Mechanical Properties of Epoxy Resin Mortar with Sand Washing Waste as Filler

Abstract

:1. Introduction

2. Experiment

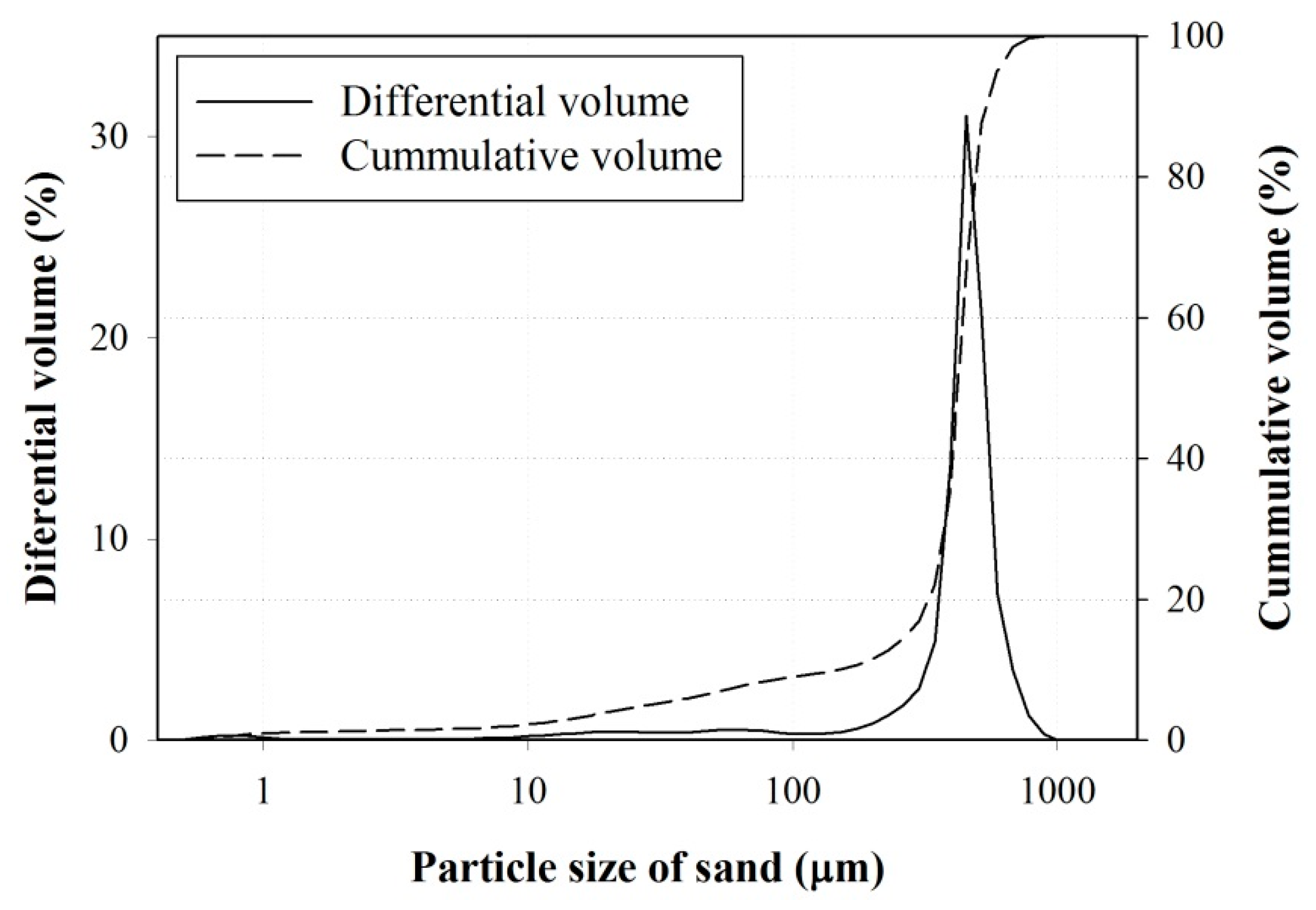

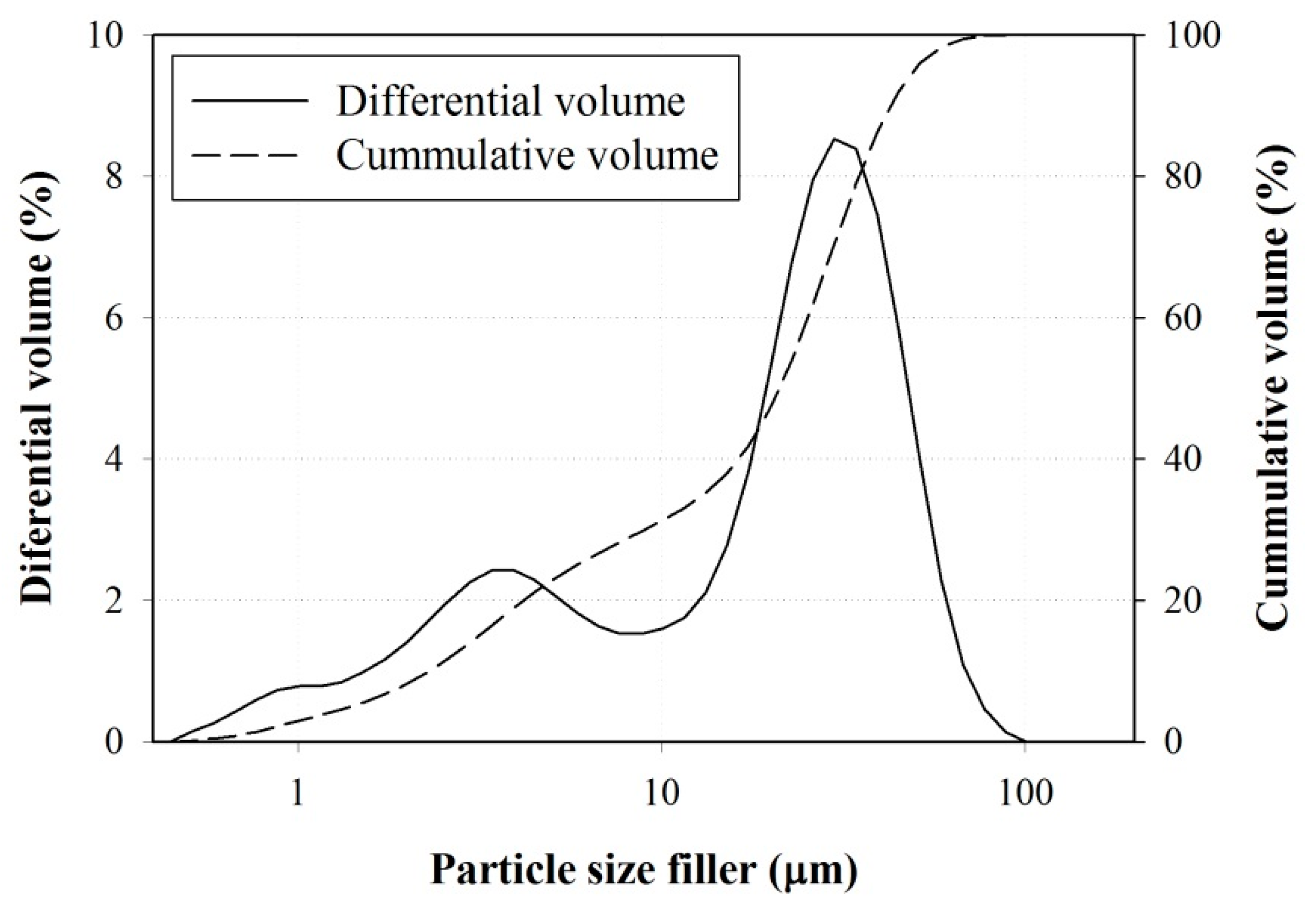

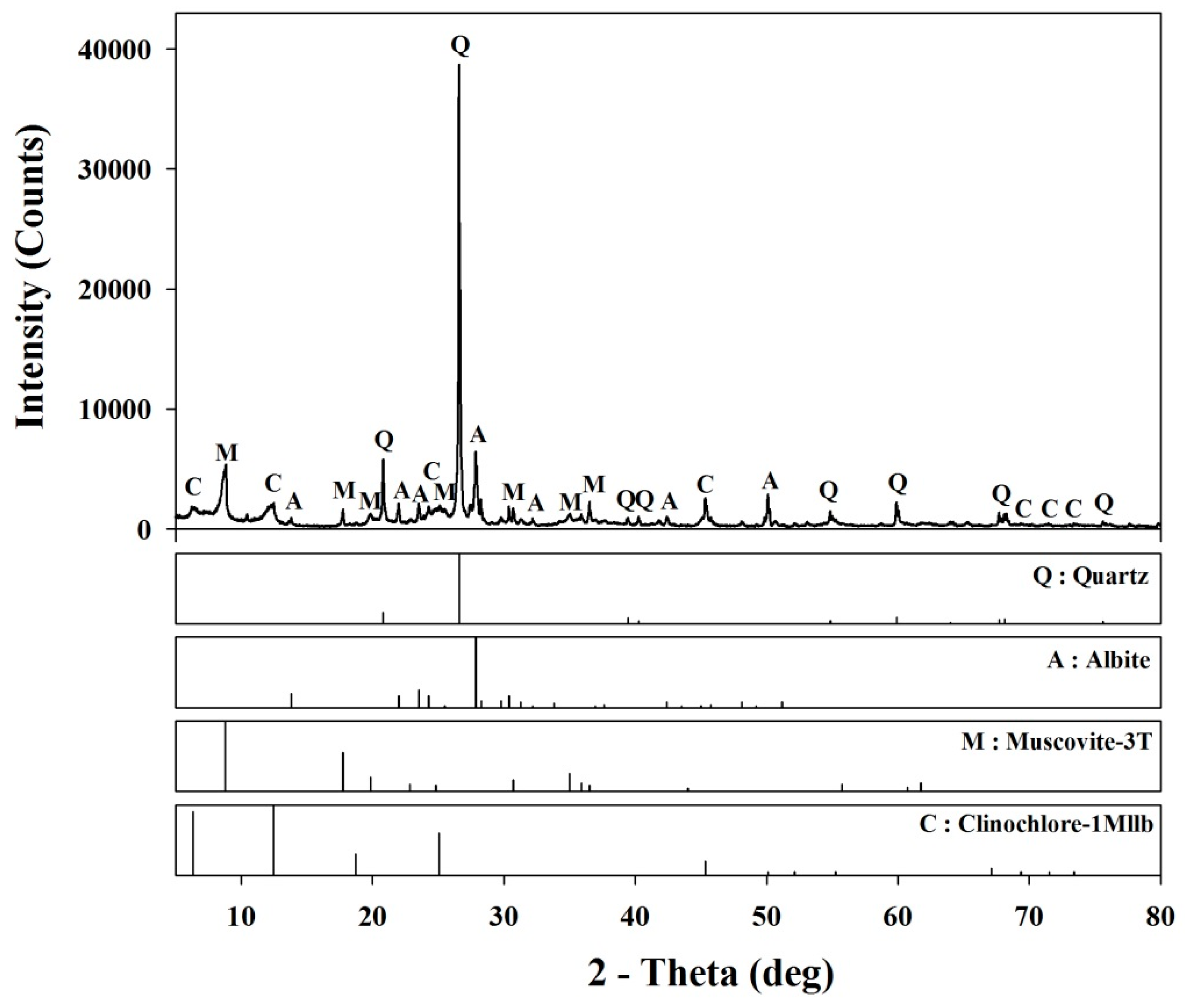

2.1. Materials

2.2. Mix Proportions

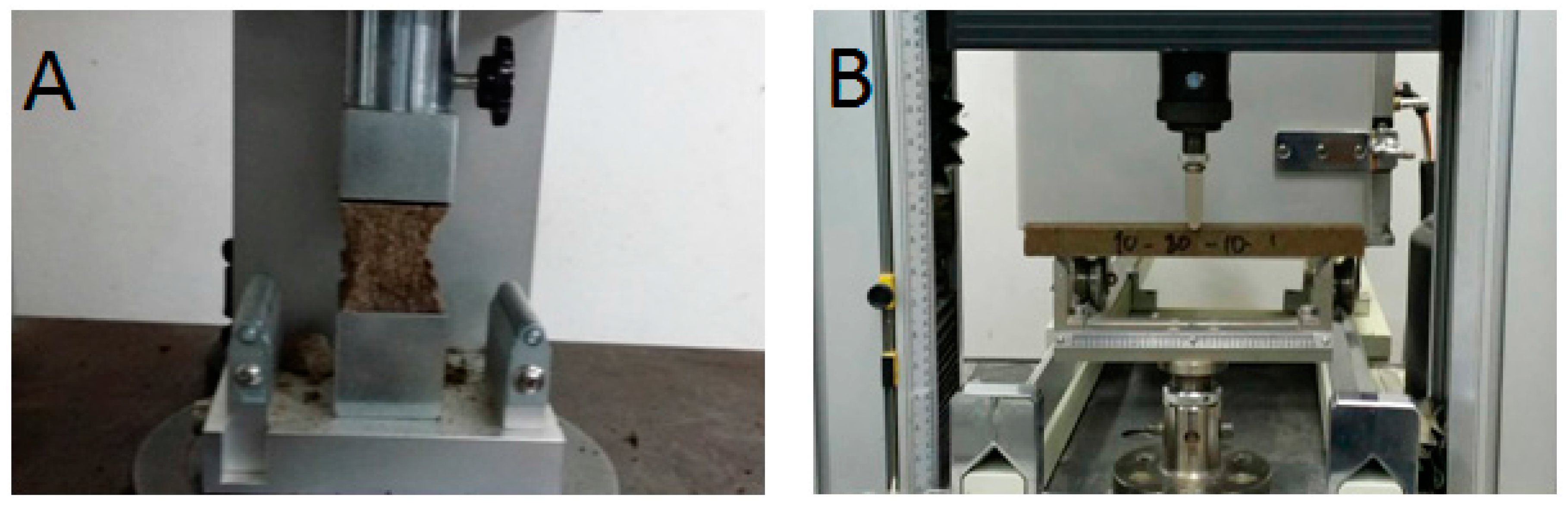

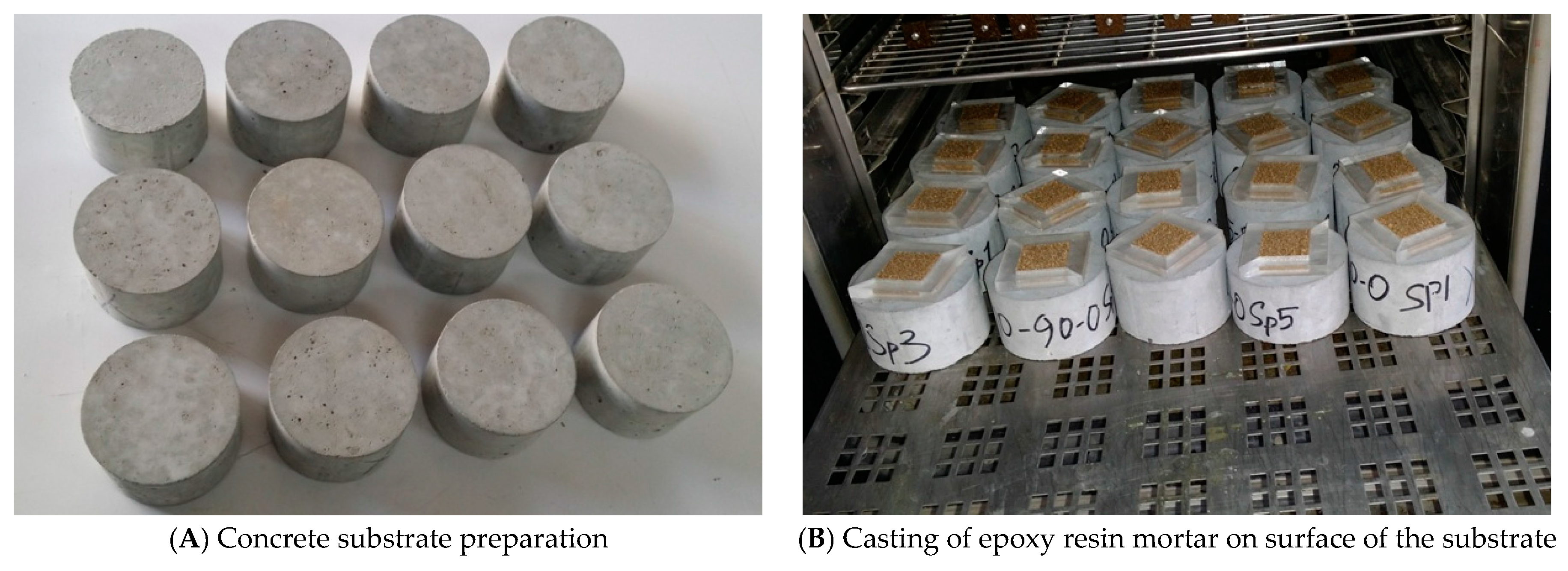

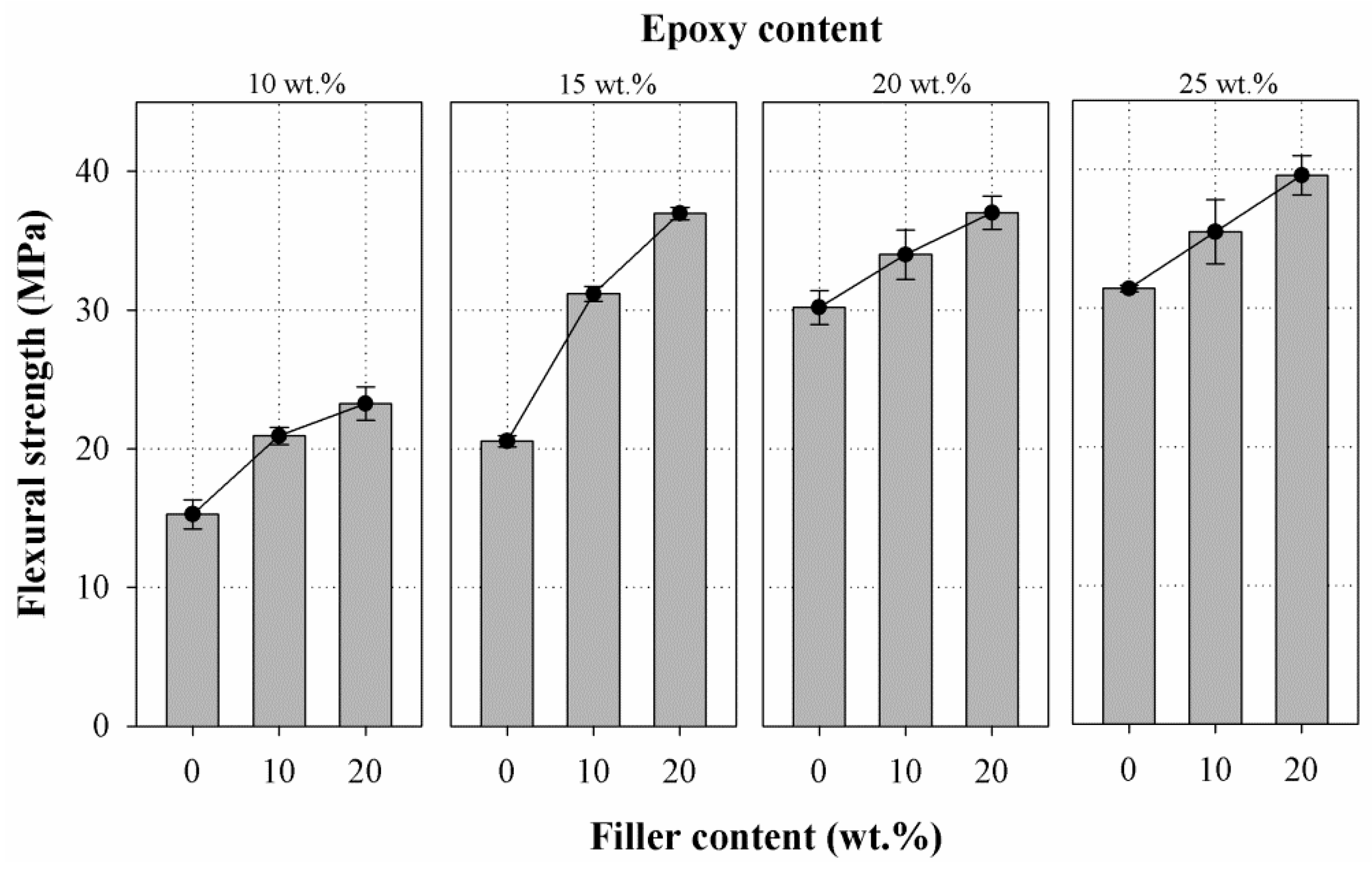

2.3. Test Method

3. Results and Discussion

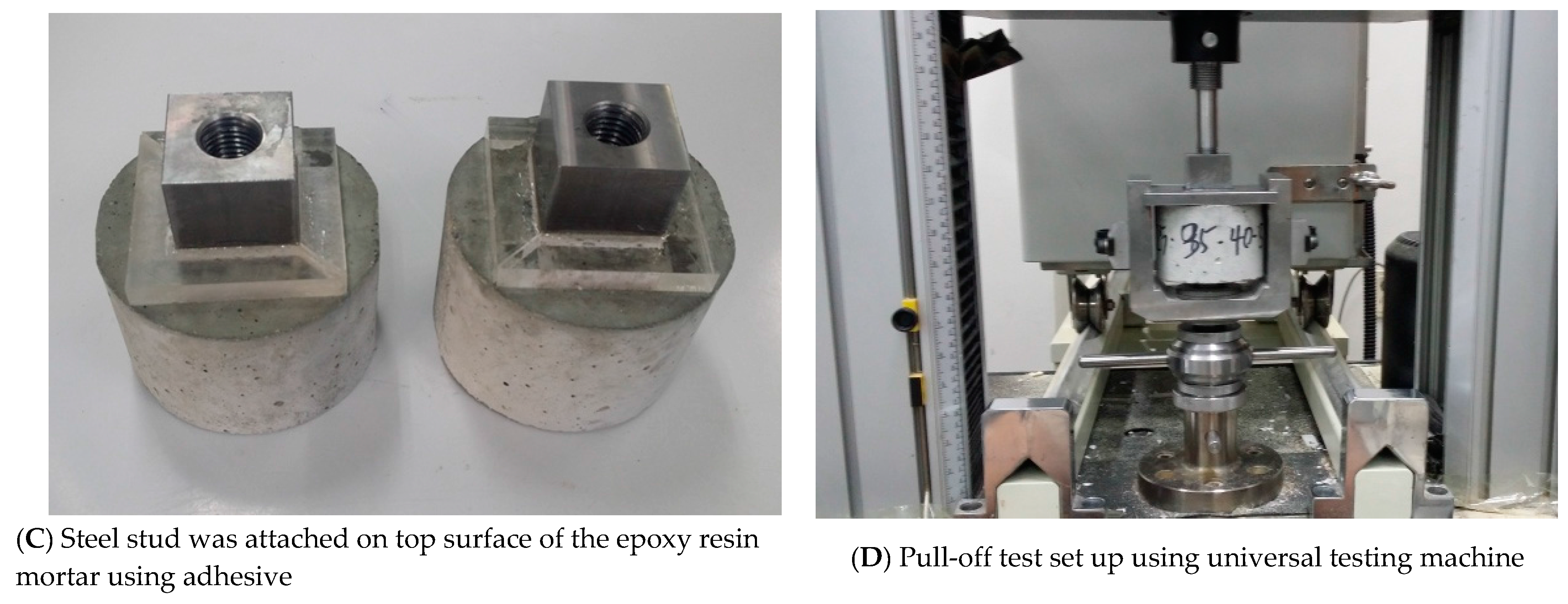

3.1. Compressive Strength

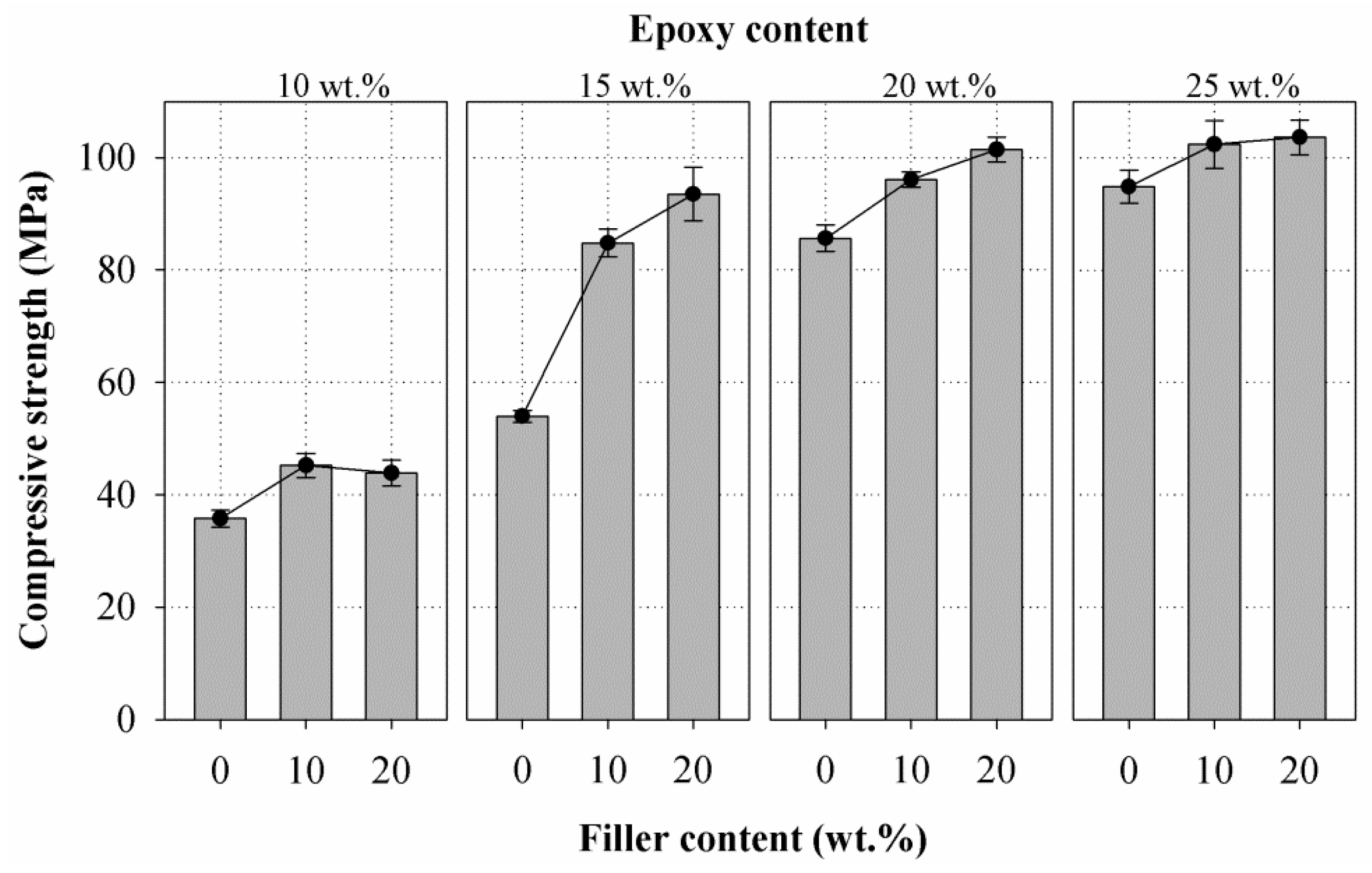

3.2. Flexural Strength

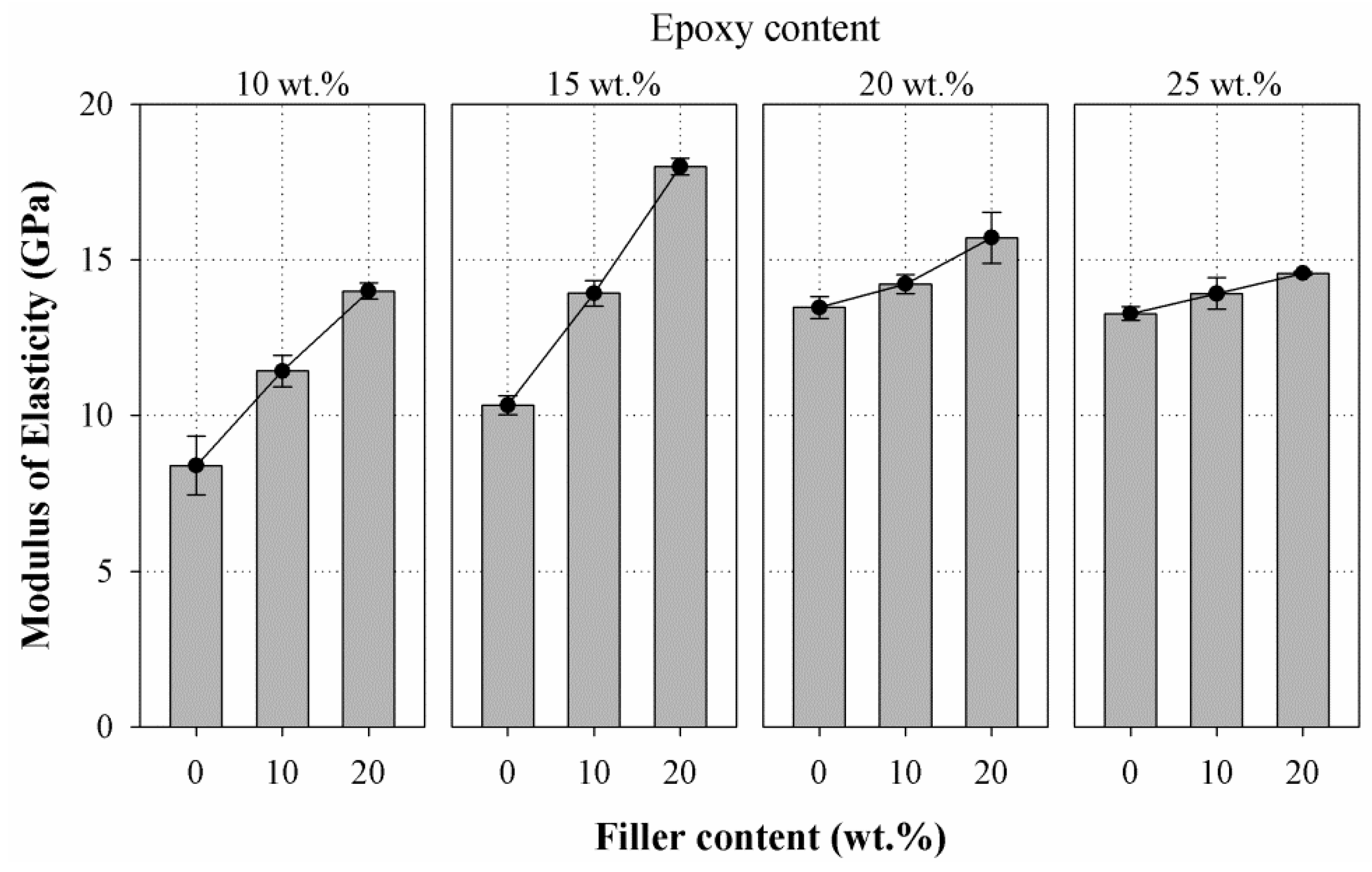

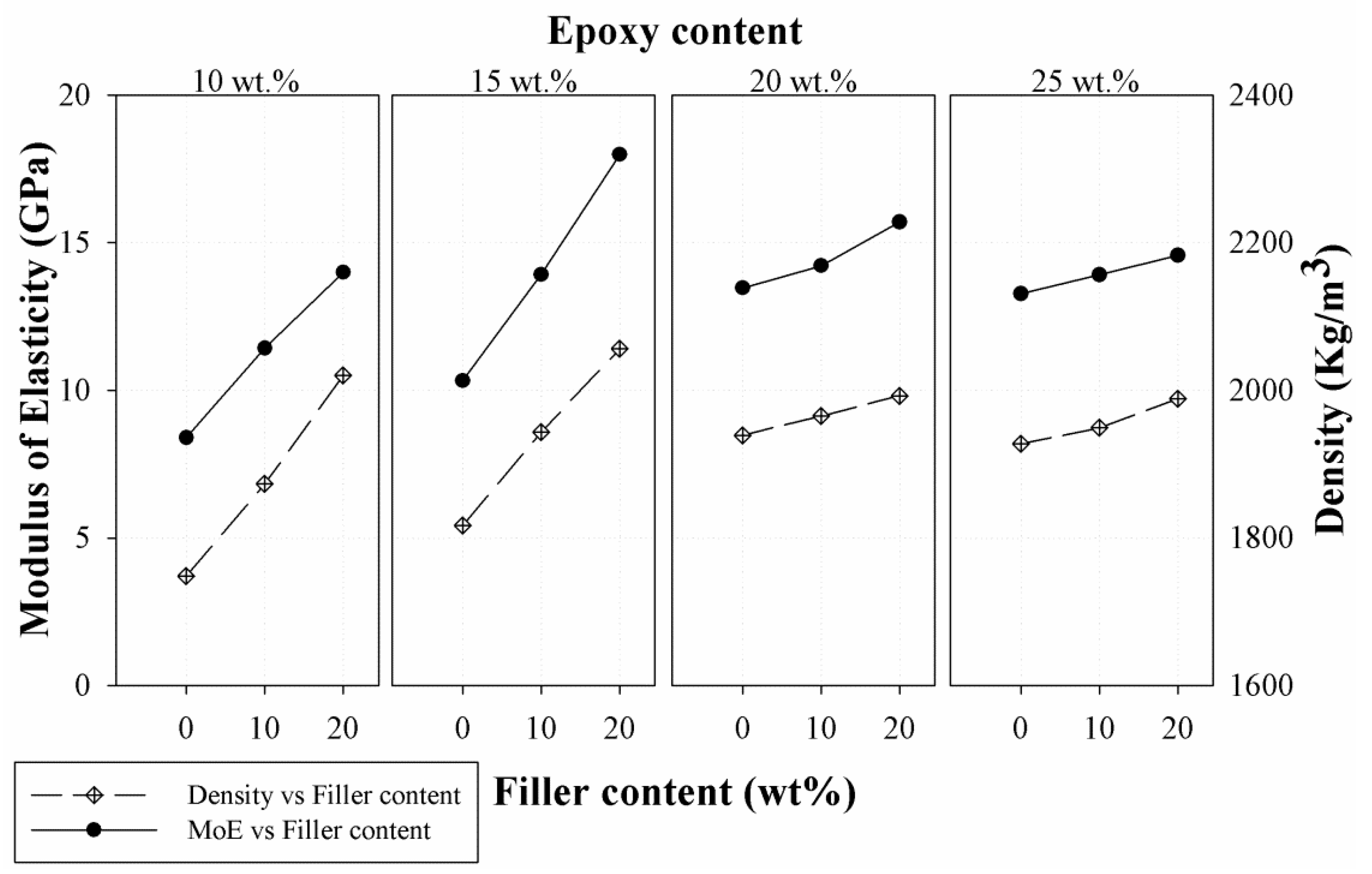

3.3. Modulus of Elasticity (MoE)

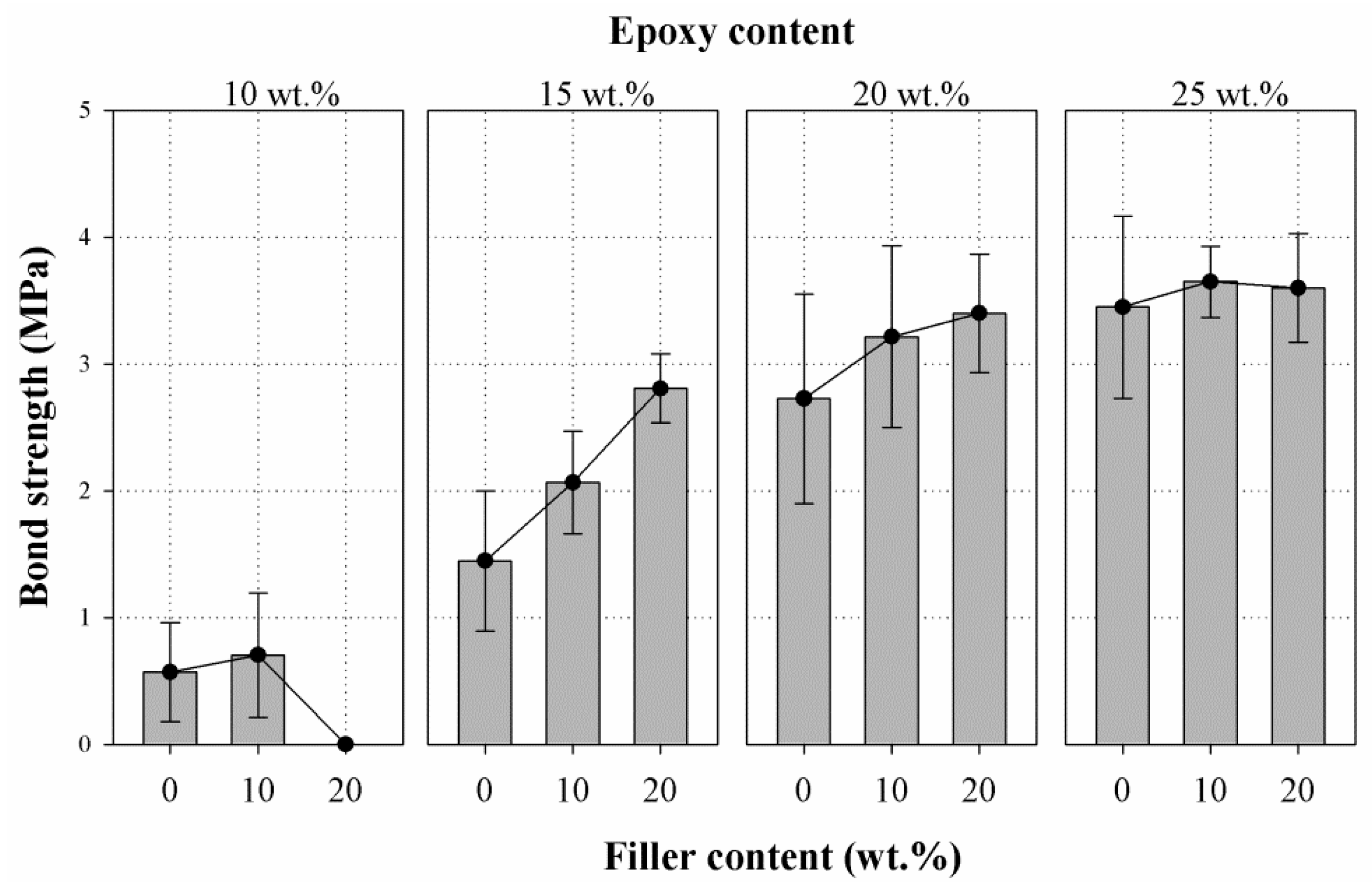

3.4. Bond Strength

4. Conclusions

- (1)

- The compressive strength, flexural strength and modulus of elasticity value of epoxy mortar containing filler up to 20 wt. % improved by an average of 1.08–1.66, 1.18–1.66, and 1.07–1.54 times, respectively, at different weight fraction of epoxy in the range of 10–25 wt. % when compared to the control specimens.

- (2)

- It was observed that when filler is used at optimum level, it can improve bond strength; all the mortars except those prepared with epoxy at 10 wt. % showed a good bond strength higher than 1.5 MPa.

- (3)

- It can be established that sand washing waste can be used as potential filler for epoxy resin mortar to obtain better compressive, flexural, stiffness, and bond strength.

- (4)

- This study does not cover all the parameters required to examine repair materials for concrete structures; further investigations on compatibility issues such as dimensional change stability of the epoxy resin mortar containing sand washing waste filler is required.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mays, G.C.; Hutchinson, A.R. Adhesives in Civil Engineering; Cambridge University Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Grantham, M.G. Concrete Repair: A Practical Guide; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Briffett, C. Building Maintenance Technology in Tropical Climates; Singapore University Press: Queenstown, Singapore, 1995. [Google Scholar]

- ElSafty, A.; Abdel-Mohti, A. Investigation of likelihood of cracking in reinforced concrete bridge decks. Int. J. Concr. Struct. Mater. 2013, 7, 79–93. [Google Scholar] [CrossRef]

- Seo, Y.; Kim, S.M. Longitudinal cracking at transverse joints caused by dowel bars in Jointed Concrete Pavements. KSCE J. Civ. Eng. 2013, 17, 395–402. [Google Scholar] [CrossRef]

- Raupach, I.M. Concrete repair according to the new European standard EN 1504. Integrative Oncology. Princ. Pract. 2005, 55, 109–116. [Google Scholar]

- Kenser, K.; Conroy, K. ACI 562-Development of a Building Code for Repair of Existing Concrete Structures; National Council of Structural Engineers Association: Chicago, IL, USA, 2014. [Google Scholar]

- Barbuta, M.; Lepadatu, D. Mechanical characteristics investigation of polymer concrete using mixture design of experiments and response surface method. Appl. Sci. 2008, 8, 2242–2249. [Google Scholar]

- Ribeiro, M.C.S.; Nóvoa, P.R.; Ferreira, A.J.M.; Marques, A.T. Flexural performance of polyester and epoxy polymer mortars under severe thermal conditions. Cem. Concr. Compos. 2004, 26, 803–809. [Google Scholar] [CrossRef]

- ACI-Committee. Causes, Evaluation, and Repairs of Cracks in Concrete Structures (224.1R-07); American Concrete Institute: Farmington Hills, MI, USA, 2007. [Google Scholar]

- Fowler, D.W. Polymers in concrete: A vision for the 21st century. Cem. Concr. Compos. 1999, 21, 449–452. [Google Scholar] [CrossRef]

- Daghash, S.M.; Soliman, E.M.; Kandil, U.F.; Reda Taha, M.M. Improving Impact Resistance of Polymer Concrete Using CNTs. Int. J. Concr. Struct. Mater. 2016, 10, 539–553. [Google Scholar] [CrossRef]

- Mays, G.C. Durability of Concrete Structures: Investigation, Repair, Protection; CRC Press: London, UK, 2002. [Google Scholar]

- Gorninski, J.P.; Dal Molin, D.C.; Kazmierczak, C.S. Study of the modulus of elasticity of polymer concrete compounds and comparative assessment of polymer concrete and Portland cement concrete. Cem. Concr. Res. 2004, 34, 2091–2095. [Google Scholar] [CrossRef]

- Decter, M.H. Durable concrete repair—Importance of compatibility and low shrinkage. Constr. Build. Mater. 1997, 11, 267–273. [Google Scholar] [CrossRef]

- Hassan, K.E.; Brooks, J.J.; Al-Alawi, L. Compatibility of repair mortars with concrete in a hot-dry environment. Cem. Concr. Compos. 2001, 23, 93–101. [Google Scholar] [CrossRef]

- Morgan, D.R. Compatibility of concrete repair materials and systems. Constr. Build. Mater. 1996, 10, 57–67. [Google Scholar] [CrossRef]

- Vaysburd, A.M. Holistic system approach to design and implementation of concrete repair. Cem. Concr. Compos. 2006, 28, 671–678. [Google Scholar] [CrossRef]

- Karade, S.; Lakhani, R.; Asthana, K.K. Evaluation of repair materials: Issues and methods. Constr. Build. Mater. World 2006, 11, 152–168. [Google Scholar]

- Golestaneh, M.; Amini, G.; Najafpour, G.; Beygi, M. Evaluation of mechanical strength of epoxy polymer concrete with silica powder as filler. World Appl. Sci. J. 2010, 9, 216–220. [Google Scholar]

- Reis, J.M.L. Fracture and flexural assessment of red mud in epoxy polymer mortars. Mater. Struct. 2015, 48, 3929–3936. [Google Scholar] [CrossRef]

- Lokuge, W.; Aravinthan, T. Effect of fly ash on the behaviour of polymer concrete with different types of resin. Mater. Des. 2013, 51, 175–181. [Google Scholar] [CrossRef]

- Atzeni, C.; Massidda, L.; Sanna, U. Mechanical properties of epoxy mortars with fly ash as filler. Cem. Concr. Compos. 1990, 12, 3–8. [Google Scholar] [CrossRef]

- Kallel, T.; Samet, B.; S’Habou, R.; Kallel, A. Optimization of sand washing waste as pozzolanic material. Int. J. Res. Rev. Appl. Sci. 2015, 23, 15–27. [Google Scholar]

- Kallel, T.; Kallel, A.; Samet, B. Durability of mortars made with sand washing waste. Constr. Build. Mater. 2016, 122, 728–735. [Google Scholar] [CrossRef]

- ASTM. ASTM C881 Standard Specification for Epoxy-Resin-Base Bonding Systems for Concrete; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. ASTM C128 Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. ASTM C29 Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM. ASTM D854 Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Korean-Standard. KS F 4043 Epoxy Resin Mortar for Restoration in Concrete Structure; Korean Agency for Technology and Standards: Seoul, Korea, 2008. [Google Scholar]

- European-Standard. EN 12190 Products and Systems for the Protection and Repair of Concrete Structures. Test Methods. Determination of Compressive Strength of Repair Mortar; European Committee for Standardization: Brussels, Belgium, 1998. [Google Scholar]

- ASTM. ASTM C580 Standard Test Method for Flexural Strength and Modulus of Elasticity of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer Concretes; American Society for Testing and Materials: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Kuhlmamr, A.L. Test method for measuring the bond strength of Latex-Modified concrete and mortar. ACI Mater. J. 1990, 87, 387–394. [Google Scholar]

- Bonaldo, E.; Barros, J.A.O.; Lourenço, P.B. Bond characterization between concrete substrate and repairing SFRC using pull-off testing. Int. J. Adhes. Adhes. 2005, 25, 463–474. [Google Scholar] [CrossRef]

| Type | Epoxy Resin | Hardener |

|---|---|---|

| Mixing proportion | 3 | 1 |

| Specific gravity | 1.14 ± 0.1 | 1.02 ± 0.1 |

| Color | Colorless | Brown |

| Viscosity (mPa·s) | 550 ± 50 | |

| Pot life (min) | 30 ± 10 at 23 °C | |

| Hardening time (h) | 24–36 at 23 °C | |

| Chemical Composition | SiO2 | Al2O3 | K2O | Fe2O3 | TiO2 | MnO2 | CaO |

|---|---|---|---|---|---|---|---|

| Sand | 87.720 | 5.915 | 6.277 | - | - | - | - |

| Filler | 70.993 | 18.070 | 1.792 | 6.450 | 0.805 | 0.282 | 1.607 |

| Specimen * | Epoxy (E) | Sand (S) | Sand Washing Waste Filler (F) |

|---|---|---|---|

| E10-F0 | 10.00 | 90.00 | 0.00 |

| E10-F10 | 10.00 | 80.00 | 10.00 |

| E10-F20 | 10.00 | 70.00 | 20.00 |

| E15-F0 | 15.00 | 85.00 | 0.00 |

| E15-F10 | 15.00 | 75.00 | 10.00 |

| E15-F20 | 15.00 | 65.00 | 20.00 |

| E20-F0 | 20.00 | 80.00 | 0.00 |

| E20-F10 | 20.00 | 70.00 | 10.00 |

| E20-F20 | 20.00 | 60.00 | 20.00 |

| E25-F0 | 25.00 | 75.00 | 0.00 |

| E25-F10 | 25.00 | 65.00 | 10.00 |

| E25-F20 | 25.00 | 55.00 | 20.00 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yemam, D.M.; Kim, B.-J.; Moon, J.-Y.; Yi, C. Mechanical Properties of Epoxy Resin Mortar with Sand Washing Waste as Filler. Materials 2017, 10, 246. https://doi.org/10.3390/ma10030246

Yemam DM, Kim B-J, Moon J-Y, Yi C. Mechanical Properties of Epoxy Resin Mortar with Sand Washing Waste as Filler. Materials. 2017; 10(3):246. https://doi.org/10.3390/ma10030246

Chicago/Turabian StyleYemam, Dinberu Molla, Baek-Joong Kim, Ji-Yeon Moon, and Chongku Yi. 2017. "Mechanical Properties of Epoxy Resin Mortar with Sand Washing Waste as Filler" Materials 10, no. 3: 246. https://doi.org/10.3390/ma10030246

APA StyleYemam, D. M., Kim, B.-J., Moon, J.-Y., & Yi, C. (2017). Mechanical Properties of Epoxy Resin Mortar with Sand Washing Waste as Filler. Materials, 10(3), 246. https://doi.org/10.3390/ma10030246