diffusional process. As mentioned above, the grain size of τ formed via coarsening of ε

1’ usually is no larger than 40 nm, thus the enhancing diffusion in the ε

1’→τ transformation dislocations should be very limited. For comparison, the growth rate and the maximal grain size of the τ-phase produced via diffusional process is much higher and larger than that formed via displacive mode.

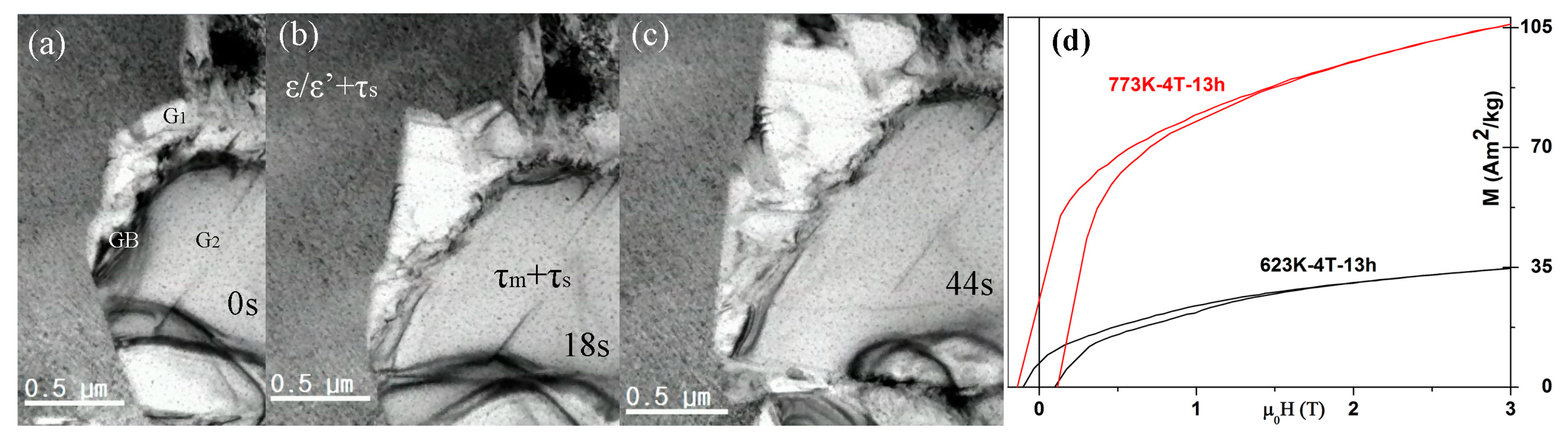

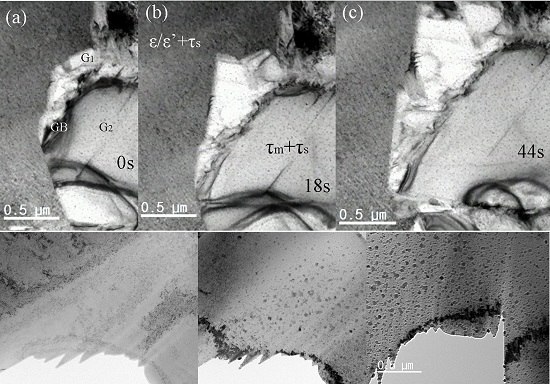

Figure 3a–c (

Video 1 in the supplementary materials) shows the growth process of the τ-phase via massive mode. These videos and micrographs captured a number of unique features of τ-phase formation in the MnAlC alloys. First, the small τ

s-grains formed via displacive transformation from ε

1’ make almost no change during the massive transformation of the surrounding ε/ε’ to τ

m, resulting in a structure of τ

s embedded in τ

m, as seen in

Figure 3a–c. It should be noted that the size of the τ

s-grains might vary a little with massive transformation rate and temperature. Since the τ

s-grains near the massive transformation frontiers do not have enough time for full coarsening of τ

s via displacive mode, the grain size of τ

s thus should be smaller than those far from the massive transformation frontiers, as proved by the smaller grain size of τ

s in

Figure 3 than that in

Figure 2. Of course, the obscure boundaries between τ

m and τ

s might also result in a seemingly smaller τ

s size. Usually, the thermally activated massive transformation is accelerated with increasing temperature, a fast enough massive transformation might transform all the samples into τ in several seconds and give little time for τ

s to grow and for us to observe by

in situ TEM. It is also possible for the metastable τ

s to be consumed by τ

m through diffusional process at higher temperatures. The τ-phase can form via massive mode without prior ε→ε’ ordering at high enough temperatures [

19]. The annealing at 773 K provides a medium massive transformation rate and thus both modes are observed

in situ.

Second, the rate of the propagation of the massive transformation front ranges from 8 nm/s to 60 nm/s, depending on the front shape. The propagation rates of the inter-phase interface with arc-shape, straight shape, and sharp-angle tip of τ

m are ~8, ~10, and ~16 nm/s, respectively. The ε/ε’ phase in the sharp angle in-between two τ

m grains transforms at a rate up to 60 nm/s, which slows down quickly when the sharp angle becomes obtuse due to ε/ε’→τ transformations. It should be noted that the high rate area is very limited while most linear growth rates are falling in the range 8–16 nm/s. Yanar et al. analyzed the growth kinetics of the τ phase in the Mn-Al-C alloys using modified Burke–Turnbull equation and postmortem TEM, yielding a linear growth velocity of ~1 μm/s [

20], which is much larger than what we observed by

in situ TEM. Yanar et al. determined the growth rate by dividing the growth distance by the estimated time of growth, while the growth distance was calculated by averaging maximum size measured in five τ colonies [

20]. We speculate that one τ colony in the postmortem TEM sample might contain several or more τ grains grown from different nuclei at the same time, thus the growth distance might be overestimated. In fact, our

in situ TEM studies showed that there are many τ grains grown from many different τ nuclei distributed in the sample. If several τ grains from different nuclei met together and grew into one τ colony, it is difficult to distinguish them by postmortem TEM observations. By applying the modified Burke–Turnbull equation and the average growth rate observed by our

in situ TEM, the activation energy for diffusional growth in MnAlC is estimated to be 182.5 kJ/mol, which falls in the range of that reported by Lu et.al but is higher than that estimated by Yanar et al. [

20,

21].

Third, new τ grains tend to grow along the boundaries of the as-formed τm grains. The growth of one τm is hindered when encountered another τm–grain. Stacking faults during the transformation are usually accumulated in the grain boundaries between the τm grains. The prominent facets that appear in the growing τ phase colonies are incoherent interfaces with no systematic orientation relationship with the parent ε/ε’ phase.

The magnetizations of MnAlC after fully PT at different temperatures through different modes further proved that one-third of the ε-phase in maximal could transform into τ via displacive mode.

Figure 3d shows the room temperature magnetic hysteresis loops of the ε-MnAlC after 13-h annealing in 4 T. The field-assisted long-time annealing provides full transformation of τ-phase in ε-MnAlC at 623 K via displacive mode and at 773 K via both modes. The saturation magnetization (35 Am

2/kg) of the 623 K annealed sample is approximately one-third of that (~105 Am

2/kg) in the 773 K annealed sample. This proved that only one of three possible ε’ variants were transformed via displacive mode into τ-phase at 623 K, a temperature at which massive transformation is impossible. This is in good agreement with the above TEM observations, in which τ

s grains covered approximately one-third of the field in view. The Curie temperature for our τ-MnAl and τ-MnAlC is measured (not shown here) to be 630 K and 550 K, respectively. The addition of carbon significantly decreased the Curie temperature of τ-MnAl.

3.5. Phase Transformation Fraction/Rate Probed by M-H/M-t Curves

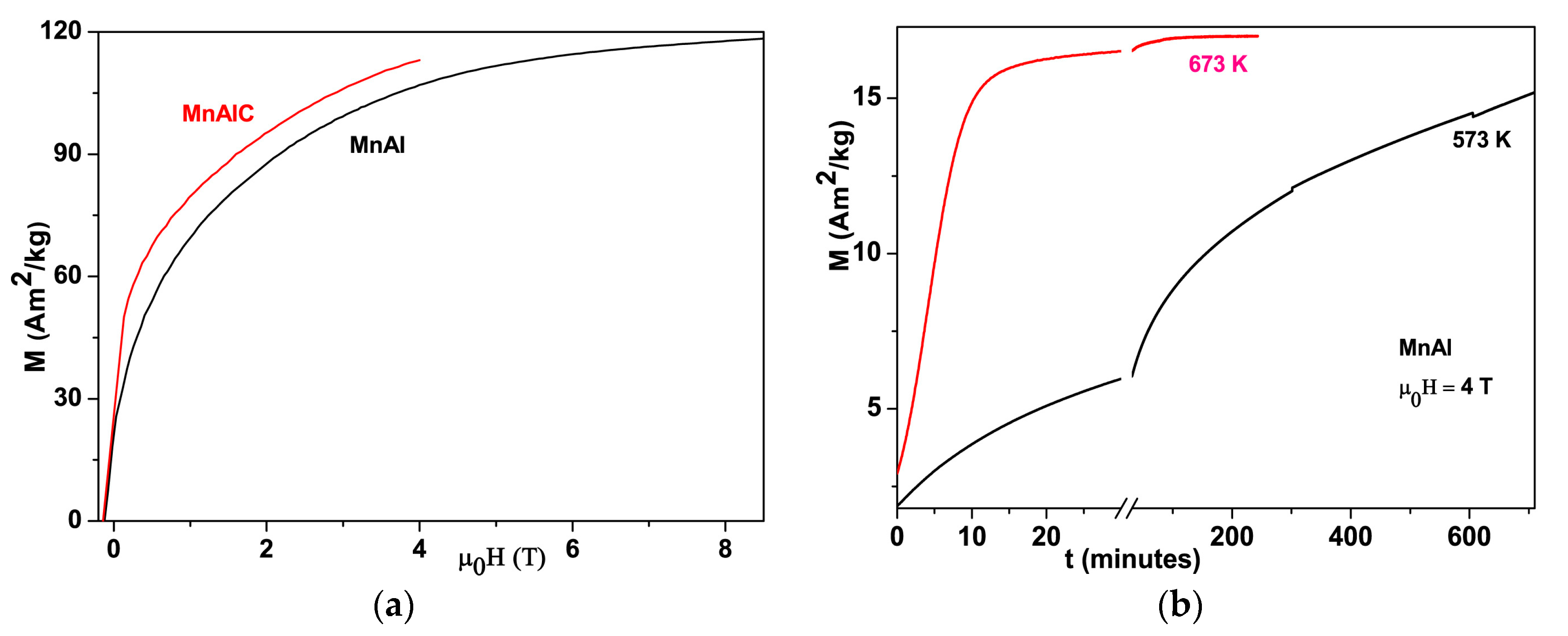

The magnetization of the samples is largely dependent on the fraction of transformation from nonmagnetic ε-phase to ferromagnetic τ-phase.

Figure 4a shows the demagnetization curves of τ-MnAl and τ-MnAlC at 300 K. The magnetization of our τ-MnAlC and τ-MnAl reached up to ~114 Am

2/kg at 4 T, and 118.3 Am

2/kg at 8.5 T, respectively. The room temperature

Ms of MnAl-based magnets prepared by the traditional two-step process, including melting and annealing steps, was reported to be ~73 Am

2/kg at 2 T [

22], ~82 Am

2/kg at 2 T [

10], 94 Am

2/kg at 3 T [

23], and 100 Am

2/kg at 14 T [

24]. The room temperature

Ms of samples prepared by one-step process, including one-step strip casting technique and direct drop synthesis method, has been reported recently to be 114 Am

2/kg at 5 T [

7], and 117 Am

2/kg at 9 T [

9], respectively. The magnetization of our samples prepared by the traditional two-step process is higher than most previously reported values, indicating higher fraction of the τ-phase in our samples and the effectiveness of our method in controlling the PT. An

Ms of ~128 Am

2/kg was reported in the samples with Zr substitution for Mn and high C content samples with 72 wt. % Mn [

13,

25]. We also studied the effect of magnetic field during annealing on the phase transformation and found that the magnetic field has little effect on the saturation magnetization of the final product.

The time dependence of magnetizations of ε-MnAl at 573 K and 673 K are shown in

Figure 4b, which to some extent shows the PT rate/fraction of ε→τ with time. The magnetization of ε-MnAl, when heated at 673 K, increases quickly within the first 15 min and then slowly until stabilizing at a certain value after 100 min, indicating full transformation of the ε- to τ- phase. However, no saturation was observed in ε-MnAl when heated at 573 K for more than 12 h, indicating very slow PT rate at this temperature. As mentioned above, for ε-MnAl, the displacive mode acts at 573 K while massive mode dominates the PT at 673 K. Fast transformation rates are the characteristics of the massive transformation. The low transformation rate of displacive mode is ascribed to the obstacle effect of ε

2’ and ε

3’ to the shearing process of ε

1’ variants. In fact, the coarsening rate of τ

s is observed to be very slow in our

in situ TEM experiments, even the temperature is as high as 773 K, as partly shown in

Figure 2b. The small crystalline size and the one-third fraction of the τ-phase formed via displacive mode can to some extent explain the higher coercivity and lower magnetization in MnAl powders obtained by flash-milling and post-annealing at lower temperatures [

26].