Effect of Hydrogen Exposure on Mechanical and Tribological Behavior of CrxN Coatings Deposited at Different Pressures on IN718

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

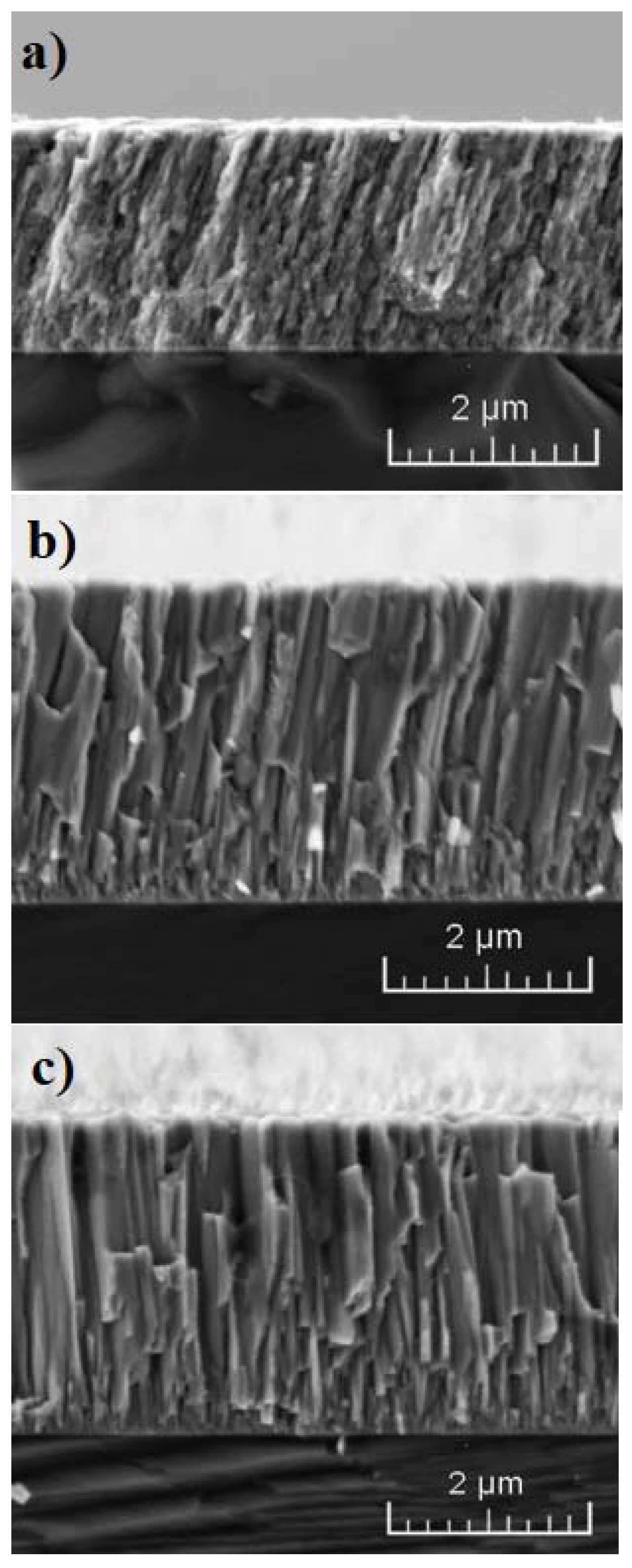

3.1. Morphology and Structural Analysis

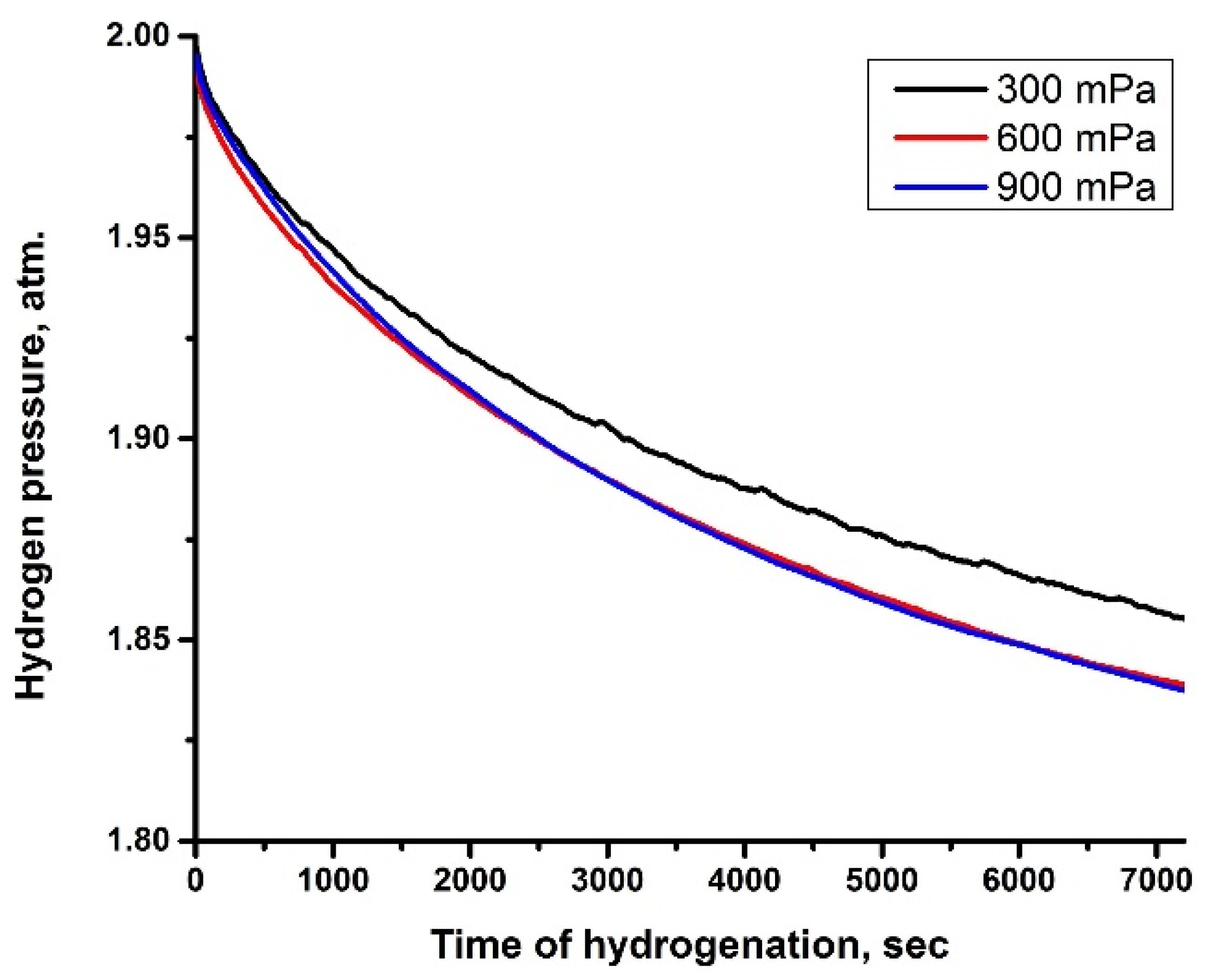

3.2. Gas-Phase Hydrogenation

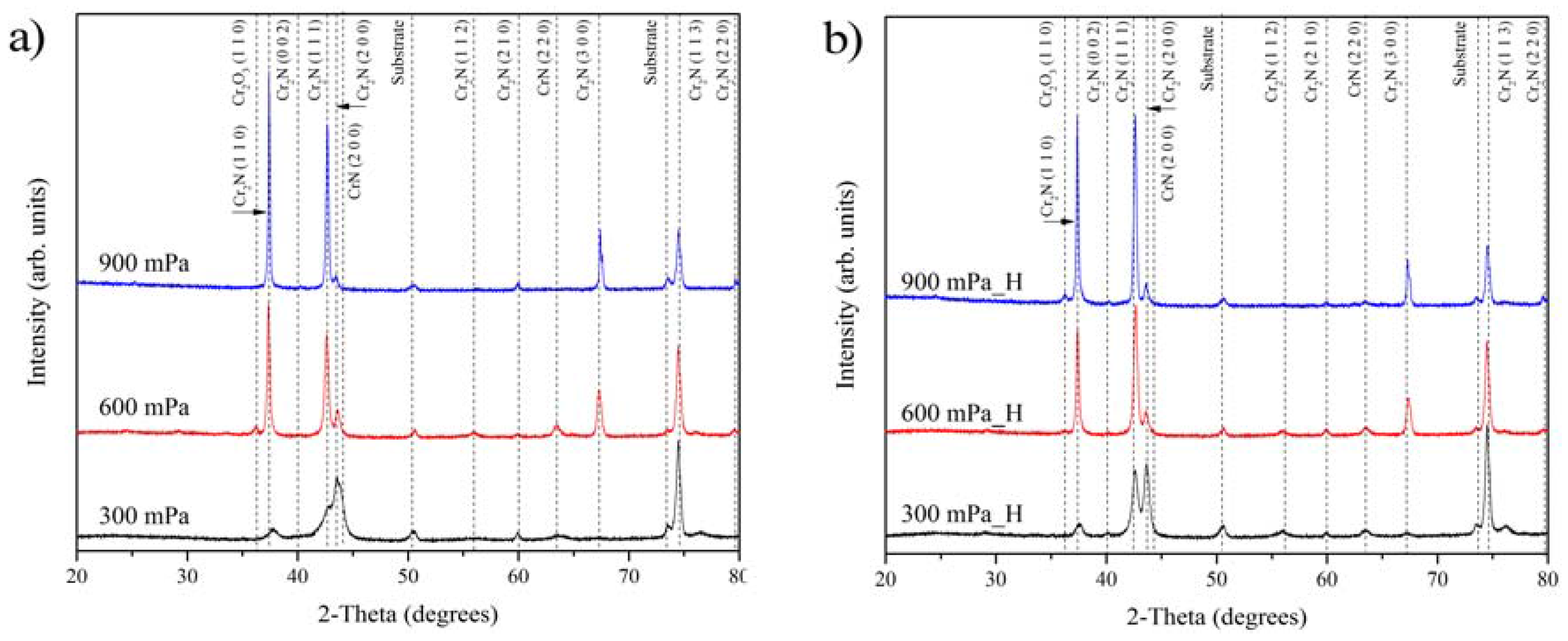

3.3. X-ray Diffraction

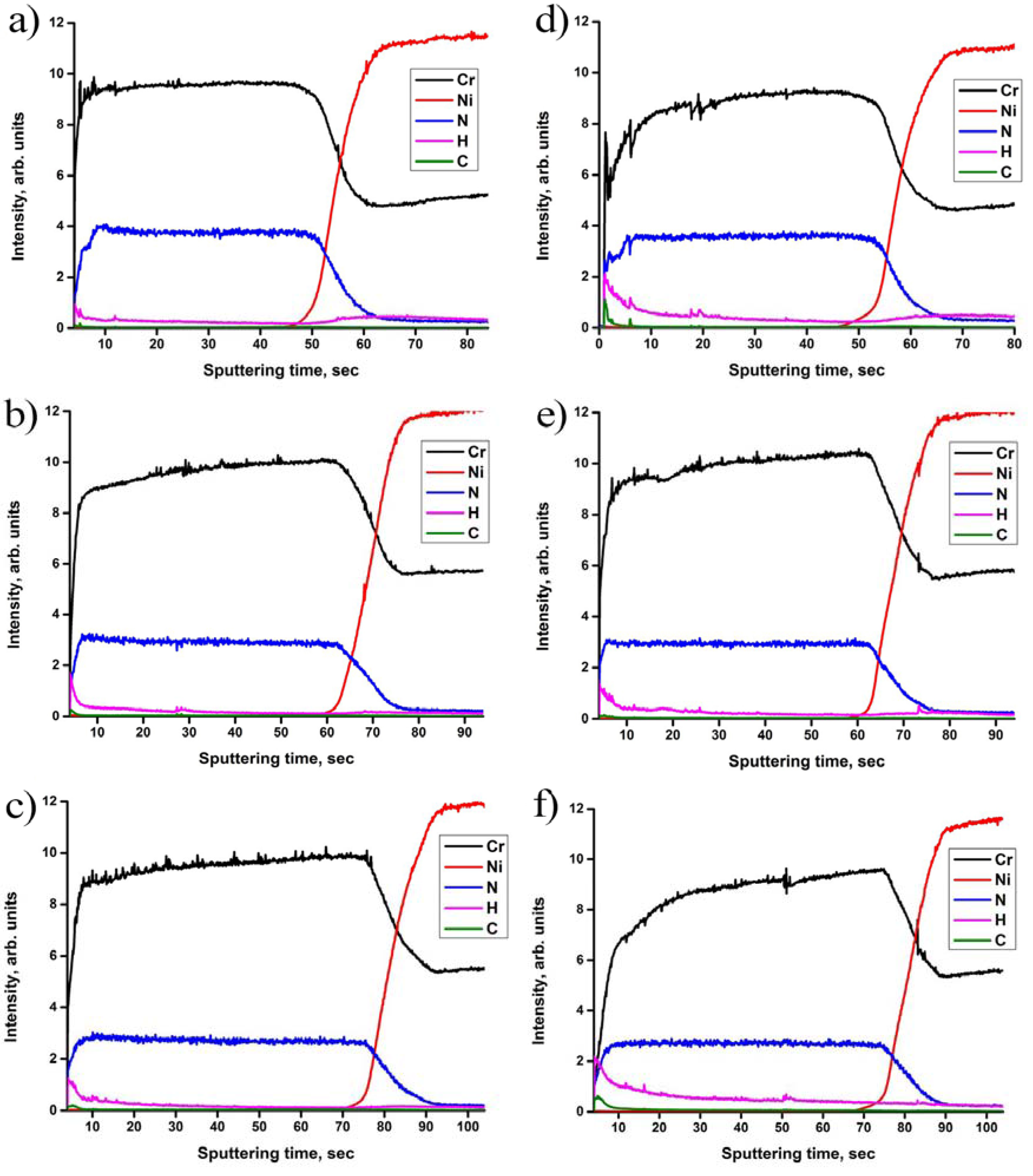

3.4. Depth Distribution of Elements

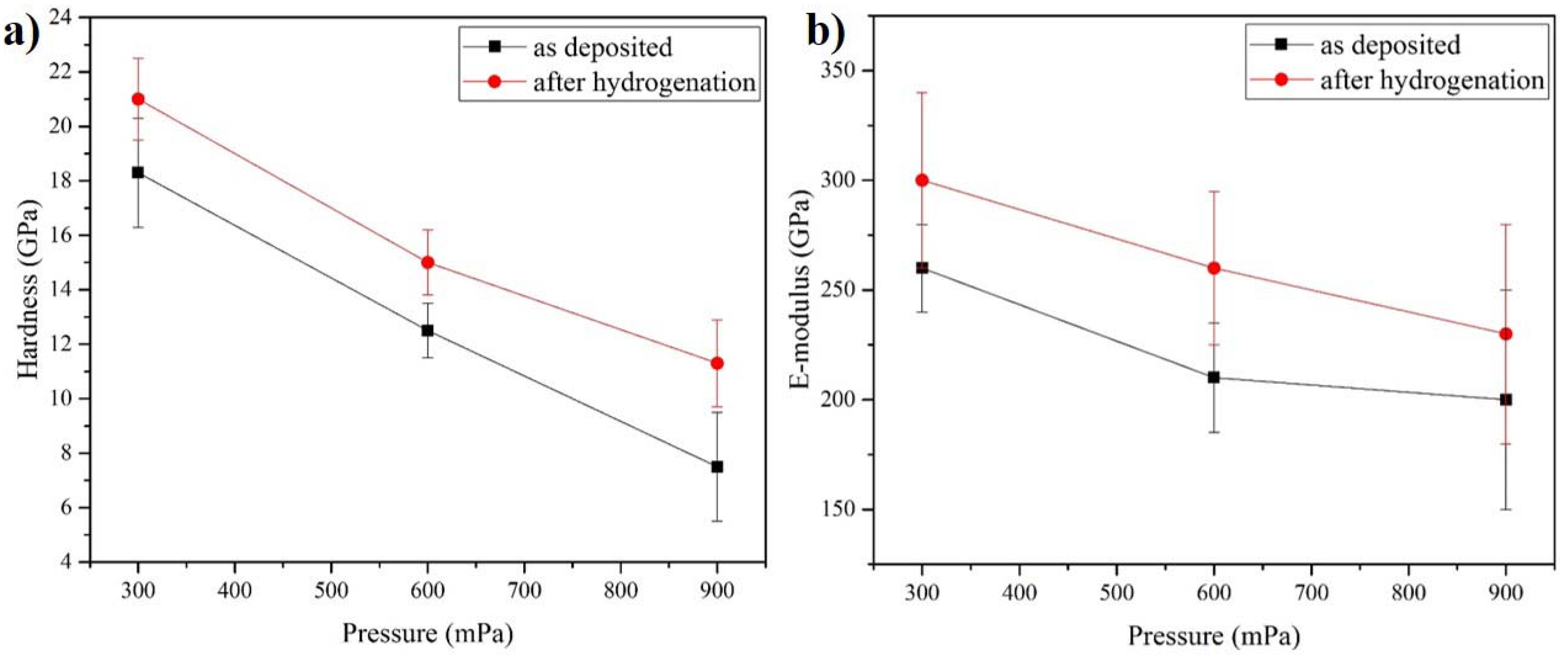

3.5. Mechanical Properties

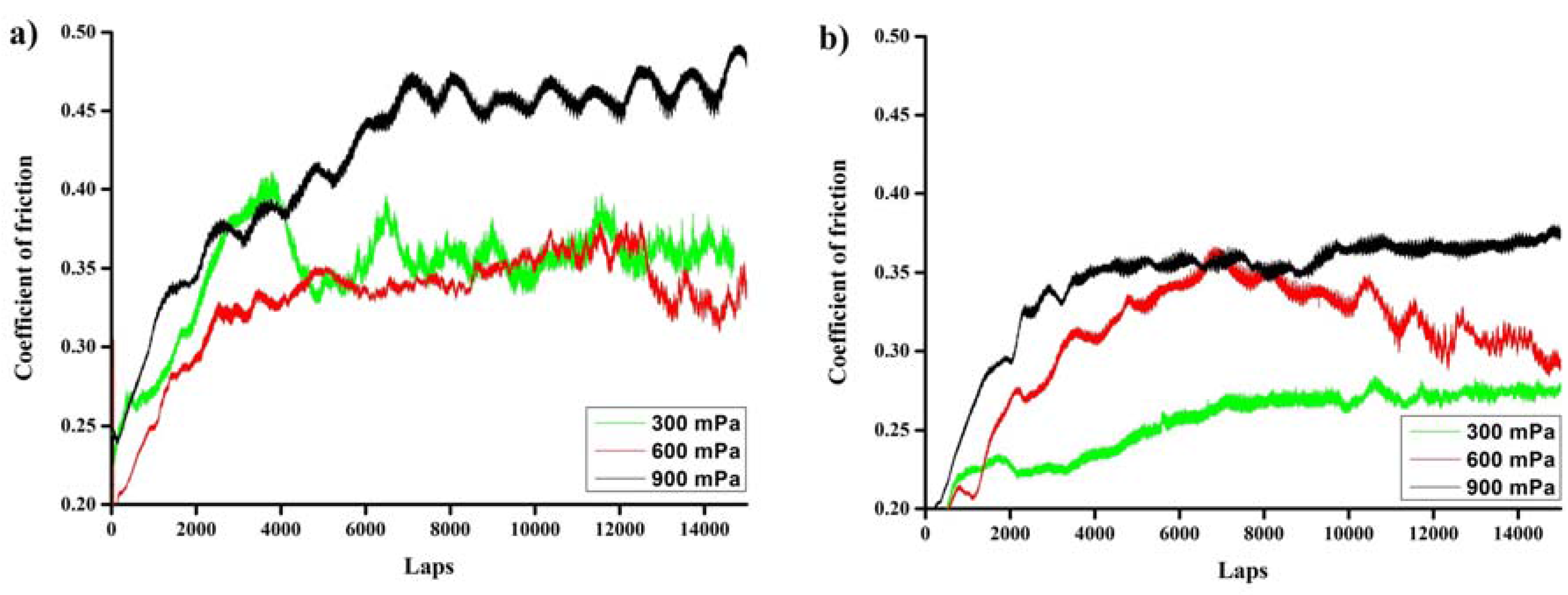

3.6. Tribology

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Niu, Y.; Wei, J.; Yu, Z. Microstructure and tribological behavior of multilayered CrN coating by arc ion plating. Surf. Coat. Technol. 2015, 275, 332–340. [Google Scholar] [CrossRef]

- Liu, B.; Deng, B.; Tao, Y. Influence of niobium ion implantation on the microstructure, mechanical and tribological properties of TiAlN/CrN nano-multilayer coatings. Surf. Coat. Technol. 2014, 240, 405–412. [Google Scholar] [CrossRef]

- Uchida, M.; Nihira, N.; Mitsuo, A.; Toyoda, K.; Kubota, K.; Aizawa, T. Friction and wear properties of CrAlN and CrVN films deposited by cathodic arc ion plating method. Surf. Coat. Technol. 2004, 177–178, 627–630. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A. Effect of substrate bias voltage on the properties of CrCN and CrN coatings deposited by cathodic arc evaporation. Vacuum 2013, 90, 145–150. [Google Scholar] [CrossRef]

- Gilewicz, A.; Warcholinski, B.; Myslinski, P.; Szymanski, W. Anti-wear multilayer coatings based on chromium nitride for wood machining tools. Wear 2010, 270, 32–38. [Google Scholar] [CrossRef]

- Wieciński, P.; Smolik, J.; Garbacz, H.; Kurzydłowski, K.J. Failure and deformation mechanisms during indentation in nanostructured Cr/CrN multilayer coatings. Surf. Coat. Technol. 2014, 240, 23–31. [Google Scholar] [CrossRef]

- Sue, J.A.; Perry, J.A.; Vetter, A.J. Young's modulus and stress of CrN deposited by cathodic vacuum arc evaporation. Surf. Coat. Technol. 1994, 68, 126–130. [Google Scholar] [CrossRef]

- Major, L.; Morgiel, J.; Major, B.; Lackner, J.M.; Waldhauser, W.; Ebner, R.; Nistor, L.; van Tendeloo, G. Crystallographic aspects related to advanced tribological multilayers of Cr/CrN and Ti/TiN types produced by pulsed laser deposition (PLD). Surf. Coat. Technol. 2006, 200, 6190–6195. [Google Scholar] [CrossRef]

- Lackner, J.M.; Waldhauser, W.; Berghauser, R.; Ebner, R.; Kothleitner, G. Growth phenomena in room temperature pulsed laser deposited chromium and chromium nitride coatings. Surf. Coat. Technol. 2005, 200, 387–390. [Google Scholar] [CrossRef]

- Kumar, S.; Raju, V.S.; Shekhar, R.; Arunachalam, J.; Khanna, A.S.; Prasad, K.G. Compositional characterization of CrN films deposited by ion beam-assisted deposition process on stainless steel. Thin Solid Films 2001, 388, 195–200. [Google Scholar] [CrossRef]

- Guglya, A.G.; Marchenko, I.G.; Malykhin, D.G.; Neklyudov, I.M. Production of Cr-N films by ion beam-assisted deposition technology: Experiment and computer simulation. Surf. Coat. Technol. 2003, 163–164, 286–292. [Google Scholar] [CrossRef]

- Egawa, M.; Miura, K.I.; Yokoi, M.; Ishigami, I. Effects of substrate bias voltage on projection growth in chromium nitride films deposited by arc ion plating. Surf. Coat. Technol. 2007, 201, 4873–4878. [Google Scholar] [CrossRef]

- Zhang, M.; Kim, K.H.; Xu, F.; Yang, X. Structure and oxidation behavior of compositionally gradient CrNx coatings prepared using arc ion plating. Surf. Coat. Technol. 2013, 228, S529–S533. [Google Scholar] [CrossRef]

- Chang, Z.K.; Wan, X.S.; Pei, Z.L.; Gong, J.; Sun, C. Microstructure and mechanical properties of CrN coating deposited by arc ion plating on Ti6Al4V substrate. Surf. Coat. Technol. 2011, 205, 4690–4696. [Google Scholar] [CrossRef]

- Tan, S.; Zhang, X.; Wu, X.; Fang, F.; Jiang, J. Comparison of chromium nitride coatings deposited by DC and RF magnetron sputtering. Thin Solid Films 2011, 519, 2116–2120. [Google Scholar] [CrossRef]

- Lee, J.-W.; Kuo, Y.-C.; Wang, C.-J.; Chang, L.-C.; Liu, K.-T. Effects of substrate bias frequencies on the characteristics of chromium nitride coatings deposited by pulsed DC reactive magnetron sputtering. Surf. Coat. Technol. 2008, 203, 721–725. [Google Scholar] [CrossRef]

- Shah, H.N.; Jayaganthan, R.; Kaur, D.; Chandra, R. Influence of sputtering parameters and nitrogen on the microstructure of chromium nitride thin films deposited on steel substrate by direct-current reactive magnetron sputtering. Thin Solid Films 2010, 518, 5762–5768. [Google Scholar] [CrossRef]

- Obrosov, A.; Naveed, M.; Volinsky, A.A.; Weiß, S. Substrate frequency effects on CrxN coatings deposited by DC magnetron sputtering. J. Mater. Eng. Perform. 2017, 26, 366–373. [Google Scholar] [CrossRef]

- Odén, M.; Almer, J.; Håkansson, G. The effects of bias voltage and annealing on the microstructure and residual stress of arc-evaporated Cr-N coatings. Surf. Coat. Technol. 1999, 120–121, 272–276. [Google Scholar] [CrossRef]

- Krella, A.; Czyżniewski, A. Cavitation resistance of Cr-N coatings deposited on austenitic stainless steel at various temperatures. Wear 2009, 266, 800–809. [Google Scholar] [CrossRef]

- Odén, M.; Ericsson, C.; Håkansson, G.; Ljungcrantz, H. Microstructure and mechanical behavior of arc-evaporated Cr-N coatings. Surf. Coat. Technol. 1999, 114, 39–51. [Google Scholar] [CrossRef]

- Wan, X.S.; Zhao, S.S.; Yang, Y.; Gong, J.; Sun, C. Effects of nitrogen pressure and pulse bias voltage on the properties of Cr-N coatings deposited by arc ion plating. Surf. Coat. Technol. 2010, 204, 1800–1810. [Google Scholar] [CrossRef]

- Shah, H.N.; Jayaganthan, R.; Kaur, D. Effect of sputtering pressure and temperature on dc magnetron sputtered CrN films. Surf. Eng. 2010, 26, 629–637. [Google Scholar] [CrossRef]

- Sjoberfg, G.; Cornu, D. Hydrogen Embrittlement of Cast Alloy 718 Effects of Homogenization, Grain Size and δ-Phase. In Superalloys 718, 625, 706 and Various Derivatives (2001); The Minerals, Metals & Materials Society (TMS): Pittsburgh, PA, USA, 2001; pp. 679–690. ISBN 0873395107, 9780873395106. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Obrosov, A.; Gulyaev, R.; Zak, A.; Ratzke, M.; Naveed, M.; Dudzinski, W.; Weiß, S. Chemical and morphological characterization of magnetron sputtered at different bias voltages Cr-Al-C coatings. Materials 2017, 10, 156. [Google Scholar] [CrossRef]

- Kashkarov, E.B.; Nikitenkov, N.N.; Sutygina, A.N.; Bezmaternykh, A.O.; Kudiiarov, V.N.; Syrtanov, M.S.; Pryamushko, T.S. Hydrogenation behavior of Ti-implanted Zr-1Nb alloy with tin films deposited using filtered vacuum arc and magnetron sputtering. Appl. Surf. Sci. 2017. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F. Progress in tribological properties of nano-composite hard coatings under water lubrication. Lubricants 2017, 5, 5. [Google Scholar] [CrossRef]

- Tamura, M.; Noma, M.; Yamashita, M. Characteristic change of hydrogen permeation in stainless steel plate by BN coating. Surf. Coat. Technol. 2014, 260, 148–154. [Google Scholar] [CrossRef]

- Sidelev, D.V.; Bleykher, G.A.; Krivobokov, V.P.; Koishybayeva, Z. High-rate magnetron sputtering with hot target. Surf. Coat. Technol. 2016, 308, 168–173. [Google Scholar] [CrossRef]

- McHale, A.E. Borides, carbides, and nitrides. In Phase Equilibria Diagrams: Phase Diagrams for Ceramists; American Ceramic Society: Washington DC, USA, 1994; Volume X, ISBN 9780944904749. [Google Scholar]

- Eufinger, K.; Janssen, E.N.; Poelman, H.; Poelman, D.; De Gryse, R.; Marin, G.B. The effect of argon pressure on the structural and photocatalytic characteristics of TiO2 thin films deposited by d.c. Magnetron sputtering. Thin Solid Films 2006, 515, 425–429. [Google Scholar] [CrossRef]

- Klabunde, F.; Löhmann, M.; Bläsing, J.; Drüsedau, T. The influence of argon pressure on the structure of sputtered molybdenum: From porous amorphous to a new type of highly textured film. J. Appl. Phys. 1996, 80, 6266–6273. [Google Scholar] [CrossRef]

- Mergel, D.; Buschendorf, D.; Eggert, S.; Grammes, R.; Samset, B. Density and refractive index of TiO2 films prepared by reactive evaporation. Thin Solid Films 2000, 371, 218–224. [Google Scholar] [CrossRef]

- Benhenda, S.; Guglielmacci, J.M.; Gillet, M. Characterization of tin films grown by reactive d.c. Triode sputtering onto copper substrates. Mater. Sci. Eng. B 1995, 34, 36–41. [Google Scholar] [CrossRef]

- Hones, P.; Sanjines, R.; Levy, F. Characterization of sputter-deposited chromium nitride thin films for hard coatings. Surf. Coat. Technol. 1997, 94, 398–402. [Google Scholar] [CrossRef]

- Wei, G.; Rar, A.; Barnard, J.A. Composition, structure, and nanomechanical properties of DC-sputtered CrNx (0 ≤ x ≤ 1) thin films. Thin Solid Films 2001, 398–399, 460–464. [Google Scholar] [CrossRef]

- Ellis, A.B. Teaching General Chemistry: A Materials Science Companion; American Chemical Society: Washington DC, USA, 1993; ISBN 978-0841227255. [Google Scholar]

- Han, S.; Lin, J.H.; Wang, G.H.; Shih, H.C. The effect of preferred orientation on the mechanical properties of chromium nitride coatings deposited on SKD11 by unbalanced magnetron sputtering. Mater. Lett. 2003, 57, 1202–1209. [Google Scholar] [CrossRef]

- Zhou, T.; Liu, D.; Zhang, Y.; Ouyang, T.; Suo, J. Microstructure and hydrogen impermeability of titanium nitride thin films deposited by direct current reactive magnetron sputtering. J. Alloys Compd. 2016, 688, 44–50. [Google Scholar] [CrossRef]

- Zhao, Z.B.; Rek, Z.U.; Yalisove, S.M.; Bilello, J.C. Phase formation and structure of magnetron sputtered chromium nitride films: In-situ and ex-situ studies. Surf. Coat. Technol. 2004, 185, 329–339. [Google Scholar] [CrossRef]

- Bull, S.J.; Rickerby, D.S. Compositional, microstructural and morphological effects on the mechanical and tribological properties of chromium nitrogen films. Surf. Coat. Technol. 1990, 43, 732–744. [Google Scholar] [CrossRef]

- Shah, H.N.; Chawla, V.; Jayaganthan, R.; Kaur, D. Microstructural characterizations and hardness evaluation of d.c. Reactive magnetron sputtered CrN thin films on stainless steel substrate. Bull. Mater. Sci. 2010, 33, 103–110. [Google Scholar] [CrossRef]

- Wang, J.; Li, Q.; Xiang, Q.-Y.; Cao, J.-L. Performances of AlN coatings as hydrogen isotopes permeation barriers. Fusion Eng. Des. 2016, 102, 94–98. [Google Scholar] [CrossRef]

- Rapoport, L.; Moshkovich, A.; Perfilyev, V.; Lapsker, I.; Kugler, M.; Kailer, A.; Renz, A.; Hollstein, T. High temperature friction behavior of CrVxN coatings. Surf. Coat. Technol. 2014, 238, 207–215. [Google Scholar] [CrossRef]

- Lin, J.; Wu, Z.L.; Zhang, X.H.; Mishra, B.; Moore, J.J.; Sproul, W.D. A comparative study of CrNx coatings synthesized by dc and pulsed dc magnetron sputtering. Thin Solid Films 2009, 517, 1887–1894. [Google Scholar] [CrossRef]

- Godet, M. The third-body approach: A mechanical view of wear. Wear 1984, 100, 437–452. [Google Scholar] [CrossRef]

- Singer, I.L. How third-body processes affect friction and wear. MRS Bull. 1998, 23, 37–40. [Google Scholar] [CrossRef]

- Moore, A.J.W.; Tegart, W.J.M. Relation between friction and hardness. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1952, 212, 452–458. [Google Scholar]

- Mo, J.L.; Zhu, M.H. Tribological characterization of chromium nitride coating deposited by filtered cathodic vacuum arc. Appl. Surf. Sci. 2009, 255, 7627–7634. [Google Scholar] [CrossRef]

| Element (at. %) | Pressure, mPa | ||

|---|---|---|---|

| 300 | 600 | 900 | |

| Cr | 59 | 62 | 66 |

| N | 41 | 38 | 34 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obrosov, A.; Sutygina, A.N.; Volinsky, A.A.; Manakhov, A.; Weiß, S.; Kashkarov, E.B. Effect of Hydrogen Exposure on Mechanical and Tribological Behavior of CrxN Coatings Deposited at Different Pressures on IN718. Materials 2017, 10, 563. https://doi.org/10.3390/ma10050563

Obrosov A, Sutygina AN, Volinsky AA, Manakhov A, Weiß S, Kashkarov EB. Effect of Hydrogen Exposure on Mechanical and Tribological Behavior of CrxN Coatings Deposited at Different Pressures on IN718. Materials. 2017; 10(5):563. https://doi.org/10.3390/ma10050563

Chicago/Turabian StyleObrosov, Aleksei, Alina N. Sutygina, Alex A. Volinsky, Anton Manakhov, Sabine Weiß, and Egor B. Kashkarov. 2017. "Effect of Hydrogen Exposure on Mechanical and Tribological Behavior of CrxN Coatings Deposited at Different Pressures on IN718" Materials 10, no. 5: 563. https://doi.org/10.3390/ma10050563

APA StyleObrosov, A., Sutygina, A. N., Volinsky, A. A., Manakhov, A., Weiß, S., & Kashkarov, E. B. (2017). Effect of Hydrogen Exposure on Mechanical and Tribological Behavior of CrxN Coatings Deposited at Different Pressures on IN718. Materials, 10(5), 563. https://doi.org/10.3390/ma10050563