Cr13Ni5Si2-Based Composite Coating on Copper Deposited Using Pulse Laser Induction Cladding

Abstract

:1. Introduction

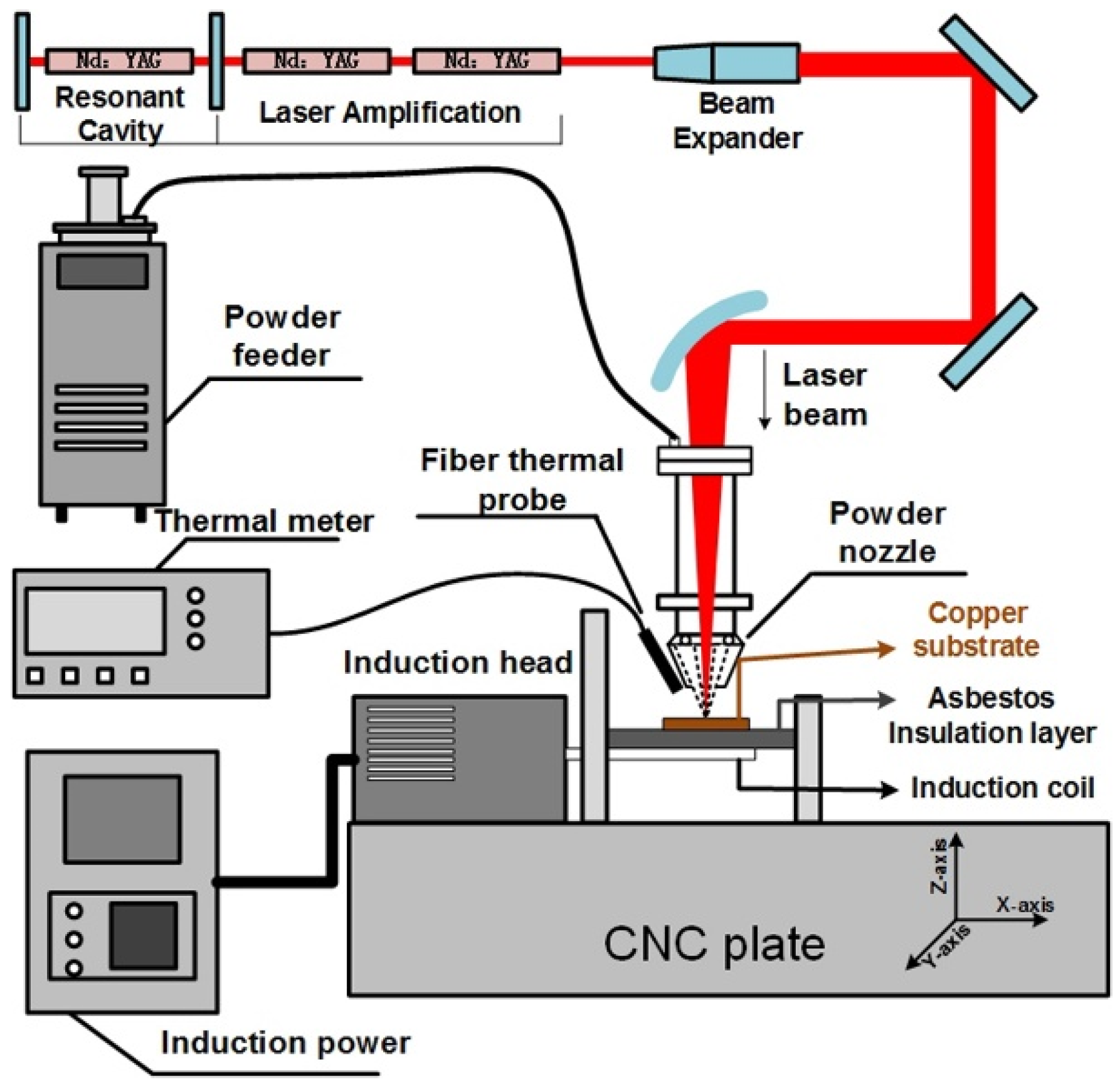

2. Experimental Details

2.1. Experimental Equipment and Materials

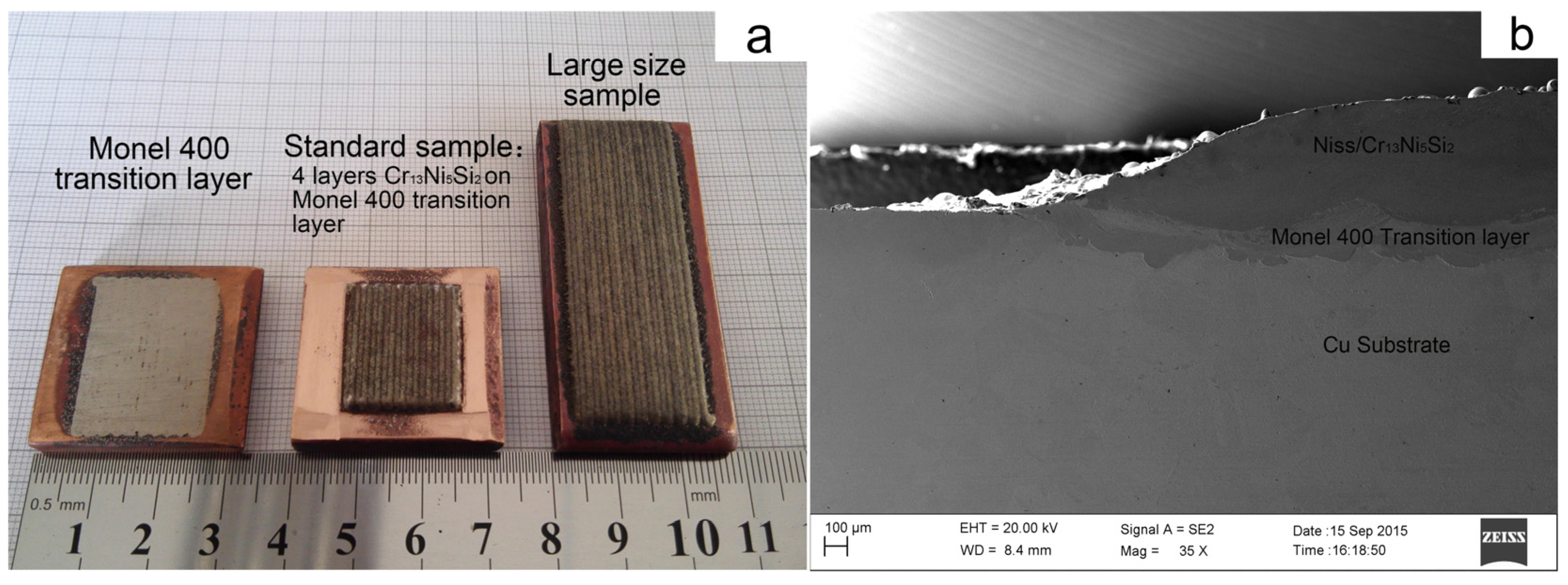

2.2. Sample Preparation

2.3. Analysis Methods

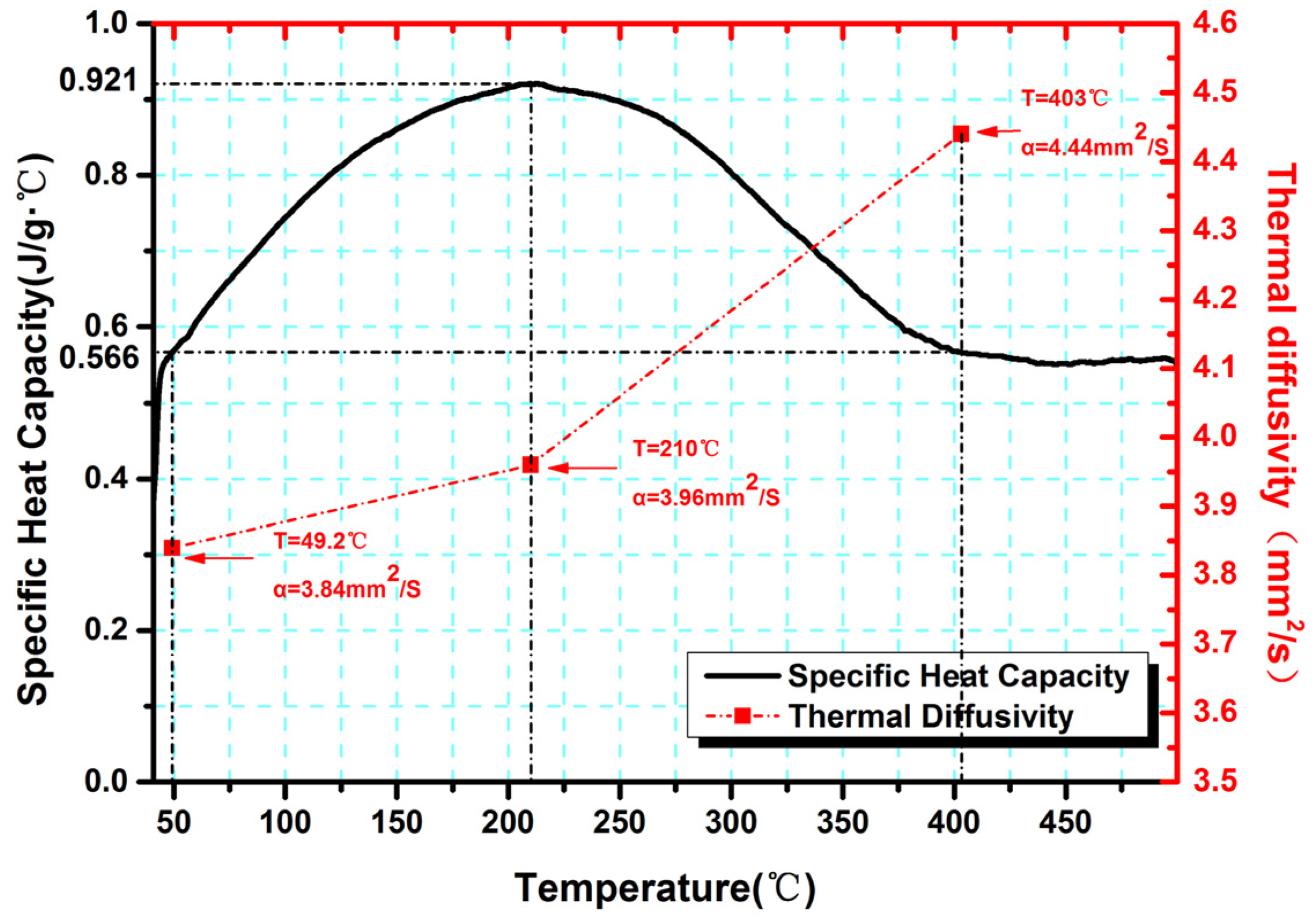

3. Results and Discussion

3.1. Macrostructure of Composite Coating

3.1.1. Crack Behavior in PLC and PLIC

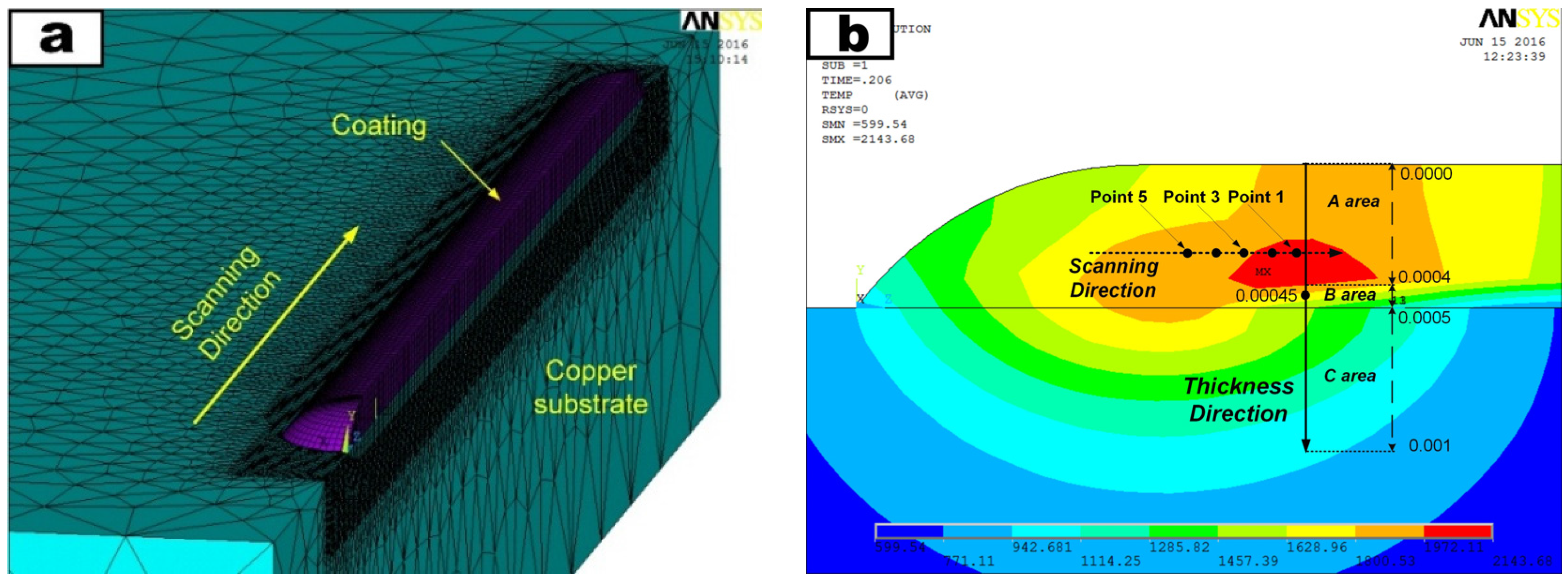

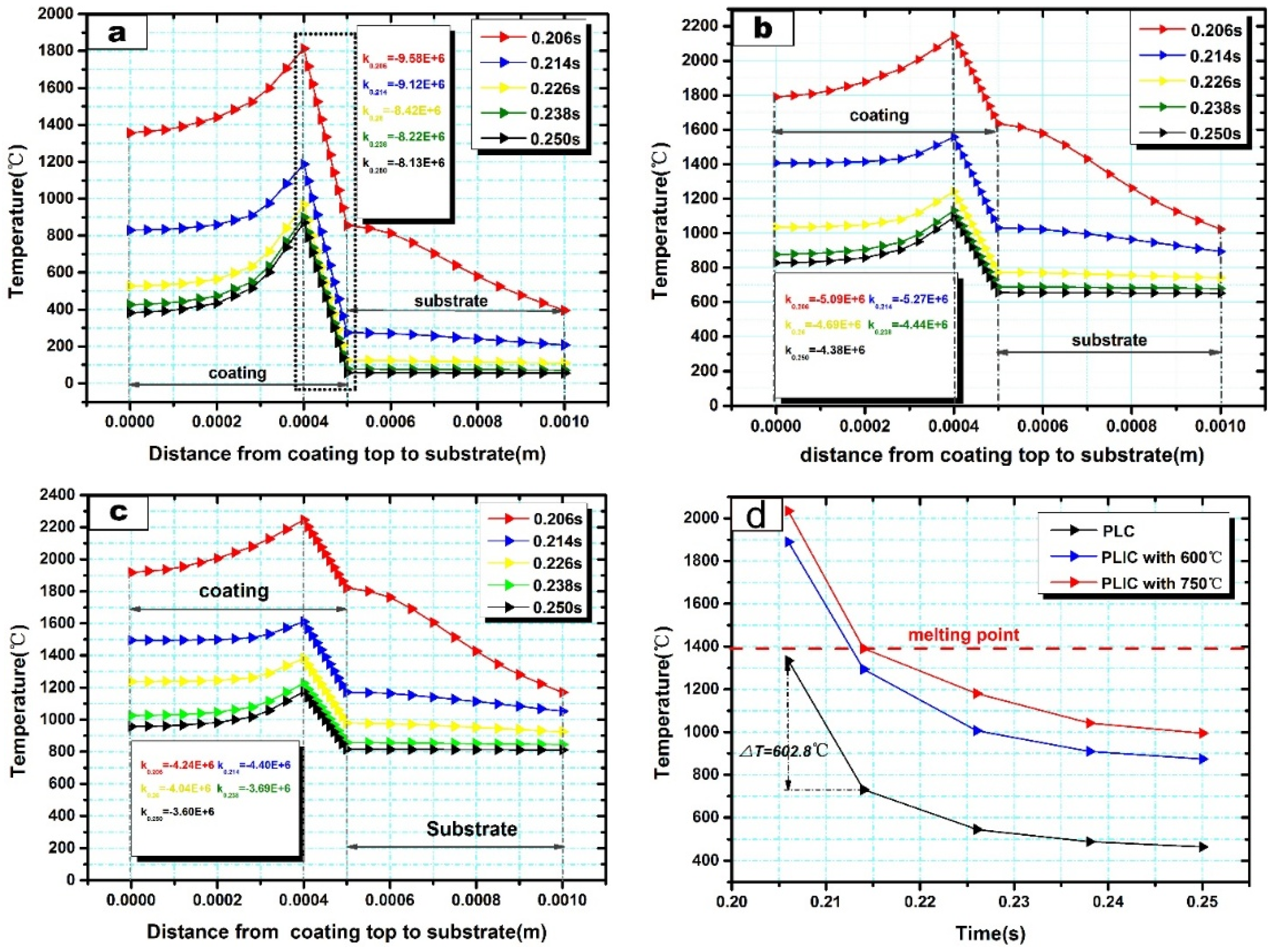

3.1.2. Finite Element Modeling

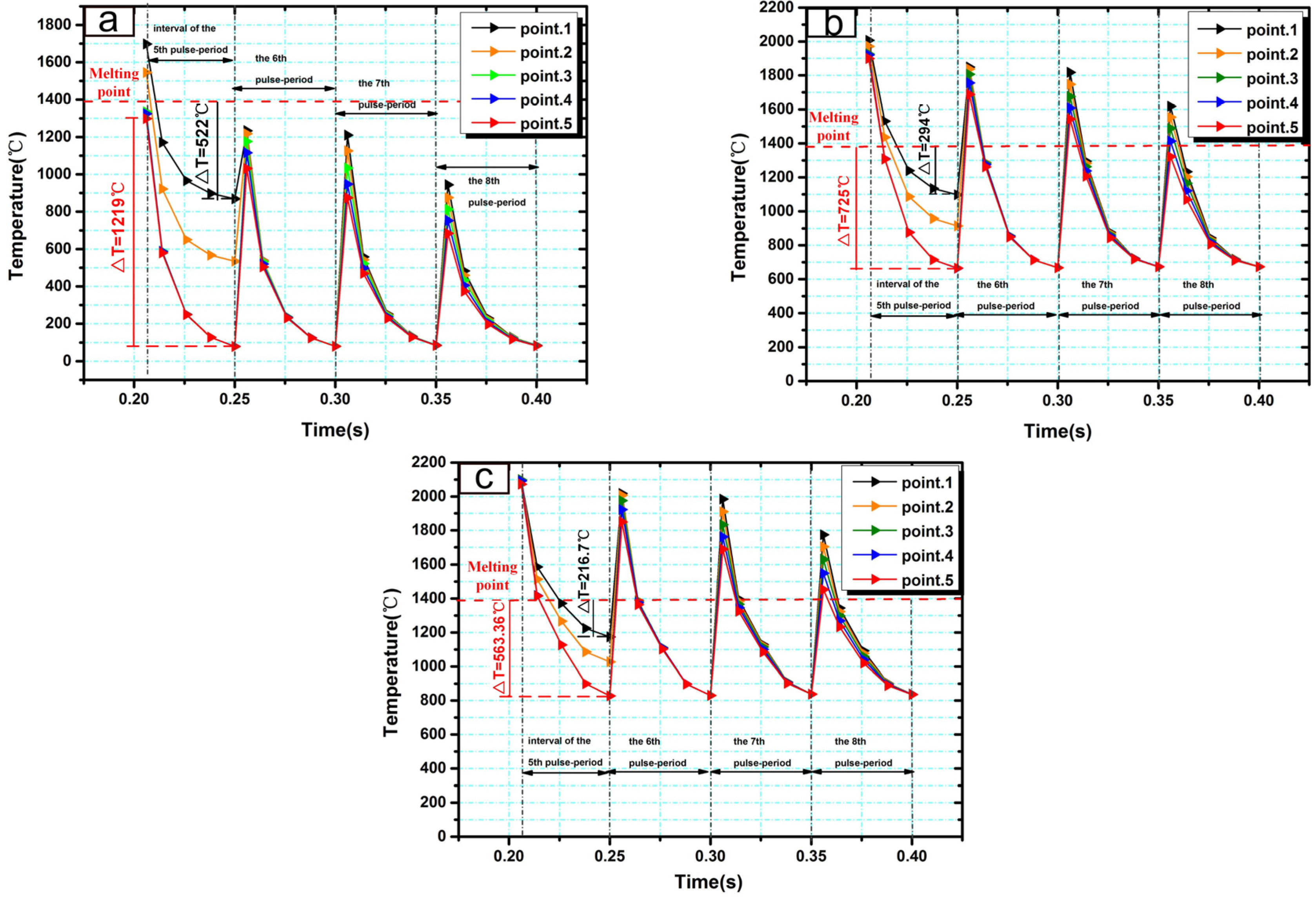

3.1.3. Temperature Evolution in PLC and PLIC

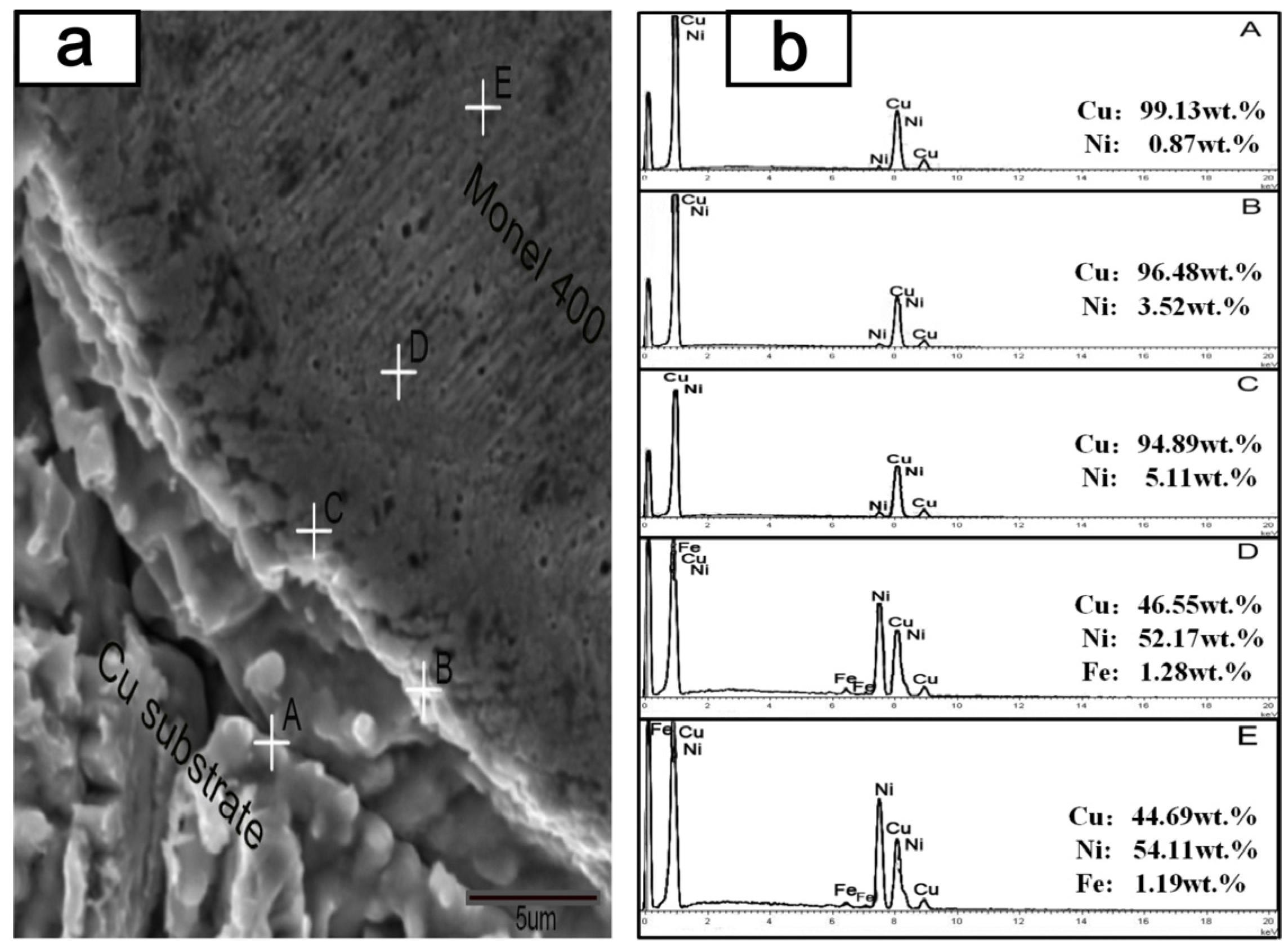

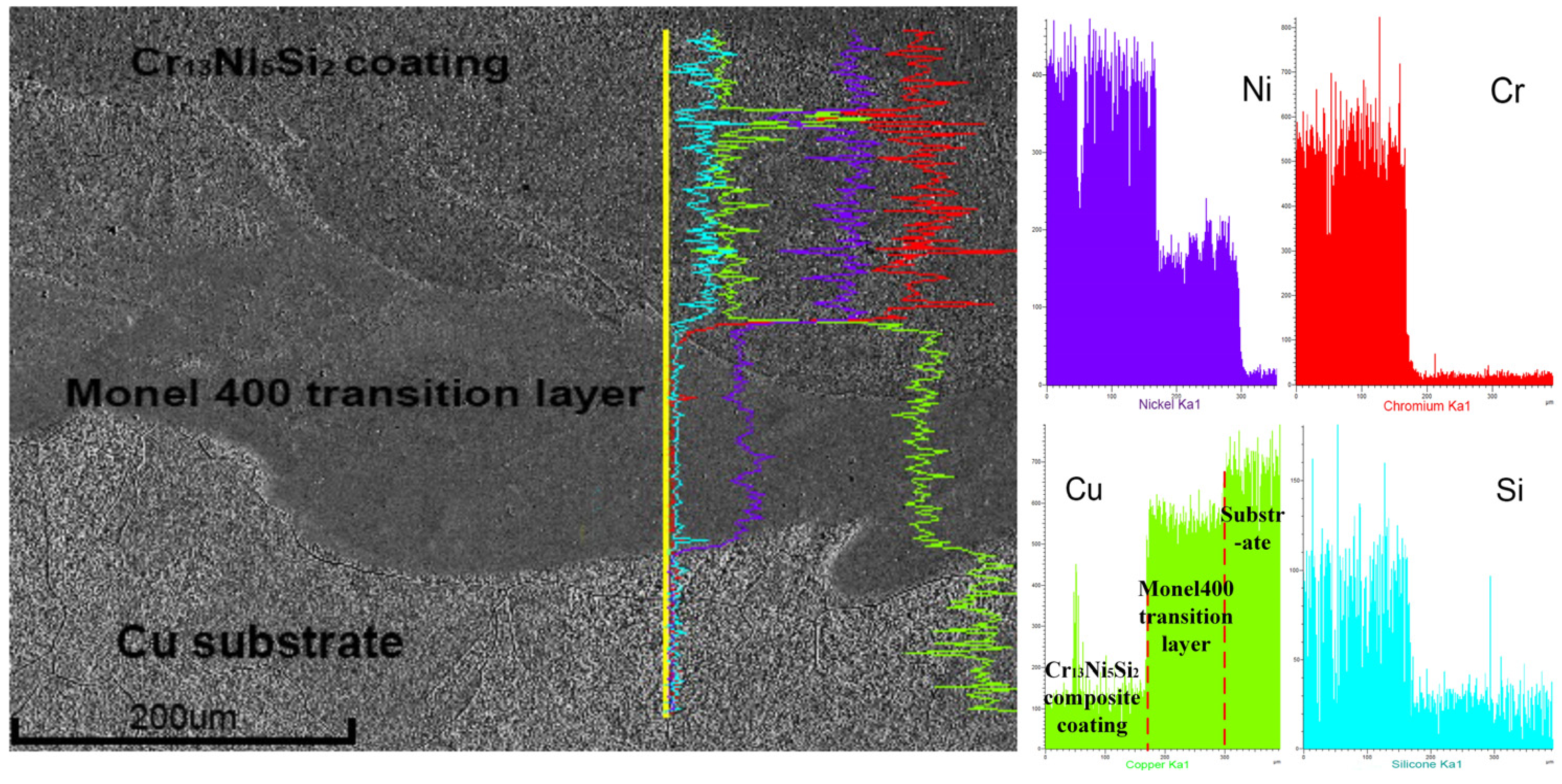

3.1.4. Metallurgical Bonding

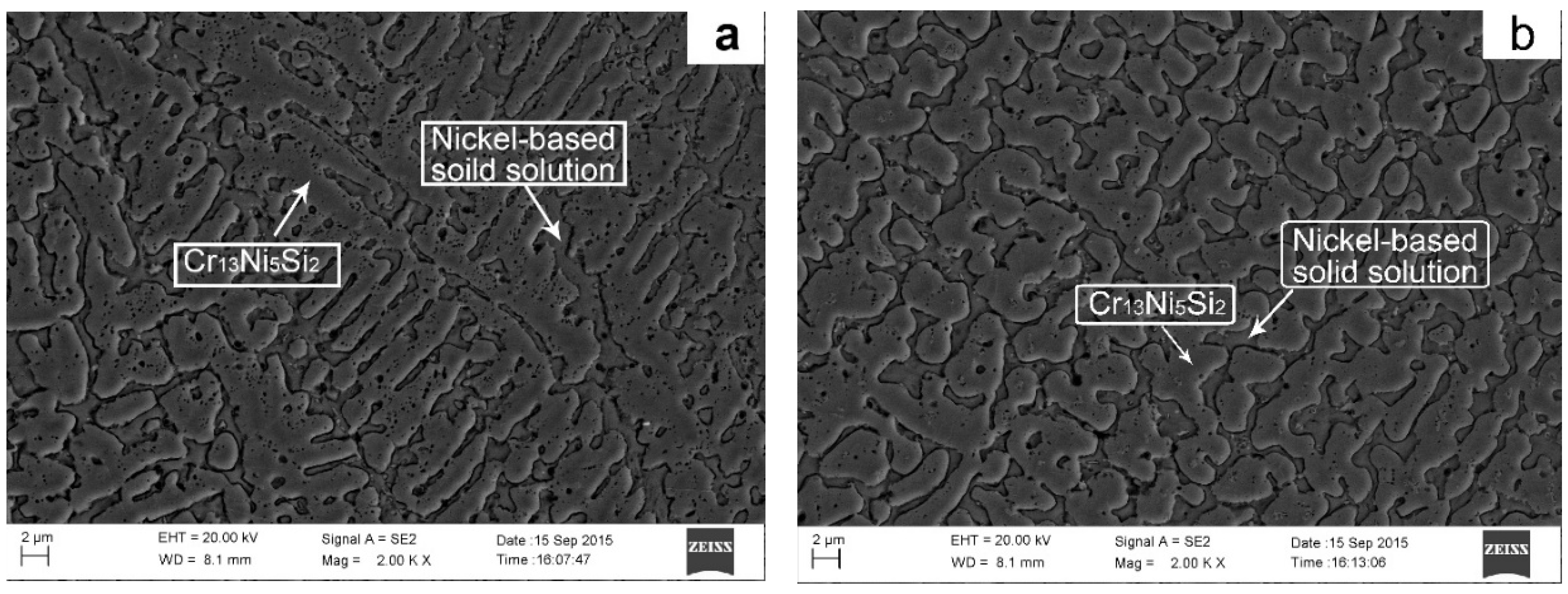

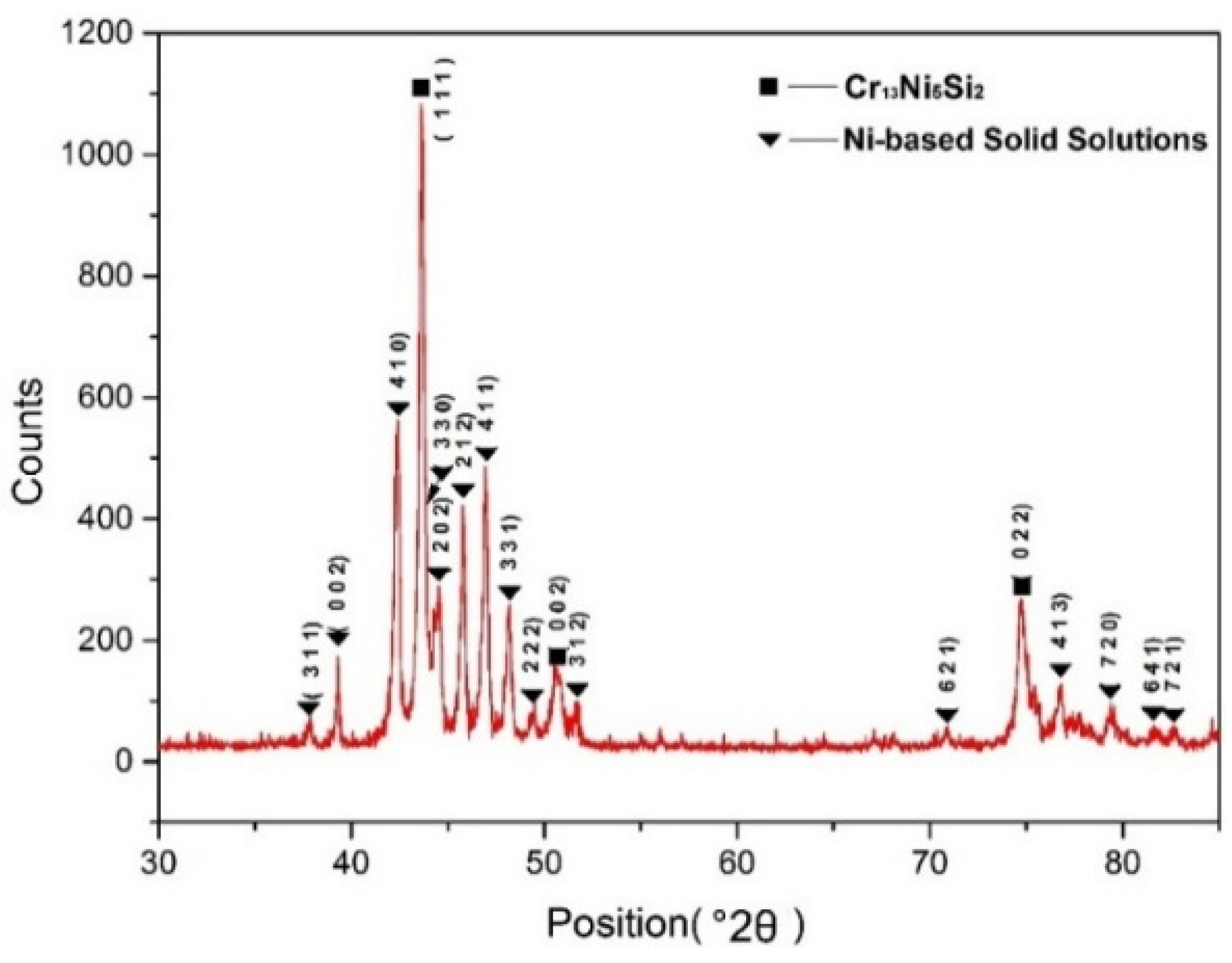

3.2. Microstructure of Composite Coating

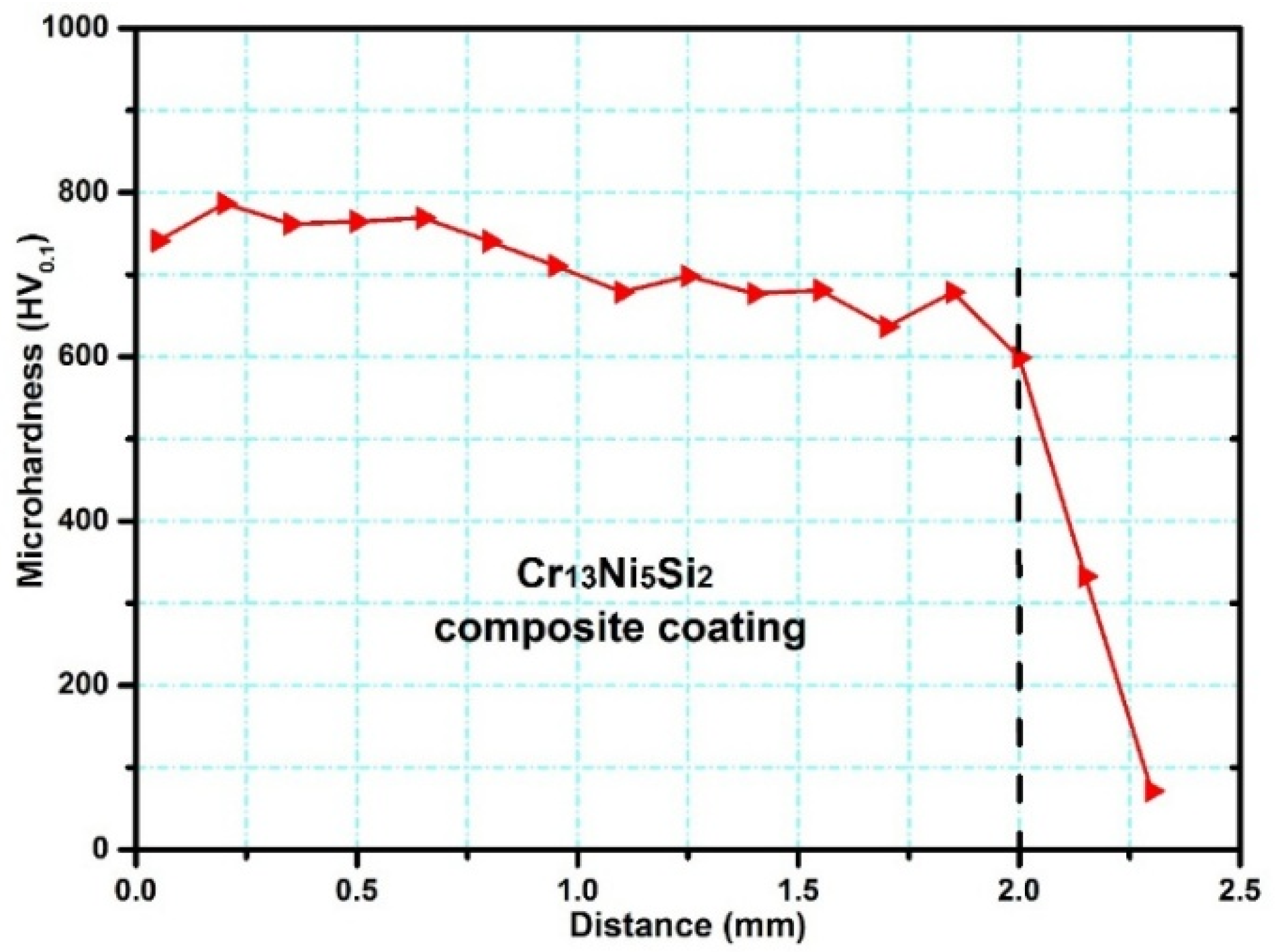

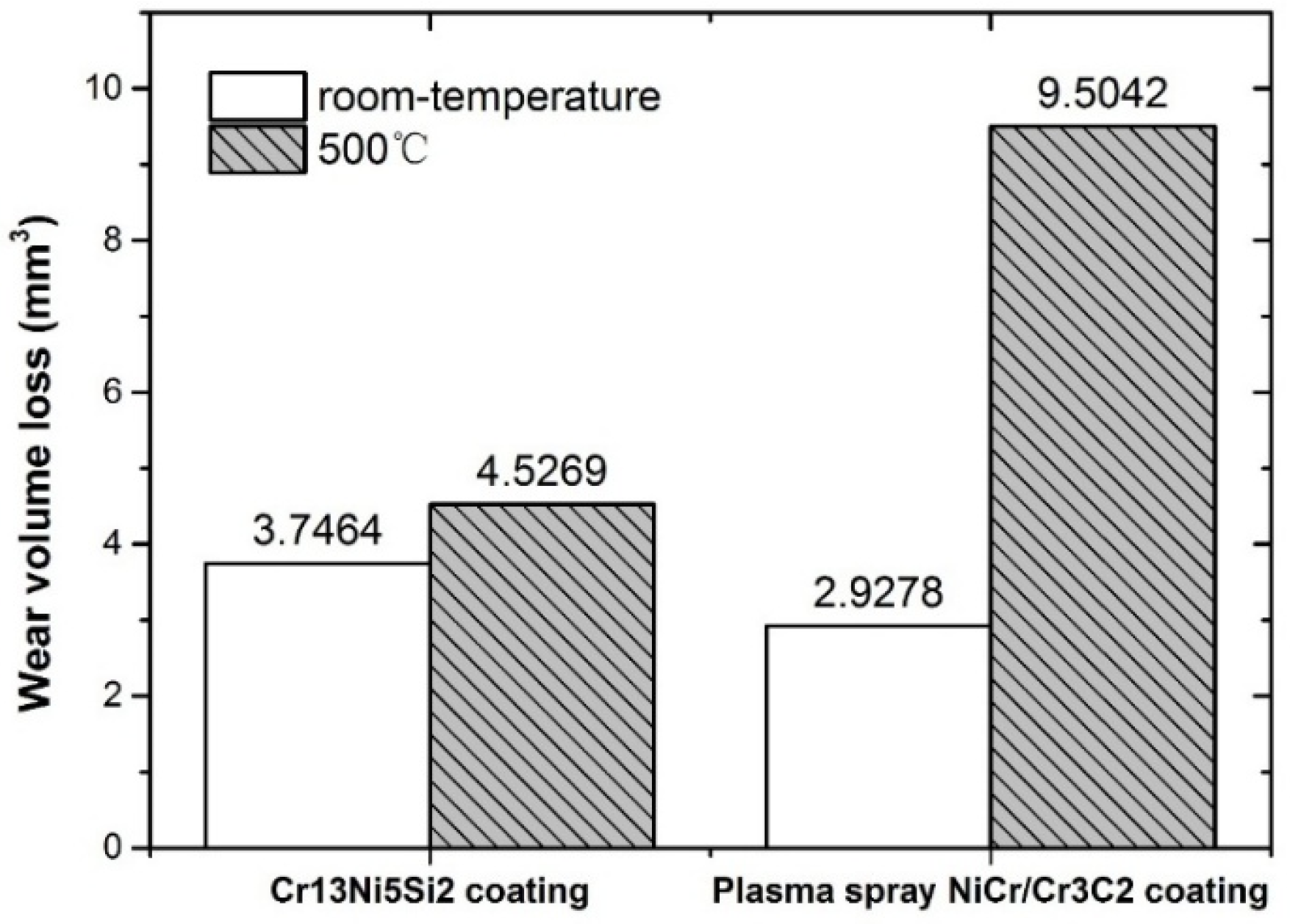

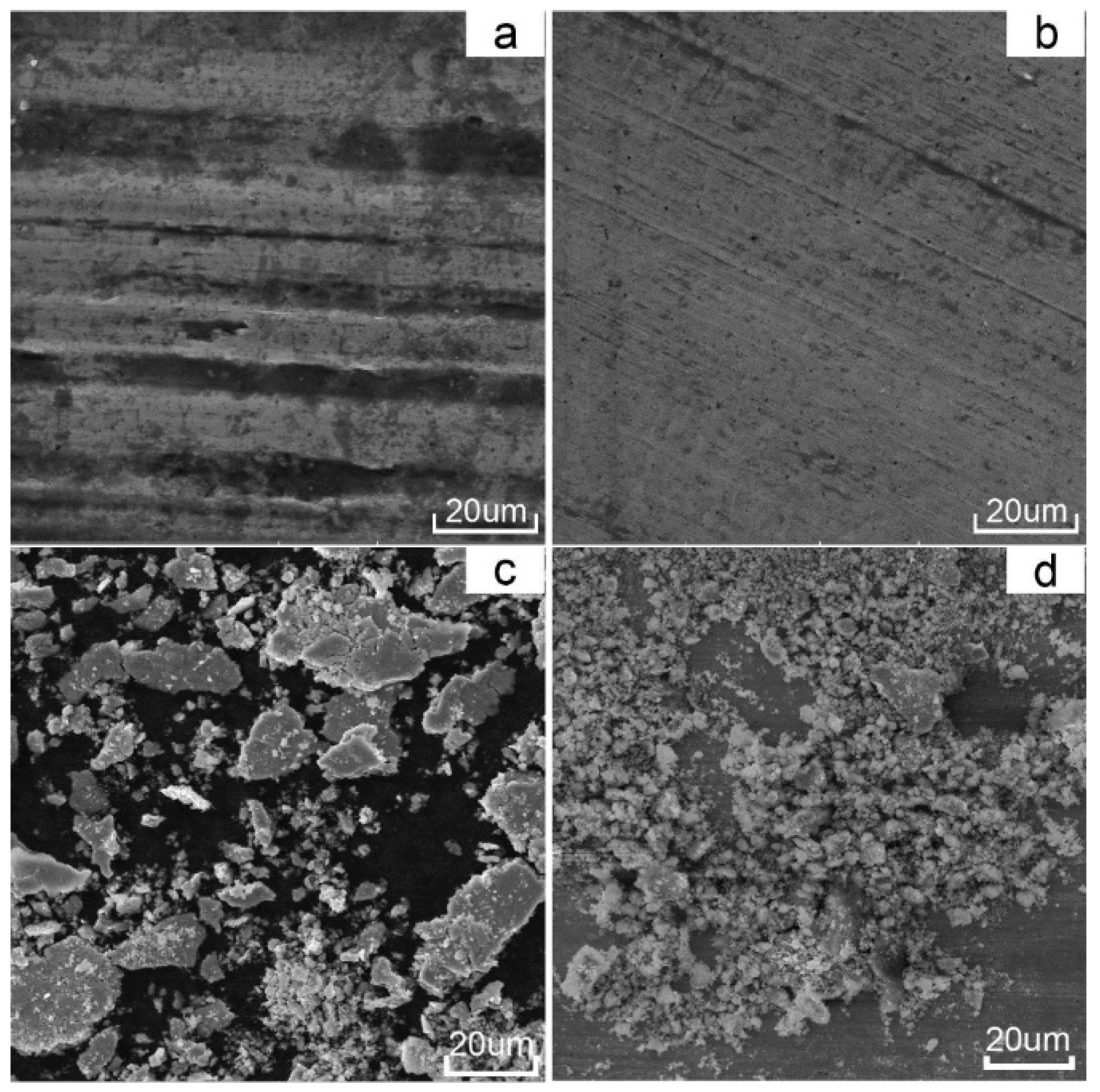

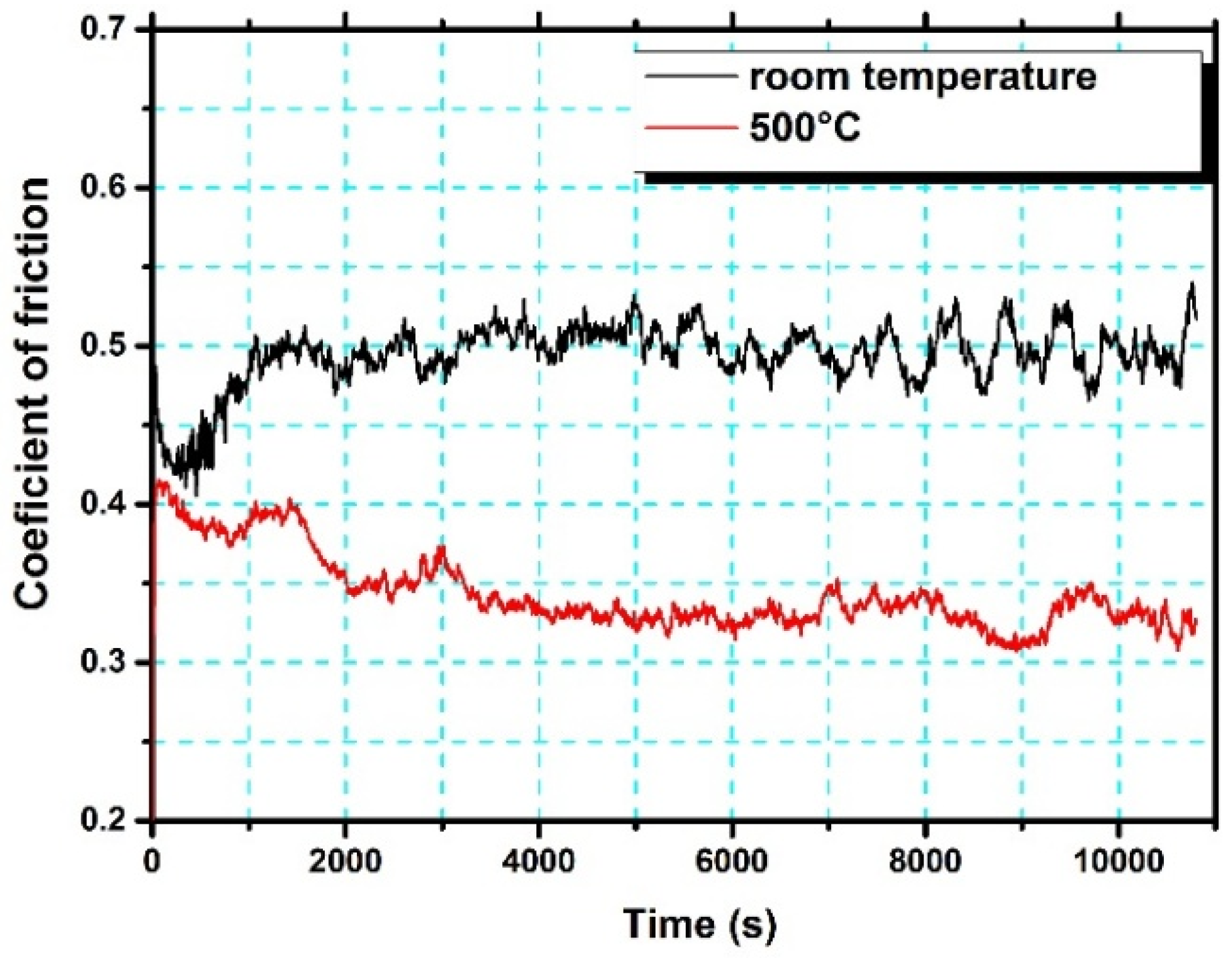

3.3. Hardness and Wear Resistance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ravnikar, D.; Dahotre, N.B.; Grum, J. Laser coating of aluminum alloy EN AW 6082-t651 with TiB2 and TiC: Microstructure and mechanical properties. Appl. Surf. Sci. 2013, 282, 914–922. [Google Scholar] [CrossRef]

- Kwok, C.T.; Wong, P.K.; Man, H.C. Laser surface alloying of copper with titanium: Part I. Electrical wear resistance in dry condition. Part II. Electrical wear resistance in wet and corrosive condition. Surf. Coat. Technol. 2016, 297, 58–73. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, Z.; Zhang, J.; Ning, Z.; Jin, H. Microstructure and antiwear property of laser cladding Ni–Co duplex coating on copper. Materials 2016, 9, 634. [Google Scholar] [CrossRef]

- Yan, H.; Wang, A.; Xu, K.; Wang, W.; Huang, Z. Microstructure and interfacial evaluation of Co-based alloy coating on copper by pulsed Nd:YAG multilayer laser cladding. J. Alloy. Compd. 2010, 505, 645–653. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Tu, Y.; Xi, M.Z.; Shi, L.K. Characterization on laser clad nickel based alloy coating on pure copper. Surf. Coat. Technol. 2008, 202, 5924–5928. [Google Scholar] [CrossRef]

- Grilloud, R. Apparatus for Producing a Surface Layer on a Metallic Workpiece. U.S. Patent 5,224,997 A, 6 July 1993. [Google Scholar]

- Farahmand, P.; Kovacevic, R. Laser cladding assisted with an induction heater (LCAIH) of Ni–60% WC coating. J. Mater. Process. Technol. 2015, 222, 244–258. [Google Scholar] [CrossRef]

- Zhou, S.; Dai, X. Microstructure evolution of fe-based WC composite coating prepared by laser induction hybrid rapid cladding. Appl. Surf. Sci. 2010, 256, 7395–7399. [Google Scholar] [CrossRef]

- Zhou, S.; Huang, Y.; Zeng, X. A study of Ni-based WC composite coatings by laser induction hybrid rapid cladding with elliptical spot. Appl. Surf. Sci. 2008, 254, 3110–3119. [Google Scholar] [CrossRef]

- Zhang, L.Q.; Wang, H.M. High-temperature sliding wear resistance of a Cr3Si/Cr13Ni5si2 multiphase intermetallic alloy. Mater. Lett. 2003, 57, 2710–2715. [Google Scholar] [CrossRef]

- Fang, Y.L.; Wang, H.M. High-temperature sliding wear resistance of a ductile metal-toughened Cr13Ni5si2 ternary metal silicide alloy. J. Alloy. Compd. 2007, 433, 114–119. [Google Scholar] [CrossRef]

- Wang, D.; Hu, Q.; Zeng, X. Influences of parameters on microstructures and mechanical properties of Cr13Ni5Si2 based composite coating by laser-induction hybrid cladding. Surf. Coat. Technol. 2015, 280, 359–369. [Google Scholar] [CrossRef]

- Farahmand, P.; Kovacevic, R. An experimental–numerical investigation of heat distribution and stress field in single- and multi-track laser cladding by a high-power direct diode laser. Opt. Laser Technol. 2014, 63, 154–168. [Google Scholar] [CrossRef]

- Ng, K.W.; Man, H.C.; Cheng, F.T.; Yue, T.M. Laser cladding of copper with molybdenum for wear resistance enhancement in electrical contacts. Appl. Surf. Sci. 2007, 253, 6236–6241. [Google Scholar] [CrossRef]

- Bruckner, F. Modeling the influence of process parameters and additional heat sources on residual stresses in laser cladding. J. Therm. Spray Technol. 2007, 16, 355–373. [Google Scholar] [CrossRef]

- Wang, D.; Hu, Q.; Zeng, X. Microstructures and performances of Cr13Ni5si2 based composite coatings deposited by laser cladding and laser-induction hybrid cladding. J. Alloy. Compd. 2014, 588, 502–508. [Google Scholar] [CrossRef]

- Akhlaghi, J.A.G.M. Computational Welding Mechanics; Springer: New York, NY, USA, 2005. [Google Scholar]

- Fang, Y.L.; Wang, H.M. Influence of Ni content on the microstructure and dry sliding wear properties of Cr13Ni5Si2/γ intermetallic alloys. Metall. Mater. Trans. A 2007, 38, 441–449. [Google Scholar] [CrossRef]

- Liu, F.; Liu, C.; Chen, S.; Tao, X.; Zhang, Y. Laser cladding Ni–Co duplex coating on copper substrate. Opt. Lasers Eng. 2010, 48, 792–799. [Google Scholar] [CrossRef]

- Inman, I.A.; Datta, P.K.; Du, H.L.; Burnell-Gray, J.S.; Pierzgalski, S.; Luo, Q. Studies of high temperature sliding wear of metallic dissimilar interfaces. Tribol. Int. 2005, 38, 812–823. [Google Scholar] [CrossRef]

| Parameters | Monel400 Transition Layer | Cr13Ni5Si2-Based Composite Coating |

|---|---|---|

| Induction temperature | 500 °C | 750 °C |

| Pulse duration (Δt) | 6 ms | 6 ms |

| Pulse repetition rate (f) | 20 Hz | 20 Hz |

| Laser average power (Paverage) | 780 W | 850 W |

| Beam diameter | 1.2 mm | 1.2 mm |

| Scan speed | 510 mm/min | 400 mm/min |

| Powder feed rate | 11.8 g/min | 16.55 g/min |

| Analysis Object | Chemical Composition (wt %) | |||

|---|---|---|---|---|

| Cr | Ni | Si | O | |

| Worn surface at room-temperature | 50.71 | 34.24 | 4.55 | 10.5 |

| Worn surface at 500 °C | 9.25 | 40.54 | 5.45 | 44.76 |

| Debris in room-temperature wear test | 46.13 | 36.89 | 2.87 | 14.12 |

| Debris in the wear test at 500 °C | 9.44 | 41.48 | 4.6 | 44.48 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Wang, H.; Zhu, G.; Zhu, X. Cr13Ni5Si2-Based Composite Coating on Copper Deposited Using Pulse Laser Induction Cladding. Materials 2017, 10, 160. https://doi.org/10.3390/ma10020160

Wang K, Wang H, Zhu G, Zhu X. Cr13Ni5Si2-Based Composite Coating on Copper Deposited Using Pulse Laser Induction Cladding. Materials. 2017; 10(2):160. https://doi.org/10.3390/ma10020160

Chicago/Turabian StyleWang, Ke, Hailin Wang, Guangzhi Zhu, and Xiao Zhu. 2017. "Cr13Ni5Si2-Based Composite Coating on Copper Deposited Using Pulse Laser Induction Cladding" Materials 10, no. 2: 160. https://doi.org/10.3390/ma10020160

APA StyleWang, K., Wang, H., Zhu, G., & Zhu, X. (2017). Cr13Ni5Si2-Based Composite Coating on Copper Deposited Using Pulse Laser Induction Cladding. Materials, 10(2), 160. https://doi.org/10.3390/ma10020160