Effect of Modified Red Pottery Clay on the Moisture Absorption Behavior and Weatherability of Polyethylene-Based Wood-Plastic Composites

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. The Preparation of Samples

2.3. Fourier Transform Infrared Spectroscopy

2.4. Sorption Measurements

2.5. Dynamic Mechanical Analysis Test

2.6. Thermogravimetry Analysis Test

2.7. UV-Accelerated Aging Test

2.8. Colorimetric Test

2.9. Mechanical Properties Test

2.10. Scanning Electron Microscopy

3. Results and Discussion

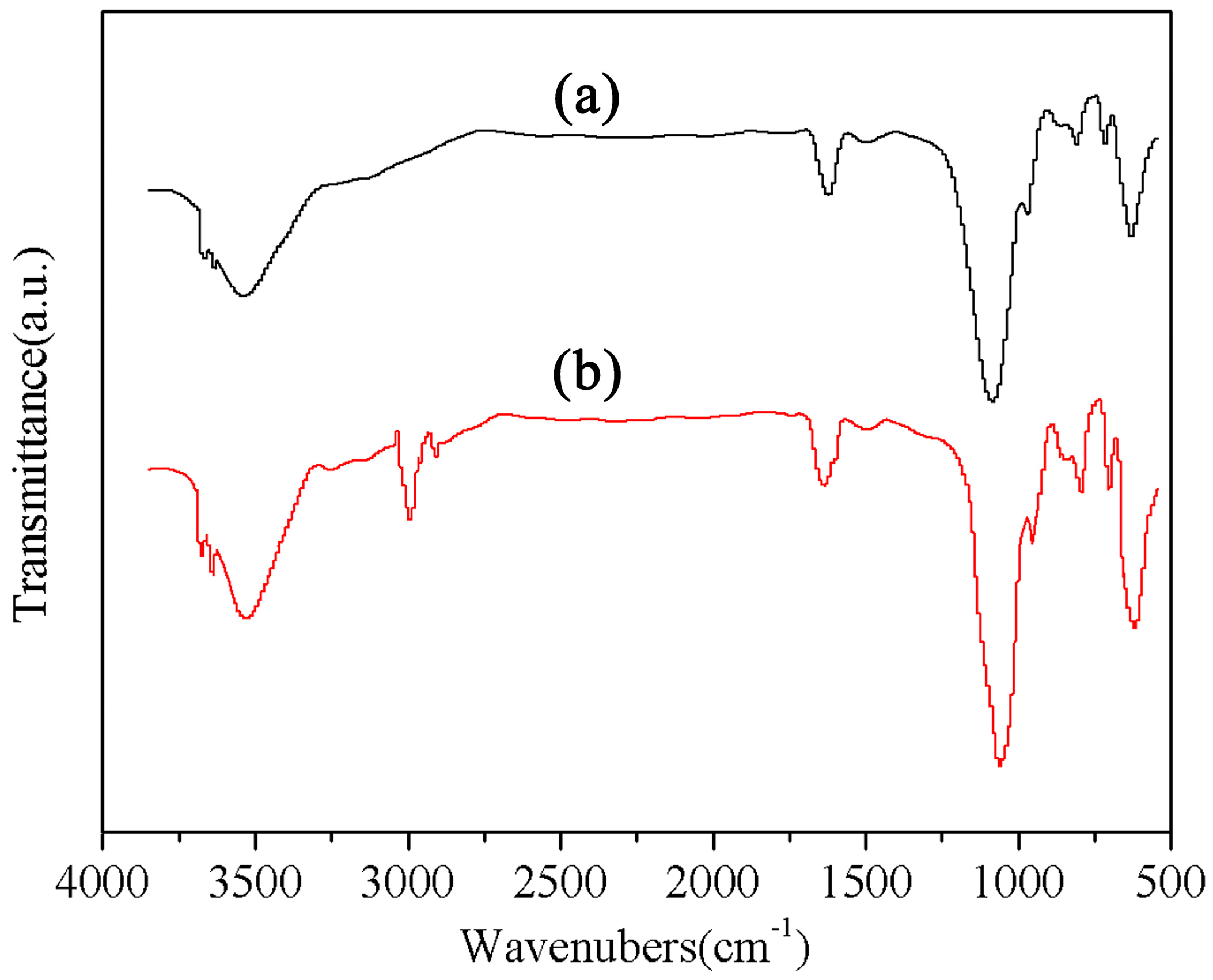

3.1. FTIR Analysis

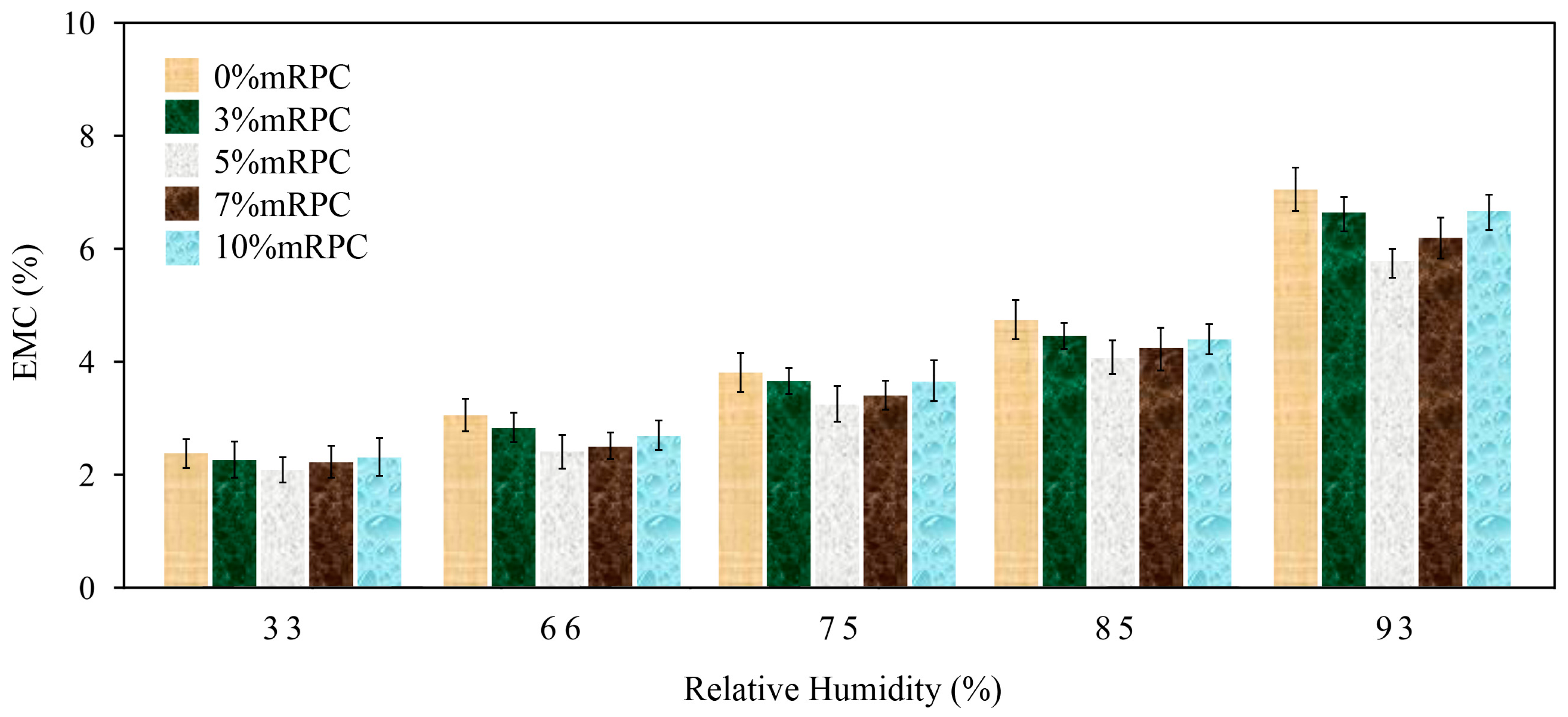

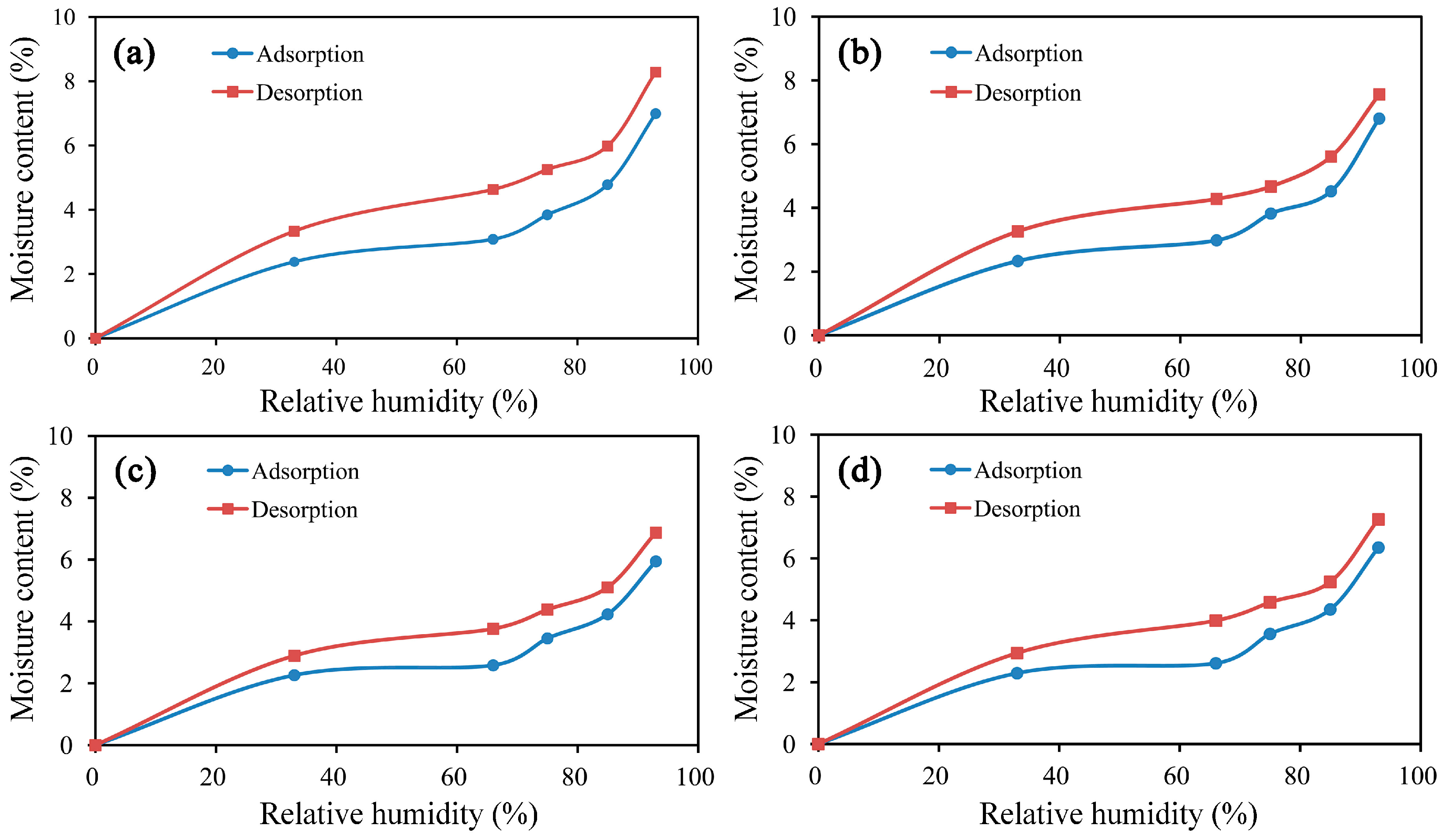

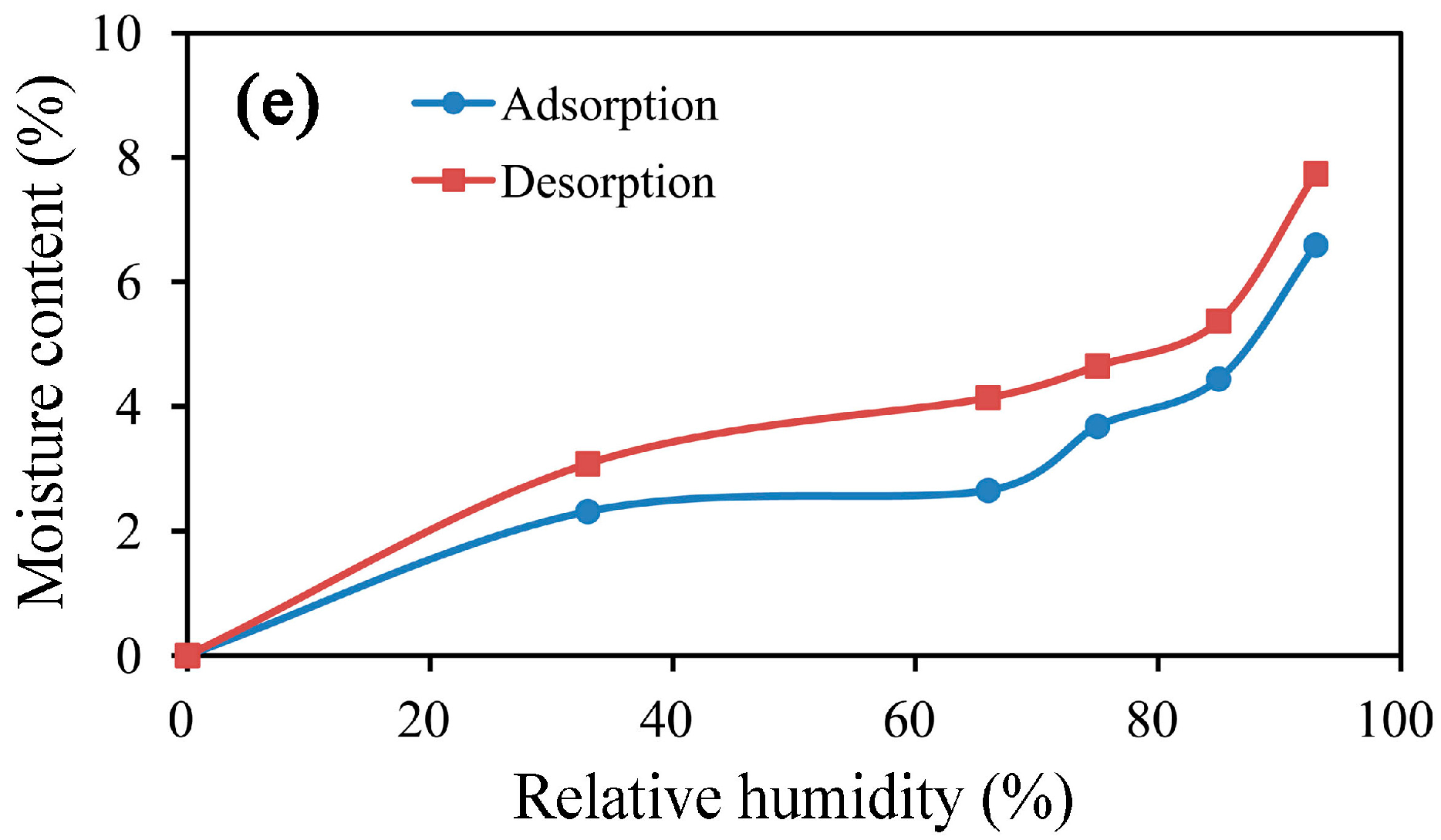

3.2. Effect of the Mass Percentage of Added mRPC on the Moisture Adsorption Characteristics of the Composites

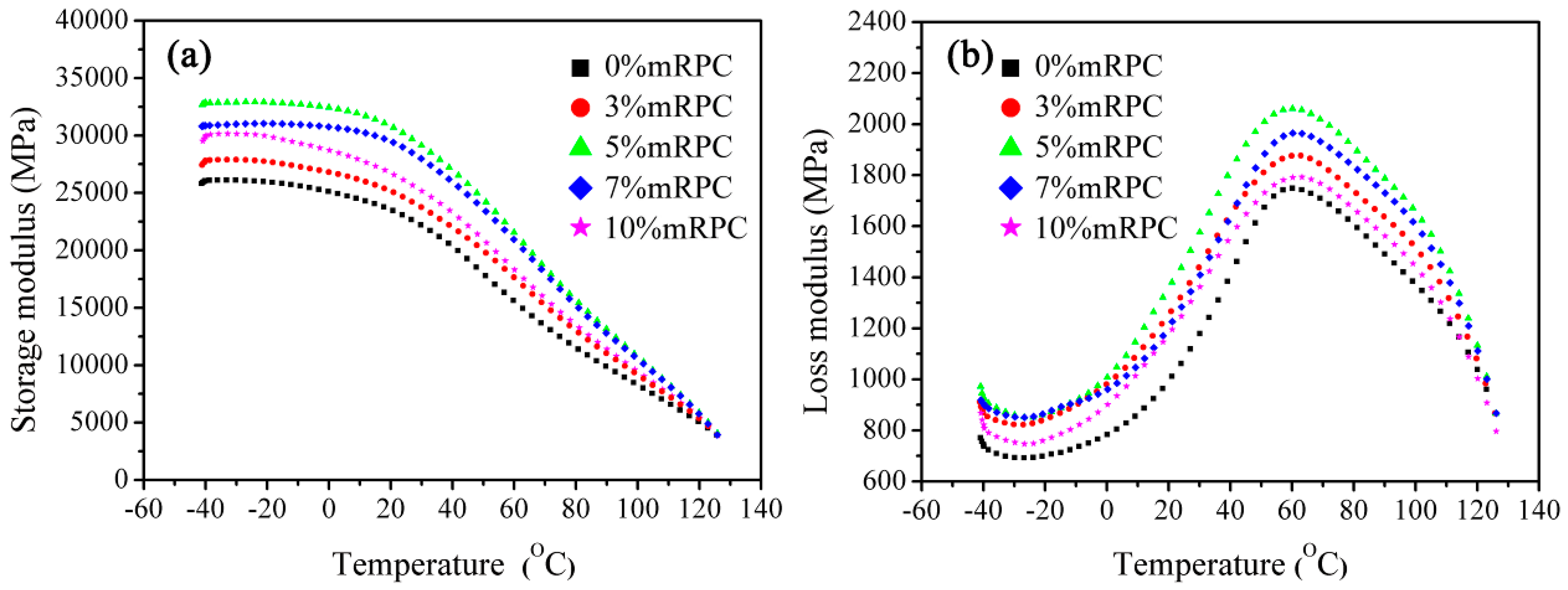

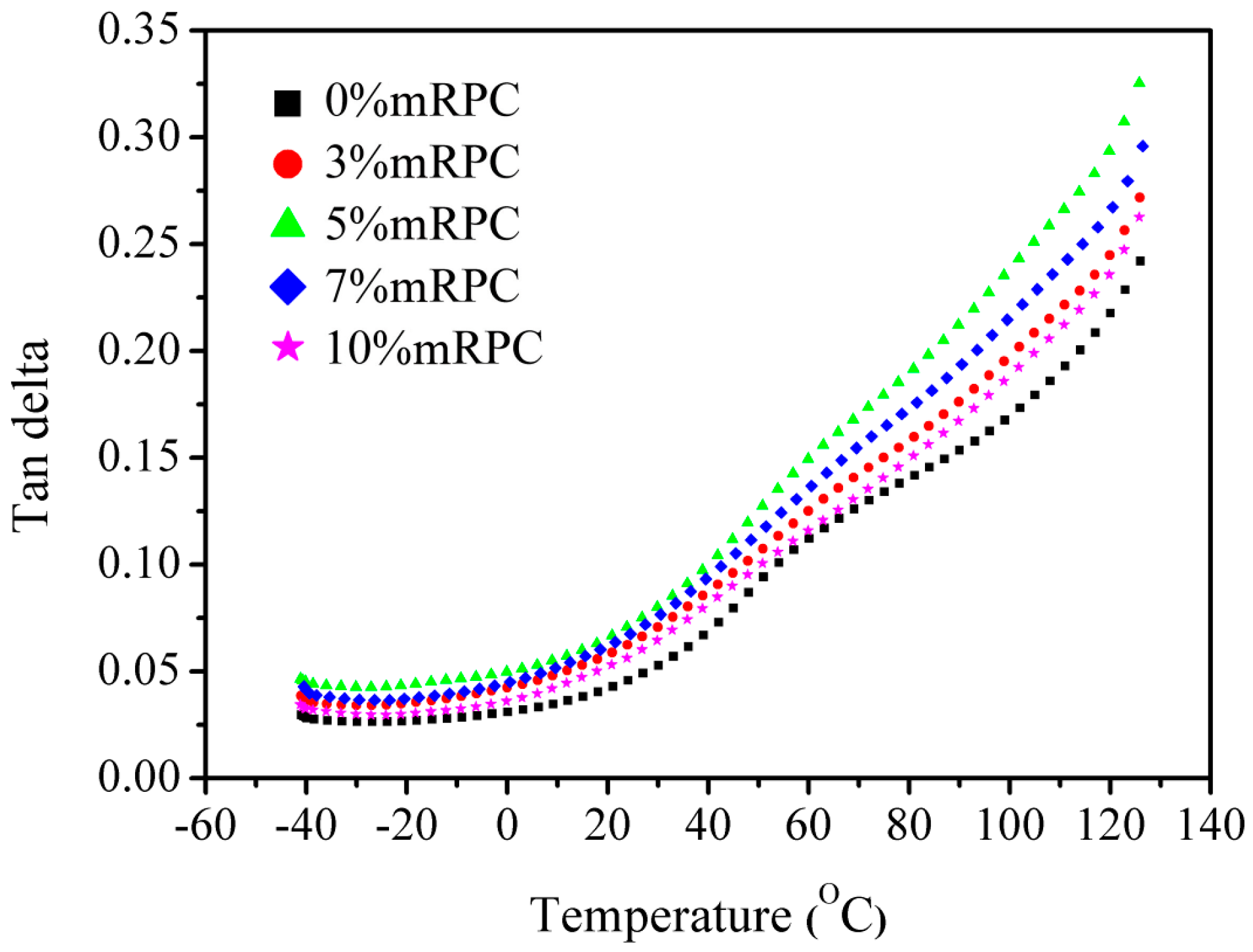

3.3. Dynamic Thermal Mechanical Analysis

3.4. Thermogravimetry Analysis

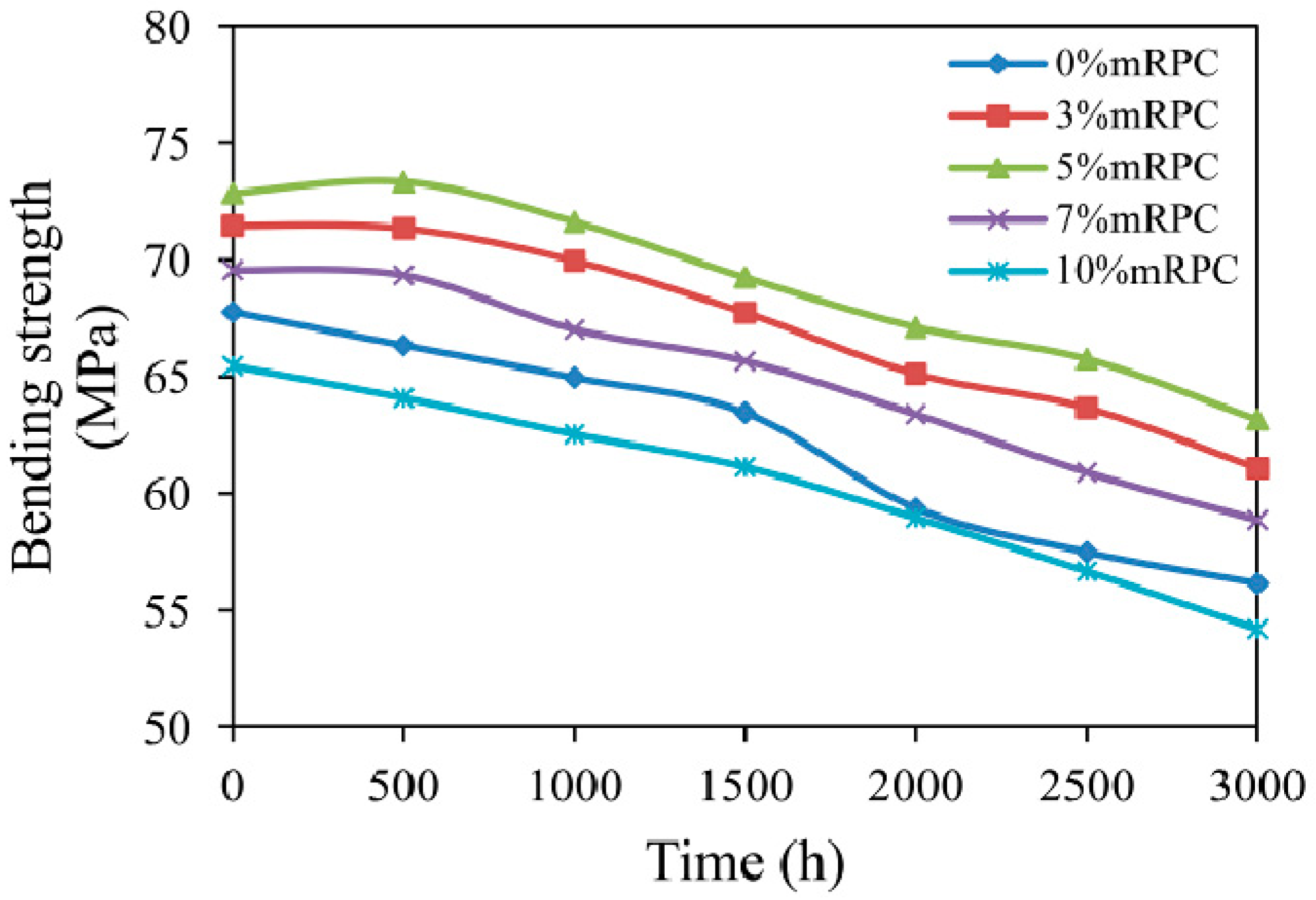

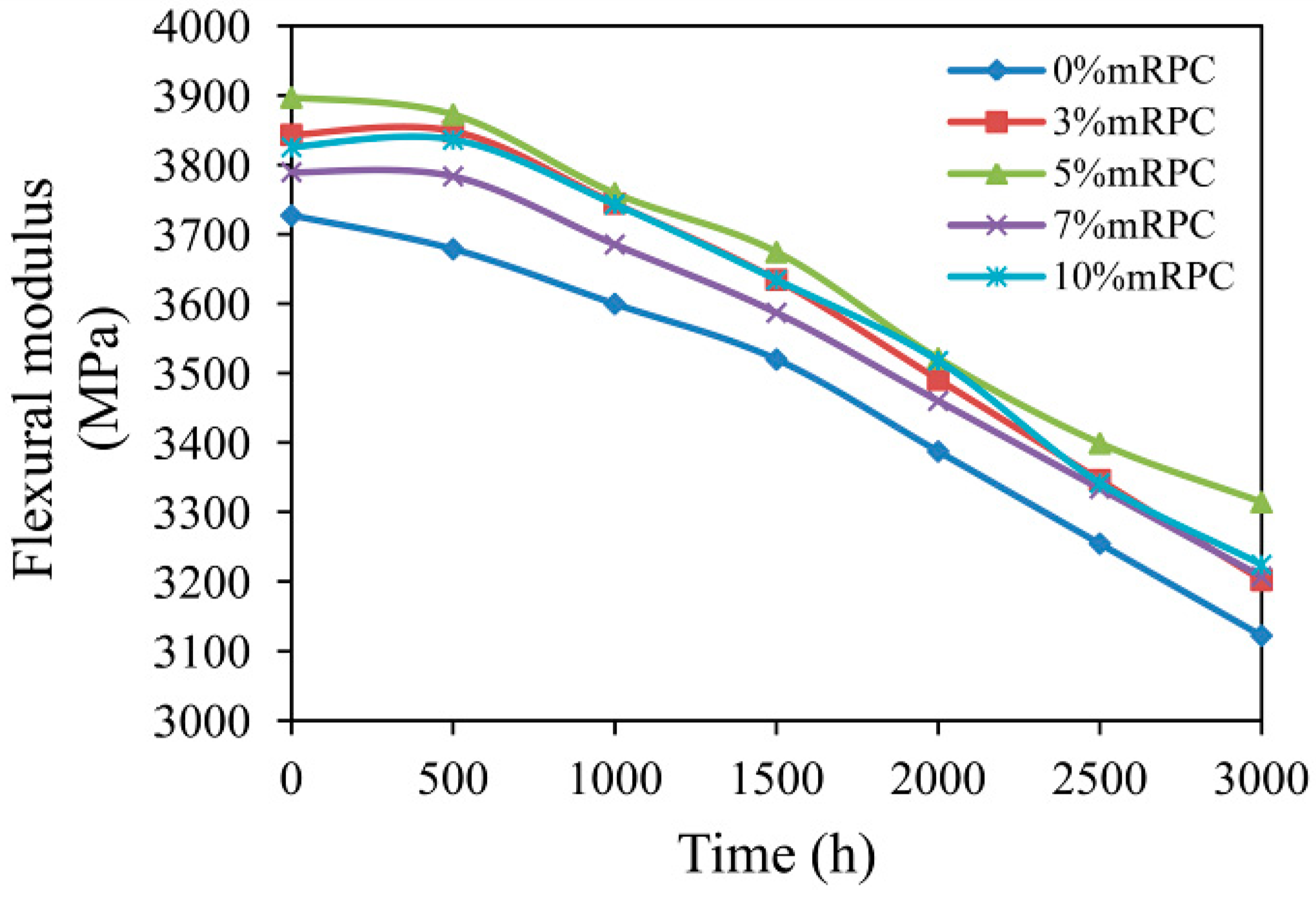

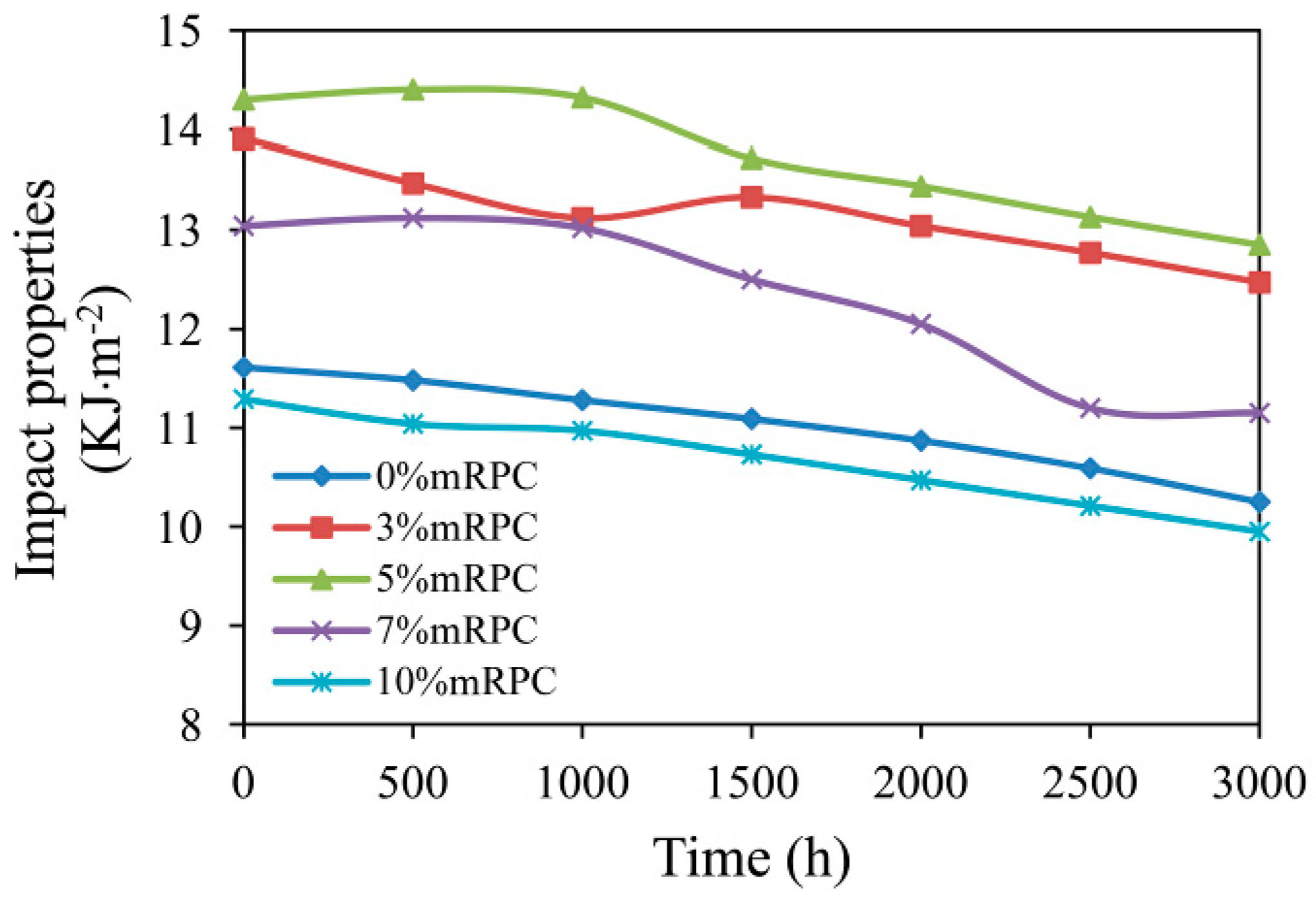

3.5. Effect of the Mass Percentage of mRPC on the Mechanical Properties of the Composites after the UV-Accelerated Aging Process

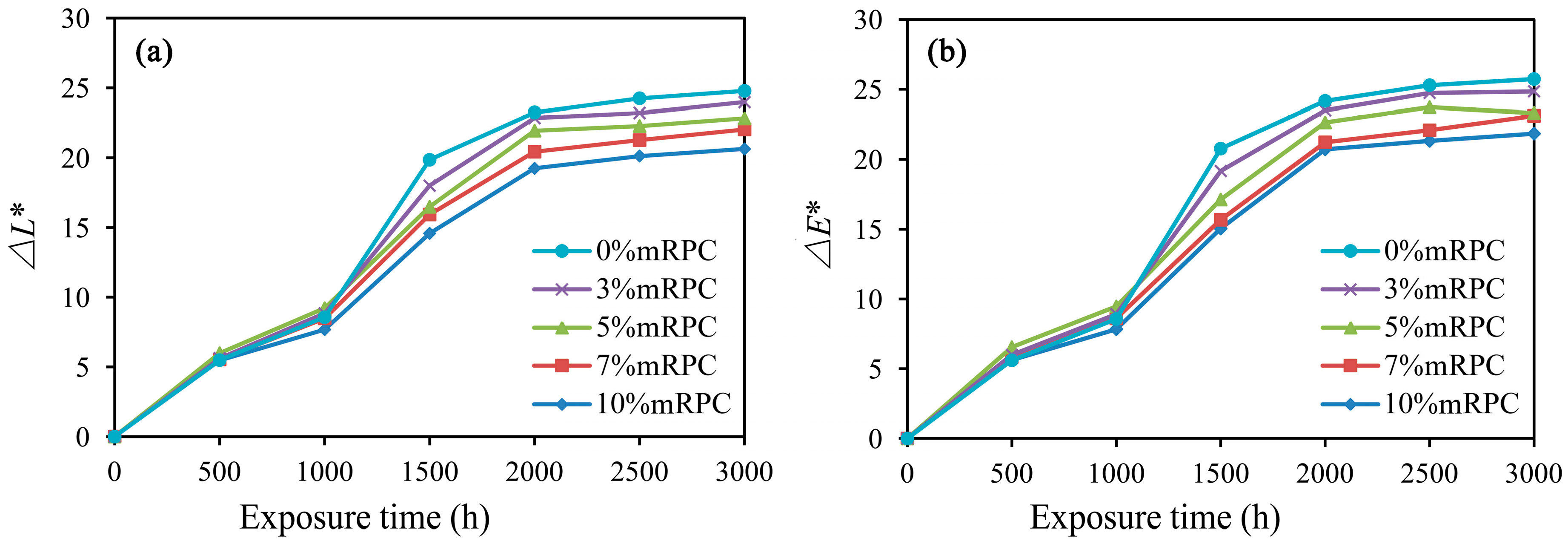

3.6. Effect of the mRPC Content on the Surface Color of the Composite after the UV-Accelerated Aging

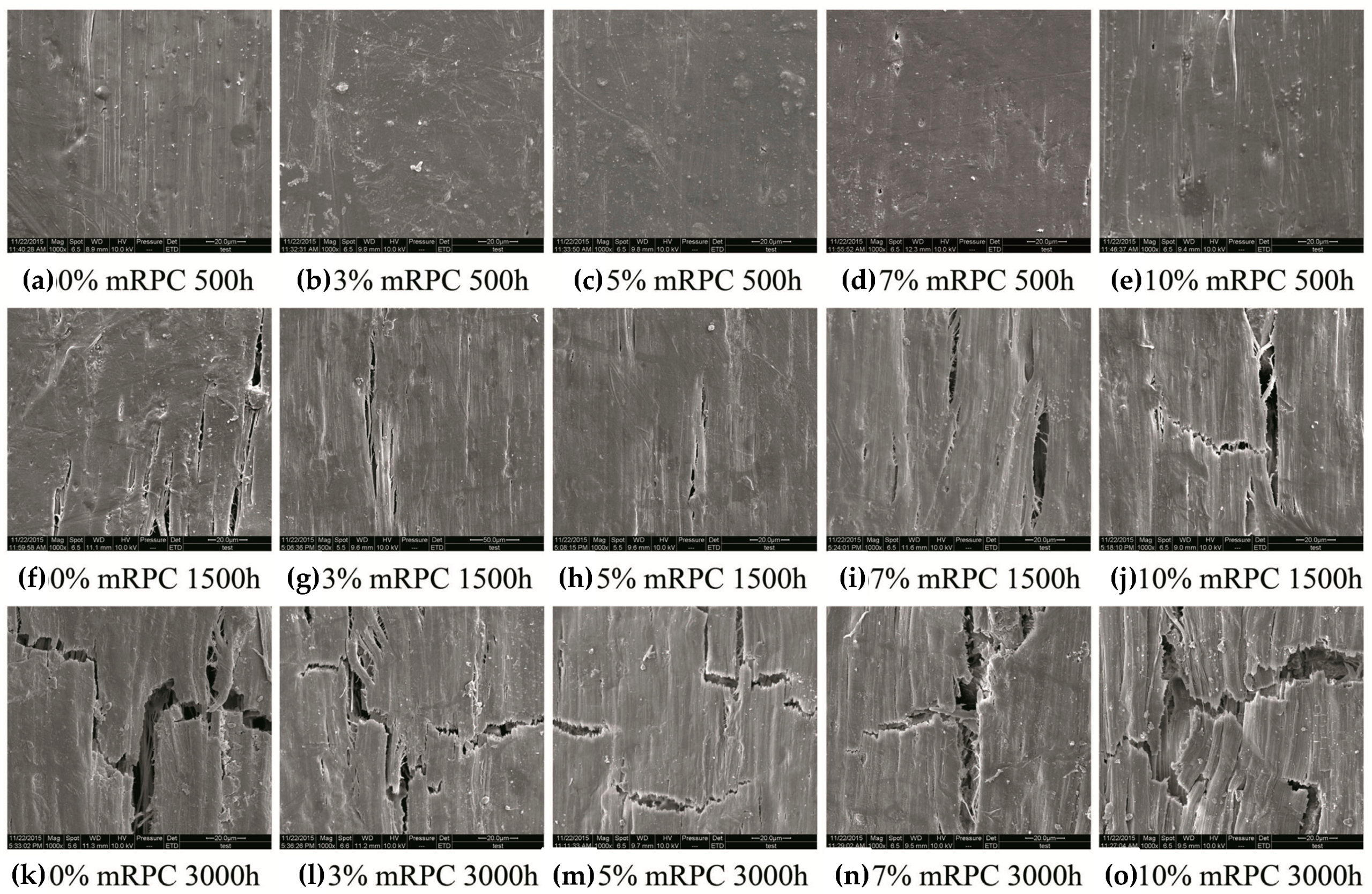

3.7. Effect of the mRPC Content on the Microstructure and Surface Morphology of the Composite after the UV-Accelerated Aging

4. Conclusions

- With increasing mRPC mass percentage, the moisture adsorption isothermal curve resembled an “S”-shaped upward curve.

- The equilibrium moisture content of the composite along the adsorption and the desorption direction both increased, whereas the equilibrium moisture content along the adsorption direction was less than that along desorption direction, resulting in a moisture hysteresis.

- The mRPC particles act as a rigid structure in the composite and significantly improve the rigidity, so it can be applied to enhance the elastic properties of the composite at elevated temperatures. The composite with 5% mRPC showed the best performance. The storage modulus was 3264 MPa, and the loss modulus increased by 16.8% due to the addition of the mRPC.

- Dynamic thermal mechanical analysis indicates the mRPC showed a more network-like distribution in the matrix. At an mRPC mass percentage of 5%, the storage modulus and the loss modulus of the composite both reached an optimum. The addition of the mRPC can enhance the viscosity of the composite. The composite showed a more obvious elastic characteristic.

- Thermal gravimetric analysis indicates that the inhibiting effect of the mRPC can influence the thermal flowability of the polymer chains and prevent their reorganization. Thus, the addition of the mRPC can increase the thermal degradation peak temperature and effectively decrease the thermal degradation rate. The composite samples with 5% mRPC showed the highest enhancement on the thermal degradation temperature.

- The flexural strength, the flexural modulus and the impact strength continuously decreased with the aging time. After an aging for 3000 h, the composite with 5% mRPC showed the smallest reduction in mechanical performance, with a flexural strength, flexural modulus and impact strength of 63.17 MPa, 3284.17 MPa and 12.85 MPa, respectively.

- The luminescence (ΔL*) and color (ΔE*) values both increased with the aging time; the maximum increase in amplitude was observed for aging times between 0 and l000 h, whereas the ΔL* and ΔE* values gradually increased after l000 h, while at the same time, the overall curve tended to become smoother. The composite with 5% mRPC showed the lowest degree of fading.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, Z.M.; Du, H.; Wang, W.H.; Wang, Q.W. Property changes of wood-fiber/HDPE composites colored by iron oxide pigments after accelerated UV weathering. J. For. Res. 2010, 21, 59–62. [Google Scholar] [CrossRef]

- Huan, S.Q.; Liu, G.X.; Han, G.P.; Cheng, W.L.; Fu, Z.Y.; Wu, Q.L.; Wang, Q.W. Effect of experimental parameters on morphological, mechanical and hydrophobic properties of electrospun polystyrene fibers. Materials 2015, 8, 2718–2734. [Google Scholar] [CrossRef]

- Kord, B.; Hosseinihashemi, S.K. Effect of fungal decay on the hygroscopic thickness swelling rate of lignocellulosic filler-polyolefin biocomposites. Mech. Compos. Mater. 2014, 49, 691–698. [Google Scholar] [CrossRef]

- Gardner, D.J.; Han, Y.; Wang, L. Wood-Plastic Composite Technology. Curr. For. Rep. 2015, 1, 139–150. [Google Scholar] [CrossRef]

- Yang, W.J.; Xie, Y.J.; Wang, H.G.; Liu, B.Y.; Wang, Q.W. Impacts of freezing and thermal treatments on dimensional and mechanical properties of wood flour-HDPE composite. J. For. Res. 2013, 24, 143–147. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S.; Chanakul, S. Mechanical properties, thermal degradation and natural weathering of high density polyethylene/rice hull composites compatibilized with maleic anhydride grafted polyethylene. J. Polym. Res. 2012, 19, 1–9. [Google Scholar] [CrossRef]

- Mohan, T.P.; Kanny, K. Melt blend studies of nanoclay-filled polypropylene (PP)-high-density polyethylene (HDPE) composites. J. Mater. Sci. 2013, 48, 8292–8301. [Google Scholar] [CrossRef]

- Liu, F.; Han, G.; Cheng, W.; Wu, Q. Sorption Isotherm of Southern Yellow Pine-High Density Polyethylene Composites. Materials 2015, 8, 368–378. [Google Scholar] [CrossRef]

- Kayaisang, S.; Saikrasun, S.; Amornsakchai, T. Potential Use of Recycled PET in Comparison with Liquid Crystalline Polyester as a Dual Functional Additive for Enhancing Heat Stability and Reinforcement for High Density Polyethylene Composite Fibers. J. Polym. Environ. 2013, 21, 191–206. [Google Scholar] [CrossRef]

- Kusuktham, B.; Teeranachaideekul, P. Mechanical Properties of High Density Polyethylene/Modified Calcium Silicate Composites. Silicon 2014, 6, 179–189. [Google Scholar] [CrossRef]

- Roumeli, E.; Terzopoulou, Z.; Pavlidou, E.; Chrissafis, K.; Papadopoulou, E.; Athanasiadou, E.; Triantafyllidis, E.; Bikiaris, D.N. Effect of maleic anhydride on the mechanical and thermal properties of hemp/high-density polyethylene green composites. J. Therm. Anal. Calorim. 2015, 121, 93–105. [Google Scholar] [CrossRef]

- Fabiyi, S.J.; McDonald, A.G. Physical Morphology and Quantitative Characterization of Chemical Changes of Weathered PVC/Pine Composites. J. Polym. Environ. 2010, 18, 57–64. [Google Scholar] [CrossRef]

- Ramachandran, A.; George, K.E.; George, T.S.; Krishnan, A. Optimisation of processing conditions of PP/HDPE/nano kaolinite clay composites by response surface methodology. Int. J. Plast. Technol. 2012, 16, 136–149. [Google Scholar] [CrossRef]

- Anjana, R.; Krishnan, A.K.; Goerge, T.S.; George, K.E. Design of experiments for thermo-mechanical behavior of polypropylene/high-density polyethylene/nanokaolinite clay composites. Polym. Bull. 2014, 71, 315–335. [Google Scholar] [CrossRef]

- Sanchez-Valdes, S.; Ramírez-Vargas, E.; Ramos de Valle, L.F.; Méndez-Nonell, J.; Martinez-Colunga, J.G.; Gutierrez-Villarreal, M.H.; Lopez-Quintanilla, M.L.; Sanchez-Adam, M.; Mendoza-Garcia, D. Effect of functionalized polyethylenes on clay dispersion in high density polyethylene nanocomposites. Polym. Bull. 2013, 70, 535–547. [Google Scholar] [CrossRef]

- Sibeko, M.A.; Luyt, A.S. Preparation and characterisation of vinylsilane crosslinked low-density polyethylene composites filled with nano clays. Polym. Bull. 2014, 71, 637–657. [Google Scholar] [CrossRef]

- Elshereafy, E.; El-Zayat, M.M.; Shaltout, N.A.; Zeid, M.M.A.; El-Miligy, A.A. Effect of gamma radiation on the properties of ethylene propylene diene monomer/styrene butadiene rubber/waste polyethylene/clay nanocomposites. J. Radioanal. Nucl. Chem. 2016, 307, 1325–1333. [Google Scholar] [CrossRef]

- Deka, B.K.; Maji, T.K.; Mandal, M. Study on properties of nanocomposites based on HDPE, LDPE, PP, PVC, wood and clay. Polym. Bull. 2011, 67, 1875–1892. [Google Scholar] [CrossRef]

- Gao, X.; Li, Q.; Cheng, W.; Han, G.; Xuan, L. Optimization of High Temperature and Pressurized Steam Modified Wood Fibers for High-Density Polyethylene Matrix Composites Using the Orthogonal Design Method. Materials 2016, 9, 847. [Google Scholar] [CrossRef]

- Tomasi, J.M.; Helman, I.D.; Pisani, W.A.; Klimek-McDonald, D.R.; Chinkanjanarot, S.; Miskioglu, I.; King, J.A.; Odegard, G.M. Accelerated hydrothermal aging of cycloaliphatic epoxy/graphene nanoparticle composites. Polym. Degrad. Stab. 2016, 133, 131–135. [Google Scholar] [CrossRef]

- Kubat, J.; Rigdahl, M.; Welander, M. Characterization of interfacial interactions in high density polyethylene filled with glass spheres using dynamic-mechanical analysis. J. Appl. Polym. Sci. 1990, 39, 1527–1539. [Google Scholar] [CrossRef]

- Guo, D. Effect of electron beam radiation processing on mechanical and thermal properties of fully biodegradable crops straw/poly (vinyl alcohol) biocomposites. Radiat. Phys. Chem. 2017, 130, 202–207. [Google Scholar] [CrossRef]

- Nicholas, J.; Mohamed, M.; Dhaliwal, G.S.; Anandan, S.; Chandrashekhara, K. Effects of accelerated environmental aging on glass fiber reinforced thermoset polyurethane composites. Compos. Part B Eng. 2016, 94, 370–378. [Google Scholar] [CrossRef]

- Kositchaiyong, A.; Rosarpitak, V.; Hamada, H.; Sombatsompop, N. Anti-fungal performance and mechanical–morphological properties of PVC and wood/PVC composites under UV-weathering aging and soil-burial exposure. Int. Biodeterior. Biodegrad. 2014, 91, 128–137. [Google Scholar] [CrossRef]

- Yang, T.H.; Yang, T.H.; Chao, W.C.; Leu, S.Y. Characterization of the property changes of extruded wood–plastic composites during year round subtropical weathering. Constr. Build. Mater. 2015, 88, 159–168. [Google Scholar] [CrossRef]

- Matuana, L.M.; Kamdem, D.P. Accelerated ultraviolet weathering of PVC/wood-flour composites. Polym. Eng. Sci. 2002, 42, 1657–1666. [Google Scholar] [CrossRef]

- Tocháček, J.; Vrátníčková, Z. Polymer life-time prediction: The role of temperature in UV accelerated ageing of polypropylene and its copolymers. Polym. Test. 2014, 36, 82–87. [Google Scholar] [CrossRef]

- Ikram, S.; Das, O.; Bhattacharyya, D. A parametric study of mechanical and flammability properties of biochar reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2016, 91, 177–188. [Google Scholar] [CrossRef]

- Meerten, Y.; Swolfs, Y.; Baets, J.; Gorbatikh, L.; Verpoest, I. Penetration impact testing of self-reinforced composites. Compos. Part A Appl. Sic. Manuf. 2015, 68, 289–295. [Google Scholar] [CrossRef]

- Tjeerdsma, B.F.; Militz, H. Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood. Holz. Roh. Werkst. 2005, 63, 102–111. [Google Scholar] [CrossRef]

- Popescu, C.M.; Hill, C.A.; Curling, S.; Ormondroyd, G.; Xie, Y. The water vapour sorption behaviour of acetylated birch wood: How acetylation affects the sorption isotherm and accessible hydroxyl content. J. Mater. Sci. 2014, 49, 2362–2371. [Google Scholar] [CrossRef]

- Kuo, P.Y.; Wang, S.Y.; Chen, J.H.; Hsueh, H.C.; Tsai, M.J. Effects of material compositions on the mechanical properties of wood–plastic composites manufactured by injection molding. Mater. Des. 2009, 30, 3489–3496. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G.; Freitag, C.; Morrell, J.J. Effects of wood fiber esterification on properties, weatherability and biodurability of wood plastic composites. Polym. Degrad. Stab. 2013, 98, 1348–1361. [Google Scholar] [CrossRef]

- Wei, L.; Stark, N.M.; McDonald, A.G. Interfacial improvements in biocomposites based on poly (3-hydroxybutyrate) and poly (3-hydroxybutyrate-co-3-hydroxyvalerate) bioplastics reinforced and grafted with α-cellulose fibers. Green Chem. 2015, 17, 4800–4814. [Google Scholar] [CrossRef]

- Muasher, M.; Sain, M. The efficacy of photostabilizers on the color change of wood filled plastic composites. Polym. Degrad. Stab. 2006, 91, 1156–1165. [Google Scholar] [CrossRef]

- Matuana, L.M.; Jin, S.; Stark, N.M. Ultraviolet weathering of HDPE/wood-flour composites coextruded with a clear HDPE cap layer. Polym. Degrad. Stab. 2011, 96, 97–106. [Google Scholar] [CrossRef]

| Mineral Composition | wt % |

|---|---|

| MgO | 6.57 |

| Al2O3 | 16.93 |

| SiO2 | 68.23 |

| Fe2O3 | 8.27 |

| Sample | MeanDiff | SEM | q Value | Prob | Alpha | Sig |

|---|---|---|---|---|---|---|

| 1,3 | −0.522 | 1.05567 | 0.69974 | 0.98695 | 0.05 | 1 |

| 2,3 | −0.398 | 1.05567 | 0.53352 | 0.99533 | 0.05 | 1 |

| 4,3 | 0.140 | 1.05567 | 0.18767 | 0.99992 | 0.05 | 1 |

| 5,3 | 0.242 | 1.05567 | 0.32440 | 0.99933 | 0.05 | 1 |

| Sample | MeanDiff | SEM | q Value | Prob | Alpha | Sig |

|---|---|---|---|---|---|---|

| 1,3 | −0.894 | 1.05567 | 1.19764 | 0.91253 | 0.05 | 1 |

| 2,3 | −0.476 | 1.05567 | 0.63767 | 0.99079 | 0.05 | 1 |

| 4,3 | 0.202 | 1.05567 | 0.27061 | 0.99967 | 0.05 | 1 |

| 5,3 | 0.396 | 1.05567 | 0.53050 | 0.99544 | 0.05 | 1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Gao, X.; Cheng, W.; Han, G. Effect of Modified Red Pottery Clay on the Moisture Absorption Behavior and Weatherability of Polyethylene-Based Wood-Plastic Composites. Materials 2017, 10, 111. https://doi.org/10.3390/ma10020111

Li Q, Gao X, Cheng W, Han G. Effect of Modified Red Pottery Clay on the Moisture Absorption Behavior and Weatherability of Polyethylene-Based Wood-Plastic Composites. Materials. 2017; 10(2):111. https://doi.org/10.3390/ma10020111

Chicago/Turabian StyleLi, Qingde, Xun Gao, Wanli Cheng, and Guangping Han. 2017. "Effect of Modified Red Pottery Clay on the Moisture Absorption Behavior and Weatherability of Polyethylene-Based Wood-Plastic Composites" Materials 10, no. 2: 111. https://doi.org/10.3390/ma10020111

APA StyleLi, Q., Gao, X., Cheng, W., & Han, G. (2017). Effect of Modified Red Pottery Clay on the Moisture Absorption Behavior and Weatherability of Polyethylene-Based Wood-Plastic Composites. Materials, 10(2), 111. https://doi.org/10.3390/ma10020111