Superplasticity of Annealed H13 Steel

Abstract

:1. Introduction

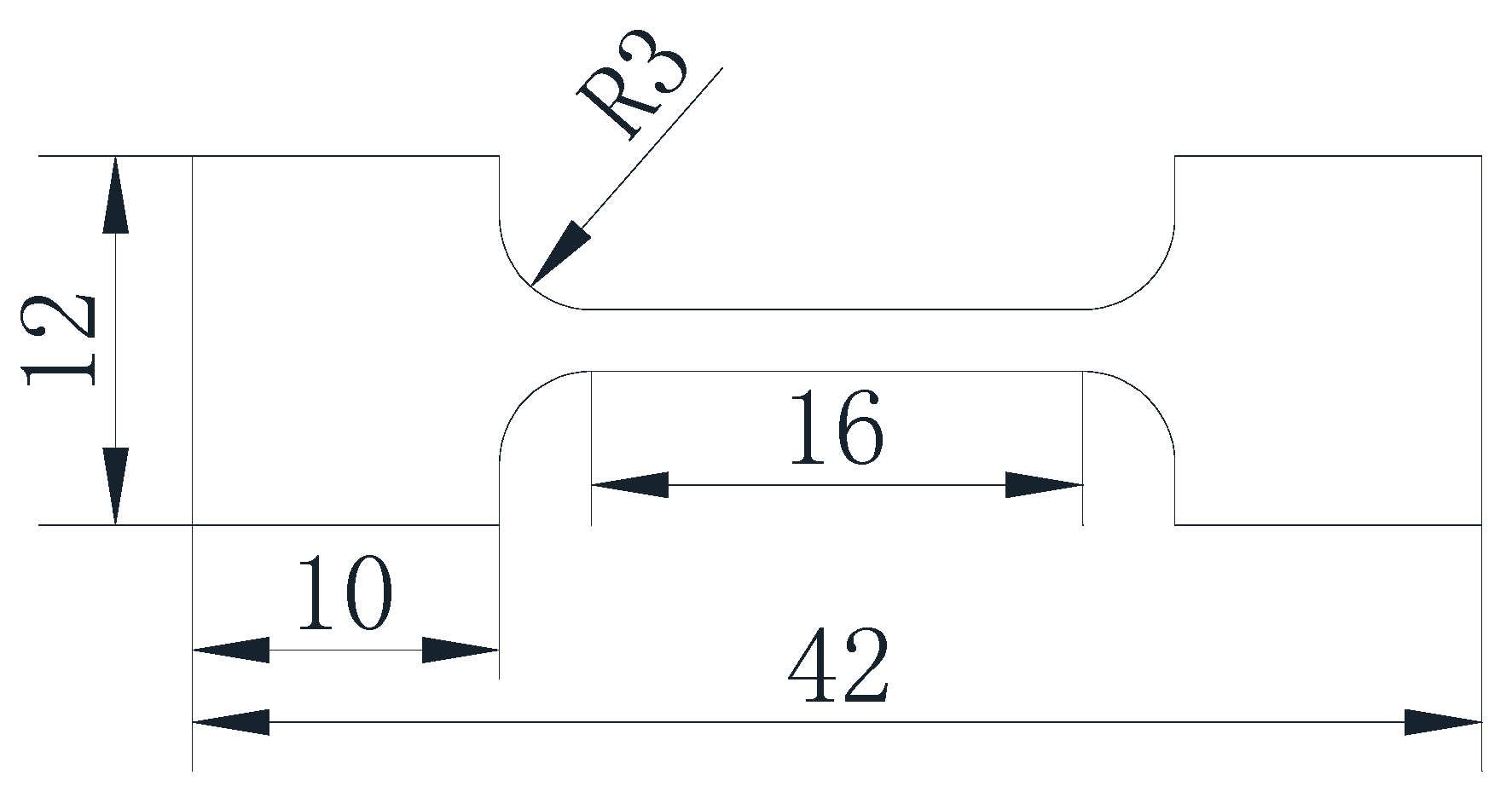

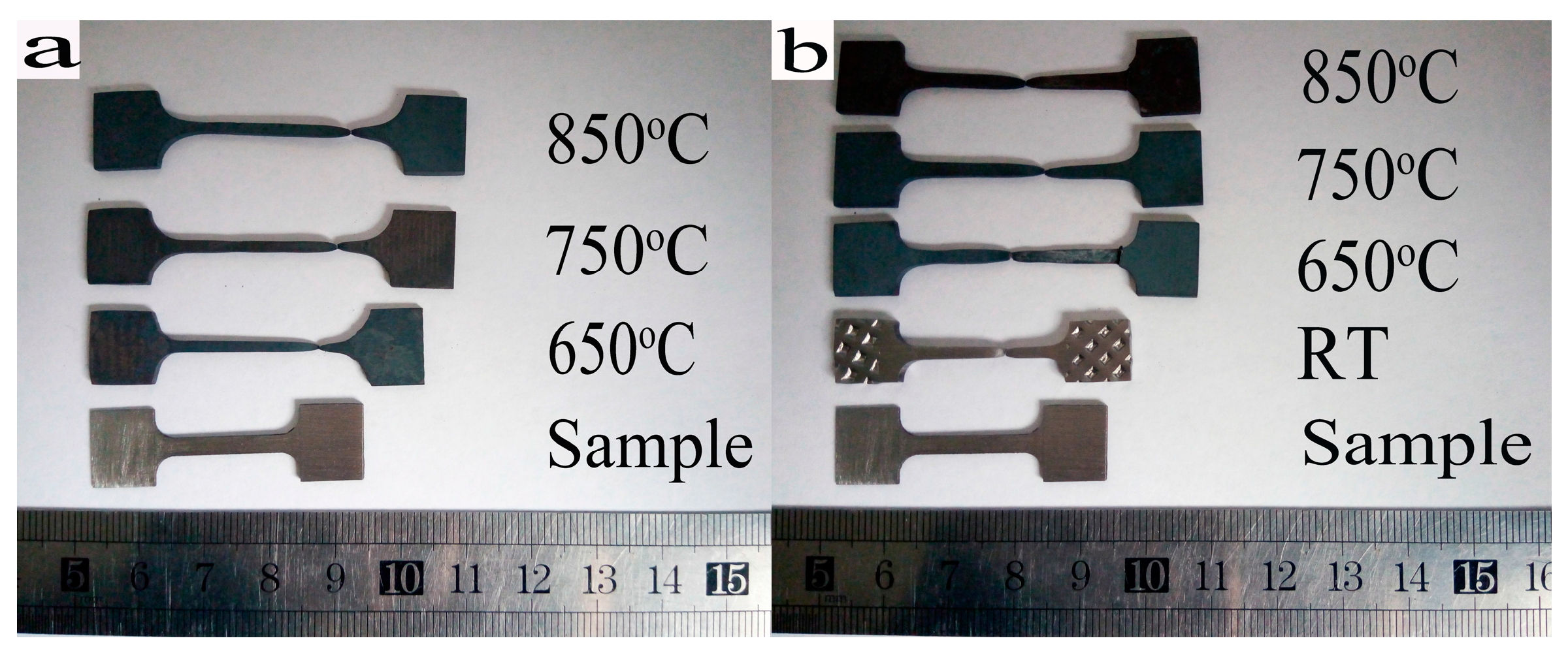

2. Experimental Materials and Methods

3. Experimental Results and Analysis

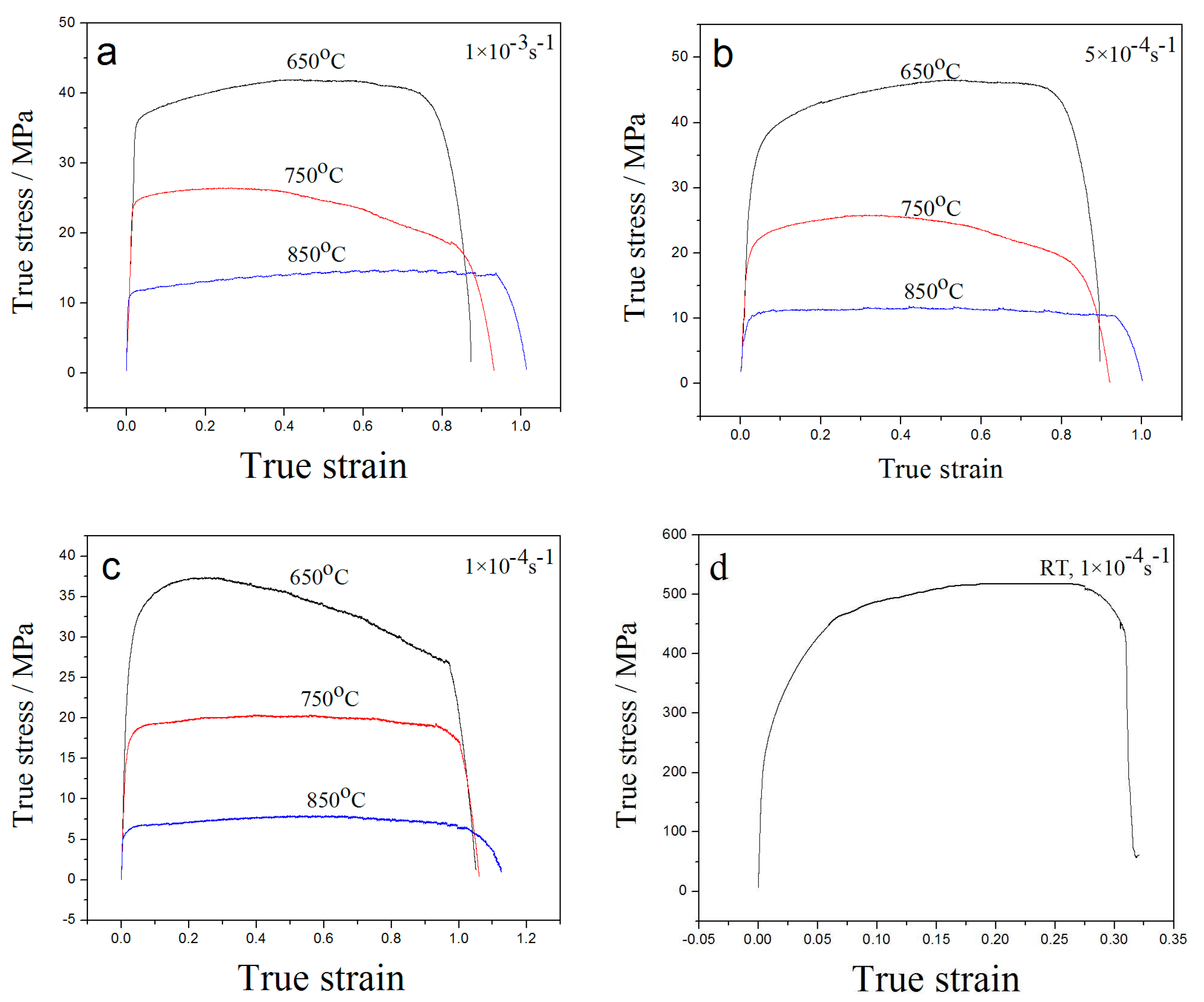

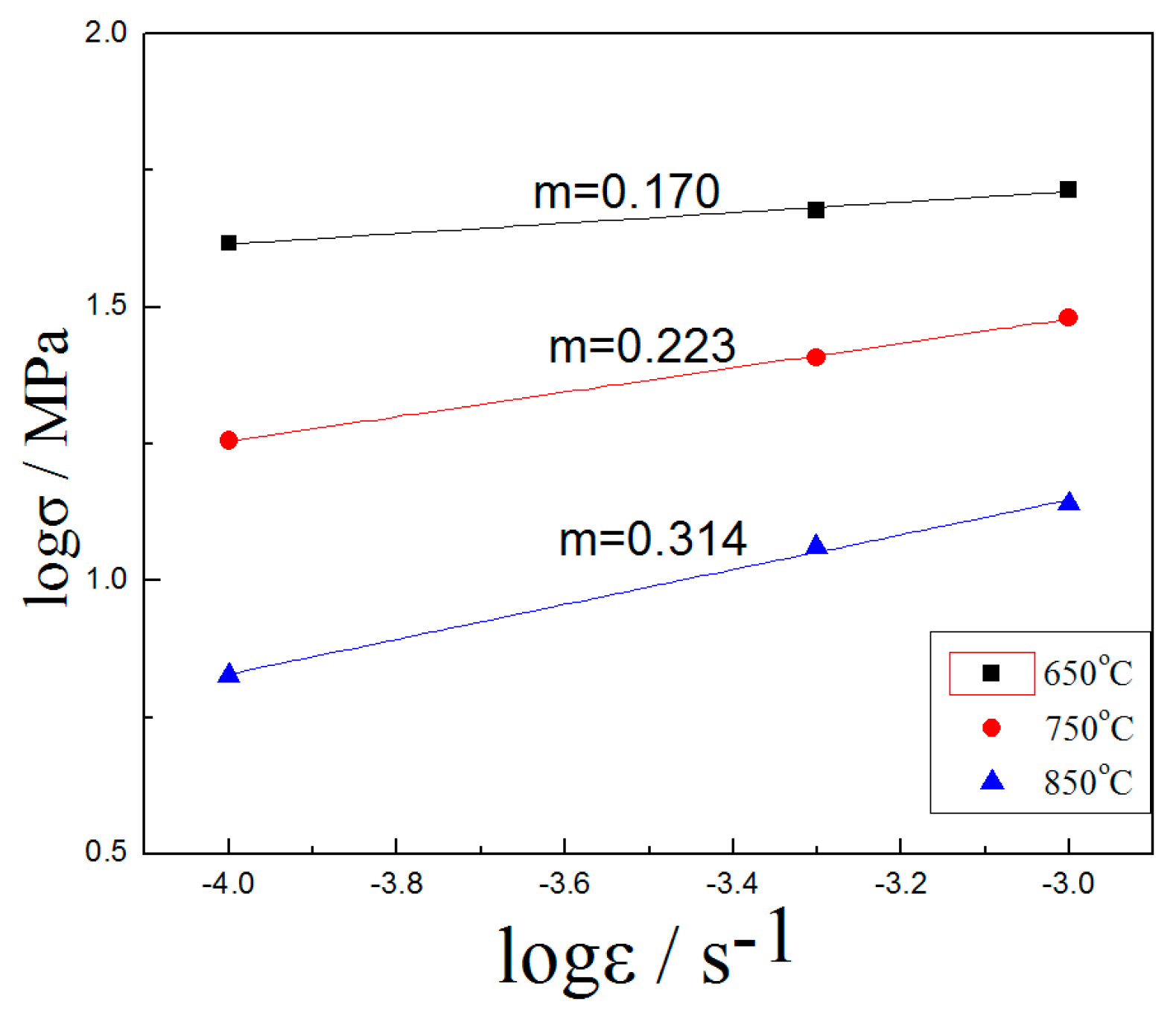

3.1. Tensile Properties Analysis

3.2. Tensile Stress–Strain Curve Analysis

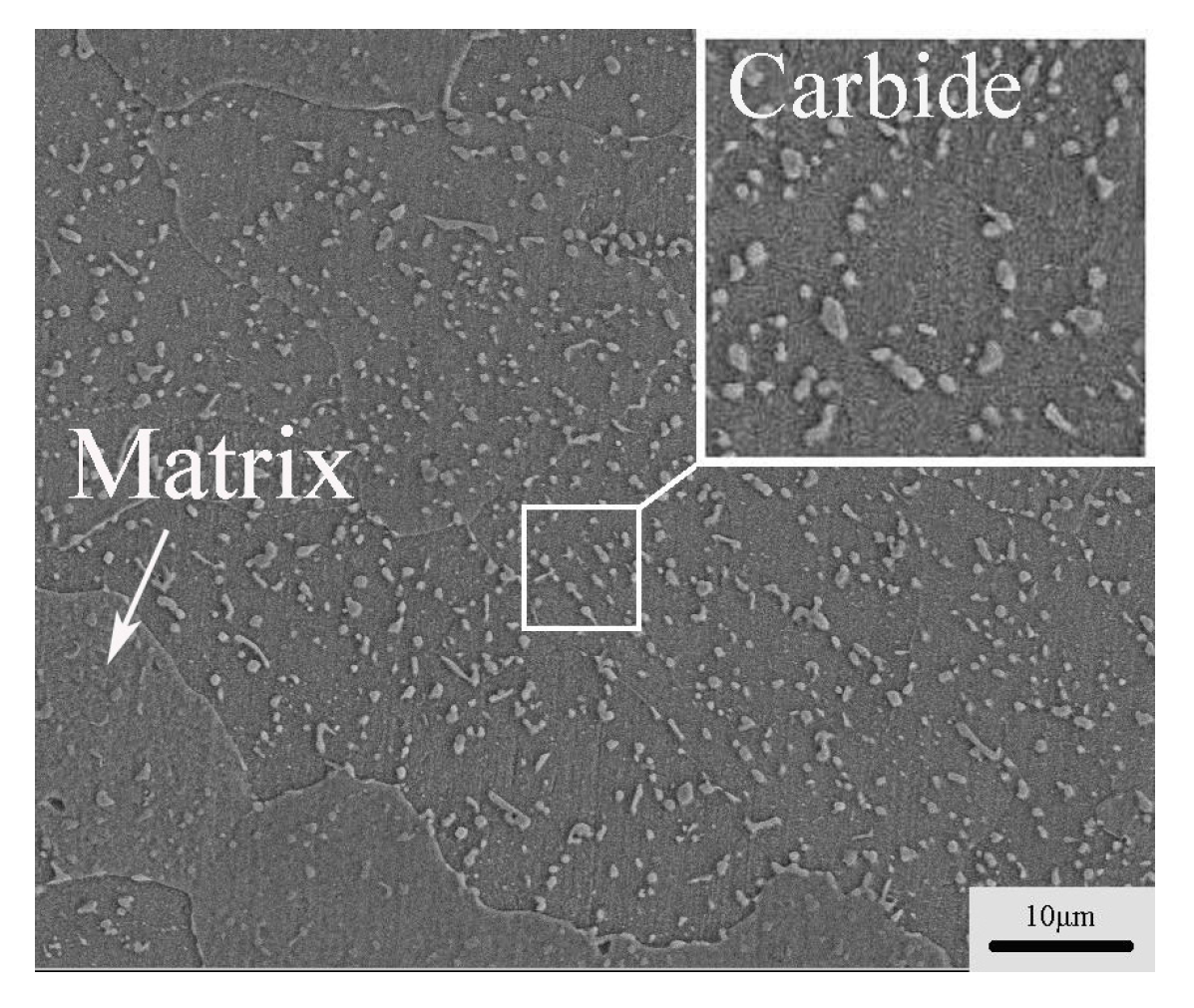

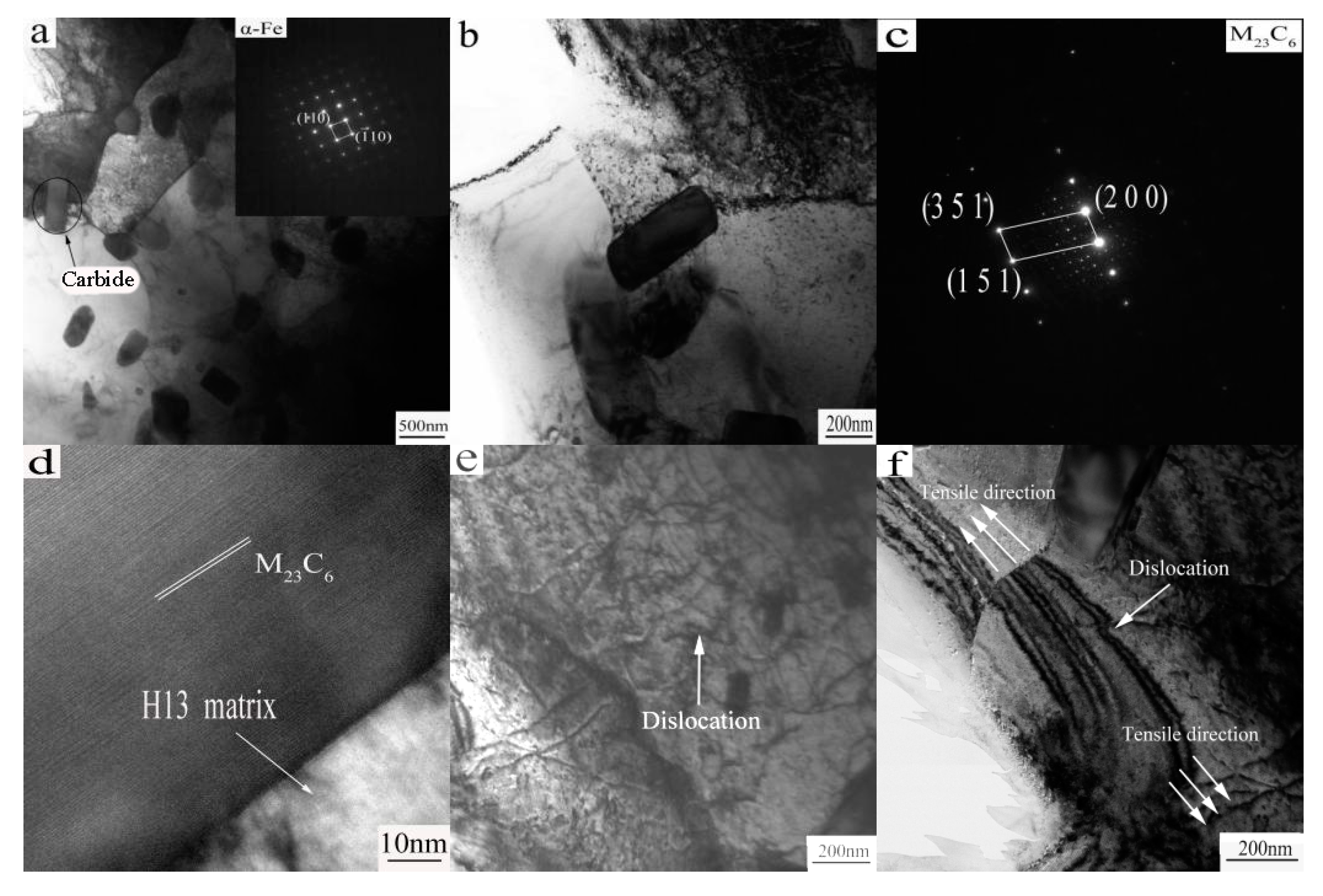

3.3. Microstructure and High Resolution Analysis

3.4. Tensile Fracture Analysis

4. Conclusions

- Conventional annealed H13 steel can reach superplasticity at the strain rate of 1 × 10−4 s−1 in the temperature range of 750–850 °C, the maximum elongation is 112.5% and the m value is 0.314.

- The grain size of H13 steel annealed is about 30–40 μm, recrystallization occurs at high temperature tensility, and fine recrystallized grains are favorable for plastic deformation.

- The fine carbides effectively inhibit the growth of recrystallized grains, which hinder the movement of dislocations and form the dislocation wall, a certain strength and plasticity of microstructures are kept at a high temperature and ultimately obtain superplasticity.

- Because of micropore polymerization, the superplastic tensile fracture forms larger pores than the fracture at room temperature. With the increase of micropores, the tensile strength decreases continuously and eventually leads to fracture.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, Y.C.; Zhao, Y.L.; Chen, H.; Liu, B.; Wang, M.K. Forging process optimization of american standard H13 hot working die steel. Shandong Metall. 2011, 33, 59–61. [Google Scholar]

- Li, Z.R. Principle and Application of Metal Superplastic Forming; Aviation Industrial Publishing House: Beijing, China, 1990. [Google Scholar]

- Mukai, T.; Watanabe, H.; Higashi, K. Application of superplasticity in commercial magnesium alloy for fabrication of structural components. Mater. Sci. Technol. 2000, 16, 1314–1319. [Google Scholar] [CrossRef]

- Zhai, F.B.; Zhang, Z.L.; Xia, E.H. Study on superplastic forming properties of H13 steel. Mech. Sci. Technol. 2001, 20, 98–99. [Google Scholar]

- Zhang, Y.Z.; Huang, J.L.; Li, Y.X. Superplastic diffused welding of hot sprayed coating when superplastie forming for preeision forging dies of bevel gears. J. Luoyang Inst. Technol. 1996, 1, 1–6. [Google Scholar]

- Hu, H.; Zhang, Y.; Han, J.C. Superplastic forming process of H13 steel forging model cavity. Met. Form. Process 1994, 4, 190–197. [Google Scholar]

- Haghdadi, N.; Cizek, P.; Beladi, H.; Hodgson, P.D. A novel high-strain-rate ferrite dynamic softening mechanism facilitated by the interphase in the austenite/ferrite microstructure. Acta Mater. 2017, 126, 44–57. [Google Scholar] [CrossRef]

- Krahmer, D.M.; Polvorosa, R.; López de Lacalle, L.N.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for specimen manufacturing in tensile testing of steel plates. Exp. Tech. 2016, 40, 1–11. [Google Scholar] [CrossRef]

- Shazly, M.; Prakash, V.; Draper, S. Mechanical behavior of Gamma-met PX under uniaxial loading at elevated temperatures and high strain rates. Int. J. Solids Struct. 2005, 41, 6485–6503. [Google Scholar] [CrossRef]

- Alhussainy, F.; Hasan, H.A.; Rogic, S.; Sheikh, M.N.; Hadi, M.N.S. Direct tensile testing of self-compacting concrete. Constr. Build. Mater. 2016, 112, 903–906. [Google Scholar] [CrossRef]

- Darolia, R.; Lewandowski, J.J.; Liu, C.T.; Martin, P.L.; Miracle, D.B.; Nathal, M.V. Structural Intermetallics. In Proceedings of the International Symposium on Structural Intermetallics, Champion, PA, USA, 26–30 September 1993. [Google Scholar]

- Hu, S.C.; Zhang, H.H.; Wu, X.C. Flow Stress behaviors of 30Cr3MoV steel during hot compression. Shanghai Met. 2011, 3, 1–5. [Google Scholar]

- Liu, Z.H.; Ren, H.P.; Li, W.X. Annealing softening for H13 steel. J. Baotou Univ. Iron Steel Technol. 1997, 16, 285–288. [Google Scholar]

- Clemens, H.; Rumberg, I.; Schretter, P. Characrerization of Ti-48Al-2Cr sheet material. Intermetallics 1994, 2, 179–184. [Google Scholar] [CrossRef]

- Padmanabhan, K.A.; Davies, G.J. Superplasticity; Springer: Berlin/Heidelberg, Germany, 1980. [Google Scholar]

- Deng, W.P.; Wang, R.F.; Xue, G.; Yang, C.F. Superplasticity of 10CrNi5MoV steel. Dev. Appl. Mater. 2014, 29, 21–24. [Google Scholar]

- Zhang, Y.Z.; Wen, J.B.; Chen, F.X. Superplasticity and superplastic forming of steel 10Ni3MnCuAl. J. Luoyang Inst. Technol. 1995, 2, 1–4. [Google Scholar]

- Wang, M.; Yao, Z.K. Study on superplasticity of W6Mo5Cr4V2 high speed steel. Forg. Stamp. Technol. 1997, 6, 36–38. [Google Scholar]

- Long, Y.T.; Xu, X.; Lin, F.Y. Superplasticity of T10A carbon tool steel. New Technol. New Process 1990, 6, 10–11. [Google Scholar]

- Yang, Y.L.; Liu, Z.B.; Kang, B.X. Superplasticity of 3Cr2W8V steel and superplastic forming of mold cavity. New Technol. Process 1987, 6, 12–14. [Google Scholar]

- Pogatscher, S.; Antrekowitsch, H.; Leitner, H.; Sologubenko, A.S.; Uggowitzer, P.J. Influence of the thermal route on the peak-aged microstructures in an Al–Mg–Si aluminum alloy. Scr. Mater. 2013, 68, 158–161. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Brady, M.P.; Lu, Z.P.; Maziasz, P.J.; Liu, C.T.; Pint, B.A.; More, K.L.; Meyer, H.M.; Payzant, E.A. Creep-resistant, Al2O3-forming austenitic stainless steels. Science 2007, 316, 433–436. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, I. Theories and applicabilitu of grain size piezometers: The role of dynamic recrystallization mechanisms. J. Struct. Geol. 2008, 30, 899–917. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, W.Z.; Zhen, L.; Zhang, X.M. Microstructure evolution during dynamic recrystallization of hot deformed superalloy 718. Mater. Sci. Eng. A 2008, 486, 321–332. [Google Scholar] [CrossRef]

- Takaki, T.; Hisakuni, Y.; Hirouchi, T.; Yamanaka, A.; Tomita, Y. Multi-phase-field simulations for dynamic recrystallization. Comput. Mater. Sci. 2009, 45, 881–888. [Google Scholar] [CrossRef]

- Fu, R.Y.; Liu, Y.K. The study of tempering and carbides of cast H13 steels. J. Met. Heat Treat. 1992, 13, 27–32. [Google Scholar]

- Wang, S.P. Fundamentals of Metallographic Analysis; Machinery Industry Press: Beijing, China, 1986. [Google Scholar]

- He, Z.B.; Fan, X.B.; Shao, F. Formability and microstructure of AA6061 Al alloy tube for hot metal gas forming at elevated temperature. Trans. Nonferrous Met. Soc. China 2012, 2, 364–369. [Google Scholar] [CrossRef]

| Country | China | America | Germany | Japan | England |

|---|---|---|---|---|---|

| standard | GB | AISI | VDEh | JIS | BS |

| name | 4Cr5MoSiV1 | H13 | X40CrMoV51 | SKD61 | BH13 |

| Experimental Material | Treatment Process | Grain Size/μm | Maximum Elongation/% | Stretching Temperature/°C | m | Stress/MPa | Strain Rate/s−1 |

|---|---|---|---|---|---|---|---|

| 10CrNi5MoV | Tempered sorbite | 22.5 | 133.5 | 730 | _ | 50 | 6.6 × 10−3 |

| 10Ni3MnCuAl | 850 °C three cycles of quenching | 15.9 | 180 | 650 | _ | 60 | 2.5 × 10−4 |

| 3Cr2W8V | 950–1050 °C two or three cycles of quenching | 2.8 | 228 | 810 | _ | 10 | 1.67 × 10−4 |

| W6Mo5Cr4V2 | 1040 °C two cycles of quenching | 5.6 | 192 | 810 | 0.27 | 58.2 | 3.33 × 10−4 |

| T10A | 780 °C three cycles of quenching | 4.7 | 415 | 680 | 0.48 | 10.9 | 2.0 × 10−4 |

| H13 steel | 1000 °C three cycles of quenching | 4.0 | 185 | 840 | 0.26 | 31 | 1.6 × 10−4 |

| H13 steel * | annealing | 30–40 | 112.8 | 850 | 0.31 | 8.38 | 1.0 × 10−4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Z.; Pei, W.; Gong, X.; Chen, H. Superplasticity of Annealed H13 Steel. Materials 2017, 10, 870. https://doi.org/10.3390/ma10080870

Duan Z, Pei W, Gong X, Chen H. Superplasticity of Annealed H13 Steel. Materials. 2017; 10(8):870. https://doi.org/10.3390/ma10080870

Chicago/Turabian StyleDuan, Zhenxin, Wen Pei, Xuebo Gong, and Hua Chen. 2017. "Superplasticity of Annealed H13 Steel" Materials 10, no. 8: 870. https://doi.org/10.3390/ma10080870

APA StyleDuan, Z., Pei, W., Gong, X., & Chen, H. (2017). Superplasticity of Annealed H13 Steel. Materials, 10(8), 870. https://doi.org/10.3390/ma10080870