Effects of Strand Lay Direction and Crossing Angle on Tribological Behavior of Winding Hoist Rope

Abstract

:1. Introduction

2. Experimental Details

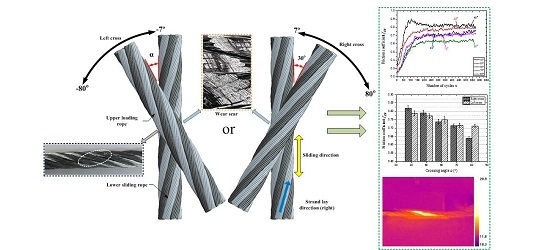

2.1. Materials and Specimens

2.2. Sliding Friction Test Rig and Test Conditions

2.3. Test Parameters and Methods

3. Results and Discussion

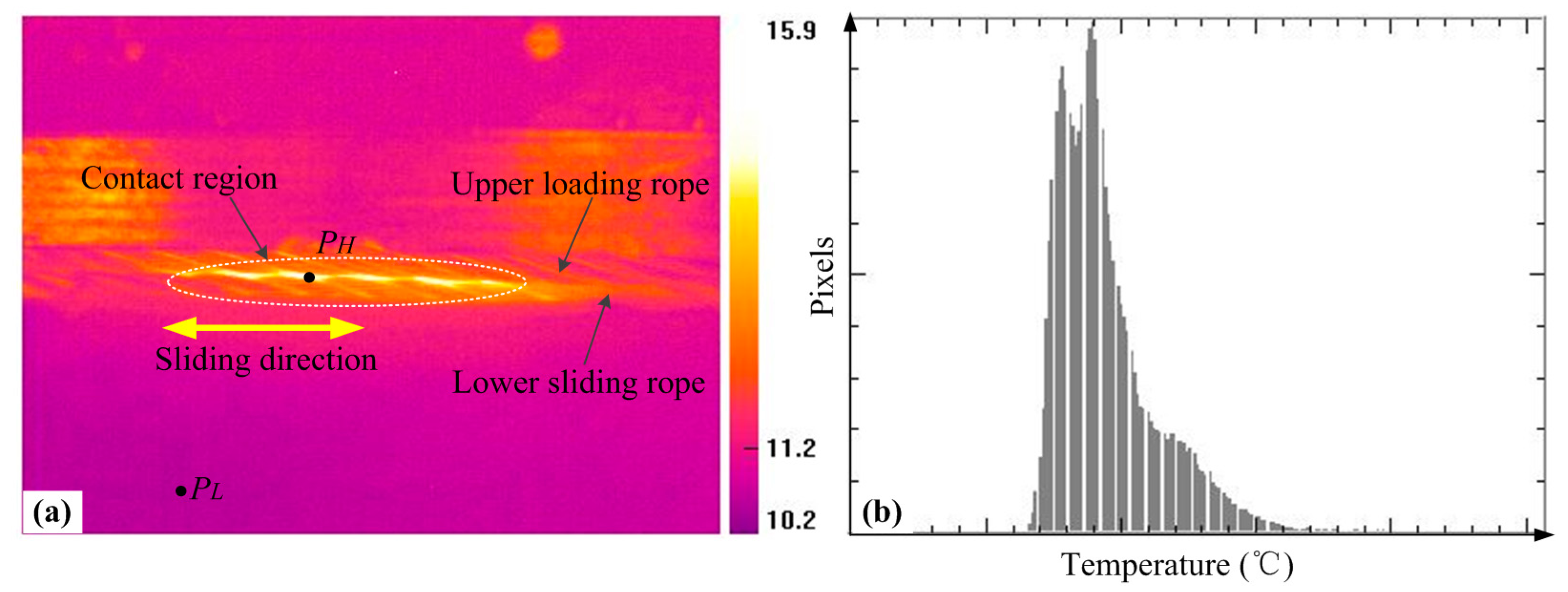

3.1. Evolution of the Friction Coefficient under Different Conditions

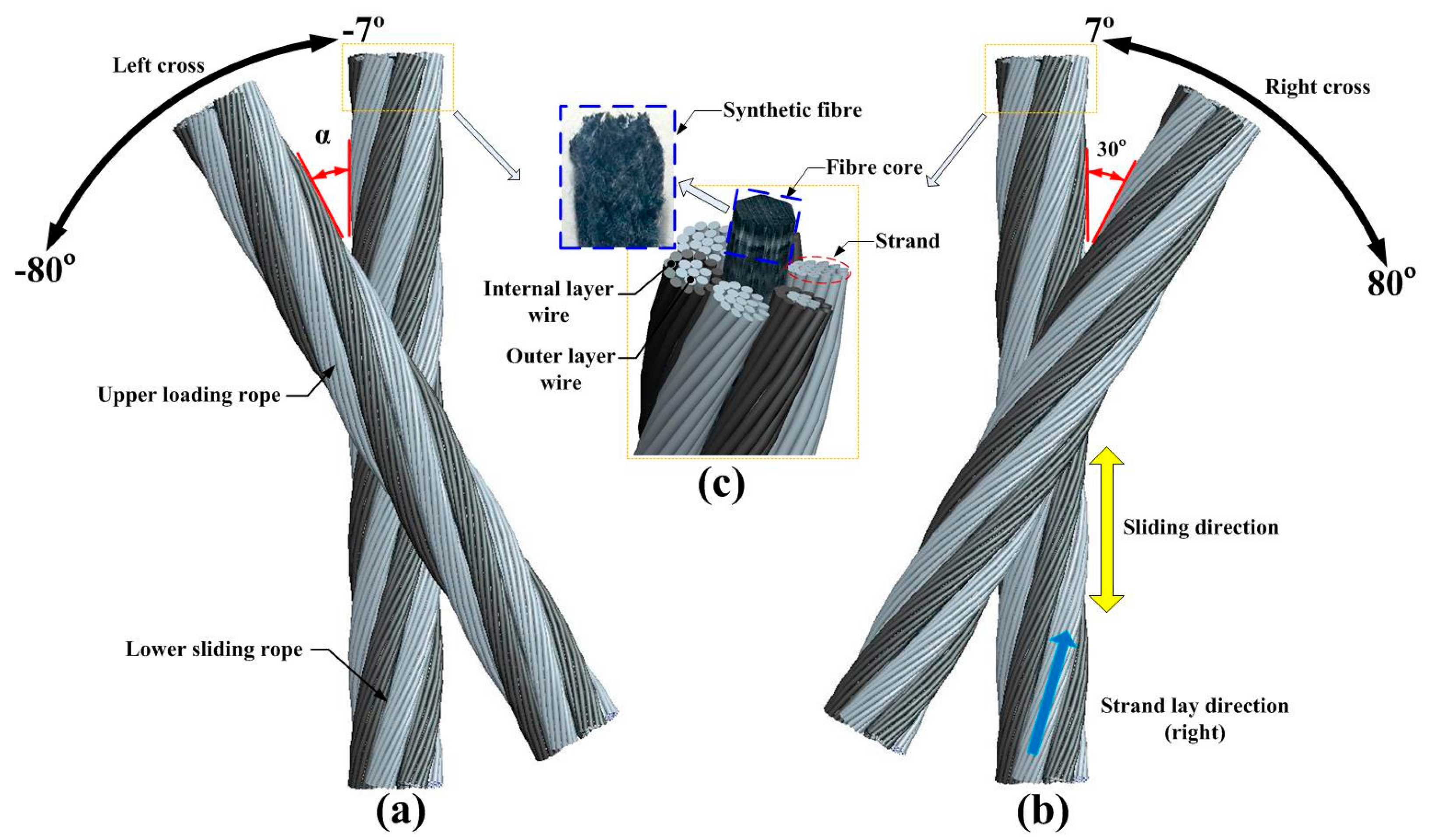

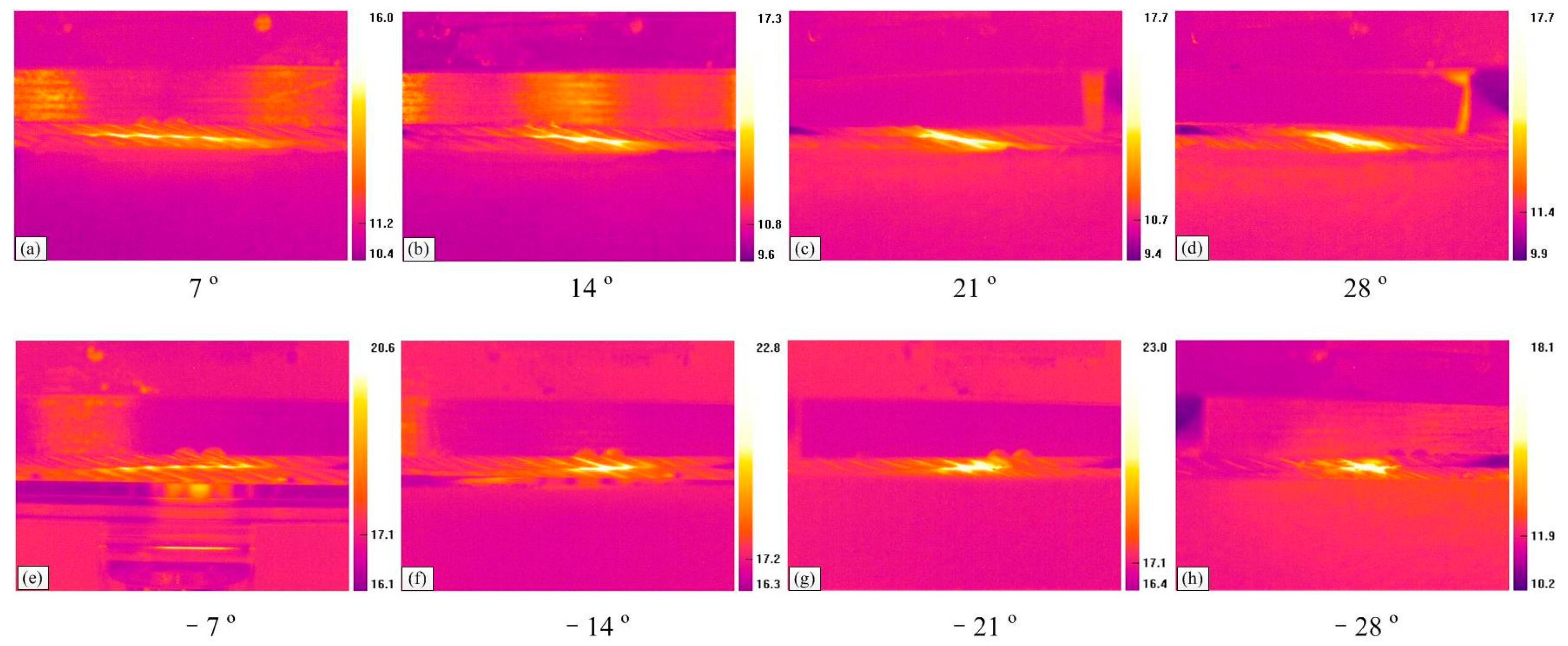

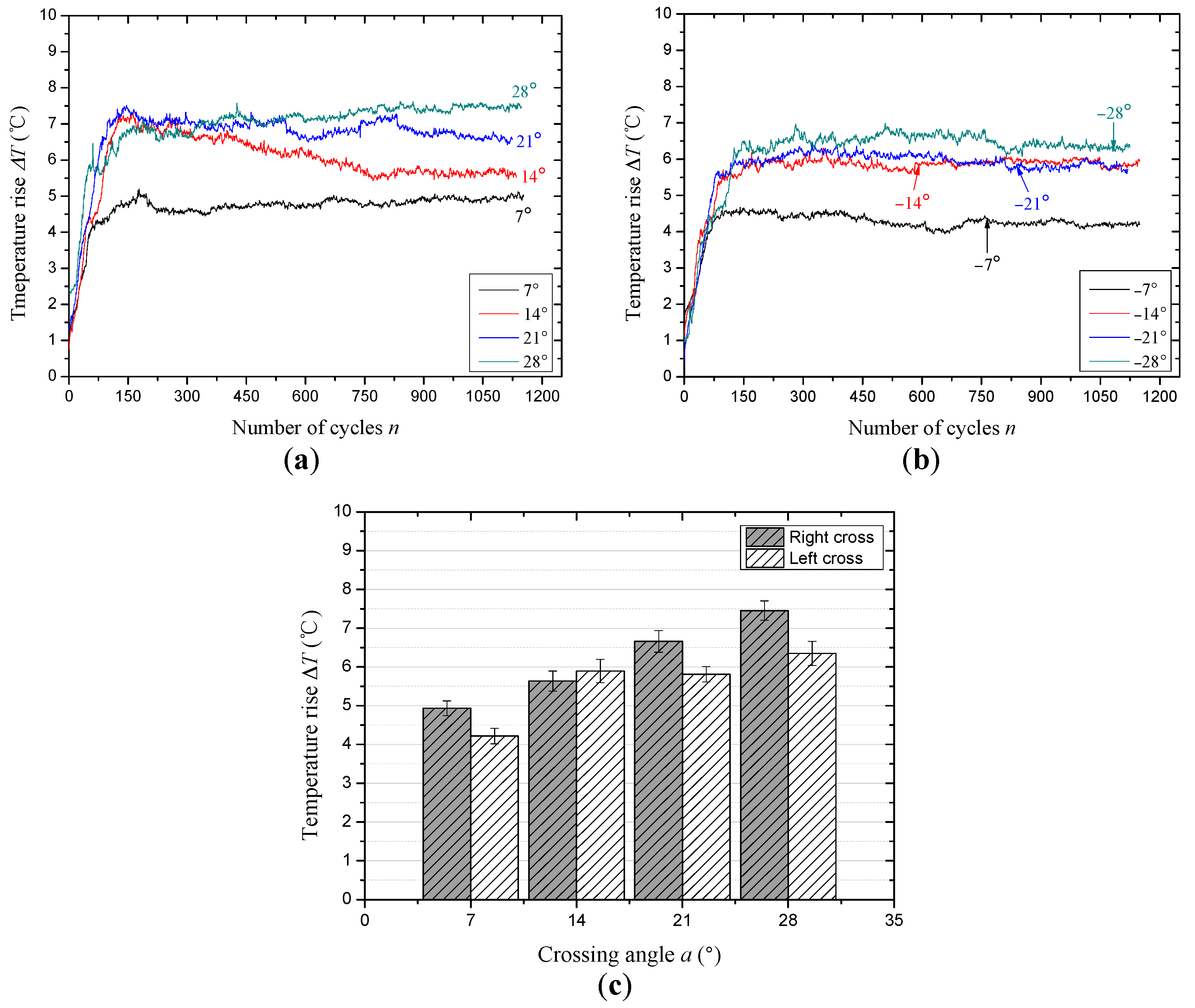

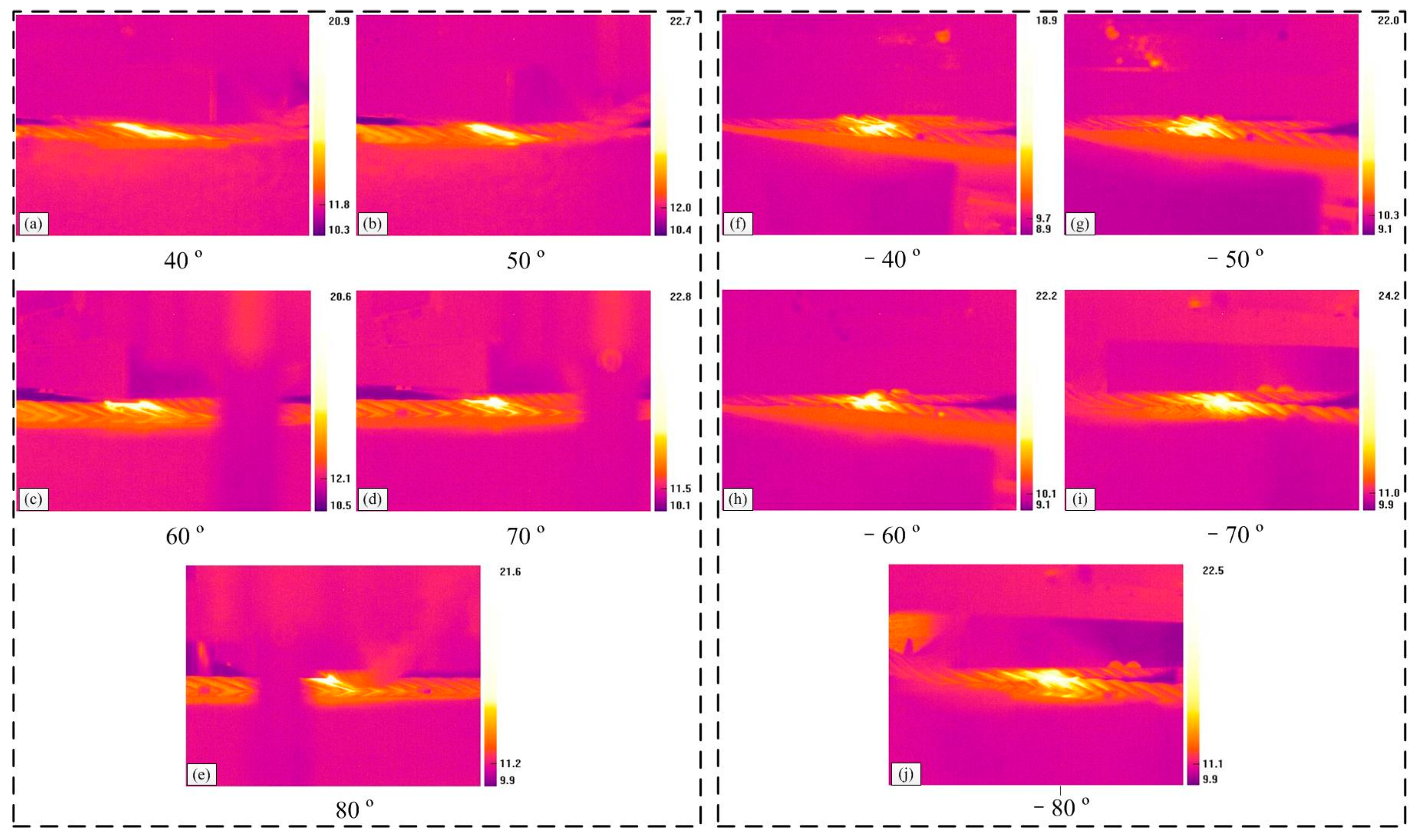

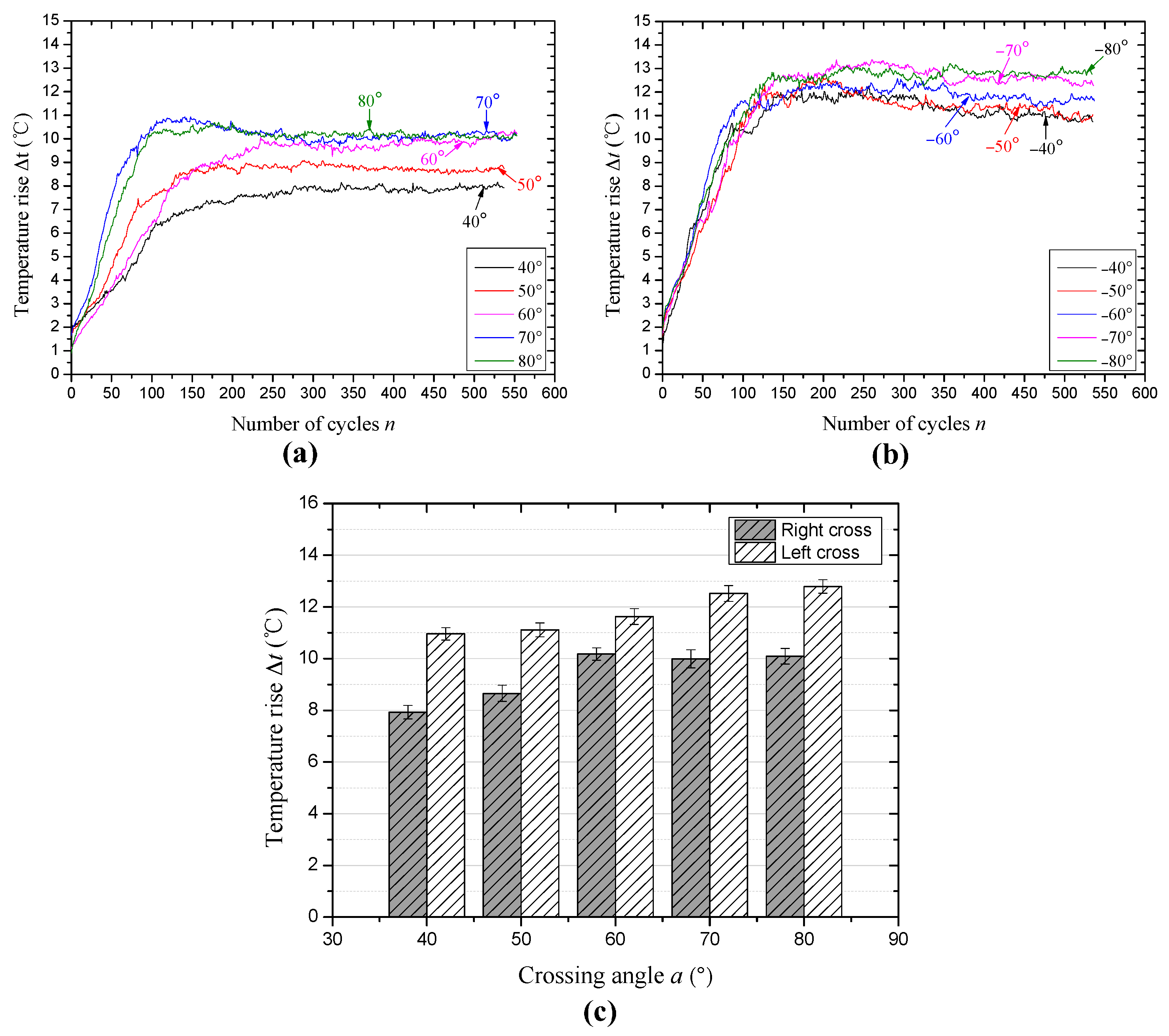

3.2. Evolution of Temperature Rise under Different Conditions

3.3. Wear Mechanism

4. Conclusions

- The friction coefficient in the steady-state period shows a decreasing tendency with an increase of the crossing angle in both cross directions. In the case of a small crossing angle (from 7° to 28°), the friction coefficient changes in a wider range under the contact condition of left cross, from approximately 0.77 to approximately 0.60. However, when the crossing angle is large (from 40° to 80°), the change of the friction coefficient is more obvious under the condition of right cross, from approximately 0.82 to approximately 0.64.

- The temperature rise in the steady-state period shows an increasing tendency with the crossing angles in both cross directions. In the case of right cross contact, the high temperature regions always distribute along the strand lay direction between the adjacent strands in most situations. Nevertheless, when the cross direction is left, the high temperature regions distribute on the upper surface of the rope strands. Additionally, when the crossing angle is small, the temperature rise is larger under the contact condition of right cross, increasing from approximately 4.9 °C to approximately 7.5 °C. However, in the case of a large crossing angle, the temperature rise is larger under the contact condition of left cross, increasing from approximately 7.5 °C to approximately 12.8 °C.

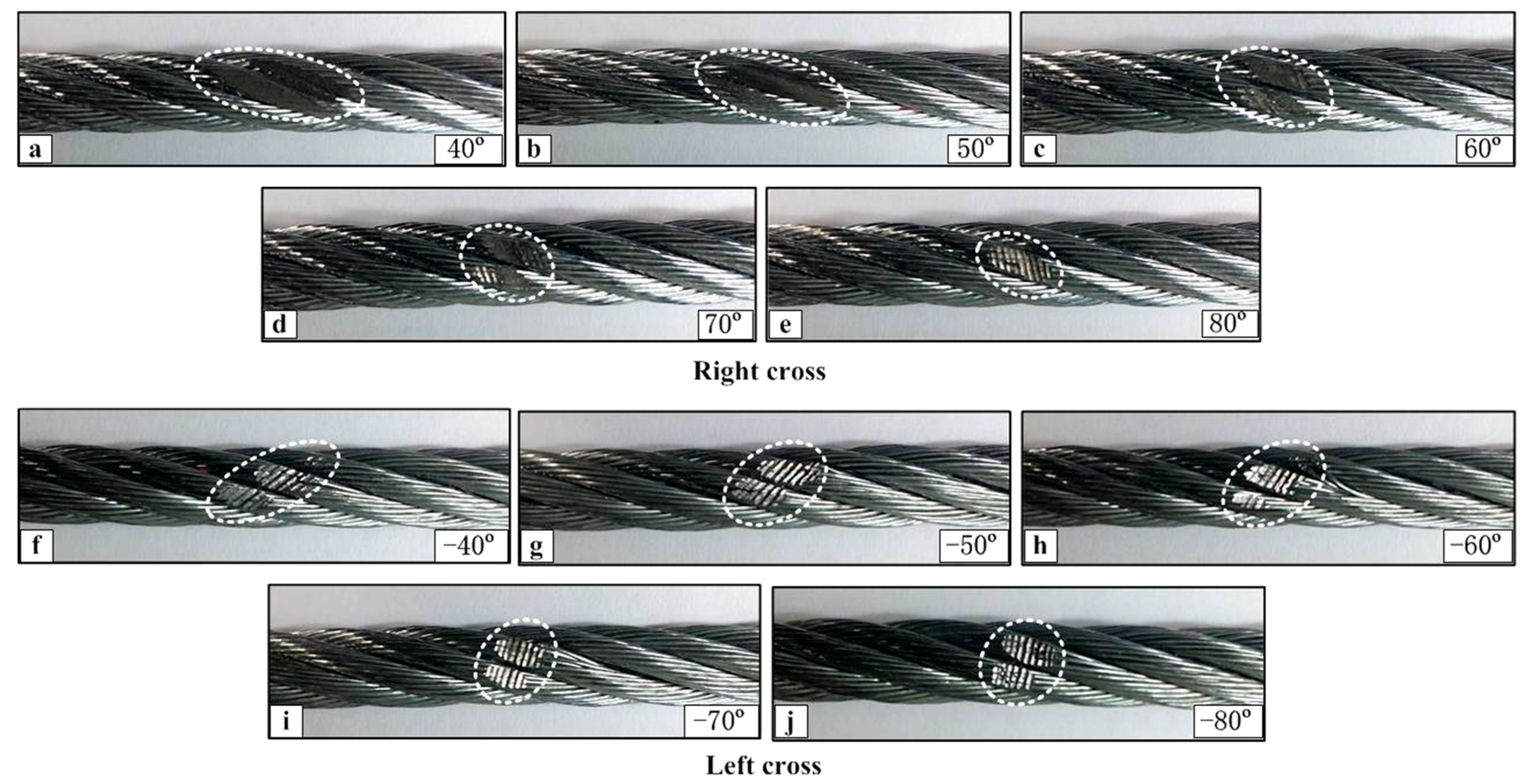

- The variation of wear scar with an increase in the crossing angle is different for different cross directions. In the case of right cross, the wear scar area gradually concentrates to the gap between the adjacent strands with the crossing angle increasing from 7° to 28°. Additionally, as the crossing angle increases from 40° to 80°, the wear scar area moves from the side surfaces in the gap to the upper surfaces of the strands. However, as the cross direction is left, the wear scar is always on the upper surfaces and becomes more concentrated with the increase of the crossing angle.

- The wear mass loss shows an increasing tendency in the small crossing angle tests and shows a decreasing tendency in the large crossing angle tests for both cross directions. The variation range of the wear mass loss is larger in the case of right cross contact.

- The differences of the wear morphology in the case of different cross directions are very obvious, in particular for the large crossing angle tests. The damage formed on the wear surface are mainly ploughing, pits, plastic deformation, and fatigue fracture. The major wear mechanisms between the winding hoist ropes in this study are adhesive wear, abrasive, and fatigue wear.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ministry of Coal Industry. The Coal Mine Safety Rules; Coal industry Publishing House: Beijing, China, 1986. [Google Scholar]

- Wang, X.Y.; Meng, X.B.; Wang, J.X. Mathematical modeling and geometric analysis for wire rope strands. Appl. Math. Model. 2015, 39, 1019–1032. [Google Scholar] [CrossRef]

- Ma, W.; Zhu, Z.C.; Peng, Y.X. Computer-aided modeling of wire ropes bent over a sheave. Adv. Eng. Softw. 2015, 90, 11–21. [Google Scholar] [CrossRef]

- Costello, G.A. Theory of Wire Rope; Springer Science & Business Media: New York, NY, USA, 1997. [Google Scholar]

- Wu, W.; Cao, X. Mechanics model and its equation of wire rope based on elastic thin rod theory. Int. J. Sol. Struct. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Stanova, E.; Fedorko, G.; Fabian, M. Computer modelling of wire strands and ropes part II: Finite element-based applications. Adv. Eng. Softw. 2011, 42, 322–331. [Google Scholar] [CrossRef]

- Kastratović, G.; Vidanović, N.; Bakić, V. On finite element analysis of sling wire rope subjected to axial loading. Ocean Eng. 2014, 88, 480–487. [Google Scholar] [CrossRef]

- Chaplin, C.R. Failure mechanisms in wire ropes. Eng. Fail. Anal. 1995, 2, 45–57. [Google Scholar] [CrossRef]

- Mahmoud, K.M. Fracture strength for a high strength steel bridge cable wire with a surface crack. Theor. Appl. Fract. Mech. 2007, 48, 152–160. [Google Scholar] [CrossRef]

- Singh, R.P.; Mallick, M.; Verma, M.K. Studies on failure behavior of wire rope used in underground coal mines. Eng. Fail. Anal. 2016, 70, 290–304. [Google Scholar] [CrossRef]

- Cruzado, A.; Hartelt, M.; Wäsche, R. Fretting wear of thin steel wires. Part 1: Influence of contact pressure. Wear 2010, 268, 1409–1416. [Google Scholar] [CrossRef]

- Cruzado, A.; Hartelt, M.; Wäsche, R. Fretting wear of thin steel wires. Part 2: Influence of crossing angle. Wear 2011, 273, 60–69. [Google Scholar] [CrossRef]

- Urchegui, M.A.; Tato, W.; Gómez, X. Wear evolution in a stranded rope subjected to cyclic bending. J. Mater. Eng. Perform. 2008, 17, 550–560. [Google Scholar] [CrossRef]

- Argatov, I.I.; Gómez, X.; Tato, W. Wear evolution in a stranded rope under cyclic bending: Implications to fatigue life estimation. Wear 2011, 271, 2857–2867. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Ge, S. Effect of displacement amplitude on fretting fatigue behavior of hoisting rope wires in low cycle fatigue. Tribol. Int. 2012, 52, 178–189. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, D.; Yin, Y. Fretting wear behaviors of hoisting rope wires in acid medium. Mater. Des. 2014, 55, 50–57. [Google Scholar] [CrossRef]

- McColl, I.R.; Waterhouse, R.B.; Harris, S.J. Lubricated fretting wear of a high-strength eutectoid steel rope wire. Wear 1995, 185, 203–212. [Google Scholar] [CrossRef]

- Oksanen, V.; Andersson, P.; Valtonen, K. Characterization of the wear of nodular cast iron rollers in contact with wire ropes. Wear 2013, 308, 199–205. [Google Scholar] [CrossRef]

- Oksanen, V.; Valtonen, K.; Andersson, P. Comparison of laboratory rolling–sliding wear tests with in-service wear of nodular cast iron rollers against wire ropes. Wear 2015, 340, 73–81. [Google Scholar] [CrossRef]

- Chen, Y.; Meng, F.; Gong, X. Interwire wear and its influence on contact behavior of wire rope strand subjected to cyclic bending load. Wear 2016, 368, 470–484. [Google Scholar] [CrossRef]

- Hirsch, M.R.; Neu, R.W. Temperature-dependent fretting damage of high strength stainless steel sheets. Wear 2016, 346, 6–14. [Google Scholar] [CrossRef]

- Velkavrh, I.; Ausserer, F.; Klien, S. The effect of gaseous atmospheres on friction and wear of steel–steel contacts. Tribol. Int. 2014, 79, 99–110. [Google Scholar] [CrossRef]

- Velkavrh, I.; Ausserer, F.; Klien, S. The influence of temperature on friction and wear of unlubricated steel/steel contacts in different gaseous atmospheres. Tribol. Int. 2016, 98, 155–171. [Google Scholar] [CrossRef]

- Pearson, S.R.; Shipway, P.H.; Abere, J.O. The effect of temperature on wear and friction of a high strength steel in fretting. Wear 2013, 303, 622–631. [Google Scholar] [CrossRef]

- Mbarek, M.; Rhaiem, S.; Kharrat, M. Experimental simulation of the friction, temperature, and wear distributions for polyamide–steel gear contact using twin-disc setup. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 1127–1138. [Google Scholar] [CrossRef]

- Cruzado, A.; Urchegui, M.A.; Gómez, X. Finite element modeling and experimental validation of fretting wear scars in thin steel wires. Wear 2012, 289, 26–38. [Google Scholar] [CrossRef]

- Cruzado, A.; Urchegui, M.A.; Gómez, X. Finite element modeling of fretting wear scars in the thin steel wires: Application in crossed cylinder arrangements. Wear 2014, 318, 98–105. [Google Scholar] [CrossRef]

- Argatov, I.; Tato, W. Asymptotic modeling of reciprocating sliding wear–comparison with finite-element simulations. Eur. J. Mech. A/Solids 2012, 34, 1–11. [Google Scholar] [CrossRef]

- Chang, X.D.; Peng, Y.X.; Zhu, Z.C. Tribological properties of winding hoisting rope between two layers with different sliding parameters. Adv. Mech. Eng. 2016, 8, 1–14. [Google Scholar]

- Peng, Y.X.; Chang, X.D.; Zhu, Z.C. Sliding friction and wear behavior of winding hoisting rope in ultra-deep coal mine under different conditions. Wear 2016, 368, 423–434. [Google Scholar]

- Vingsbo, O.; Söderberg, S. On fretting maps. Wear 1988, 126, 131–147. [Google Scholar] [CrossRef]

- Pearson, S.R.; Shipway, P.H. Is the wear coefficient dependent upon slip amplitude in fretting? Vingsbo and Söderberg revisited. Wear 2015, 330–331, 93–102. [Google Scholar] [CrossRef]

- Feyrer, K. Wire Ropes; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Xiao, X.M.; Yin, Y.; Bao, J.S. Review on the friction and wear of brake materials. Adv. Mech. Eng. 2016, 8, 1–10. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Diameter of the rope | 9.3 mm |

| Radius of the steel wires | 0.3 mm |

| Strand lay length | 70 mm |

| Strand lay angle | 15.5° |

| Strand lay direction | Right |

| Nominal tensile strength | 1570 MPa |

| Breaking force | 52,500 N |

| Test Parameters | Left Cross | Right Cross | ||

|---|---|---|---|---|

| Contact load (Fn) | 150 N | 150 N | 150 N | 150 N |

| Crossing angle (α) | −7°; −14°; −21°; −28° | −40°; −50°; −60°; −70°; −80° | 7°; 14°; 21°; 28° | 40°; 50°; 60°; 70°; 80° |

| Stroke (x) | 10 mm | 20 mm | 10 mm | 20 mm |

| Number of cycles (n) | 1136 | 568 | 1136 | 568 |

| Velocity (v) | 6 mm/s | 12 mm/s | 6 mm/s | 12 mm/s |

| Tensile force (F) | 2000 N | 2000 N | 2000 N | 2000 N |

| Sliding distance (s) | 22,720 mm | 22,720 mm | 22,720 mm | 22,720 mm |

| Lubricant condition | Dry-friction | Dry-friction | Dry-friction | Dry-friction |

| Temperature | Room temperature | Room temperature | Room temperature | Room temperature |

| Humidity (%) | 60 ± 5 | 60 ± 5 | 60 ± 5 | 60 ± 5 |

| Atmosphere | Laboratory air | Laboratory air | Laboratory air | Laboratory air |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, X.-d.; Peng, Y.-x.; Zhu, Z.-c.; Gong, X.-s.; Yu, Z.-f.; Mi, Z.-t.; Xu, C.-m. Effects of Strand Lay Direction and Crossing Angle on Tribological Behavior of Winding Hoist Rope. Materials 2017, 10, 630. https://doi.org/10.3390/ma10060630

Chang X-d, Peng Y-x, Zhu Z-c, Gong X-s, Yu Z-f, Mi Z-t, Xu C-m. Effects of Strand Lay Direction and Crossing Angle on Tribological Behavior of Winding Hoist Rope. Materials. 2017; 10(6):630. https://doi.org/10.3390/ma10060630

Chicago/Turabian StyleChang, Xiang-dong, Yu-xing Peng, Zhen-cai Zhu, Xian-sheng Gong, Zhang-fa Yu, Zhen-tao Mi, and Chun-ming Xu. 2017. "Effects of Strand Lay Direction and Crossing Angle on Tribological Behavior of Winding Hoist Rope" Materials 10, no. 6: 630. https://doi.org/10.3390/ma10060630

APA StyleChang, X.-d., Peng, Y.-x., Zhu, Z.-c., Gong, X.-s., Yu, Z.-f., Mi, Z.-t., & Xu, C.-m. (2017). Effects of Strand Lay Direction and Crossing Angle on Tribological Behavior of Winding Hoist Rope. Materials, 10(6), 630. https://doi.org/10.3390/ma10060630